NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: coolant reservoir, oil, clock, set clock, catalytic converter, transmission, coolant capacity

Page 1421 of 1659

HEL935

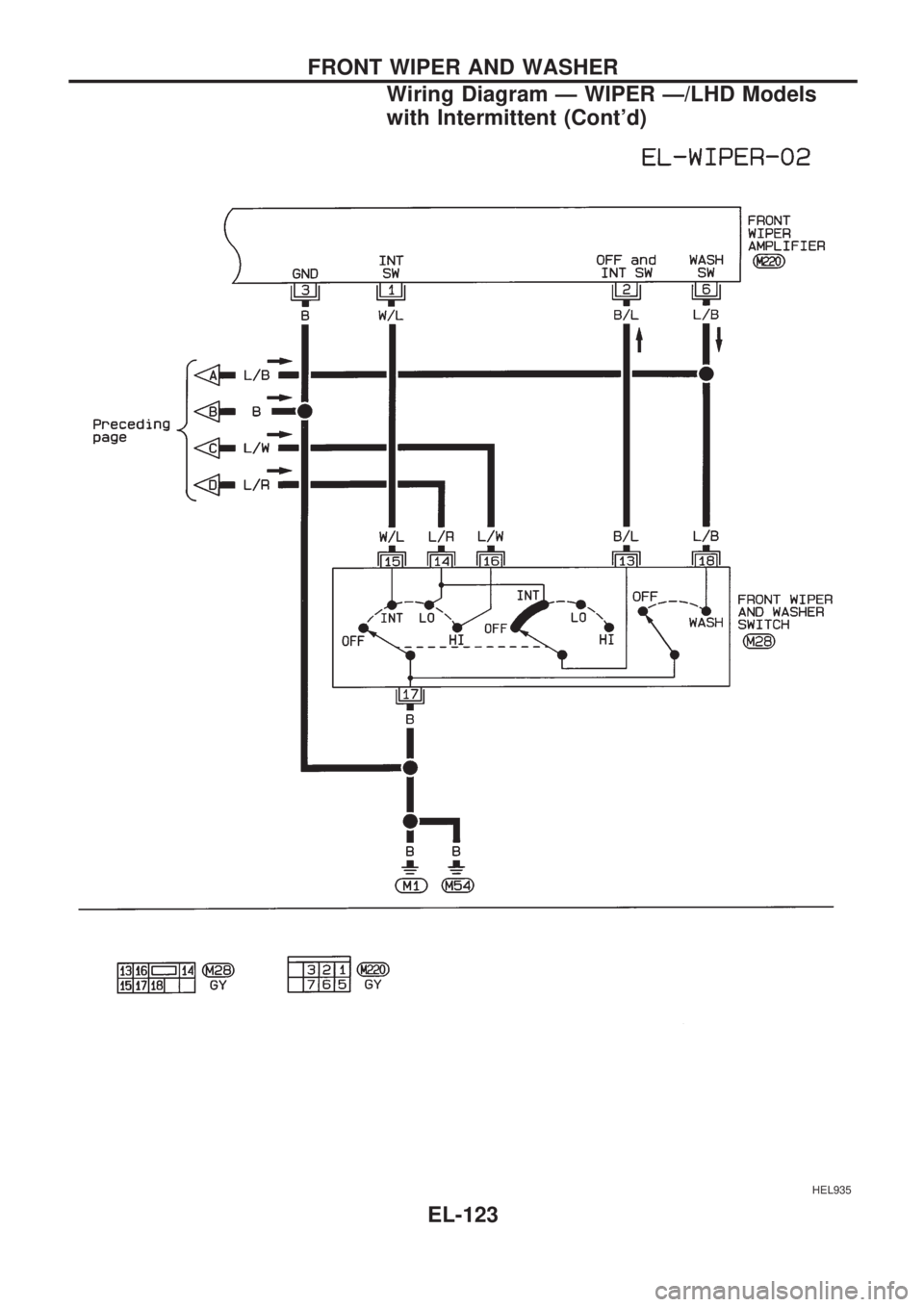

FRONT WIPER AND WASHER

Wiring Diagram Ð WIPER Ð/LHD Models

with Intermittent (Cont'd)

