NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1661 of 2267

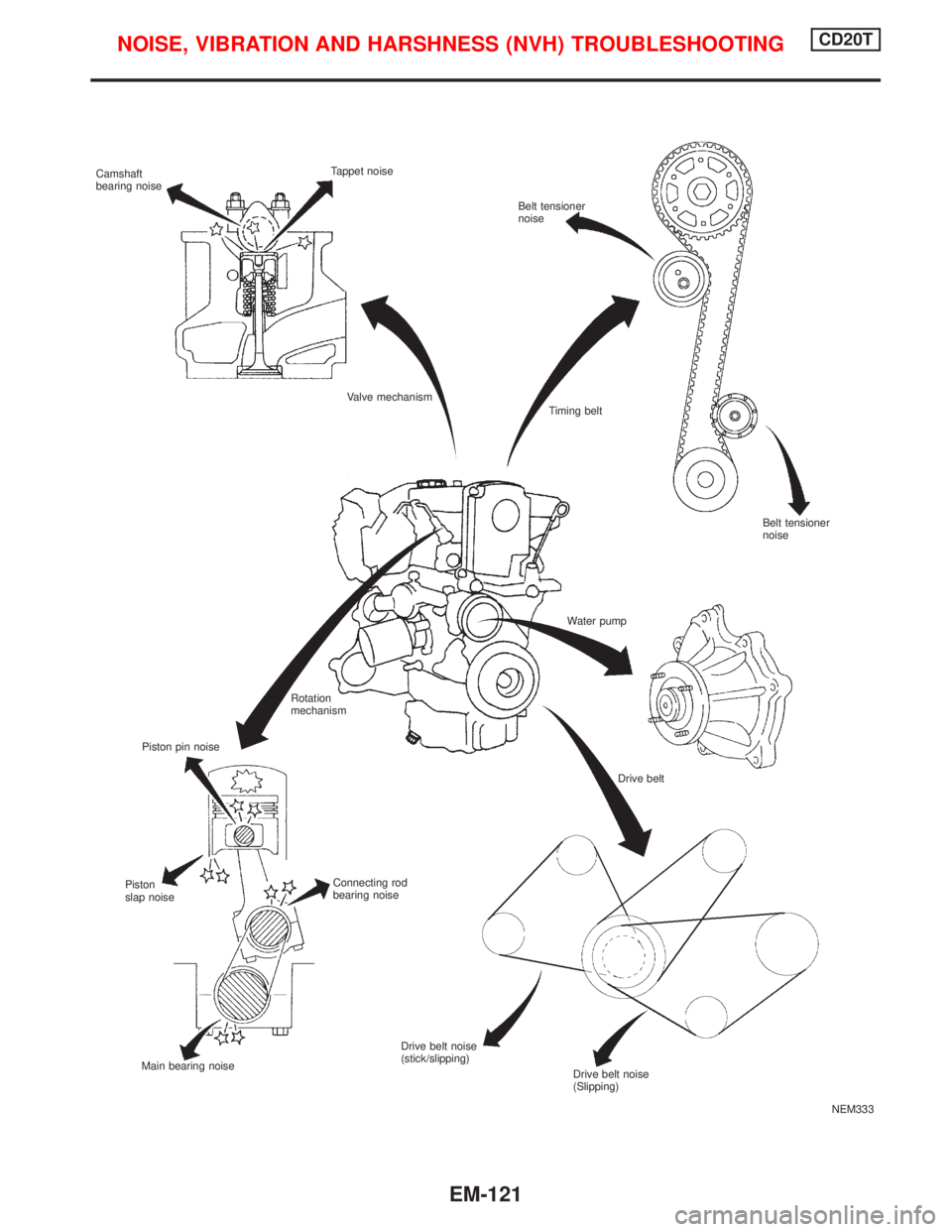

NEM333 Camshaft

bearing noiseTappet noise

Belt tensioner

noise

Valve mechanism

Piston pin noiseTiming belt

Water pump

Rotation

mechanism

Drive belt

Connecting rod

bearing noise Piston

slap noise

Main bearing noiseDrive belt noise

(stick/slipping)

