engine NISSAN PATROL 1998 Y61 / 5.G Engine Control Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 192, PDF Size: 4.28 MB

Page 1 of 192

ENGINE CONTROL SYSTEMSECTION

EC

CONTENTS

DIAGNOSTIC TROUBLE CODE INDEX .........................1

Alphabetical & Numerical Index for DTC ....................1

PRECAUTIONS AND PREPARATION ............................2

Special Service Tools ..................................................2

Commercial Service Tool .............................................3

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............4

PRECAUTIONS AND PREPARATION ............................5

Engine Fuel & Emission Control System ....................5

Precautions ..................................................................6

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM ........................................................................\

...8

ECCS-D Component Parts Location ...........................8

Circuit Diagram .......................................................... 11

System Diagram ........................................................12

Vacuum Hose Drawing ..............................................13

System Chart .............................................................14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION ...............................................15

Fuel Injection System ................................................15

Fuel Injection Timing System ....................................18

Air Conditioning Cut Control ......................................19

Fuel Cut Control (at no load & high engine

speed) ........................................................................\

20

CRANKCASE VENTILATION SYSTEM ........................21

Description .................................................................21

Inspection...................................................................21

INJECTION NOZZLE .....................................................22

Removal and Installation ...........................................22

Disassembly (No. 2 - 4 nozzles) ...............................22

Inspection (No. 2 - 4 nozzles) ...................................23

Cleaning (No. 2 - 4 nozzles) .....................................23

Assembly (No. 2 - 4 nozzles) ....................................24

Test and Adjustment ..................................................25

ELECTRONIC FUEL INJECTION PUMP ......................27

Removal .....................................................................27

Installation ..................................................................28

Disassembly and Assembly .......................................29

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION ...............................................................30

DTC and MIL Detection Logic ...................................30

Diagnostic Trouble Code (DTC) ................................30 Malfunction Indicator Lamp (MIL) ..............................31

CONSULT ..................................................................36

TROUBLE DIAGNOSIS Ð Introduction ......................42

Introduction ................................................................42

Diagnostic Worksheet ................................................43

TROUBLE DIAGNOSIS Ð Work Flow ........................44

Work Flow ..................................................................44

Description for Work Flow .........................................45

TROUBLE DIAGNOSIS Ð Basic Inspection ..............46

Basic Inspection.........................................................46

TROUBLE DIAGNOSIS Ð General Description ........48

Symptom Matrix Chart ...............................................48

CONSULT Reference Value in Data Monitor

Mode ........................................................................\

..51

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................\

..53

ECM Terminals and Reference Value .......................54

TROUBLEDIAGNOSISFORPOWERSUPPLY ..........63

MainPowerSupplyandGroundCircuit....................63

TROUBLE DIAGNOSIS FOR ``CAM POS SEN

(PUMP)''(DTC11) .........................................................69

CamshaftPositionSensor(CMPS)(PUMP).............69

TROUBLEDIAGNOSISFOR``MASSAIRFLOW

SEN''(DTC12) ..............................................................74

MassAirFlowSensor(MAFS)..................................74

TROUBLEDIAGNOSISFOR``COOLANTTEMP

SEN''(DTC13) ..............................................................79

EngineCoolantTemperature(ECT)Sensor.............79

TROUBLEDIAGNOSISFOR``VEHICLESPEED

SEN''(DTC14) ..............................................................83

VehicleSpeedSensor(VSS)....................................83

TROUBLEDIAGNOSISFOR``CONTSLEEVPOS

SEN''(DTC15) ..............................................................87

ControlSleevePositionSensor(CSPS)...................87

TROUBLEDIAGNOSISFOR``ADJUST

RESISTOR''(DTC17) ...................................................92

AdjustmentResistor...................................................92

TROUBLEDIAGNOSISFOR``F/INJF/B2''

(DTC18),``F/INJF/B''(DTC22),``ELECTRIC

GOV''(DTC25) ..............................................................96

ElectricGovernor.......................................................96

EC

Page 2 of 192

TROUBLEDIAGNOSISFOR``F/INJTIMGF/B''

