NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 101 of 192

TEC429

TROUBLE DIAGNOSIS FOR ``F/INJ F/B 2'' (DTC 18),

``F/INJ F/B'' (DTC 22), ``ELECTRIC GOV'' (DTC 25)

Electric Governor (Cont'd)

EC-99

Page 102 of 192

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK POWER SUPPLY.

Refer to EC-63.

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector

and electronic fuel injection pump har-

ness connector.

3. Check harness continuity between ter-

minal

V1and ECM terminals101,107.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK GROUND CIRCUIT.

Check harness continuity between termi-

nal

V5and ECM terminals102,108.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Repair open circuit or short

to ground or short to power

in harness or connectors.

CHECK COMPONENT

(Electric governor).

Refer to ``COMPONENT INSPECTION''

below.

OK

cNG

Take proper action.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

COMPONENT INSPECTION

Electric governor

1. Disconnect electronic fuel injection pump harness connector.

2. Check continuity between terminals

V1andV5.

Resistance: Approximately 0.68W[at 23ÉC (73ÉF)]

If NG, take proper action.

SEF679VA

SEF752V

SEF753V

SEF684V

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``F/INJ F/B 2'' (DTC 18),

``F/INJ F/B'' (DTC 22), ``ELECTRIC GOV'' (DTC 25)

Electric Governor (Cont'd)