Belt tensioner

noise

Drive belt noise

(Slipping)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGCD20T

EM-121

Page 1662 of 2267

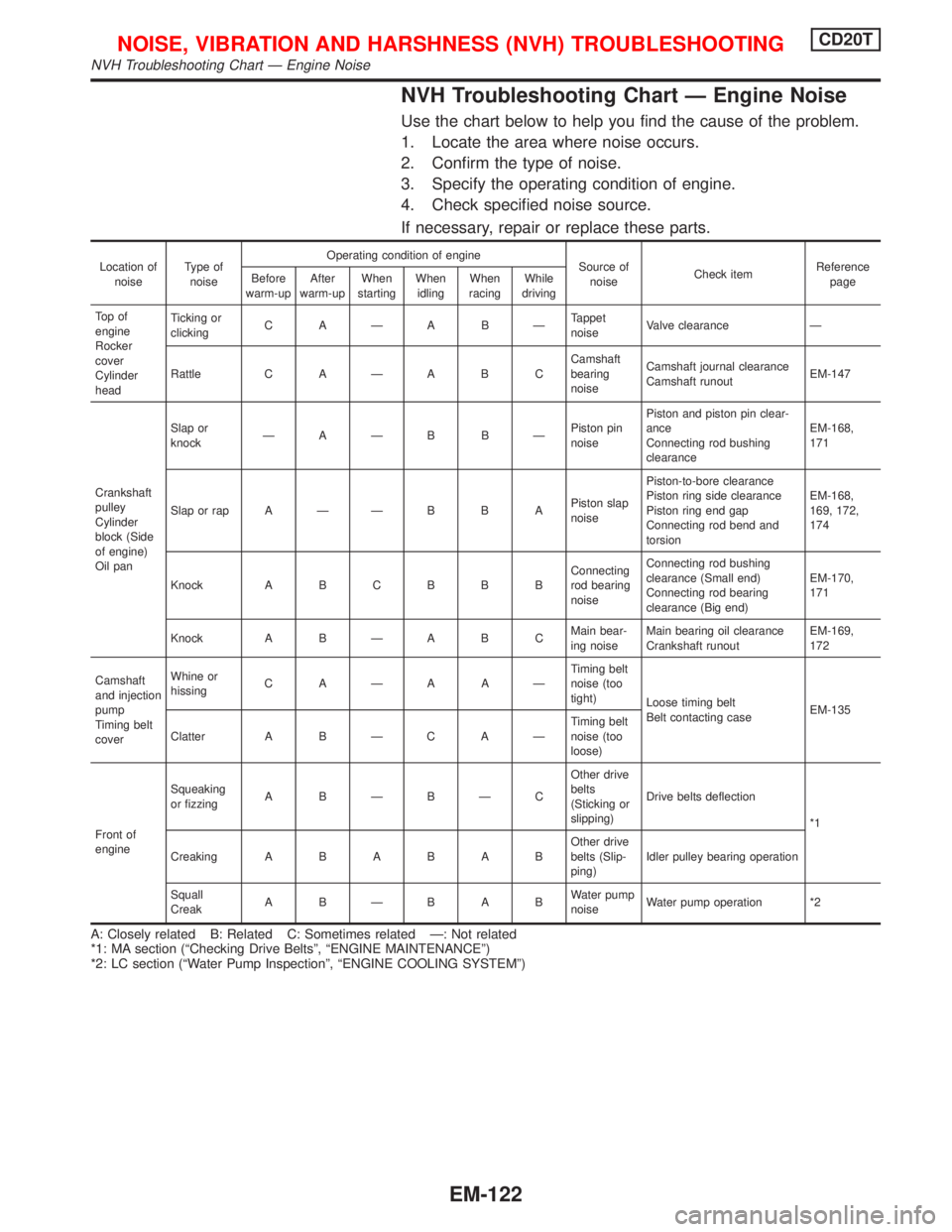

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the problem.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance Ð

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-147

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-168,

171

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-168,

169, 172,

174

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-170,

171

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-169,

172

Camshaft

and injection

pump

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-135

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or fizzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts deflection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (ªChecking Drive Beltsº, ªENGINE MAINTENANCEº)

*2: LC section (ªWater Pump Inspectionº, ªENGINE COOLING SYSTEMº)

