NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical User Guide

PATROL 1998 Y61 / 5.G

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/619/w960_619-0.png

NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical User Guide

Trending: tow, seat adjustment, ignition, key, ECU, seats, differential

Page 11 of 65

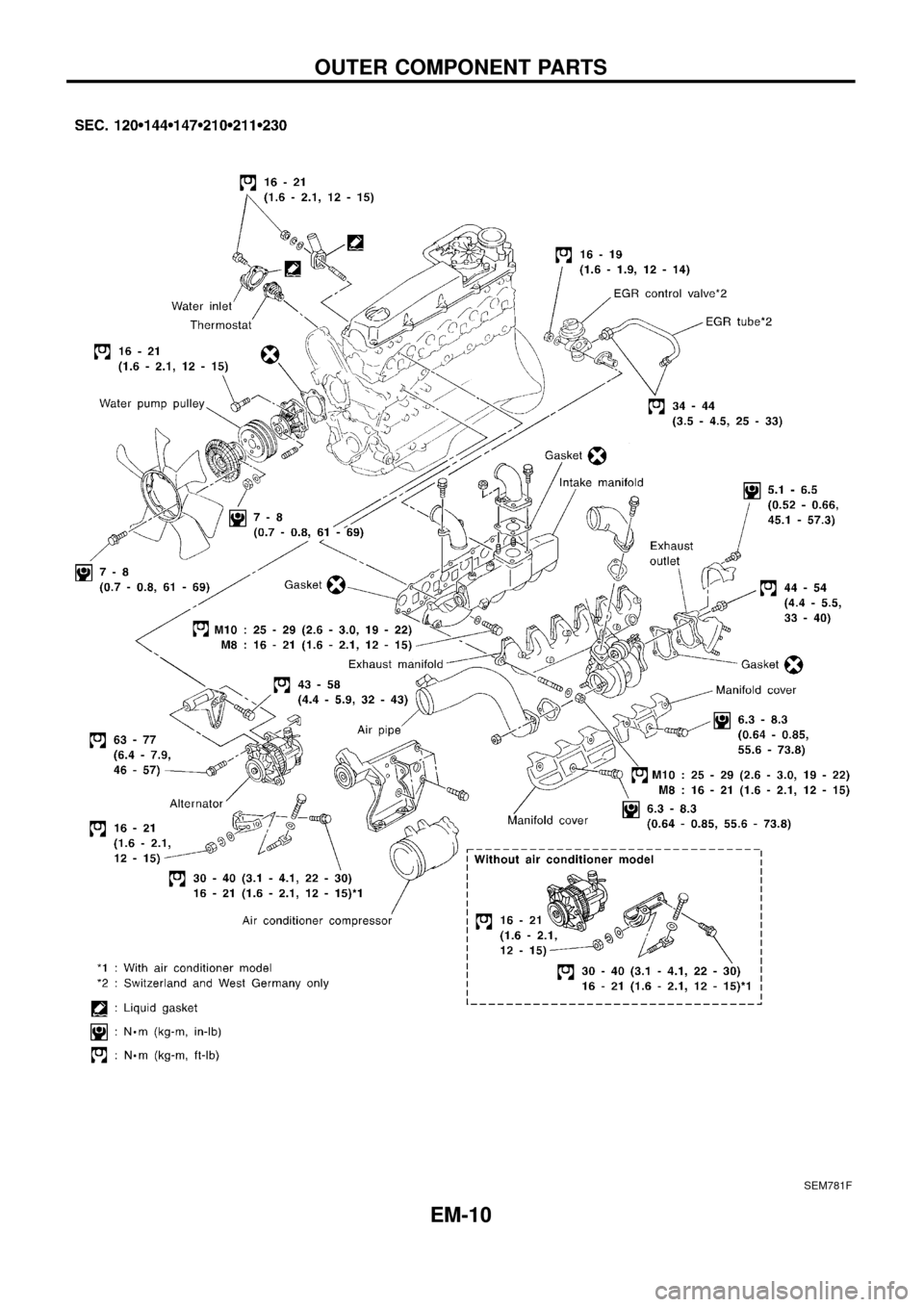

SEM781F

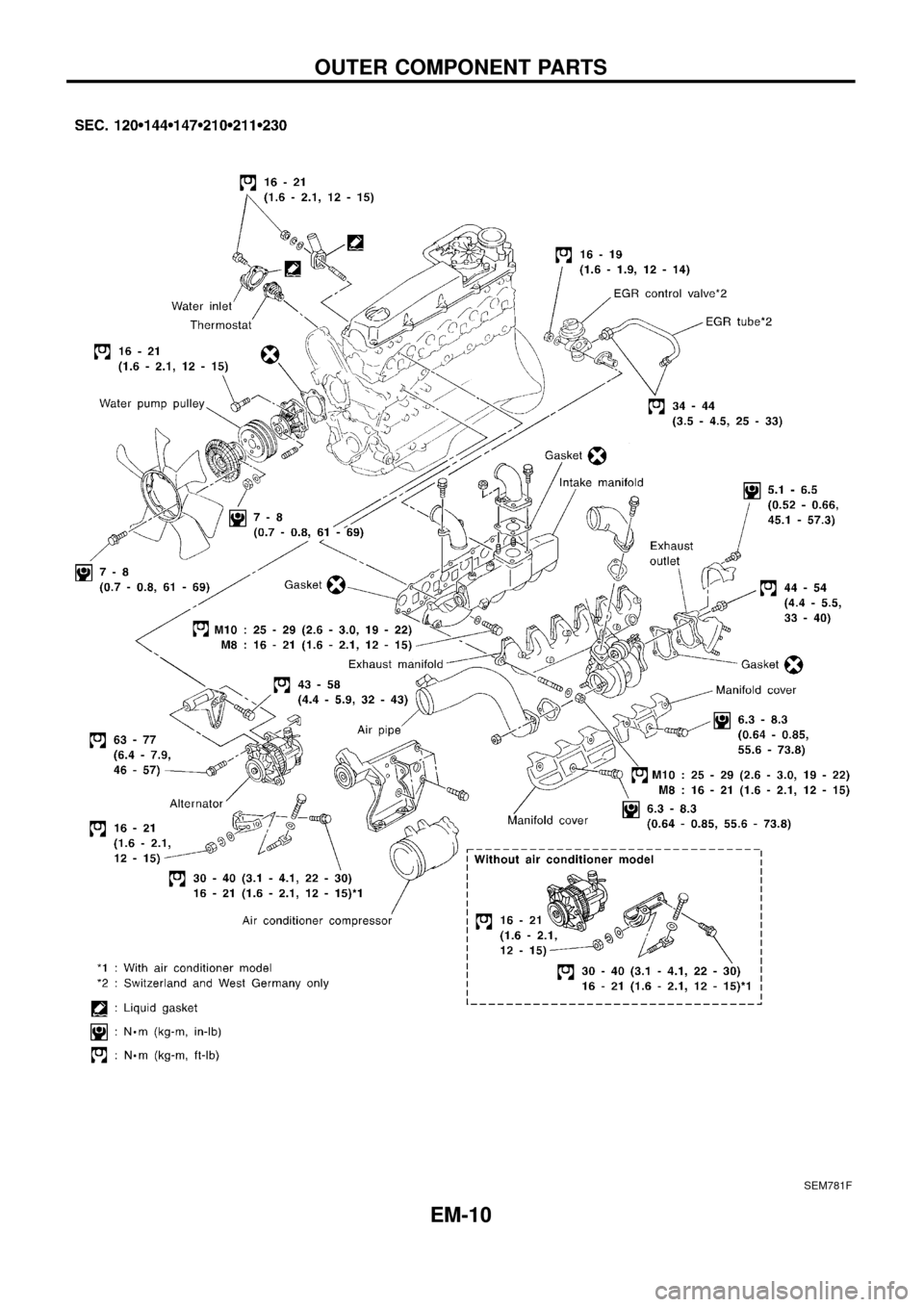

OUTER COMPONENT PARTS

EM-10

Page 12 of 65

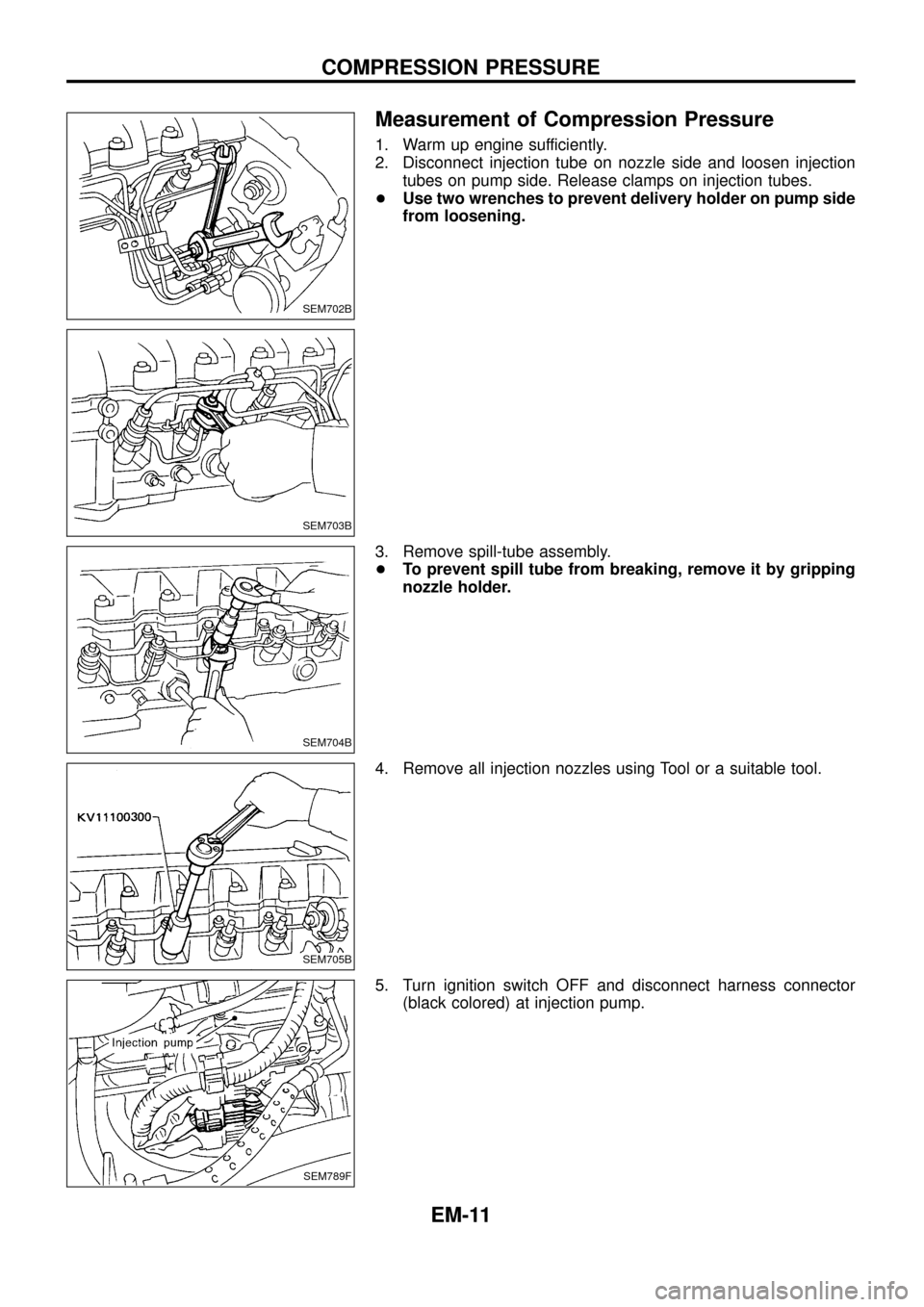

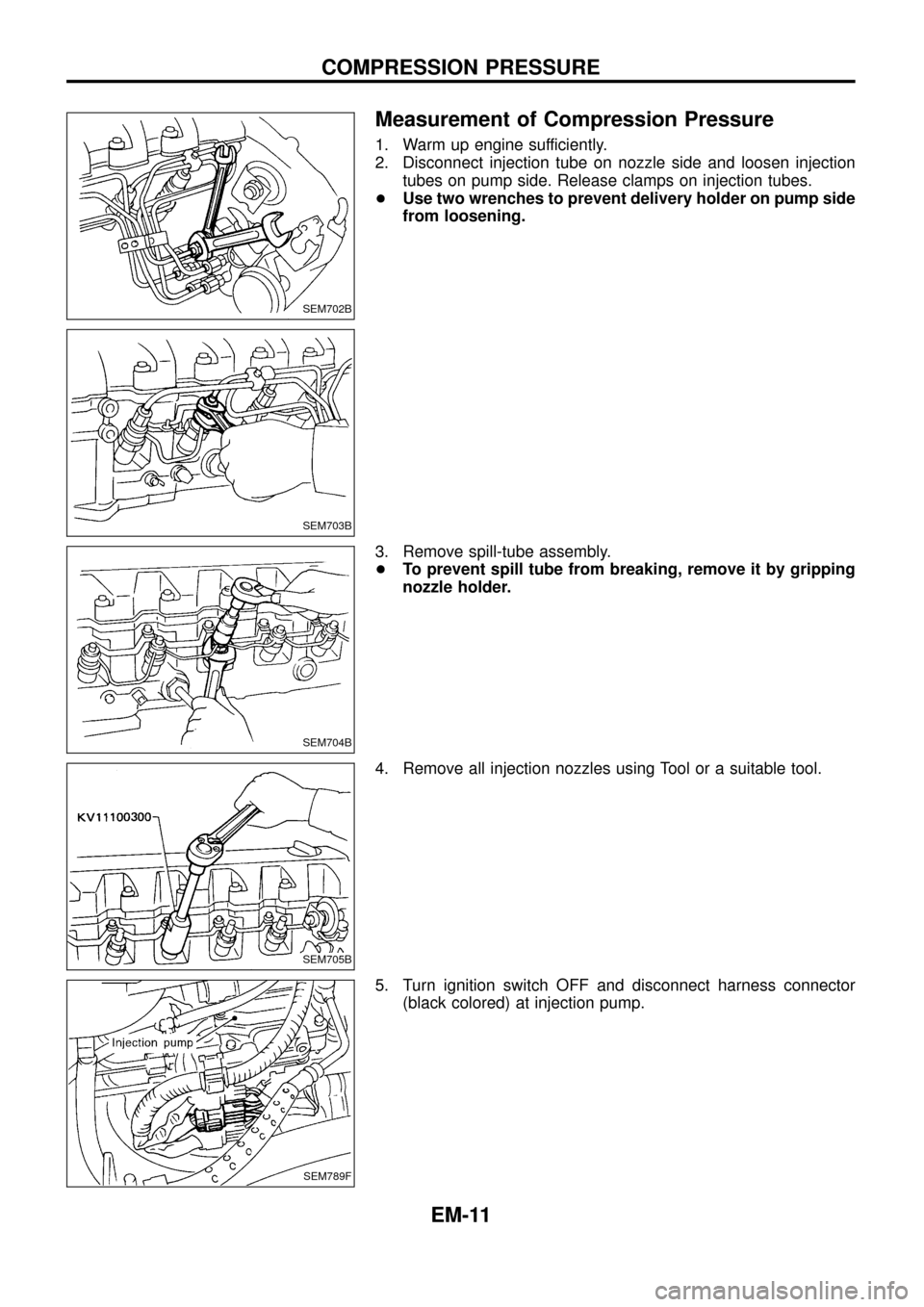

Measurement of Compression Pressure

1. Warm up engine sufficiently.

2. Disconnect injection tube on nozzle side and loosen injection

tubes on pump side. Release clamps on injection tubes.

+Use two wrenches to prevent delivery holder on pump side

from loosening.

3. Remove spill-tube assembly.

+To prevent spill tube from breaking, remove it by gripping

nozzle holder.

4. Remove all injection nozzles using Tool or a suitable tool.

5. Turn ignition switch OFF and disconnect harness connector

(black colored) at injection pump.

