NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1691 of 2267

Assembly

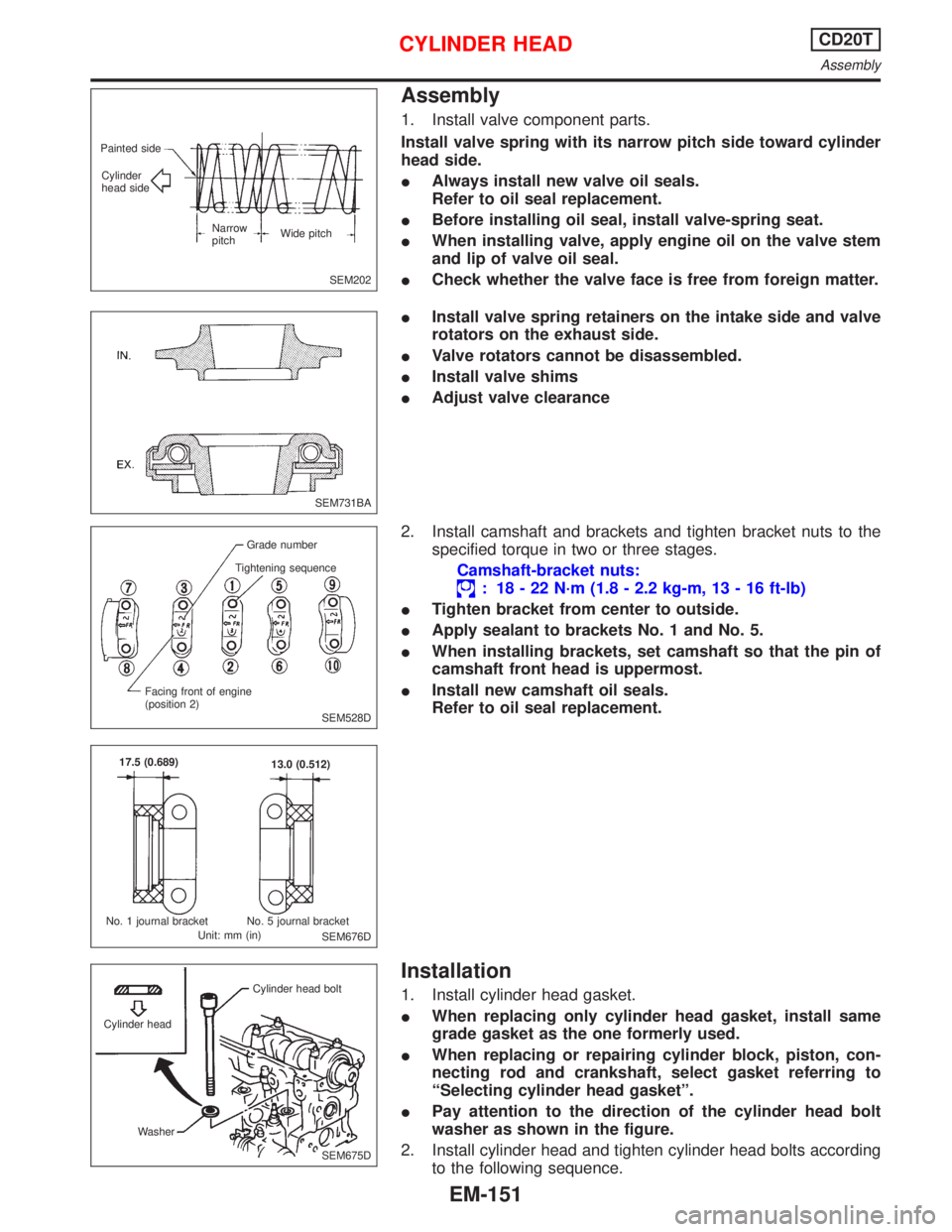

1. Install valve component parts.

Install valve spring with its narrow pitch side toward cylinder

head side.

IAlways install new valve oil seals.

Refer to oil seal replacement.

IBefore installing oil seal, install valve-spring seat.

IWhen installing valve, apply engine oil on the valve stem

and lip of valve oil seal.

ICheck whether the valve face is free from foreign matter.

IInstall valve spring retainers on the intake side and valve

rotators on the exhaust side.

IValve rotators cannot be disassembled.