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGCD20T

NVH Troubleshooting Chart Ð Engine Noise

EM-122

Page 1663 of 2267

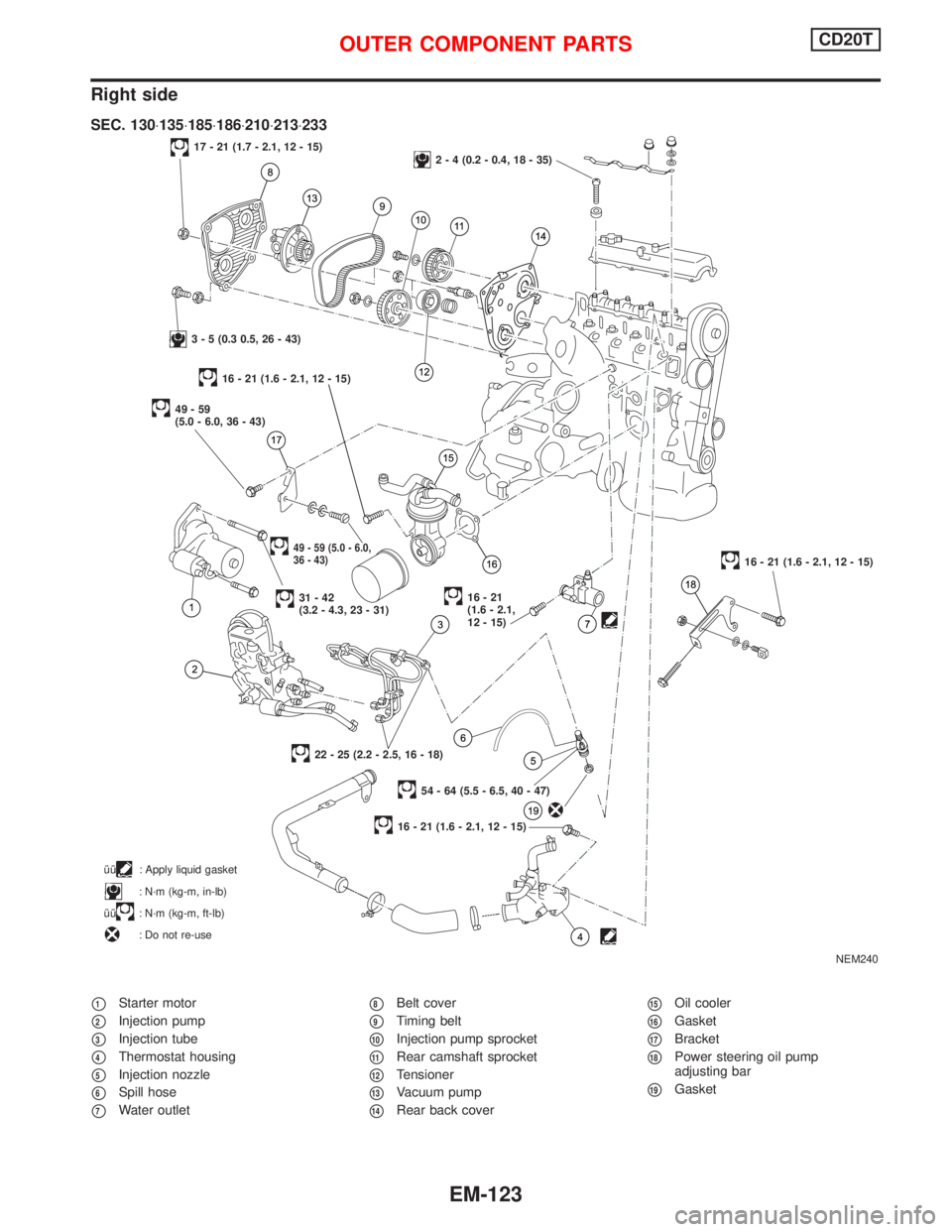

Right side

p1Starter motor

p2Injection pump

p3Injection tube

p4Thermostat housing

p5Injection nozzle

p6Spill hose

p7Water outlet

p8Belt cover

p9Timing belt

p10Injection pump sprocket

p11Rear camshaft sprocket

p12Tensioner

p13Vacuum pump

p14Rear back cover

p15Oil cooler

p16Gasket

p17Bracket

p18Power steering oil pump

adjusting bar

p19Gasket

NEM240

17 - 21 (1.7 - 2.1, 12 - 15)2 - 4 (0.2 - 0.4, 18 - 35)

3 - 5 (0.3 0.5, 26 - 43)

49-59

(5.0 - 6.0, 36 - 43)

49 - 59 (5.0 - 6.0,

36 - 43)

31-42

(3.2 - 4.3, 23 - 31)16-21

(1.6 - 2.1,

12 - 15)

16 - 21 (1.6 - 2.1, 12 - 15)

54 - 64 (5.5 - 6.5, 40 - 47)

22 - 25 (2.2 - 2.5, 16 - 18)

16 - 21 (1.6 - 2.1, 12 - 15)

SEC. 130×135×185×186×210×213×233

îî: Apply liquid gasket

: N´m (kg-m, in-lb)

îî

: N´m (kg-m, ft-lb)

: Do not re-use

16 - 21 (1.6 - 2.1, 12 - 15)

OUTER COMPONENT PARTSCD20T

EM-123

Page 1664 of 2267

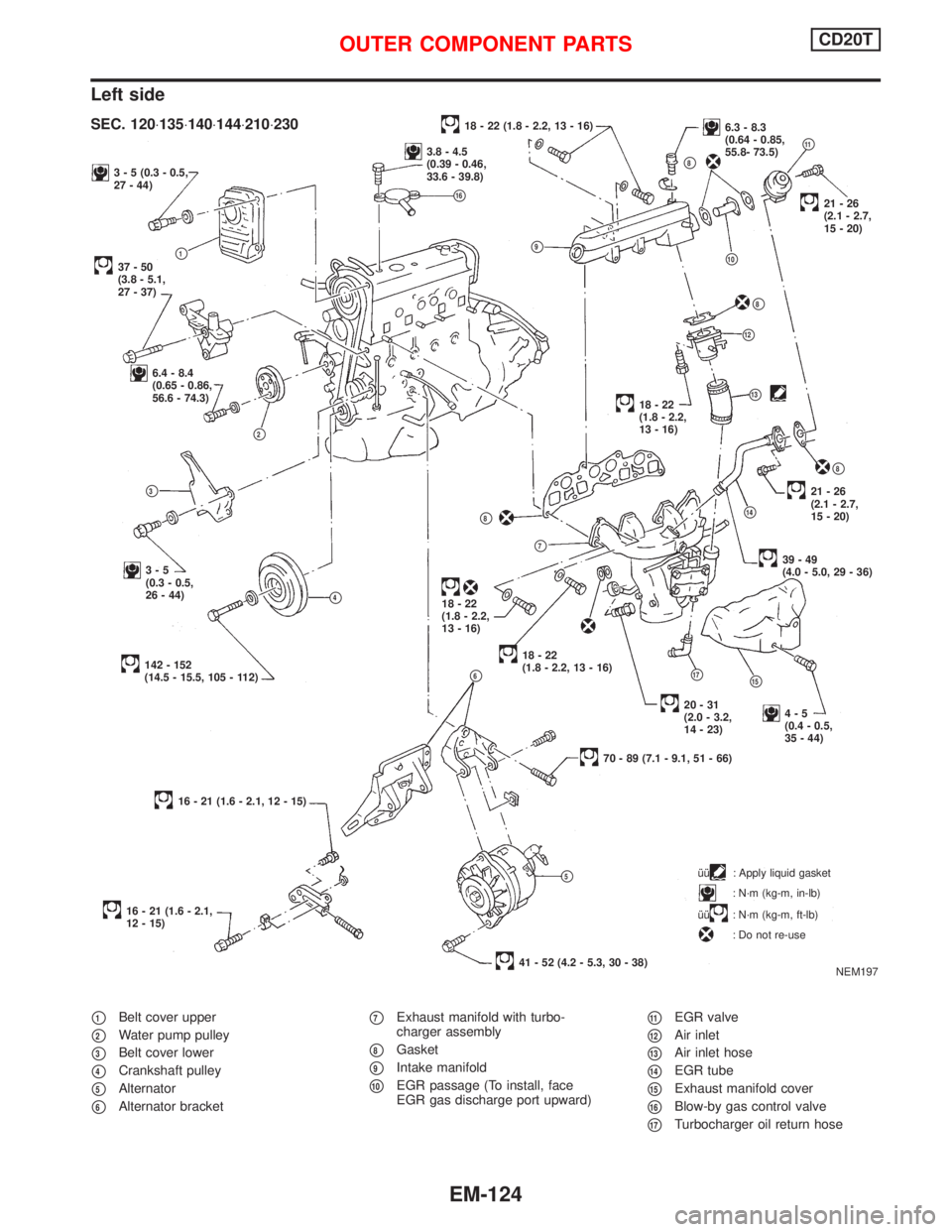

Left side

p1Belt cover upper

p2Water pump pulley

p3Belt cover lower

p4Crankshaft pulley

p5Alternator

p6Alternator bracket

p7Exhaust manifold with turbo-

charger assembly

p8Gasket

p9Intake manifold

p10EGR passage (To install, face

EGR gas discharge port upward)

p11EGR valve

p12Air inlet

p13Air inlet hose

p14EGR tube

p15Exhaust manifold cover

p16Blow-by gas control valve

p17Turbocharger oil return hose

3 - 5 (0.3 - 0.5,

27 - 44)