(DTC21).......................................................................101

InjectionTimingControlValve.................................101

TROUBLEDIAGNOSISFOR``ACCELPOSSW

(F/C)''(DTC23) ...........................................................106

AcceleratorSwitch(F/C)..........................................106

TROUBLEDIAGNOSISFOR``ECM1''(DTC27),

``ECM2''(DTC31) .......................................................111

EngineControlModule(ECM)-ECCS-DControl

Module.....................................................................111

TROUBLEDIAGNOSISFOR``OVERHEAT''

(DTC28) .......................................................................113

CoolingFan(Overheat)...........................................113

TROUBLEDIAGNOSISFOR``I/CINT/ATEMP

SEN''(DTC33) ............................................................122

ChargeAirTemperatureSensor..............................122

TROUBLEDIAGNOSISFOR``NEEDLELIFT

SEN''(DTC34) ............................................................126

NeedleLiftSensor(NLS)........................................126

TROUBLE DIAGNOSIS FOR ``FUEL CUT S/V 1''

(DTC 36), ``FCV SHORT'' (DTC 37), ``FUEL CUT

S/V2''(DTC38) ...........................................................130

FuelCutSolenoidValve..........................................130

TROUBLE DIAGNOSIS FOR ``FUEL TEMP

SENSOR''(DTC42) ....................................................135

FuelTemperatureSensor(FTS)..............................135 TROUBLE DIAGNOSIS FOR ``ACCEL POS

SENSOR''(DTC43)

....................................................139

AcceleratorPositionSensor....................................139

TROUBLE DIAGNOSIS FOR ``CRANK POS SEN

(TDC)''(DTC47) ..........................................................144

CrankshaftPositionSensor(TDC)..........................144

TROUBLEDIAGNOSISFOR``GOVCUT

CIRCUIT''(DTC48) .....................................................149

GovernorCutCircuit................................................149

TROUBLEDIAGNOSESFORNON-DETECTABLE

ITEMS ........................................................................\

...151

GlowControlSystem...............................................151

EGRC-SolenoidValveA,BandThrottleControl

SolenoidValve.........................................................156

StartSignal..............................................................163

AcceleratorPositionSwitch.....................................165

Park/NeutralPositionSwitch...................................170

A/TControl...............................................................175

ChargeAirCoolerFanControl................................178

HeatUpSwitch........................................................183

AirConditionerControl............................................187

MIL&DataLinkConnectors...................................188

SERVICEDATAANDSPECIFICATIONS(SDS) ........189

GeneralSpeci®cations.............................................189

InjectionNozzle.......................................................189

InspectionandAdjustment......................................189

When you read wiring diagrams:

+ Read GI section, ``HOW TO READ WIRING DIAGRAMS''.

+ See EL section, ``POWER SUPPLY ROUTING'' for power distribution circuit.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL

INCIDENT''.

