NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 851 of 1033

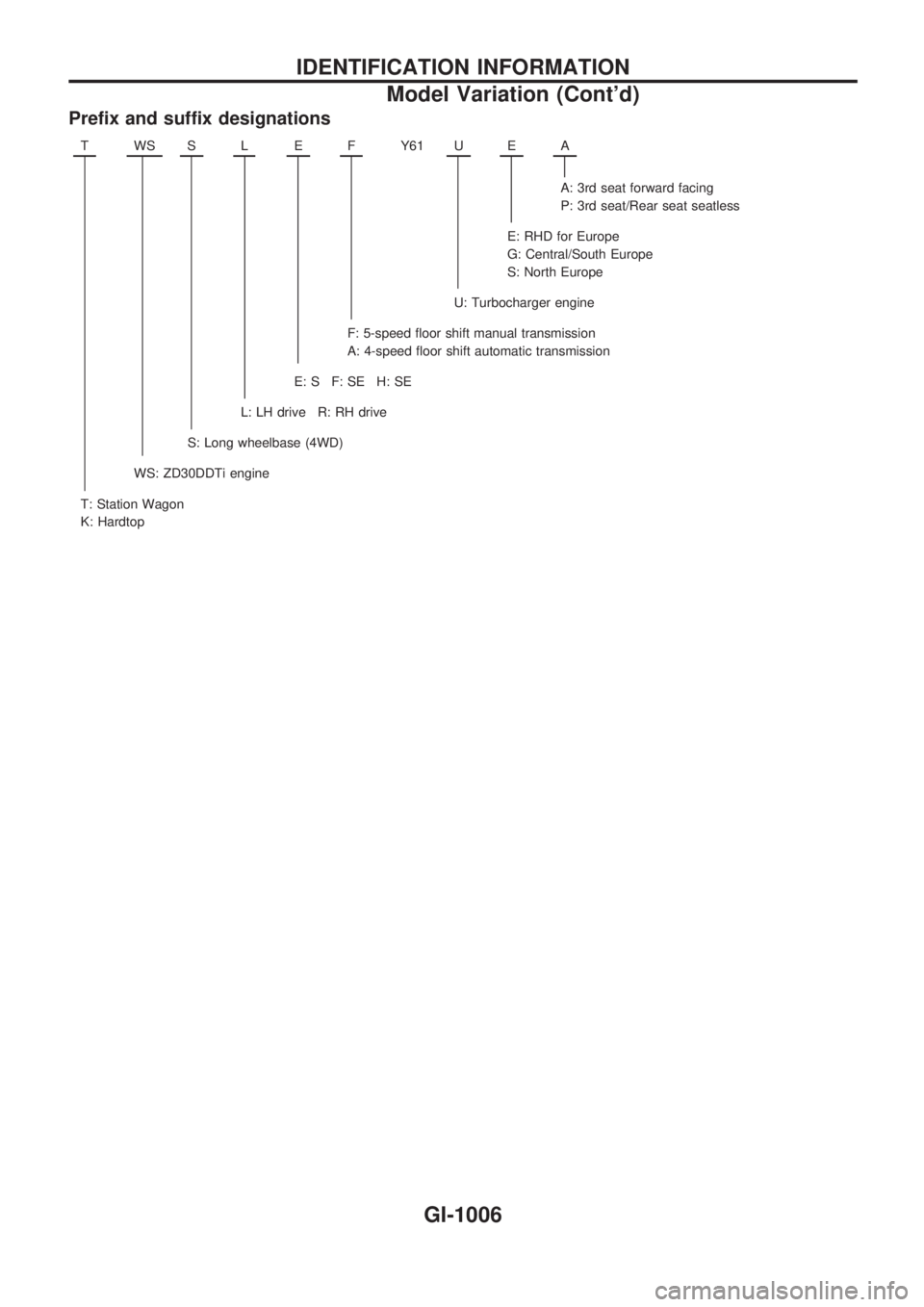

Prefix and suffix designations

TWSSLEFY61 UEA

A: 3rd seat forward facing

P: 3rd seat/Rear seat seatless

E: RHD for Europe

G: Central/South Europe

S: North Europe

U: Turbocharger engine

F: 5-speed floor shift manual transmission

A: 4-speed floor shift automatic transmission

E:SF:SEH:SE

L: LH drive R: RH drive

S: Long wheelbase (4WD)

WS: ZD30DDTi engine

T: Station Wagon

K: Hardtop

IDENTIFICATION INFORMATION

Model Variation (Cont'd)