37-50

(3.8 - 5.1,

27 - 37)p1

6.4 - 8.4

(0.65 - 0.86,

56.6 - 74.3)

p2

p9

p3

3-5

(0.3 - 0.5,

26 - 44)

p4

142 - 152

(14.5 - 15.5, 105 - 112)p6

16 - 21 (1.6 - 2.1, 12 - 15)

16 - 21 (1.6 - 2.1,

12 - 15)îî

: Apply liquid gasket

: N´m (kg-m, in-lb)

îî

: N´m (kg-m, ft-lb)

: Do not re-use

18 - 22 (1.8 - 2.2, 13 - 16)6.3 - 8.3

(0.64 - 0.85,

55.8- 73.5)

p11

p8

p10

.21-26

(2.1 - 2.7,

15 - 20)

p8

p12

p1318-22

(1.8 - 2.2,

13 - 16)

p8

21-26

(2.1 - 2.7,

15 - 20)

p14

39-49

(4.0 - 5.0, 29 - 36)

p8

p7

18-22

(1.8 - 2.2,

13 - 16)

.18-22

(1.8 - 2.2, 13 - 16)

p17p15

4-5

(0.4 - 0.5,

35 - 44)

70 - 89 (7.1 - 9.1, 51 - 66)

p5

41 - 52 (4.2 - 5.3, 30 - 38)

NEM197

SEC. 120×135×140×144×210×230

3.8 - 4.5

(0.39 - 0.46,

33.6 - 39.8)

p16

20-31

(2.0 - 3.2,

14 - 23)

OUTER COMPONENT PARTSCD20T

EM-124

Page 1665 of 2267

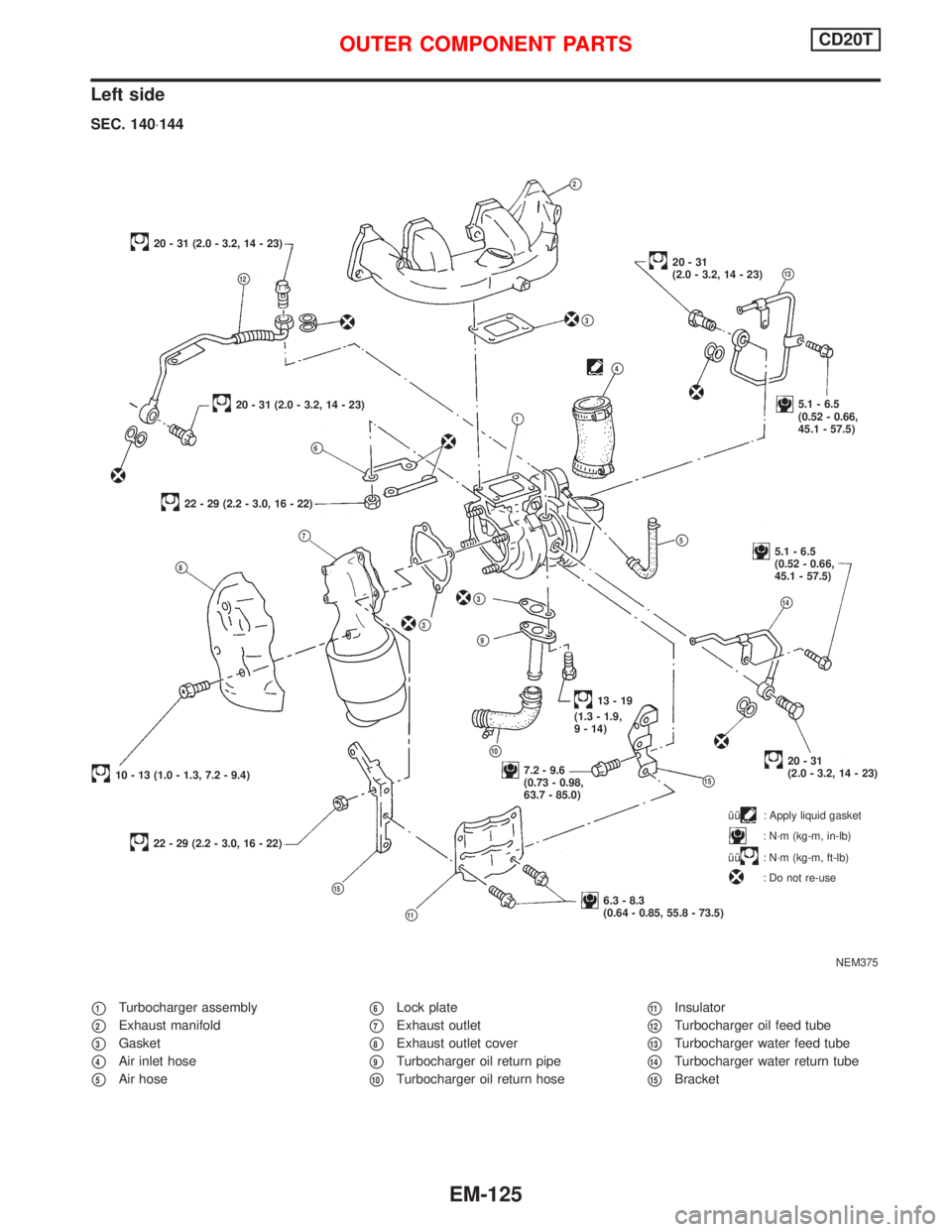

Left side

p1Turbocharger assembly

p2Exhaust manifold

p3Gasket

p4Air inlet hose

p5Air hose

p6Lock plate

p7Exhaust outlet

p8Exhaust outlet cover

p9Turbocharger oil return pipe

p10Turbocharger oil return hose

p11Insulator

p12Turbocharger oil feed tube

p13Turbocharger water feed tube

p14Turbocharger water return tube

p15Bracket

NEM375

p2

20 - 31 (2.0 - 3.2, 14 - 23)

p12

20 - 31 (2.0 - 3.2, 14 - 23)

p6

22 - 29 (2.2 - 3.0, 16 - 22)

p4

p3

p7

p8

p3

p3

p9

10 - 13 (1.0 - 1.3, 7.2 - 9.4)

