NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: tires, height, headlamp, change wheel, cooling, jump start terminals, roof

Page 1241 of 1659

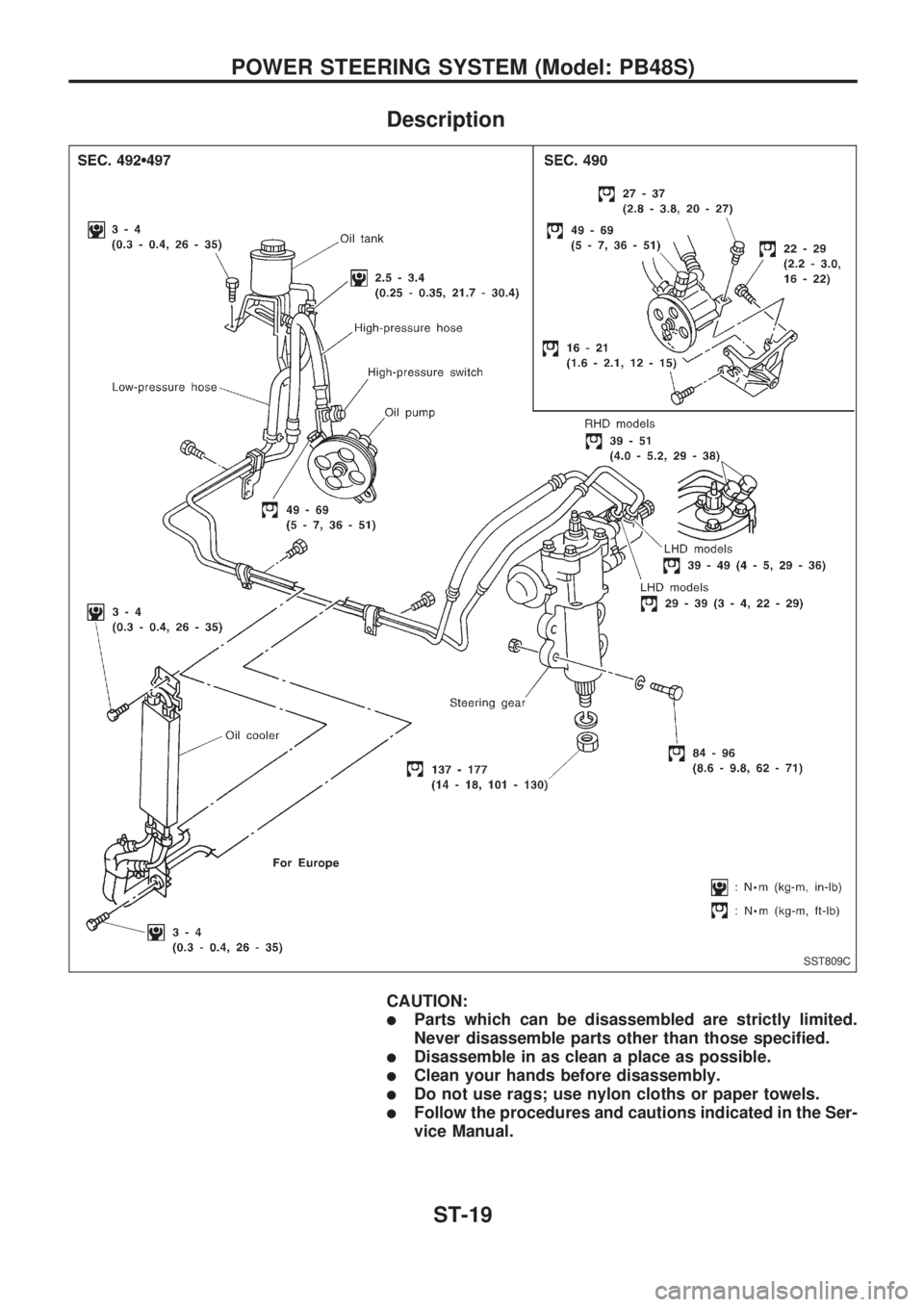

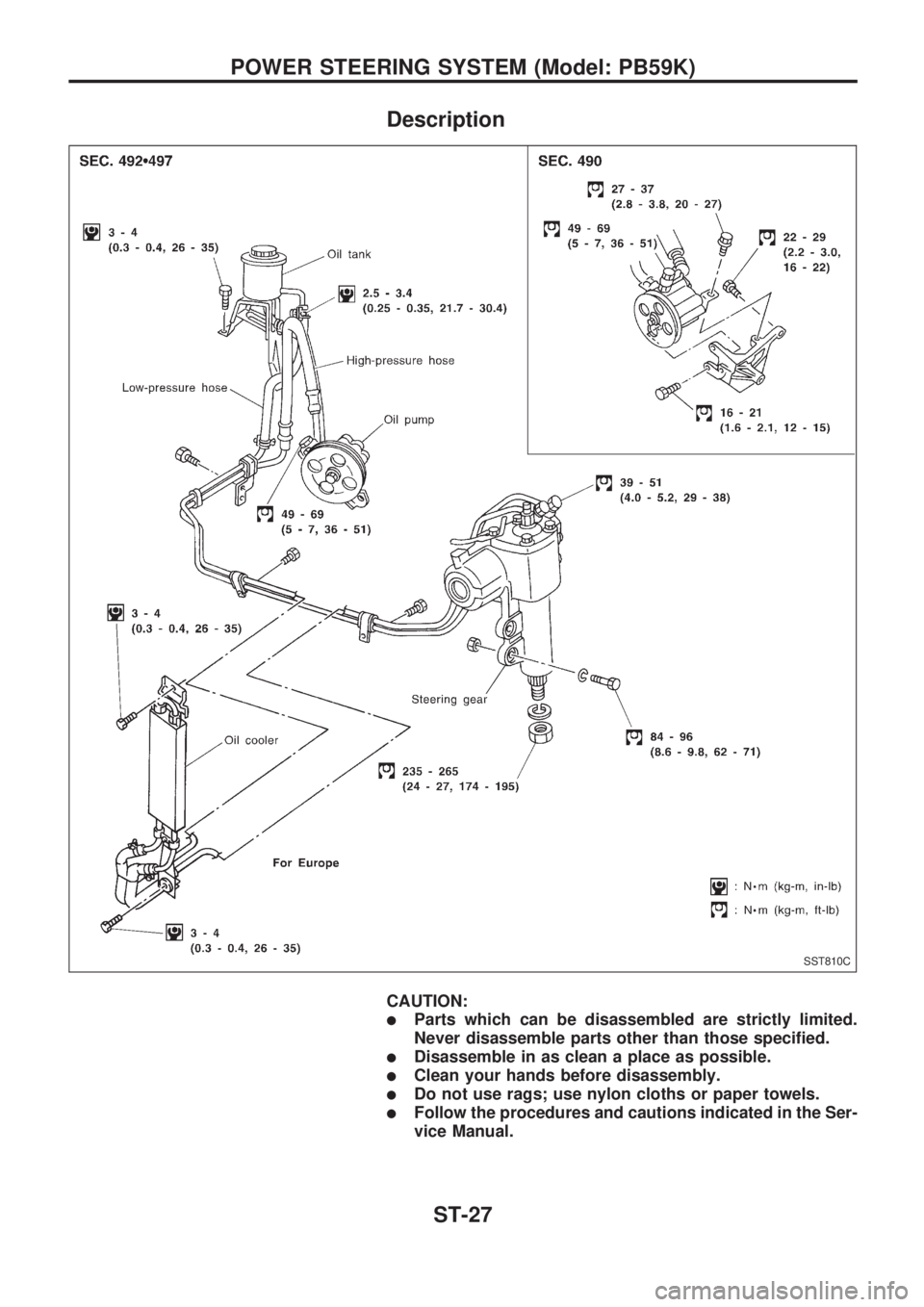

Description

CAUTION:

lParts which can be disassembled are strictly limited.

Never disassemble parts other than those specified.

lDisassemble in as clean a place as possible.

lClean your hands before disassembly.

lDo not use rags; use nylon cloths or paper towels.

lFollow the procedures and cautions indicated in the Ser-

vice Manual.

SST809C

POWER STEERING SYSTEM (Model: PB48S)

ST-19

Page 1242 of 1659

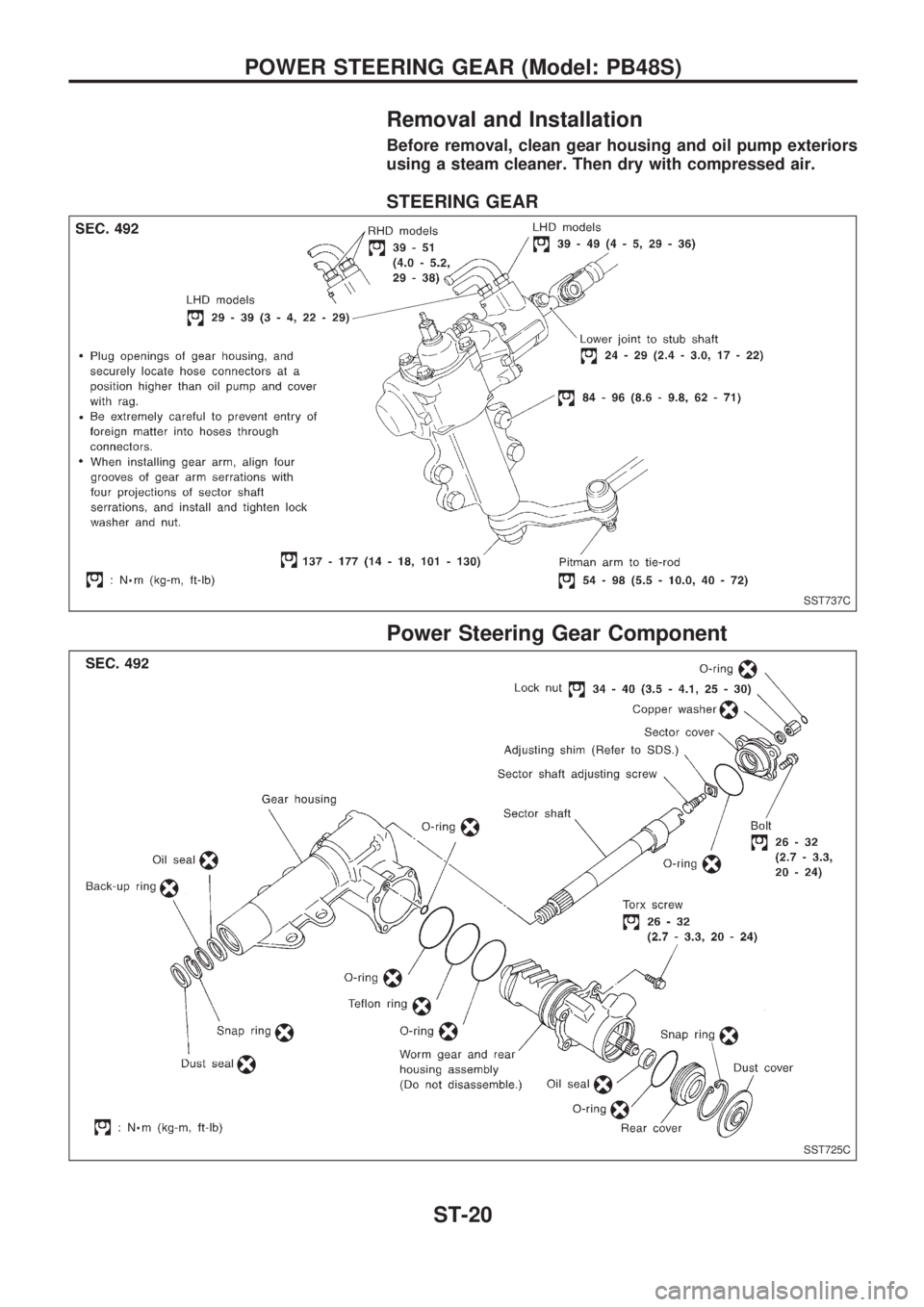

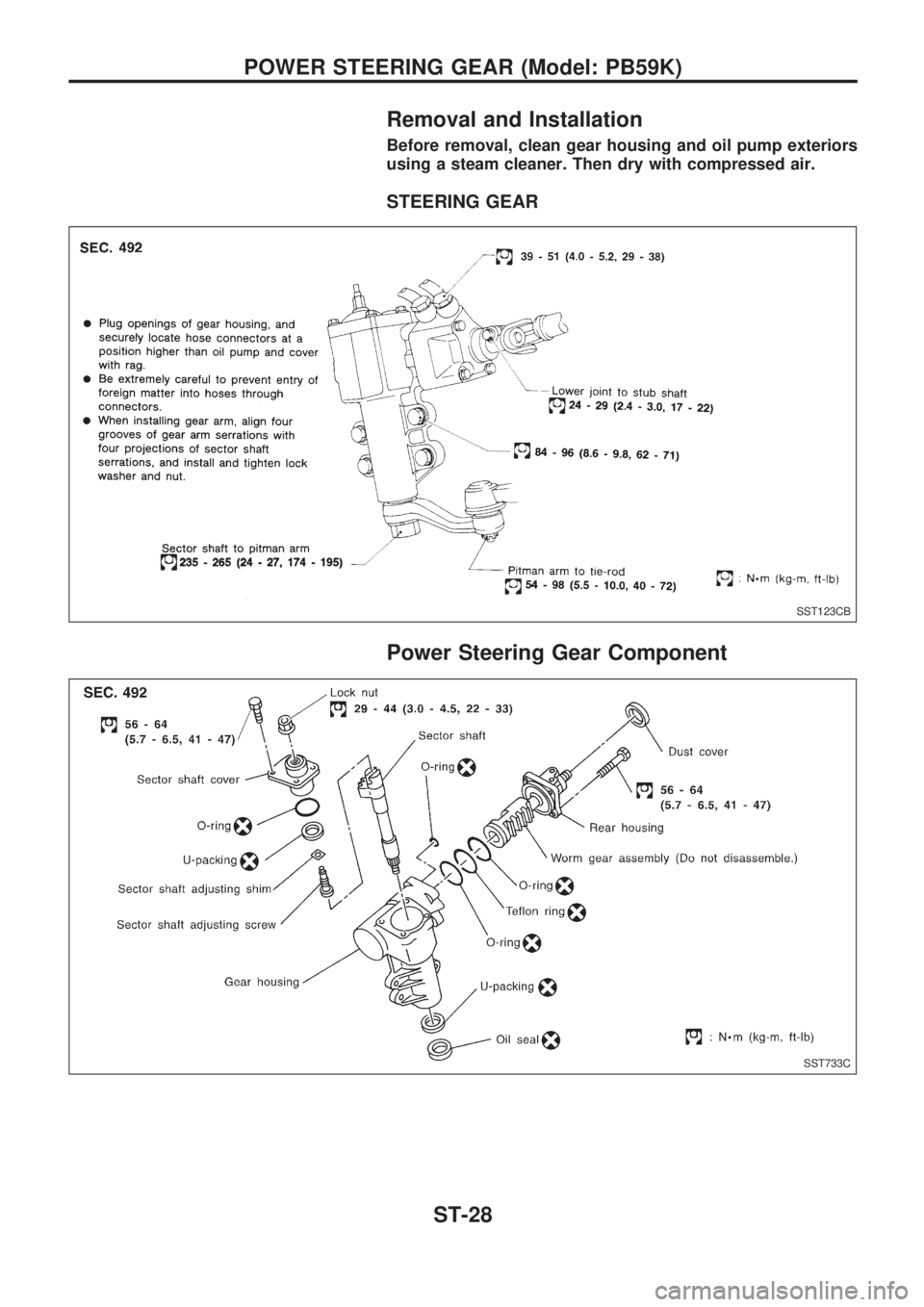

Removal and Installation

Before removal, clean gear housing and oil pump exteriors

using a steam cleaner. Then dry with compressed air.

STEERING GEAR

Power Steering Gear Component

SST737C

SST725C

POWER STEERING GEAR (Model: PB48S)

