NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: oil level, wiring, recommended oil, spark plugs replace, engine oil capacity, reset, steering wheel adjustment

Page 1281 of 1659

Mainshaft

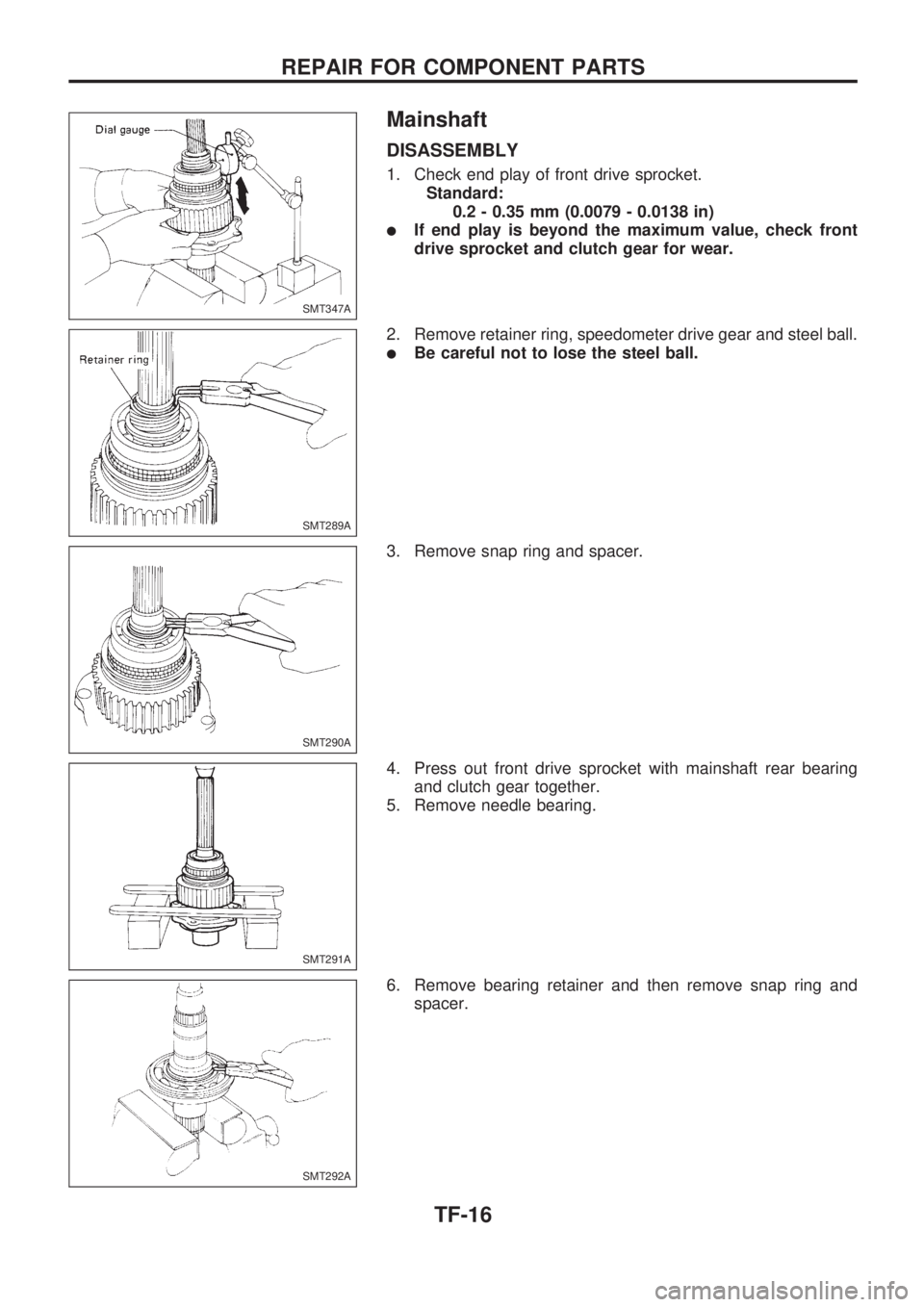

DISASSEMBLY

1. Check end play of front drive sprocket.

Standard:

0.2 - 0.35 mm (0.0079 - 0.0138 in)

lIf end play is beyond the maximum value, check front

drive sprocket and clutch gear for wear.

2. Remove retainer ring, speedometer drive gear and steel ball.

lBe careful not to lose the steel ball.

3. Remove snap ring and spacer.

4. Press out front drive sprocket with mainshaft rear bearing

and clutch gear together.

5. Remove needle bearing.

6. Remove bearing retainer and then remove snap ring and

spacer.

