NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 831 of 1659

Voltage check method

1. Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid dis-

connected) powered through the fuse.

2. Turn the ignition key to the ON or START position. Verify battery voltage at the B

+side of the fuse ter-

minal (one lead on the B

+terminal side of the fuse block and one lead on a known good ground).

3. With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

4. With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check

for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

5. With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid

(point C).

no voltage; retrace steps and check power to fuse block.

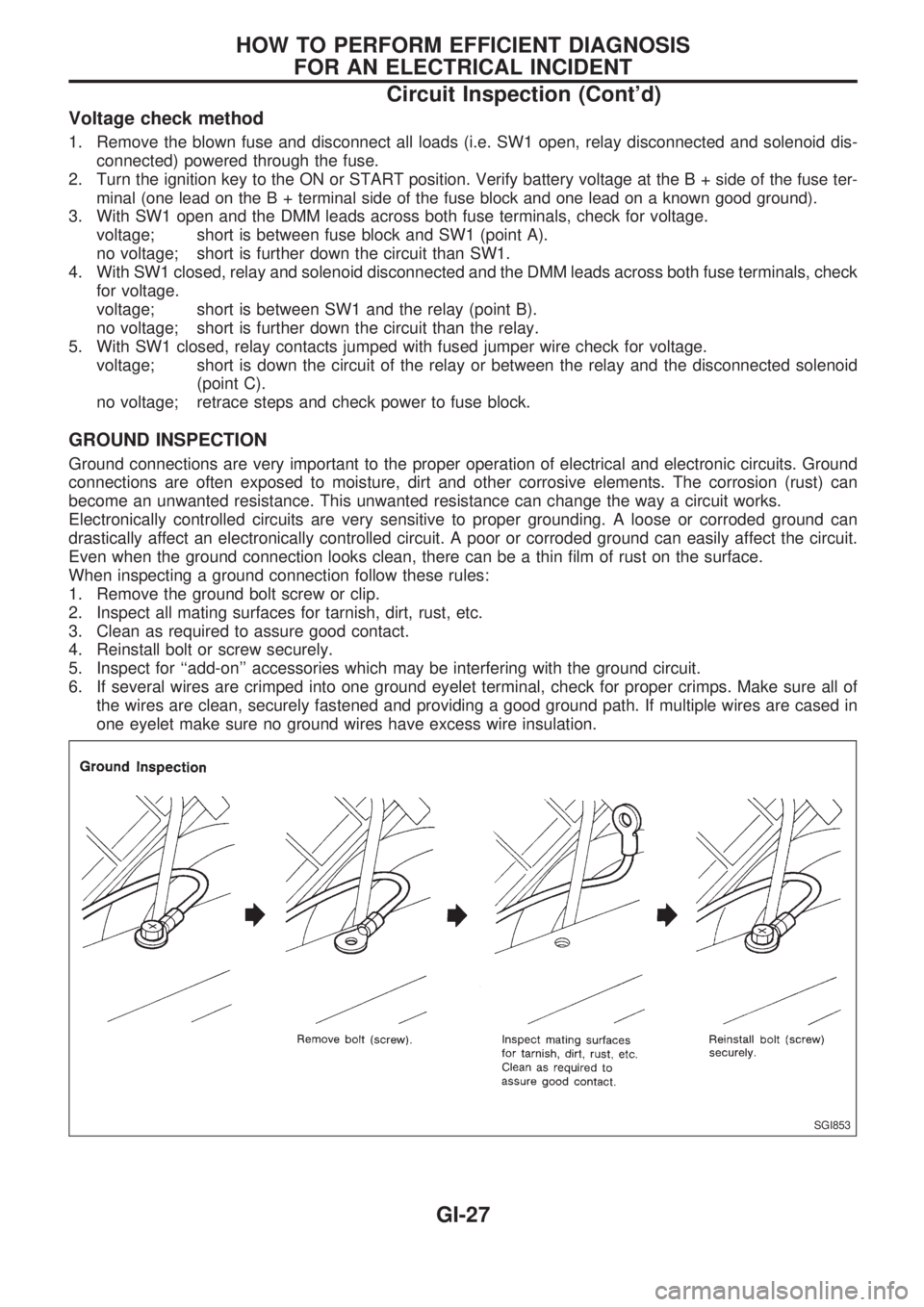

GROUND INSPECTION

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

1. Remove the ground bolt screw or clip.

2. Inspect all mating surfaces for tarnish, dirt, rust, etc.

3. Clean as required to assure good contact.

4. Reinstall bolt or screw securely.

5. Inspect for ``add-on'' accessories which may be interfering with the ground circuit.

6. If several wires are crimped into one ground eyelet terminal, check for proper crimps. Make sure all of

the wires are clean, securely fastened and providing a good ground path. If multiple wires are cased in

one eyelet make sure no ground wires have excess wire insulation.