GI-1006

Page 852 of 1033

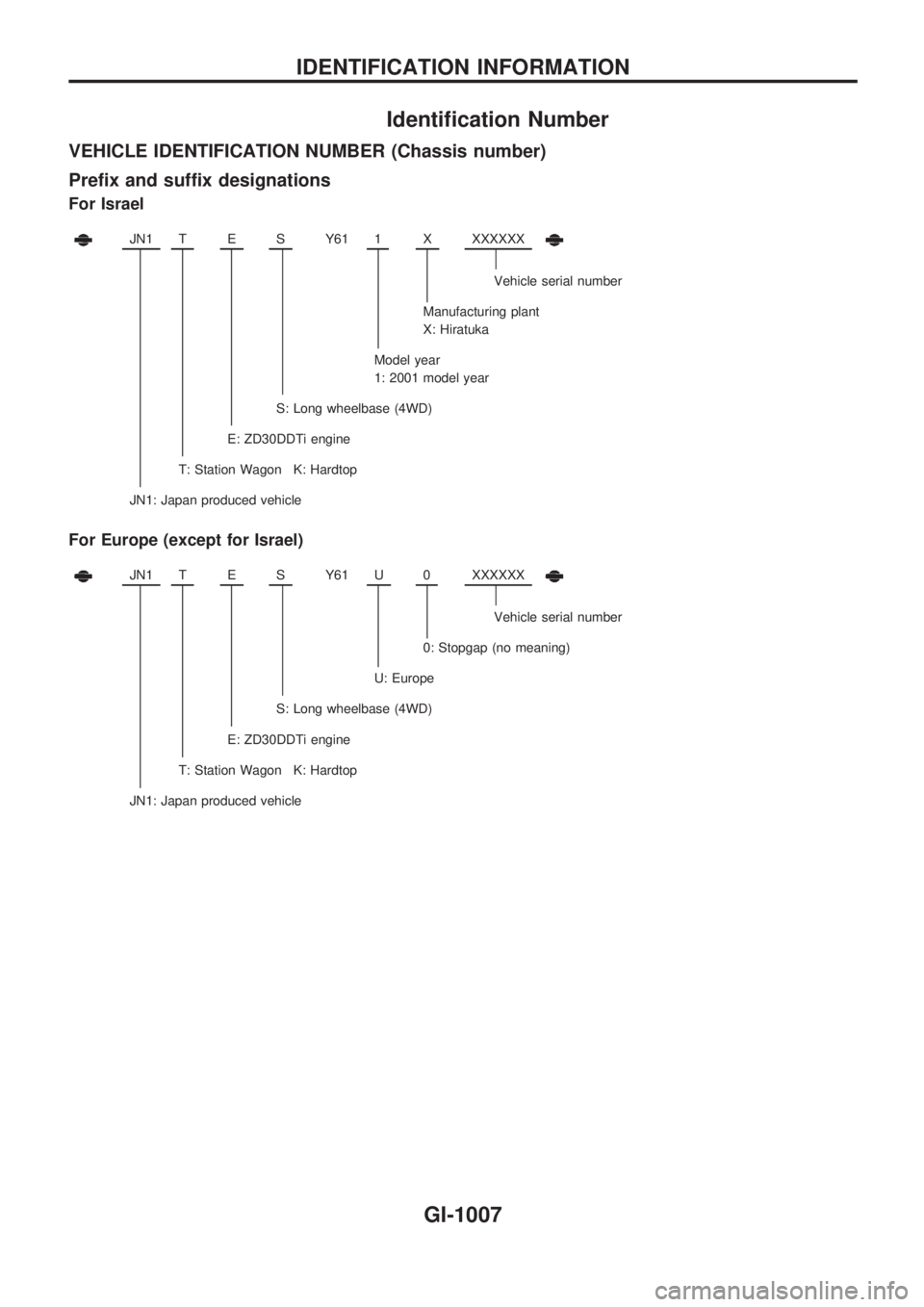

Identification Number

VEHICLE IDENTIFICATION NUMBER (Chassis number)

Prefix and suffix designations

For Israel

JN1TESY61 1XXXXXXX

Vehicle serial number

Manufacturing plant

X: Hiratuka

Model year

1: 2001 model year

S: Long wheelbase (4WD)

E: ZD30DDTi engine

T: Station Wagon K: Hardtop

JN1: Japan produced vehicle

For Europe (except for Israel)

JN1TESY61 U0XXXXXX

Vehicle serial number

0: Stopgap (no meaning)

U: Europe

S: Long wheelbase (4WD)