22 - 29 (2.2 - 3.0, 16 - 22)

p15

p11

7.2 - 9.6

(0.73 - 0.98,

63.7 - 85.0)

.p10

p15

6.3 - 8.3

(0.64 - 0.85, 55.8 - 73.5)

20-31

(2.0 - 3.2, 14 - 23)

13-19

(1.3 - 1.9,

9 - 14)

p14

5.1 - 6.5

(0.52 - 0.66,

45.1 - 57.5)p5

p1

20-31

(2.0 - 3.2, 14 - 23)p13

5.1 - 6.5

(0.52 - 0.66,

45.1 - 57.5)

SEC. 140×144

îî: Apply liquid gasket

: N´m (kg-m, in-lb)

îî

: N´m (kg-m, ft-lb)

: Do not re-use

OUTER COMPONENT PARTSCD20T

EM-125

Page 1666 of 2267

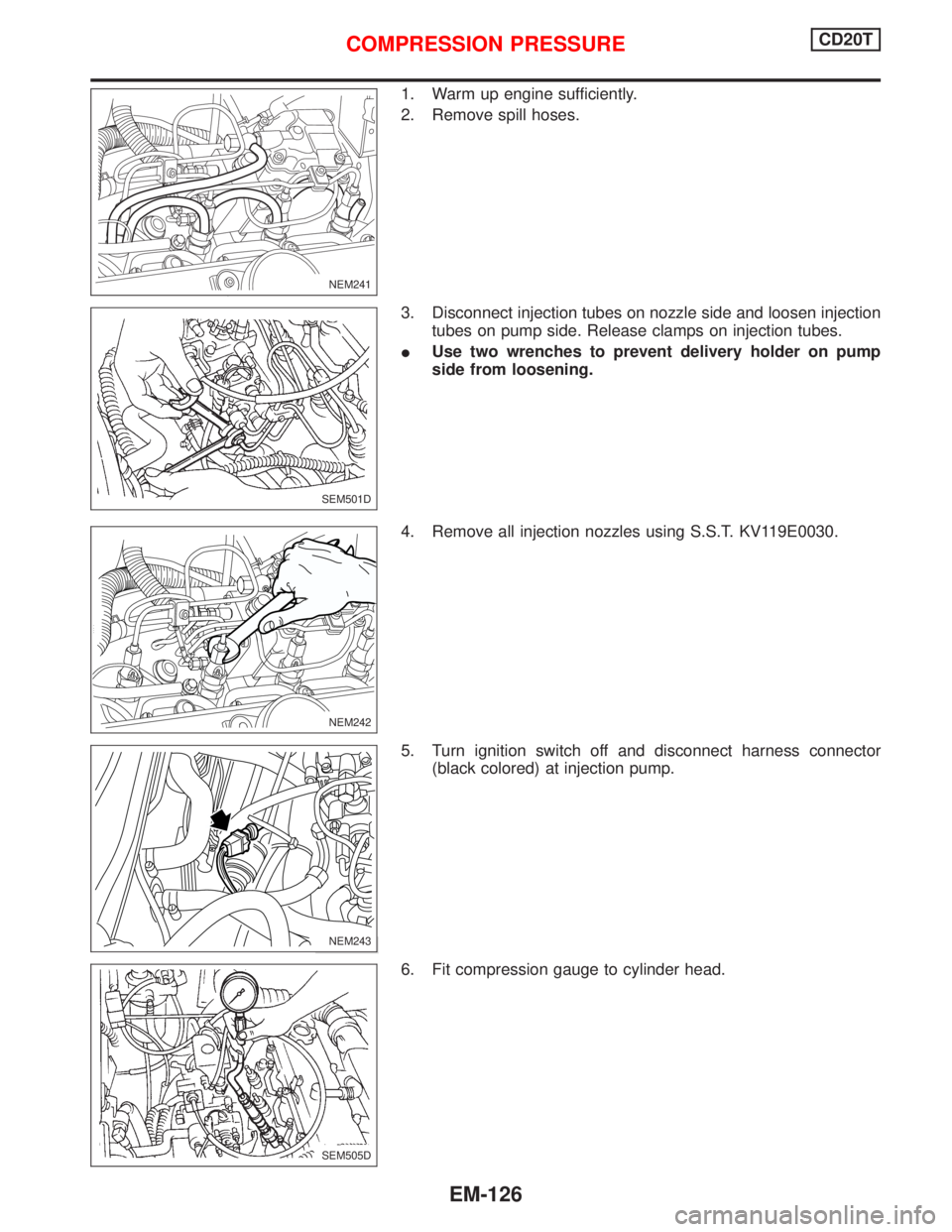

1. Warm up engine sufficiently.

2. Remove spill hoses.

3. Disconnect injection tubes on nozzle side and loosen injection

tubes on pump side. Release clamps on injection tubes.

IUse two wrenches to prevent delivery holder on pump

side from loosening.

4. Remove all injection nozzles using S.S.T. KV119E0030.

5. Turn ignition switch off and disconnect harness connector

(black colored) at injection pump.