EL-123

Page 1422 of 1659

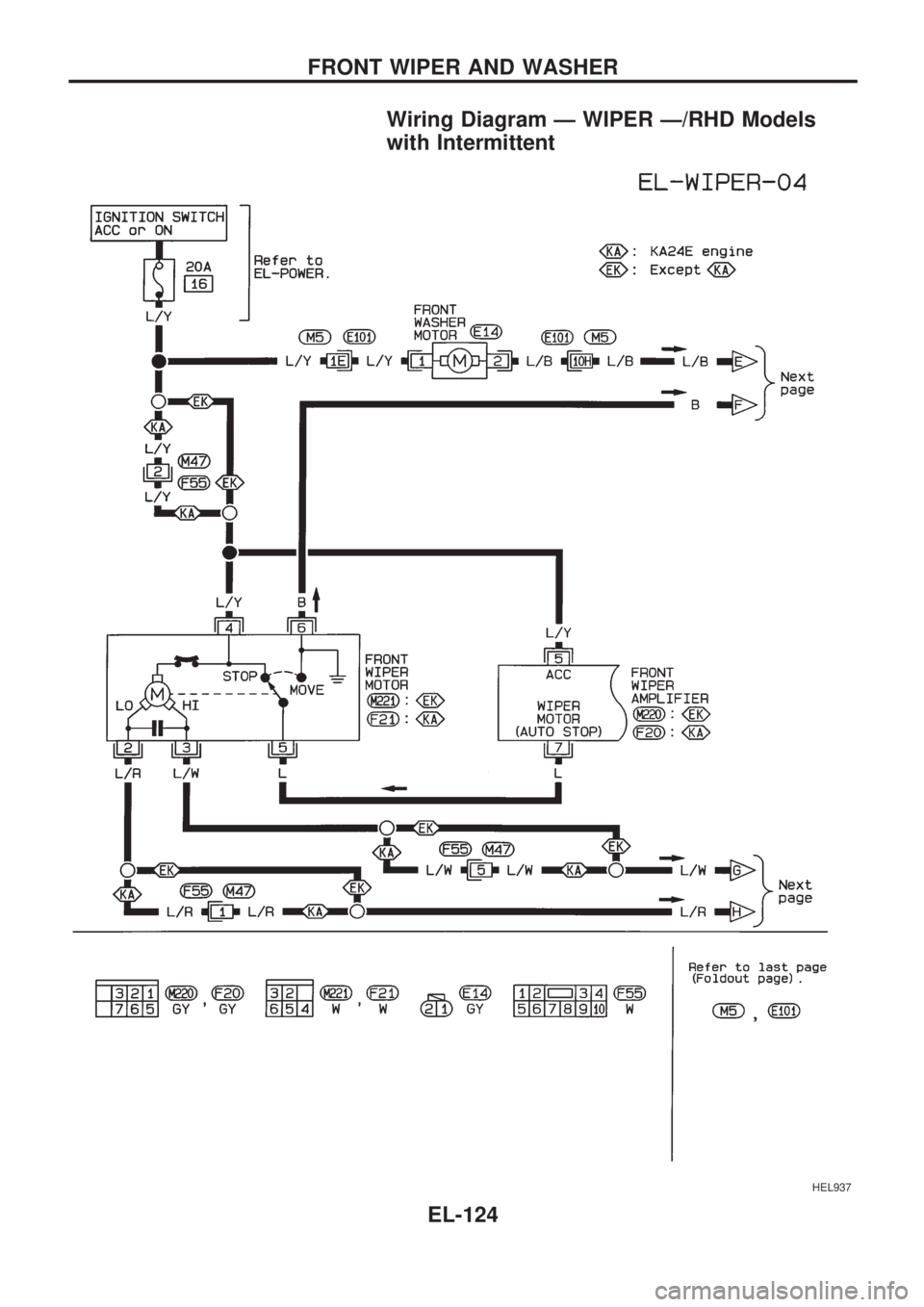

Wiring Diagram Ð WIPER Ð/RHD Models

with Intermittent

HEL937

FRONT WIPER AND WASHER

EL-124

Page 1423 of 1659

HEL372A

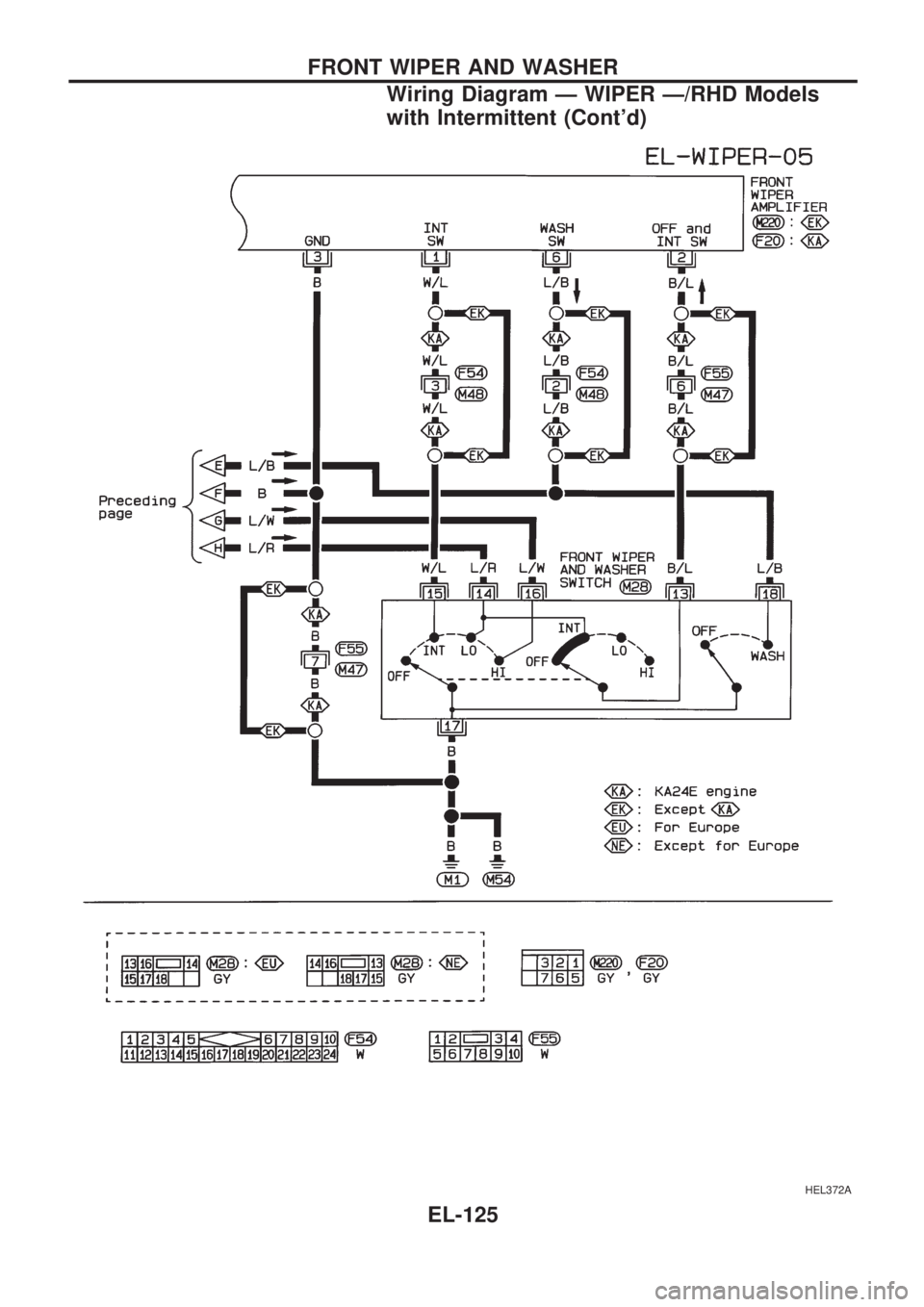

FRONT WIPER AND WASHER

Wiring Diagram Ð WIPER Ð/RHD Models

with Intermittent (Cont'd)