SEM702B

SEM703B

SEM704B

SEM705B

SEM789F

COMPRESSION PRESSURE

EM-11

Page 13 of 65

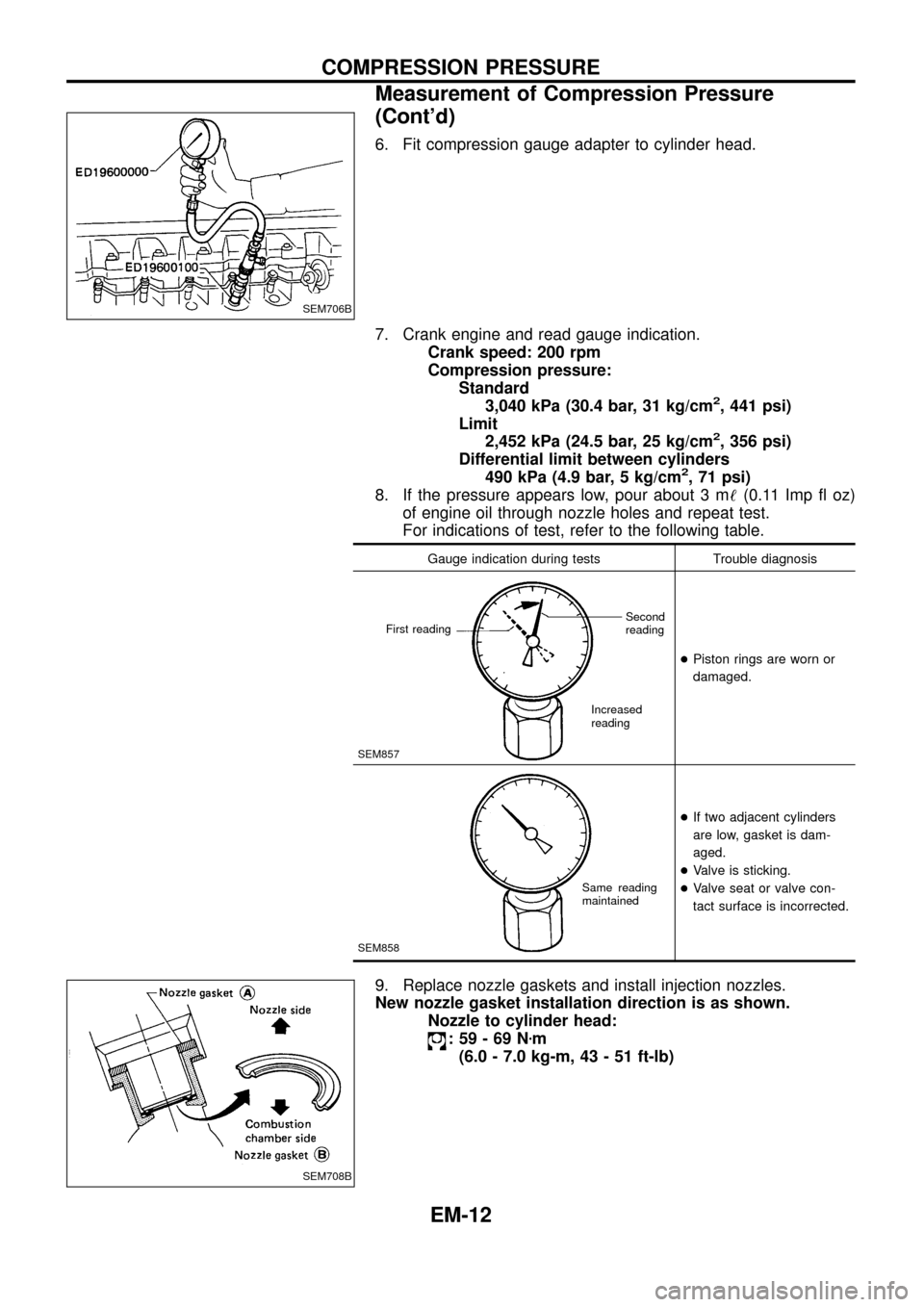

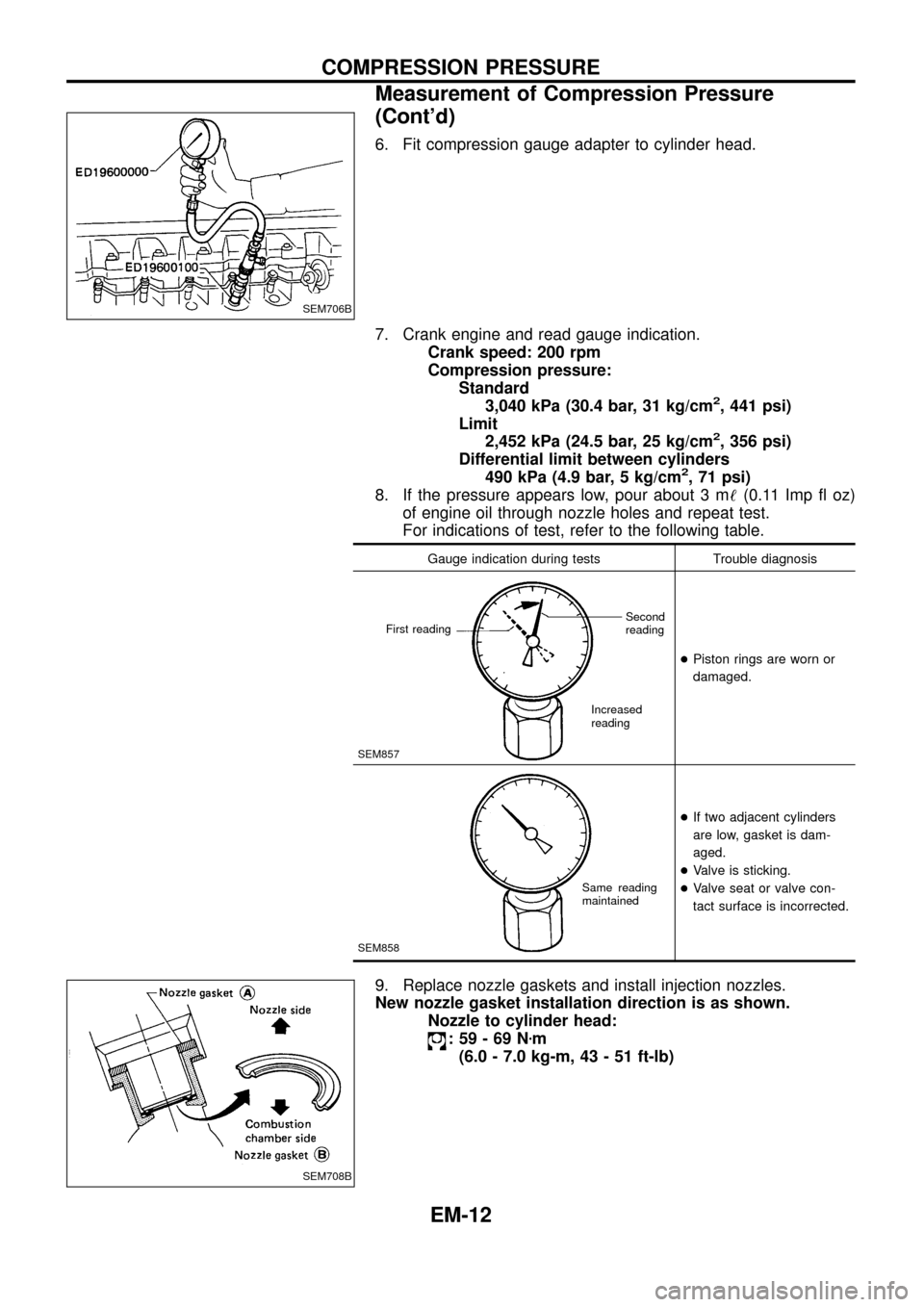

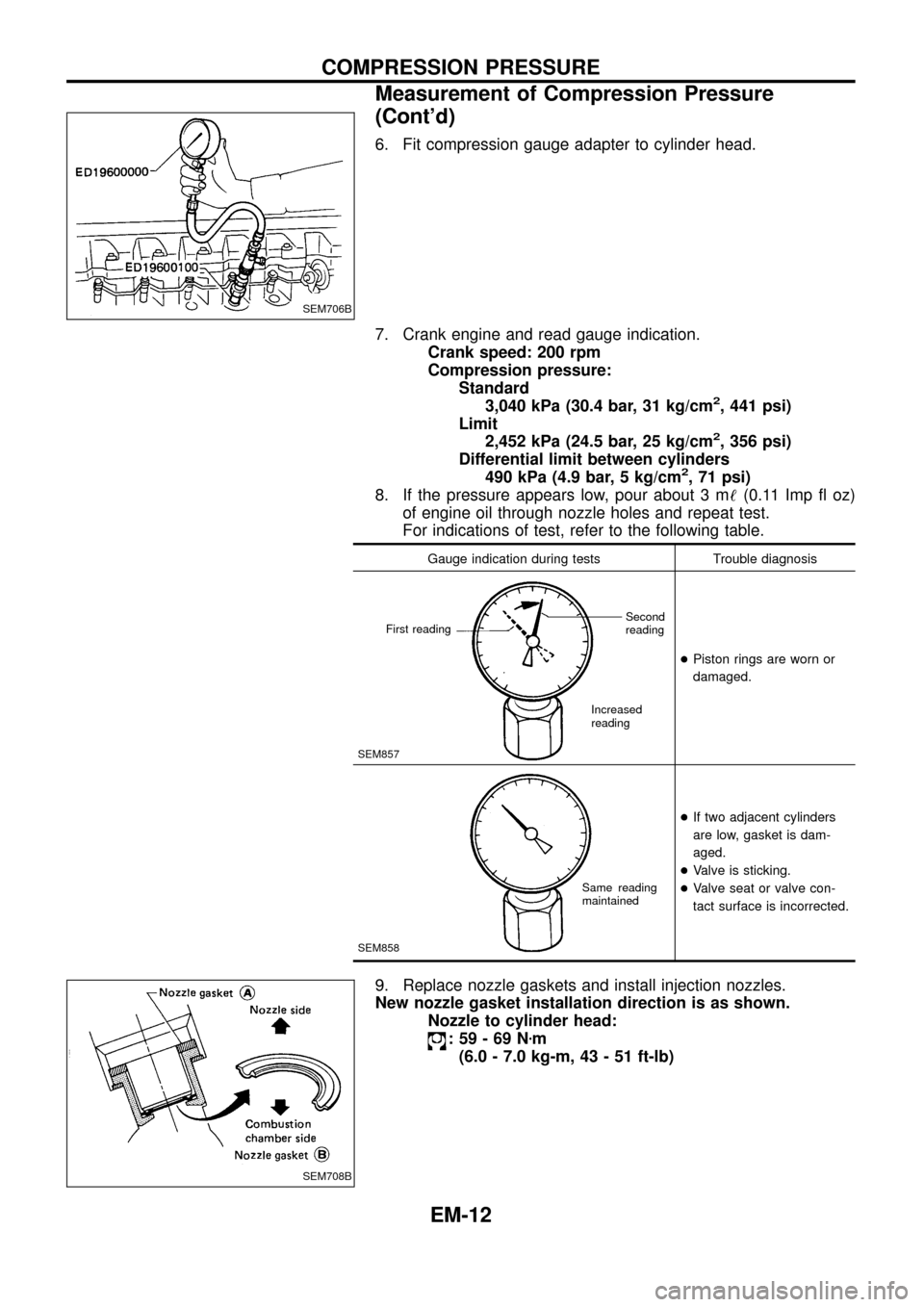

6. Fit compression gauge adapter to cylinder head.

7. Crank engine and read gauge indication.

Crank speed: 200 rpm

Compression pressure:

Standard

3,040 kPa (30.4 bar, 31 kg/cm

2, 441 psi)

Limit

2,452 kPa (24.5 bar, 25 kg/cm

2, 356 psi)

Differential limit between cylinders

490 kPa (4.9 bar, 5 kg/cm

2, 71 psi)

8. If the pressure appears low, pour about 3 m!(0.11 Imp ¯ oz)

of engine oil through nozzle holes and repeat test.

For indications of test, refer to the following table.

Gauge indication during tests Trouble diagnosis

SEM857

+Piston rings are worn or

damaged.

SEM858

+If two adjacent cylinders

are low, gasket is dam-

aged.

+Valve is sticking.

+Valve seat or valve con-

tact surface is incorrected.

9. Replace nozzle gaskets and install injection nozzles.

New nozzle gasket installation direction is as shown.

Nozzle to cylinder head:

:59-69Nzm

(6.0 - 7.0 kg-m, 43 - 51 ft-lb)

SEM706B

SEM708B

COMPRESSION PRESSURE

Measurement of Compression Pressure

(Cont'd)

