NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1651 of 2267

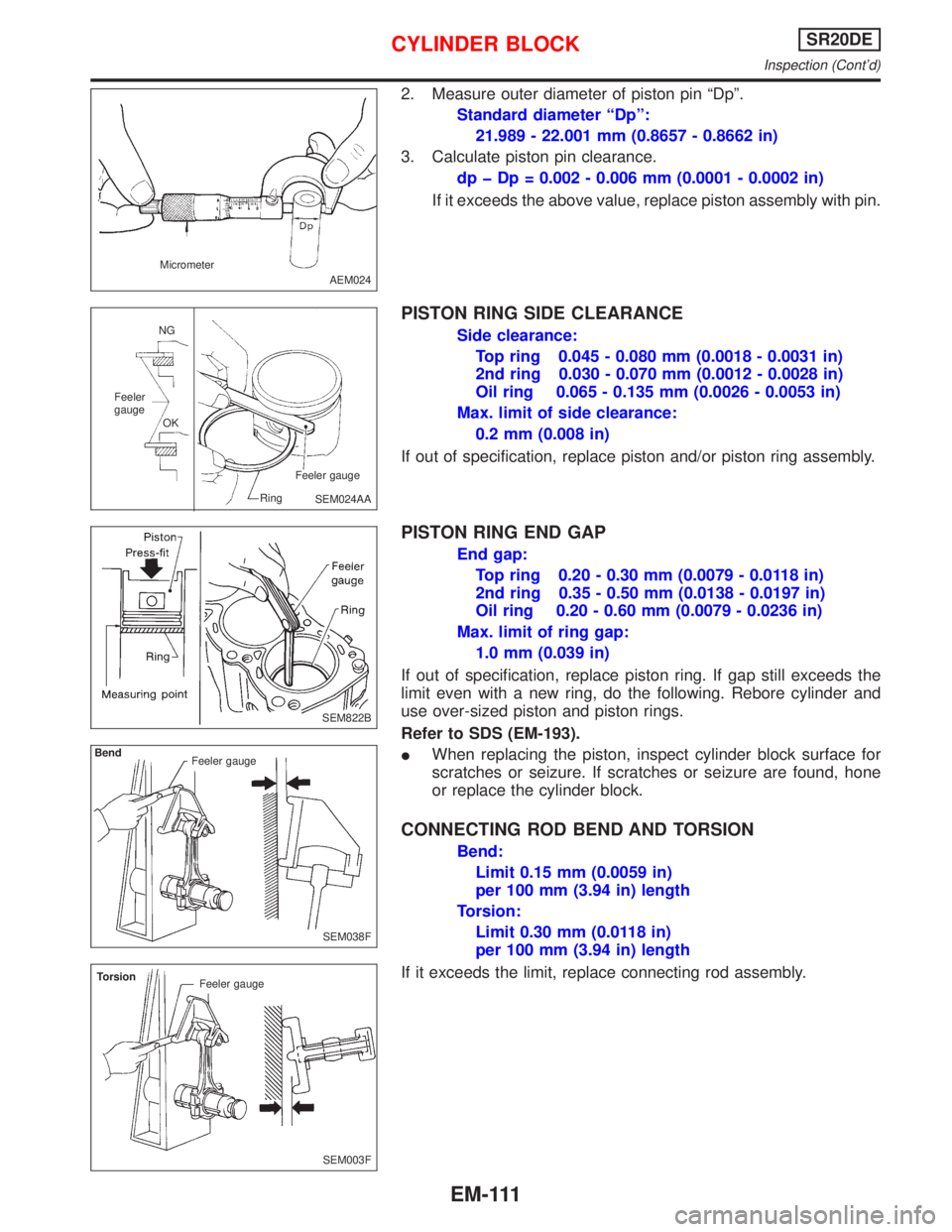

2. Measure outer diameter of piston pin ªDpº.

Standard diameter ªDpº:

21.989 - 22.001 mm (0.8657 - 0.8662 in)

3. Calculate piston pin clearance.

dp þ Dp = 0.002 - 0.006 mm (0.0001 - 0.0002 in)

If it exceeds the above value, replace piston assembly with pin.

PISTON RING SIDE CLEARANCE

Side clearance:

Top ring 0.045 - 0.080 mm (0.0018 - 0.0031 in)

2nd ring 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Oil ring 0.065 - 0.135 mm (0.0026 - 0.0053 in)

Max. limit of side clearance:

0.2 mm (0.008 in)

If out of specification, replace piston and/or piston ring assembly.

PISTON RING END GAP

End gap:

Top ring 0.20 - 0.30 mm (0.0079 - 0.0118 in)

2nd ring 0.35 - 0.50 mm (0.0138 - 0.0197 in)

Oil ring 0.20 - 0.60 mm (0.0079 - 0.0236 in)

Max. limit of ring gap:

1.0 mm (0.039 in)

If out of specification, replace piston ring. If gap still exceeds the

limit even with a new ring, do the following. Rebore cylinder and

use over-sized piston and piston rings.

Refer to SDS (EM-193).

IWhen replacing the piston, inspect cylinder block surface for

scratches or seizure. If scratches or seizure are found, hone

or replace the cylinder block.

CONNECTING ROD BEND AND TORSION

Bend:

Limit 0.15 mm (0.0059 in)

per 100 mm (3.94 in) length

Torsion:

Limit 0.30 mm (0.0118 in)

per 100 mm (3.94 in) length

If it exceeds the limit, replace connecting rod assembly.