ST-20

Page 1243 of 1659

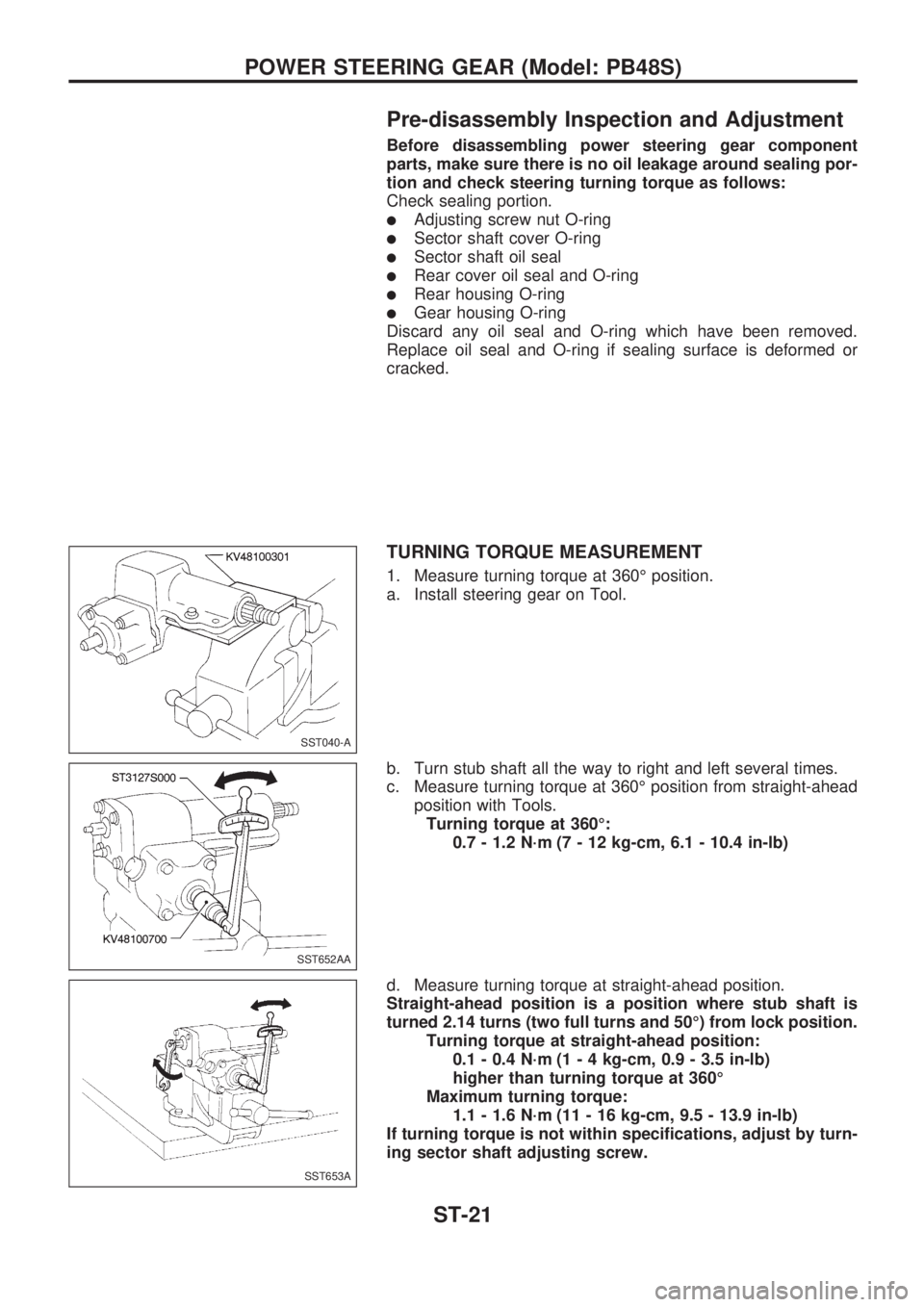

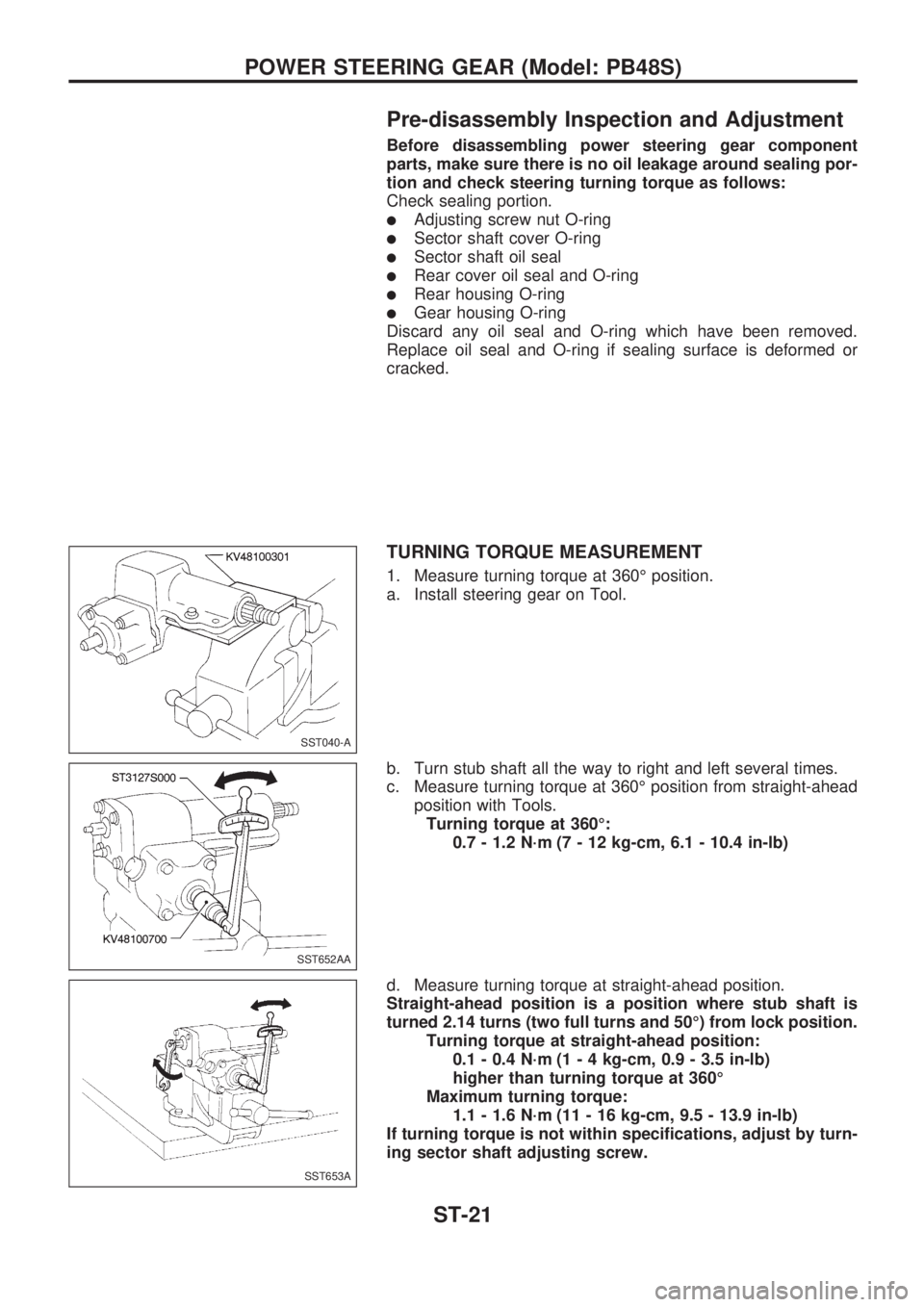

Pre-disassembly Inspection and Adjustment

Before disassembling power steering gear component

parts, make sure there is no oil leakage around sealing por-

tion and check steering turning torque as follows:

Check sealing portion.

lAdjusting screw nut O-ring

lSector shaft cover O-ring

lSector shaft oil seal

lRear cover oil seal and O-ring

lRear housing O-ring

lGear housing O-ring

Discard any oil seal and O-ring which have been removed.

Replace oil seal and O-ring if sealing surface is deformed or

cracked.

TURNING TORQUE MEASUREMENT

1. Measure turning torque at 360É position.

a. Install steering gear on Tool.

b. Turn stub shaft all the way to right and left several times.

c. Measure turning torque at 360É position from straight-ahead

position with Tools.

Turning torque at 360É:

0.7 - 1.2 N´m (7 - 12 kg-cm, 6.1 - 10.4 in-lb)

d. Measure turning torque at straight-ahead position.

Straight-ahead position is a position where stub shaft is

turned 2.14 turns (two full turns and 50É) from lock position.

Turning torque at straight-ahead position:

0.1 - 0.4 N´m (1 - 4 kg-cm, 0.9 - 3.5 in-lb)

higher than turning torque at 360É

Maximum turning torque:

1.1 - 1.6 N´m (11 - 16 kg-cm, 9.5 - 13.9 in-lb)

If turning torque is not within specifications, adjust by turn-

ing sector shaft adjusting screw.

SST040-A

SST652AA

SST653A

POWER STEERING GEAR (Model: PB48S)

