NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: charging, tire size, power steering, oil change, jump start terminals, headlamp, air bleeding

Page 1431 of 1659

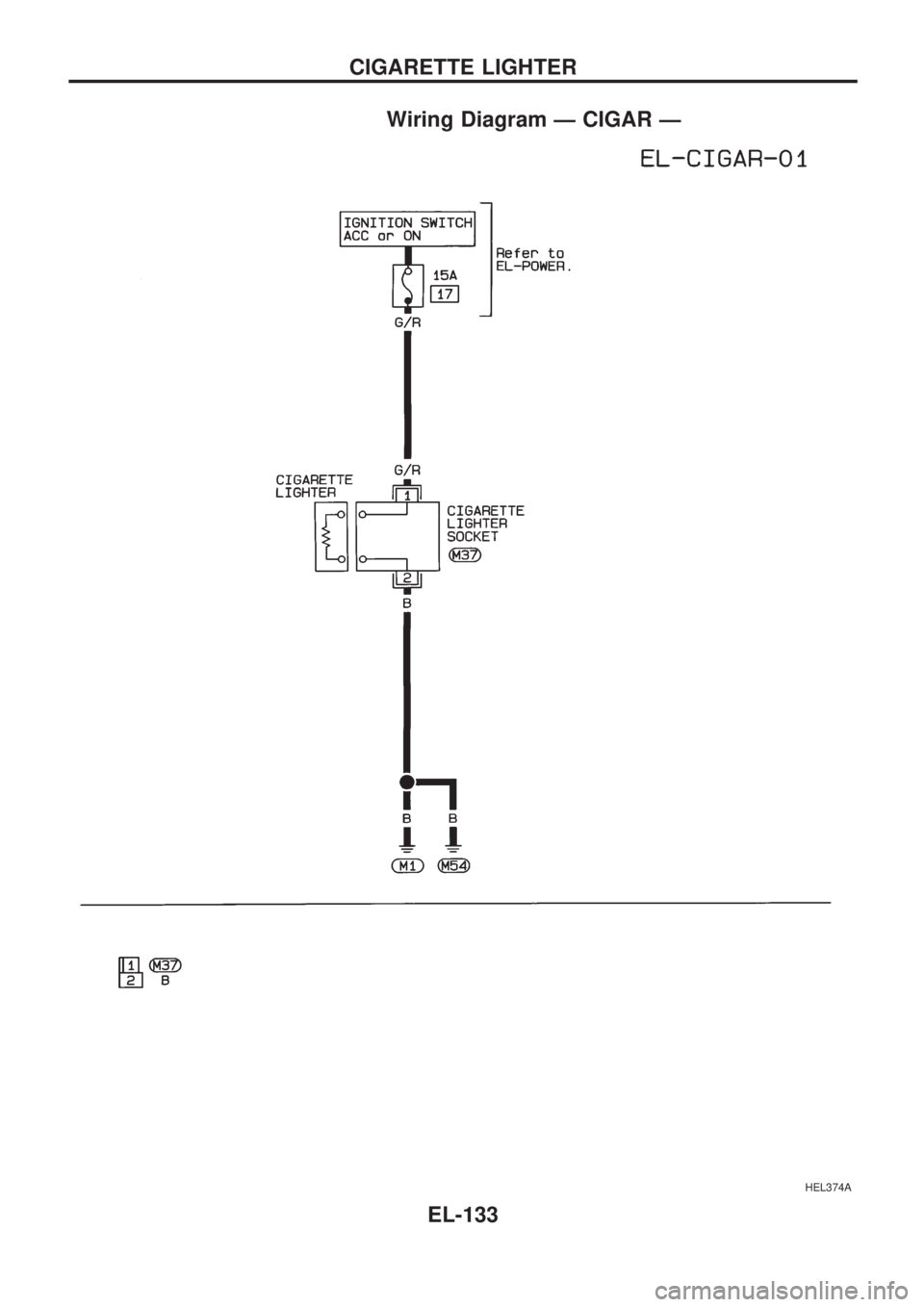

Wiring Diagram Ð CIGAR Ð

HEL374A

CIGARETTE LIGHTER

EL-133

Page 1432 of 1659

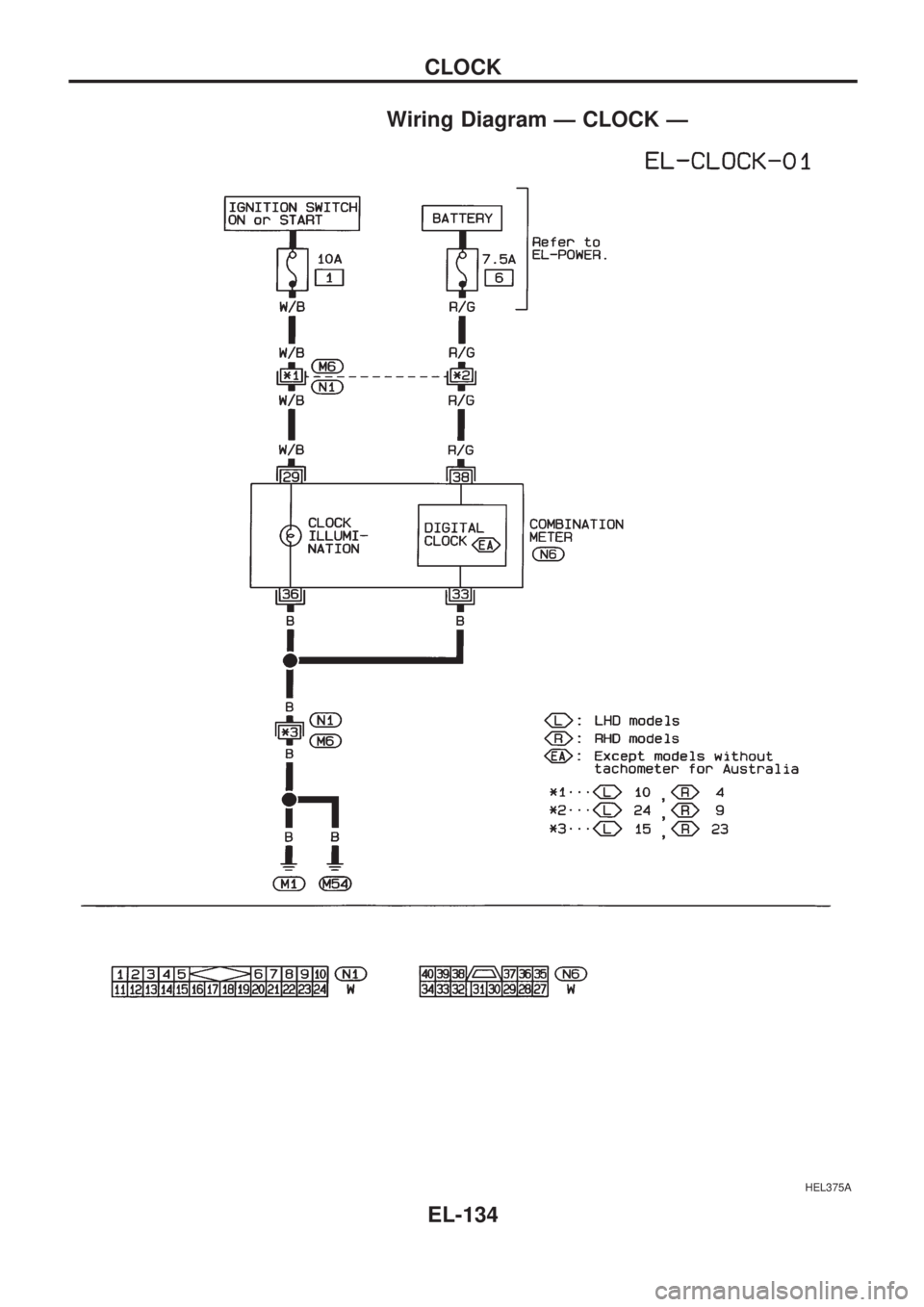

Wiring Diagram Ð CLOCK Ð