SGI853

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-27

Page 832 of 1659

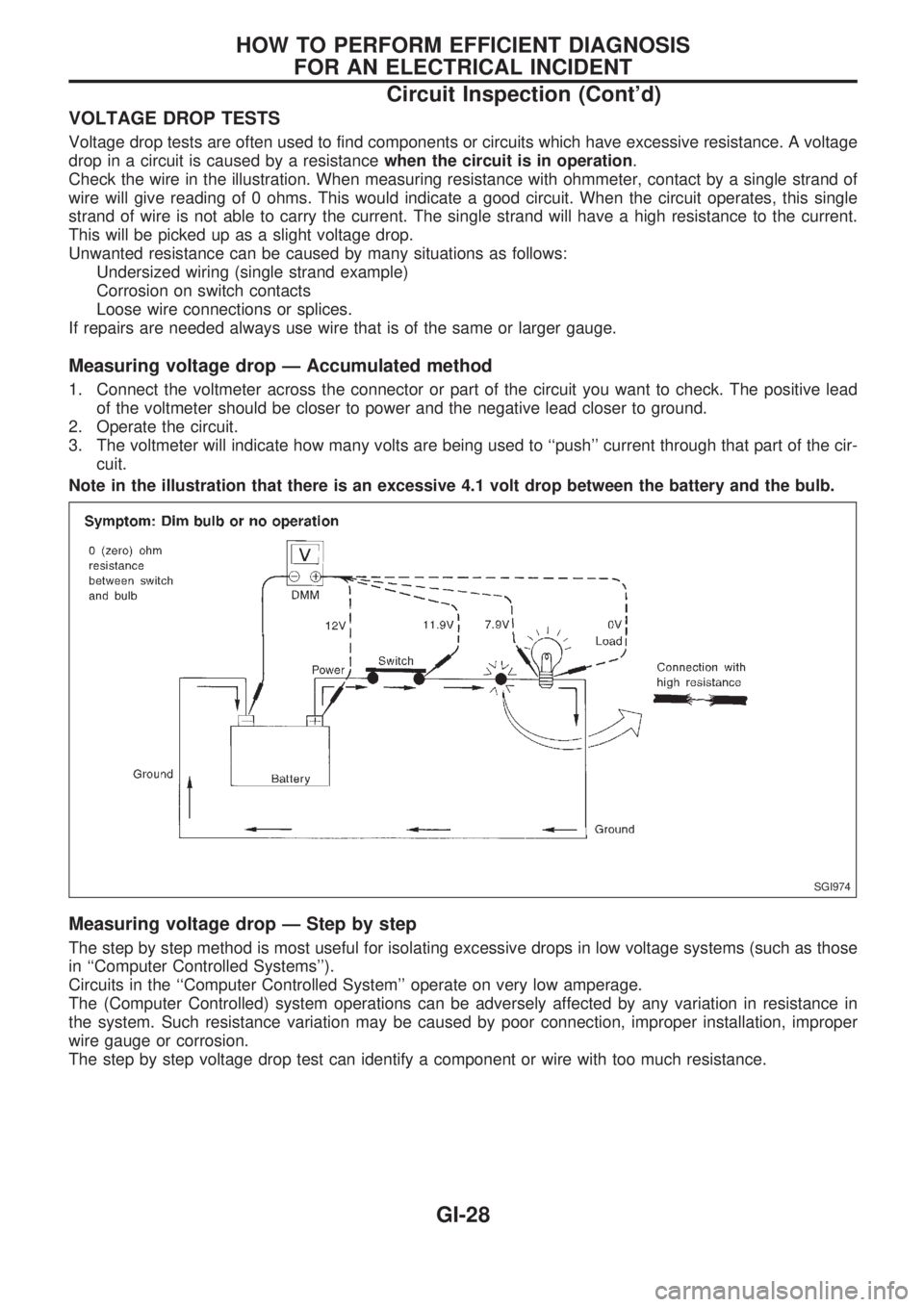

VOLTAGE DROP TESTS

Voltage drop tests are often used to find components or circuits which have excessive resistance. A voltage

drop in a circuit is caused by a resistancewhen the circuit is in operation.

Check the wire in the illustration. When measuring resistance with ohmmeter, contact by a single strand of

wire will give reading of 0 ohms. This would indicate a good circuit. When the circuit operates, this single

strand of wire is not able to carry the current. The single strand will have a high resistance to the current.

This will be picked up as a slight voltage drop.

Unwanted resistance can be caused by many situations as follows:

Undersized wiring (single strand example)

Corrosion on switch contacts

Loose wire connections or splices.

If repairs are needed always use wire that is of the same or larger gauge.

Measuring voltage drop Ð Accumulated method

1. Connect the voltmeter across the connector or part of the circuit you want to check. The positive lead

of the voltmeter should be closer to power and the negative lead closer to ground.

2. Operate the circuit.

3. The voltmeter will indicate how many volts are being used to ``push'' current through that part of the cir-

cuit.

Note in the illustration that there is an excessive 4.1 volt drop between the battery and the bulb.