E: ZD30DDTi engine

T: Station Wagon K: Hardtop

JN1: Japan produced vehicle

IDENTIFICATION INFORMATION

GI-1007

Page 853 of 1033

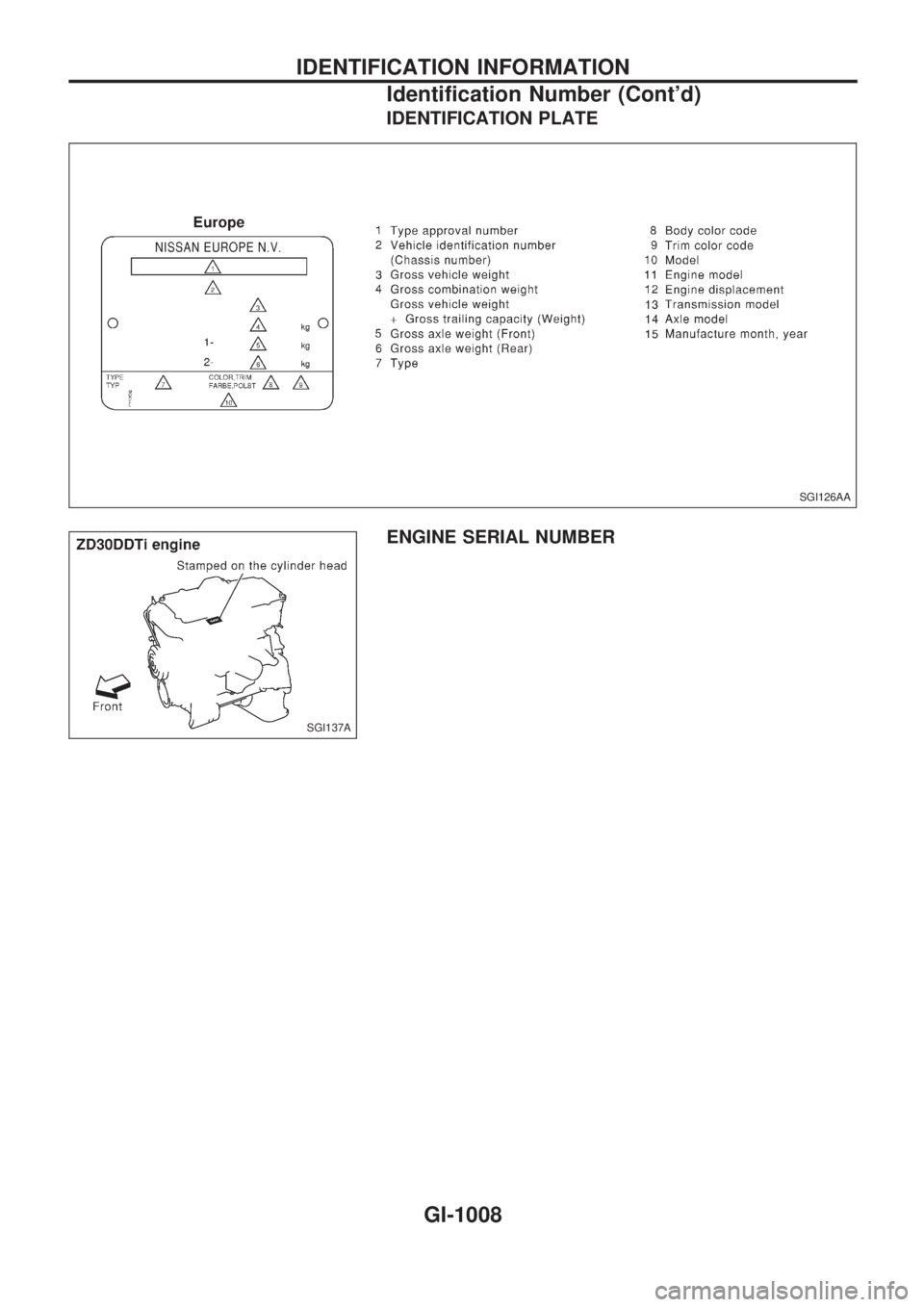

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

SGI126AA

SGI137A

IDENTIFICATION INFORMATION

Identification Number (Cont'd)