HEL375A

CLOCK

EL-134

Page 1433 of 1659

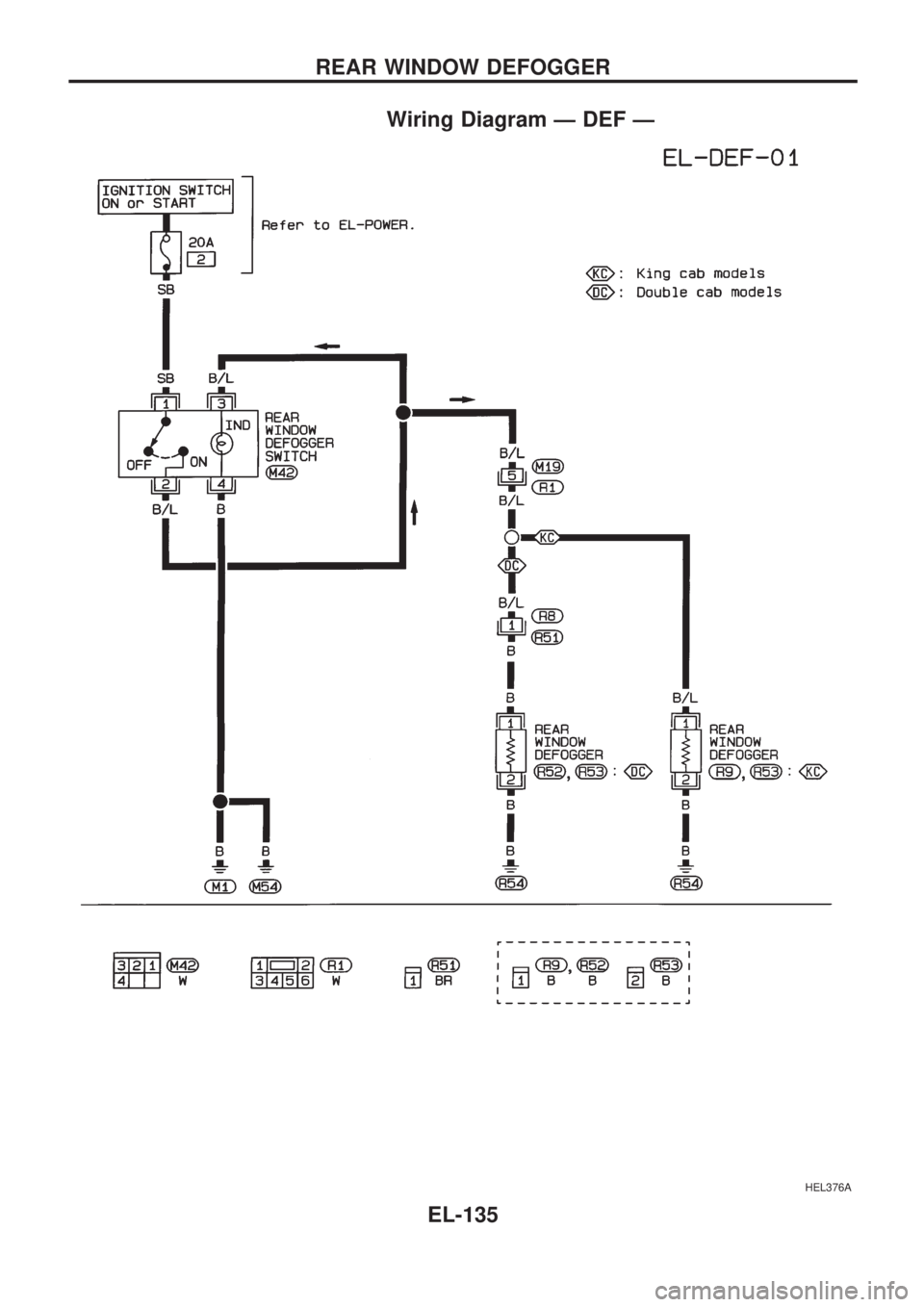

Wiring Diagram Ð DEF Ð

HEL376A

REAR WINDOW DEFOGGER

EL-135

Page 1434 of 1659

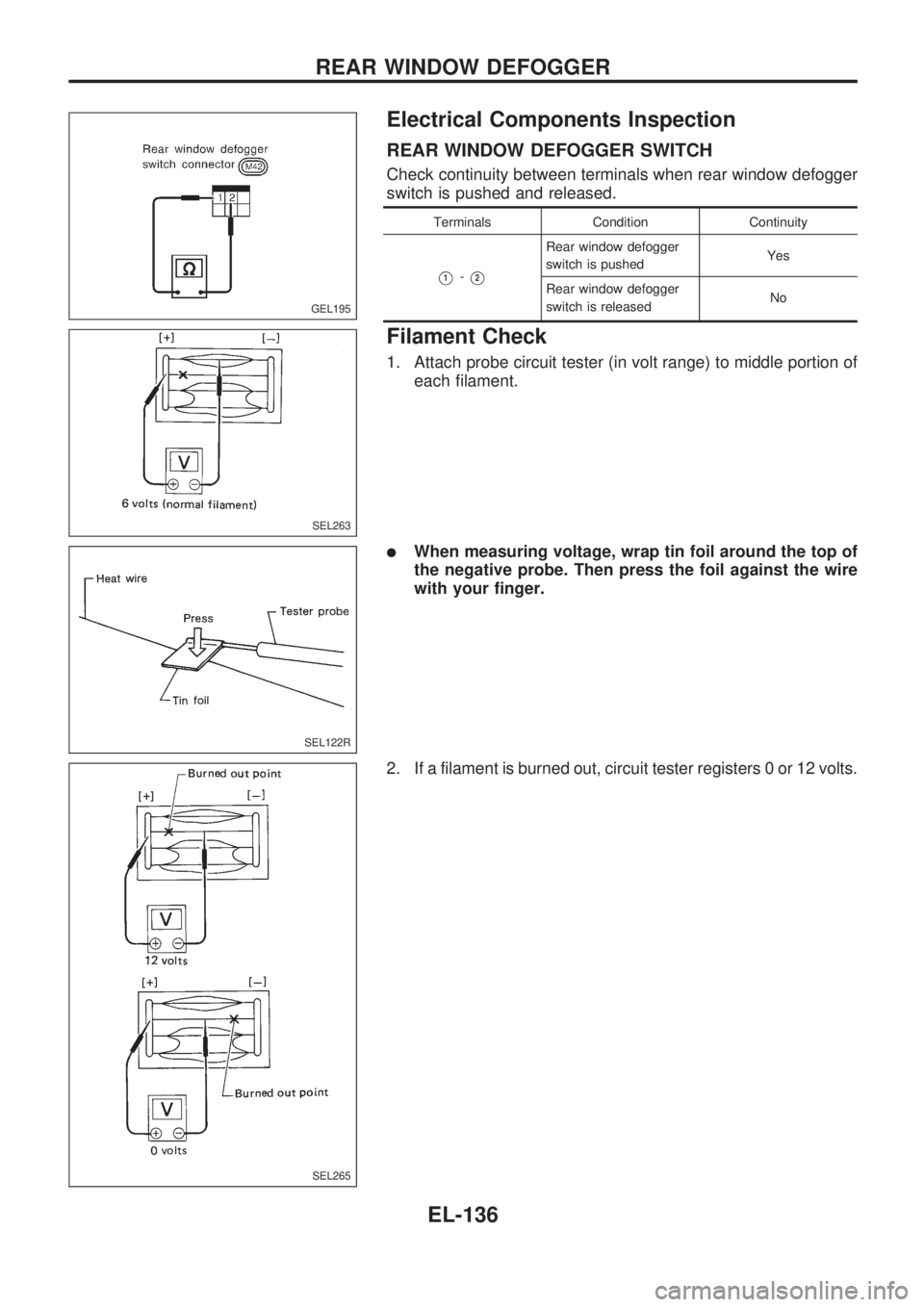

Electrical Components Inspection

REAR WINDOW DEFOGGER SWITCH

Check continuity between terminals when rear window defogger

switch is pushed and released.

Terminals Condition Continuity

V1-V2

Rear window defogger

switch is pushedYes

Rear window defogger

switch is releasedNo

Filament Check

1. Attach probe circuit tester (in volt range) to middle portion of

each filament.

lWhen measuring voltage, wrap tin foil around the top of

the negative probe. Then press the foil against the wire

with your finger.