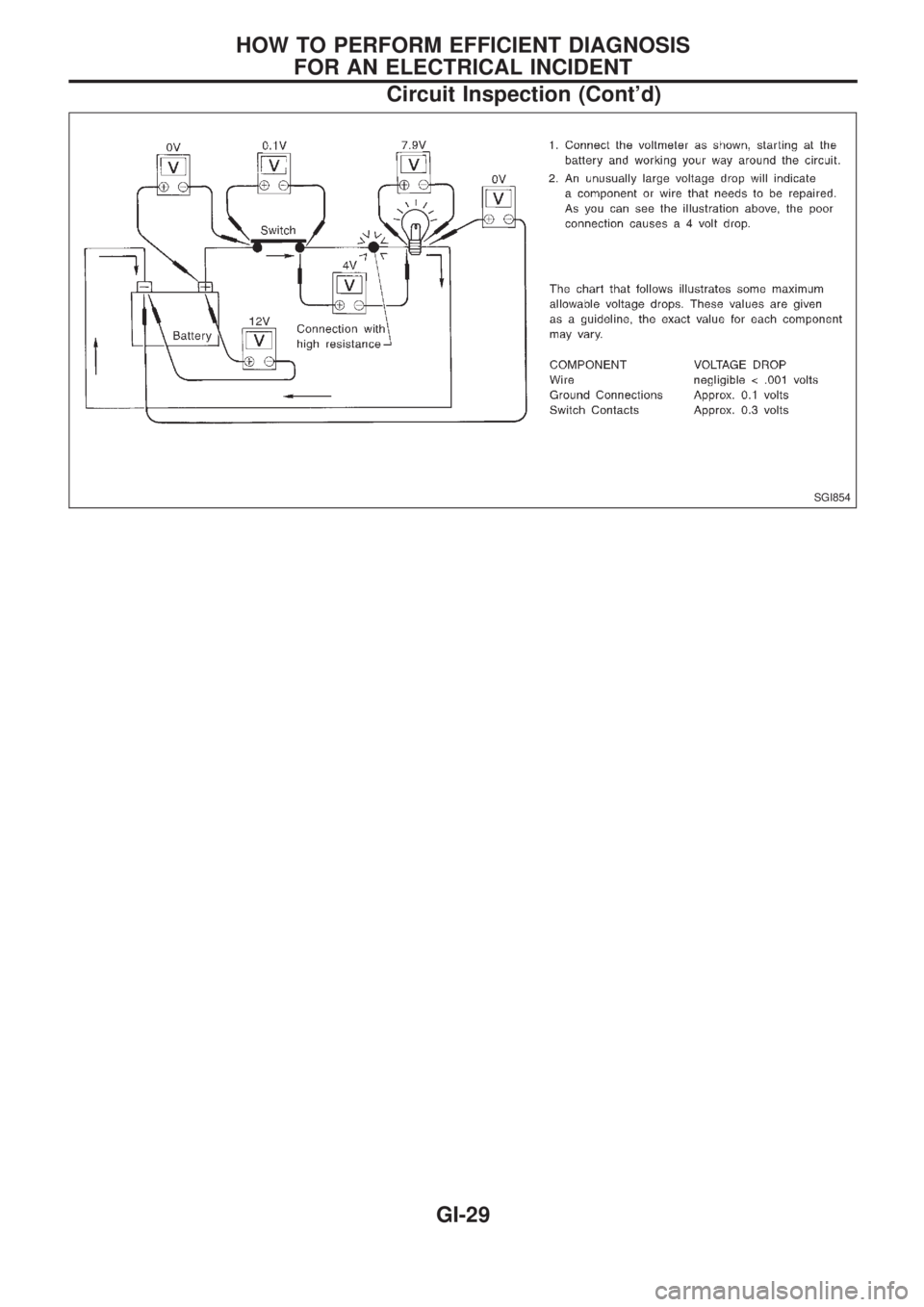

Measuring voltage drop Ð Step by step

The step by step method is most useful for isolating excessive drops in low voltage systems (such as those

in ``Computer Controlled Systems'').

Circuits in the ``Computer Controlled System'' operate on very low amperage.

The (Computer Controlled) system operations can be adversely affected by any variation in resistance in

the system. Such resistance variation may be caused by poor connection, improper installation, improper