EL-125

Page 1424 of 1659

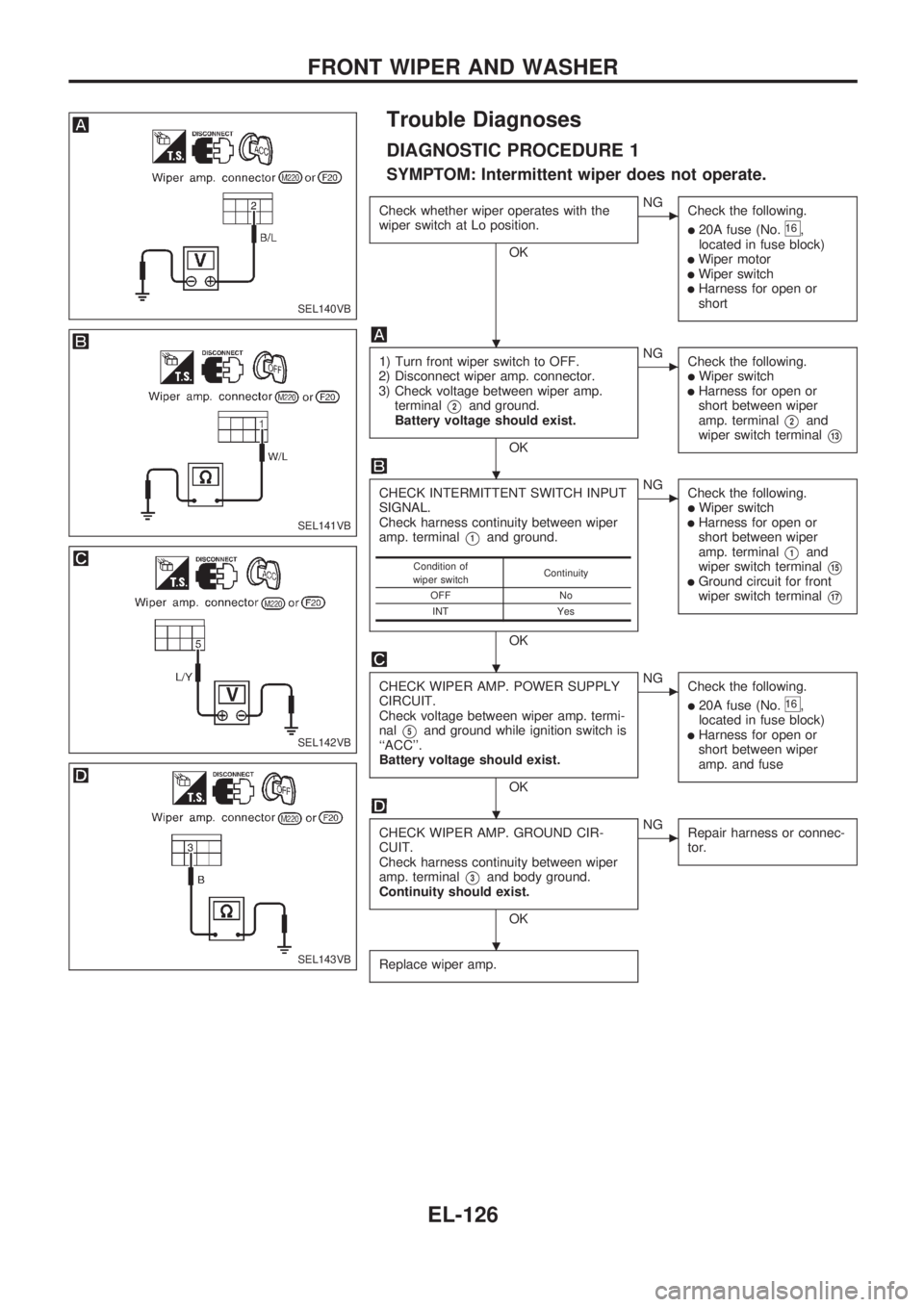

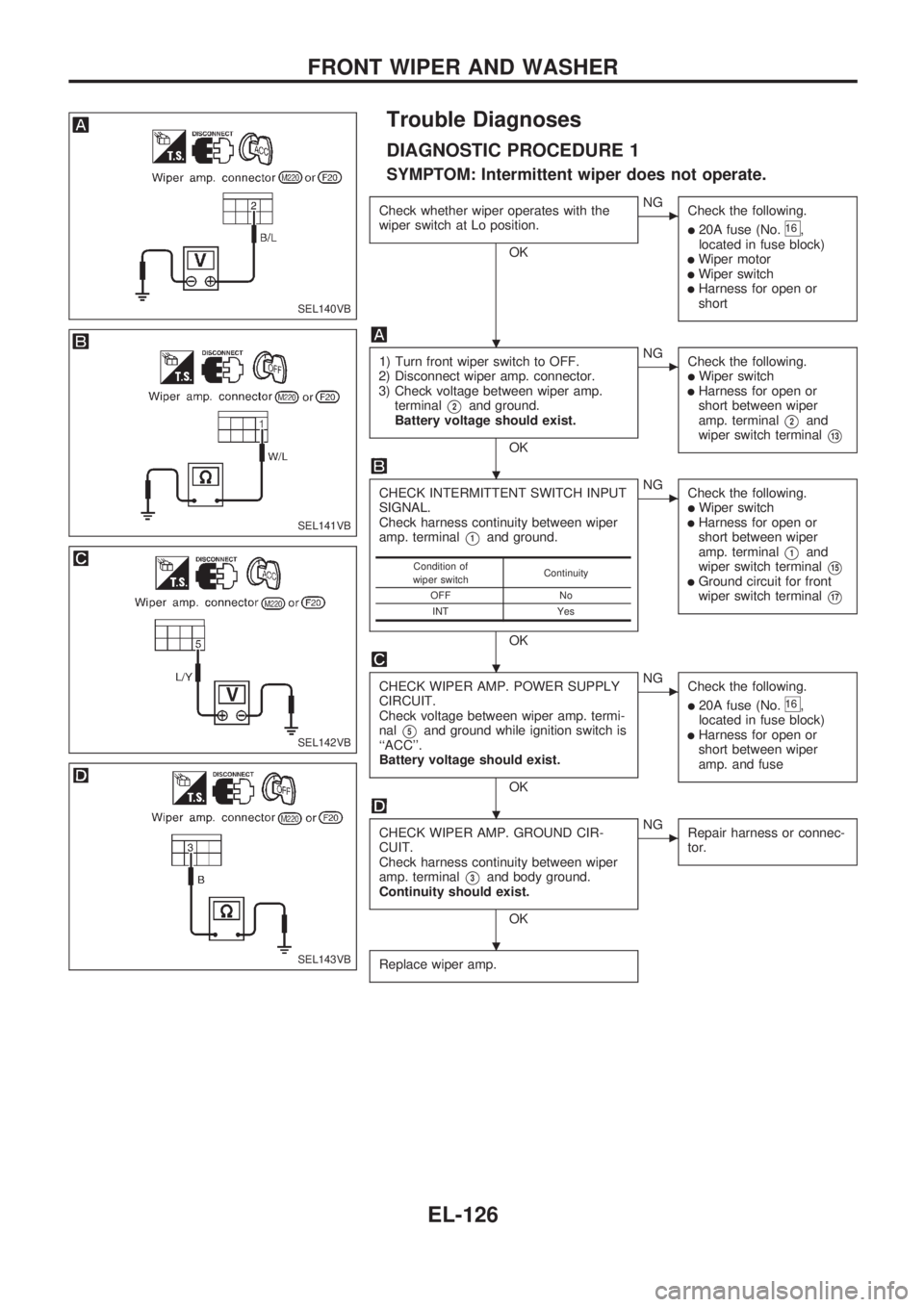

Trouble Diagnoses

DIAGNOSTIC PROCEDURE 1

SYMPTOM: Intermittent wiper does not operate.

