NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: OBD port, radio controls, open hood, keyless, service, sensor, brake light

Page 1331 of 1659

Movement ``!''

Compare movement ``!'' in height of pinion when it is pushed out

with magnetic switch energized and when it is pulled out by hand

until it touches stopper.

Movement ``!'':

Refer to SDS, EL-33.

lNot in the specified value ... Adjust by adjusting plate.

Service Data and Specifications (SDS)

STARTER

TypeM3T70381 M3T29482D S13-327

MITSUBISHI HITACHI

Non-reduction Reduction

Applied model2WD 4WD 2WD

KA24 TD25

Standard Standard

System voltage V 12

No-load

Terminal voltage V 11.5 11.0

Current A Less than 60 Less than 160

Revolution rpm More than 6,500 More than 4,000

Minimum diameter of commutator

mm (in)31.4 (1.236) 35.5 (1.398)

Minimum length of brush

mm (in)11.5 (0.453) 9.0 (0.354)

Brush spring tension N (kg, lb)13.7 - 25.5

(1.4 - 2.6, 3.1 - 5.7)Ð

Clearance between bearing metal and

armature shaft

mm (in)Ð Less than 0.2 (0.008) Ð

Clearance ``!'' between pinion front edge

and pinion stopper

mm (in)0.5 - 2.0

(0.020 - 0.079)Ð

Movement ``!'' in height of pinion assembly

mm (in)Ð0.3 - 1.5

(0.012 - 0.059)

SEL497D

SEL633BA

STARTING SYSTEM

Assembly (Cont'd)