wire gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

SGI974

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-28

Page 833 of 1659

SGI854

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-29

Page 834 of 1659

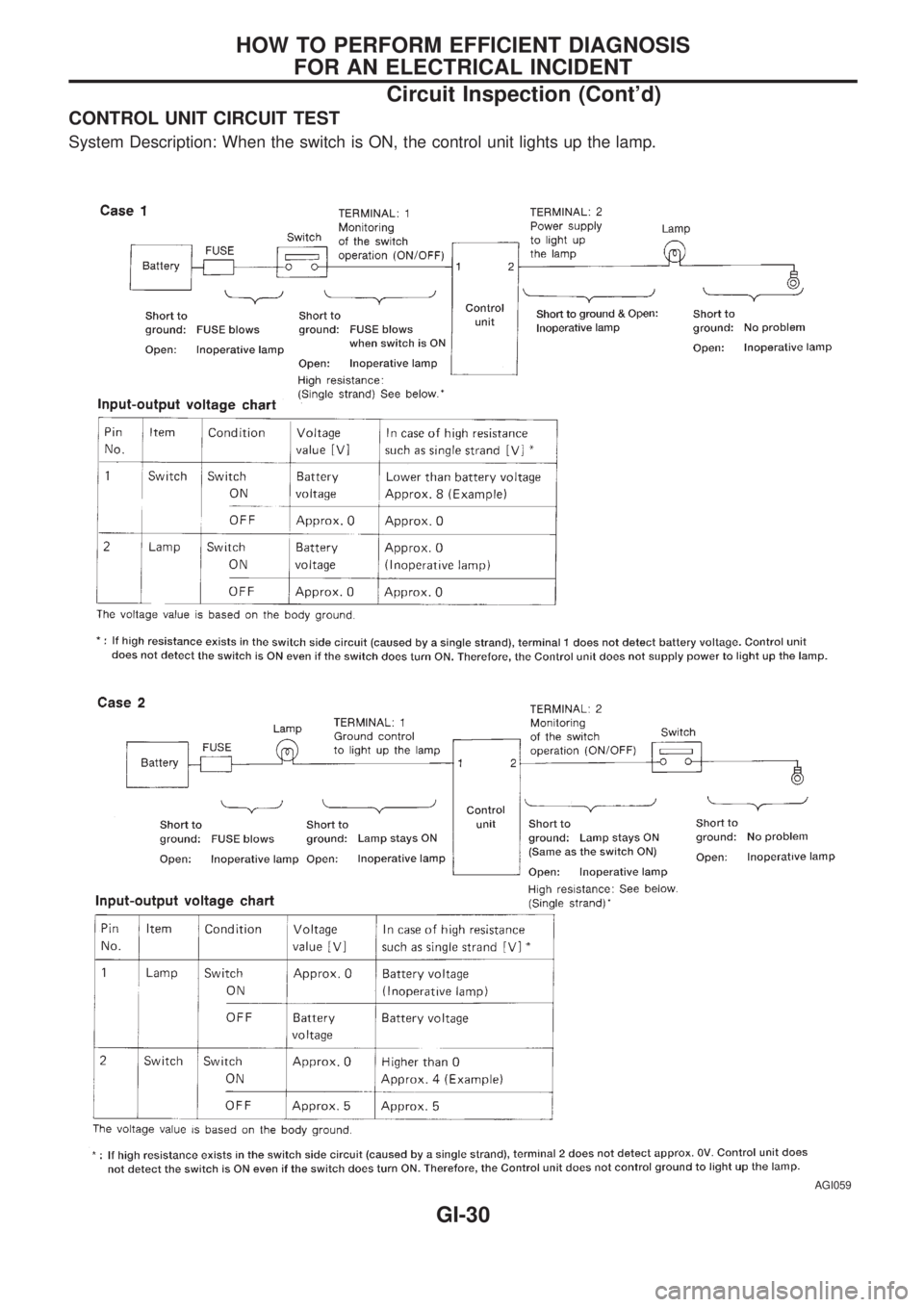

CONTROL UNIT CIRCUIT TEST

System Description: When the switch is ON, the control unit lights up the lamp.

AGI059

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-30

Page 835 of 1659

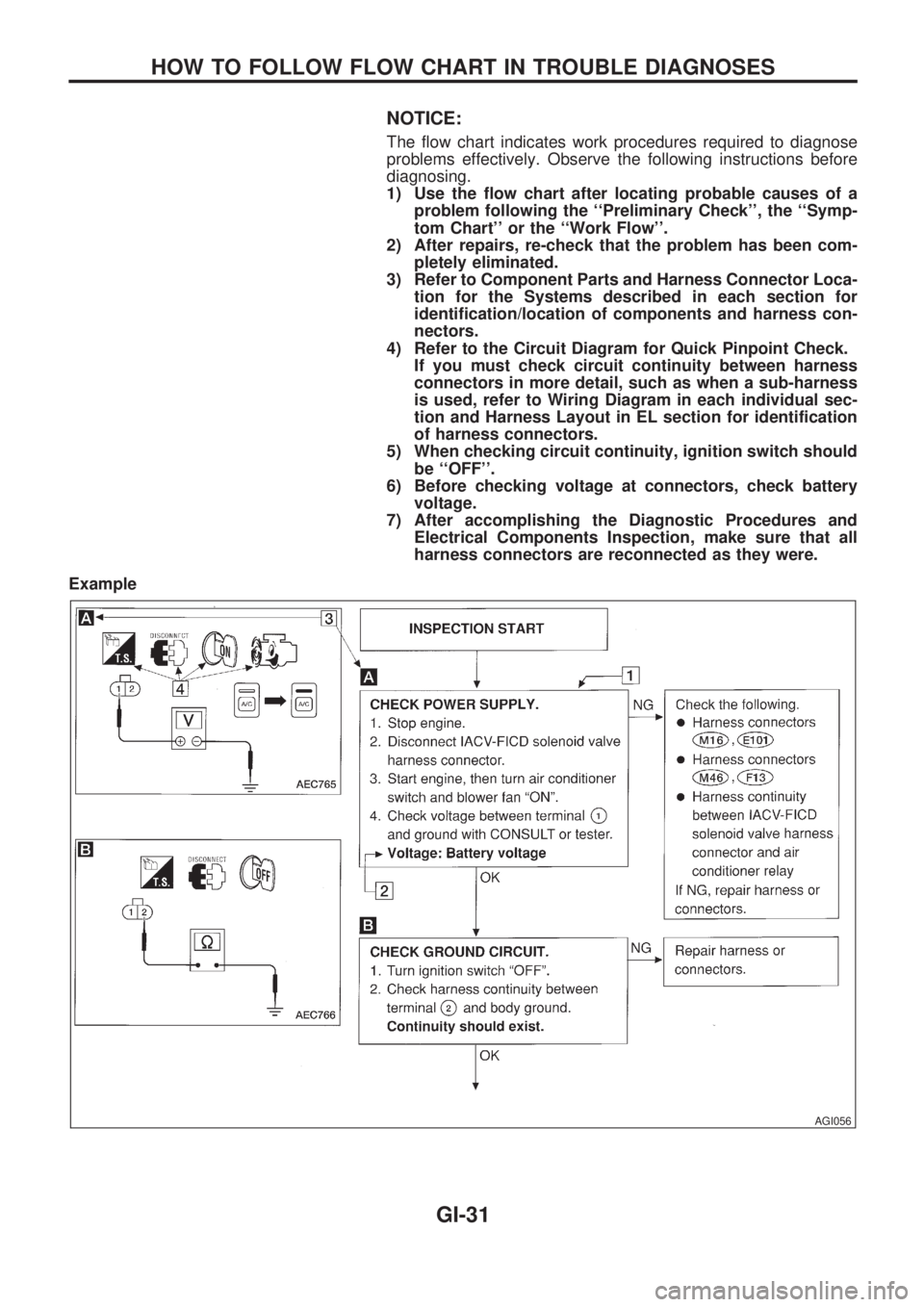

NOTICE:

The flow chart indicates work procedures required to diagnose

problems effectively. Observe the following instructions before

diagnosing.