EM-12

First readingSecond

reading

Increased

reading

Same reading

maintained

Page 14 of 65

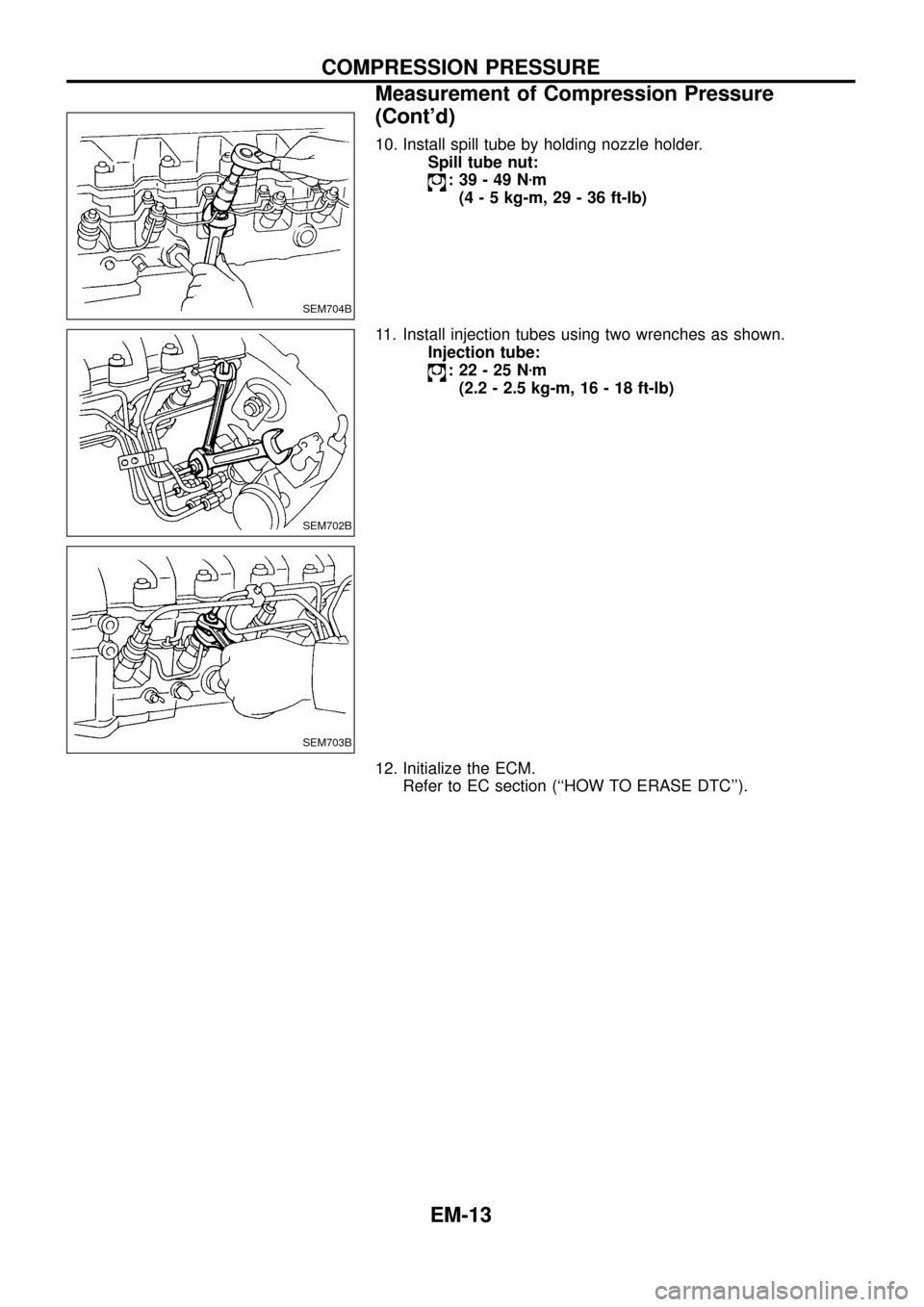

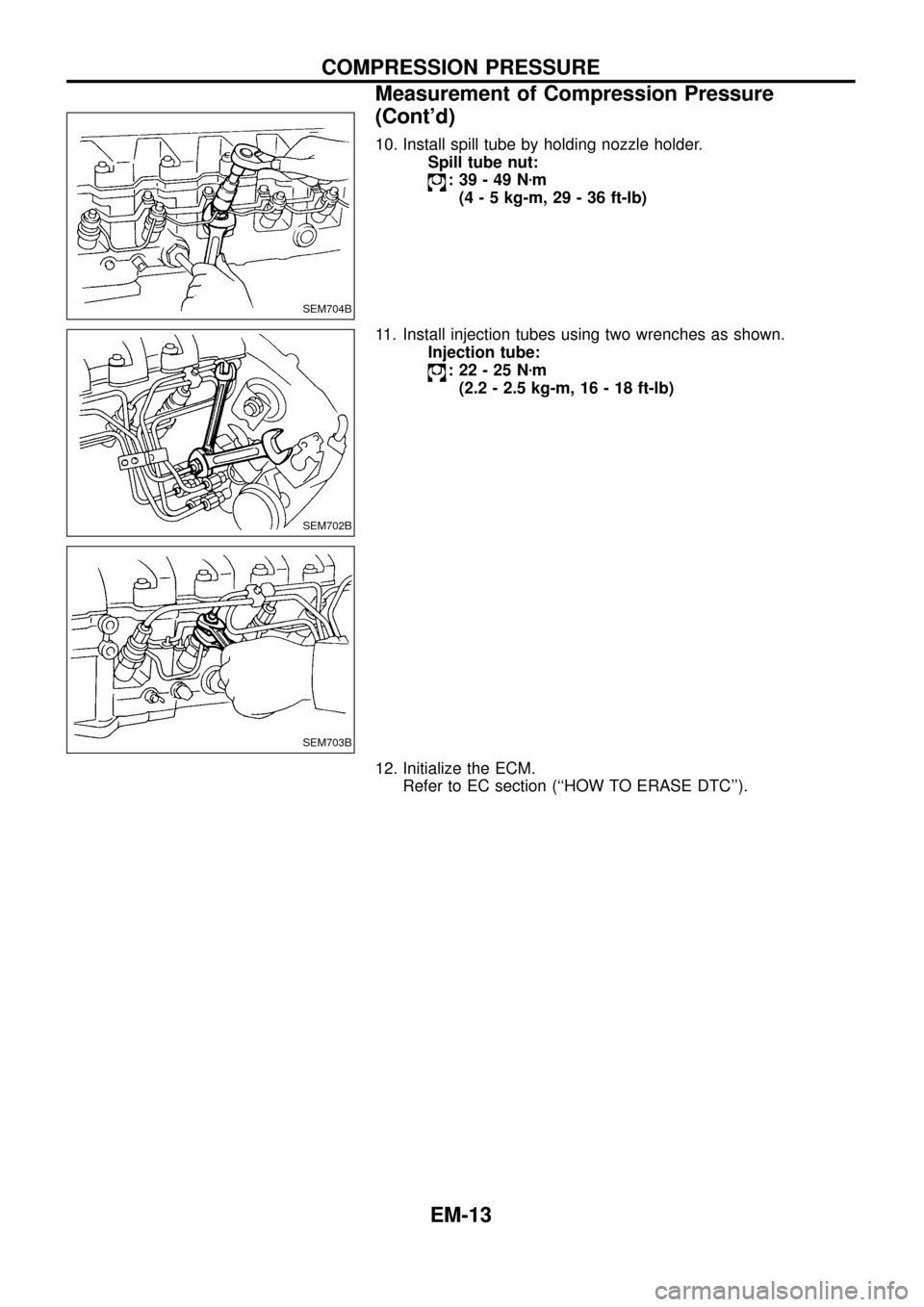

10. Install spill tube by holding nozzle holder.

Spill tube nut:

:39-49Nzm

(4 - 5 kg-m, 29 - 36 ft-lb)

11. Install injection tubes using two wrenches as shown.

Injection tube:

:22-25Nzm

(2.2 - 2.5 kg-m, 16 - 18 ft-lb)

12. Initialize the ECM.

Refer to EC section (``HOW TO ERASE DTC'').

SEM704B

SEM702B

SEM703B

COMPRESSION PRESSURE

Measurement of Compression Pressure

(Cont'd)

EM-13

Page 15 of 65

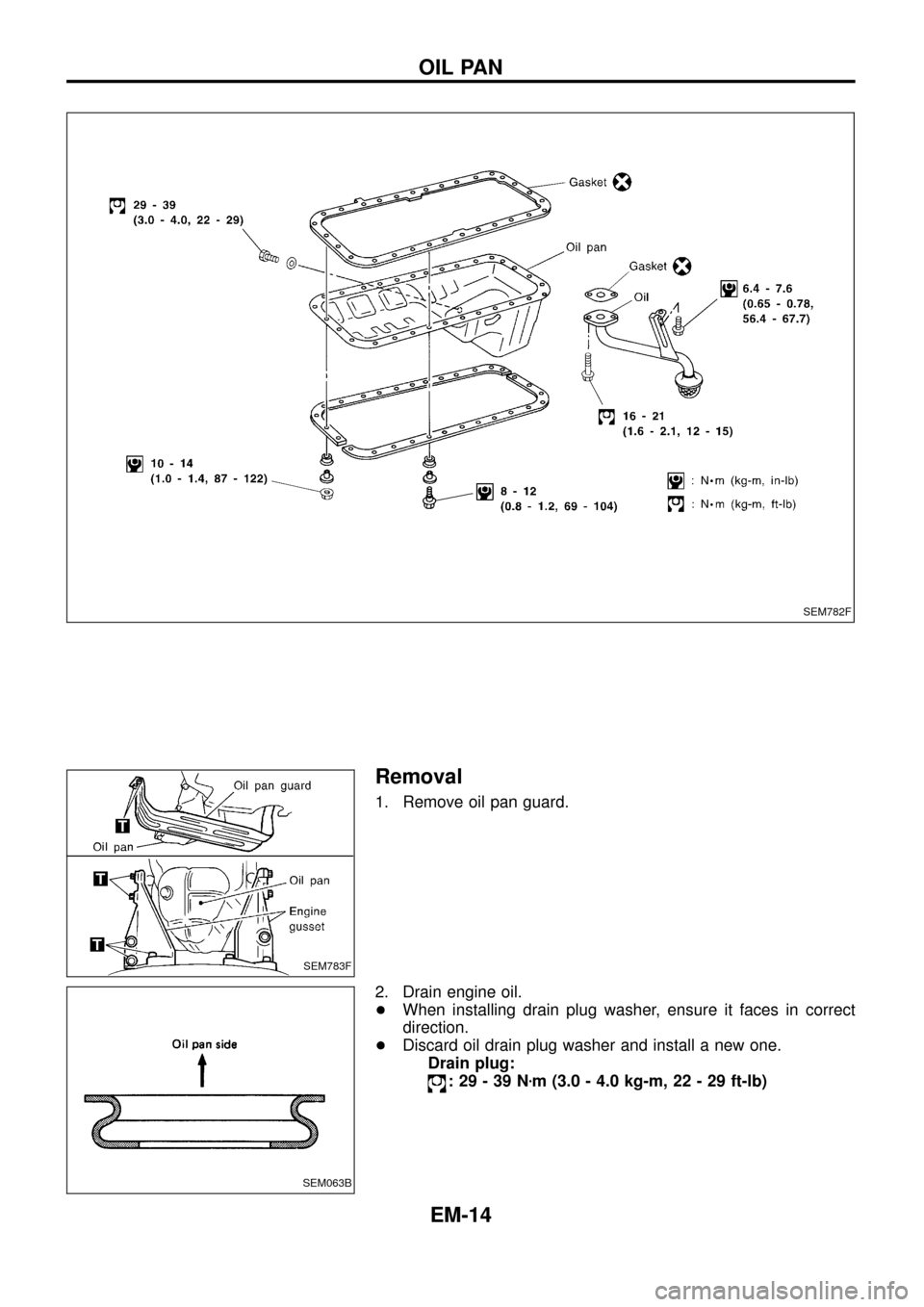

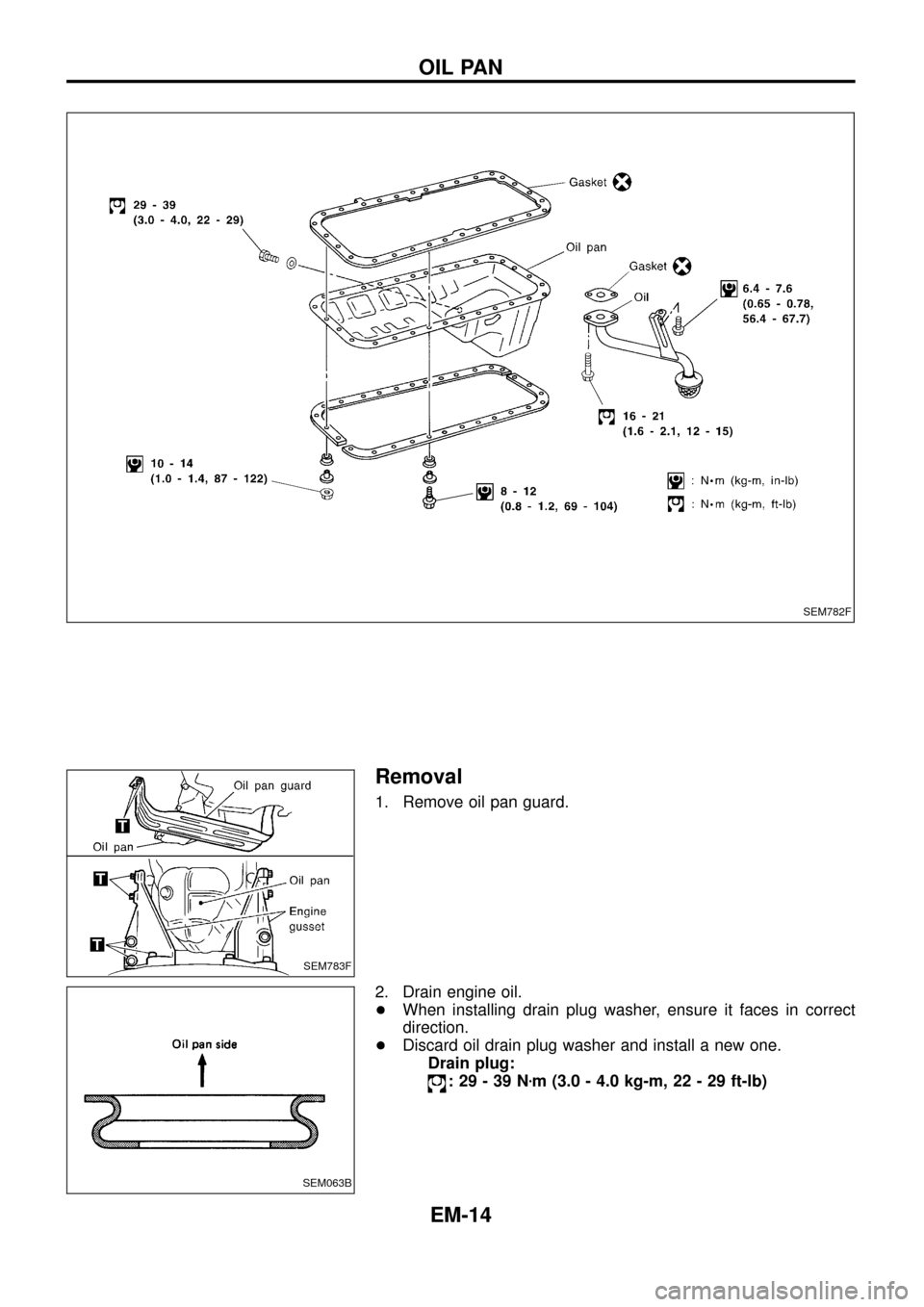

Removal

1. Remove oil pan guard.

2. Drain engine oil.

+When installing drain plug washer, ensure it faces in correct

direction.

+Discard oil drain plug washer and install a new one.