IInstall valve shims

IAdjust valve clearance

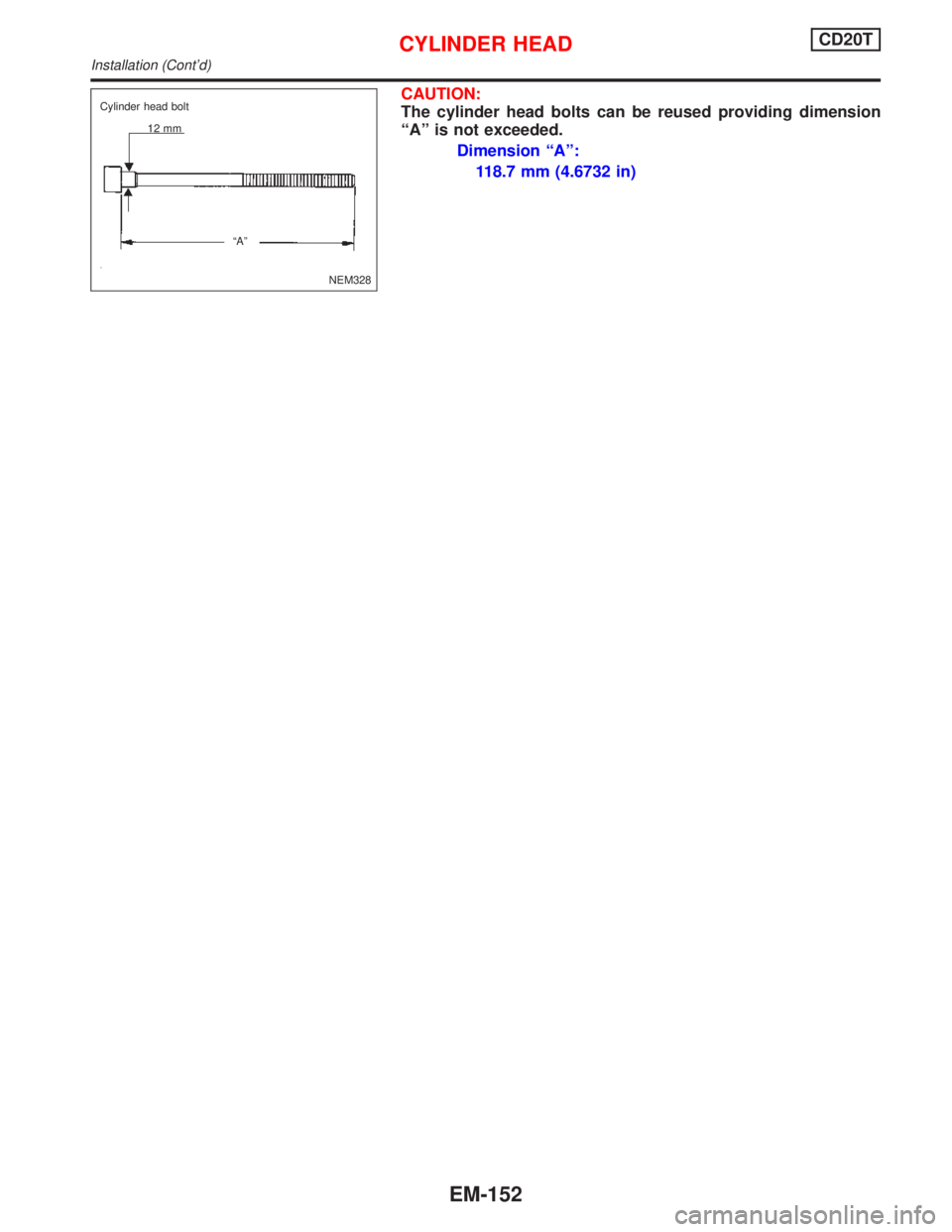

2. Install camshaft and brackets and tighten bracket nuts to the

specified torque in two or three stages.

Camshaft-bracket nuts:

: 18 - 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

ITighten bracket from center to outside.

IApply sealant to brackets No. 1 and No. 5.

IWhen installing brackets, set camshaft so that the pin of

camshaft front head is uppermost.

IInstall new camshaft oil seals.

Refer to oil seal replacement.

Installation

1. Install cylinder head gasket.

IWhen replacing only cylinder head gasket, install same

grade gasket as the one formerly used.

IWhen replacing or repairing cylinder block, piston, con-

necting rod and crankshaft, select gasket referring to

ªSelecting cylinder head gasketº.

IPay attention to the direction of the cylinder head bolt

washer as shown in the figure.

2. Install cylinder head and tighten cylinder head bolts according

to the following sequence.

SEM202 Painted side

Cylinder

head side

Narrow

pitchWide pitch

SEM731BA

SEM528D Grade number

Tightening sequence

Facing front of engine

(position 2)

SEM676D 17.5 (0.689)

13.0 (0.512)

No. 1 journal bracket No. 5 journal bracket

Unit: mm (in)

SEM675D Cylinder headCylinder head bolt

Washer

CYLINDER HEADCD20T

Assembly

EM-151

Page 1692 of 2267

CAUTION:

The cylinder head bolts can be reused providing dimension

ªAº is not exceeded.

Dimension ªAº:

118.7 mm (4.6732 in)

NEM328 Cylinder head bolt

12 mm

ªAº

CYLINDER HEADCD20T

Installation (Cont'd)