6. Fit compression gauge to cylinder head.

NEM241

SEM501D

NEM242

NEM243

SEM505D

COMPRESSION PRESSURECD20T

EM-126

Page 1667 of 2267

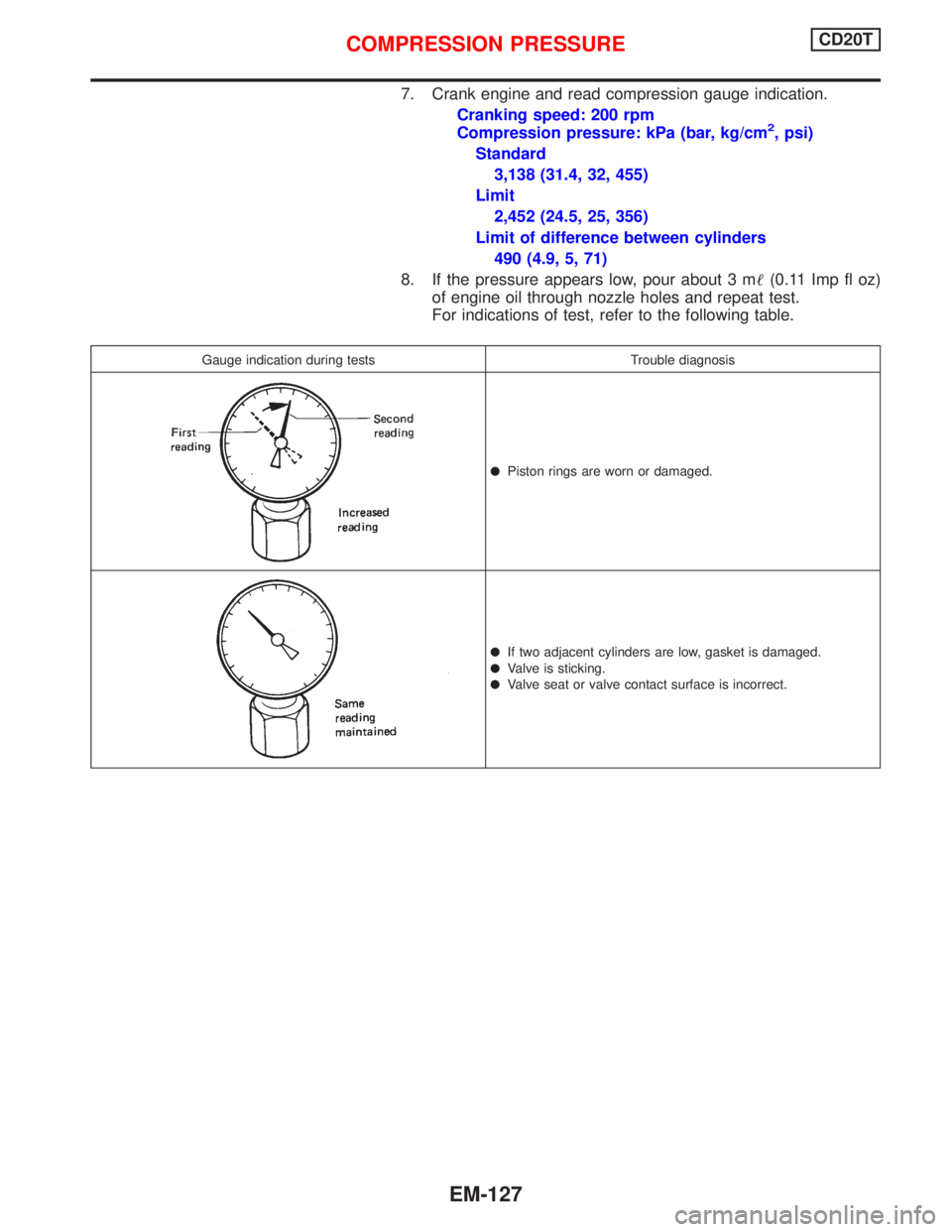

7. Crank engine and read compression gauge indication.

Cranking speed: 200 rpm

Compression pressure: kPa (bar, kg/cm

2, psi)

Standard

3,138 (31.4, 32, 455)

Limit

2,452 (24.5, 25, 356)

Limit of difference between cylinders

490 (4.9, 5, 71)

8. If the pressure appears low, pour about 3 m(0.11 Imp fl oz)

of engine oil through nozzle holes and repeat test.

For indications of test, refer to the following table.

Gauge indication during tests Trouble diagnosis

lPiston rings are worn or damaged.

lIf two adjacent cylinders are low, gasket is damaged.

lValve is sticking.

lValve seat or valve contact surface is incorrect.