EC-100

Page 103 of 192

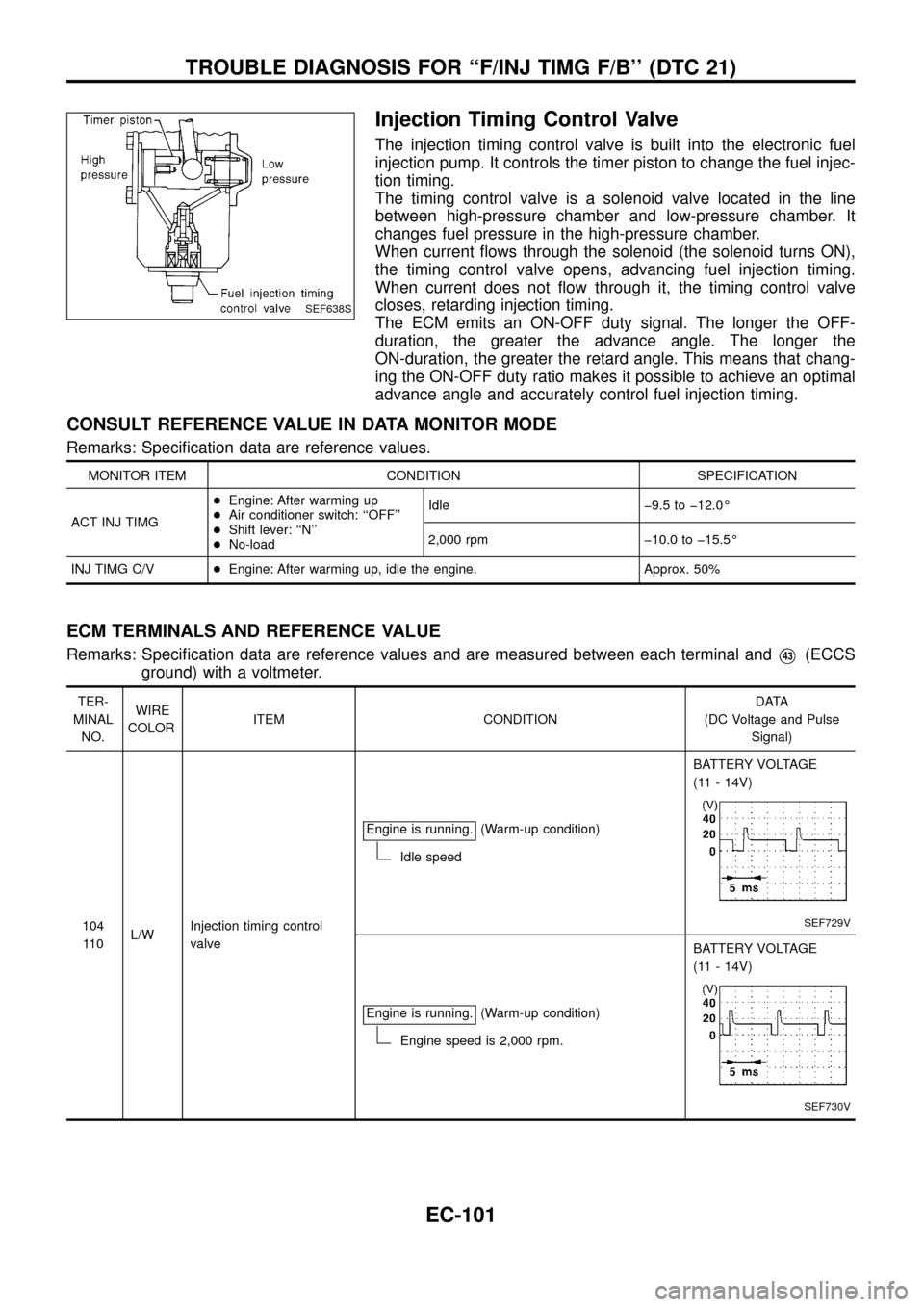

Injection Timing Control Valve

The injection timing control valve is built into the electronic fuel

injection pump. It controls the timer piston to change the fuel injec-

tion timing.

The timing control valve is a solenoid valve located in the line

between high-pressure chamber and low-pressure chamber. It

changes fuel pressure in the high-pressure chamber.

When current ¯ows through the solenoid (the solenoid turns ON),

the timing control valve opens, advancing fuel injection timing.

When current does not ¯ow through it, the timing control valve

closes, retarding injection timing.

The ECM emits an ON-OFF duty signal. The longer the OFF-

duration, the greater the advance angle. The longer the

ON-duration, the greater the retard angle. This means that chang-

ing the ON-OFF duty ratio makes it possible to achieve an optimal

advance angle and accurately control fuel injection timing.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACT INJ TIMG+Engine: After warming up

+Air conditioner switch: ``OFF''

+Shift lever: ``N''

+No-loadIdle þ9.5 to þ12.0É

2,000 rpm þ10.0 to þ15.5É

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50%

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

104

11 0L/WInjection timing control

valveEngine is running.

(Warm-up condition)

Idle speedBATTERY VOLTAGE

(11 - 14V)

SEF729V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.BATTERY VOLTAGE

(11 - 14V)

SEF730V

SEF638S

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

EC-101

Page 104 of 192

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible cause)

21+Injection timing feedback system does not operate

properly. (This system consists essentially of ECM,

injection timing control valve and needle lift sensor.)+Harness or connectors

[Injection timing control valve, needle lift sensor,

crankshaft position sensor (TDC) circuits]

+Injection timing control valve

+Needle lift sensor

+Crankshaft position sensor (TDC)

+Air in fuel line

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

Note: If both DTC 21 and 34 or 47 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC 34 or 47. (See EC-126

or EC-144.)

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Start engine and warm it up to normal operating tem-

perature.

3) Run engine for 2 seconds at 3,000 rpm. Return engine

speed to idle, then increase to 3,000 rpm under no load.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine and warm it up to normal operating tem-

perature.

2) Run engine for 2 seconds at 3,000 rpm. Return engine

speed to idle, then increase to 3,000 rpm under no load.

3) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

4) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

Note: If a malfunction occurs intermittently, conduct suitable

driving pattern for 10 minutes. This makes it possible to

determine DTC.