Drain plug:

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

SEM782F

SEM783F

SEM063B

OIL PAN

EM-14

Page 16 of 65

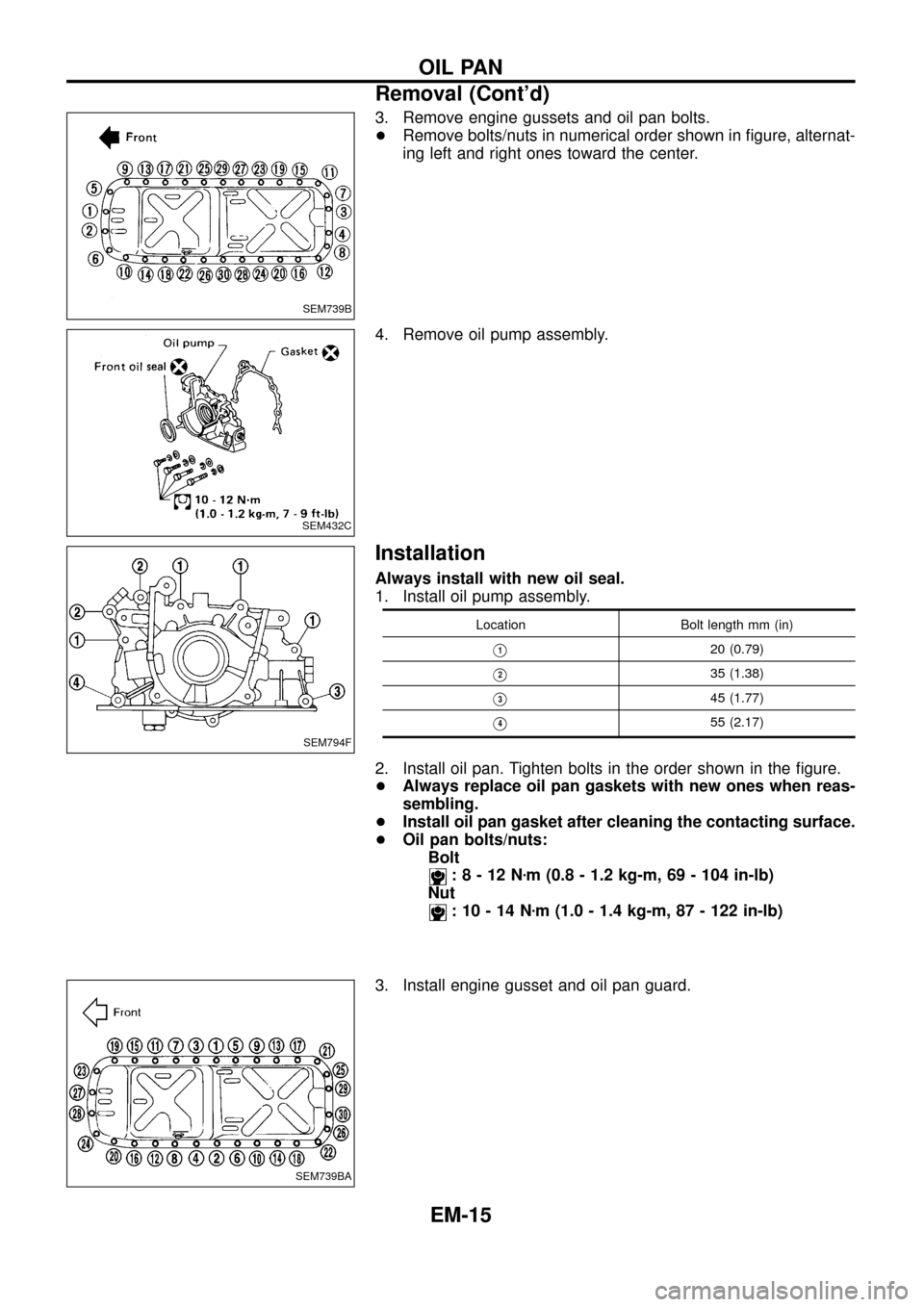

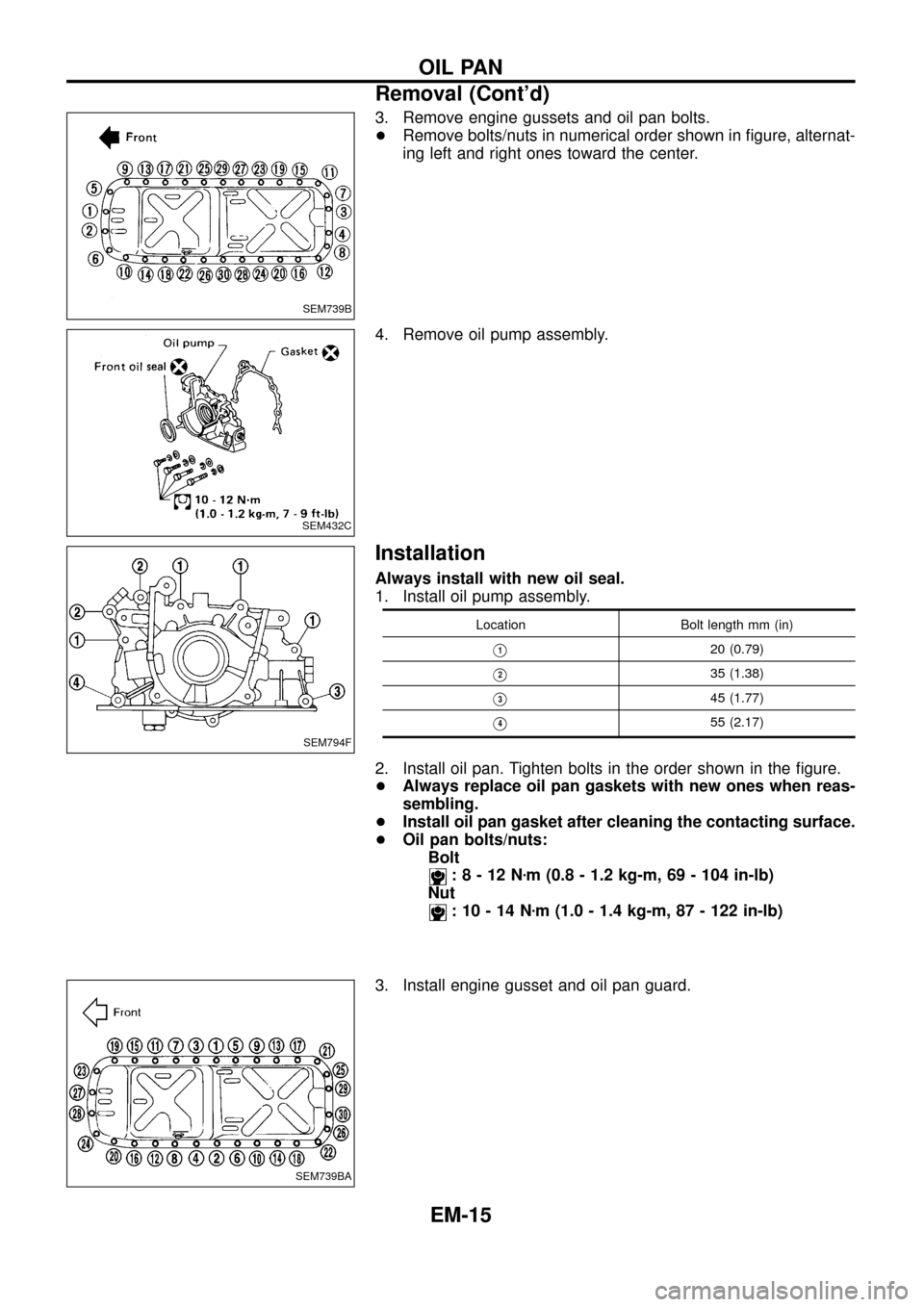

3. Remove engine gussets and oil pan bolts.

+Remove bolts/nuts in numerical order shown in ®gure, alternat-

ing left and right ones toward the center.

4. Remove oil pump assembly.

Installation

Always install with new oil seal.

1. Install oil pump assembly.

Location Bolt length mm (in)

V120 (0.79)

V235 (1.38)

V345 (1.77)

V455 (2.17)

2. Install oil pan. Tighten bolts in the order shown in the ®gure.

+Always replace oil pan gaskets with new ones when reas-

sembling.

+Install oil pan gasket after cleaning the contacting surface.

+Oil pan bolts/nuts:

Bolt

:8-12Nzm (0.8 - 1.2 kg-m, 69 - 104 in-lb)

Nut

:10-14Nzm (1.0 - 1.4 kg-m, 87 - 122 in-lb)

3. Install engine gusset and oil pan guard.

SEM739B

SEM432C

SEM794F

SEM739BA

OIL PAN

Removal (Cont'd)