COMPRESSION PRESSURECD20T

EM-127

Page 1668 of 2267

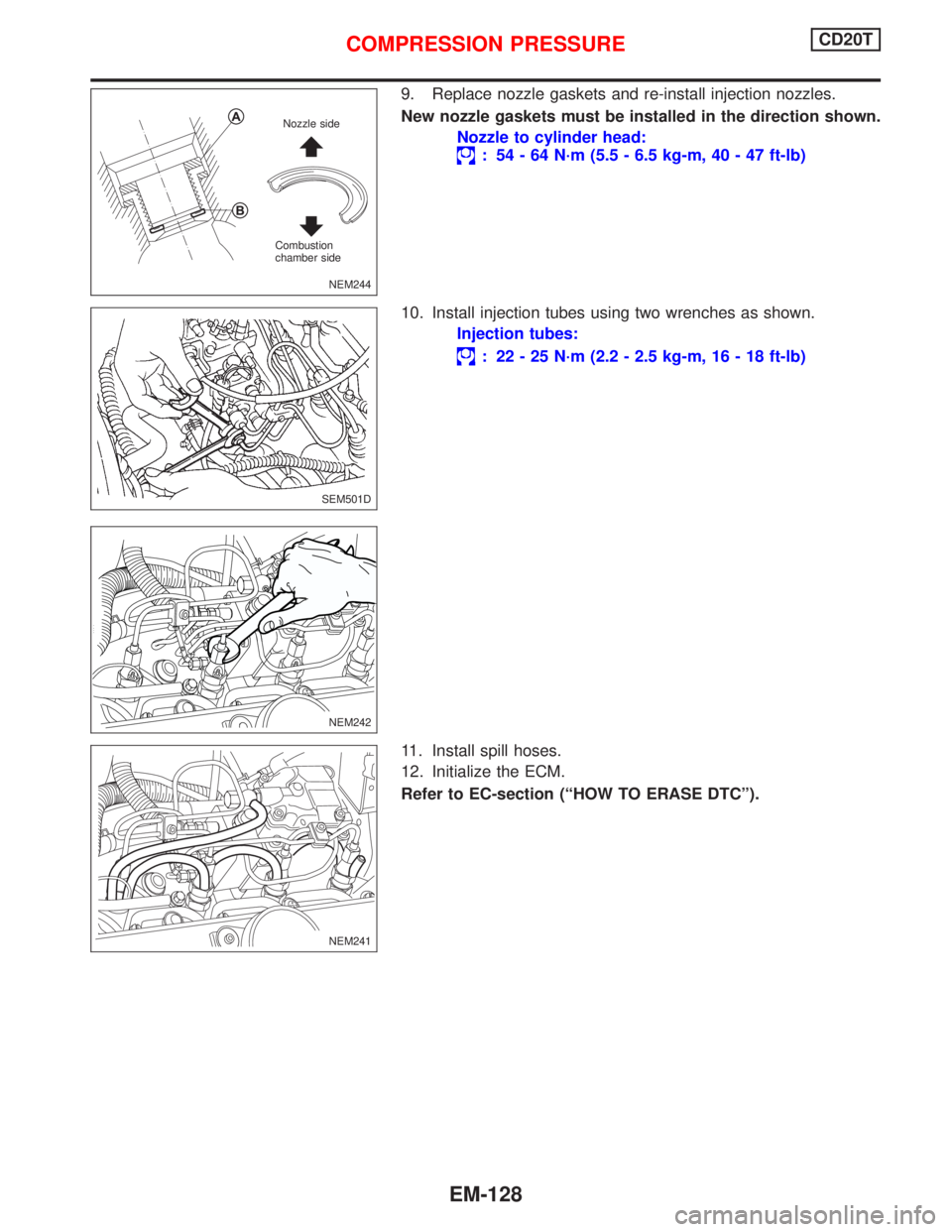

9. Replace nozzle gaskets and re-install injection nozzles.

New nozzle gaskets must be installed in the direction shown.

Nozzle to cylinder head:

: 54 - 64 N´m (5.5 - 6.5 kg-m, 40 - 47 ft-lb)

10. Install injection tubes using two wrenches as shown.

Injection tubes:

: 22 - 25 N´m (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

11. Install spill hoses.

12. Initialize the ECM.

Refer to EC-section (ªHOW TO ERASE DTCº).

NEM244 Nozzle side

Combustion

chamber side

SEM501D

NEM242

NEM241

COMPRESSION PRESSURECD20T

EM-128

Page 1669 of 2267

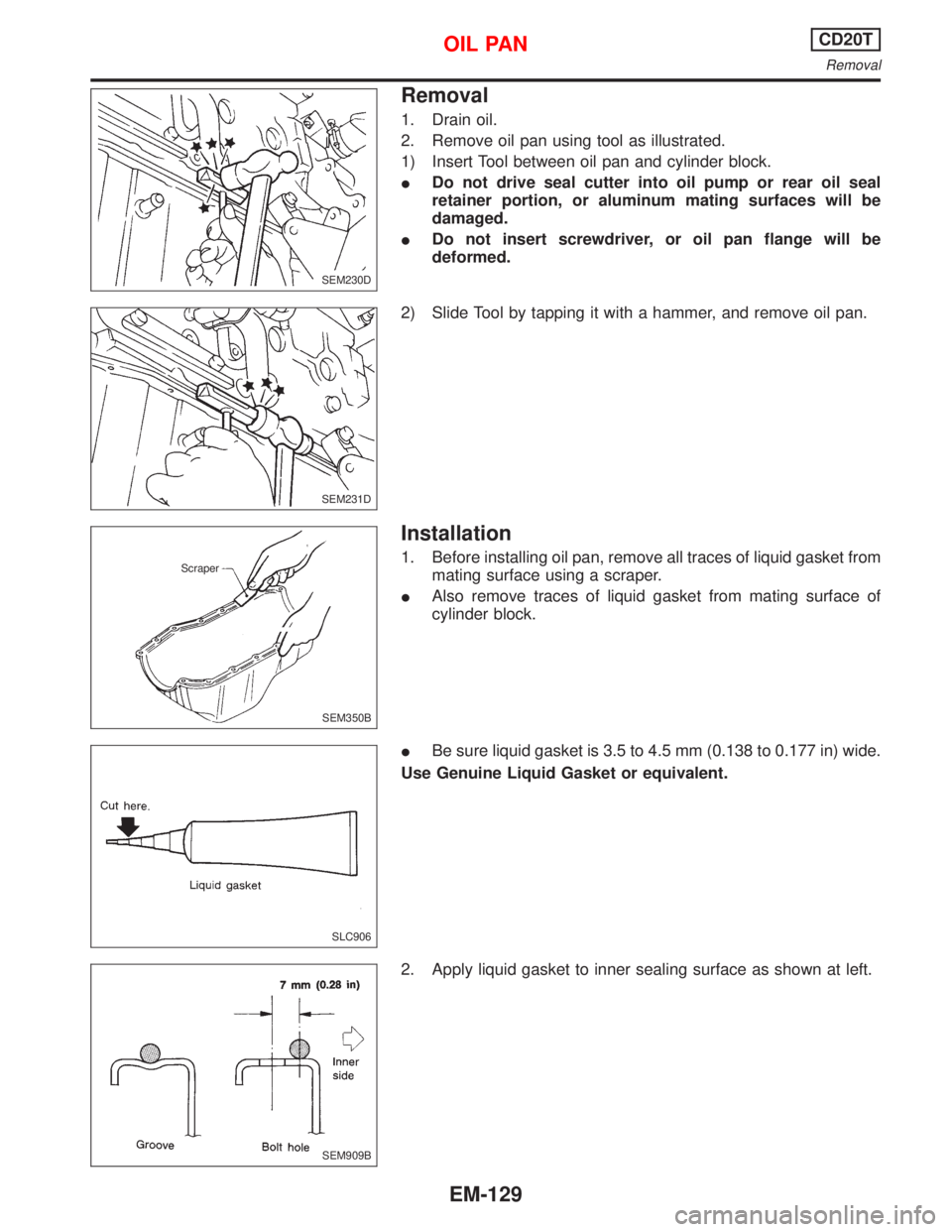

Removal

1. Drain oil.

2. Remove oil pan using tool as illustrated.

1) Insert Tool between oil pan and cylinder block.