GI-1008

Page 854 of 1033

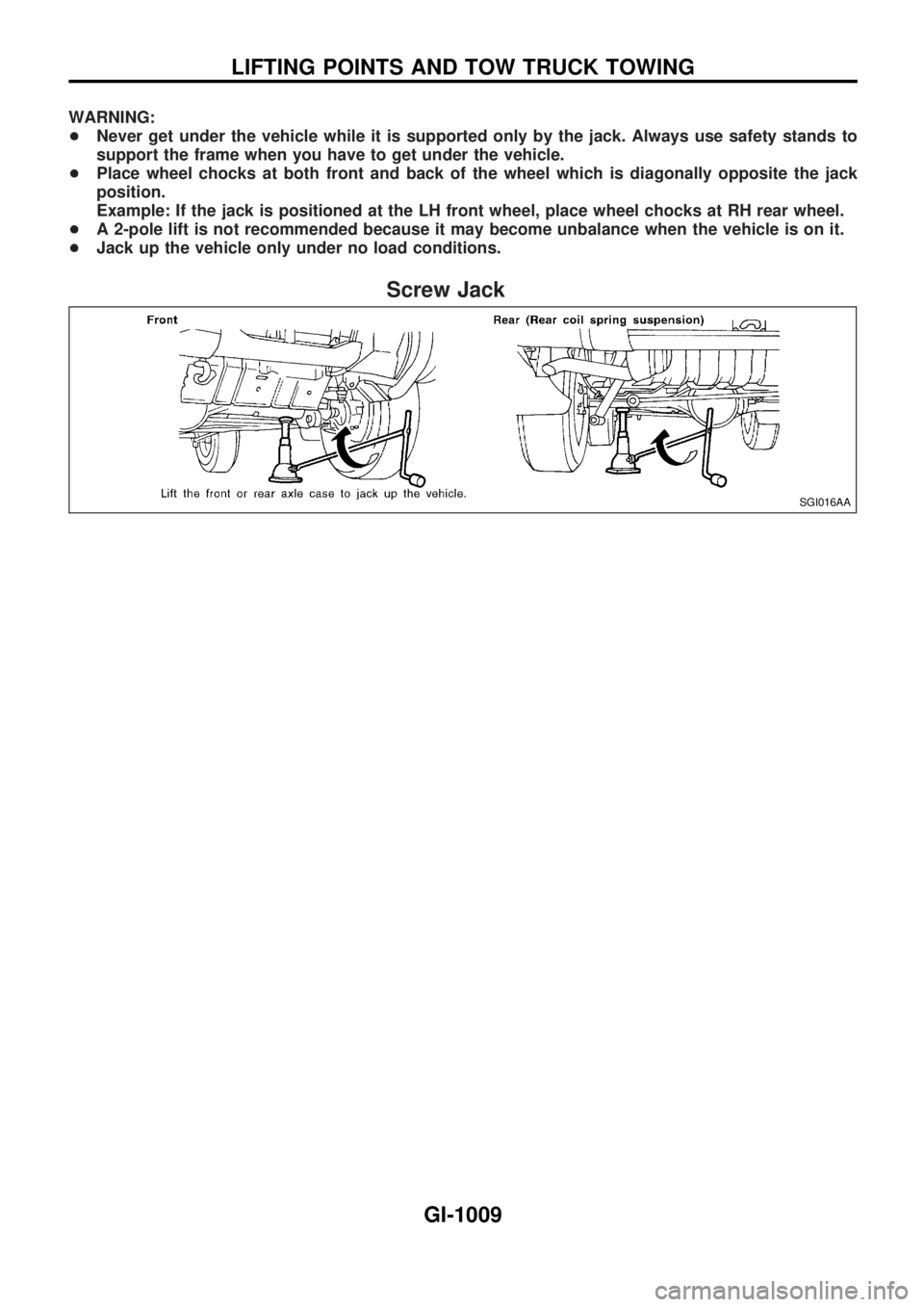

WARNING:

+Never get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

+Place wheel chocks at both front and back of the wheel which is diagonally opposite the jack

position.

Example: If the jack is positioned at the LH front wheel, place wheel chocks at RH rear wheel.

+A 2-pole lift is not recommended because it may become unbalance when the vehicle is on it.

+Jack up the vehicle only under no load conditions.