2. If a filament is burned out, circuit tester registers 0 or 12 volts.

GEL195

SEL263

SEL122R

SEL265

REAR WINDOW DEFOGGER

EL-136

Page 1435 of 1659

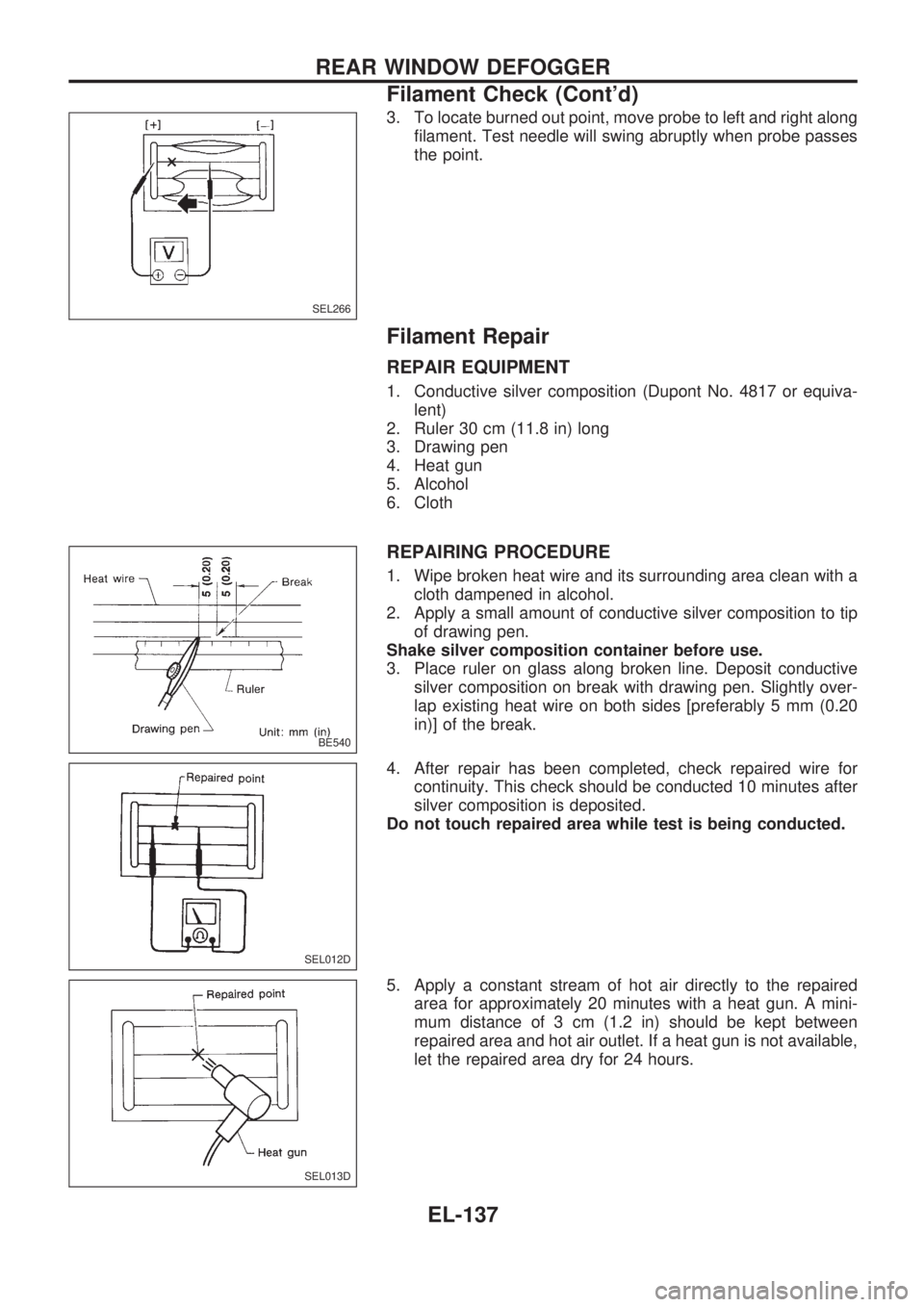

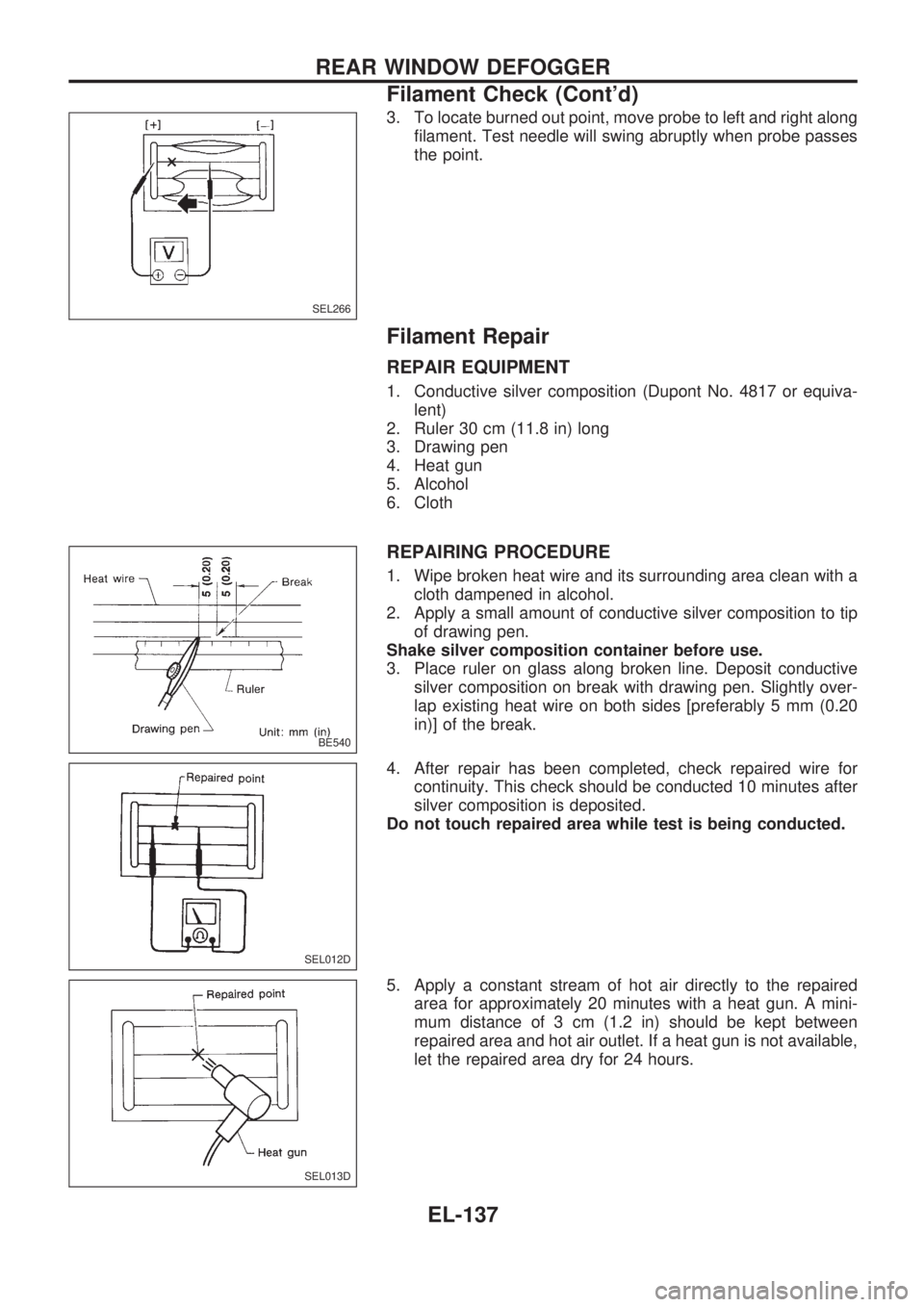

3. To locate burned out point, move probe to left and right along

filament. Test needle will swing abruptly when probe passes

the point.

Filament Repair

REPAIR EQUIPMENT

1. Conductive silver composition (Dupont No. 4817 or equiva-

lent)

2. Ruler 30 cm (11.8 in) long

3. Drawing pen

4. Heat gun

5. Alcohol

6. Cloth

REPAIRING PROCEDURE

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened in alcohol.

2. Apply a small amount of conductive silver composition to tip

of drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit conductive

silver composition on break with drawing pen. Slightly over-

lap existing heat wire on both sides [preferably 5 mm (0.20

in)] of the break.

4. After repair has been completed, check repaired wire for

continuity. This check should be conducted 10 minutes after

silver composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired

area for approximately 20 minutes with a heat gun. A mini-

mum distance of 3 cm (1.2 in) should be kept between

repaired area and hot air outlet. If a heat gun is not available,

let the repaired area dry for 24 hours.