AEM024 Micrometer

SEM024AA NG

OK Feeler

gauge

Feeler gauge

Ring

SEM822B

SEM038F Bend

Feeler gauge

SEM003F Torsion

Feeler gauge

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-111

Page 1652 of 2267

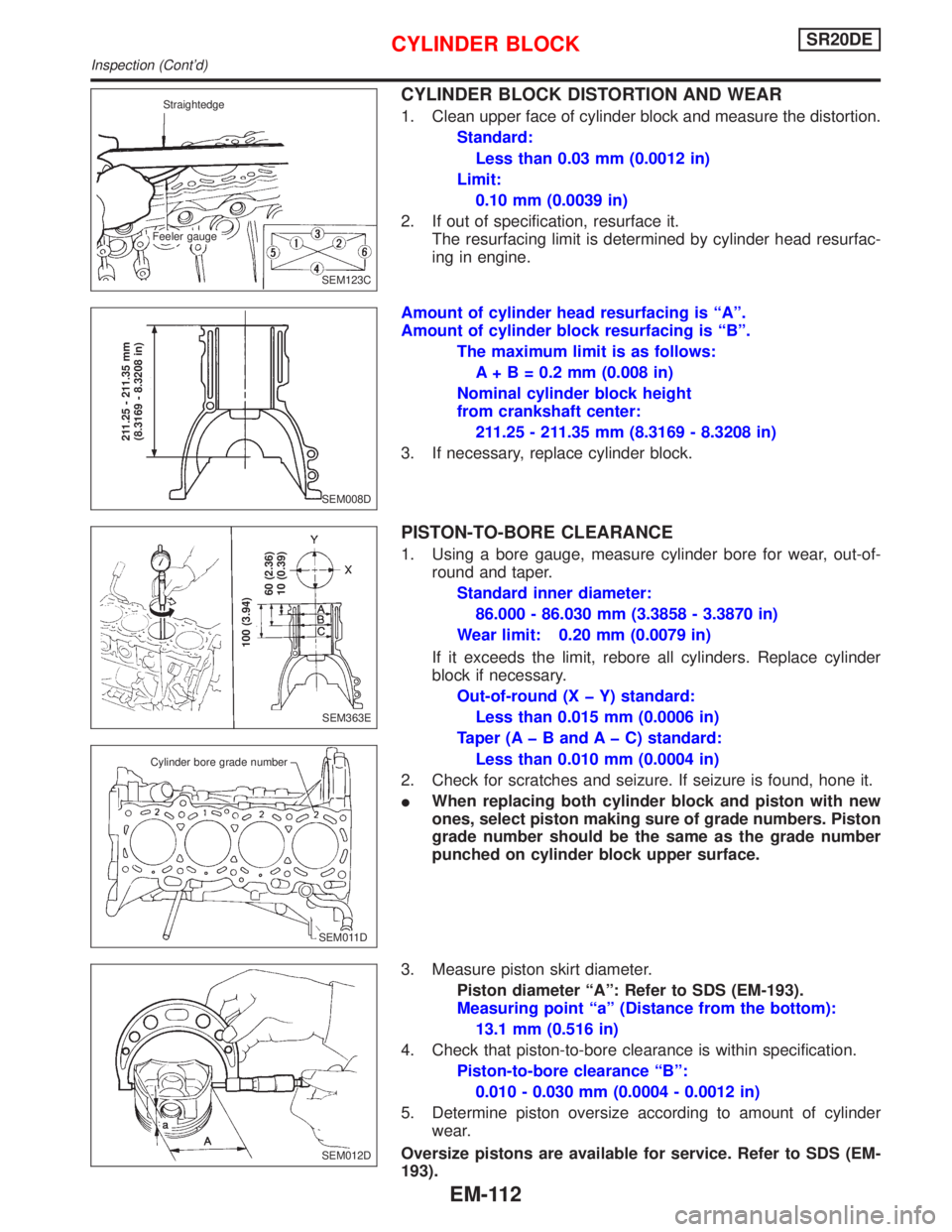

CYLINDER BLOCK DISTORTION AND WEAR

1. Clean upper face of cylinder block and measure the distortion.

Standard:

Less than 0.03 mm (0.0012 in)

Limit:

0.10 mm (0.0039 in)

2. If out of specification, resurface it.

The resurfacing limit is determined by cylinder head resurfac-

ing in engine.

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

Nominal cylinder block height

from crankshaft center:

211.25 - 211.35 mm (8.3169 - 8.3208 in)

3. If necessary, replace cylinder block.

PISTON-TO-BORE CLEARANCE

1. Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper.

Standard inner diameter:

86.000 - 86.030 mm (3.3858 - 3.3870 in)

Wear limit: 0.20 mm (0.0079 in)

If it exceeds the limit, rebore all cylinders. Replace cylinder

block if necessary.

Out-of-round (X þ Y) standard:

Less than 0.015 mm (0.0006 in)

Taper (A þ B and A þ C) standard:

Less than 0.010 mm (0.0004 in)

2. Check for scratches and seizure. If seizure is found, hone it.

IWhen replacing both cylinder block and piston with new

ones, select piston making sure of grade numbers. Piston

grade number should be the same as the grade number

punched on cylinder block upper surface.

3. Measure piston skirt diameter.

Piston diameter ªAº: Refer to SDS (EM-193).

Measuring point ªaº (Distance from the bottom):

13.1 mm (0.516 in)

4. Check that piston-to-bore clearance is within specification.

Piston-to-bore clearance ªBº:

0.010 - 0.030 mm (0.0004 - 0.0012 in)

5. Determine piston oversize according to amount of cylinder

wear.

Oversize pistons are available for service. Refer to SDS (EM-

193).

SEM123C Straightedge

Feeler gauge

SEM008D

211.25 - 211.35 mm

(8.3169 - 8.3208 in)

SEM363E

100 (3.94)

60 (2.36)

10 (0.39)

.SEM011D

Cylinder bore grade number

SEM012D

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-112

Page 1653 of 2267

6. Cylinder bore size is determined by adding piston-to-bore

clearance to piston diameter ªAº.

Rebored size calculation:

D= A+BþC

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston-to-bore clearance

C: Honing allowance 0.02 mm (0.0008 in)

7. Install main bearing caps, and tighten to the specified torque.

IOtherwise, cylinder bores may be distorted in final assem-

bly.

8. Cut cylinder bores.

IWhen any cylinder needs boring, all other cylinders must

also be bored.

IDo not cut too much out of cylinder bore at a time. Cut

only 0.05 mm (0.0020 in) or so in diameter at a time.

9. Hone cylinders to obtain specified piston-to-bore clearance.

10. Measure finished cylinder bore for out-of-round and taper.

IMeasurement should be done after cylinder bore cools

down.