SMT347A

SMT289A

SMT290A

SMT291A

SMT292A

REPAIR FOR COMPONENT PARTS

TF-16

Page 1282 of 1659

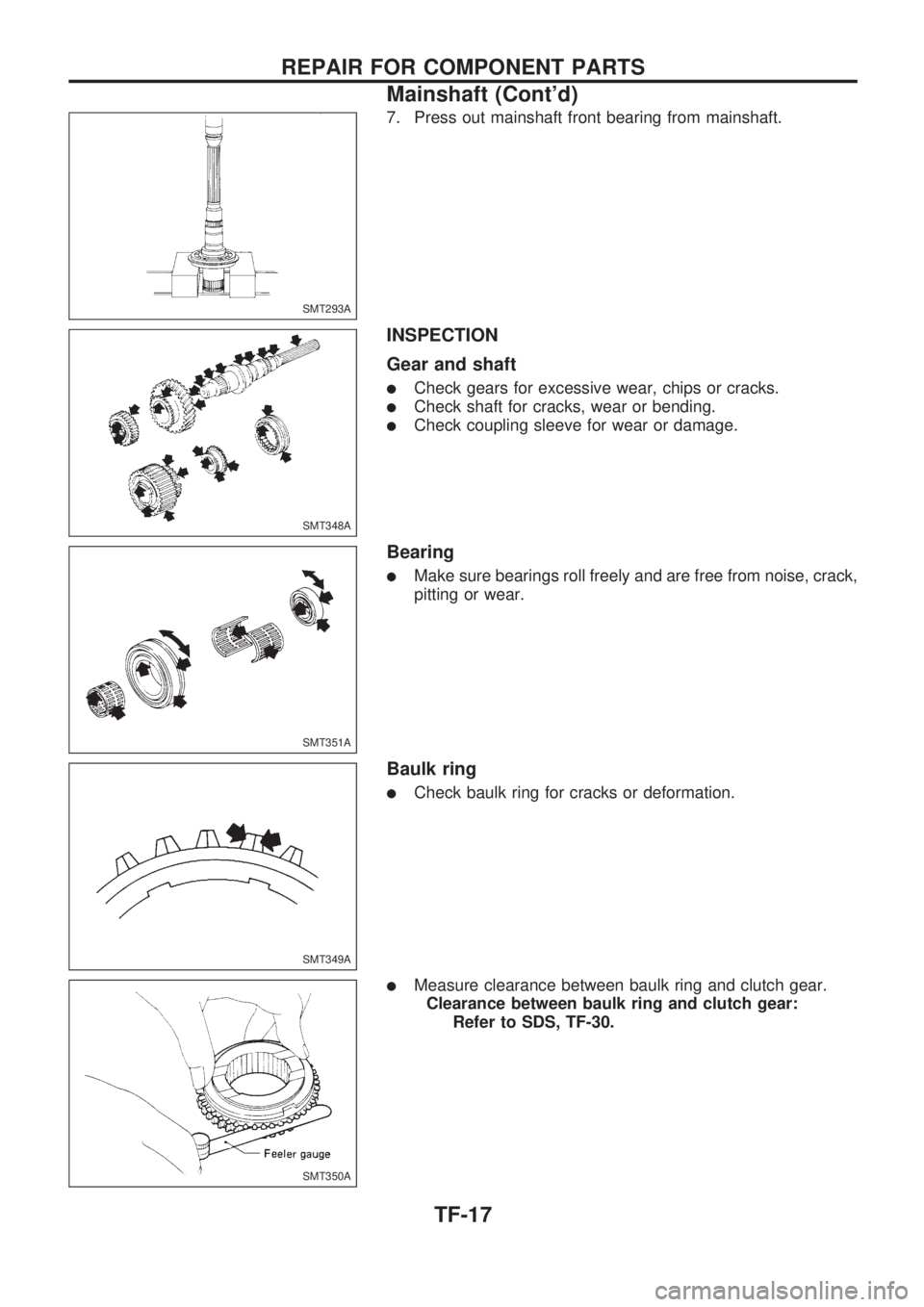

7. Press out mainshaft front bearing from mainshaft.

INSPECTION

Gear and shaft

lCheck gears for excessive wear, chips or cracks.

lCheck shaft for cracks, wear or bending.

lCheck coupling sleeve for wear or damage.

Bearing

lMake sure bearings roll freely and are free from noise, crack,

pitting or wear.

Baulk ring

lCheck baulk ring for cracks or deformation.

lMeasure clearance between baulk ring and clutch gear.

Clearance between baulk ring and clutch gear:

Refer to SDS, TF-30.

SMT293A

SMT348A

SMT351A

SMT349A

SMT350A

REPAIR FOR COMPONENT PARTS

Mainshaft (Cont'd)