Check whether wiper operates with the

wiper switch at Lo position.

OK

cNG

Check the following.

l20A fuse (No.16,

located in fuse block)

lWiper motorlWiper switchlHarness for open or

short

1) Turn front wiper switch to OFF.

2) Disconnect wiper amp. connector.

3) Check voltage between wiper amp.

terminal

V2and ground.

Battery voltage should exist.

OK

cNG

Check the following.

lWiper switchlHarness for open or

short between wiper

amp. terminal

V2and

wiper switch terminal

V13

CHECK INTERMITTENT SWITCH INPUT

SIGNAL.

Check harness continuity between wiper

amp. terminal

V1and ground.

OK

cNG

Check the following.

lWiper switchlHarness for open or

short between wiper

amp. terminal

V1and

wiper switch terminal

V15lGround circuit for front

wiper switch terminal

V17

CHECK WIPER AMP. POWER SUPPLY

CIRCUIT.

Check voltage between wiper amp. termi-

nal

V5and ground while ignition switch is

``ACC''.

Battery voltage should exist.

OK

cNG

Check the following.

l20A fuse (No.16,

located in fuse block)

lHarness for open or

short between wiper

amp. and fuse

CHECK WIPER AMP. GROUND CIR-

CUIT.

Check harness continuity between wiper

amp. terminal

V3and body ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tor.

Replace wiper amp.

Condition of

wiper switchContinuity

OFF No

INT Yes

SEL140VB

SEL141VB

SEL142VB

SEL143VB

.

.

.

.

.