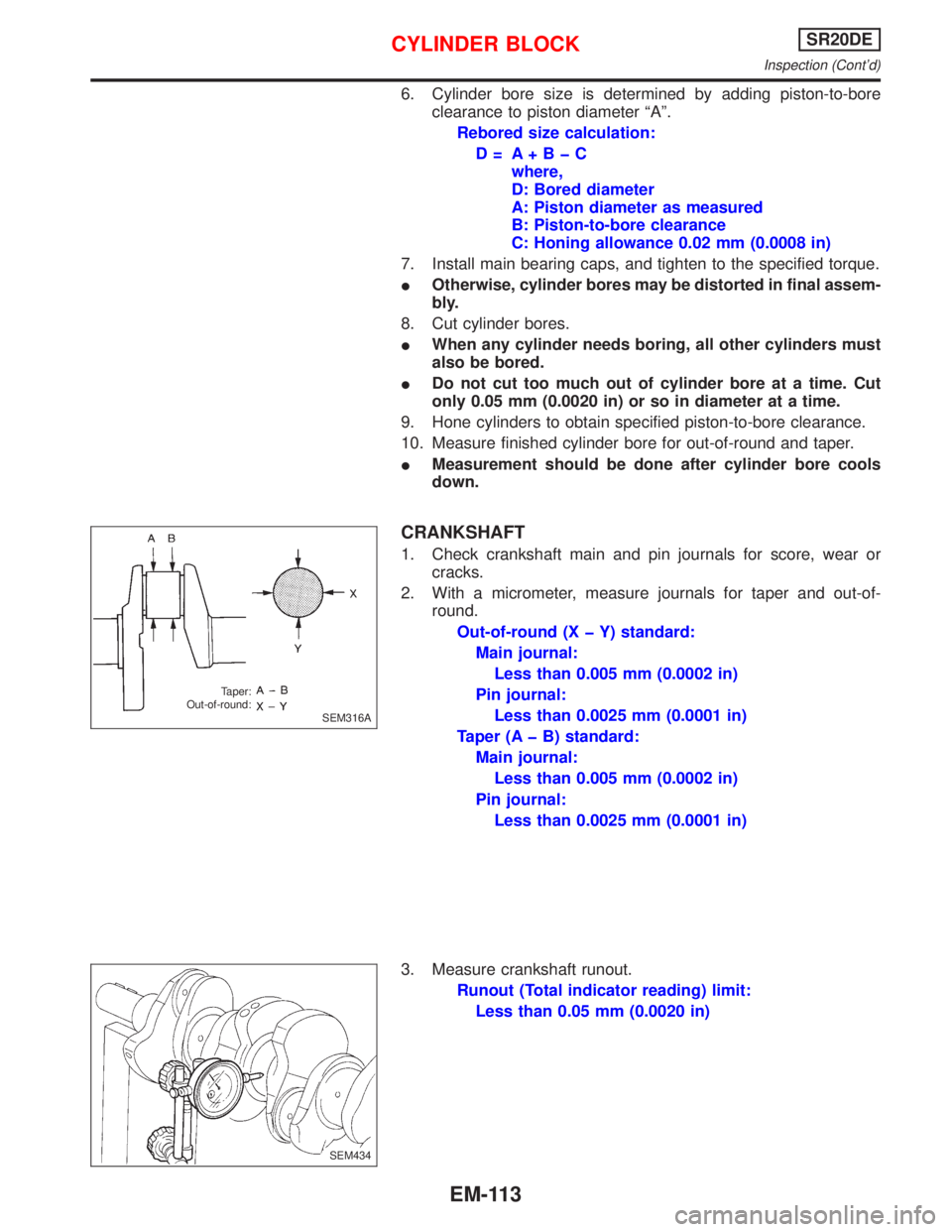

CRANKSHAFT

1. Check crankshaft main and pin journals for score, wear or

cracks.

2. With a micrometer, measure journals for taper and out-of-

round.

Out-of-round (X þ Y) standard:

Main journal:

Less than 0.005 mm (0.0002 in)

Pin journal:

Less than 0.0025 mm (0.0001 in)

Taper (A þ B) standard:

Main journal:

Less than 0.005 mm (0.0002 in)

Pin journal:

Less than 0.0025 mm (0.0001 in)

3. Measure crankshaft runout.

Runout (Total indicator reading) limit:

Less than 0.05 mm (0.0020 in)

SEM316A Taper:

Out-of-round:

.SEM434

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-113

Page 1654 of 2267

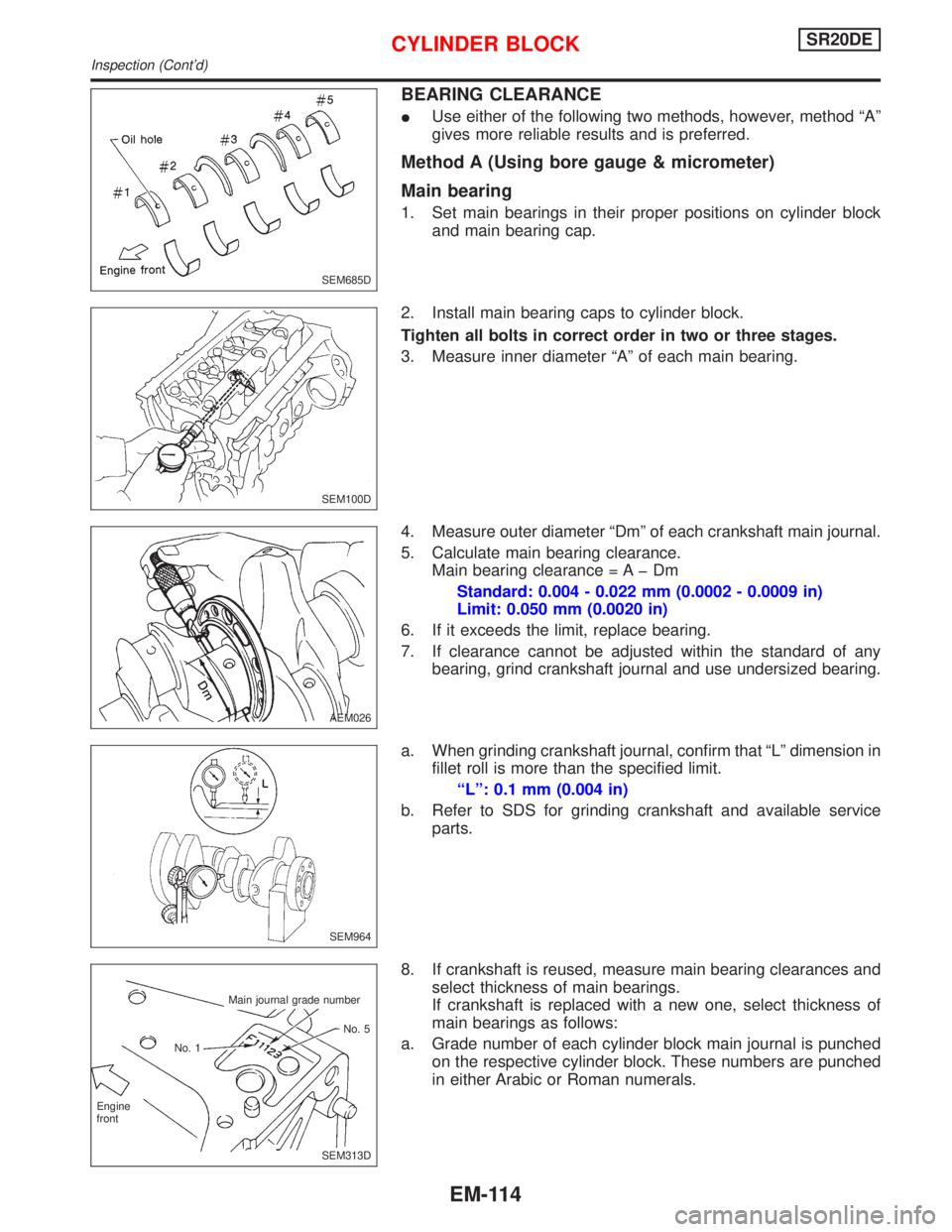

BEARING CLEARANCE

IUse either of the following two methods, however, method ªAº

gives more reliable results and is preferred.