EM-15

Page 17 of 65

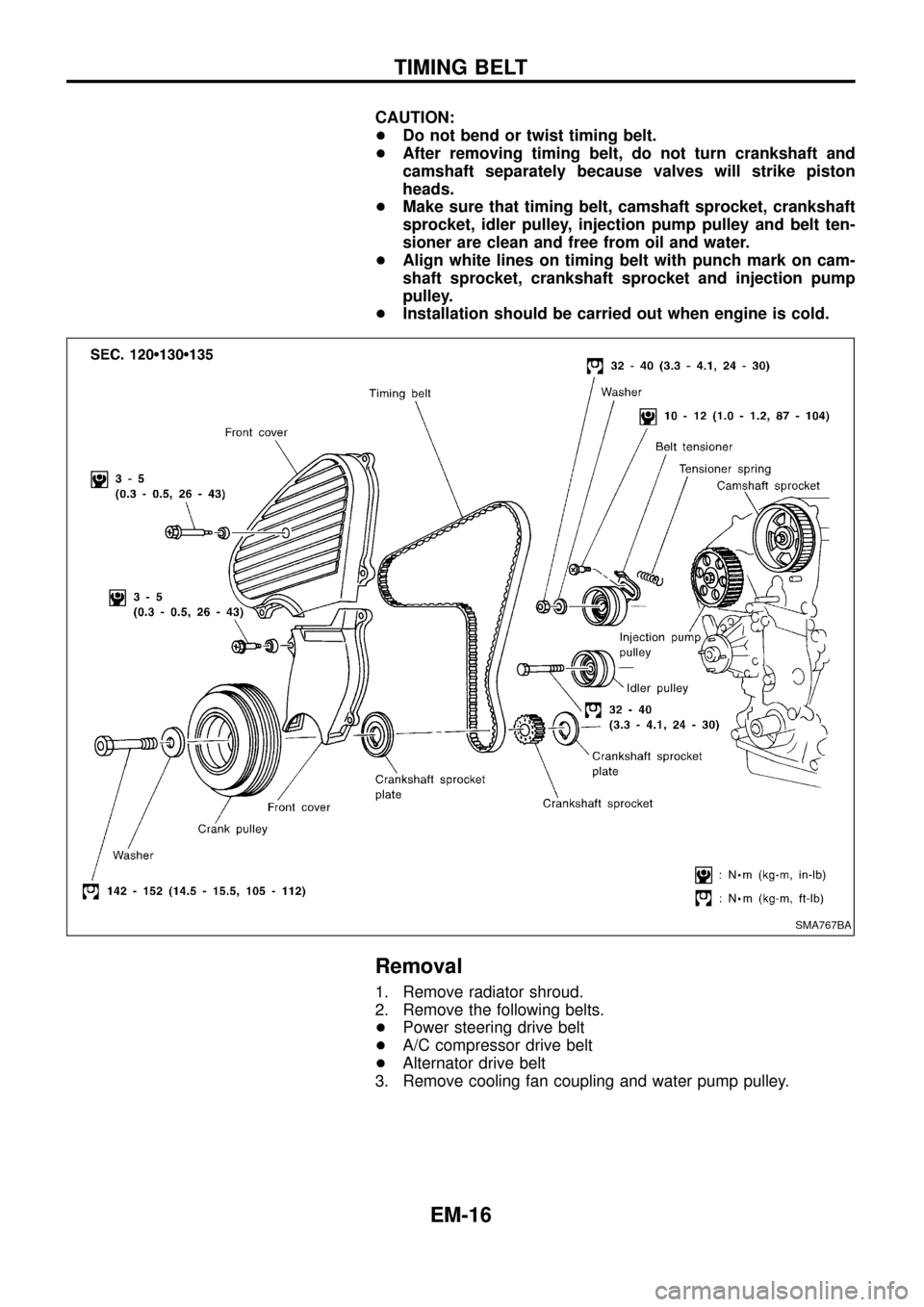

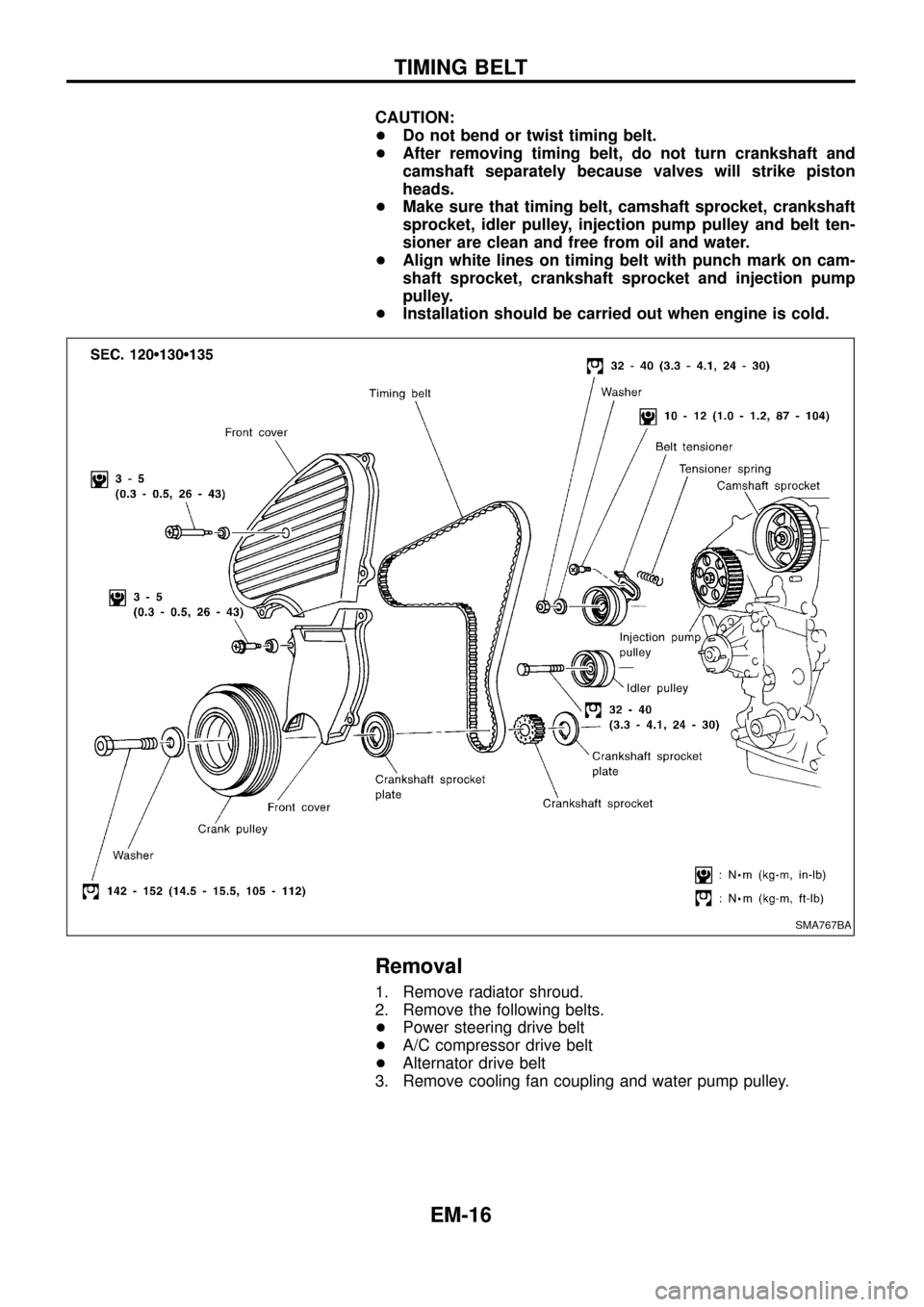

CAUTION:

+Do not bend or twist timing belt.

+After removing timing belt, do not turn crankshaft and

camshaft separately because valves will strike piston

heads.

+Make sure that timing belt, camshaft sprocket, crankshaft

sprocket, idler pulley, injection pump pulley and belt ten-

sioner are clean and free from oil and water.

+Align white lines on timing belt with punch mark on cam-