EL-33

Page 1332 of 1659

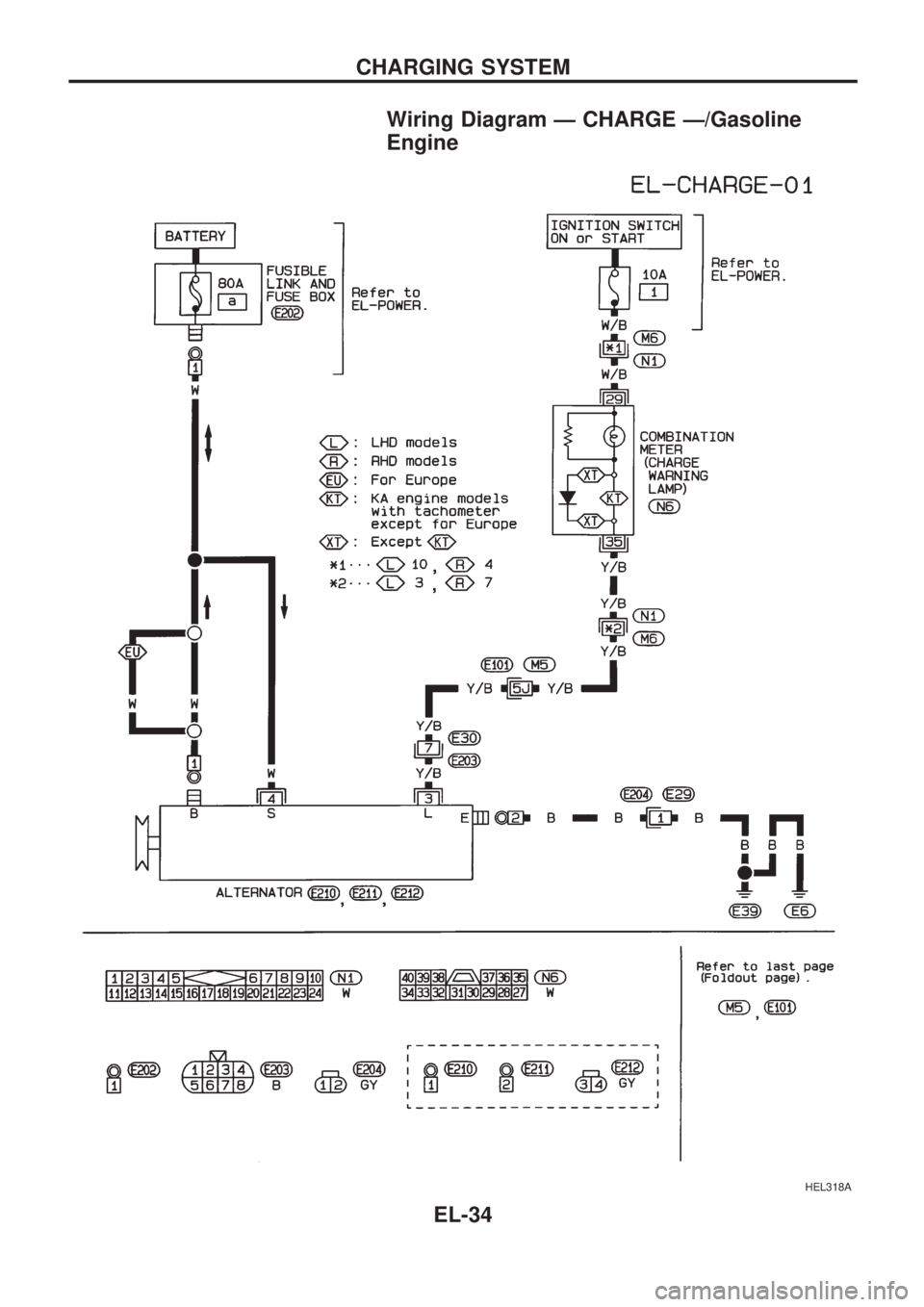

Wiring Diagram Ð CHARGE Ð/Gasoline

Engine

HEL318A

CHARGING SYSTEM

EL-34

Page 1333 of 1659

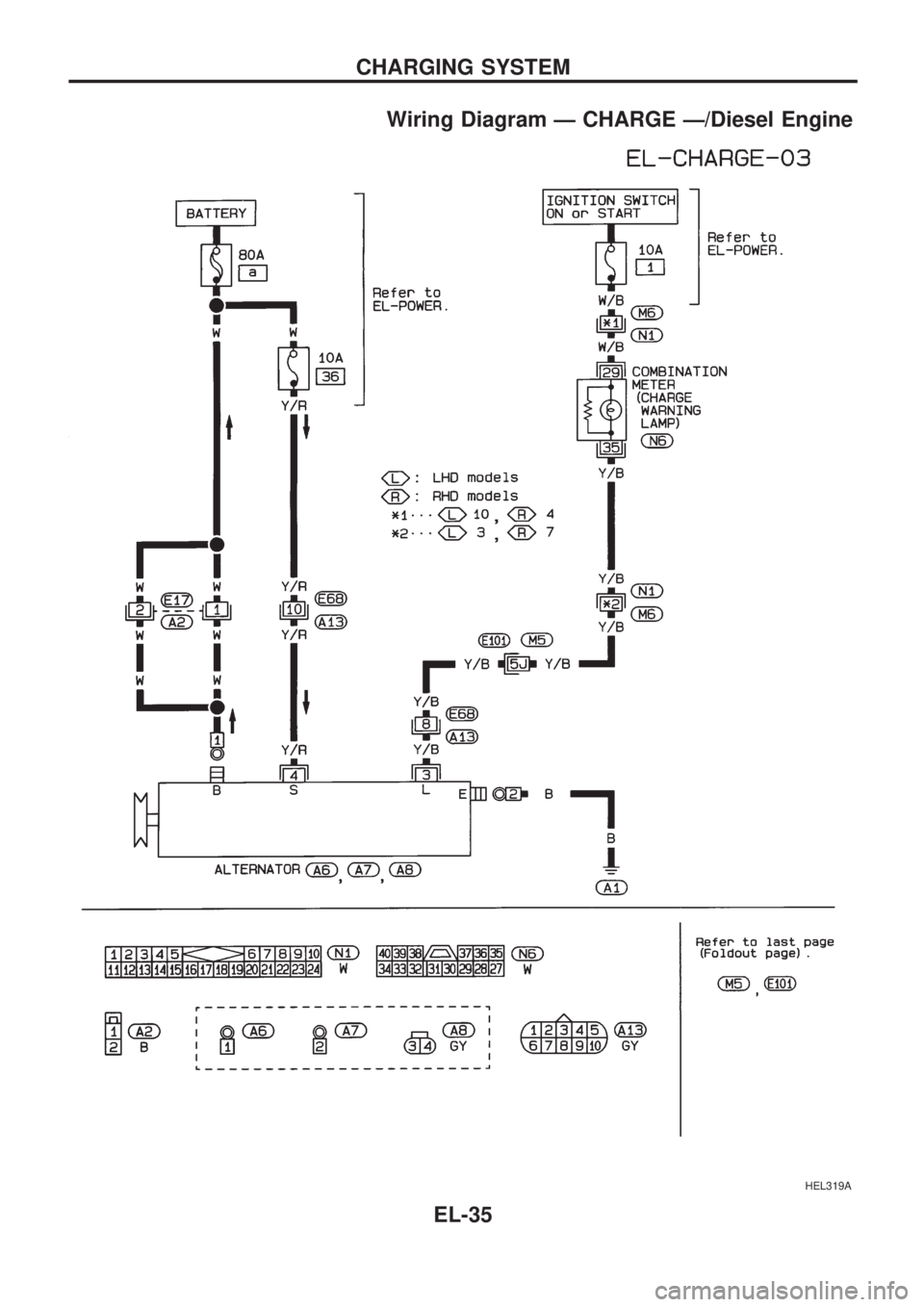