Method A (Using bore gauge & micrometer)

Main bearing

1. Set main bearings in their proper positions on cylinder block

and main bearing cap.

2. Install main bearing caps to cylinder block.

Tighten all bolts in correct order in two or three stages.

3. Measure inner diameter ªAº of each main bearing.

4. Measure outer diameter ªDmº of each crankshaft main journal.

5. Calculate main bearing clearance.

Main bearing clearance = A þ Dm

Standard: 0.004 - 0.022 mm (0.0002 - 0.0009 in)

Limit: 0.050 mm (0.0020 in)

6. If it exceeds the limit, replace bearing.

7. If clearance cannot be adjusted within the standard of any

bearing, grind crankshaft journal and use undersized bearing.

a. When grinding crankshaft journal, confirm that ªLº dimension in

fillet roll is more than the specified limit.

ªLº: 0.1 mm (0.004 in)

b. Refer to SDS for grinding crankshaft and available service

parts.

8. If crankshaft is reused, measure main bearing clearances and

select thickness of main bearings.

If crankshaft is replaced with a new one, select thickness of

main bearings as follows:

a. Grade number of each cylinder block main journal is punched

on the respective cylinder block. These numbers are punched

in either Arabic or Roman numerals.

SEM685D

SEM100D

AEM026

SEM964

SEM313D Main journal grade number

No. 1No. 5

Engine

front

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-114

Page 1655 of 2267

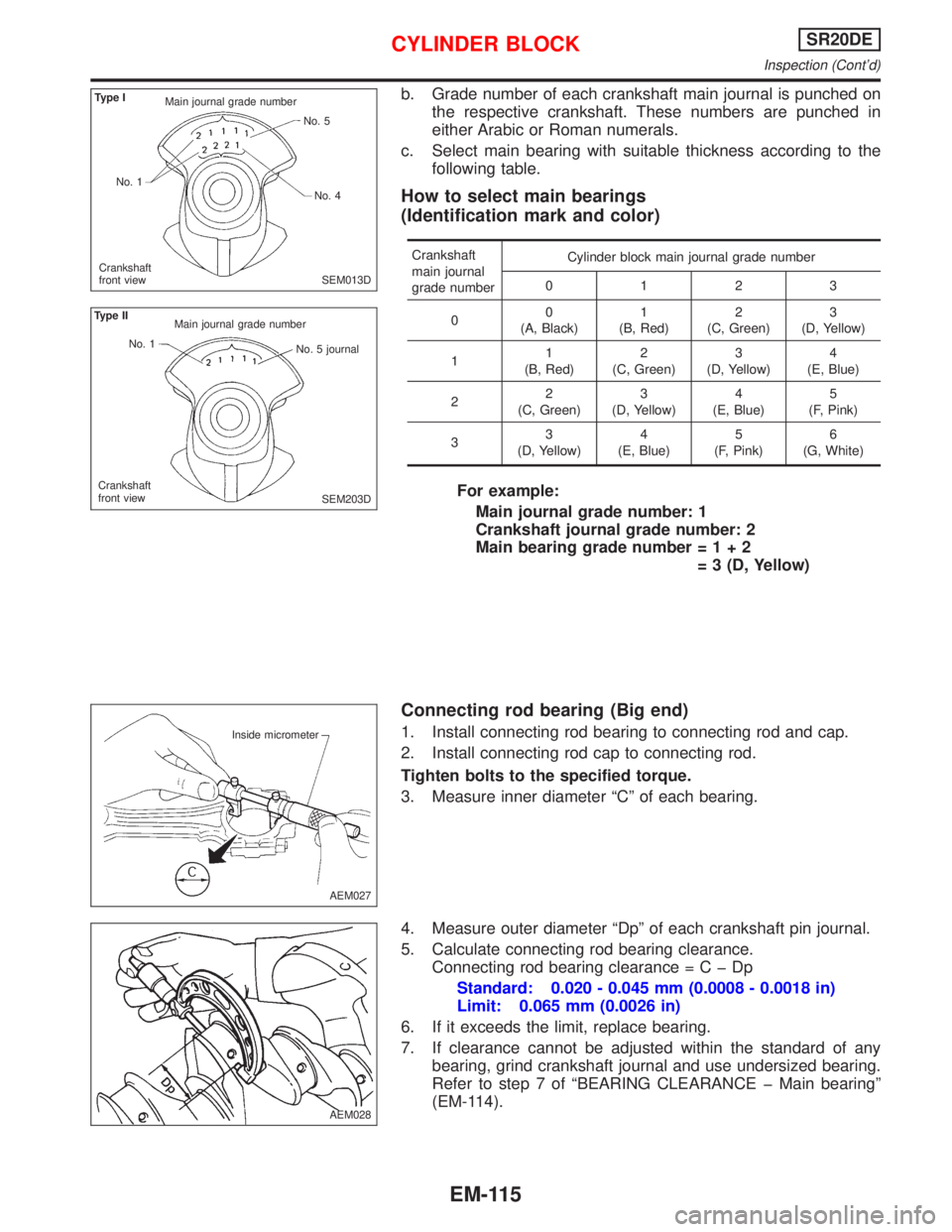

b. Grade number of each crankshaft main journal is punched on

the respective crankshaft. These numbers are punched in

either Arabic or Roman numerals.

c. Select main bearing with suitable thickness according to the

following table.

How to select main bearings

(Identification mark and color)

Crankshaft

main journal

grade numberCylinder block main journal grade number

0123

00

(A, Black)1

(B, Red)2

(C, Green)3

(D, Yellow)

11

(B, Red)2

(C, Green)3

(D, Yellow)4

(E, Blue)

22

(C, Green)3

(D, Yellow)4

(E, Blue)5

(F, Pink)

33

(D, Yellow)4

(E, Blue)5

(F, Pink)6

(G, White)

For example:

Main journal grade number: 1

Crankshaft journal grade number: 2

Main bearing grade number=1+2

= 3 (D, Yellow)

Connecting rod bearing (Big end)

1. Install connecting rod bearing to connecting rod and cap.

2. Install connecting rod cap to connecting rod.

Tighten bolts to the specified torque.