EM-152

Page 1693 of 2267

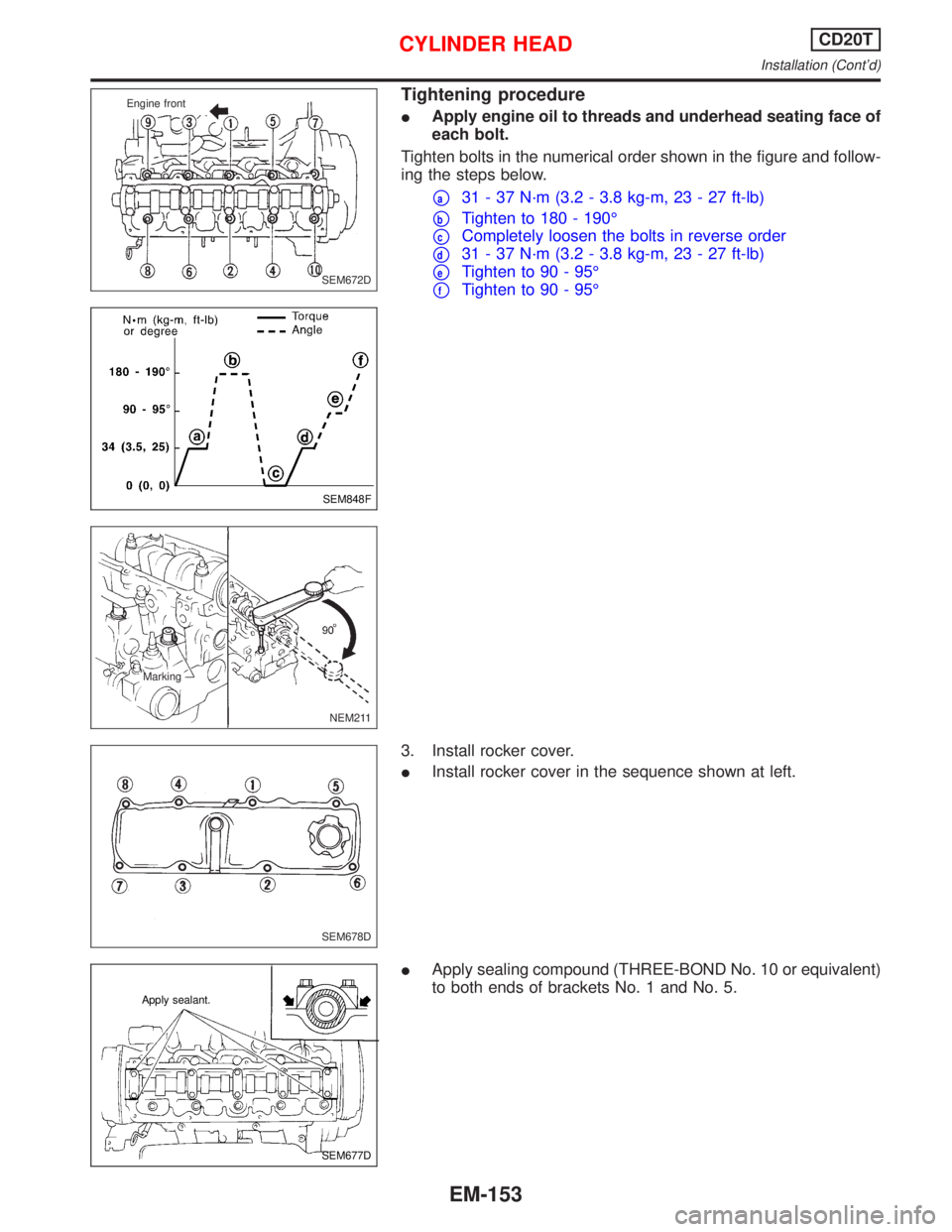

Tightening procedure

IApply engine oil to threads and underhead seating face of

each bolt.

Tighten bolts in the numerical order shown in the figure and follow-

ing the steps below.

pa31 - 37 N´m (3.2 - 3.8 kg-m, 23 - 27 ft-lb)

pbTighten to 180 - 190É

pcCompletely loosen the bolts in reverse order

pd31 - 37 N´m (3.2 - 3.8 kg-m, 23 - 27 ft-lb)

peTighten to 90 - 95É

pfTighten to 90 - 95É

3. Install rocker cover.

IInstall rocker cover in the sequence shown at left.

IApply sealing compound (THREE-BOND No. 10 or equivalent)

to both ends of brackets No. 1 and No. 5.SEM672D Engine front

SEM848F

NEM211 Marking

SEM678D

SEM677D Apply sealant.

CYLINDER HEADCD20T

Installation (Cont'd)

EM-153

Page 1694 of 2267

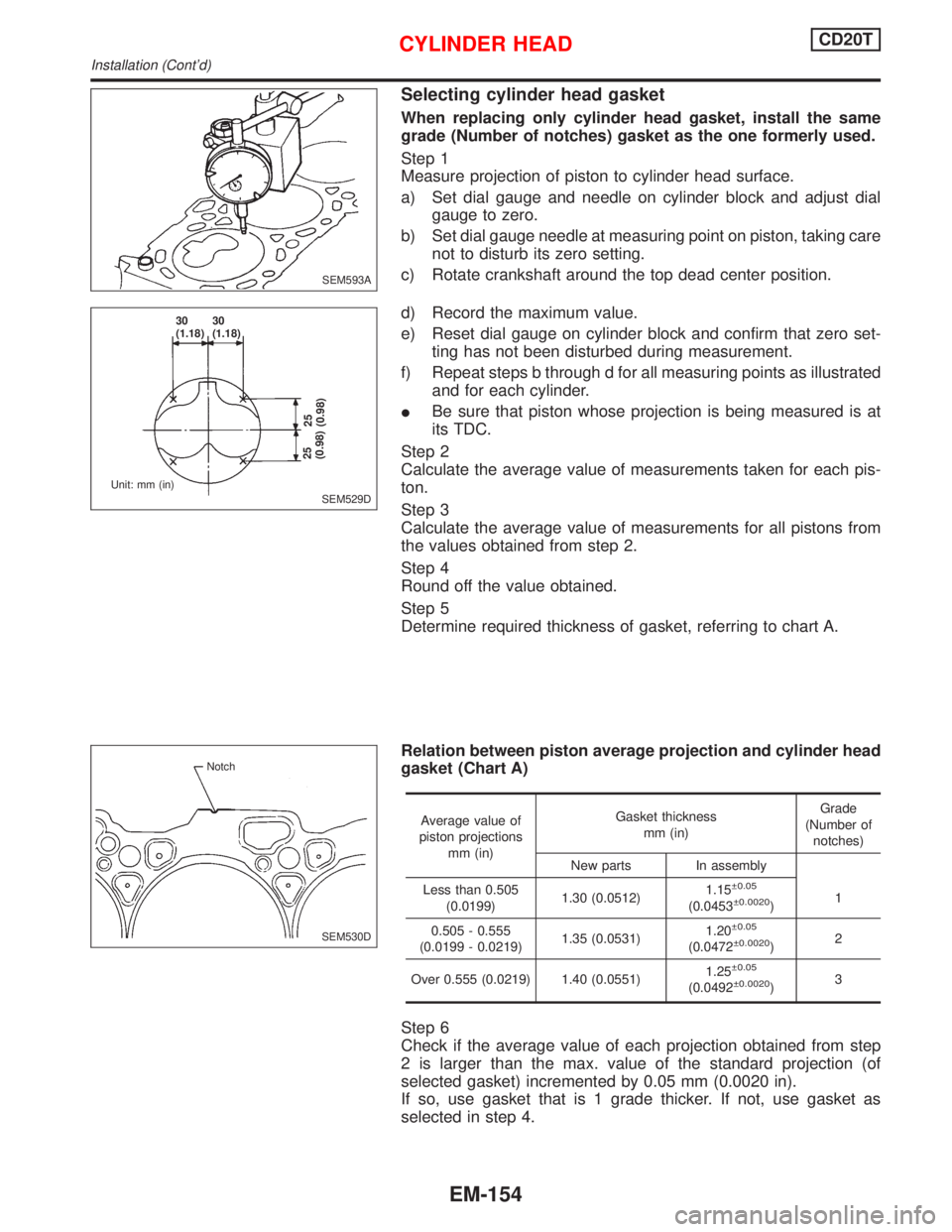

Selecting cylinder head gasket

When replacing only cylinder head gasket, install the same

grade (Number of notches) gasket as the one formerly used.