TF-17

Page 1283 of 1659

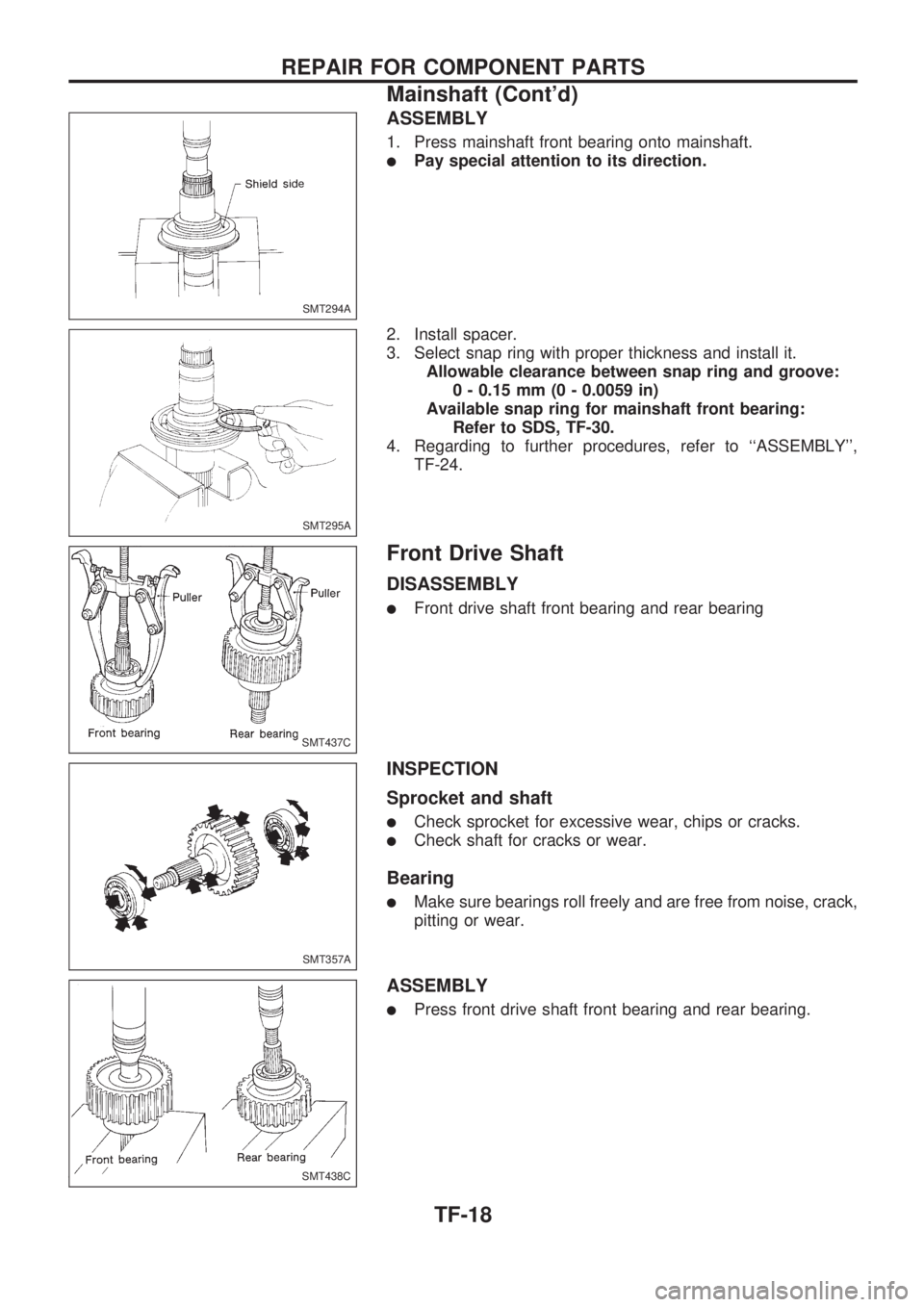

ASSEMBLY

1. Press mainshaft front bearing onto mainshaft.

lPay special attention to its direction.

2. Install spacer.

3. Select snap ring with proper thickness and install it.

Allowable clearance between snap ring and groove:

0 - 0.15 mm (0 - 0.0059 in)

Available snap ring for mainshaft front bearing:

Refer to SDS, TF-30.

4. Regarding to further procedures, refer to ``ASSEMBLY'',

TF-24.

Front Drive Shaft

DISASSEMBLY

lFront drive shaft front bearing and rear bearing

INSPECTION

Sprocket and shaft

lCheck sprocket for excessive wear, chips or cracks.

lCheck shaft for cracks or wear.

Bearing

lMake sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

lPress front drive shaft front bearing and rear bearing.

SMT294A

SMT295A

SMT437C

SMT357A

SMT438C

REPAIR FOR COMPONENT PARTS

Mainshaft (Cont'd)

TF-18

Page 1284 of 1659

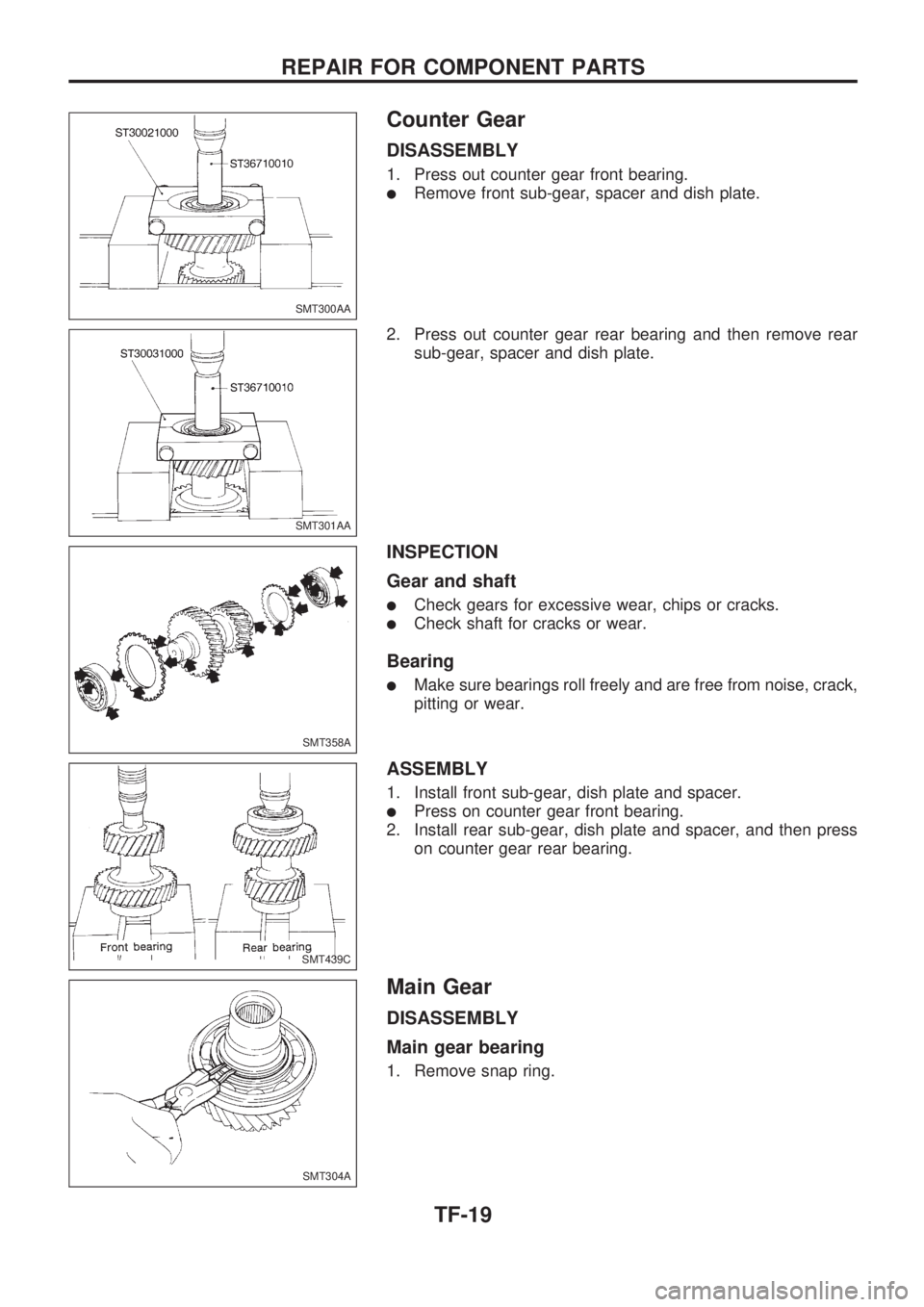

Counter Gear

DISASSEMBLY

1. Press out counter gear front bearing.

lRemove front sub-gear, spacer and dish plate.