Page 4 of 192

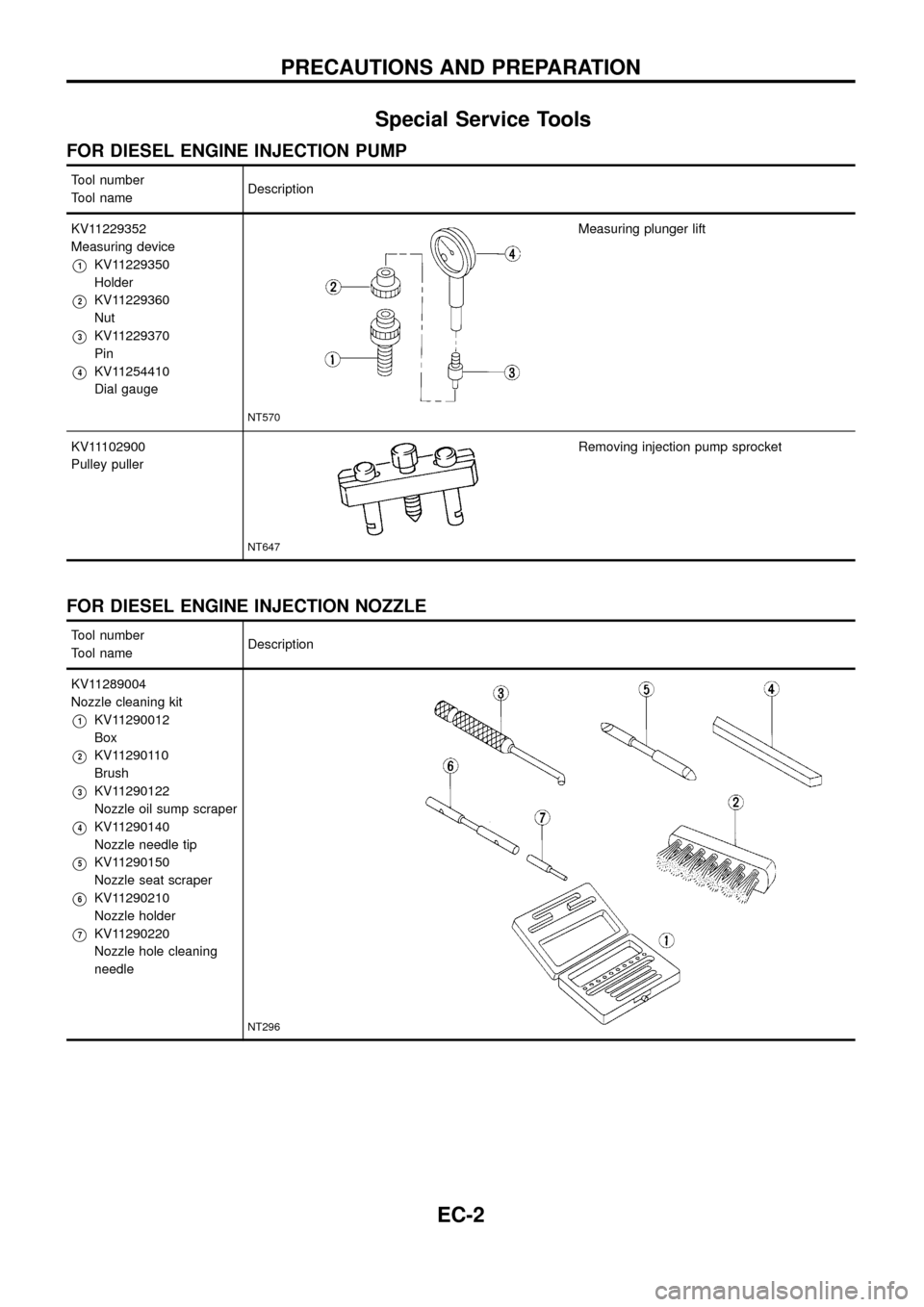

Special Service Tools

FOR DIESEL ENGINE INJECTION PUMP

Tool number

Tool nameDescription

KV11229352

Measuring device

V1KV11229350

Holder

V2KV11229360

Nut

V3KV11229370

Pin

V4KV11254410

Dial gauge

NT570

Measuring plunger lift

KV11102900

Pulley puller

NT647

Removing injection pump sprocket

FOR DIESEL ENGINE INJECTION NOZZLE

Tool number

Tool nameDescription

KV11289004

Nozzle cleaning kit

V1KV11290012

Box

V2KV11290110

Brush

V3KV11290122

Nozzle oil sump scraper

V4KV11290140

Nozzle needle tip

V5KV11290150

Nozzle seat scraper

V6KV11290210

Nozzle holder