shaft sprocket, crankshaft sprocket and injection pump

pulley.

+Installation should be carried out when engine is cold.

Removal

1. Remove radiator shroud.

2. Remove the following belts.

+Power steering drive belt

+A/C compressor drive belt

+Alternator drive belt

3. Remove cooling fan coupling and water pump pulley.

SMA767BA

TIMING BELT

EM-16

Page 18 of 65

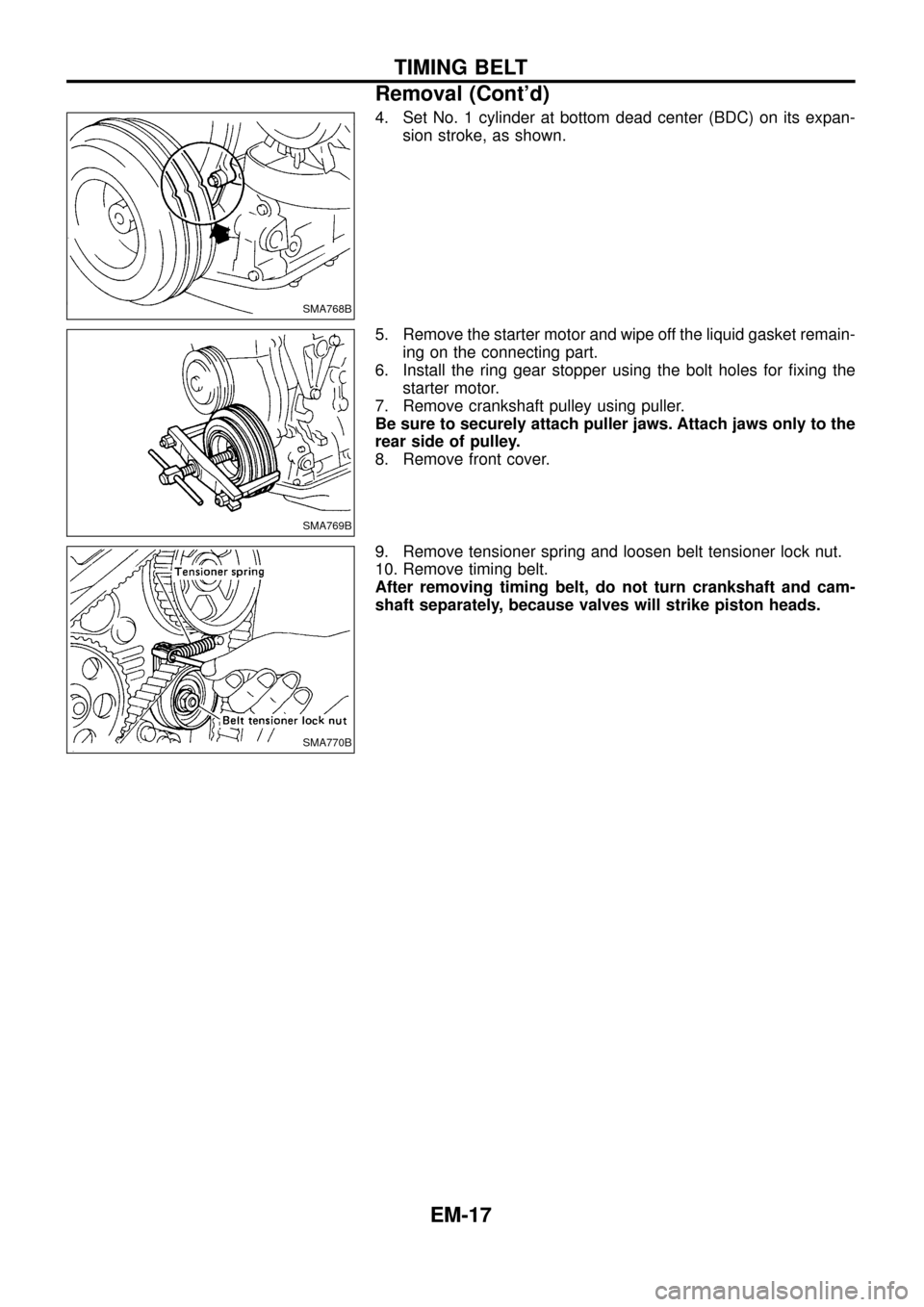

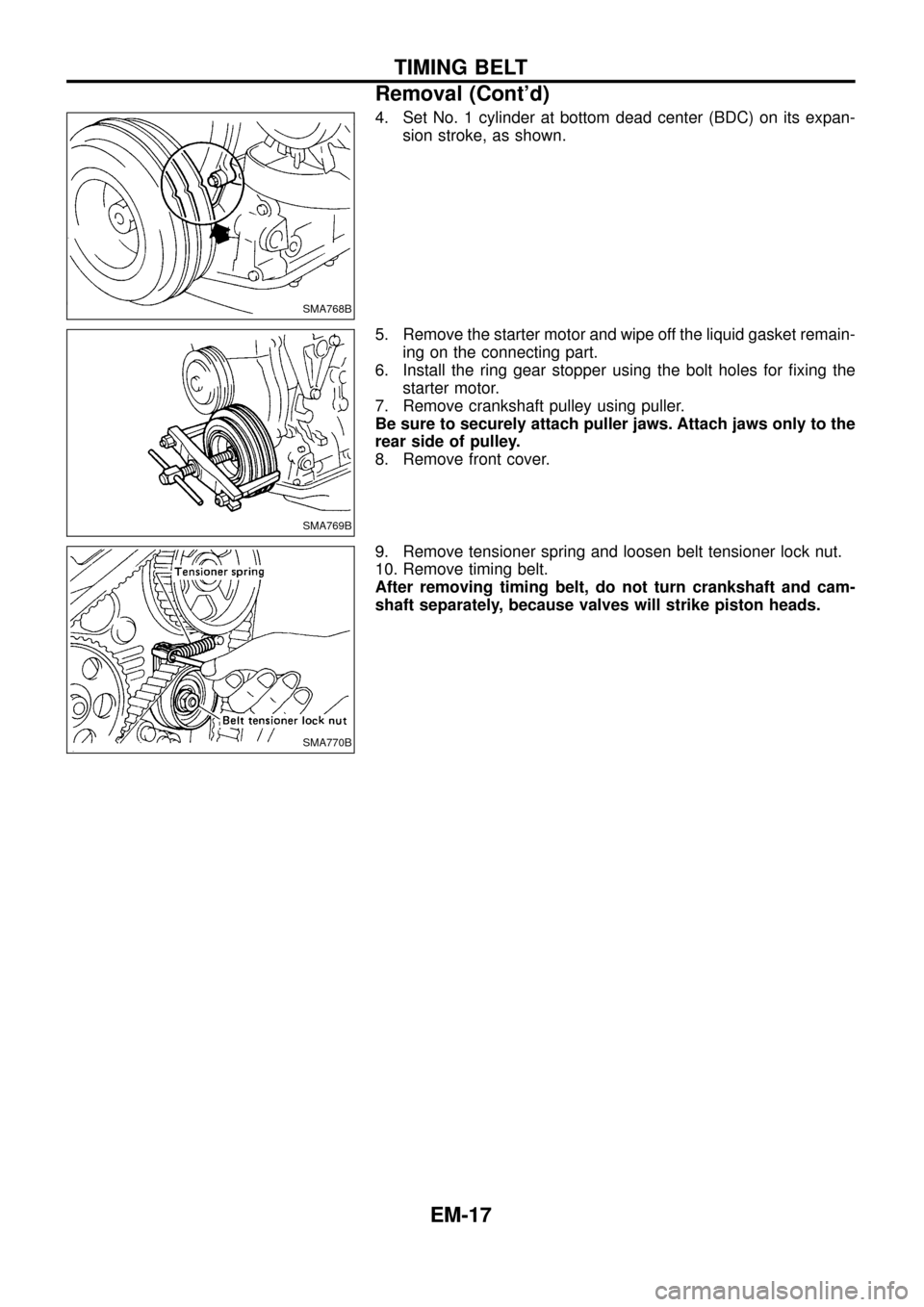

4. Set No. 1 cylinder at bottom dead center (BDC) on its expan-

sion stroke, as shown.