ST-21

Page 1244 of 1659

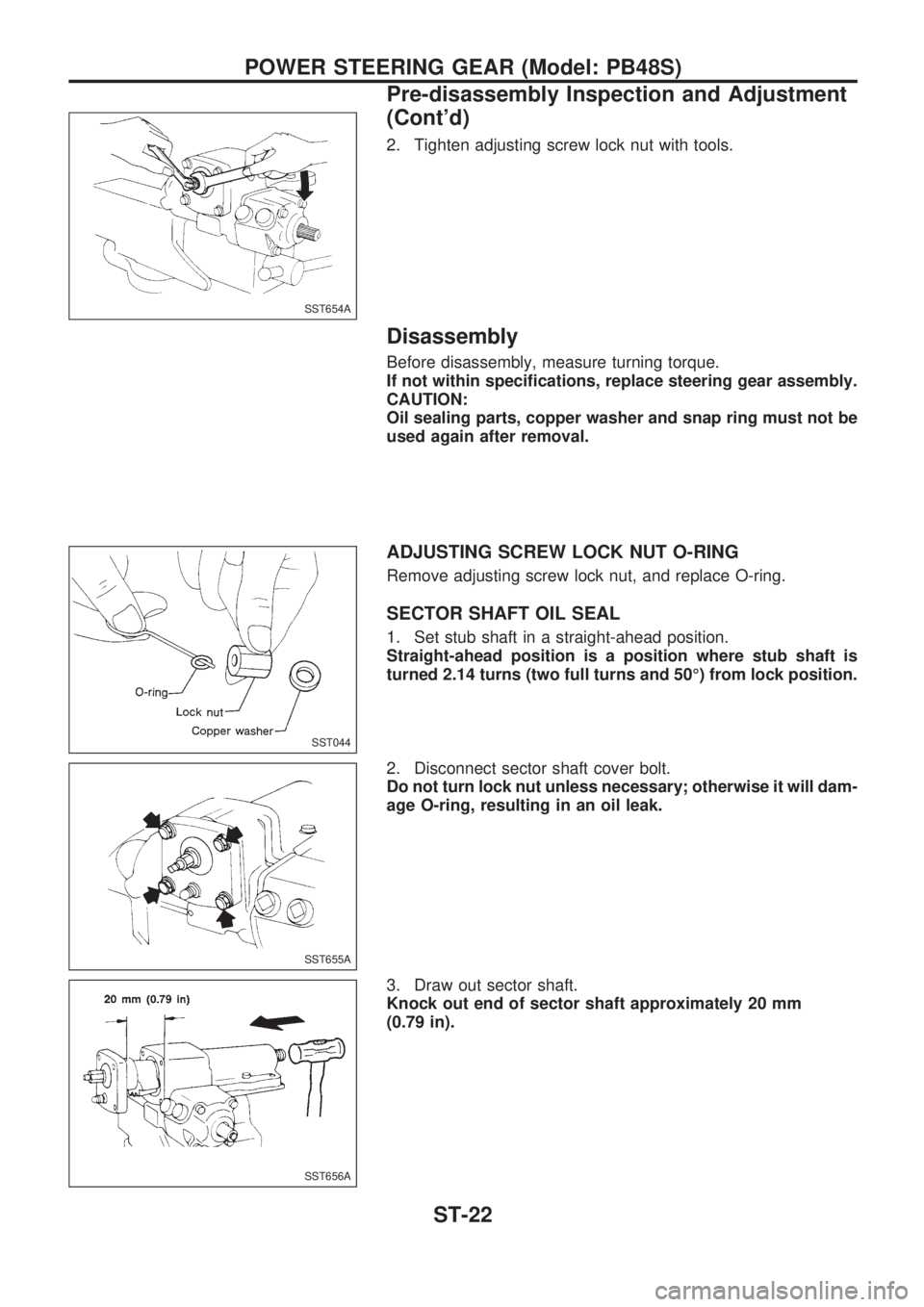

2. Tighten adjusting screw lock nut with tools.

Disassembly

Before disassembly, measure turning torque.

If not within specifications, replace steering gear assembly.

CAUTION:

Oil sealing parts, copper washer and snap ring must not be

used again after removal.

ADJUSTING SCREW LOCK NUT O-RING

Remove adjusting screw lock nut, and replace O-ring.

SECTOR SHAFT OIL SEAL

1. Set stub shaft in a straight-ahead position.

Straight-ahead position is a position where stub shaft is

turned 2.14 turns (two full turns and 50É) from lock position.

2. Disconnect sector shaft cover bolt.

Do not turn lock nut unless necessary; otherwise it will dam-

age O-ring, resulting in an oil leak.

3. Draw out sector shaft.

Knock out end of sector shaft approximately 20 mm

(0.79 in).

SST654A

SST044

SST655A

SST656A

POWER STEERING GEAR (Model: PB48S)

Pre-disassembly Inspection and Adjustment

(Cont'd)