V7KV11290220

Nozzle hole cleaning

needle

NT296

PRECAUTIONS AND PREPARATION

EC-2

Page 7 of 192

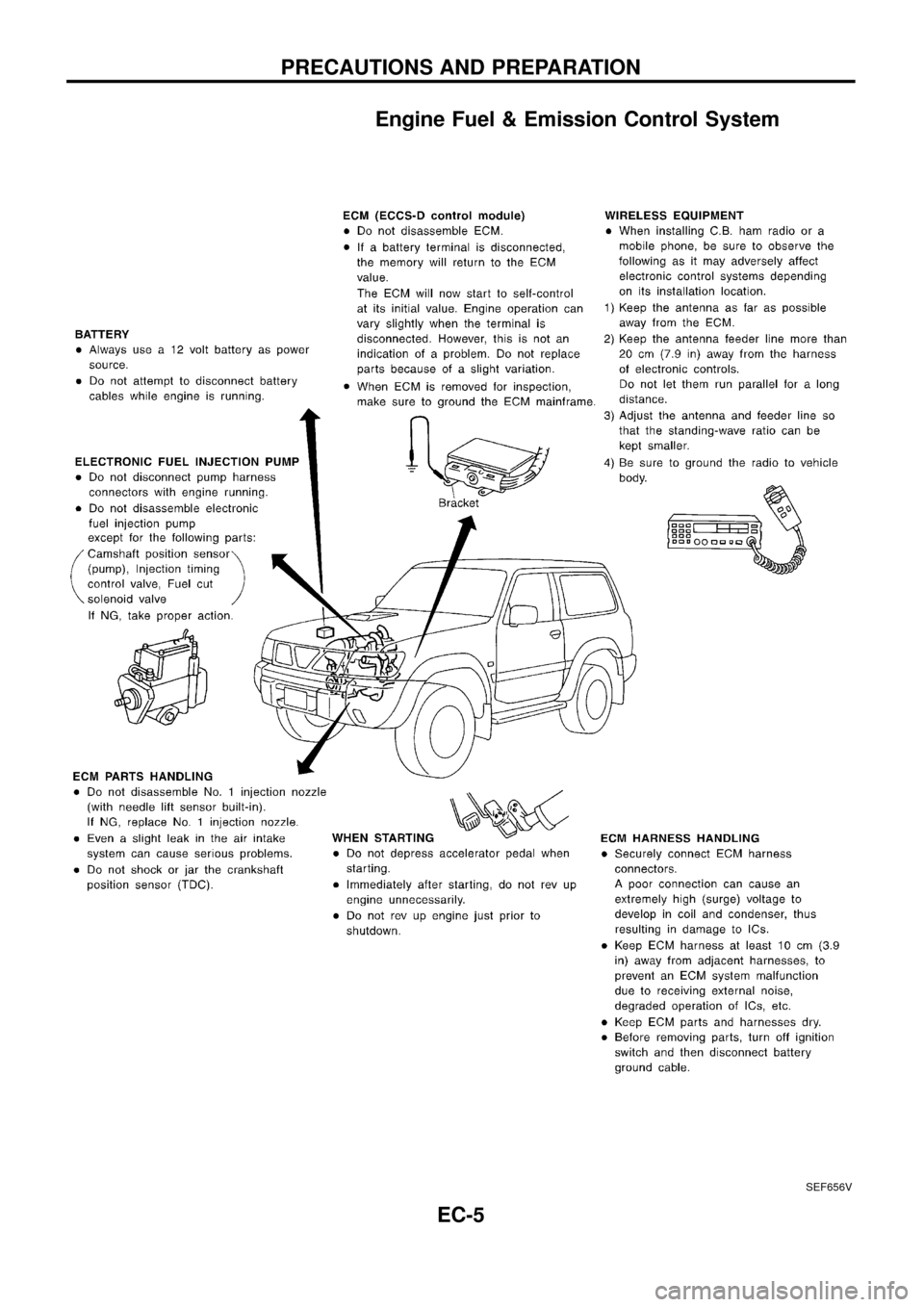

Engine Fuel & Emission Control System

SEF656V

PRECAUTIONS AND PREPARATION

EC-5

Page 8 of 192

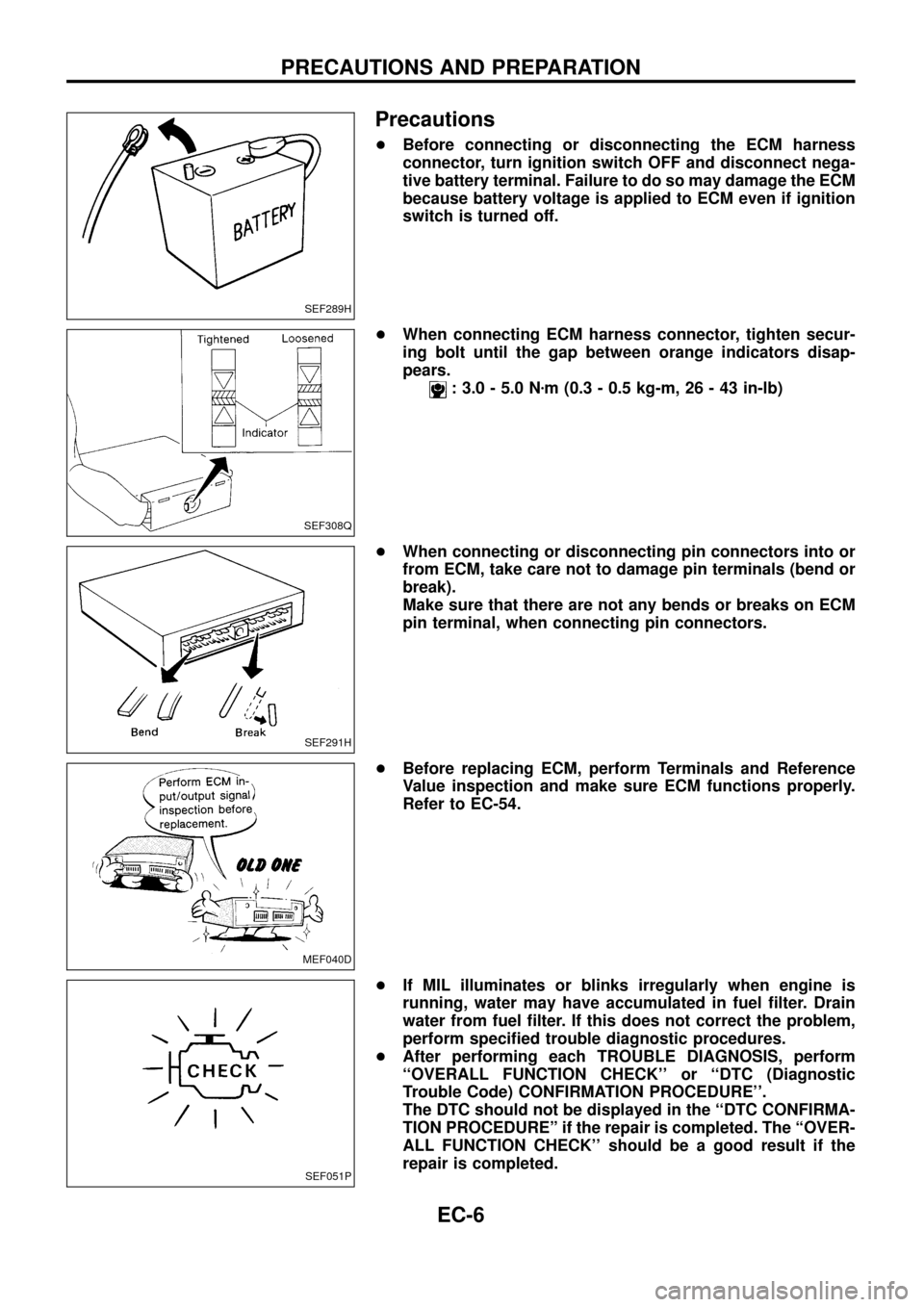

Precautions

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

+When connecting ECM harness connector, tighten secur-

ing bolt until the gap between orange indicators disap-

pears.

: 3.0 - 5.0 Nzm (0.3 - 0.5 kg-m, 26 - 43 in-lb)

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

+Before replacing ECM, perform Terminals and Reference

Value inspection and make sure ECM functions properly.

Refer to EC-54.

+If MIL illuminates or blinks irregularly when engine is

running, water may have accumulated in fuel ®lter. Drain

water from fuel ®lter. If this does not correct the problem,

perform speci®ed trouble diagnostic procedures.

+After performing each TROUBLE DIAGNOSIS, perform

``OVERALL FUNCTION CHECK'' or ``DTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDURE''.

The DTC should not be displayed in the ``DTC CONFIRMA-

TION PROCEDUREº if the repair is completed. The ``OVER-

ALL FUNCTION CHECK'' should be a good result if the

repair is completed.