3. Measure inner diameter ªCº of each bearing.

4. Measure outer diameter ªDpº of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance=CþDp

Standard: 0.020 - 0.045 mm (0.0008 - 0.0018 in)

Limit: 0.065 mm (0.0026 in)

6. If it exceeds the limit, replace bearing.

7. If clearance cannot be adjusted within the standard of any

bearing, grind crankshaft journal and use undersized bearing.

Refer to step 7 of ªBEARING CLEARANCE þ Main bearingº

(EM-114).

SEM013D Type I

Main journal grade number

No. 5

No. 4 No. 1

Crankshaft

front view

SEM203D Type II

Main journal grade number

No. 1

No. 5 journal

Crankshaft

front view

AEM027 Inside micrometer

AEM028

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-115

Page 1656 of 2267

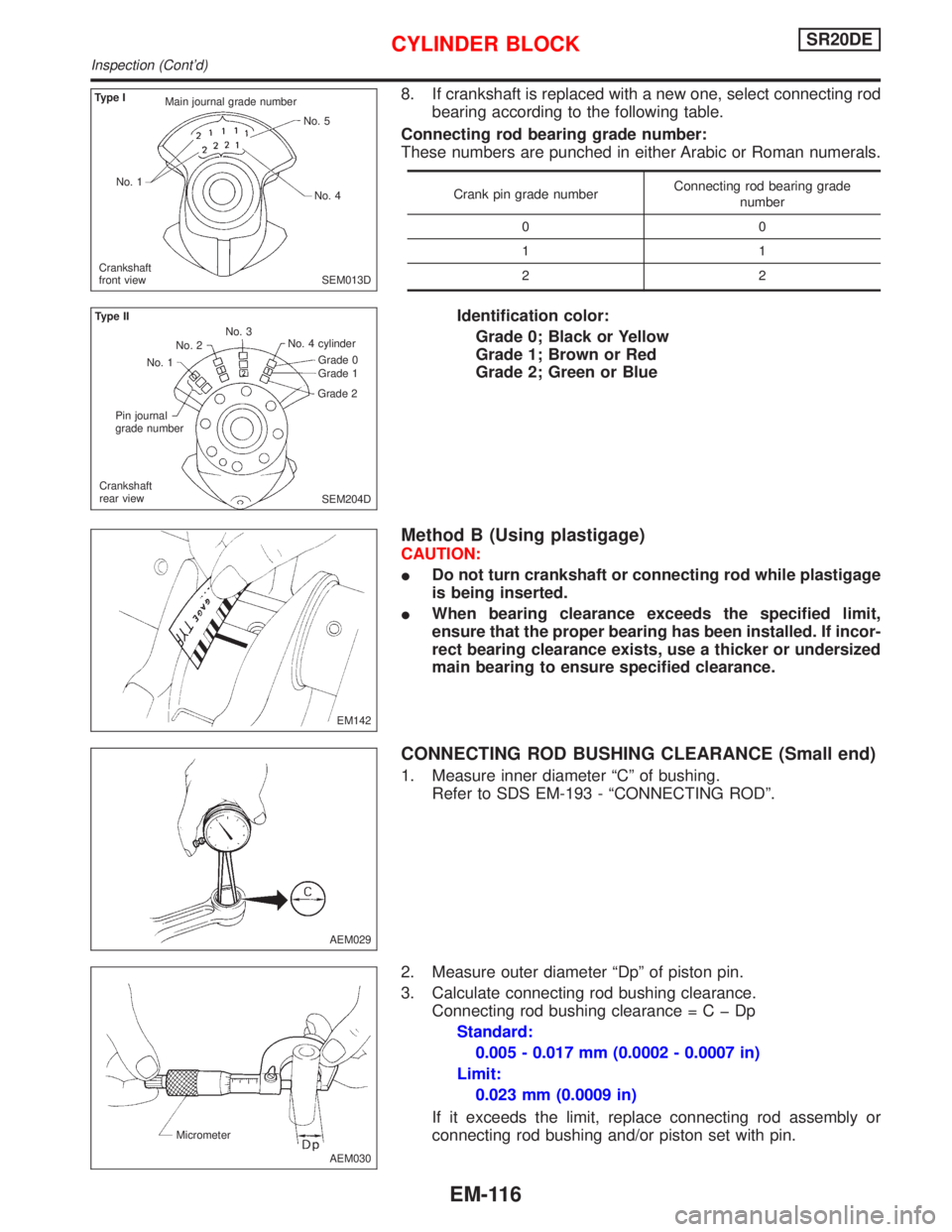

8. If crankshaft is replaced with a new one, select connecting rod

bearing according to the following table.

Connecting rod bearing grade number:

These numbers are punched in either Arabic or Roman numerals.

Crank pin grade numberConnecting rod bearing grade

number

00

11

22

Identification color:

Grade 0; Black or Yellow

Grade 1; Brown or Red

Grade 2; Green or Blue

Method B (Using plastigage)

CAUTION:

IDo not turn crankshaft or connecting rod while plastigage

is being inserted.

IWhen bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. If incor-

rect bearing clearance exists, use a thicker or undersized

main bearing to ensure specified clearance.

CONNECTING ROD BUSHING CLEARANCE (Small end)

1. Measure inner diameter ªCº of bushing.

Refer to SDS EM-193 - ªCONNECTING RODº.

2. Measure outer diameter ªDpº of piston pin.

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

Limit:

0.023 mm (0.0009 in)

If it exceeds the limit, replace connecting rod assembly or

connecting rod bushing and/or piston set with pin.