ST-22

Page 1245 of 1659

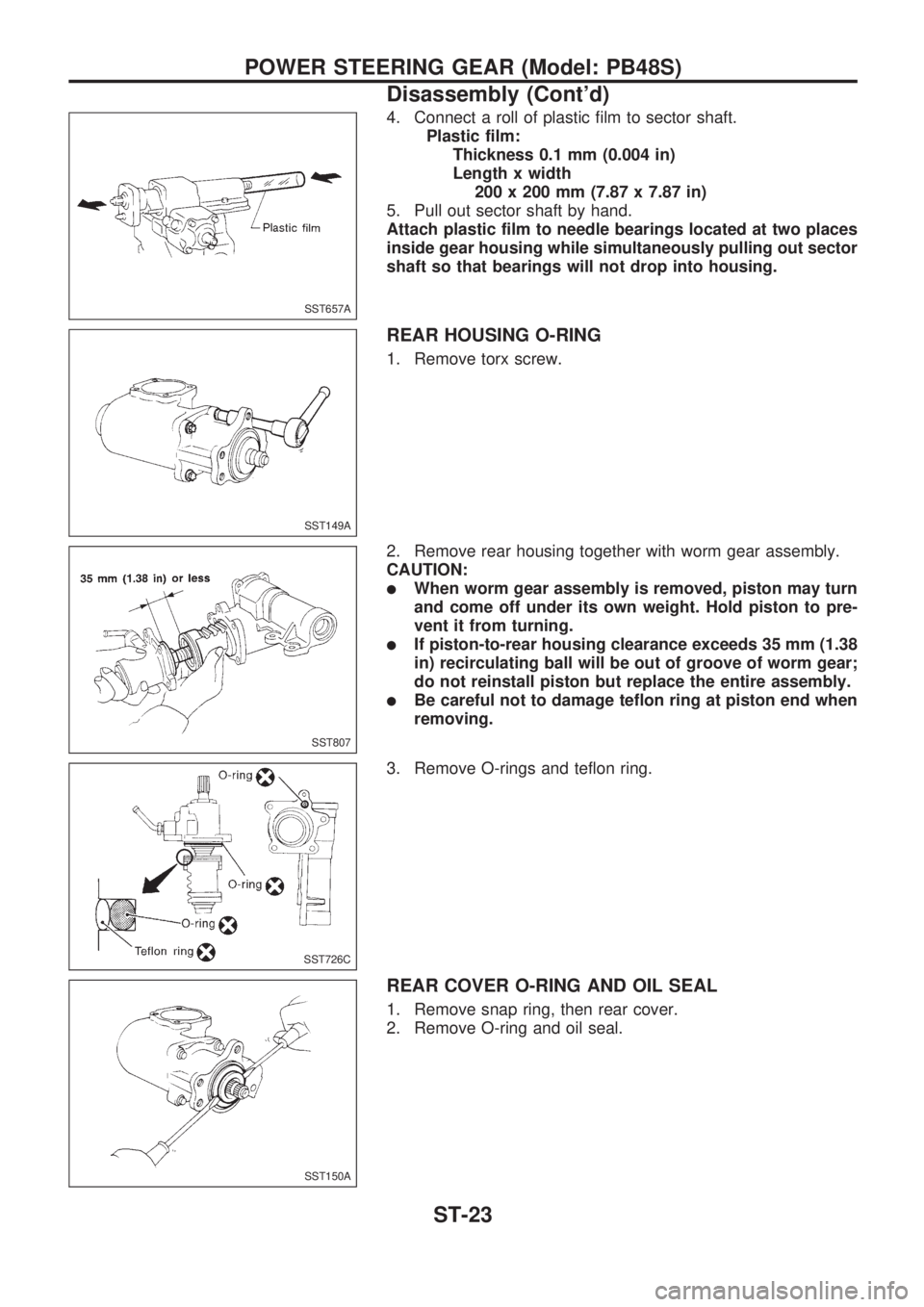

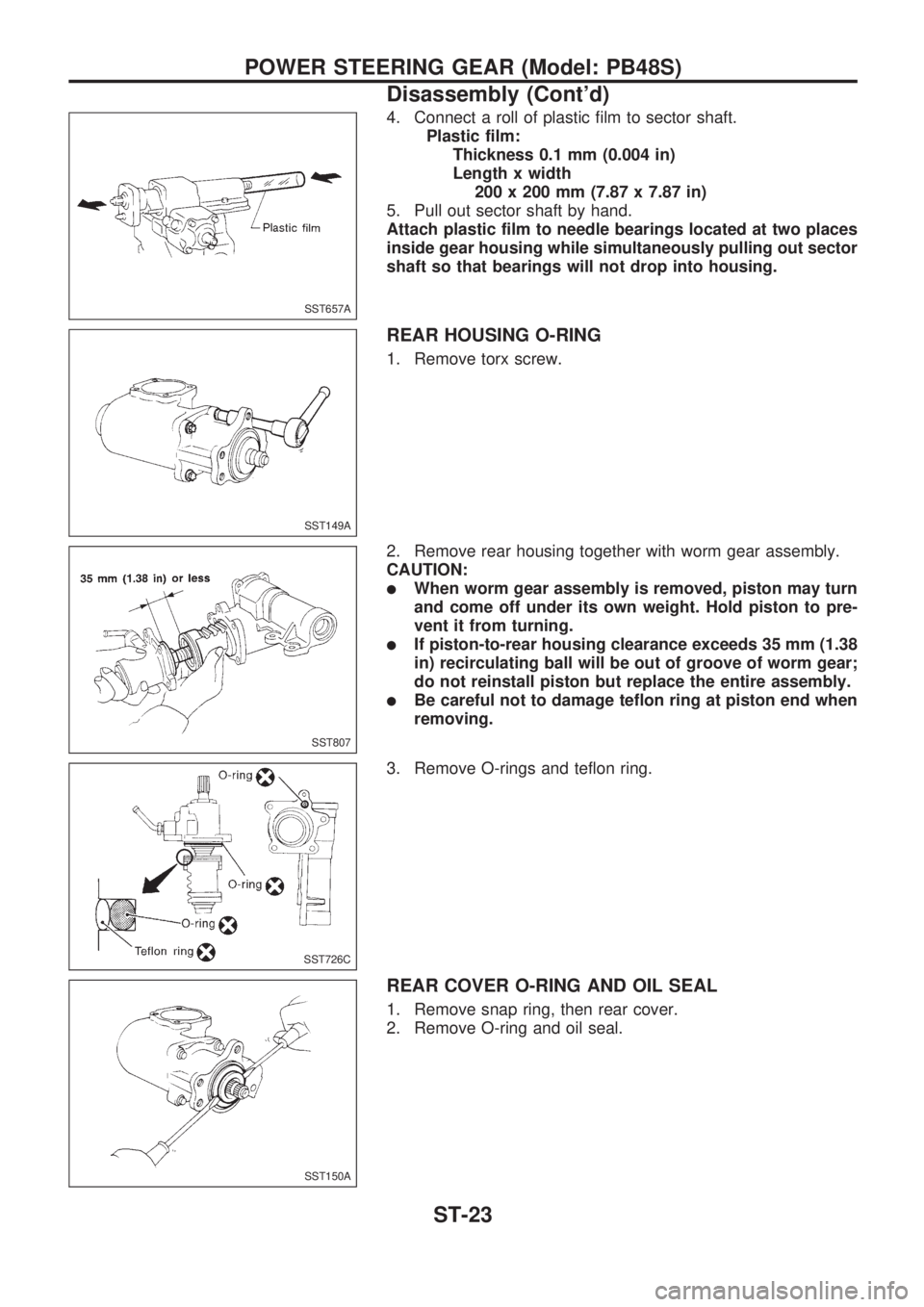

4. Connect a roll of plastic film to sector shaft.

Plastic film:

Thickness 0.1 mm (0.004 in)

Length x width

200 x 200 mm (7.87 x 7.87 in)

5. Pull out sector shaft by hand.

Attach plastic film to needle bearings located at two places

inside gear housing while simultaneously pulling out sector

shaft so that bearings will not drop into housing.

REAR HOUSING O-RING

1. Remove torx screw.

2. Remove rear housing together with worm gear assembly.

CAUTION:

lWhen worm gear assembly is removed, piston may turn

and come off under its own weight. Hold piston to pre-

vent it from turning.

lIf piston-to-rear housing clearance exceeds 35 mm (1.38

in) recirculating ball will be out of groove of worm gear;

do not reinstall piston but replace the entire assembly.

lBe careful not to damage teflon ring at piston end when

removing.

3. Remove O-rings and teflon ring.

REAR COVER O-RING AND OIL SEAL

1. Remove snap ring, then rear cover.

2. Remove O-ring and oil seal.

SST657A

SST149A

SST807

SST726C

SST150A

POWER STEERING GEAR (Model: PB48S)

Disassembly (Cont'd)