2. Press out counter gear rear bearing and then remove rear

sub-gear, spacer and dish plate.

INSPECTION

Gear and shaft

lCheck gears for excessive wear, chips or cracks.

lCheck shaft for cracks or wear.

Bearing

lMake sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

1. Install front sub-gear, dish plate and spacer.

lPress on counter gear front bearing.

2. Install rear sub-gear, dish plate and spacer, and then press

on counter gear rear bearing.

Main Gear

DISASSEMBLY

Main gear bearing

1. Remove snap ring.

SMT300AA

SMT301AA

SMT358A

SMT439C

SMT304A

REPAIR FOR COMPONENT PARTS

TF-19

Page 1285 of 1659

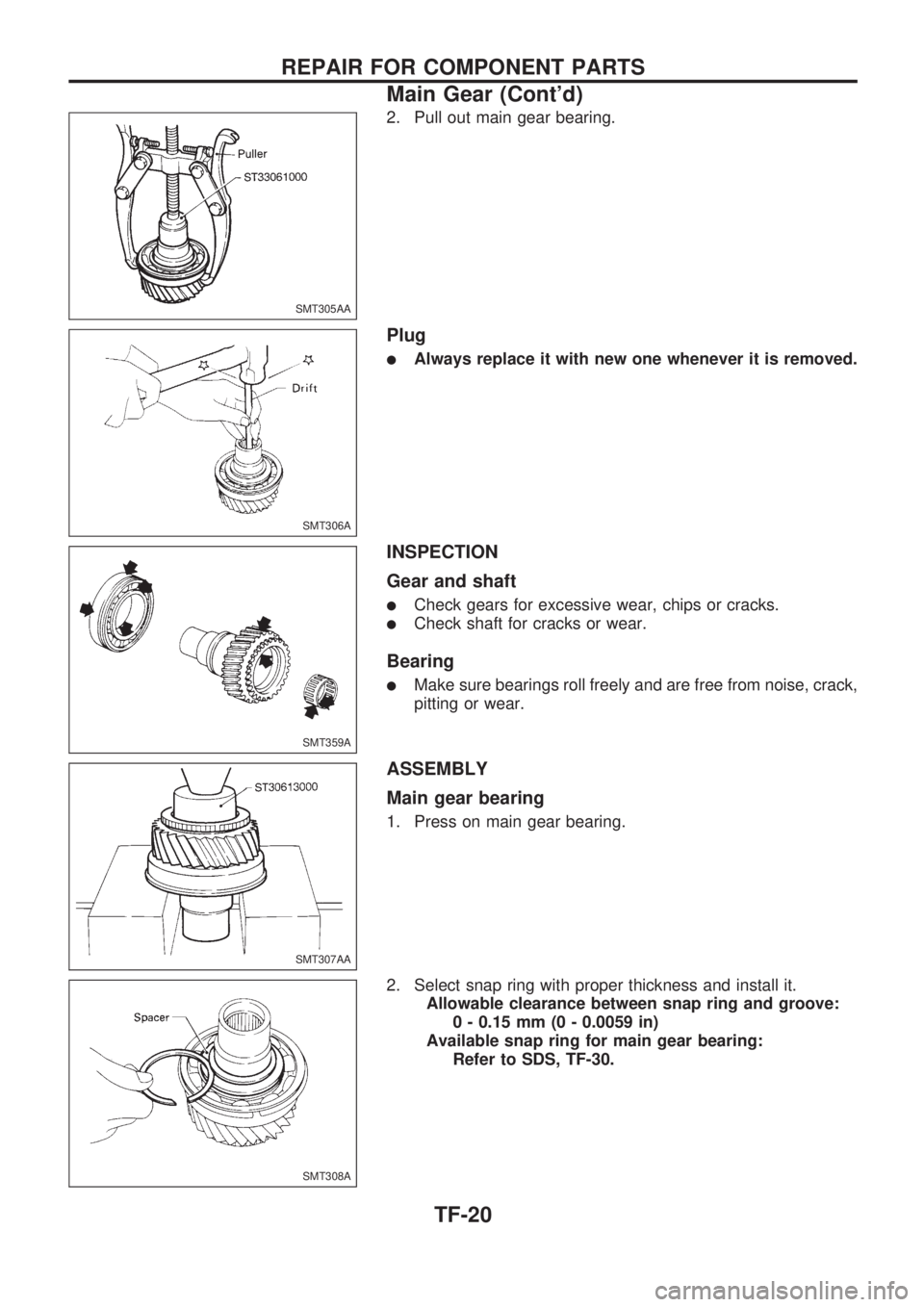

2. Pull out main gear bearing.

Plug

lAlways replace it with new one whenever it is removed.

INSPECTION

Gear and shaft

lCheck gears for excessive wear, chips or cracks.

lCheck shaft for cracks or wear.

Bearing

lMake sure bearings roll freely and are free from noise, crack,

pitting or wear.

ASSEMBLY

Main gear bearing

1. Press on main gear bearing.

2. Select snap ring with proper thickness and install it.

Allowable clearance between snap ring and groove:

0 - 0.15 mm (0 - 0.0059 in)

Available snap ring for main gear bearing:

Refer to SDS, TF-30.