Wiring Diagram Ð CHARGE Ð/Diesel Engine

HEL319A

CHARGING SYSTEM

EL-35

Page 1334 of 1659

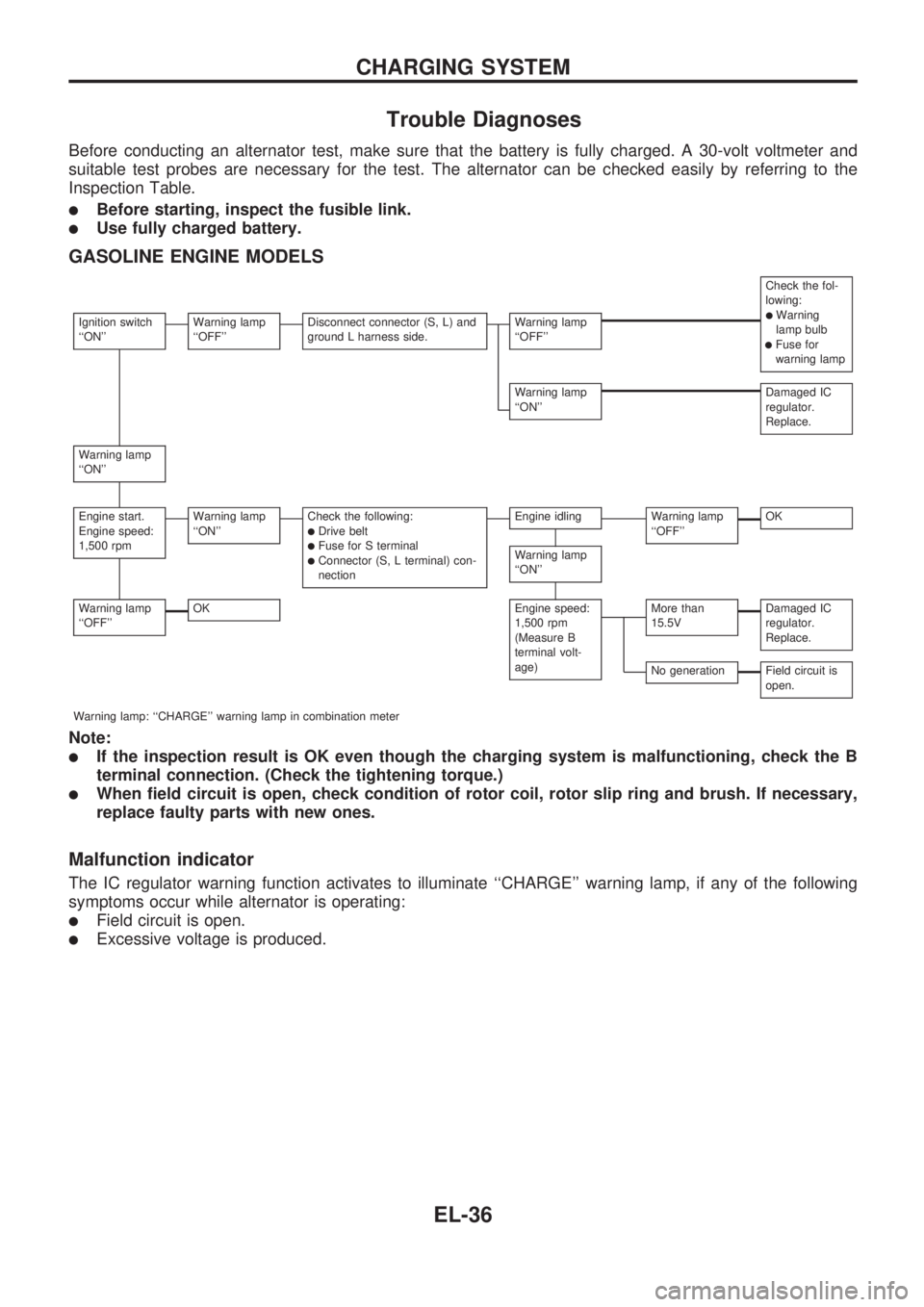

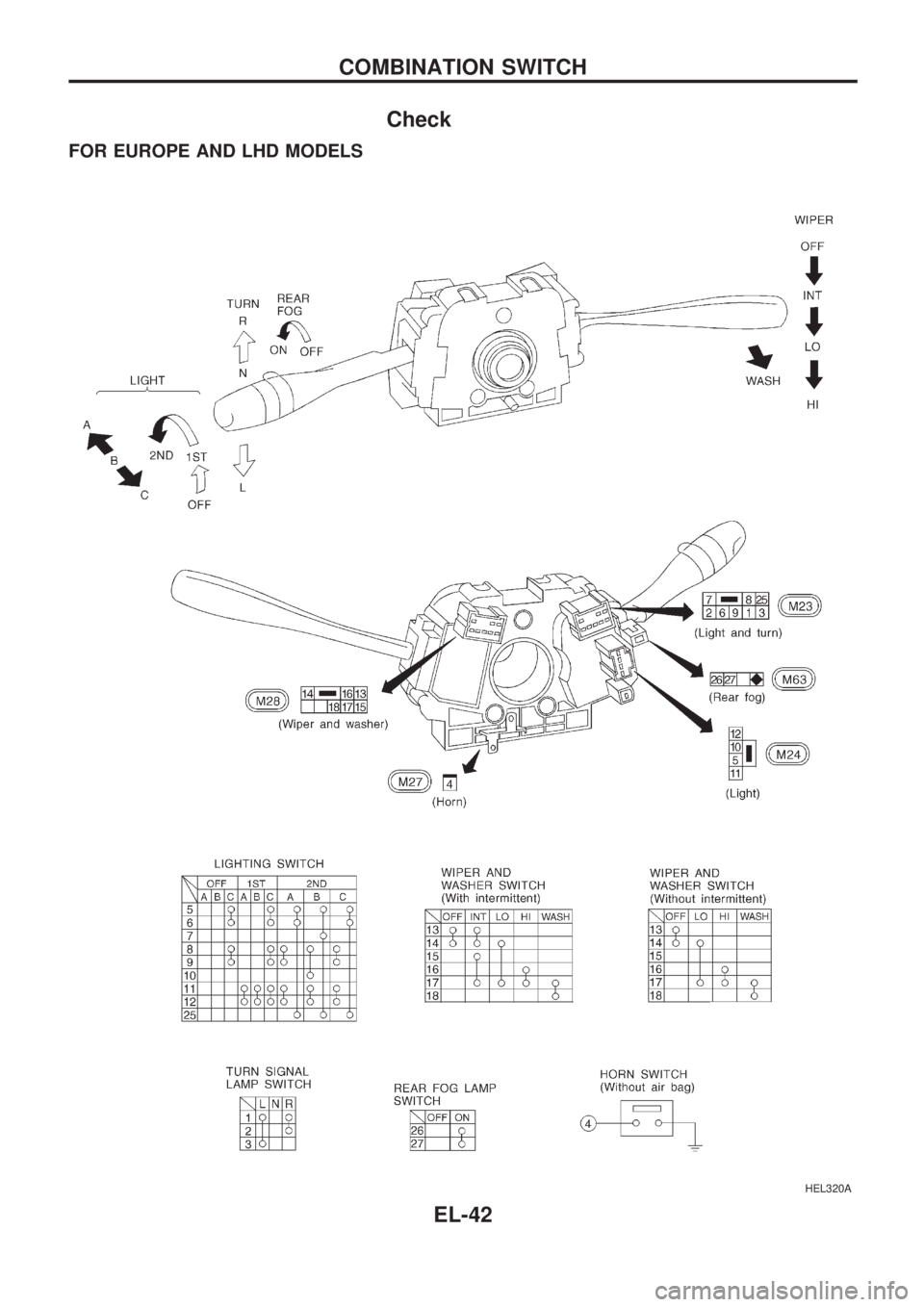

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and

suitable test probes are necessary for the test. The alternator can be checked easily by referring to the

Inspection Table.

lBefore starting, inspect the fusible link.

lUse fully charged battery.