ST-23

Page 1246 of 1659

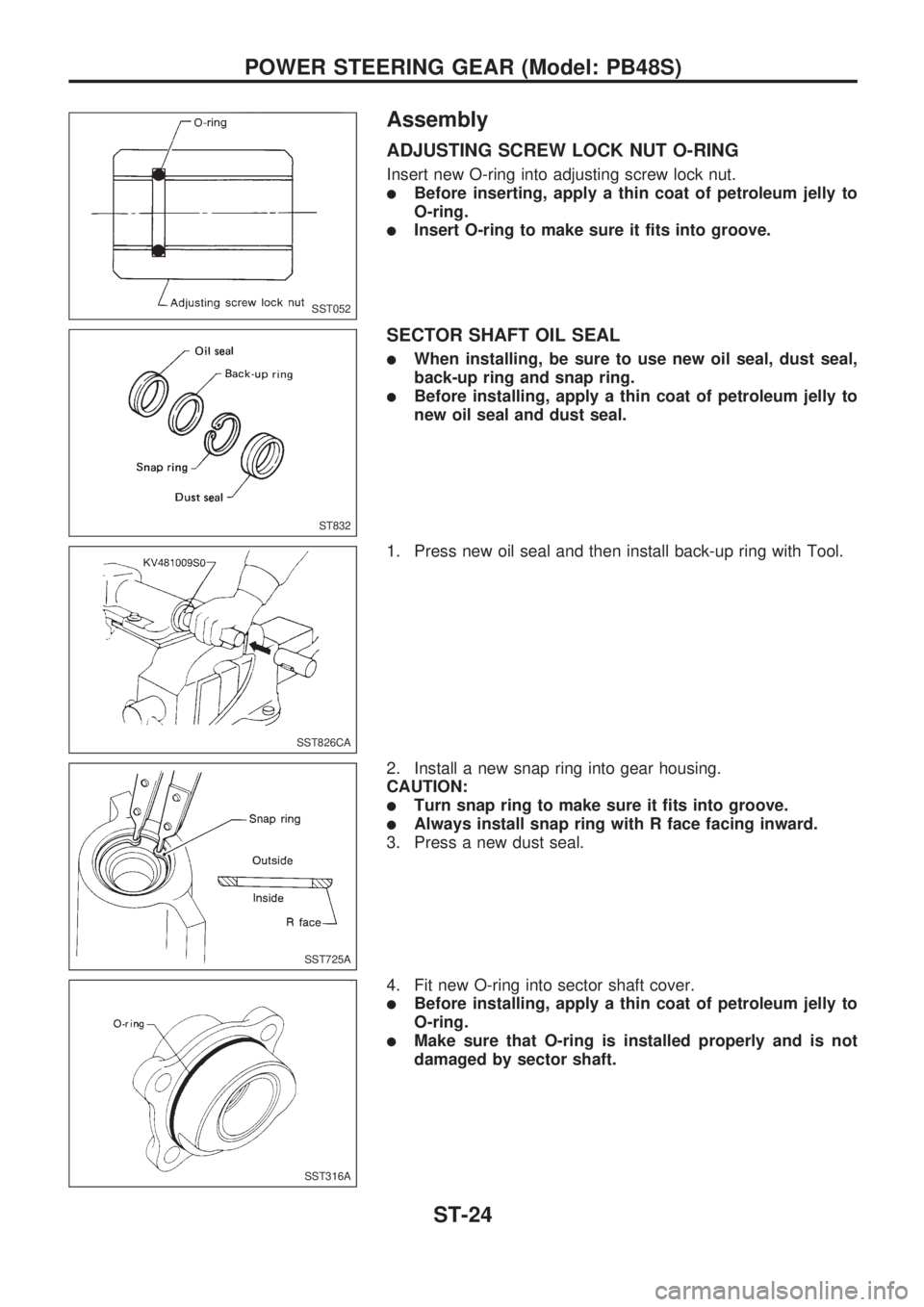

Assembly

ADJUSTING SCREW LOCK NUT O-RING

Insert new O-ring into adjusting screw lock nut.

lBefore inserting, apply a thin coat of petroleum jelly to

O-ring.

lInsert O-ring to make sure it fits into groove.

SECTOR SHAFT OIL SEAL

lWhen installing, be sure to use new oil seal, dust seal,

back-up ring and snap ring.

lBefore installing, apply a thin coat of petroleum jelly to

new oil seal and dust seal.

1. Press new oil seal and then install back-up ring with Tool.

2. Install a new snap ring into gear housing.

CAUTION:

lTurn snap ring to make sure it fits into groove.

lAlways install snap ring with R face facing inward.

3. Press a new dust seal.

4. Fit new O-ring into sector shaft cover.

lBefore installing, apply a thin coat of petroleum jelly to

O-ring.

lMake sure that O-ring is installed properly and is not

damaged by sector shaft.

SST052

ST832

SST826CA

SST725A

SST316A

POWER STEERING GEAR (Model: PB48S)

ST-24

Page 1247 of 1659

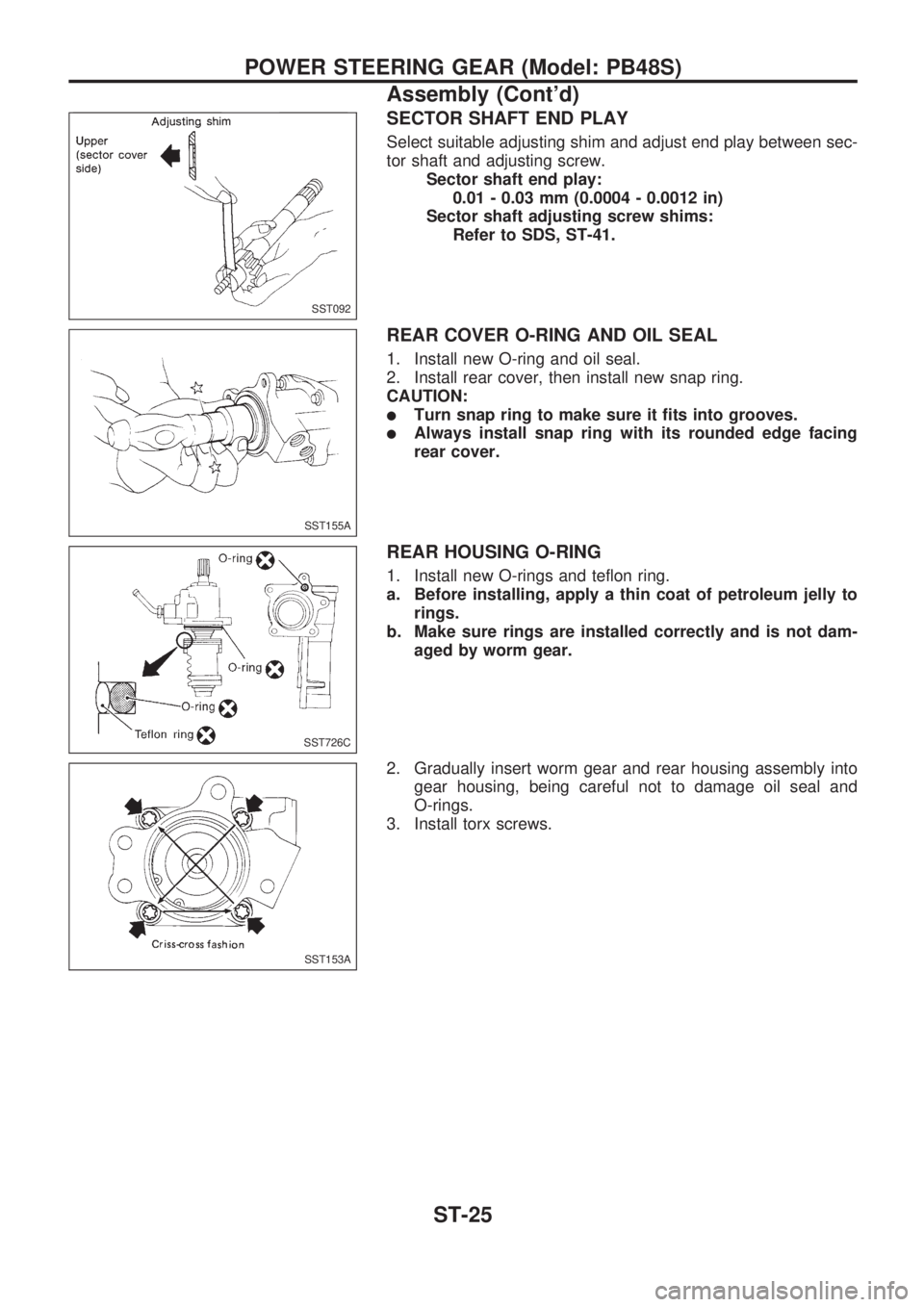

SECTOR SHAFT END PLAY

Select suitable adjusting shim and adjust end play between sec-

tor shaft and adjusting screw.