1) Use the flow chart after locating probable causes of a

problem following the ``Preliminary Check'', the ``Symp-

tom Chart'' or the ``Work Flow''.

2) After repairs, re-check that the problem has been com-

pletely eliminated.

3) Refer to Component Parts and Harness Connector Loca-

tion for the Systems described in each section for

identification/location of components and harness con-

nectors.

4) Refer to the Circuit Diagram for Quick Pinpoint Check.

If you must check circuit continuity between harness

connectors in more detail, such as when a sub-harness

is used, refer to Wiring Diagram in each individual sec-

tion and Harness Layout in EL section for identification

of harness connectors.

5) When checking circuit continuity, ignition switch should

be ``OFF''.

6) Before checking voltage at connectors, check battery

voltage.

7) After accomplishing the Diagnostic Procedures and

Electrical Components Inspection, make sure that all

harness connectors are reconnected as they were.

Example

AGI056

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-31

Page 836 of 1659

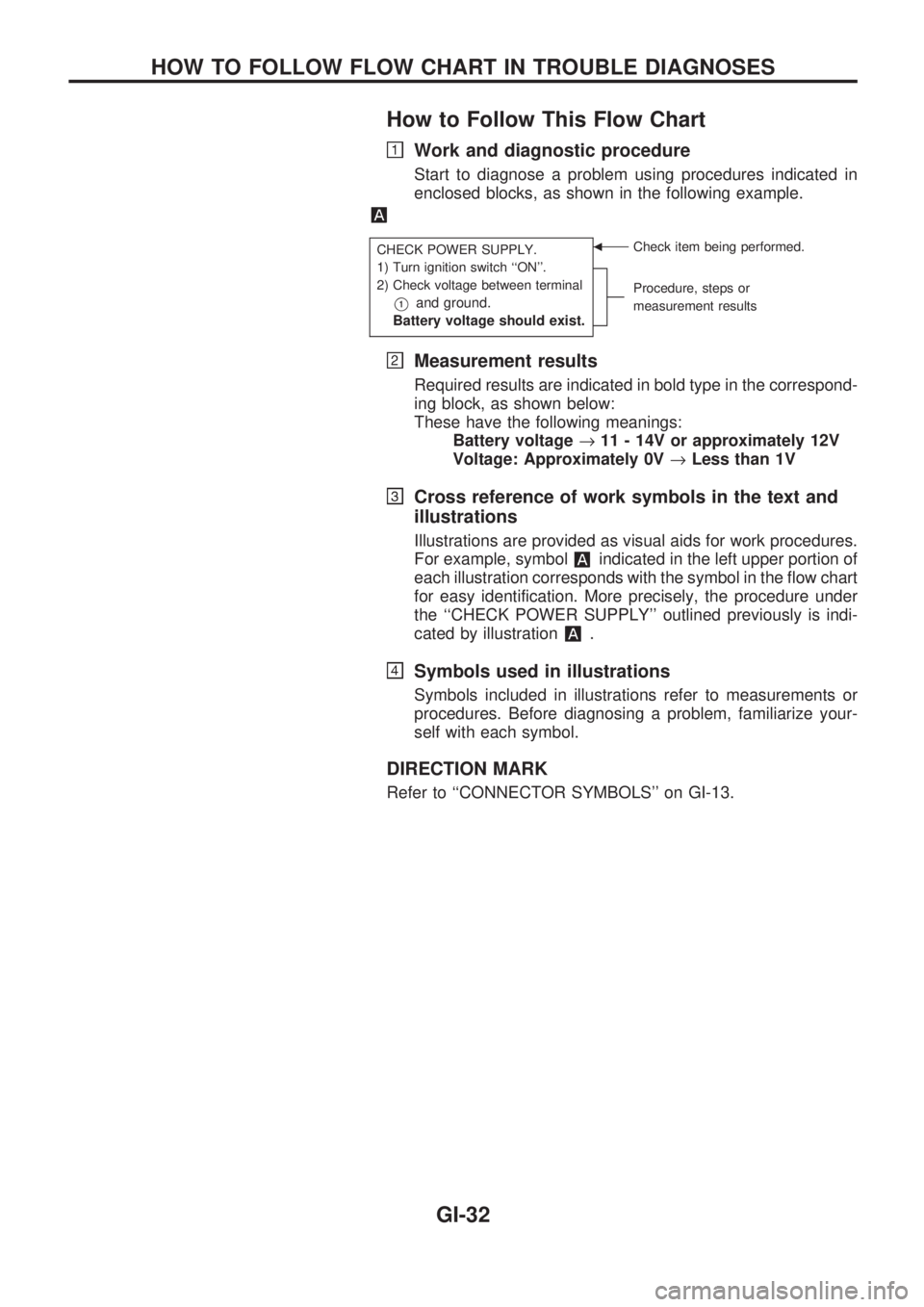

How to Follow This Flow Chart

Work and diagnostic procedure

Start to diagnose a problem using procedures indicated in

enclosed blocks, as shown in the following example.

CHECK POWER SUPPLY.

1) Turn ignition switch ``ON''.

2) Check voltage between terminal

V1and ground.

Battery voltage should exist.

bCheck item being performed.

Procedure, steps or

measurement results

Measurement results

Required results are indicated in bold type in the correspond-

ing block, as shown below:

These have the following meanings:

Battery voltage®11 - 14V or approximately 12V

Voltage: Approximately 0V®Less than 1V

Cross reference of work symbols in the text and

illustrations

Illustrations are provided as visual aids for work procedures.