GASOLINE ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine start.

Engine speed:

1,500 rpmWarning lamp

``ON''Check the following:lDrive beltlFuse for S terminallConnector (S, L terminal) con-

nection

Engine idlingWarning lamp

``OFF''OK

Warning lamp

``ON''

Warning lamp

``OFF''OKEngine speed:

1,500 rpm

(Measure B

terminal volt-

age)More than

15.5VDamaged IC

regulator.

Replace.

No generationField circuit is

open.

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection. (Check the tightening torque.)

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

Malfunction indicator

The IC regulator warning function activates to illuminate ``CHARGE'' warning lamp, if any of the following

symptoms occur while alternator is operating:

lField circuit is open.

lExcessive voltage is produced.

CHARGING SYSTEM

EL-36

Page 1335 of 1659

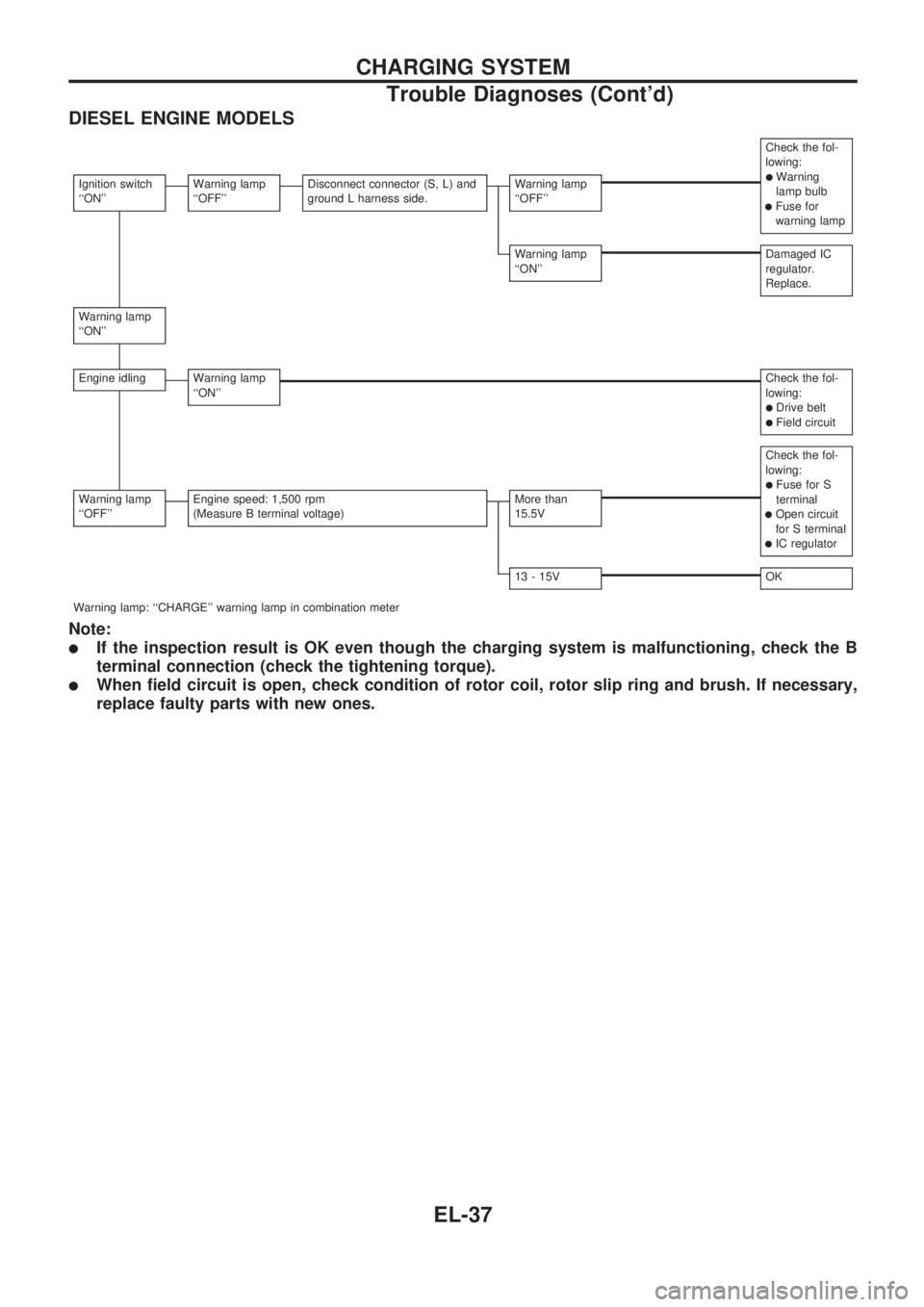

DIESEL ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine idlingWarning lamp

``ON''Check the fol-

lowing:

lDrive beltlField circuit

Check the fol-

lowing:

lFuse for S

terminal

lOpen circuit

for S terminal

lIC regulator

Warning lamp

``OFF''Engine speed: 1,500 rpm

(Measure B terminal voltage)More than

15.5V

13 - 15VOK

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection (check the tightening torque).