FRONT WIPER AND WASHER

EL-126

Page 1425 of 1659

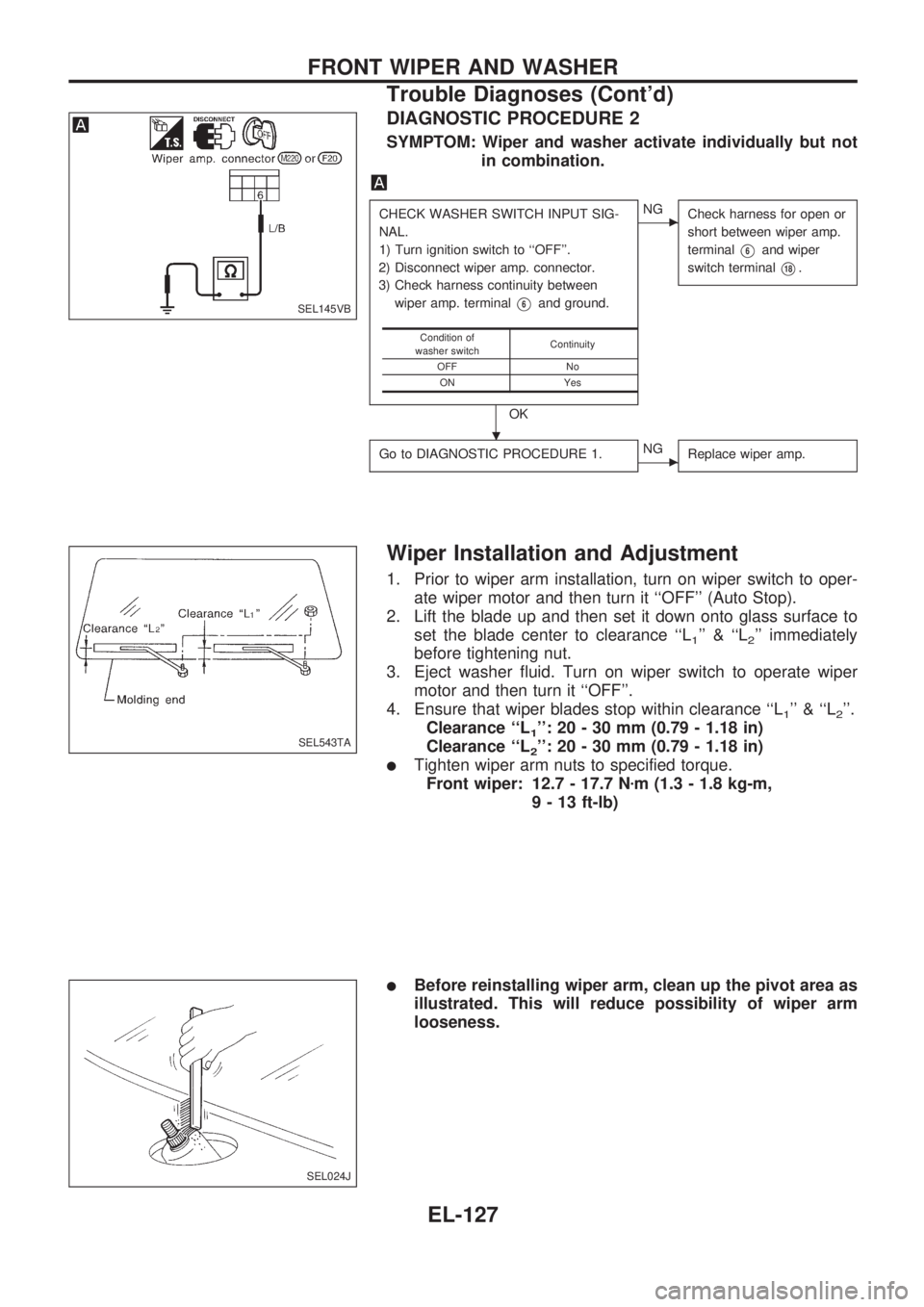

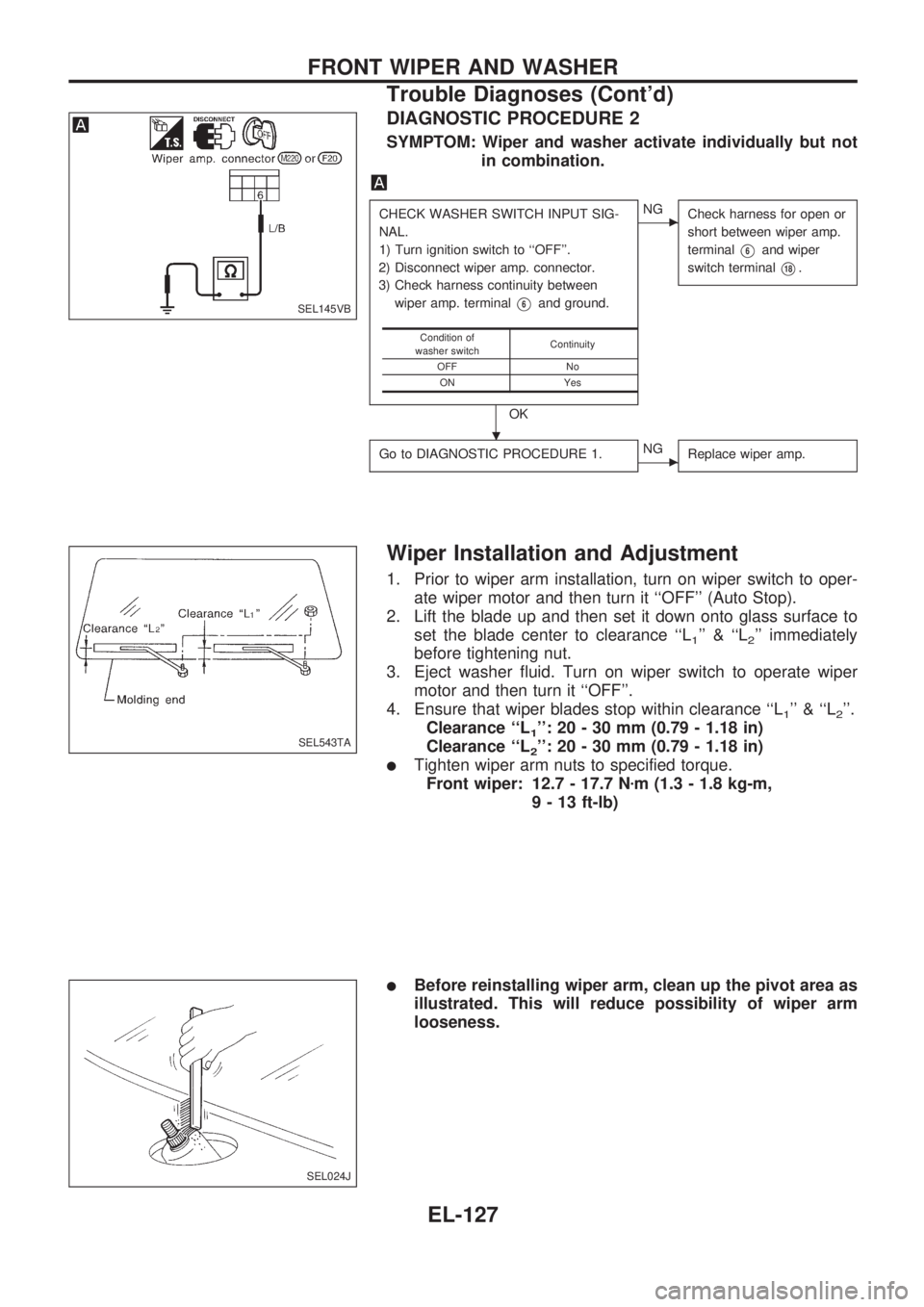

DIAGNOSTIC PROCEDURE 2

SYMPTOM: Wiper and washer activate individually but not

in combination.

CHECK WASHER SWITCH INPUT SIG-

NAL.

1) Turn ignition switch to ``OFF''.

2) Disconnect wiper amp. connector.

3) Check harness continuity between

wiper amp. terminal

V6and ground.

OK

cNG

Check harness for open or

short between wiper amp.

terminal

V6and wiper

switch terminal

V18.

Go to DIAGNOSTIC PROCEDURE 1.cNG

Replace wiper amp.

Condition of

washer switchContinuity

OFF No

ON Yes

Wiper Installation and Adjustment

1. Prior to wiper arm installation, turn on wiper switch to oper-

ate wiper motor and then turn it ``OFF'' (Auto Stop).

2. Lift the blade up and then set it down onto glass surface to

set the blade center to clearance ``L

1'' & ``L2'' immediately

before tightening nut.

3. Eject washer fluid. Turn on wiper switch to operate wiper

motor and then turn it ``OFF''.

4. Ensure that wiper blades stop within clearance ``L

1'' & ``L2''.

Clearance ``L

1'': 20 - 30 mm (0.79 - 1.18 in)

Clearance ``L

2'': 20 - 30 mm (0.79 - 1.18 in)

lTighten wiper arm nuts to specified torque.

Front wiper: 12.7 - 17.7 Nzm (1.3 - 1.8 kg-m,

9 - 13 ft-lb)

lBefore reinstalling wiper arm, clean up the pivot area as

illustrated. This will reduce possibility of wiper arm

looseness.

SEL145VB

SEL543TA

SEL024J

.

FRONT WIPER AND WASHER

Trouble Diagnoses (Cont'd)