SMT305AA

SMT306A

SMT359A

SMT307AA

SMT308A

REPAIR FOR COMPONENT PARTS

Main Gear (Cont'd)

TF-20

Page 1286 of 1659

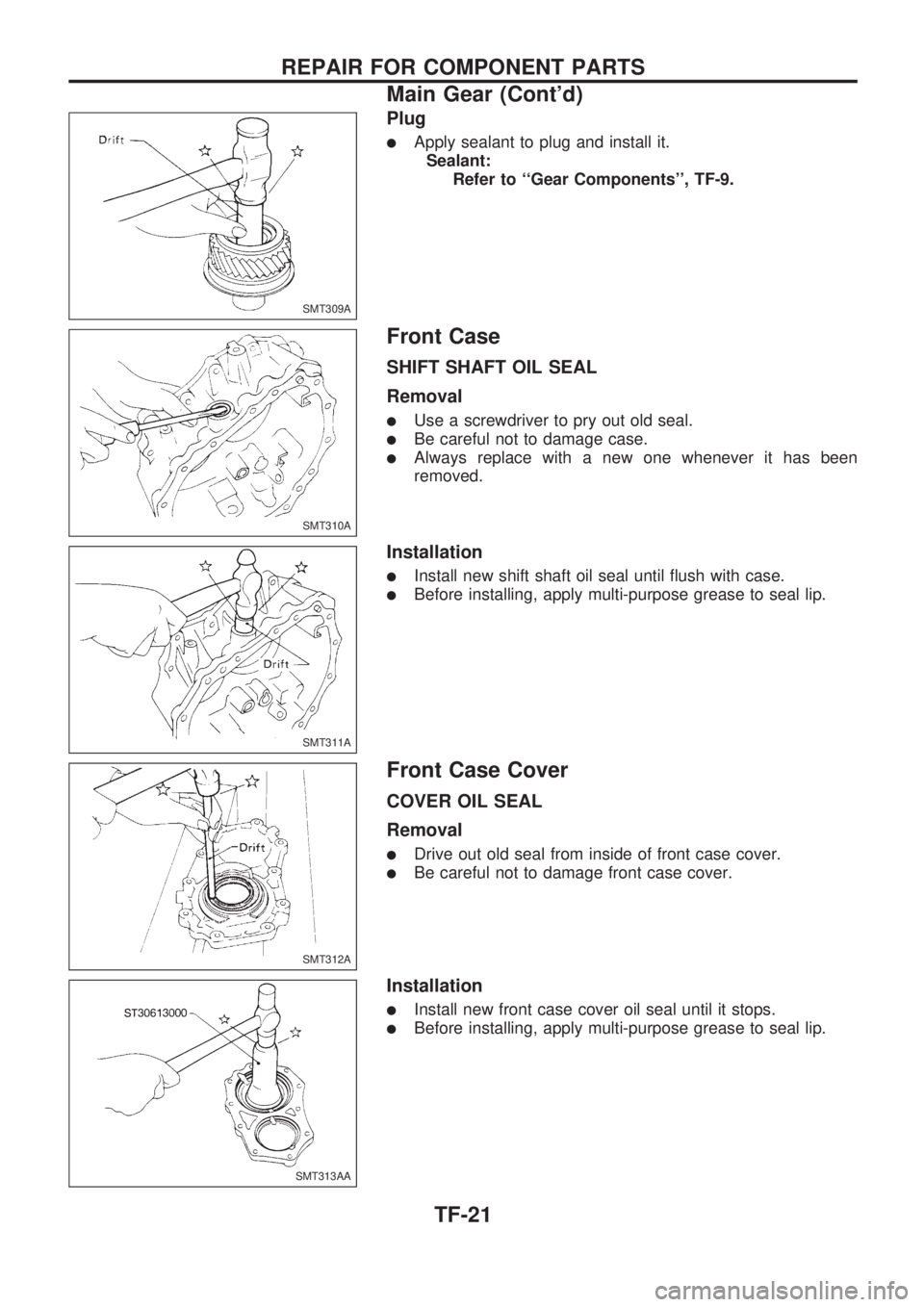

Plug

lApply sealant to plug and install it.

Sealant:

Refer to ``Gear Components'', TF-9.

Front Case

SHIFT SHAFT OIL SEAL

Removal

lUse a screwdriver to pry out old seal.

lBe careful not to damage case.

lAlways replace with a new one whenever it has been

removed.

Installation

lInstall new shift shaft oil seal until flush with case.

lBefore installing, apply multi-purpose grease to seal lip.

Front Case Cover

COVER OIL SEAL

Removal

lDrive out old seal from inside of front case cover.

lBe careful not to damage front case cover.

Installation

lInstall new front case cover oil seal until it stops.

lBefore installing, apply multi-purpose grease to seal lip.

SMT309A

SMT310A

SMT311A

SMT312A

SMT313AA

REPAIR FOR COMPONENT PARTS

Main Gear (Cont'd)