SEL266

BE540

SEL012D

SEL013D

REAR WINDOW DEFOGGER

Filament Check (Cont'd)

EL-137

Page 1436 of 1659

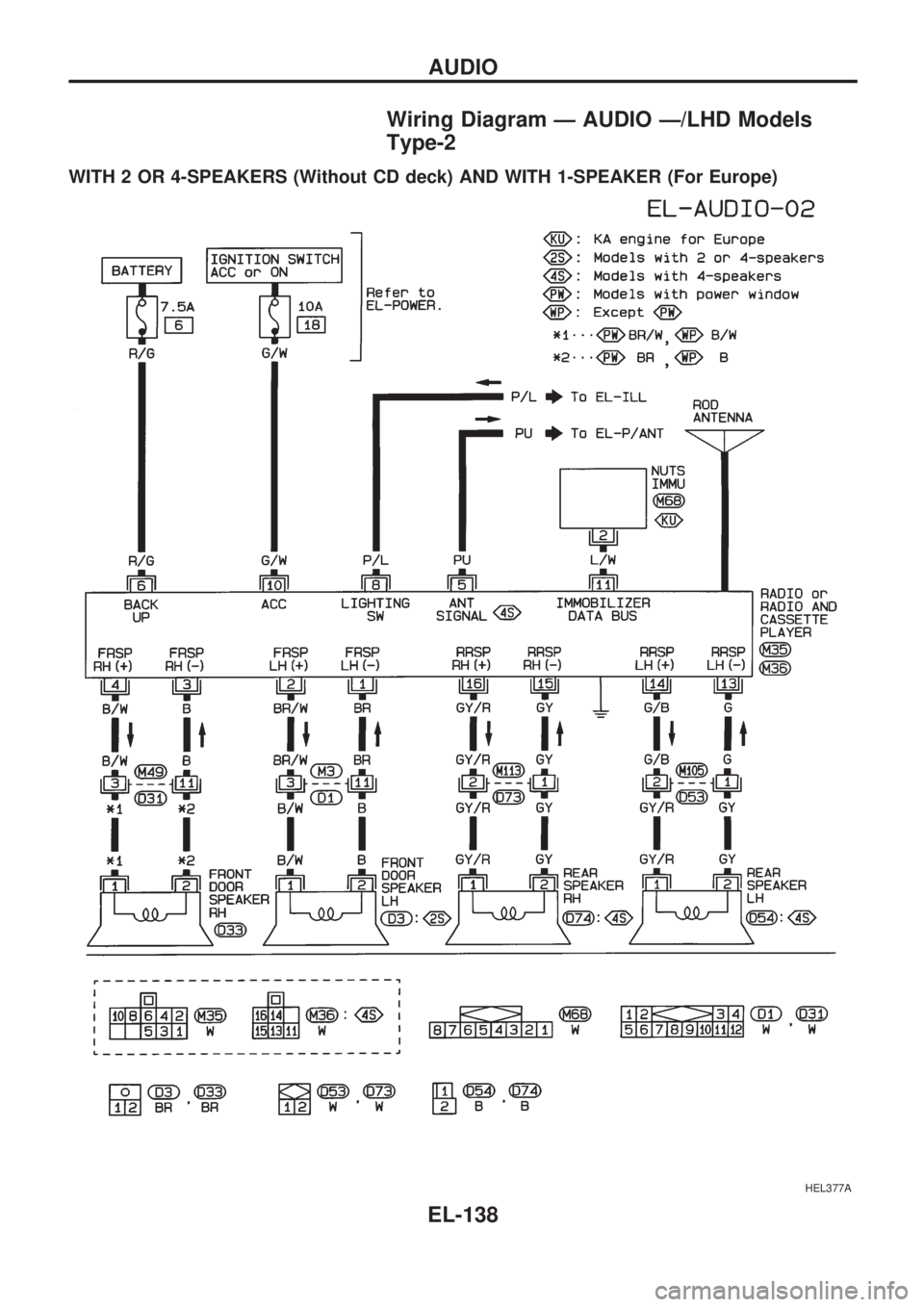

Wiring Diagram Ð AUDIO Ð/LHD Models

Type-2

WITH 2 OR 4-SPEAKERS (Without CD deck) AND WITH 1-SPEAKER (For Europe)