SEF751V

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

Injection Timing Control Valve (Cont'd)

EC-102

Page 105 of 192

TEC430

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

Injection Timing Control Valve (Cont'd)

EC-103

Page 106 of 192

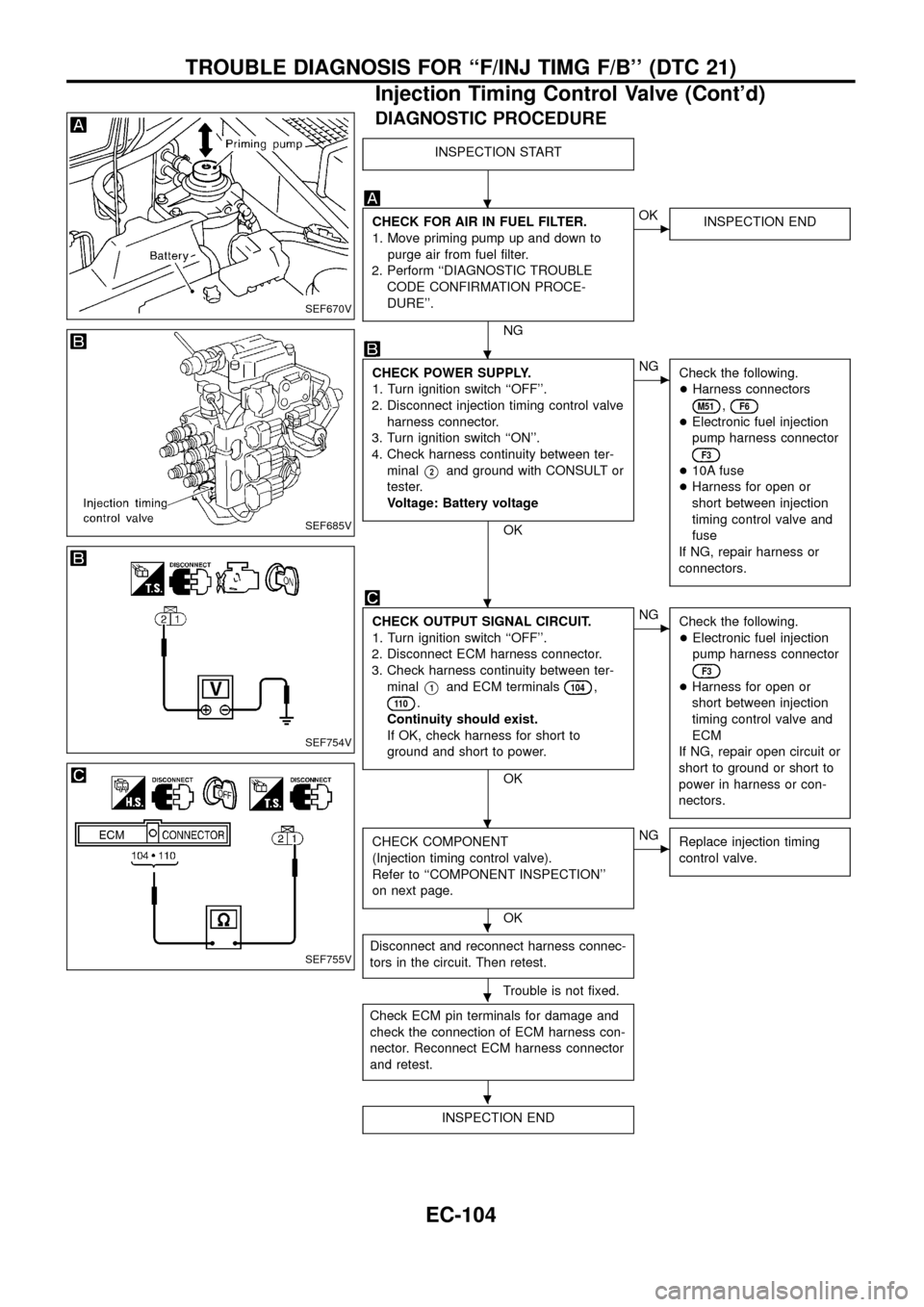

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK FOR AIR IN FUEL FILTER.