SEF289H

SEF308Q

SEF291H

MEF040D

SEF051P

PRECAUTIONS AND PREPARATION

EC-6

Page 10 of 192

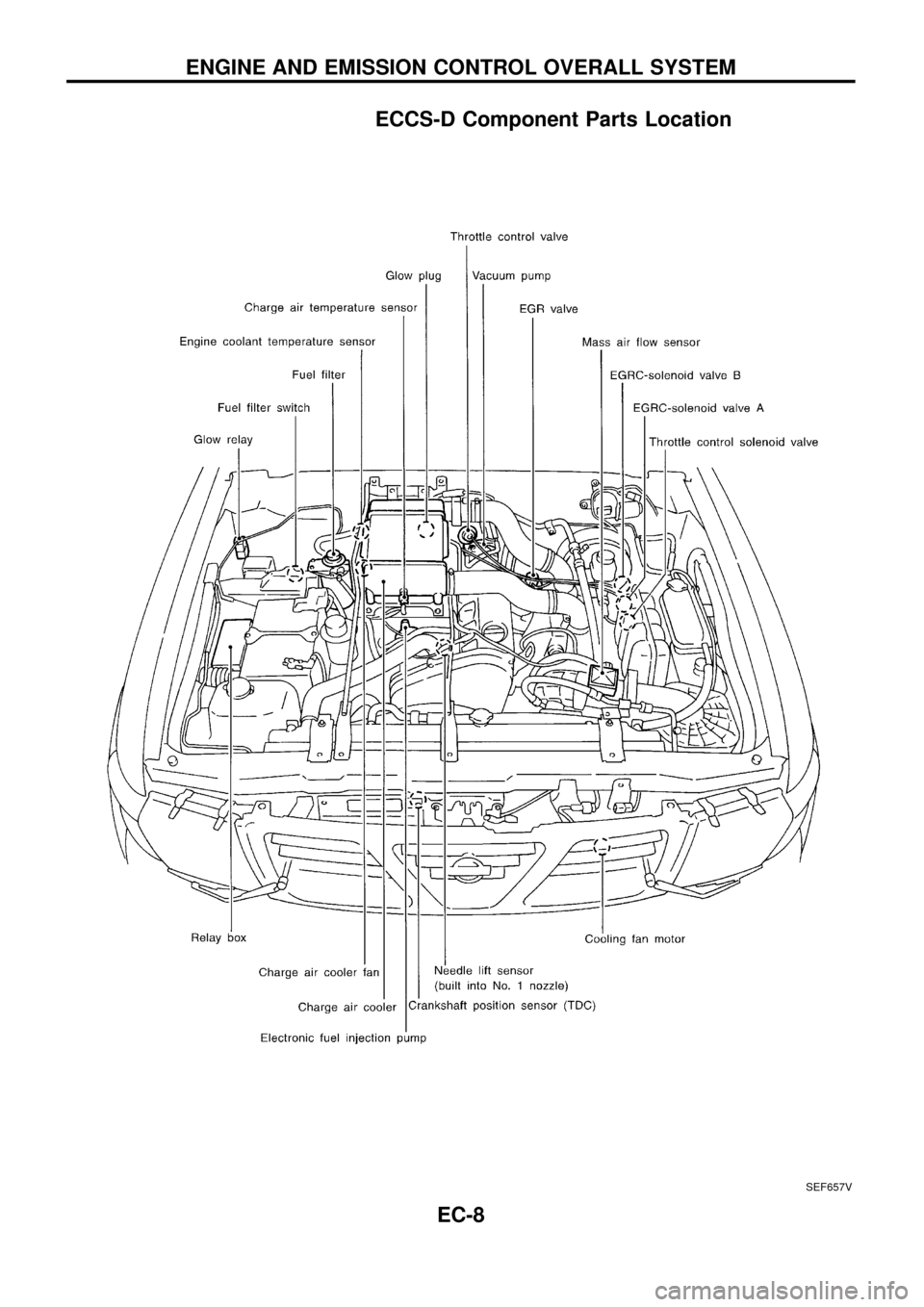

ECCS-D Component Parts Location

SEF657V

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

EC-8

Page 11 of 192

SEF658V

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

ECCS-D Component Parts Location (Cont'd)