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

CHARGING SYSTEM

Trouble Diagnoses (Cont'd)

EL-37

Page 1336 of 1659

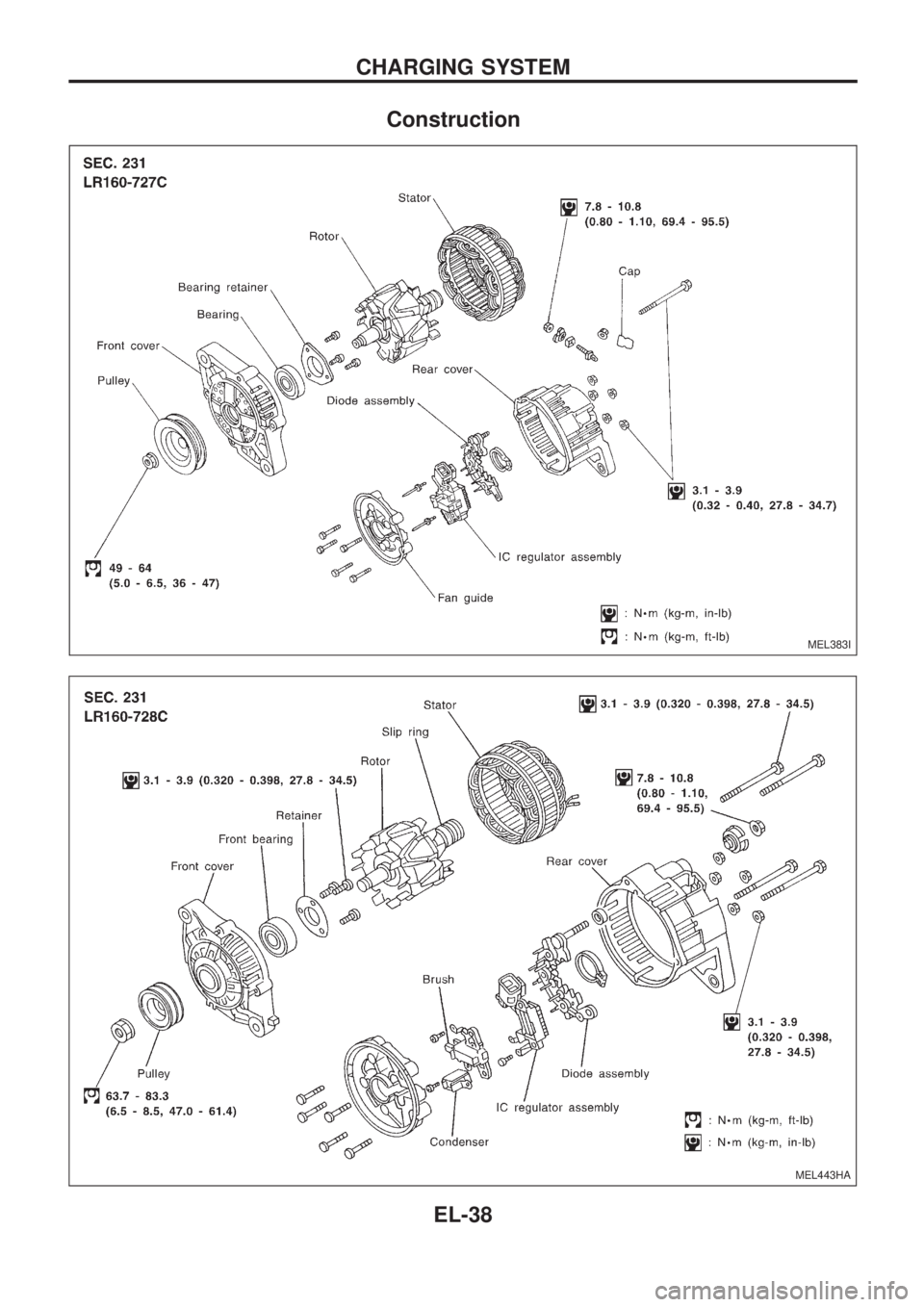

Construction

MEL383I

MEL443HA

CHARGING SYSTEM

EL-38

Page 1337 of 1659

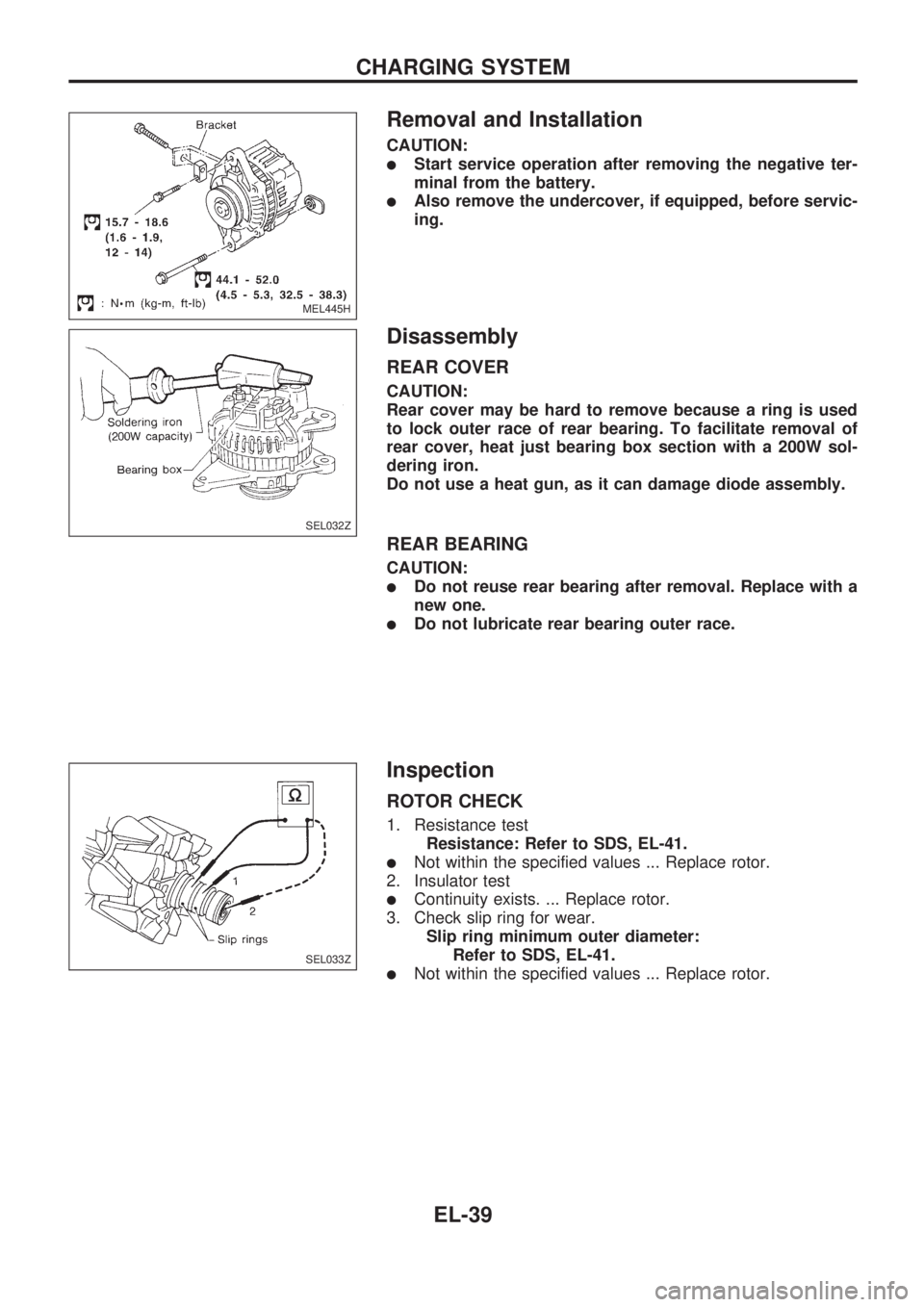

Removal and Installation

CAUTION:

lStart service operation after removing the negative ter-

minal from the battery.

lAlso remove the undercover, if equipped, before servic-

ing.

Disassembly

REAR COVER

CAUTION:

Rear cover may be hard to remove because a ring is used

to lock outer race of rear bearing. To facilitate removal of

rear cover, heat just bearing box section with a 200W sol-

dering iron.

Do not use a heat gun, as it can damage diode assembly.

REAR BEARING

CAUTION:

lDo not reuse rear bearing after removal. Replace with a

new one.

lDo not lubricate rear bearing outer race.

Inspection

ROTOR CHECK

1. Resistance test

Resistance: Refer to SDS, EL-41.

lNot within the specified values ... Replace rotor.

2. Insulator test

lContinuity exists. ... Replace rotor.

3. Check slip ring for wear.

Slip ring minimum outer diameter:

Refer to SDS, EL-41.

lNot within the specified values ... Replace rotor.

MEL445H

.