Step 1

Measure projection of piston to cylinder head surface.

a) Set dial gauge and needle on cylinder block and adjust dial

gauge to zero.

b) Set dial gauge needle at measuring point on piston, taking care

not to disturb its zero setting.

c) Rotate crankshaft around the top dead center position.

d) Record the maximum value.

e) Reset dial gauge on cylinder block and confirm that zero set-

ting has not been disturbed during measurement.

f) Repeat steps b through d for all measuring points as illustrated

and for each cylinder.

IBe sure that piston whose projection is being measured is at

its TDC.

Step 2

Calculate the average value of measurements taken for each pis-

ton.

Step 3

Calculate the average value of measurements for all pistons from

the values obtained from step 2.

Step 4

Round off the value obtained.

Step 5

Determine required thickness of gasket, referring to chart A.

Relation between piston average projection and cylinder head

gasket (Chart A)

Average value of

piston projections

mm (in)Gasket thickness

mm (in)Grade

(Number of

notches)

New parts In assembly

Less than 0.505

(0.0199)1.30 (0.0512)1.15

0.05

(0.0453 0.0020)1

0.505 - 0.555

(0.0199 - 0.0219)1.35 (0.0531)1.20

0.05

(0.0472 0.0020)2

Over 0.555 (0.0219) 1.40 (0.0551)1.25

0.05

(0.0492 0.0020)3

Step 6

Check if the average value of each projection obtained from step

2 is larger than the max. value of the standard projection (of

selected gasket) incremented by 0.05 mm (0.0020 in).

If so, use gasket that is 1 grade thicker. If not, use gasket as

selected in step 4.

SEM593A

SEM529D 30

(1.18)30

(1.18)

Unit: mm (in)

25

(0.98)25

(0.98)

SEM530D Notch

CYLINDER HEADCD20T

Installation (Cont'd)

EM-154

Page 1695 of 2267

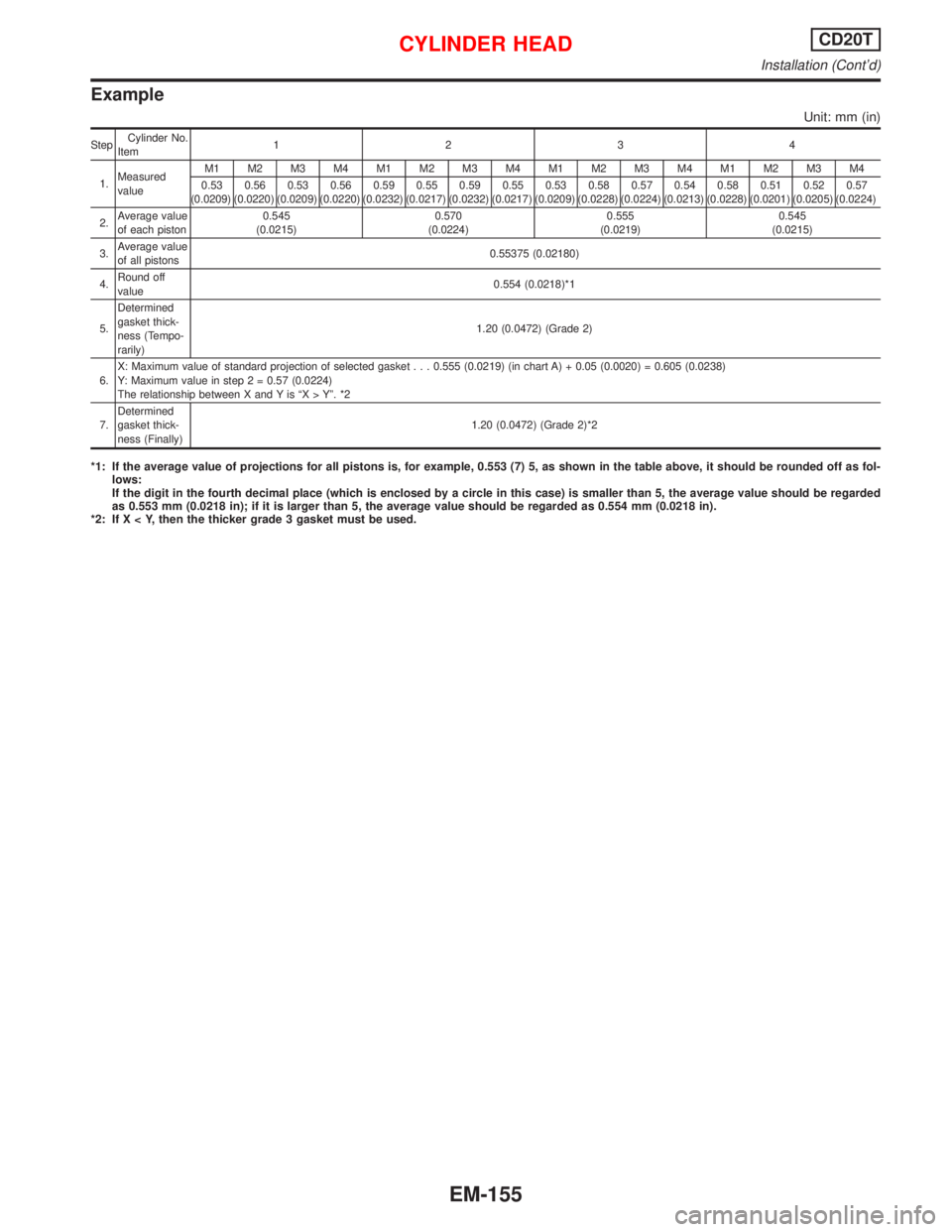

Example

Unit: mm (in)

StepCylinder No.