EL-127

Page 1426 of 1659

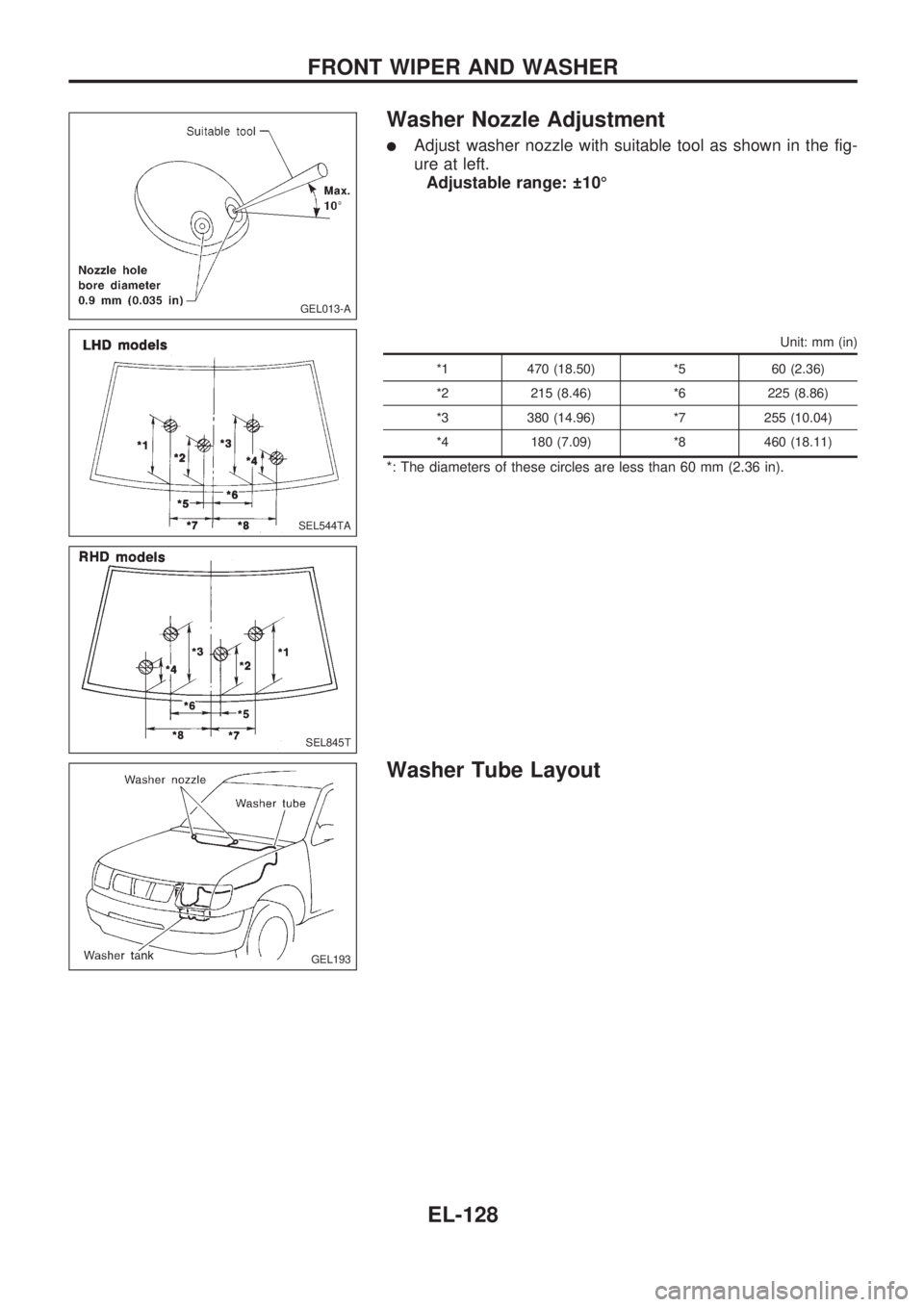

Washer Nozzle Adjustment

lAdjust washer nozzle with suitable tool as shown in the fig-

ure at left.

Adjustable range: 10É

Unit: mm (in)

*1 470 (18.50) *5 60 (2.36)

*2 215 (8.46) *6 225 (8.86)

*3 380 (14.96) *7 255 (10.04)

*4 180 (7.09) *8 460 (18.11)

*: The diameters of these circles are less than 60 mm (2.36 in).

Washer Tube Layout

GEL013-A

SEL544TA

SEL845T

GEL193

FRONT WIPER AND WASHER

EL-128

Page 1427 of 1659

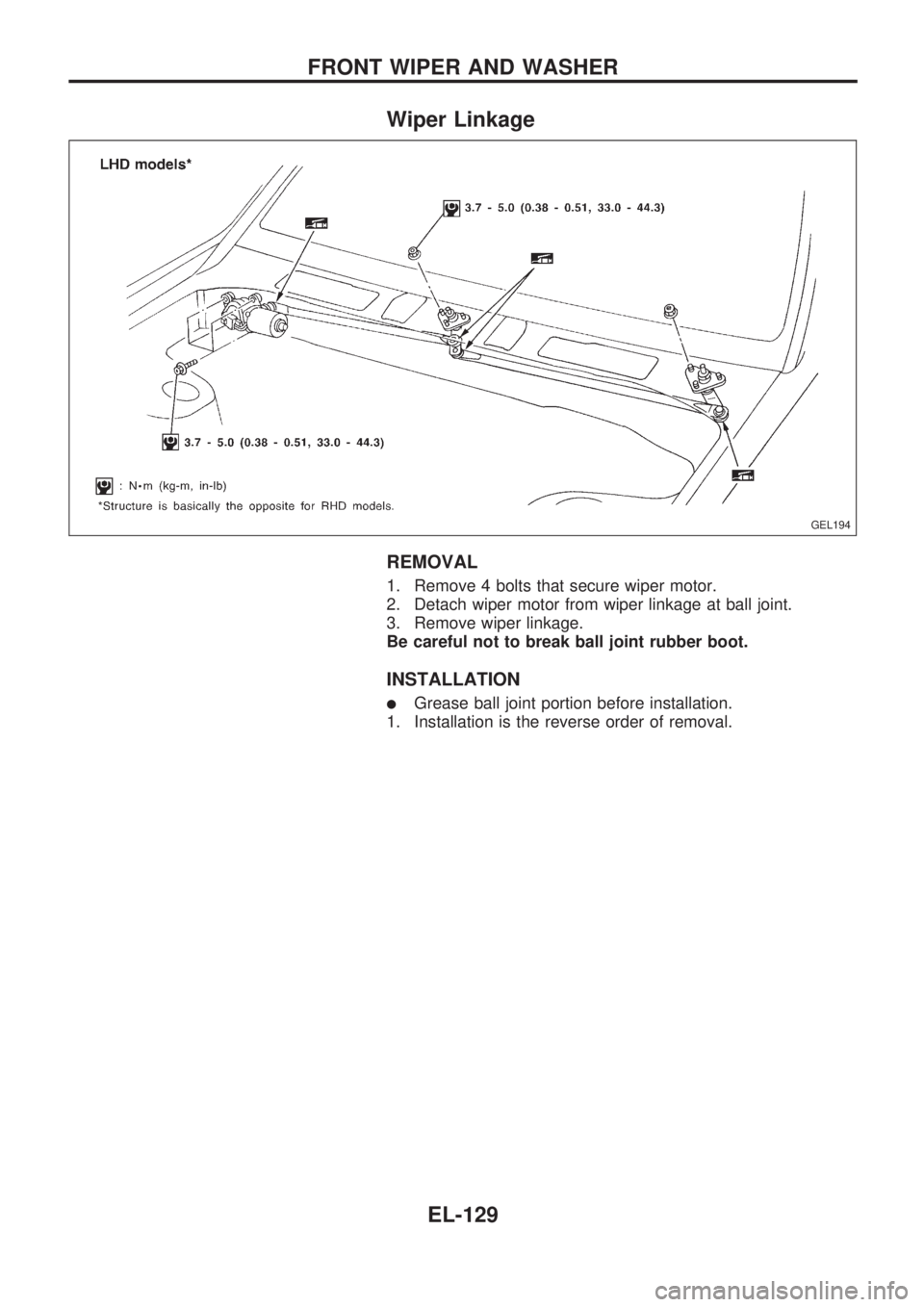

Wiper Linkage

REMOVAL

1. Remove 4 bolts that secure wiper motor.

2. Detach wiper motor from wiper linkage at ball joint.

3. Remove wiper linkage.

Be careful not to break ball joint rubber boot.