IDo not drive seal cutter into oil pump or rear oil seal

retainer portion, or aluminum mating surfaces will be

damaged.

IDo not insert screwdriver, or oil pan flange will be

deformed.

2) Slide Tool by tapping it with a hammer, and remove oil pan.

Installation

1. Before installing oil pan, remove all traces of liquid gasket from

mating surface using a scraper.

IAlso remove traces of liquid gasket from mating surface of

cylinder block.

IBe sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in) wide.

Use Genuine Liquid Gasket or equivalent.

2. Apply liquid gasket to inner sealing surface as shown at left.

SEM230D

SEM231D

SEM350B Scraper

SLC906

SEM909B

OIL PANCD20T

Removal

EM-129

Page 1670 of 2267

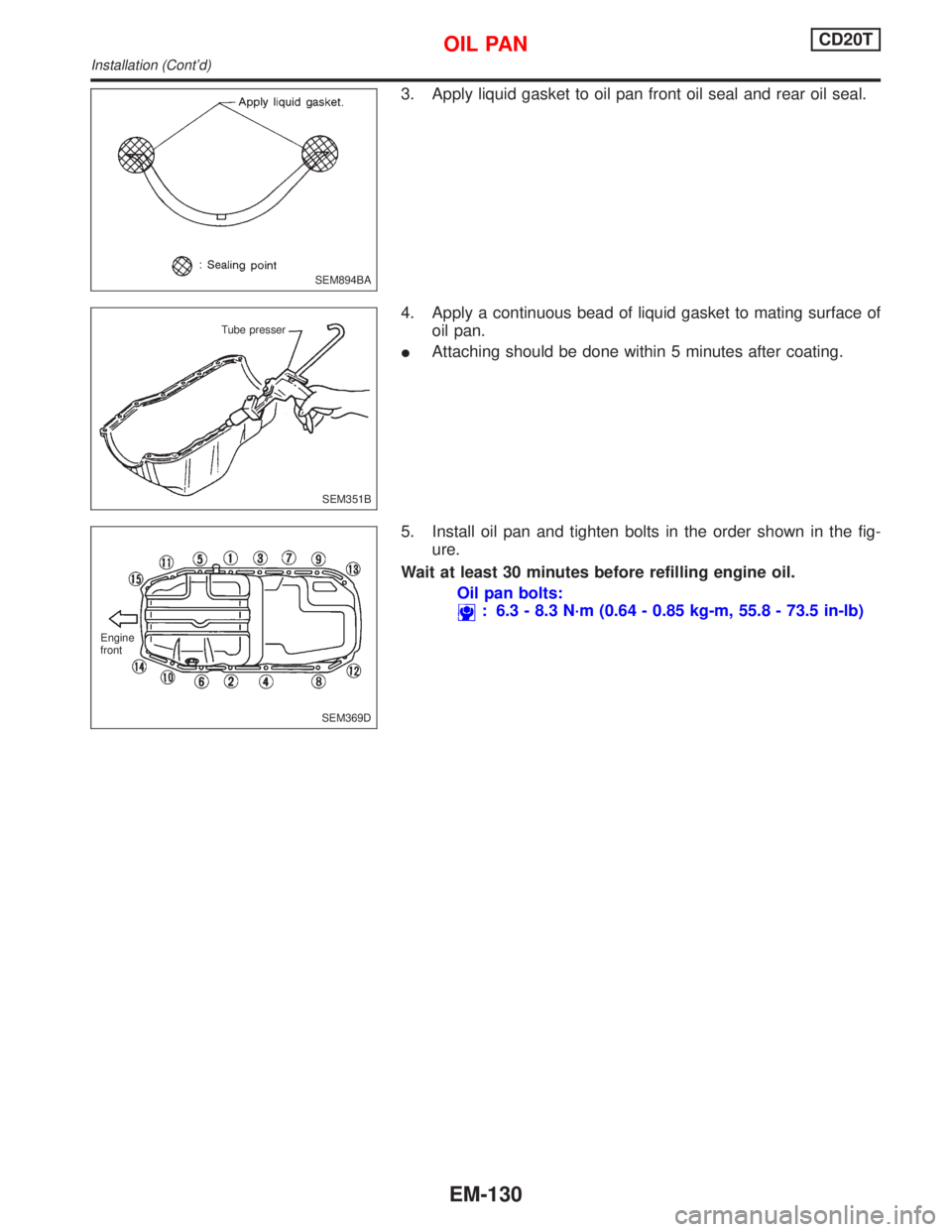

3. Apply liquid gasket to oil pan front oil seal and rear oil seal.

4. Apply a continuous bead of liquid gasket to mating surface of

oil pan.

IAttaching should be done within 5 minutes after coating.

5. Install oil pan and tighten bolts in the order shown in the fig-

ure.

Wait at least 30 minutes before refilling engine oil.

Oil pan bolts:

: 6.3 - 8.3 N´m (0.64 - 0.85 kg-m, 55.8 - 73.5 in-lb)

SEM894BA

SEM351B Tube presser

SEM369D Engine

front

OIL PANCD20T

Installation (Cont'd)

EM-130