Screw Jack

SGI016AA

LIFTING POINTS AND TOW TRUCK TOWING

GI-1009

Page 855 of 1033

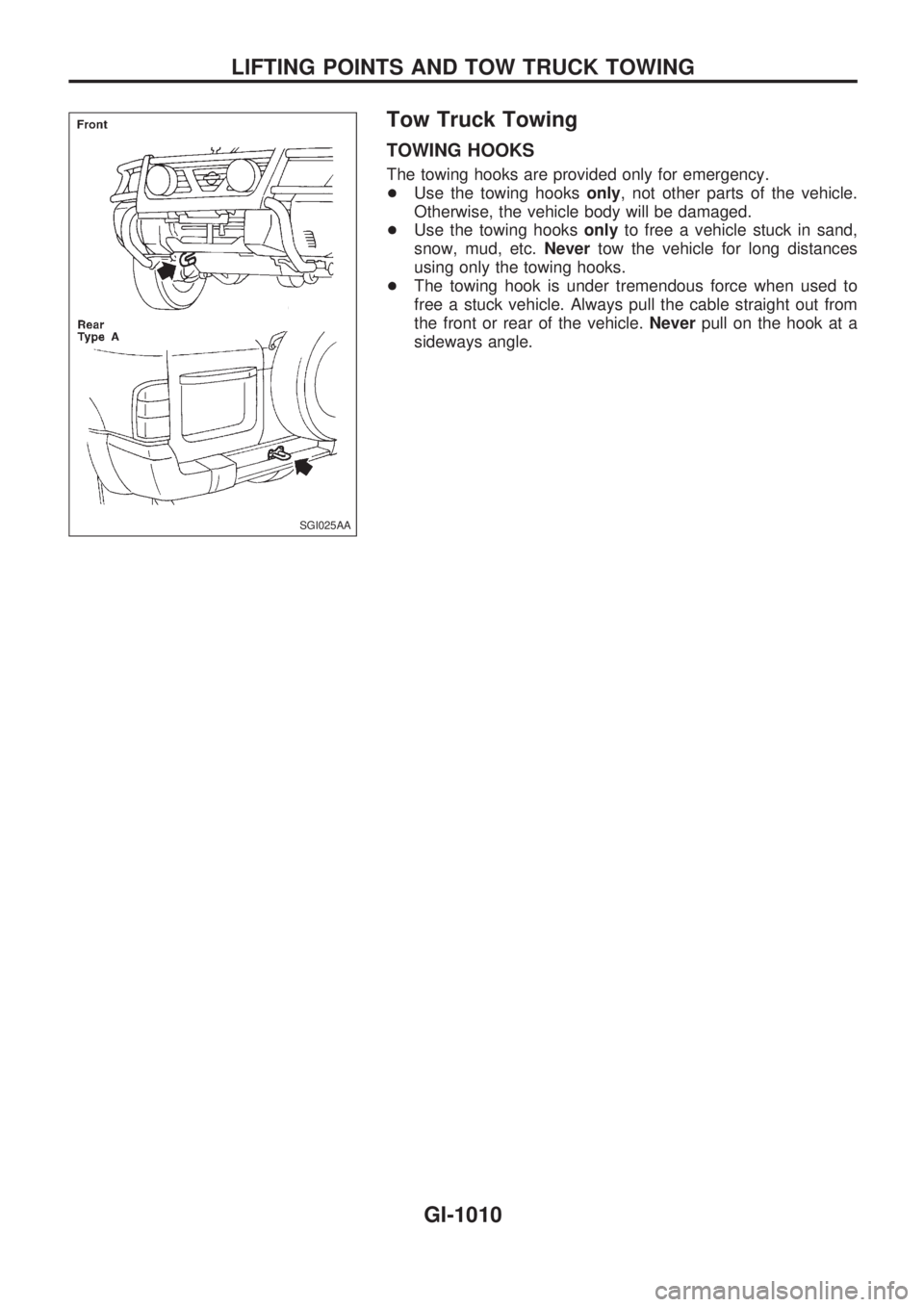

Tow Truck Towing

TOWING HOOKS

The towing hooks are provided only for emergency.

+Use the towing hooksonly, not other parts of the vehicle.

Otherwise, the vehicle body will be damaged.

+Use the towing hooksonlyto free a vehicle stuck in sand,

snow, mud, etc.Nevertow the vehicle for long distances

using only the towing hooks.

+The towing hook is under tremendous force when used to

free a stuck vehicle. Always pull the cable straight out from

the front or rear of the vehicle.Neverpull on the hook at a

sideways angle.

SGI025AA

LIFTING POINTS AND TOW TRUCK TOWING

GI-1010

Page 856 of 1033

HEATER &

AIR CONDITIONER

SECTION

HA

MODIFICATION NOTICE:

+Wiring diagrams have been changed.

+Cooler cycle for ZD30DDTi engine has been added.