Item1234

1.Measured

valueM1 M2 M3 M4 M1 M2 M3 M4 M1 M2 M3 M4 M1 M2 M3 M4

0.53

(0.0209)0.56

(0.0220)0.53

(0.0209)0.56

(0.0220)0.59

(0.0232)0.55

(0.0217)0.59

(0.0232)0.55

(0.0217)0.53

(0.0209)0.58

(0.0228)0.57

(0.0224)0.54

(0.0213)0.58

(0.0228)0.51

(0.0201)0.52

(0.0205)0.57

(0.0224)

2.Average value

of each piston0.545

(0.0215)0.570

(0.0224)0.555

(0.0219)0.545

(0.0215)

3.Average value

of all pistons0.55375 (0.02180)

4.Round off

value0.554 (0.0218)*1

5.Determined

gasket thick-

ness (Tempo-

rarily)1.20 (0.0472) (Grade 2)

6.X: Maximum value of standard projection of selected gasket...0.555 (0.0219) (in chart A) + 0.05 (0.0020) = 0.605 (0.0238)

Y: Maximum value in step 2 = 0.57 (0.0224)

The relationship between X and Y is ªX > Yº. *2

7.Determined

gasket thick-

ness (Finally)1.20 (0.0472) (Grade 2)*2

*1: If the average value of projections for all pistons is, for example, 0.553 (7) 5, as shown in the table above, it should be rounded off as fol-

lows:

If the digit in the fourth decimal place (which is enclosed by a circle in this case) is smaller than 5, the average value should be regarded

as 0.553 mm (0.0218 in); if it is larger than 5, the average value should be regarded as 0.554 mm (0.0218 in).

*2: If X < Y, then the thicker grade 3 gasket must be used.

CYLINDER HEADCD20T

Installation (Cont'd)

EM-155

Page 1696 of 2267

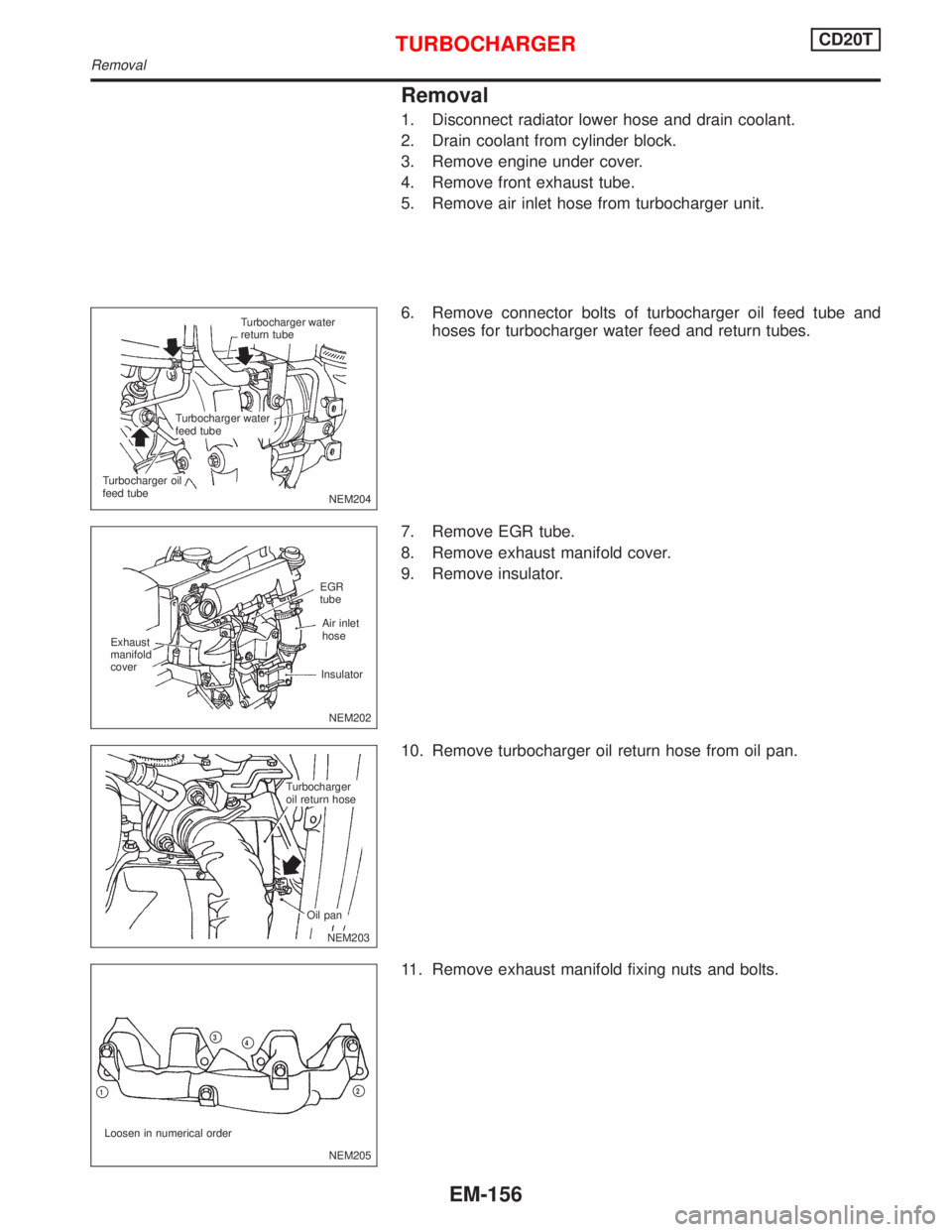

Removal

1. Disconnect radiator lower hose and drain coolant.

2. Drain coolant from cylinder block.

3. Remove engine under cover.

4. Remove front exhaust tube.

5. Remove air inlet hose from turbocharger unit.

6. Remove connector bolts of turbocharger oil feed tube and

hoses for turbocharger water feed and return tubes.