For example, symbol

indicated in the left upper portion of

each illustration corresponds with the symbol in the flow chart

for easy identification. More precisely, the procedure under

the ``CHECK POWER SUPPLY'' outlined previously is indi-

cated by illustration

.

Symbols used in illustrations

Symbols included in illustrations refer to measurements or

procedures. Before diagnosing a problem, familiarize your-

self with each symbol.

DIRECTION MARK

Refer to ``CONNECTOR SYMBOLS'' on GI-13.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-32

Page 837 of 1659

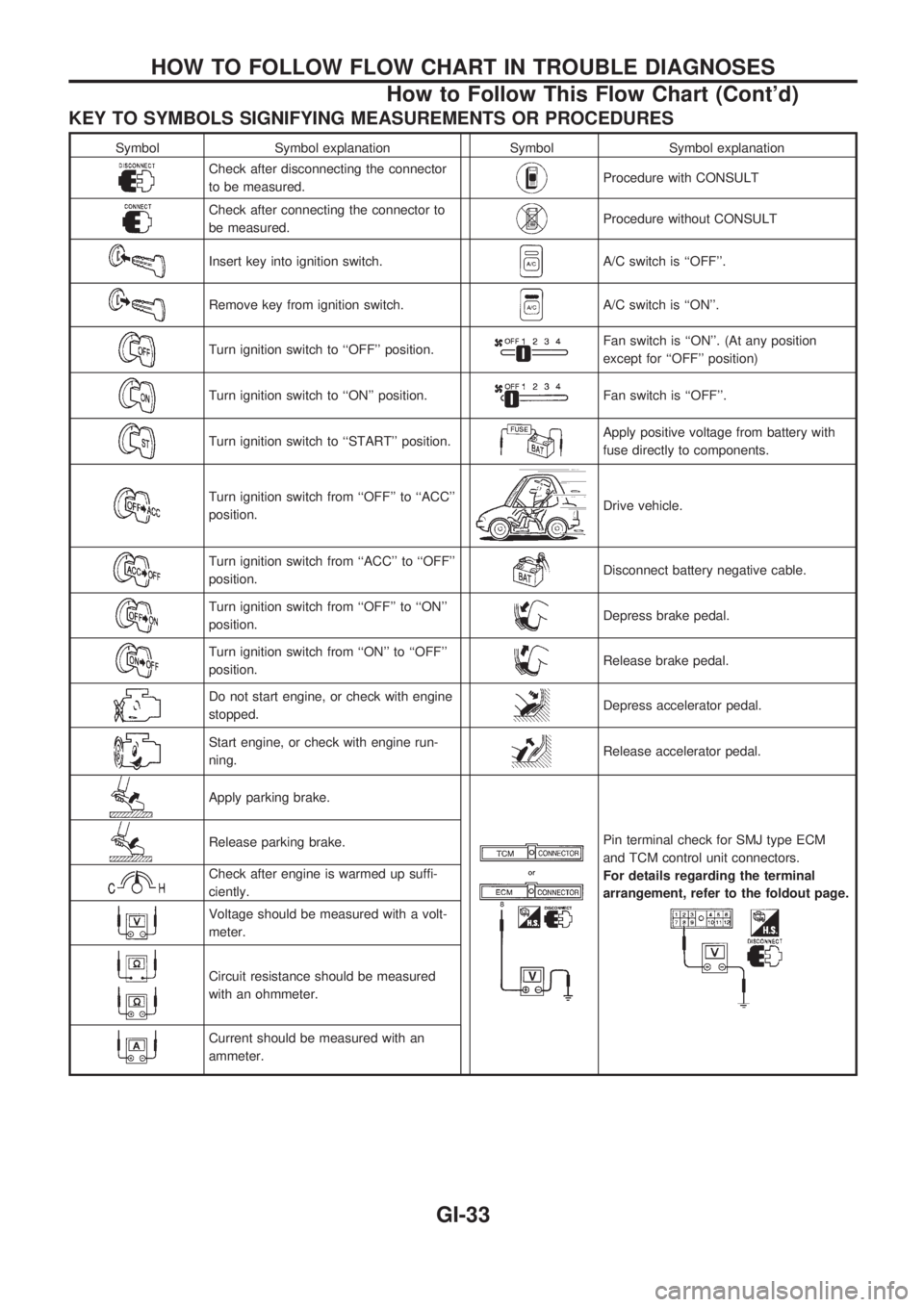

KEY TO SYMBOLS SIGNIFYING MEASUREMENTS OR PROCEDURES

Symbol Symbol explanation Symbol Symbol explanation

Check after disconnecting the connector

to be measured.Procedure with CONSULT

Check after connecting the connector to

be measured.Procedure without CONSULT

Insert key into ignition switch.A/C switch is ``OFF''.

Remove key from ignition switch.A/C switch is ``ON''.

Turn ignition switch to ``OFF'' position.Fan switch is ``ON''. (At any position

except for ``OFF'' position)

Turn ignition switch to ``ON'' position.Fan switch is ``OFF''.

Turn ignition switch to ``START'' position.Apply positive voltage from battery with

fuse directly to components.

Turn ignition switch from ``OFF'' to ``ACC''

position.Drive vehicle.

Turn ignition switch from ``ACC'' to ``OFF''

position.Disconnect battery negative cable.

Turn ignition switch from ``OFF'' to ``ON''

position.Depress brake pedal.