SEM013D Type I

Main journal grade number

No. 5

No. 4 No. 1

Crankshaft

front view

SEM204D Type II

No. 1No. 2No. 3

No. 4 cylinder

Grade 0

Grade 1

Grade 2

Pin journal

grade number

Crankshaft

rear view

EM142

AEM029

AEM030 Micrometer

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-116

Page 1657 of 2267

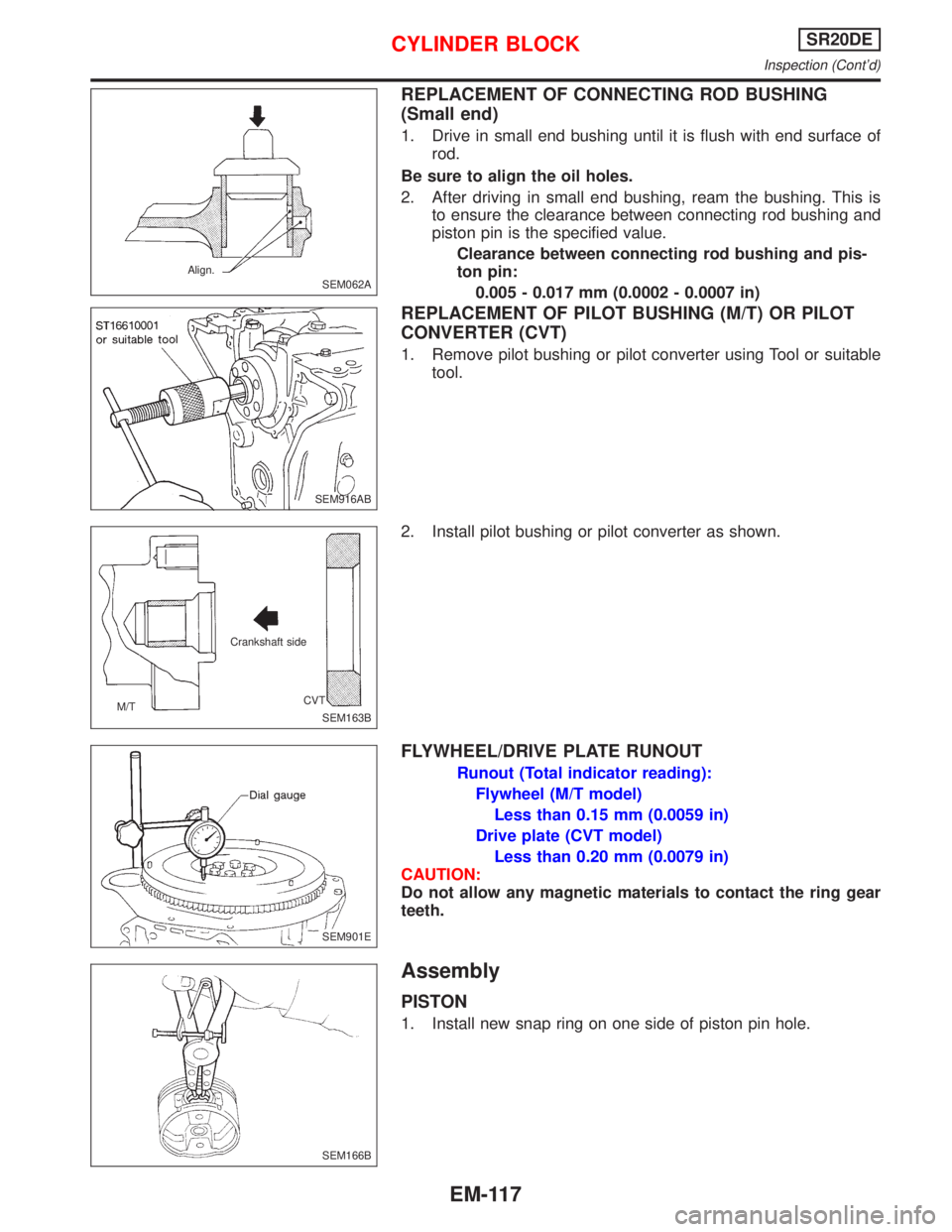

REPLACEMENT OF CONNECTING ROD BUSHING

(Small end)

1. Drive in small end bushing until it is flush with end surface of

rod.

Be sure to align the oil holes.

2. After driving in small end bushing, ream the bushing. This is

to ensure the clearance between connecting rod bushing and

piston pin is the specified value.

Clearance between connecting rod bushing and pis-

ton pin:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

REPLACEMENT OF PILOT BUSHING (M/T) OR PILOT

CONVERTER (CVT)

1. Remove pilot bushing or pilot converter using Tool or suitable

tool.

2. Install pilot bushing or pilot converter as shown.

FLYWHEEL/DRIVE PLATE RUNOUT

Runout (Total indicator reading):

Flywheel (M/T model)

Less than 0.15 mm (0.0059 in)

Drive plate (CVT model)

Less than 0.20 mm (0.0079 in)

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Assembly

PISTON

1. Install new snap ring on one side of piston pin hole.

SEM062A Align.

SEM916AB

SEM163B M/TCrankshaft side

CVT

.SEM901E

SEM166B

CYLINDER BLOCKSR20DE

Inspection (Cont'd)