TF-21

Page 1287 of 1659

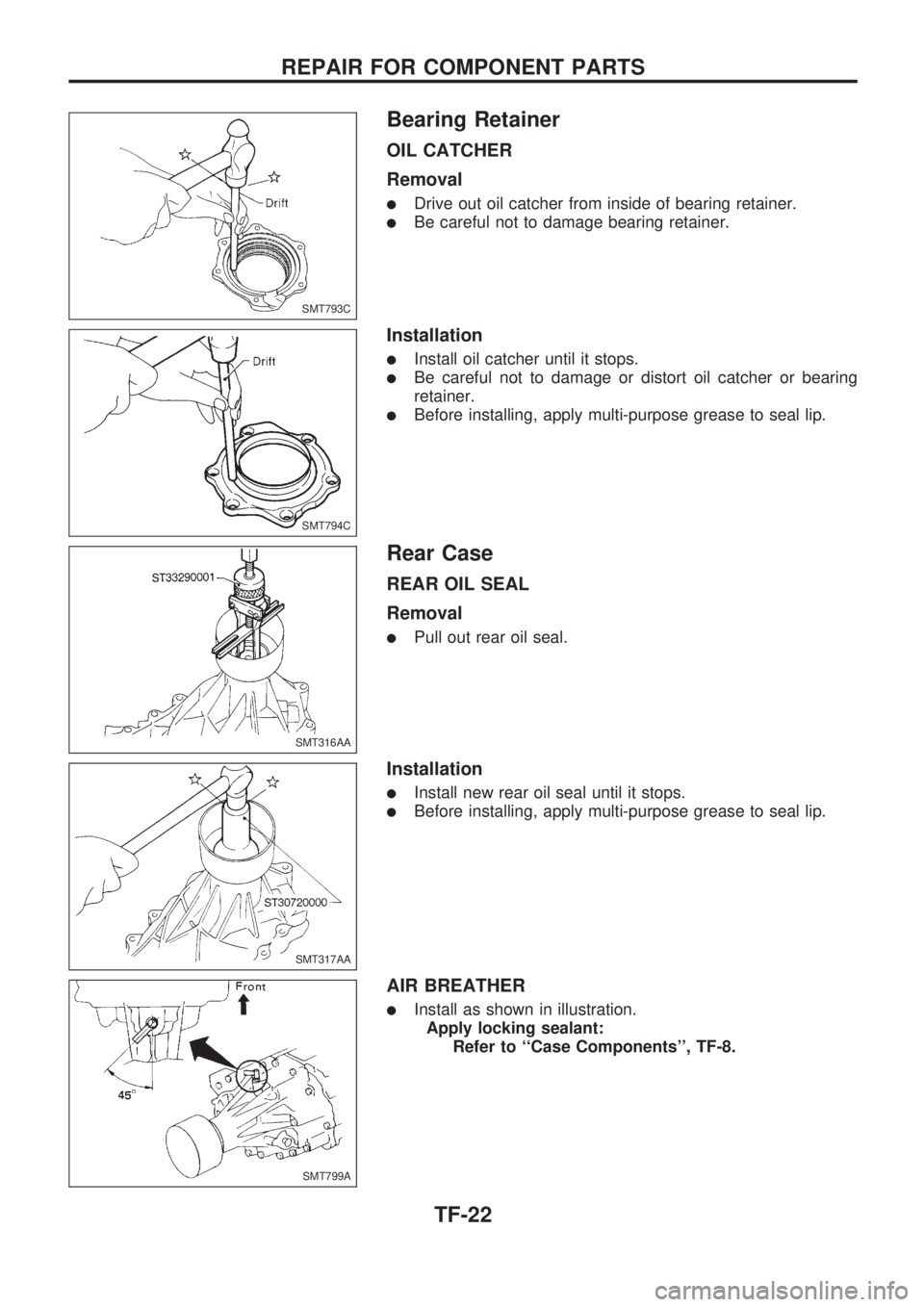

Bearing Retainer

OIL CATCHER

Removal

lDrive out oil catcher from inside of bearing retainer.

lBe careful not to damage bearing retainer.

Installation

lInstall oil catcher until it stops.

lBe careful not to damage or distort oil catcher or bearing

retainer.

lBefore installing, apply multi-purpose grease to seal lip.

Rear Case

REAR OIL SEAL

Removal

lPull out rear oil seal.

Installation

lInstall new rear oil seal until it stops.

lBefore installing, apply multi-purpose grease to seal lip.

AIR BREATHER

lInstall as shown in illustration.

Apply locking sealant:

Refer to ``Case Components'', TF-8.