HEL377A

AUDIO

EL-138

Page 1437 of 1659

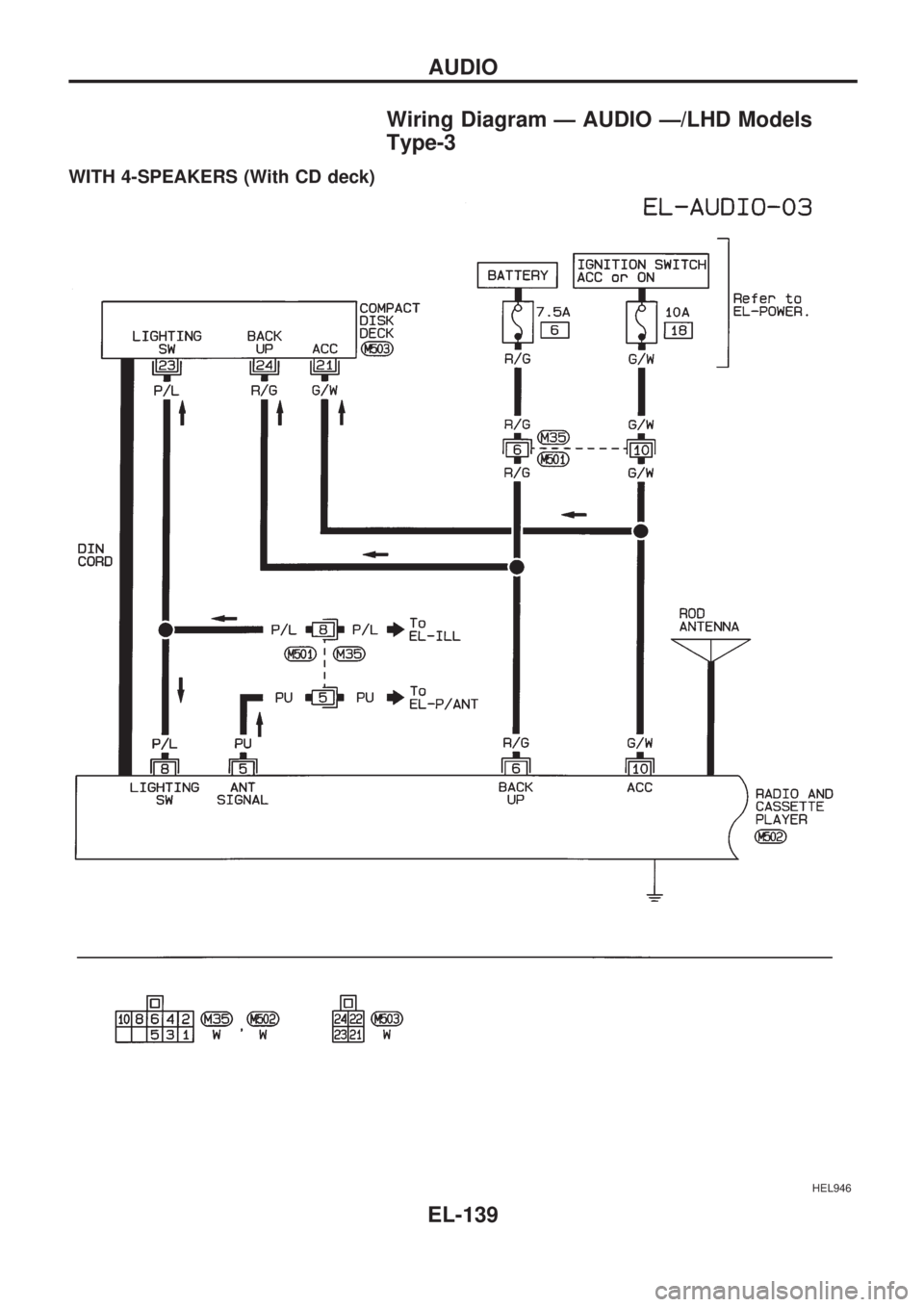

Wiring Diagram Ð AUDIO Ð/LHD Models

Type-3

WITH 4-SPEAKERS (With CD deck)

HEL946

AUDIO

EL-139

Page 1438 of 1659

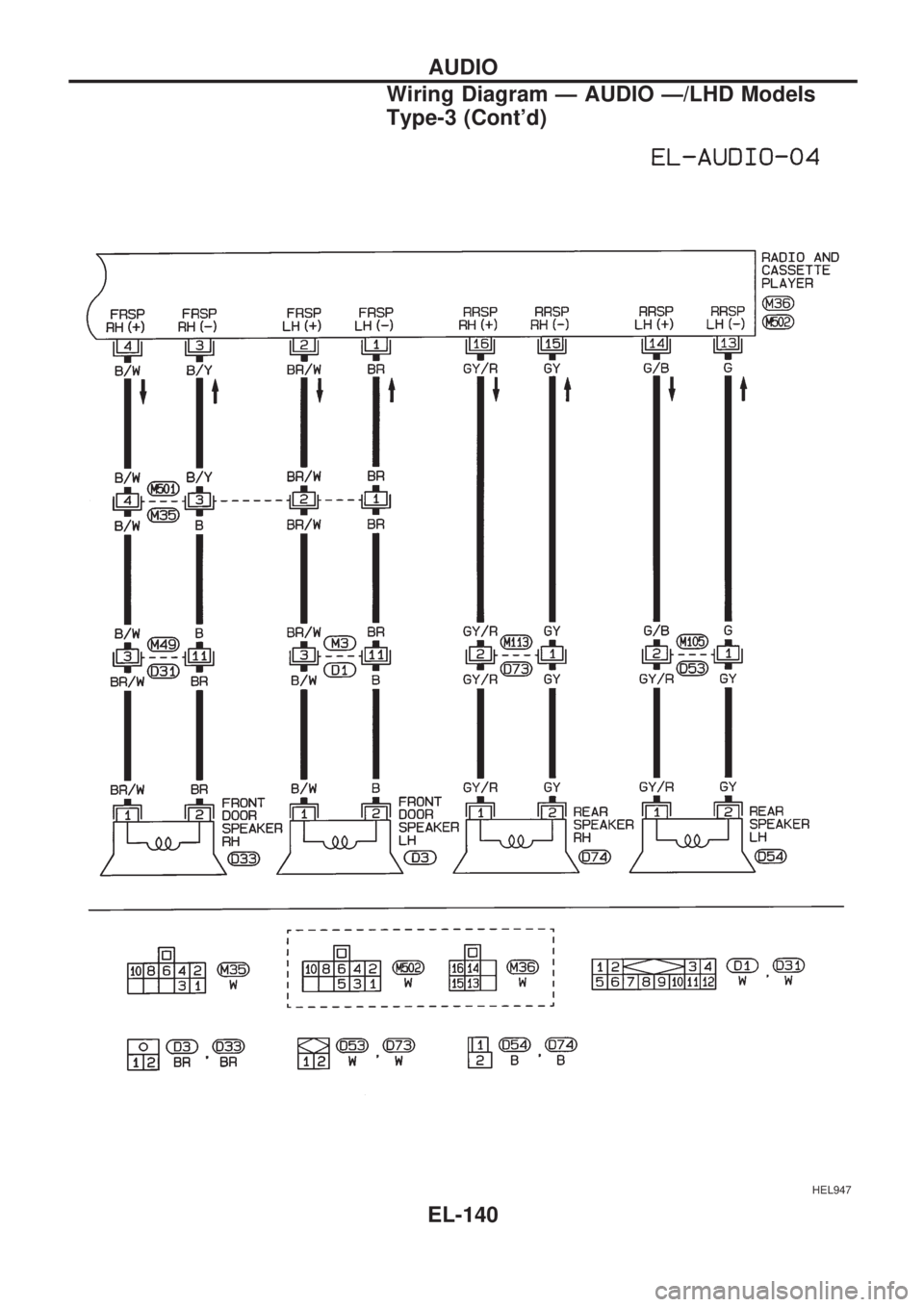

HEL947

AUDIO

Wiring Diagram Ð AUDIO Ð/LHD Models

Type-3 (Cont'd)