EC-9

Page 12 of 192

SEF659V

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

ECCS-D Component Parts Location (Cont'd)

EC-10

Page 13 of 192

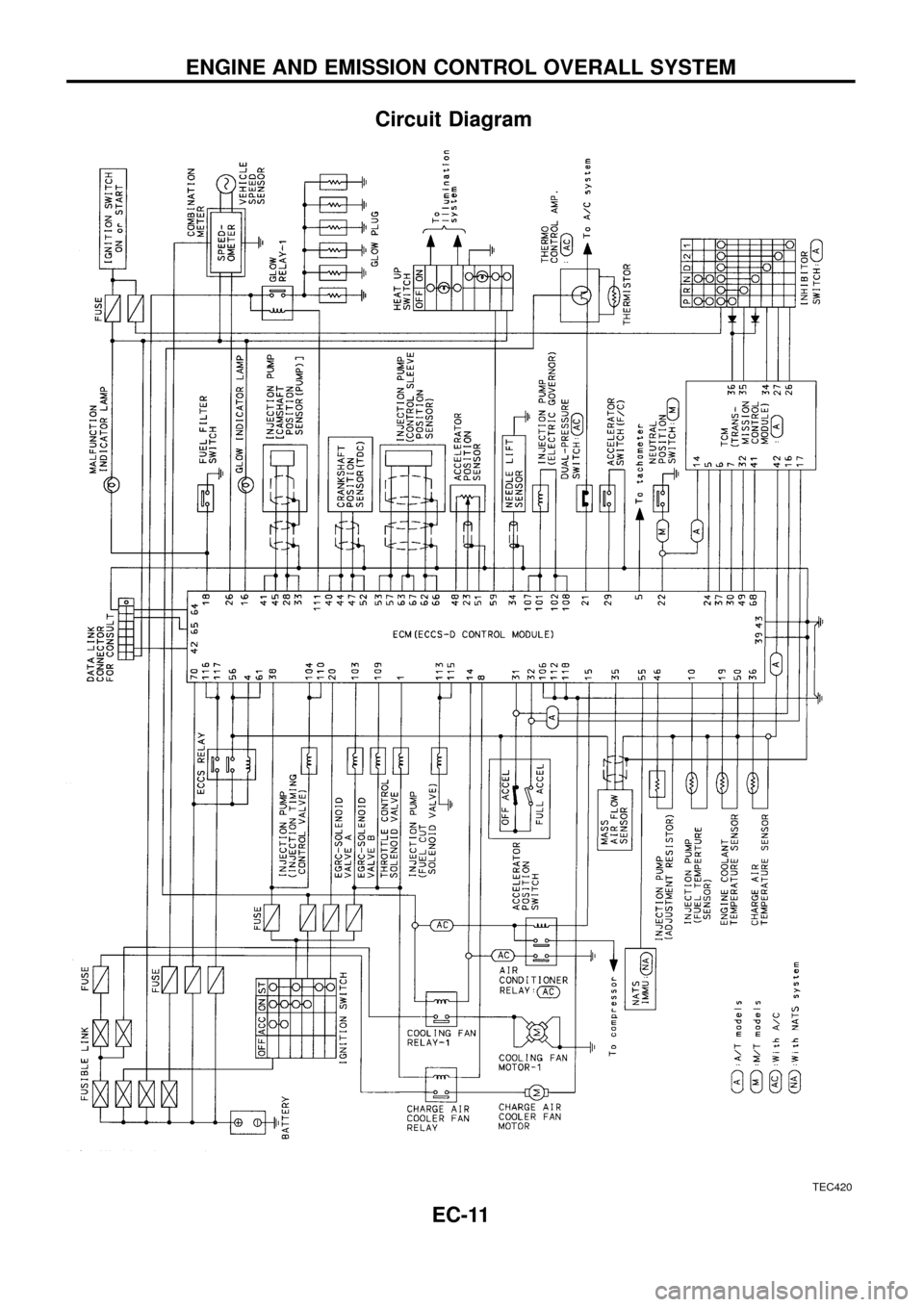

Circuit Diagram