SMT793C

SMT794C

SMT316AA

SMT317AA

SMT799A

REPAIR FOR COMPONENT PARTS

TF-22

Page 1288 of 1659

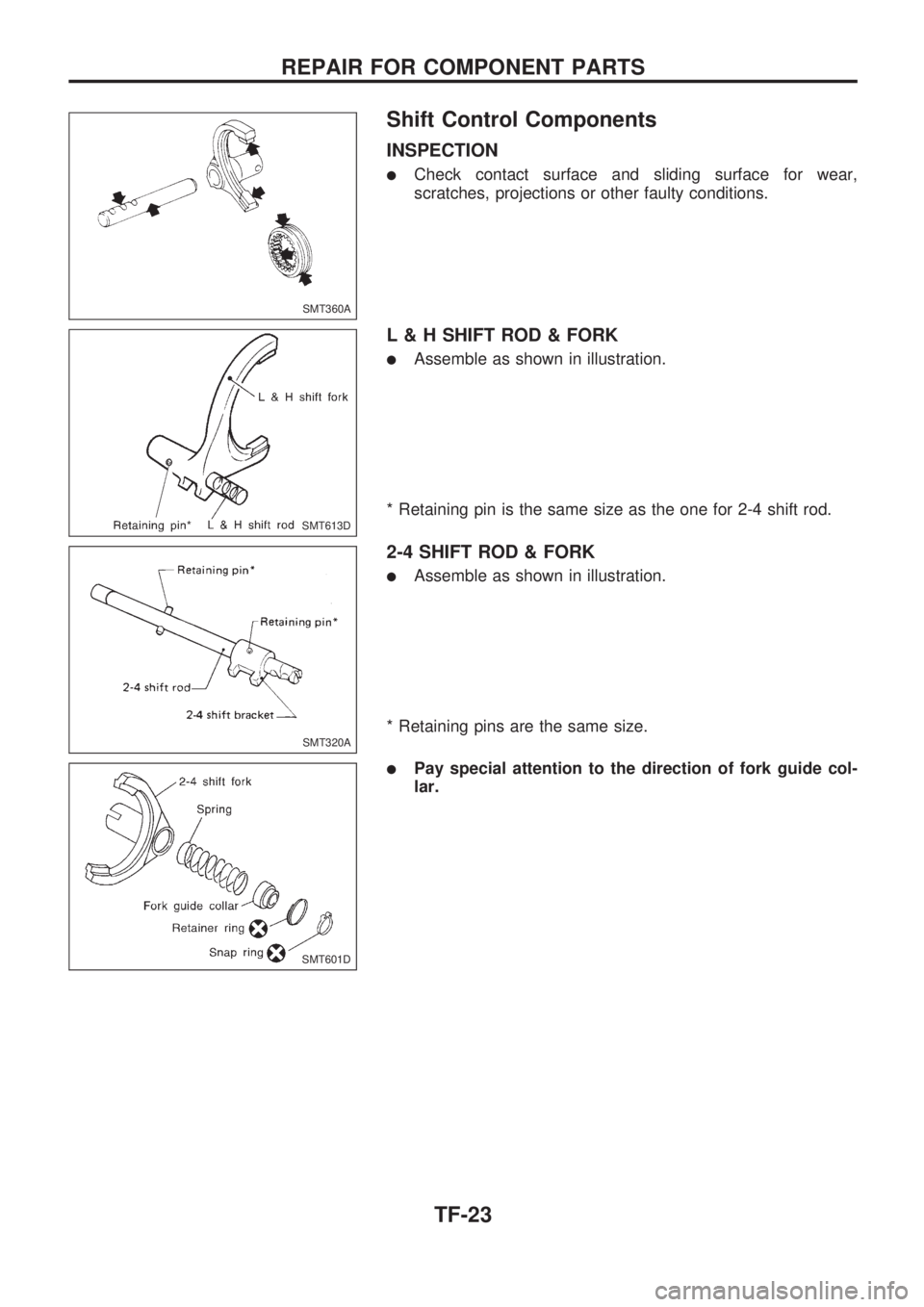

Shift Control Components

INSPECTION

lCheck contact surface and sliding surface for wear,

scratches, projections or other faulty conditions.

L & H SHIFT ROD & FORK

lAssemble as shown in illustration.

* Retaining pin is the same size as the one for 2-4 shift rod.

2-4 SHIFT ROD & FORK

lAssemble as shown in illustration.

* Retaining pins are the same size.

lPay special attention to the direction of fork guide col-

lar.

SMT360A

SMT613D

SMT320A

SMT601D

REPAIR FOR COMPONENT PARTS

TF-23

Page 1289 of 1659

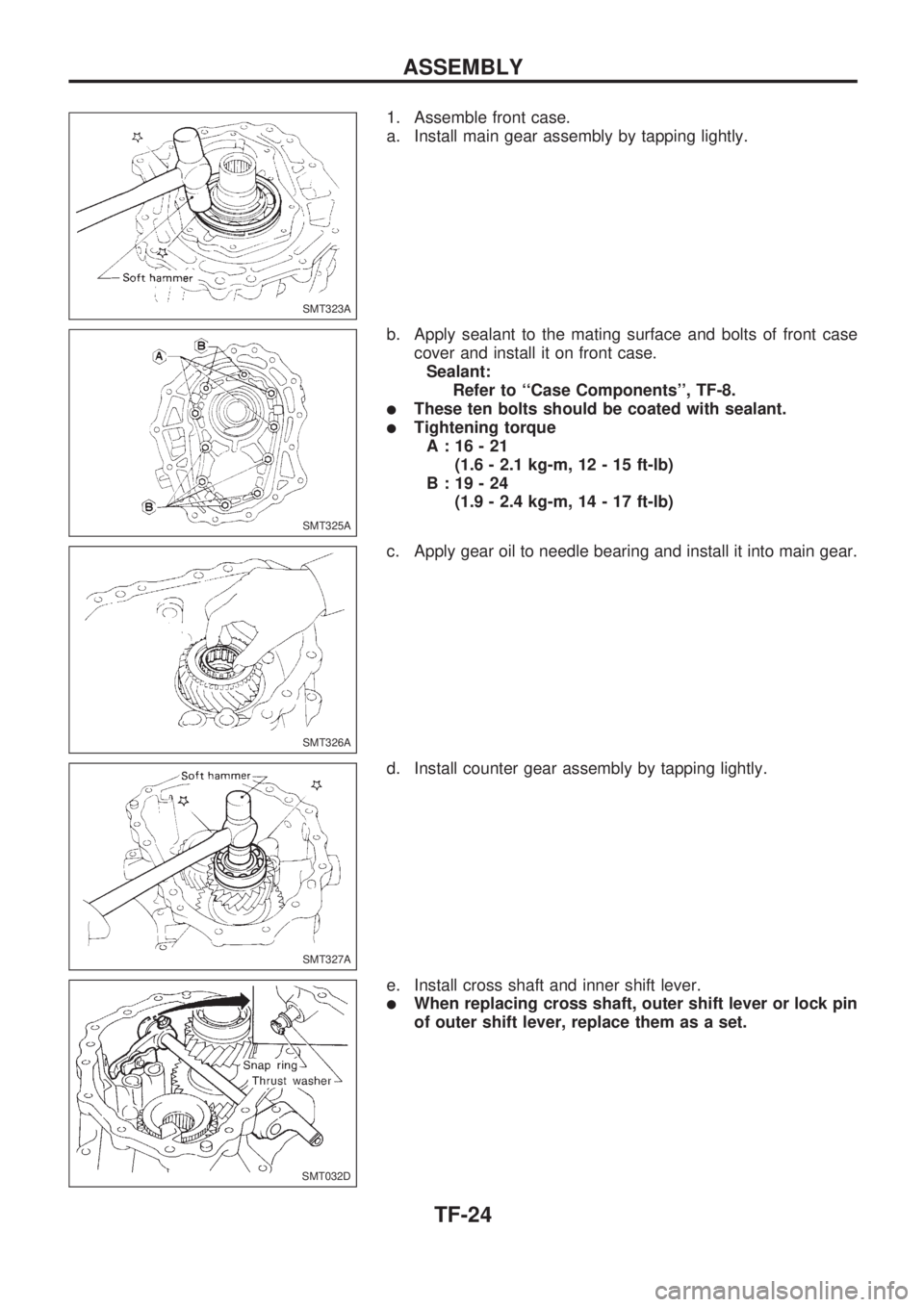

1. Assemble front case.

a. Install main gear assembly by tapping lightly.

b. Apply sealant to the mating surface and bolts of front case

cover and install it on front case.