5. Remove the starter motor and wipe off the liquid gasket remain-

ing on the connecting part.

6. Install the ring gear stopper using the bolt holes for ®xing the

starter motor.

7. Remove crankshaft pulley using puller.

Be sure to securely attach puller jaws. Attach jaws only to the

rear side of pulley.

8. Remove front cover.

9. Remove tensioner spring and loosen belt tensioner lock nut.

10. Remove timing belt.

After removing timing belt, do not turn crankshaft and cam-

shaft separately, because valves will strike piston heads.

SMA768B

SMA769B

SMA770B

TIMING BELT

Removal (Cont'd)

EM-17

Page 19 of 65

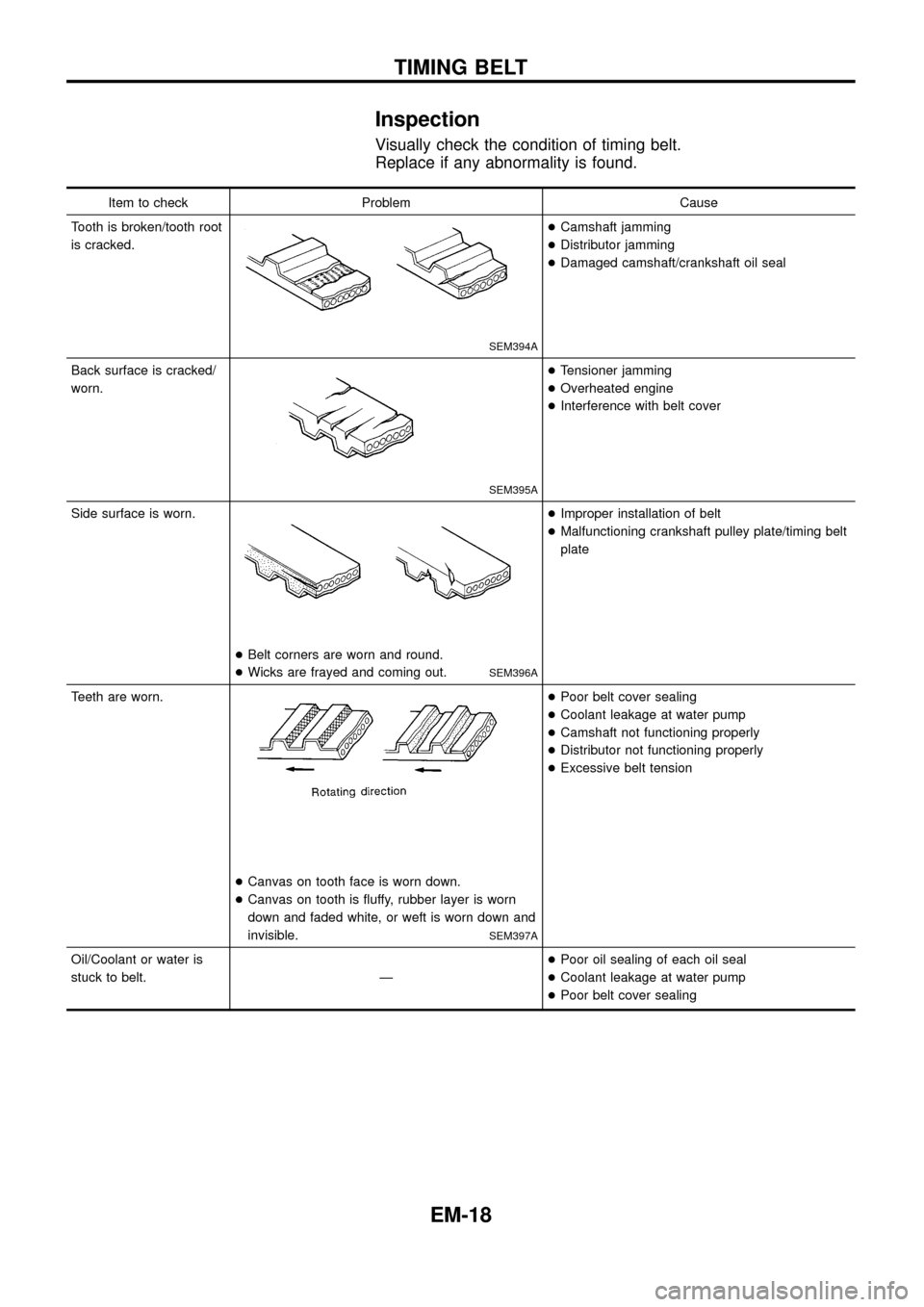

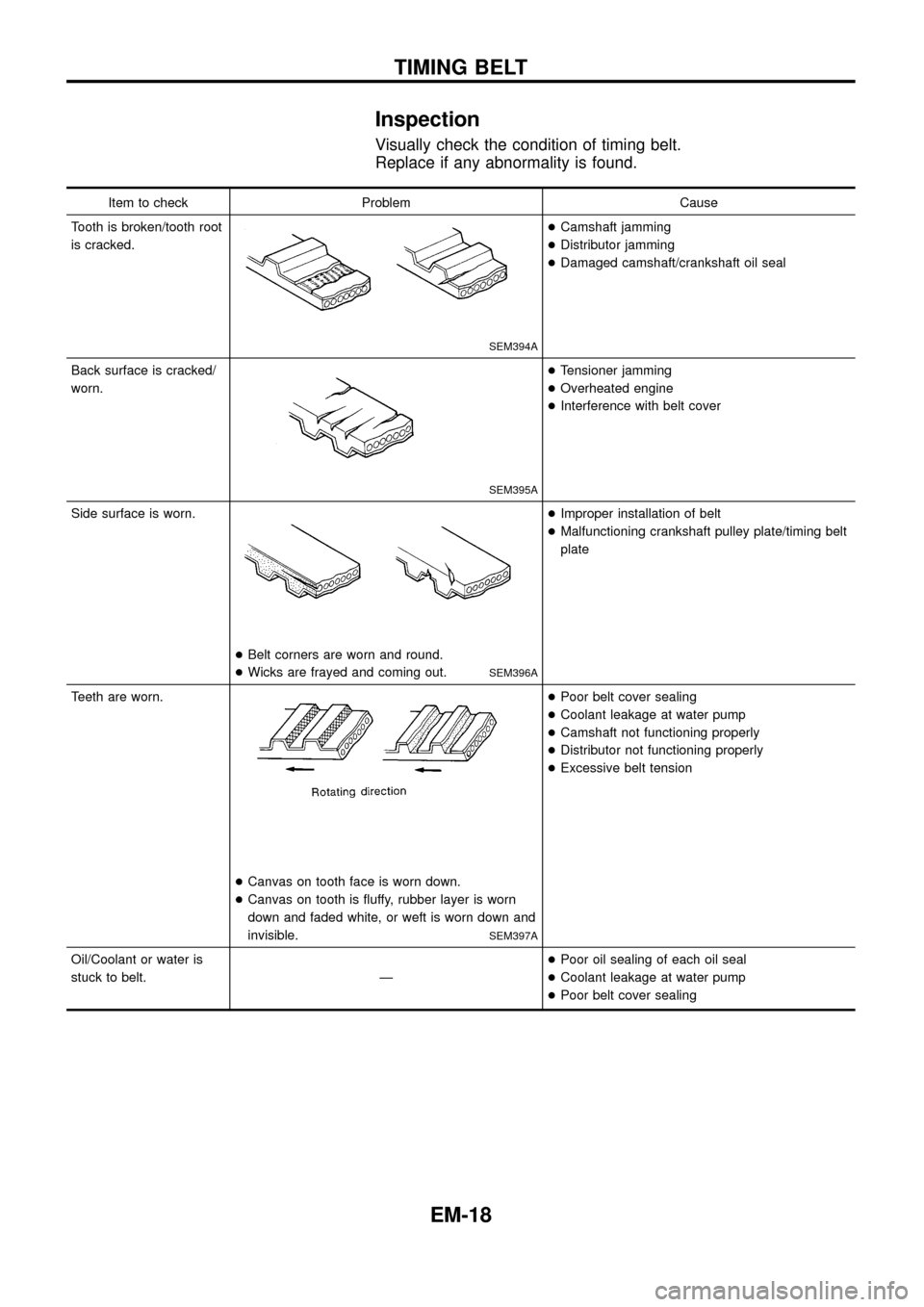

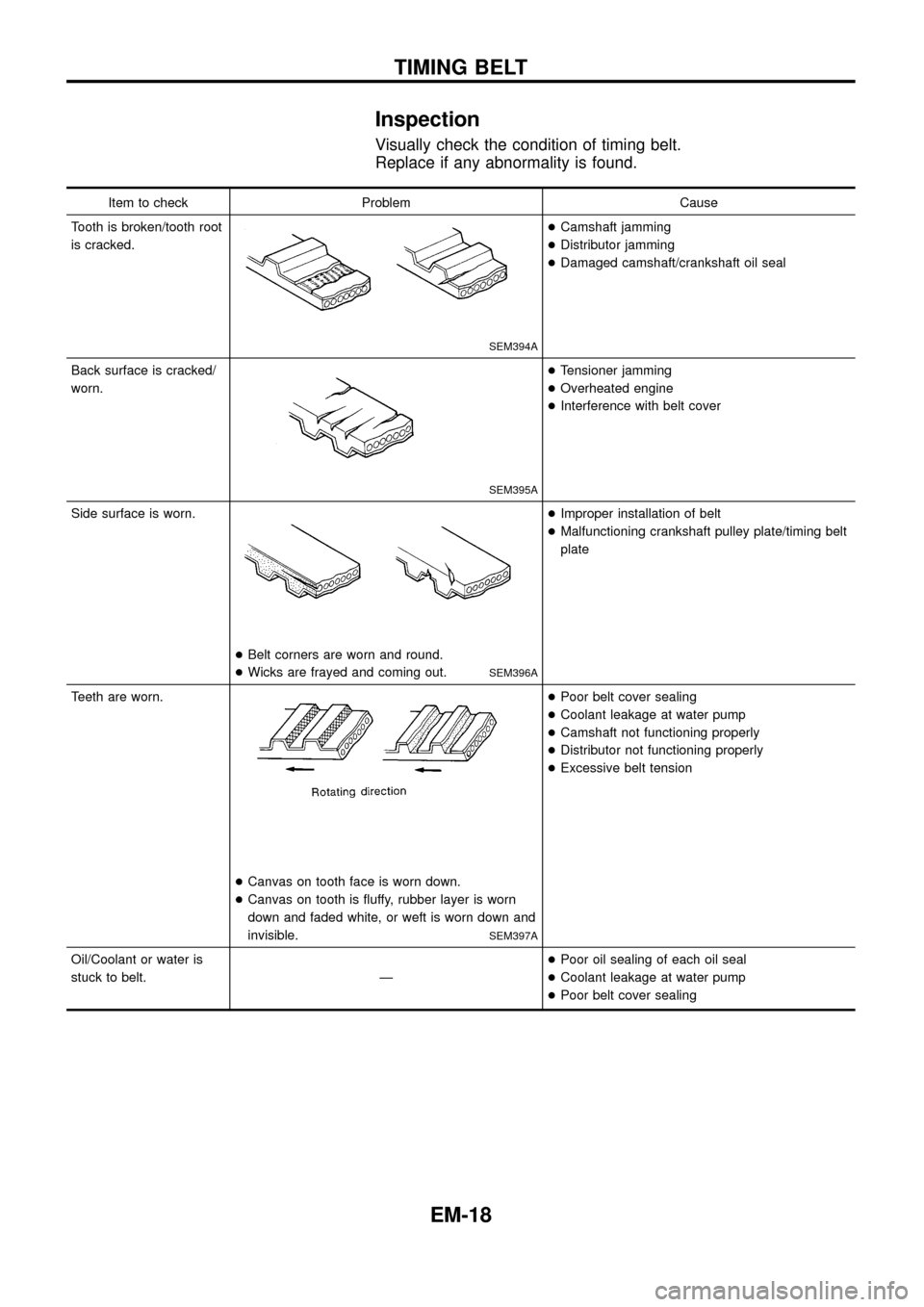

Inspection

Visually check the condition of timing belt.

Replace if any abnormality is found.

Item to check Problem Cause

Tooth is broken/tooth root

is cracked.

SEM394A

+Camshaft jamming

+Distributor jamming

+Damaged camshaft/crankshaft oil seal

Back surface is cracked/

worn.

SEM395A

+Tensioner jamming

+Overheated engine

+Interference with belt cover

Side surface is worn.

+Belt corners are worn and round.

+Wicks are frayed and coming out.

SEM396A

+Improper installation of belt