TEC420

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

EC-11

Page 14 of 192

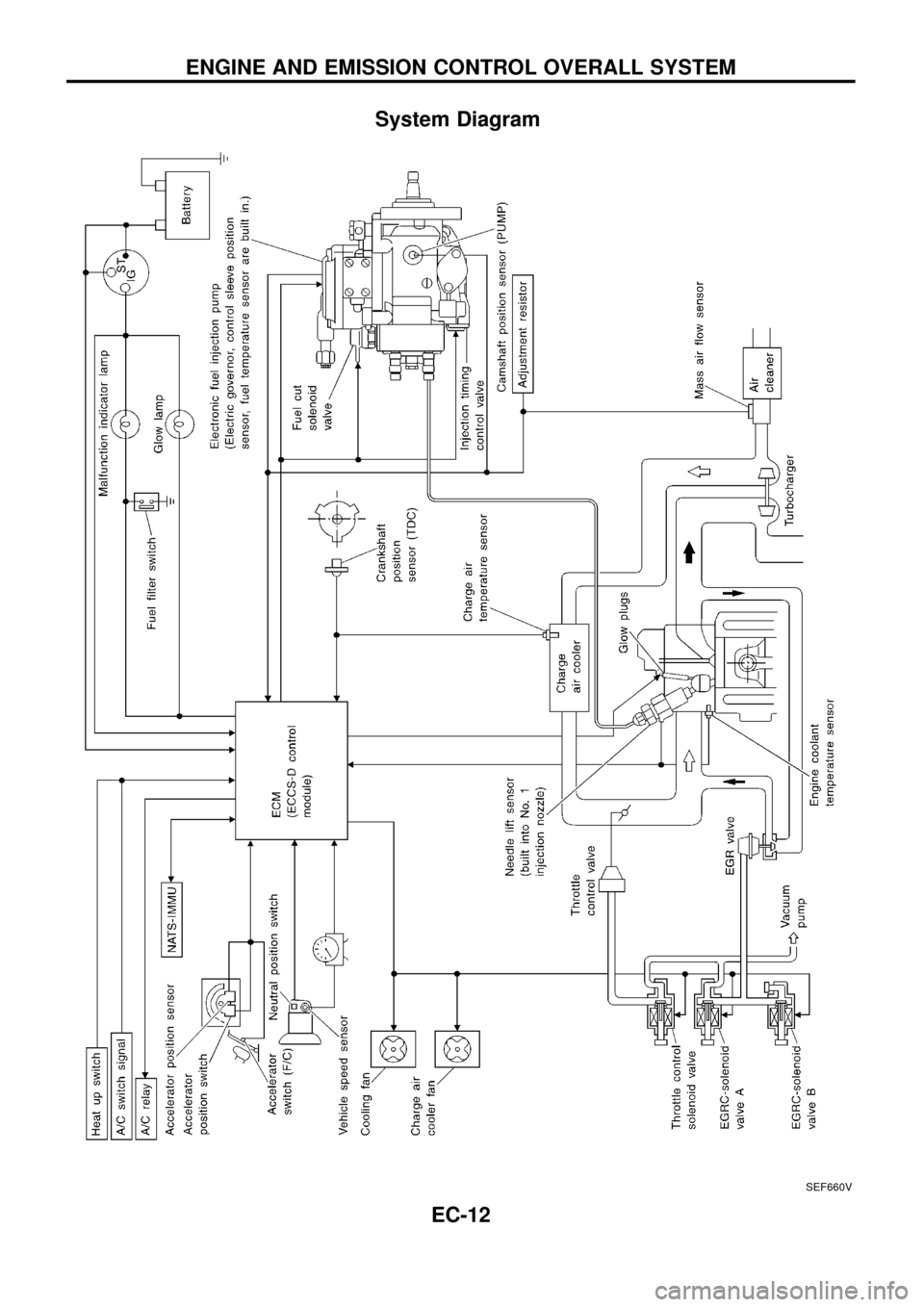

System Diagram

SEF660V

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

EC-12