Sealant:

Refer to ``Case Components'', TF-8.

lThese ten bolts should be coated with sealant.

lTightening torque

A:16-21

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

B:19-24

(1.9 - 2.4 kg-m, 14 - 17 ft-lb)

c. Apply gear oil to needle bearing and install it into main gear.

d. Install counter gear assembly by tapping lightly.

e. Install cross shaft and inner shift lever.

lWhen replacing cross shaft, outer shift lever or lock pin

of outer shift lever, replace them as a set.

SMT323A

SMT325A

SMT326A

SMT327A

SMT032D

ASSEMBLY

TF-24

Page 1290 of 1659

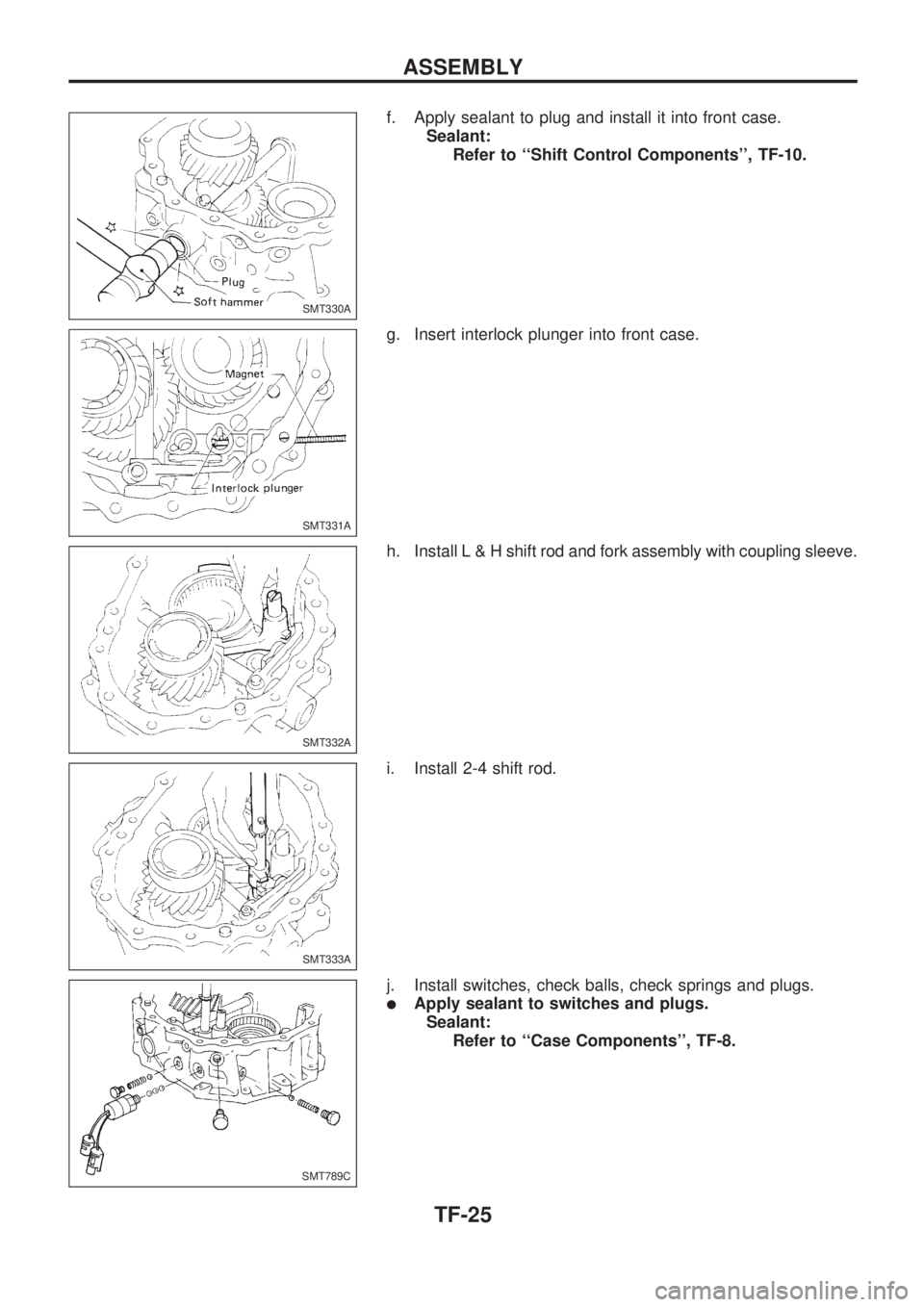

f. Apply sealant to plug and install it into front case.

Sealant:

Refer to ``Shift Control Components'', TF-10.

g. Insert interlock plunger into front case.

h. InstallL&Hshift rod and fork assembly with coupling sleeve.

i. Install 2-4 shift rod.

j. Install switches, check balls, check springs and plugs.

lApply sealant to switches and plugs.

Sealant:

Refer to ``Case Components'', TF-8.

SMT330A

SMT331A

SMT332A

SMT333A

SMT789C

ASSEMBLY

TF-25

Trending: adding oil, spare wheel, maintenance, oil dipstick, gas type, audio, air bleeding