EM-117

Page 1658 of 2267

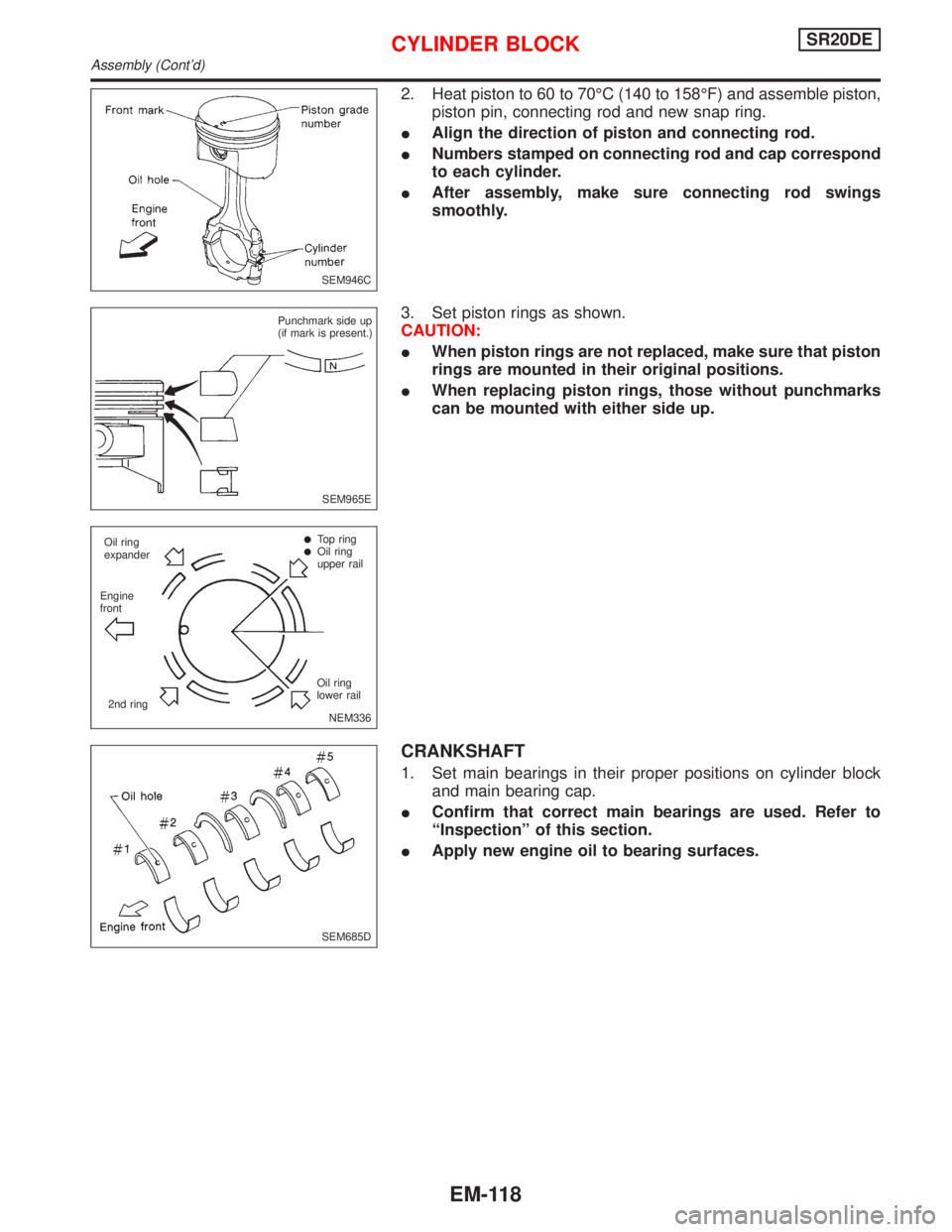

2. Heat piston to 60 to 70ÉC (140 to 158ÉF) and assemble piston,

piston pin, connecting rod and new snap ring.

IAlign the direction of piston and connecting rod.

INumbers stamped on connecting rod and cap correspond

to each cylinder.

IAfter assembly, make sure connecting rod swings

smoothly.

3. Set piston rings as shown.

CAUTION:

IWhen piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

IWhen replacing piston rings, those without punchmarks

can be mounted with either side up.

CRANKSHAFT

1. Set main bearings in their proper positions on cylinder block

and main bearing cap.

IConfirm that correct main bearings are used. Refer to

ªInspectionº of this section.

IApply new engine oil to bearing surfaces.

SEM946C

SEM965E Punchmark side up

(if mark is present.)

NEM336 Oil ring

expander

Engine

front

2nd ring

lTop ringlOil ring

upper rail

Oil ring

lower rail

SEM685D

CYLINDER BLOCKSR20DE

Assembly (Cont'd)

EM-118

Page 1659 of 2267

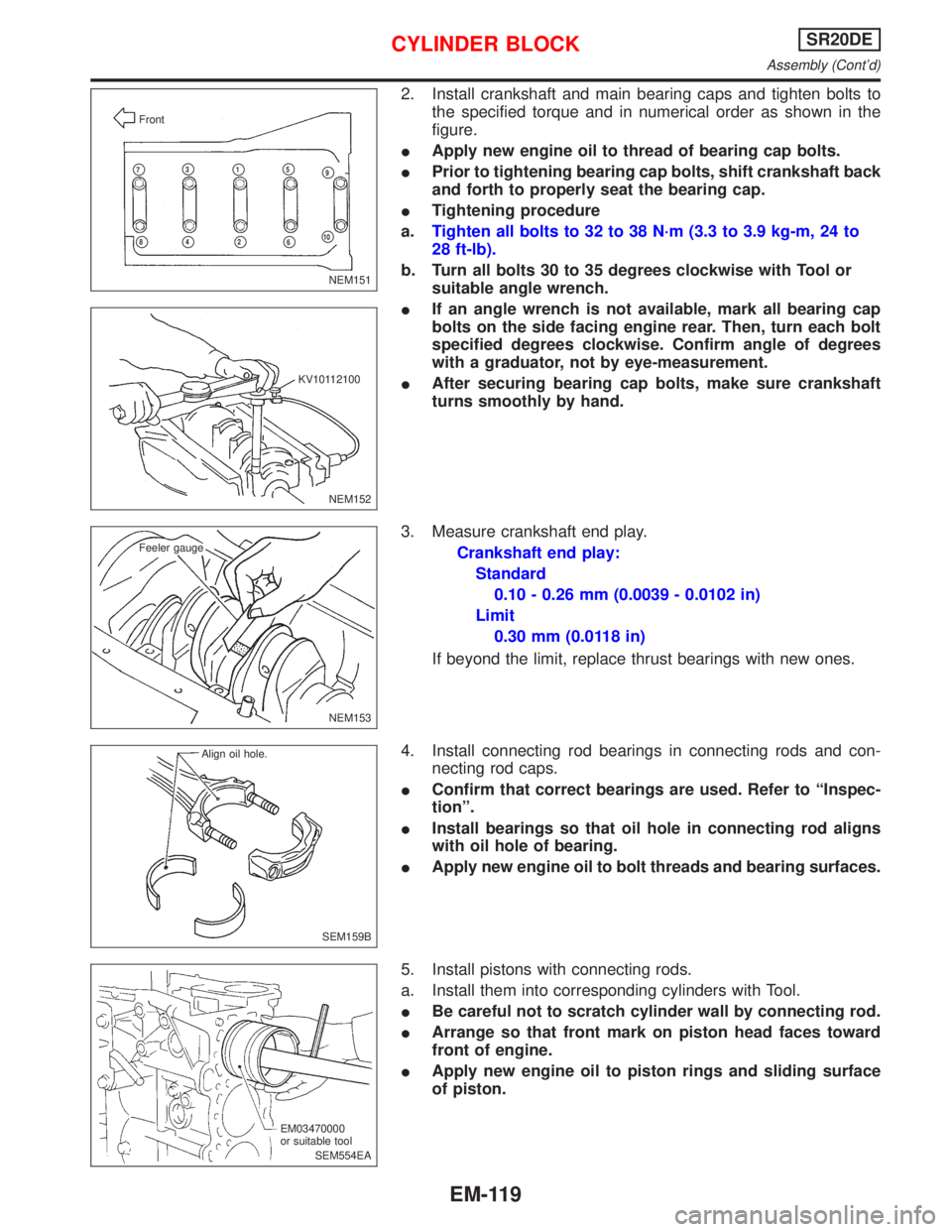

2. Install crankshaft and main bearing caps and tighten bolts to

the specified torque and in numerical order as shown in the

figure.

IApply new engine oil to thread of bearing cap bolts.

IPrior to tightening bearing cap bolts, shift crankshaft back

and forth to properly seat the bearing cap.

ITightening procedure

a.Tighten all bolts to 32 to 38 N´m (3.3 to 3.9 kg-m, 24 to

28 ft-lb).

b. Turn all bolts 30 to 35 degrees clockwise with Tool or

suitable angle wrench.