SEL032Z

SEL033Z

CHARGING SYSTEM

EL-39

Page 1338 of 1659

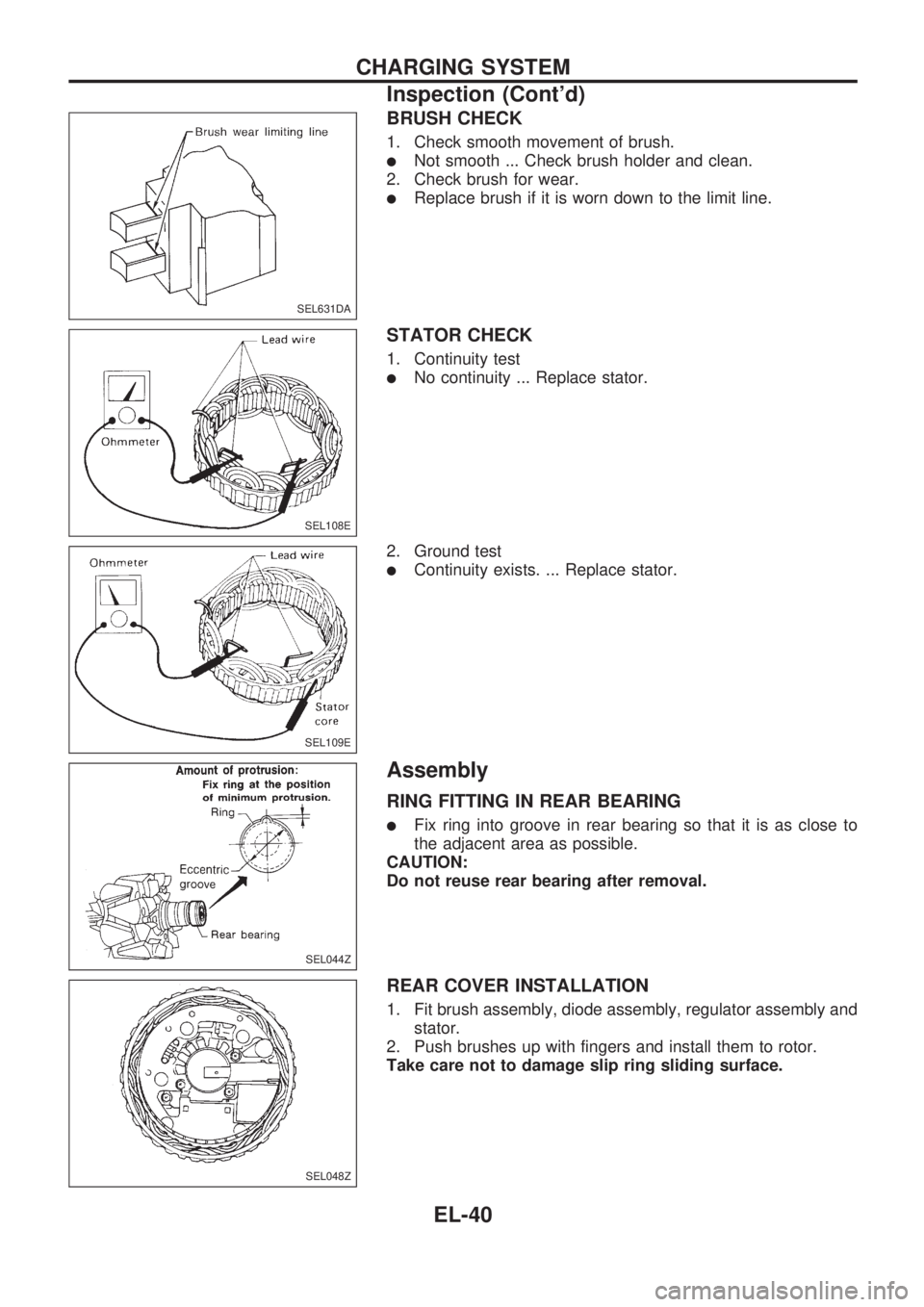

BRUSH CHECK

1. Check smooth movement of brush.

lNot smooth ... Check brush holder and clean.

2. Check brush for wear.

lReplace brush if it is worn down to the limit line.

STATOR CHECK

1. Continuity test

lNo continuity ... Replace stator.

2. Ground test

lContinuity exists. ... Replace stator.

Assembly

RING FITTING IN REAR BEARING

lFix ring into groove in rear bearing so that it is as close to

the adjacent area as possible.

CAUTION:

Do not reuse rear bearing after removal.

REAR COVER INSTALLATION

1. Fit brush assembly, diode assembly, regulator assembly and

stator.

2. Push brushes up with fingers and install them to rotor.

Take care not to damage slip ring sliding surface.

SEL631DA

SEL108E

SEL109E

SEL044Z

SEL048Z

CHARGING SYSTEM

Inspection (Cont'd)

EL-40

Page 1339 of 1659

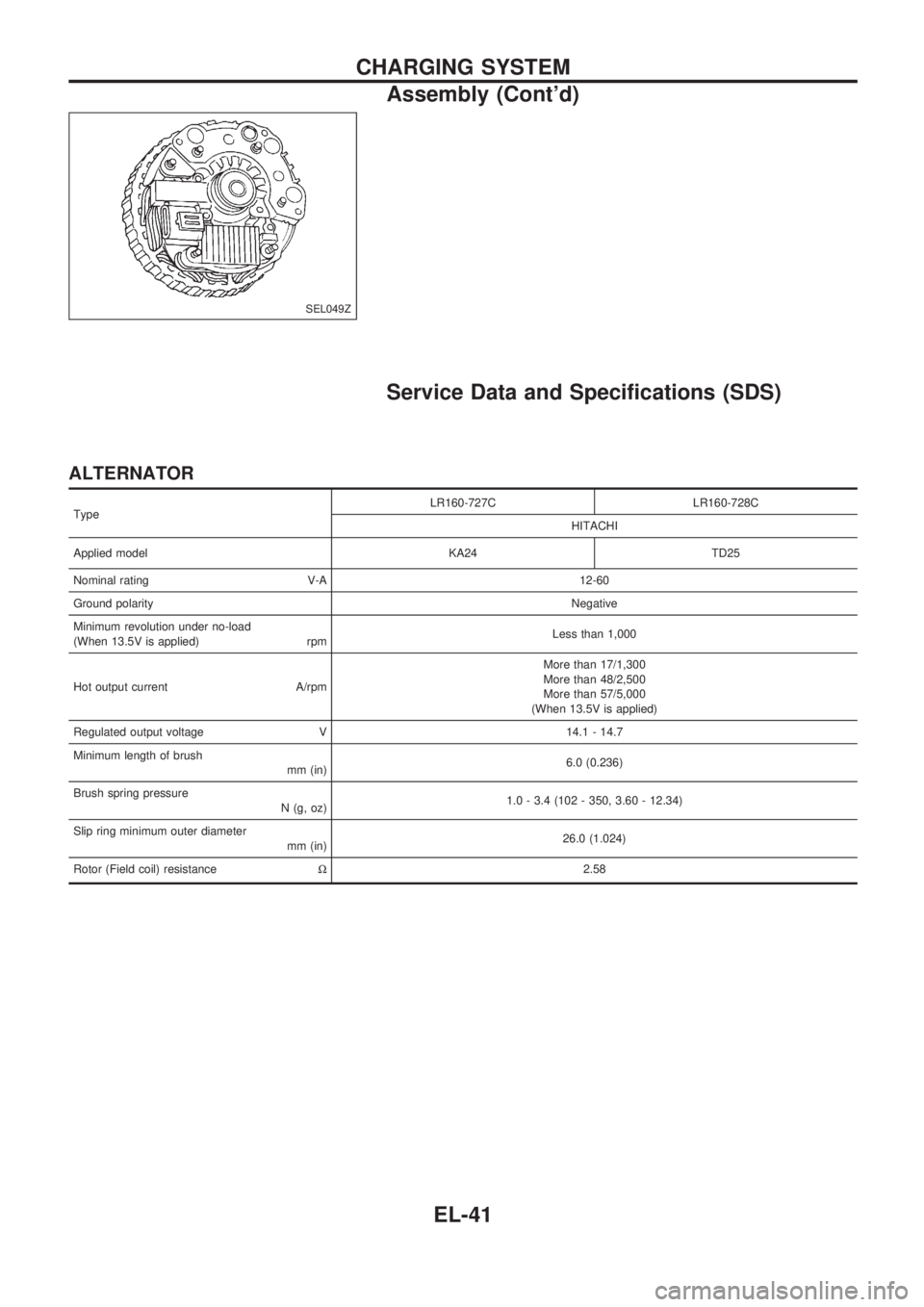

Service Data and Specifications (SDS)