7. Remove EGR tube.

8. Remove exhaust manifold cover.

9. Remove insulator.

10. Remove turbocharger oil return hose from oil pan.

11. Remove exhaust manifold fixing nuts and bolts.

NEM204

.Turbocharger water

return tube

.Turbocharger water

feed tube

.Turbocharger oil

feed tube

NEM202 Exhaust

manifold

coverAir inlet

hose EGR

tube

Insulator

.NEM203

.Turbocharger

oil return hose

.Oil pan

NEM205 Loosen in numerical order

p1p2

p3p4

TURBOCHARGERCD20T

Removal

EM-156

Page 1697 of 2267

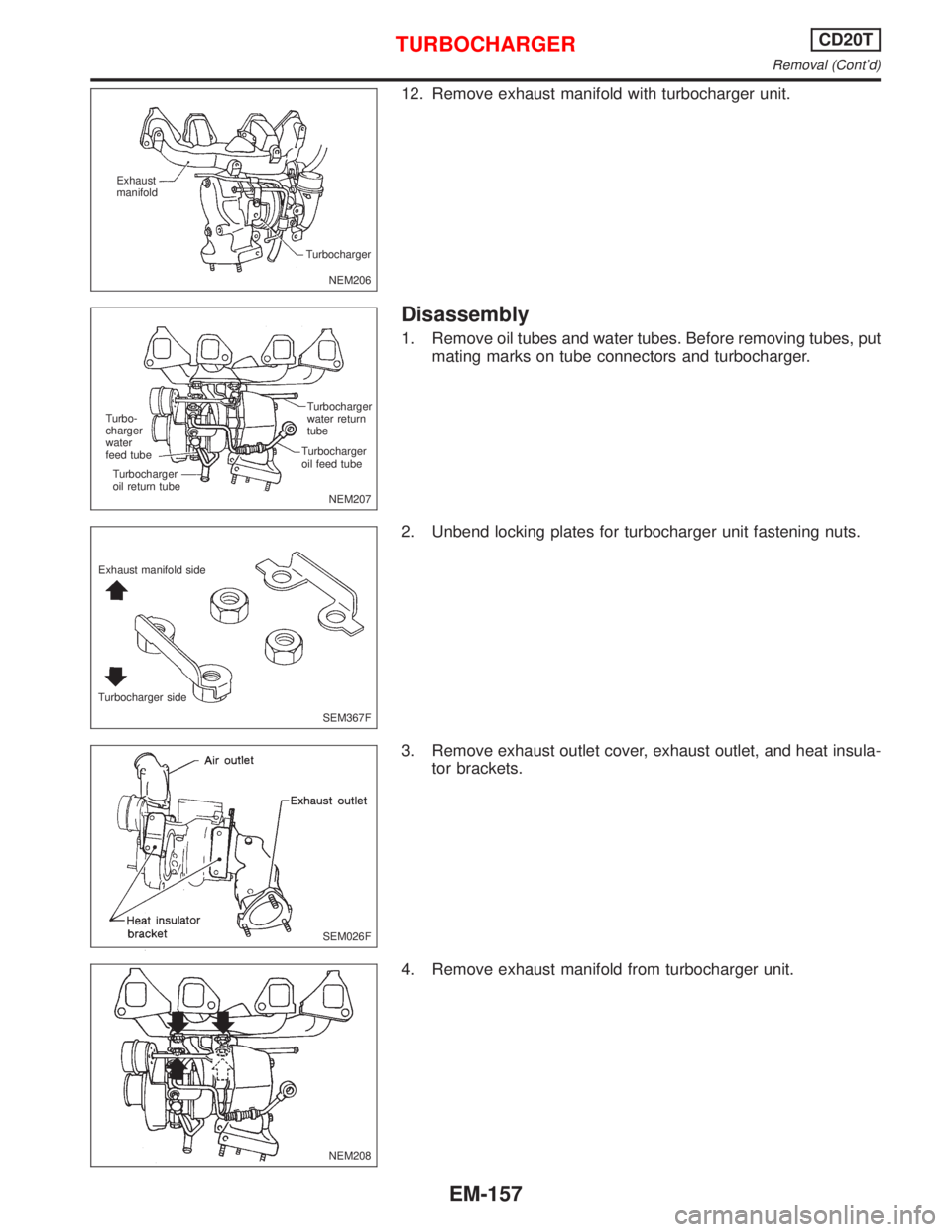

12. Remove exhaust manifold with turbocharger unit.

Disassembly

1. Remove oil tubes and water tubes. Before removing tubes, put

mating marks on tube connectors and turbocharger.

2. Unbend locking plates for turbocharger unit fastening nuts.

3. Remove exhaust outlet cover, exhaust outlet, and heat insula-

tor brackets.

4. Remove exhaust manifold from turbocharger unit.

NEM206 Exhaust

manifold

Turbocharger

NEM207 Turbocharger

water return

tube

Turbocharger

oil feed tube Turbo-

charger

water

feed tube

Turbocharger

oil return tube

SEM367F Exhaust manifold side

Turbocharger side

SEM026F

NEM208

TURBOCHARGERCD20T

Removal (Cont'd)