Sector shaft end play:

0.01 - 0.03 mm (0.0004 - 0.0012 in)

Sector shaft adjusting screw shims:

Refer to SDS, ST-41.

REAR COVER O-RING AND OIL SEAL

1. Install new O-ring and oil seal.

2. Install rear cover, then install new snap ring.

CAUTION:

lTurn snap ring to make sure it fits into grooves.

lAlways install snap ring with its rounded edge facing

rear cover.

REAR HOUSING O-RING

1. Install new O-rings and teflon ring.

a. Before installing, apply a thin coat of petroleum jelly to

rings.

b. Make sure rings are installed correctly and is not dam-

aged by worm gear.

2. Gradually insert worm gear and rear housing assembly into

gear housing, being careful not to damage oil seal and

O-rings.

3. Install torx screws.

SST092

SST155A

SST726C

SST153A

POWER STEERING GEAR (Model: PB48S)

Assembly (Cont'd)

ST-25

Page 1248 of 1659

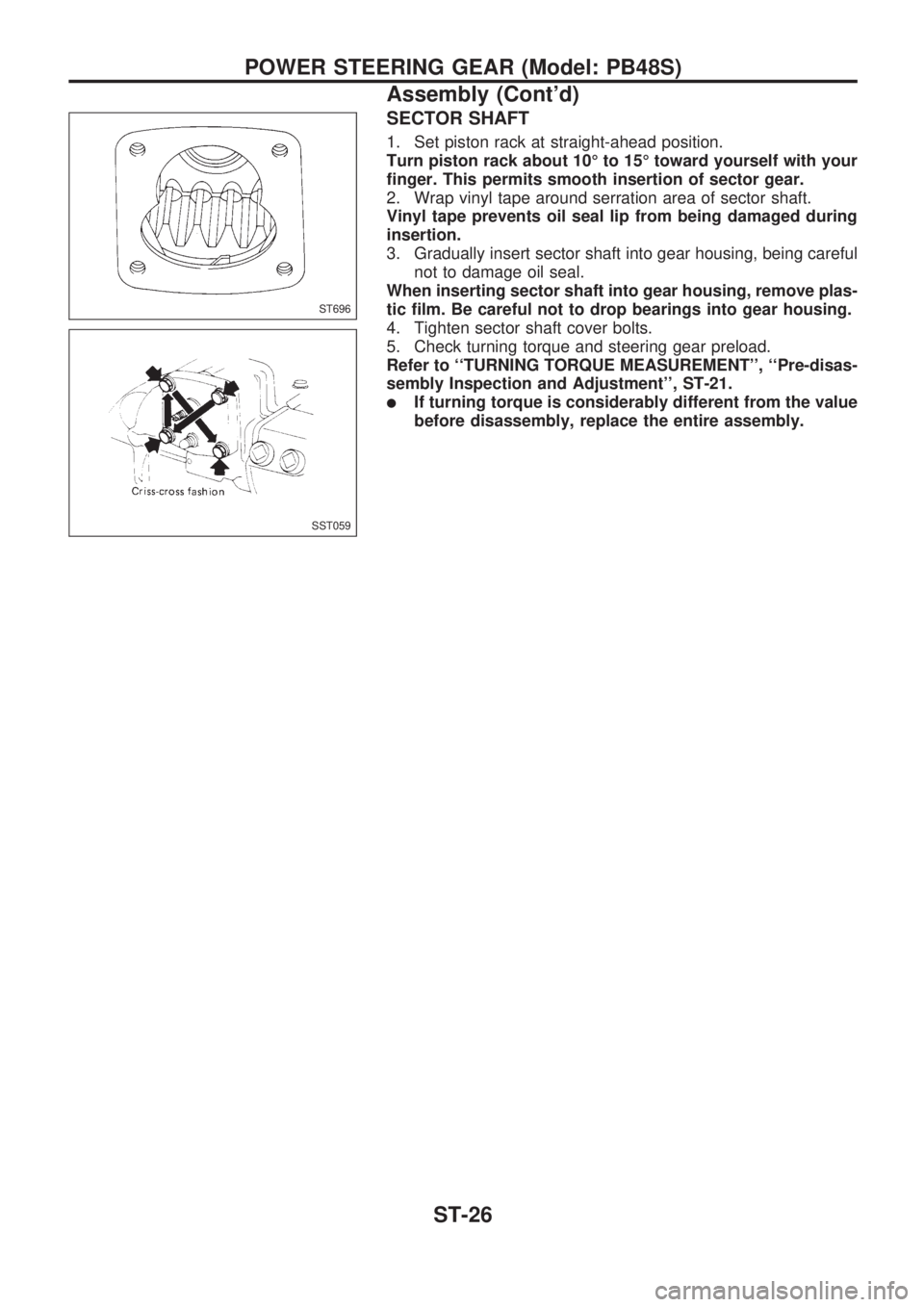

SECTOR SHAFT

1. Set piston rack at straight-ahead position.

Turn piston rack about 10É to 15É toward yourself with your

finger. This permits smooth insertion of sector gear.

2. Wrap vinyl tape around serration area of sector shaft.

Vinyl tape prevents oil seal lip from being damaged during

insertion.

3. Gradually insert sector shaft into gear housing, being careful

not to damage oil seal.

When inserting sector shaft into gear housing, remove plas-

tic film. Be careful not to drop bearings into gear housing.

4. Tighten sector shaft cover bolts.

5. Check turning torque and steering gear preload.

Refer to ``TURNING TORQUE MEASUREMENT'', ``Pre-disas-

sembly Inspection and Adjustment'', ST-21.

lIf turning torque is considerably different from the value

before disassembly, replace the entire assembly.

ST696

SST059

POWER STEERING GEAR (Model: PB48S)

Assembly (Cont'd)

ST-26

Page 1249 of 1659

Description

CAUTION:

lParts which can be disassembled are strictly limited.

Never disassemble parts other than those specified.

lDisassemble in as clean a place as possible.

lClean your hands before disassembly.

lDo not use rags; use nylon cloths or paper towels.

lFollow the procedures and cautions indicated in the Ser-

vice Manual.

SST810C

POWER STEERING SYSTEM (Model: PB59K)

ST-27

Page 1250 of 1659

Removal and Installation

Before removal, clean gear housing and oil pump exteriors

using a steam cleaner. Then dry with compressed air.

STEERING GEAR

Power Steering Gear Component

SST123CB

SST733C

POWER STEERING GEAR (Model: PB59K)

ST-28

Trending: diagram, change wheel, maintenance, fuel filter, fuel cap release, jacking points, rear view mirror