INSTALLATION

lGrease ball joint portion before installation.

1. Installation is the reverse order of removal.

GEL194

FRONT WIPER AND WASHER

EL-129

Page 1428 of 1659

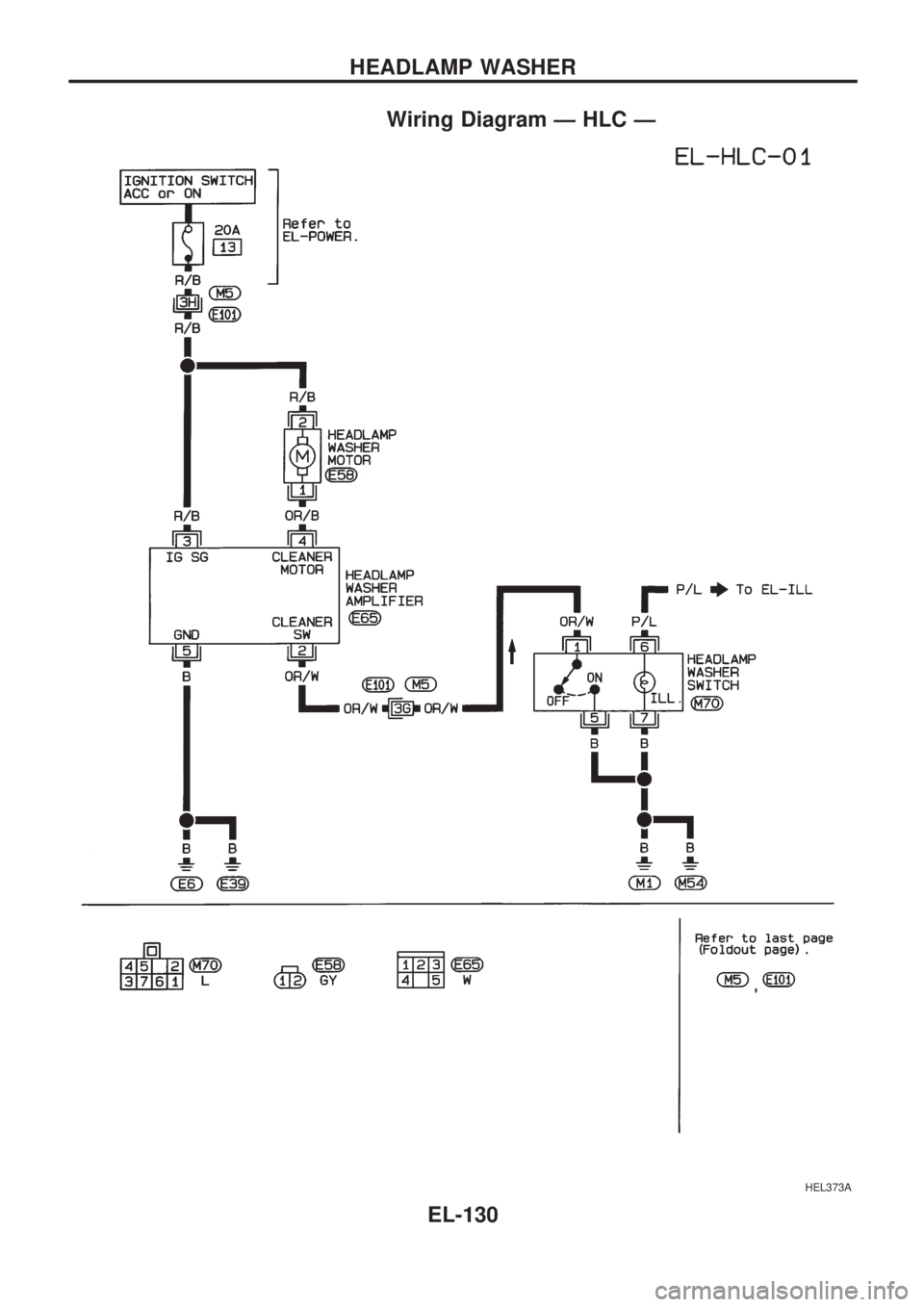

Wiring Diagram Ð HLC Ð

HEL373A

HEADLAMP WASHER

EL-130

Page 1429 of 1659

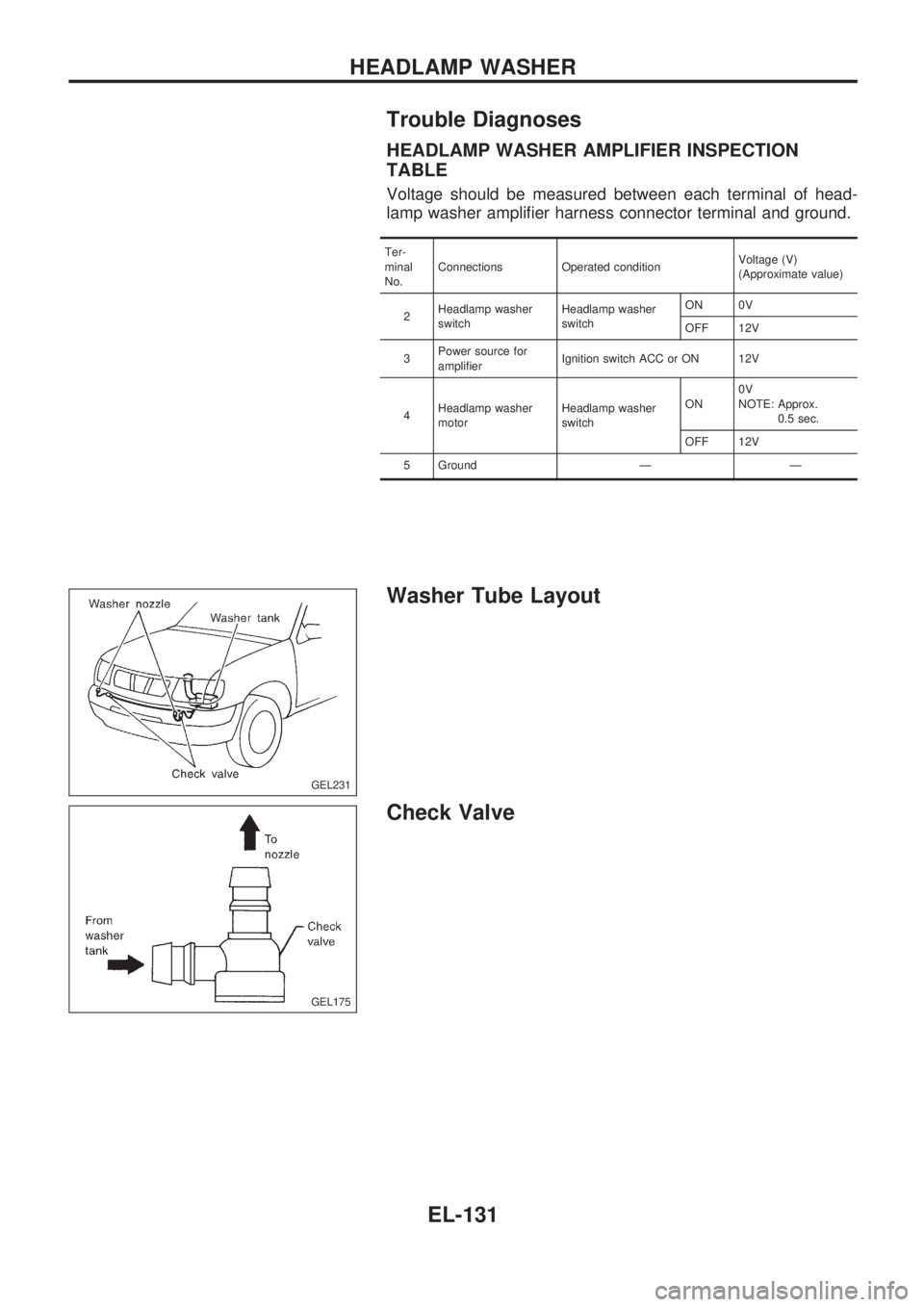

Trouble Diagnoses

HEADLAMP WASHER AMPLIFIER INSPECTION

TABLE

Voltage should be measured between each terminal of head-

lamp washer amplifier harness connector terminal and ground.

Ter-

minal