EM-157

Page 1698 of 2267

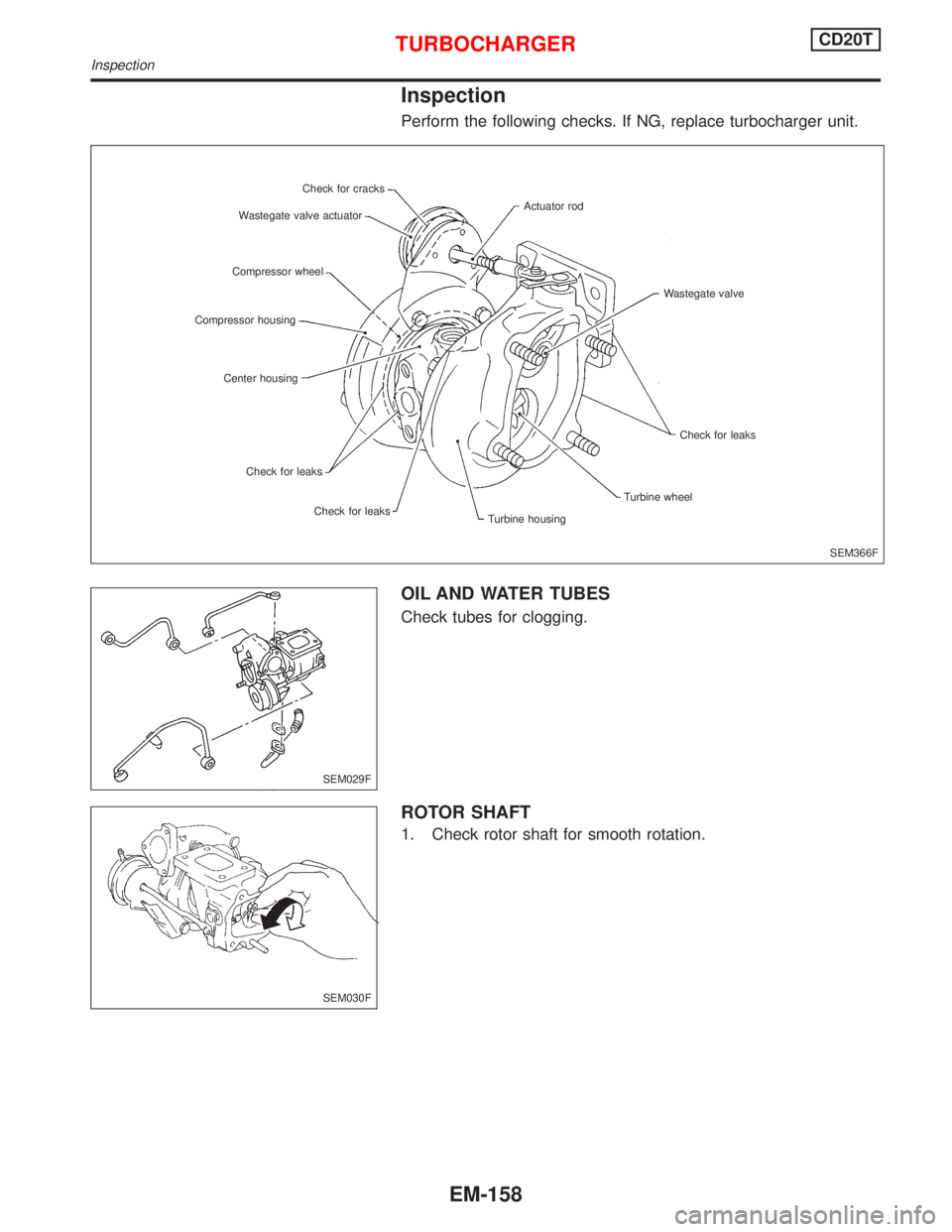

Inspection

Perform the following checks. If NG, replace turbocharger unit.

OIL AND WATER TUBES

Check tubes for clogging.

ROTOR SHAFT

1. Check rotor shaft for smooth rotation.

SEM366F Check for cracks

Wastegate valve actuator

Compressor wheel

Compressor housing

Center housing

Check for leaks

Check for leaks

Turbine housingTurbine wheelCheck for leaks Wastegate valve Actuator rod

SEM029F

SEM030F

TURBOCHARGERCD20T

Inspection

EM-158

Page 1699 of 2267

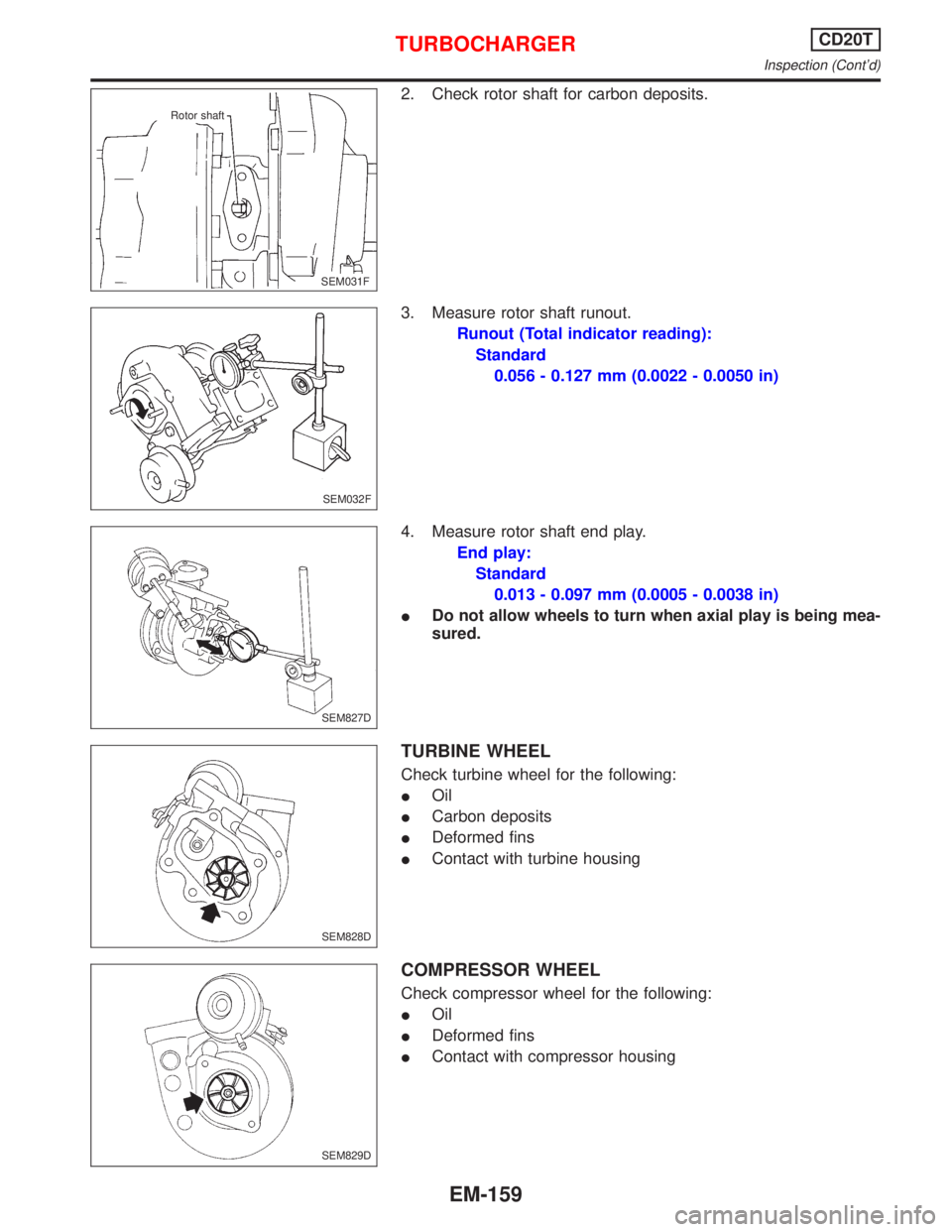

2. Check rotor shaft for carbon deposits.

3. Measure rotor shaft runout.

Runout (Total indicator reading):

Standard

0.056 - 0.127 mm (0.0022 - 0.0050 in)

4. Measure rotor shaft end play.

End play:

Standard

0.013 - 0.097 mm (0.0005 - 0.0038 in)

IDo not allow wheels to turn when axial play is being mea-

sured.