CONTENTS

PRECAUTIONS AND PREPARATION............... 1002

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 1002

Precautions for Refrigerant Connection .......... 1002

MANUAL

TROUBLE DIAGNOSES..................................... 1005

Wiring Diagram Ð HEATER Ð ....................... 1005

Wiring Diagram Ð R/HEAT Ð/LHD Models ... 1006

Wiring Diagram Ð A/C, M Ð/ZD Engine ........ 1007

AUTO

TROUBLE DIAGNOSES..................................... 1009

Circuit Diagram ................................................ 1009

Wiring Diagram Ð A/C, A Ð/ZD Engine......... 1010REAR COOLER

TROUBLE DIAGNOSES..................................... 1013

Wiring Diagram Ð R/COOL Ð/LHD Models

with Front Auto A/C ......................................... 1013

Wiring Diagram Ð R/COOL Ð/LHD Models

with Front Manual A/C ..................................... 1015

Wiring Diagram Ð R/COOL Ð/RHD Models

with Front Auto A/C ......................................... 1017

Wiring Diagram Ð R/COOL Ð/RHD Models

with Front Manual A/C ..................................... 1019

MANUAL AND AUTO

SERVICE PROCEDURES................................... 1021

Refrigerant Lines.............................................. 1021

Compressor Mounting...................................... 1023

HA

Page 857 of 1033

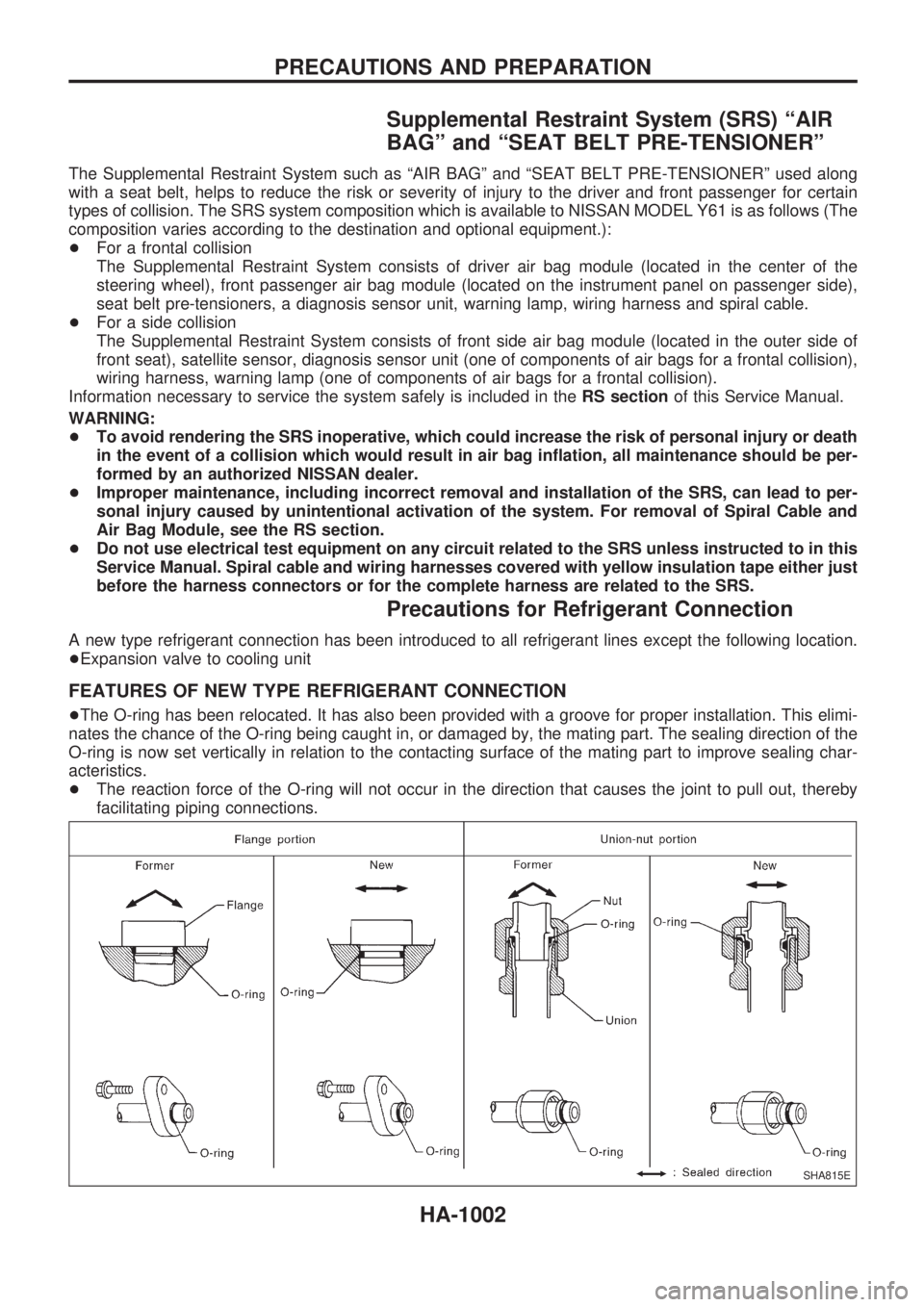

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Refrigerant Connection

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

+Expansion valve to cooling unit

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

+The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of the

O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing char-

acteristics.

+The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby

facilitating piping connections.