No.Connections Operated conditionVoltage (V)

(Approximate value)

2Headlamp washer

switchHeadlamp washer

switchON 0V

OFF 12V

3Power source for

amplifierIgnition switch ACC or ON 12V

4Headlamp washer

motorHeadlamp washer

switchON0V

NOTE: Approx.

0.5 sec.

OFF 12V

5 Ground Ð Ð

Washer Tube Layout

Check Valve

GEL231

GEL175

HEADLAMP WASHER

EL-131

Page 1430 of 1659

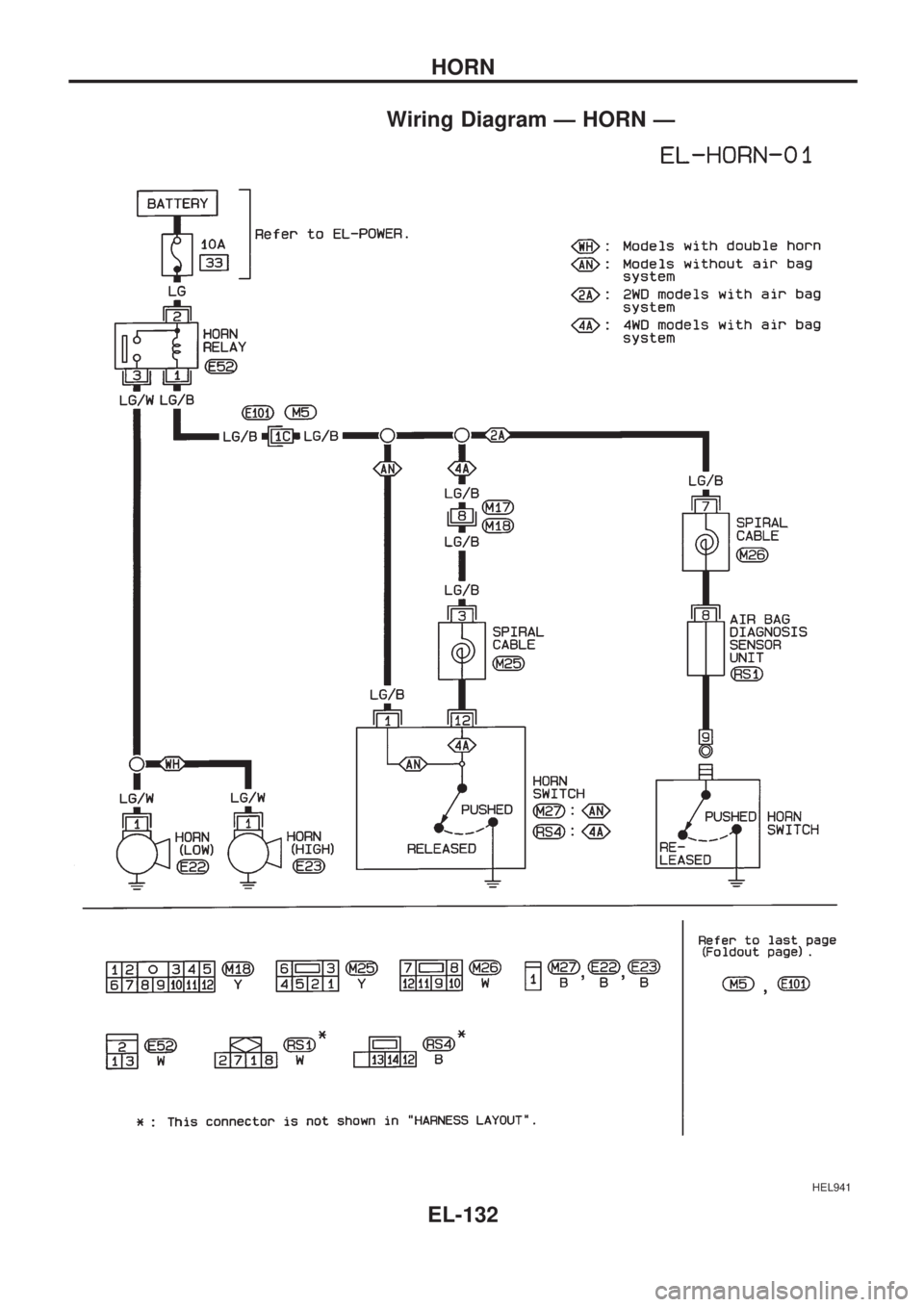

Wiring Diagram Ð HORN Ð

HEL941

HORN

EL-132

Trending: clock, charging, parking brake, boot, power steering, injector pump, battery