1. Move priming pump up and down to

purge air from fuel ®lter.

2. Perform ``DIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCE-

DURE''.

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn ignition switch ``OFF''.

2. Disconnect injection timing control valve

harness connector.

3. Turn ignition switch ``ON''.

4. Check harness continuity between ter-

minal

V2and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M51,F6

+Electronic fuel injection

pump harness connector

F3

+10A fuse

+Harness for open or

short between injection

timing control valve and

fuse

If NG, repair harness or

connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ter-

minal

V1and ECM terminals104,

11 0.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Electronic fuel injection

pump harness connector

F3

+Harness for open or

short between injection

timing control valve and

ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK COMPONENT

(Injection timing control valve).

Refer to ``COMPONENT INSPECTION''

on next page.

OK

cNG

Replace injection timing

control valve.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

SEF670V

SEF685V

SEF754V

SEF755V

.

.

.

.

.

.

.

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

Injection Timing Control Valve (Cont'd)

EC-104

Page 107 of 192

COMPONENT INSPECTION

Injection timing control valve

1. Reconnect injection timing control valve harness connector.

2. Disconnect electronic fuel injection pump harness connector.

3. Check resistance between terminals

V3andV7.

Resistance: Approximately 11W[at 20ÉC (68ÉF)]

If NG, replace injection timing control valve.

SEF686V

TROUBLE DIAGNOSIS FOR ``F/INJ TIMG F/B'' (DTC 21)

Injection Timing Control Valve (Cont'd)

EC-105

Page 108 of 192

Accelerator Switch (F/C)

The accelerator switch is installed to the accelerator pedal assem-

bly. The switch senses accelerator position and sends an ON-OFF

signal to the ECM. The ECM uses the signal to control the fuel cut

operation at deceleration for better fuel efficiency.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: released CLOSE

Accelerator pedal: slightly open OPEN

DECELER F/CUT+Engine: After warming upIdle OFF

When accelerator pedal is

released quickly with engine

speed at 3,000 rpm or more.ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

29 R/L Accelerator switch (F/C)Ignition switch ``ON''

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ``ON''

Accelerator pedal depressedApproximately 0V

ON BOARD DIAGNOSIS LOGIC

Diagnostic

Trouble Code

No.Malfunction is detected when ....Check Items

(Possible cause)

23+The OFF signal (short) is sent to the ECM for a cer-

tain period of time even when the accelerator pedal is

not being depressed.+Harness or connectors

(The switch circuit is shorted.)

+Accelerator switch (F/C)

SEF687V

TROUBLE DIAGNOSIS FOR ``ACCEL POS SW (F/C)'' (DTC 23)

EC-106

Page 109 of 192

DIAGNOSTIC TROUBLE CODE CONFIRMATION

PROCEDURE

1) Turn ignition switch ``ON'' and select ``DATA MONITOR''

mode with CONSULT.

2) Depress and release accelerator pedal once for 15 sec-

onds.

3) Repeat step 2 for 26 times.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Turn ignition switch ``ON''.

2) Depress and release accelerator pedal once for 15 sec-

onds.

3) Repeat step 2 for 26 times.

4) Turn ignition switch ``OFF'', wait at least 5 seconds and

then turn ``ON''.

5) Perform ``Diagnostic Test Mode II (Self-diagnostic

results)'' with ECM.

SEF756V

TROUBLE DIAGNOSIS FOR ``ACCEL POS SW (F/C)'' (DTC 23)

Accelerator Switch (F/C) (Cont'd)

EC-107

Page 110 of 192

TEC431

TROUBLE DIAGNOSIS FOR ``ACCEL POS SW (F/C)'' (DTC 23)

Accelerator Switch (F/C) (Cont'd)

EC-108