SHA815E

PRECAUTIONS AND PREPARATION

HA-1002

Page 858 of 1033

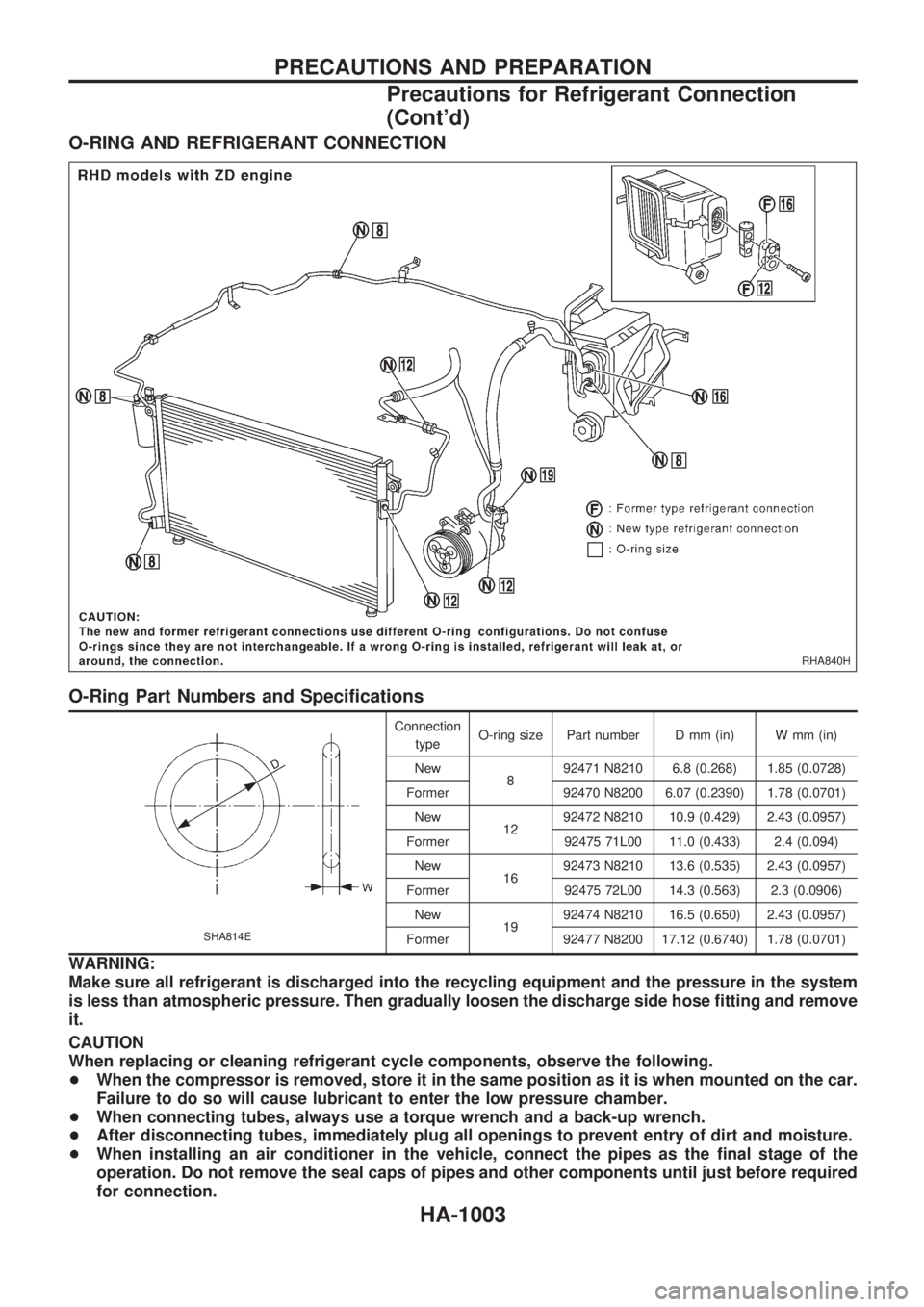

O-RING AND REFRIGERANT CONNECTION

O-Ring Part Numbers and Specifications

SHA814E

Connection

typeO-ring size Part number D mm (in) W mm (in)

New

892471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 92470 N8200 6.07 (0.2390) 1.78 (0.0701)

New

1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.4 (0.094)

New

1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.3 (0.0906)

New

1992474 N8210 16.5 (0.650) 2.43 (0.0957)

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701)

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system

is less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove

it.

CAUTION

When replacing or cleaning refrigerant cycle components, observe the following.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

+When connecting tubes, always use a torque wrench and a back-up wrench.

+After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

+When installing an air conditioner in the vehicle, connect the pipes as the final stage of the

operation. Do not remove the seal caps of pipes and other components until just before required

for connection.