Turn ignition switch from ``ON'' to ``OFF''

position.Release brake pedal.

Do not start engine, or check with engine

stopped.Depress accelerator pedal.

Start engine, or check with engine run-

ning.Release accelerator pedal.

Apply parking brake.

Pin terminal check for SMJ type ECM

and TCM control unit connectors.

For details regarding the terminal

arrangement, refer to the foldout page.Release parking brake.

Check after engine is warmed up suffi-

ciently.

Voltage should be measured with a volt-

meter.

Circuit resistance should be measured

with an ohmmeter.

Current should be measured with an

ammeter.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

How to Follow This Flow Chart (Cont'd)

GI-33

Page 838 of 1659

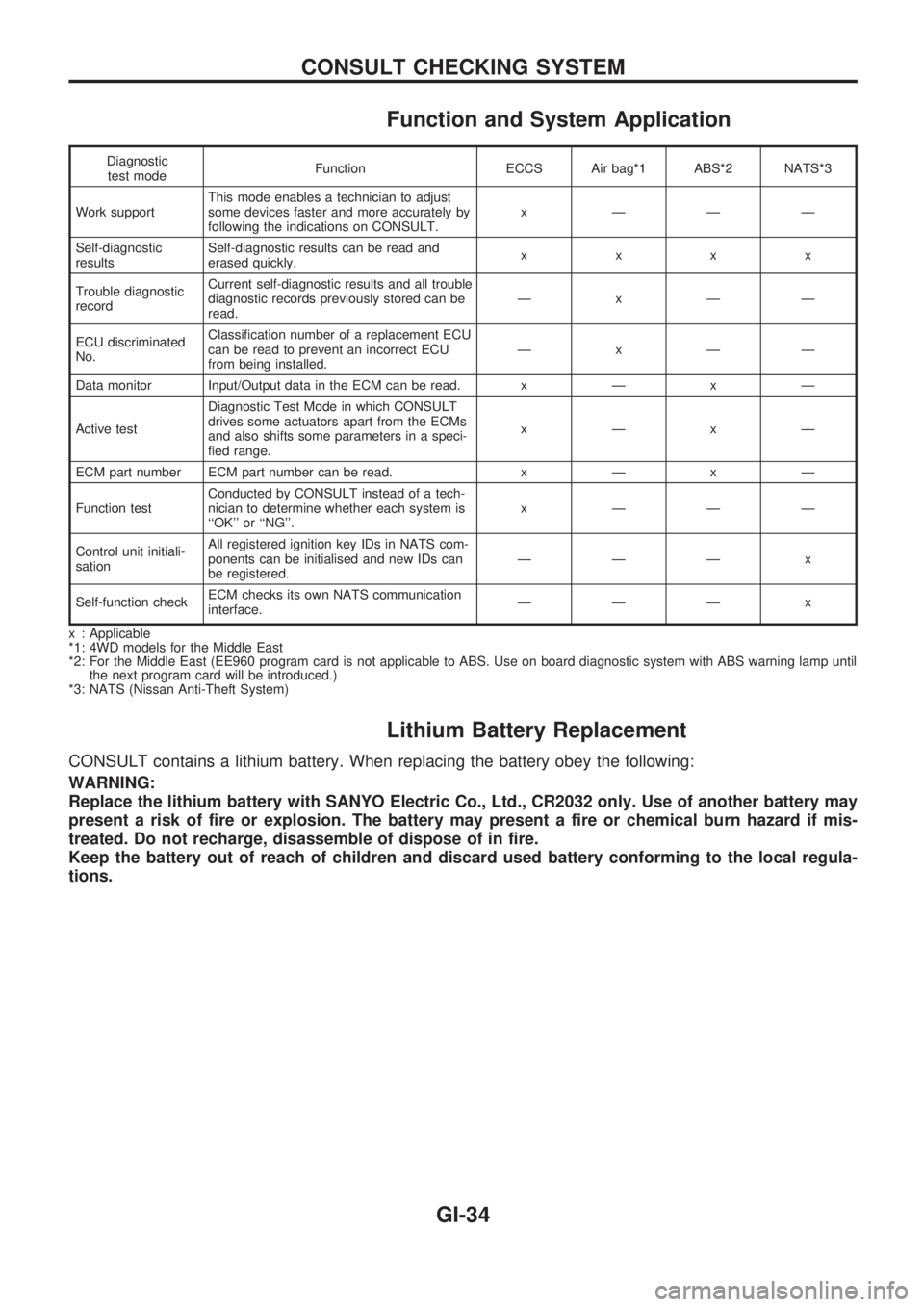

Function and System Application

Diagnostic

test modeFunction ECCS Air bag*1 ABS*2 NATS*3

Work supportThis mode enables a technician to adjust

some devices faster and more accurately by

following the indications on CONSULT.x ÐÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read and

erased quickly.xxxx

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐxÐÐ

ECU discriminated

No.Classification number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐxÐÐ

Data monitor Input/Output data in the ECM can be read.xÐxÐ

Active testDiagnostic Test Mode in which CONSULT

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

fied range.xÐxÐ

ECM part number ECM part number can be read.xÐxÐ

Function testConducted by CONSULT instead of a tech-

nician to determine whether each system is

``OK'' or ``NG''.x ÐÐÐ

Control unit initiali-

sationAll registered ignition key IDs in NATS com-

ponents can be initialised and new IDs can

be registered.ÐÐÐ x

Self-function checkECM checks its own NATS communication

interface.ÐÐÐ x

x : Applicable

*1: 4WD models for the Middle East

*2: For the Middle East (EE960 program card is not applicable to ABS. Use on board diagnostic system with ABS warning lamp until

the next program card will be introduced.)