IIf an angle wrench is not available, mark all bearing cap

bolts on the side facing engine rear. Then, turn each bolt

specified degrees clockwise. Confirm angle of degrees

with a graduator, not by eye-measurement.

IAfter securing bearing cap bolts, make sure crankshaft

turns smoothly by hand.

3. Measure crankshaft end play.

Crankshaft end play:

Standard

0.10 - 0.26 mm (0.0039 - 0.0102 in)

Limit

0.30 mm (0.0118 in)

If beyond the limit, replace thrust bearings with new ones.

4. Install connecting rod bearings in connecting rods and con-

necting rod caps.

IConfirm that correct bearings are used. Refer to ªInspec-

tionº.

IInstall bearings so that oil hole in connecting rod aligns

with oil hole of bearing.

IApply new engine oil to bolt threads and bearing surfaces.

5. Install pistons with connecting rods.

a. Install them into corresponding cylinders with Tool.

IBe careful not to scratch cylinder wall by connecting rod.

IArrange so that front mark on piston head faces toward

front of engine.

IApply new engine oil to piston rings and sliding surface

of piston.

NEM151 Front

p7p3p1p5p9

p8p4p2p6p10

NEM152 KV10112100

NEM153 Feeler gauge

SEM159B Align oil hole.

SEM554EA EM03470000

or suitable tool

CYLINDER BLOCKSR20DE

Assembly (Cont'd)

EM-119

Page 1660 of 2267

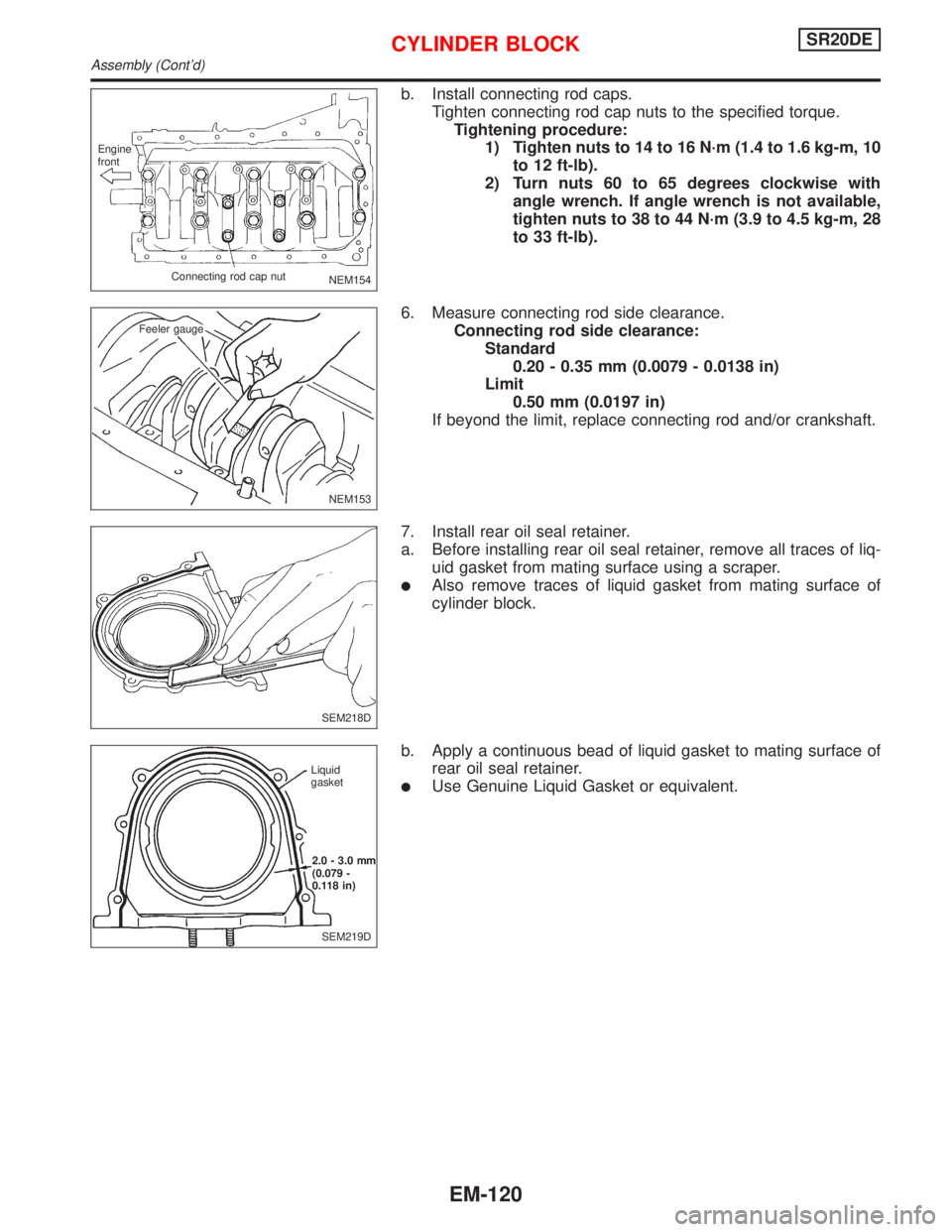

b. Install connecting rod caps.

Tighten connecting rod cap nuts to the specified torque.

Tightening procedure:

1) Tighten nuts to 14 to 16 N´m (1.4 to 1.6 kg-m, 10

to 12 ft-lb).

2) Turn nuts 60 to 65 degrees clockwise with

angle wrench. If angle wrench is not available,

tighten nuts to 38 to 44 N´m (3.9 to 4.5 kg-m, 28

to 33 ft-lb).

6. Measure connecting rod side clearance.

Connecting rod side clearance:

Standard

0.20 - 0.35 mm (0.0079 - 0.0138 in)

Limit

0.50 mm (0.0197 in)

If beyond the limit, replace connecting rod and/or crankshaft.

7. Install rear oil seal retainer.

a. Before installing rear oil seal retainer, remove all traces of liq-

uid gasket from mating surface using a scraper.

lAlso remove traces of liquid gasket from mating surface of

cylinder block.

b. Apply a continuous bead of liquid gasket to mating surface of

rear oil seal retainer.

lUse Genuine Liquid Gasket or equivalent.

NEM154 Engine

front

Connecting rod cap nut

NEM153 Feeler gauge

SEM218D

SEM219D Liquid

gasket

2.0 - 3.0 mm

(0.079 -

0.118 in)

CYLINDER BLOCKSR20DE

Assembly (Cont'd)

EM-120