EL-140

Page 1439 of 1659

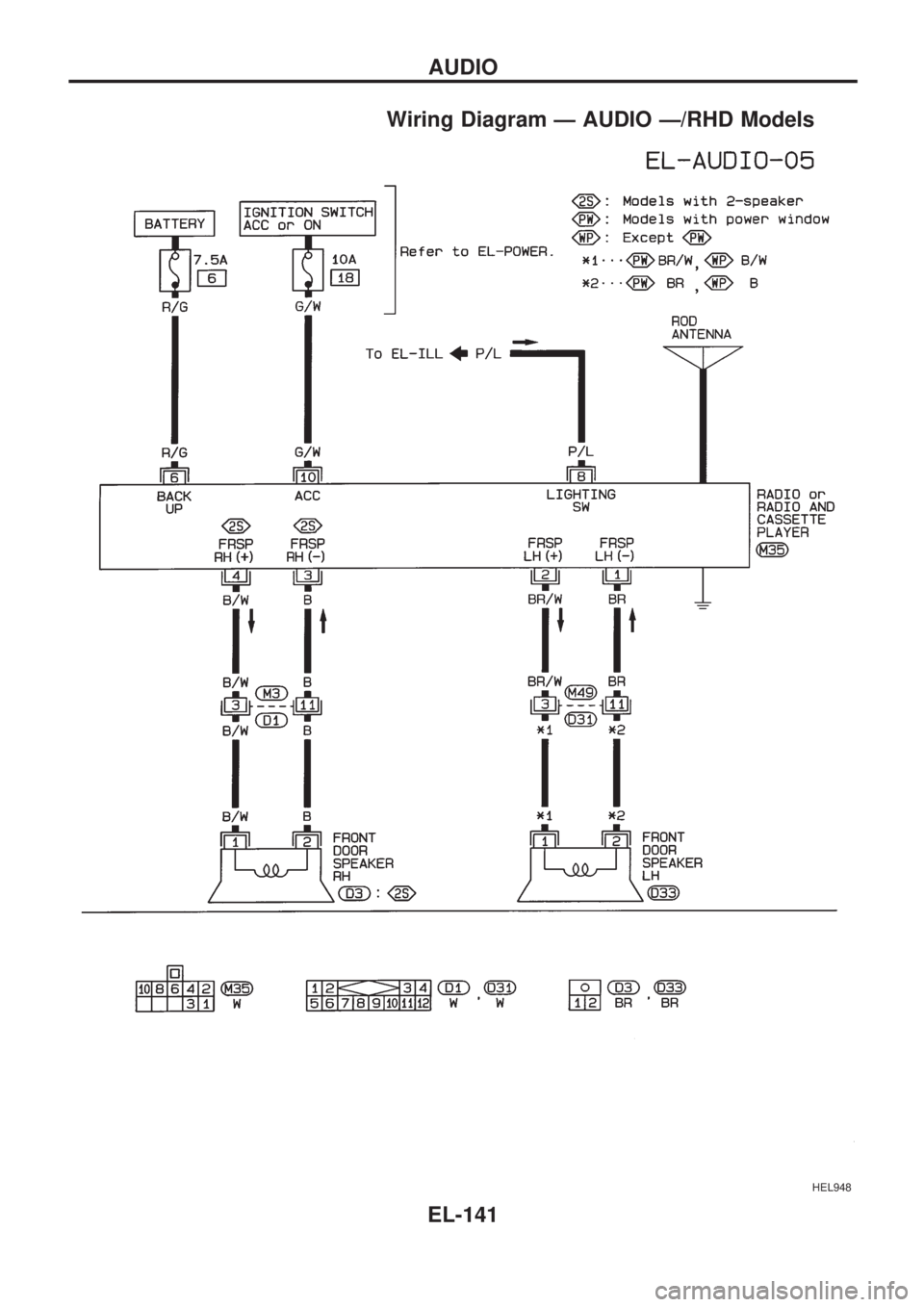

Wiring Diagram Ð AUDIO Ð/RHD Models

HEL948

AUDIO

EL-141

Page 1440 of 1659

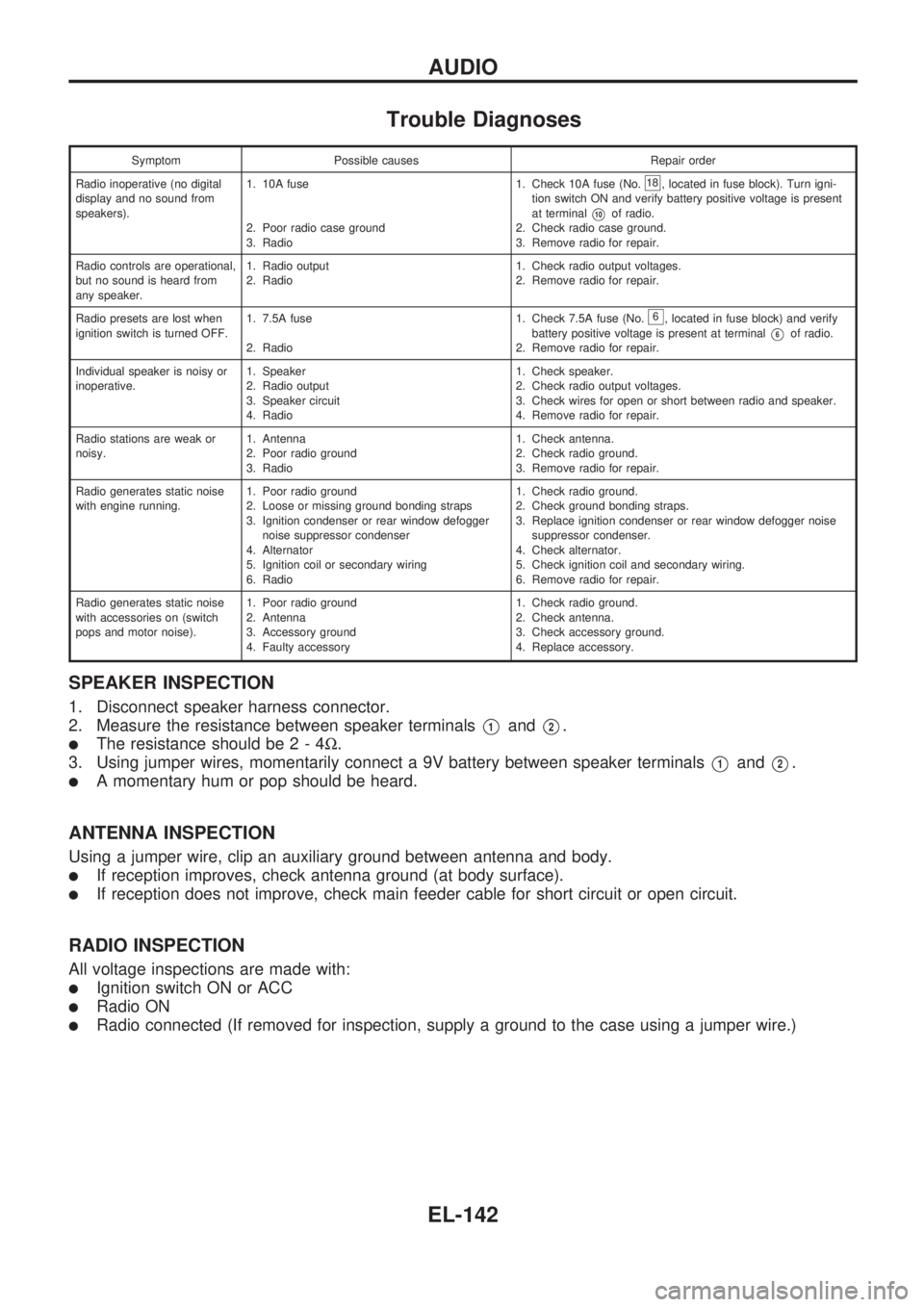

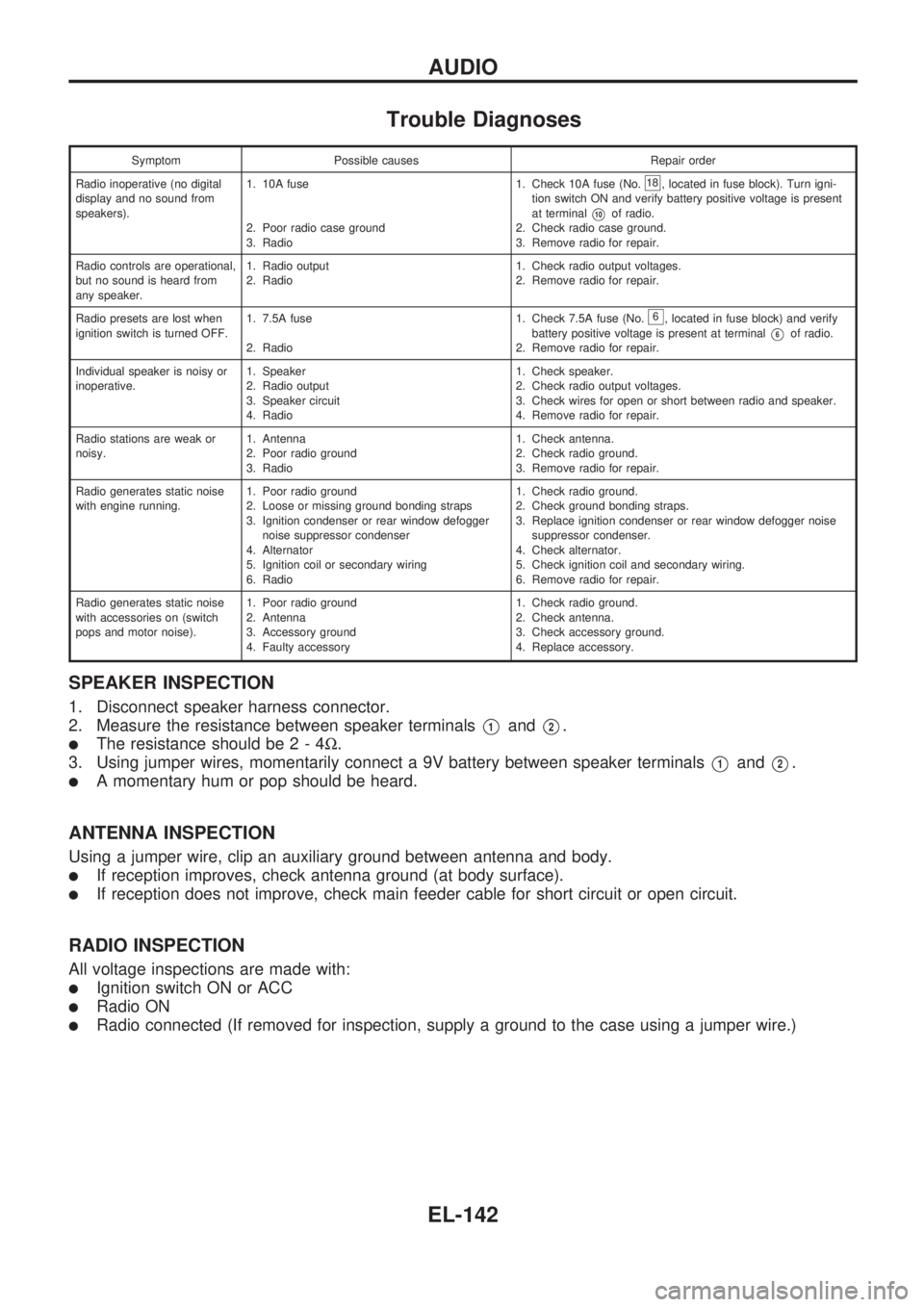

Trouble Diagnoses

Symptom Possible causes Repair order

Radio inoperative (no digital

display and no sound from

speakers).1. 10A fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse (No.

18, located in fuse block). Turn igni-

tion switch ON and verify battery positive voltage is present

at terminal

V10of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are operational,

but no sound is heard from

any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 7.5A fuse

2. Radio1. Check 7.5A fuse (No.

6, located in fuse block) and verify

battery positive voltage is present at terminal

V6of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

Radio generates static noise

with engine running.1. Poor radio ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger noise

suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates static noise

with accessories on (switch

pops and motor noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

SPEAKER INSPECTION

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminals

V1andV2.

lThe resistance should be2-4W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminals

V1andV2.

lA momentary hum or pop should be heard.

ANTENNA INSPECTION

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

RADIO INSPECTION

All voltage inspections are made with:

lIgnition switch ON or ACC

lRadio ON

lRadio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-142

Trending: fuse chart, brake pads replacement, el 133, brake, engine coolant, oil viscosity, fuel filter