ALTERNATOR

TypeLR160-727C LR160-728C

HITACHI

Applied model KA24 TD25

Nominal rating V-A 12-60

Ground polarityNegative

Minimum revolution under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current A/rpmMore than 17/1,300

More than 48/2,500

More than 57/5,000

(When 13.5V is applied)

Regulated output voltage V 14.1 - 14.7

Minimum length of brush

mm (in)6.0 (0.236)

Brush spring pressure

N (g, oz)1.0 - 3.4 (102 - 350, 3.60 - 12.34)

Slip ring minimum outer diameter

mm (in)26.0 (1.024)

Rotor (Field coil) resistanceW2.58

SEL049Z

CHARGING SYSTEM

Assembly (Cont'd)

EL-41

Page 1340 of 1659

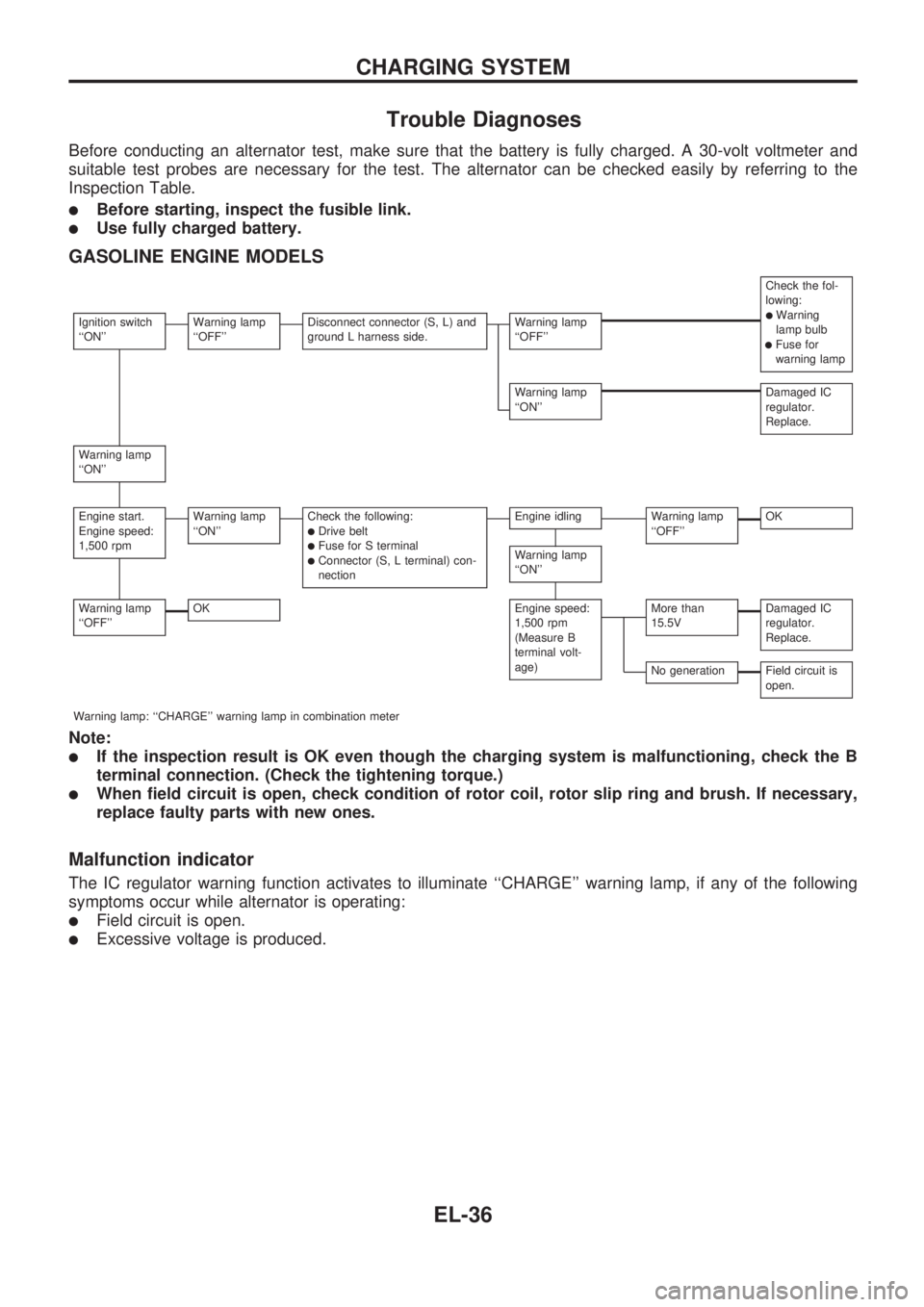

Check

FOR EUROPE AND LHD MODELS

HEL320A

COMBINATION SWITCH

EL-42

Trending: relay, brake fluid, service reset, bulb, temperature sensor, engine, instrument panel