RHA840H

PRECAUTIONS AND PREPARATION

Precautions for Refrigerant Connection

(Cont'd)

HA-1003

Page 859 of 1033

+Allow components stored in cool areas to warm to working area temperature before removing

seal caps. This prevents condensation from forming inside A/C components.

+Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

+Always replace used O-rings.

+When connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful

not to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

+O-ring must be closely attached to dented portion of tube.

+When replacing the O-ring, be careful not to damage O-ring and tube.

+Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure

that the O-ring is installed to tube correctly.

+After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

PRECAUTIONS AND PREPARATION

Precautions for Refrigerant Connection

(Cont'd)

HA-1004

Page 860 of 1033

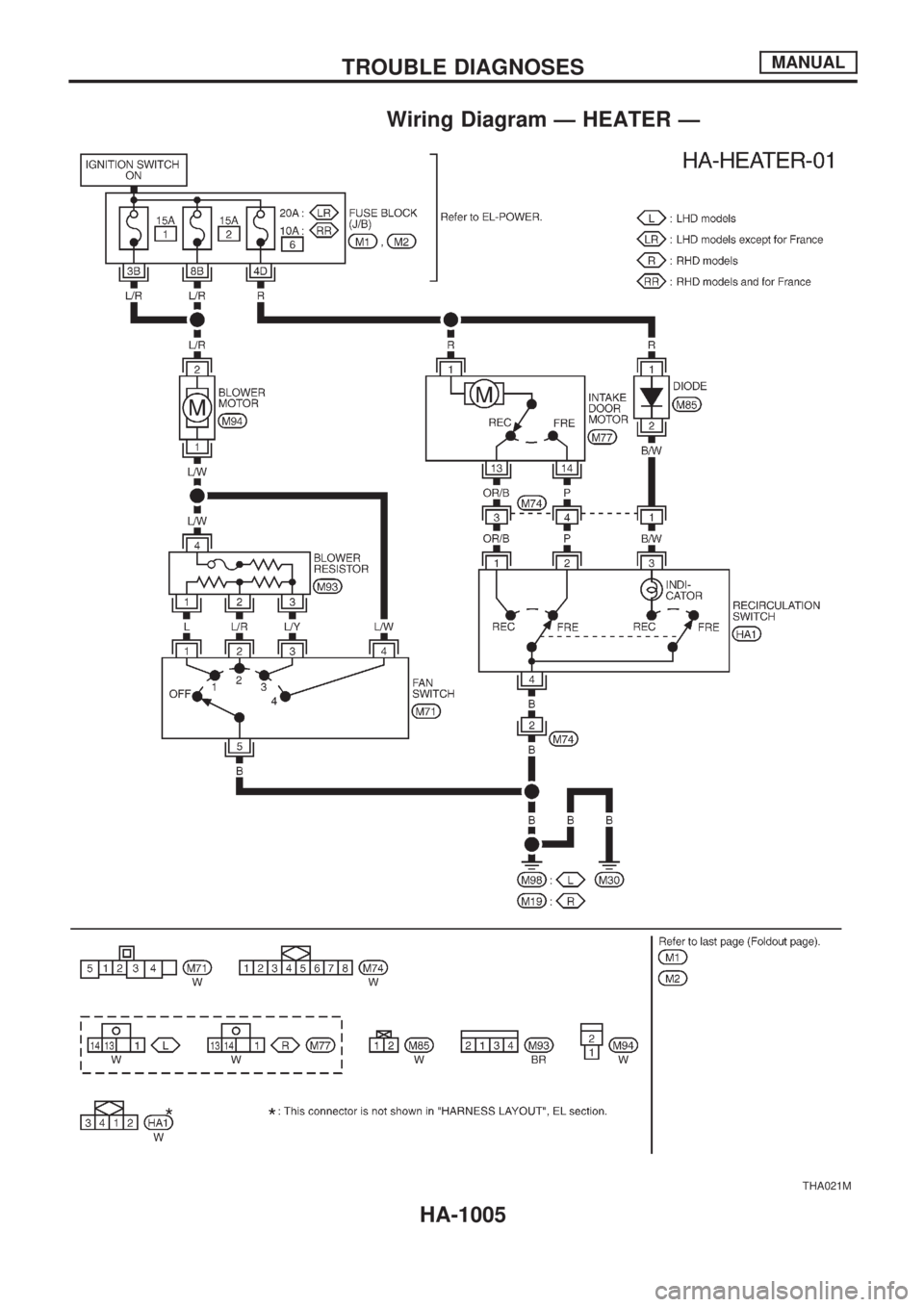

Wiring Diagram Ð HEATER Ð

THA021M

TROUBLE DIAGNOSESMANUAL

HA-1005