+Malfunctioning crankshaft pulley plate/timing belt

plate

Teeth are worn.

+Canvas on tooth face is worn down.

+Canvas on tooth is ¯uffy, rubber layer is worn

down and faded white, or weft is worn down and

invisible.

SEM397A

+Poor belt cover sealing

+Coolant leakage at water pump

+Camshaft not functioning properly

+Distributor not functioning properly

+Excessive belt tension

Oil/Coolant or water is

stuck to belt. Ð+Poor oil sealing of each oil seal

+Coolant leakage at water pump

+Poor belt cover sealing

TIMING BELT

EM-18

Page 20 of 65

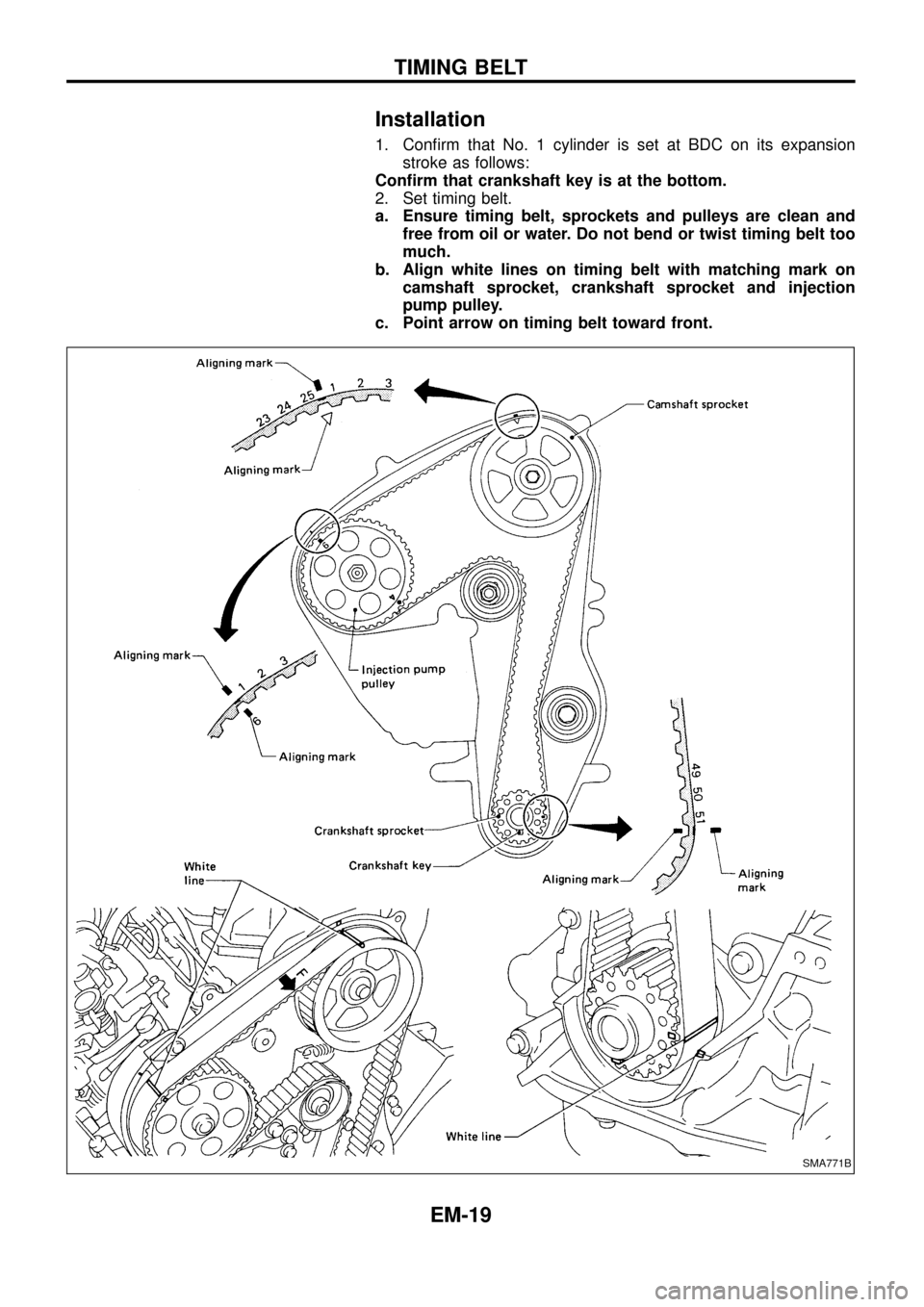

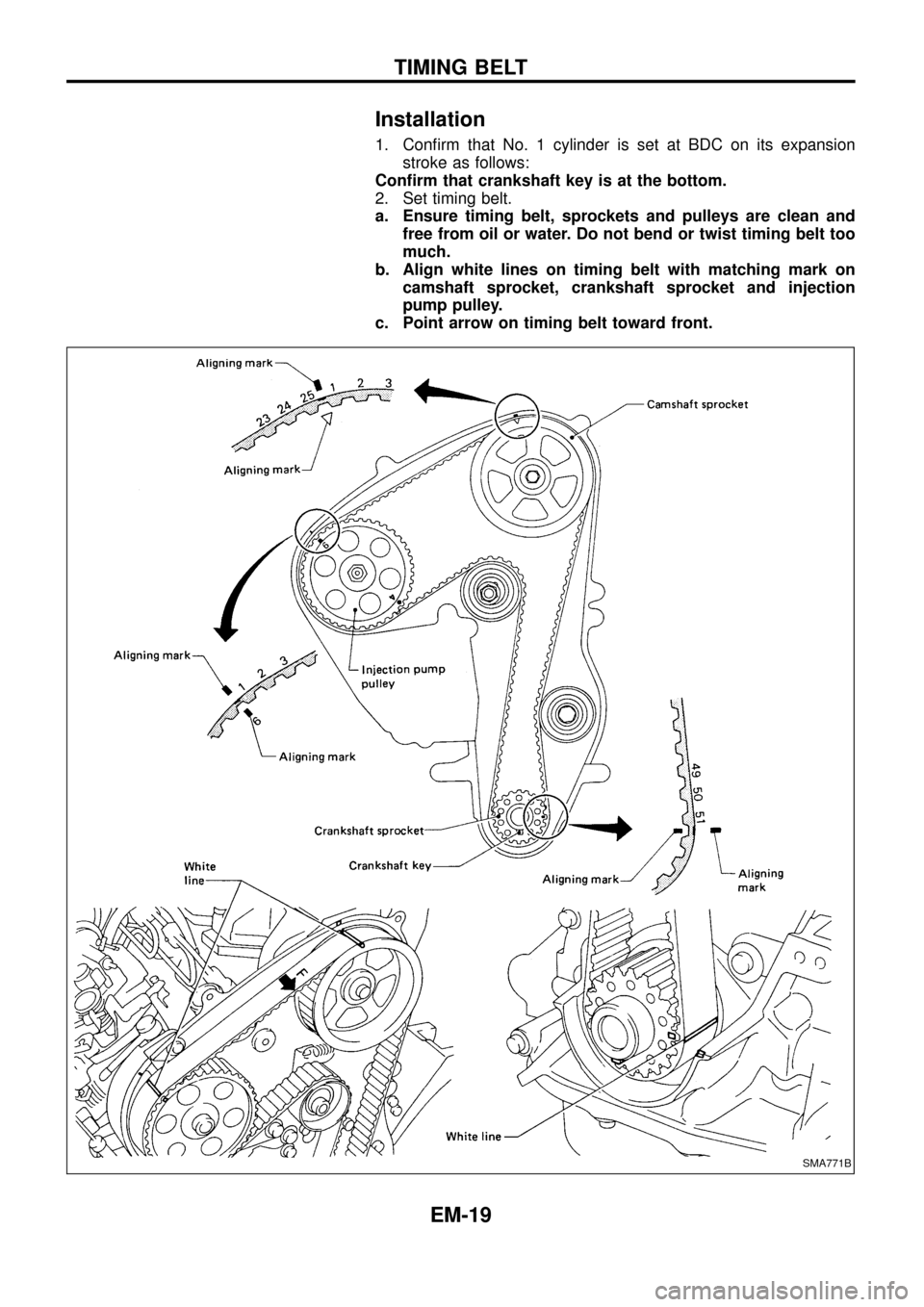

Installation

1. Con®rm that No. 1 cylinder is set at BDC on its expansion

stroke as follows:

Con®rm that crankshaft key is at the bottom.

2. Set timing belt.

a. Ensure timing belt, sprockets and pulleys are clean and

free from oil or water. Do not bend or twist timing belt too

much.

b. Align white lines on timing belt with matching mark on

camshaft sprocket, crankshaft sprocket and injection

pump pulley.

c. Point arrow on timing belt toward front.

SMA771B

TIMING BELT

EM-19

Trending: wheel size, fuel cap, power steering, seats, differential, cooling, engine overheat