TURBINE WHEEL

Check turbine wheel for the following:

IOil

ICarbon deposits

IDeformed fins

IContact with turbine housing

COMPRESSOR WHEEL

Check compressor wheel for the following:

IOil

IDeformed fins

IContact with compressor housing

.SEM031F Rotor shaft

SEM032F

SEM827D

SEM828D

SEM829D

TURBOCHARGERCD20T

Inspection (Cont'd)

EM-159

Page 1700 of 2267

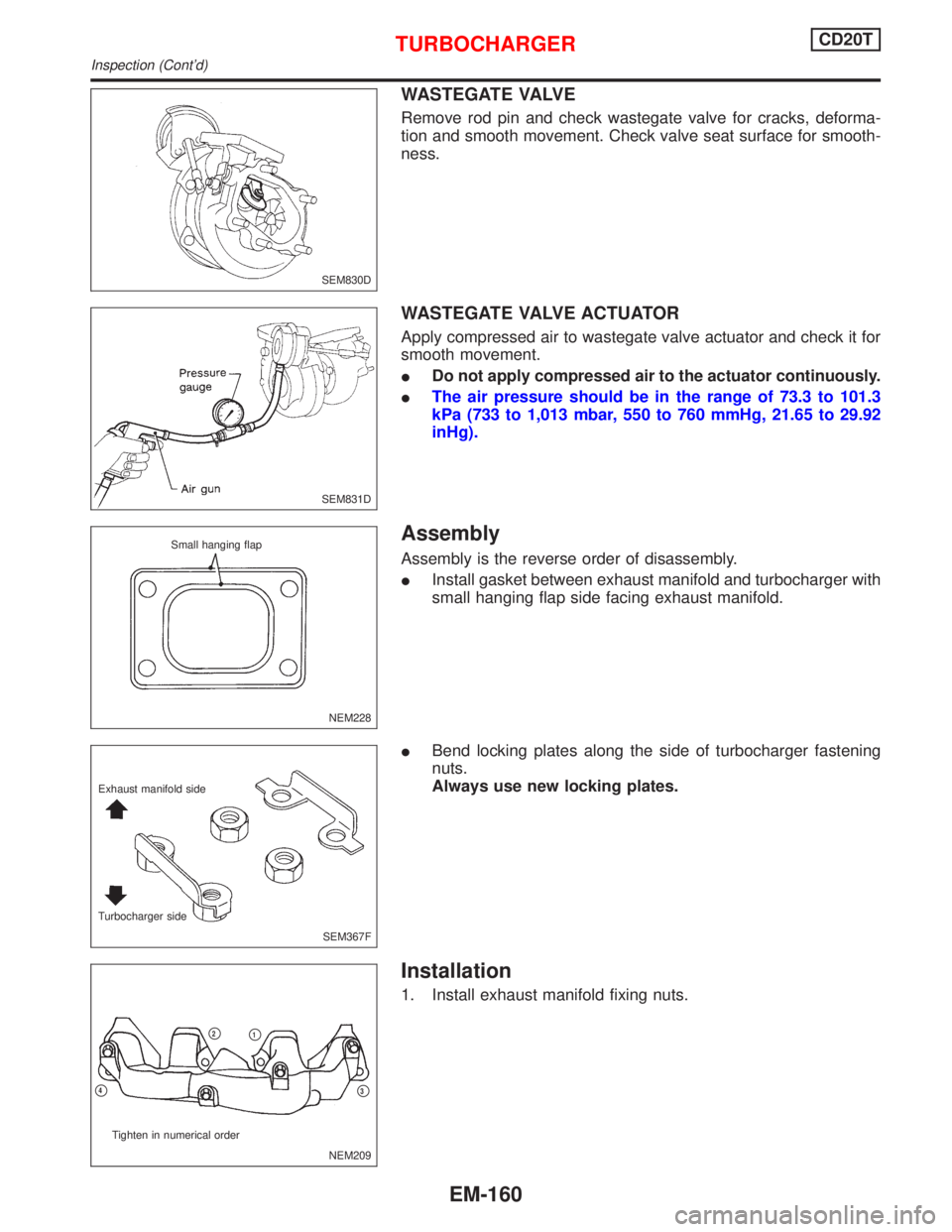

WASTEGATE VALVE

Remove rod pin and check wastegate valve for cracks, deforma-

tion and smooth movement. Check valve seat surface for smooth-

ness.

WASTEGATE VALVE ACTUATOR

Apply compressed air to wastegate valve actuator and check it for

smooth movement.

IDo not apply compressed air to the actuator continuously.

IThe air pressure should be in the range of 73.3 to 101.3

kPa (733 to 1,013 mbar, 550 to 760 mmHg, 21.65 to 29.92

inHg).

Assembly

Assembly is the reverse order of disassembly.

IInstall gasket between exhaust manifold and turbocharger with

small hanging flap side facing exhaust manifold.

IBend locking plates along the side of turbocharger fastening

nuts.

Always use new locking plates.

Installation

1. Install exhaust manifold fixing nuts.

SEM830D

SEM831D

NEM228 Small hanging flap

SEM367F Exhaust manifold side

Turbocharger side

NEM209 Tighten in numerical order

p4

p2p1

p3

TURBOCHARGERCD20T

Inspection (Cont'd)

EM-160