*3: NATS (Nissan Anti-Theft System)

Lithium Battery Replacement

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd., CR2032 only. Use of another battery may

present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

CONSULT CHECKING SYSTEM

GI-34

Page 839 of 1659

Checking Equipment

When ordering the below equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT

V1CONSULT unit

and accessories

V2Program card

lEE960

lNATS-E940* for NATS

NT004

*: An order for NATS program card must be placed only with NISSAN EUROPE N.V.

CONSULT CHECKING SYSTEM

GI-35

Page 840 of 1659

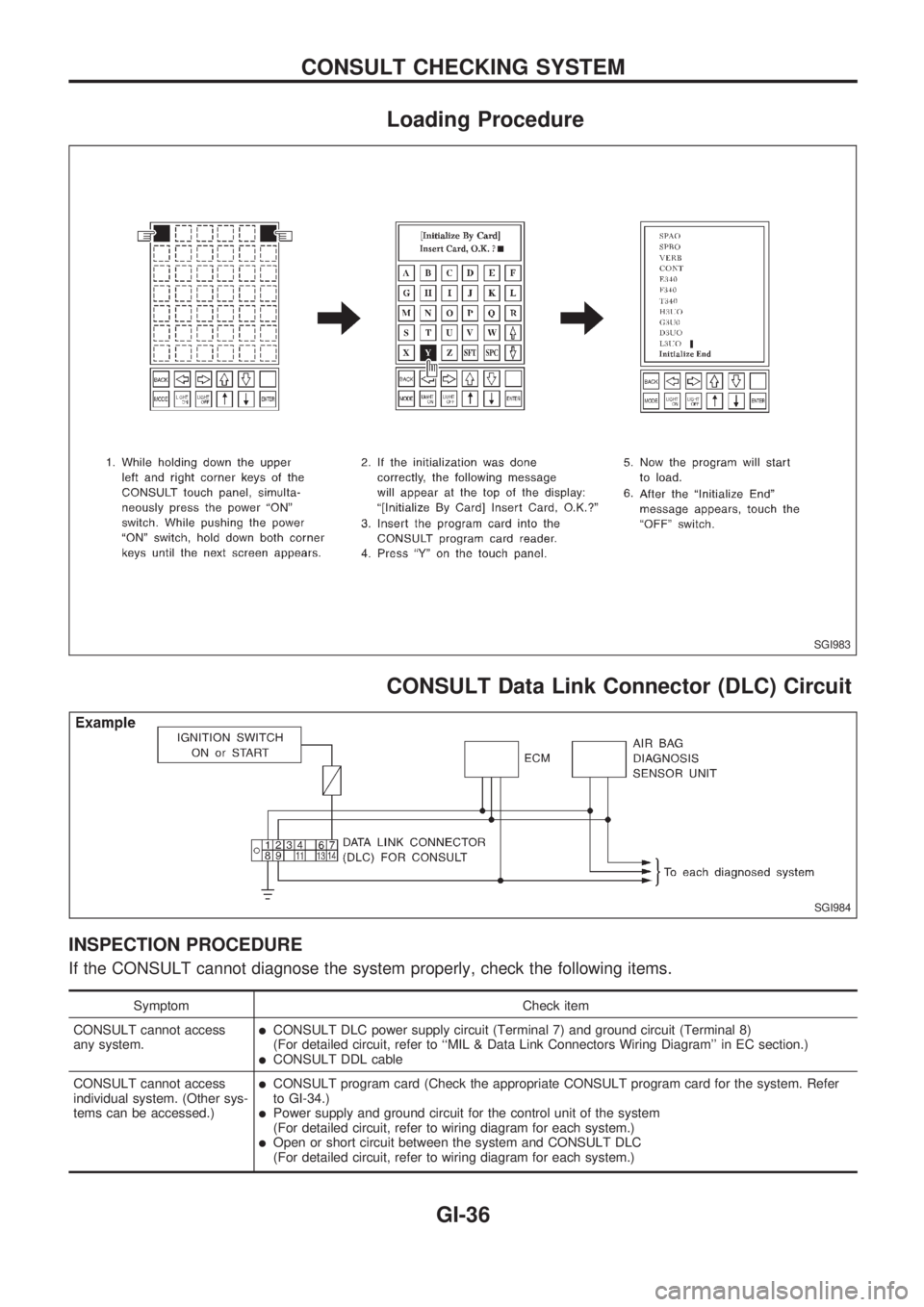

Loading Procedure

CONSULT Data Link Connector (DLC) Circuit

INSPECTION PROCEDURE

If the CONSULT cannot diagnose the system properly, check the following items.

Symptom Check item

CONSULT cannot access

any system.

lCONSULT DLC power supply circuit (Terminal 7) and ground circuit (Terminal 8)

(For detailed circuit, refer to ``MIL & Data Link Connectors Wiring Diagram'' in EC section.)

lCONSULT DDL cable

CONSULT cannot access

individual system. (Other sys-

tems can be accessed.)

lCONSULT program card (Check the appropriate CONSULT program card for the system. Refer

to GI-34.)

lPower supply and ground circuit for the control unit of the system

(For detailed circuit, refer to wiring diagram for each system.)

lOpen or short circuit between the system and CONSULT DLC

(For detailed circuit, refer to wiring diagram for each system.)

SGI983

SGI984

CONSULT CHECKING SYSTEM

GI-36