NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1671 of 2267

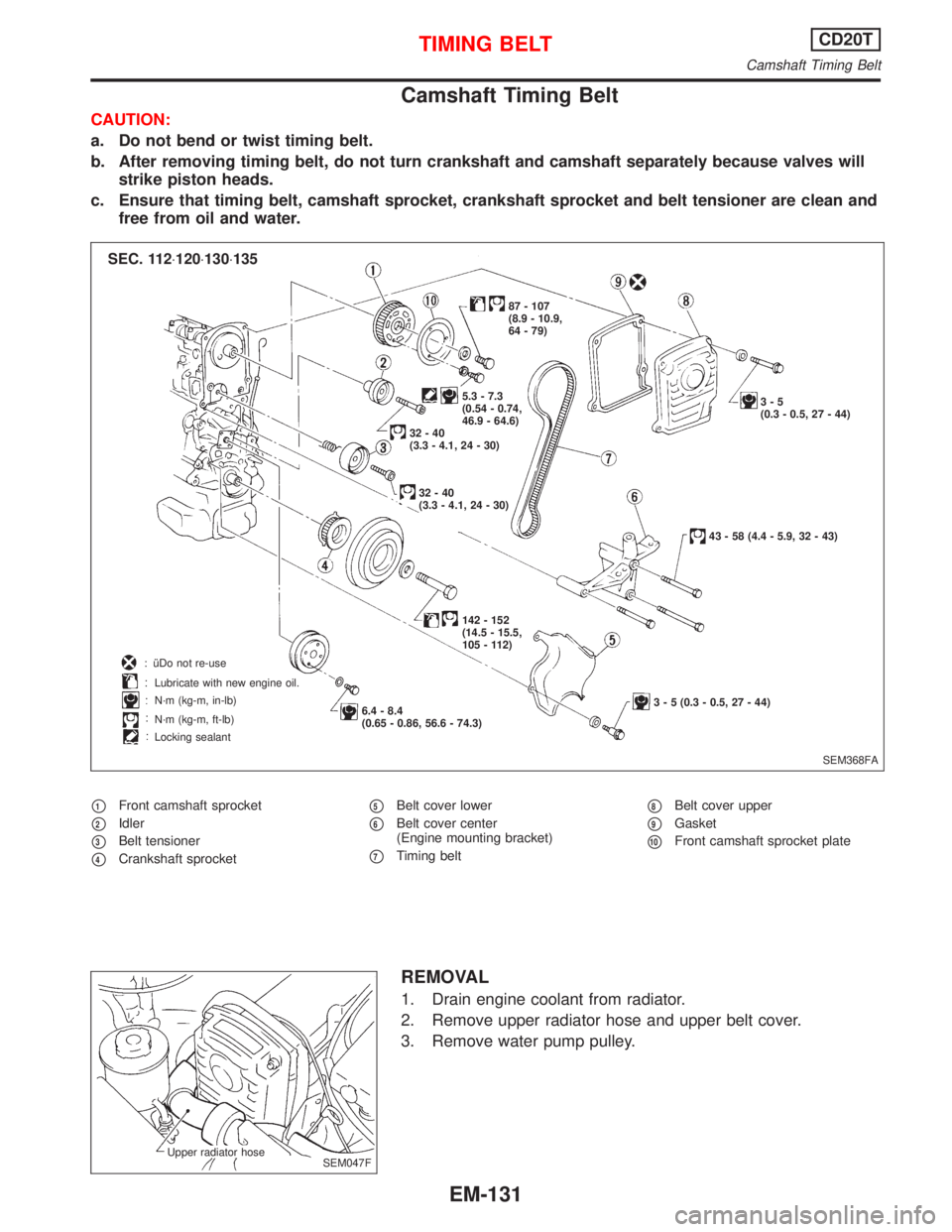

Camshaft Timing Belt

CAUTION:

a. Do not bend or twist timing belt.

b. After removing timing belt, do not turn crankshaft and camshaft separately because valves will

strike piston heads.

c. Ensure that timing belt, camshaft sprocket, crankshaft sprocket and belt tensioner are clean and

free from oil and water.

p1Front camshaft sprocket

p2Idler

p3Belt tensioner

p4Crankshaft sprocket

p5Belt cover lower

p6Belt cover center

(Engine mounting bracket)

p7Timing belt

p8Belt cover upper

p9Gasket

p10Front camshaft sprocket plate

REMOVAL

1. Drain engine coolant from radiator.

2. Remove upper radiator hose and upper belt cover.

3. Remove water pump pulley.

SEM368FA 6.4 - 8.4

(0.65 - 0.86, 56.6 - 74.3) Lubricate with new engine oil.

N´m (kg-m, in-lb)

N´m (kg-m, ft-lb)

Locking sealant5.3 - 7.3

(0.54 - 0.74,

46.9 - 64.6)3-5

(0.3 - 0.5, 27 - 44) 87 - 107

(8.9 - 10.9,

64 - 79)

32-40

(3.3 - 4.1, 24 - 30)

32-40

(3.3 - 4.1, 24 - 30)

142 - 152

(14.5 - 15.5,

105 - 112)

3 - 5 (0.3 - 0.5, 27 - 44)43 - 58 (4.4 - 5.9, 32 - 43)

SEC. 112×120×130×135

: îDo not re-use

SEM047F Upper radiator hose

TIMING BELTCD20T

Camshaft Timing Belt

EM-131

Page 1672 of 2267

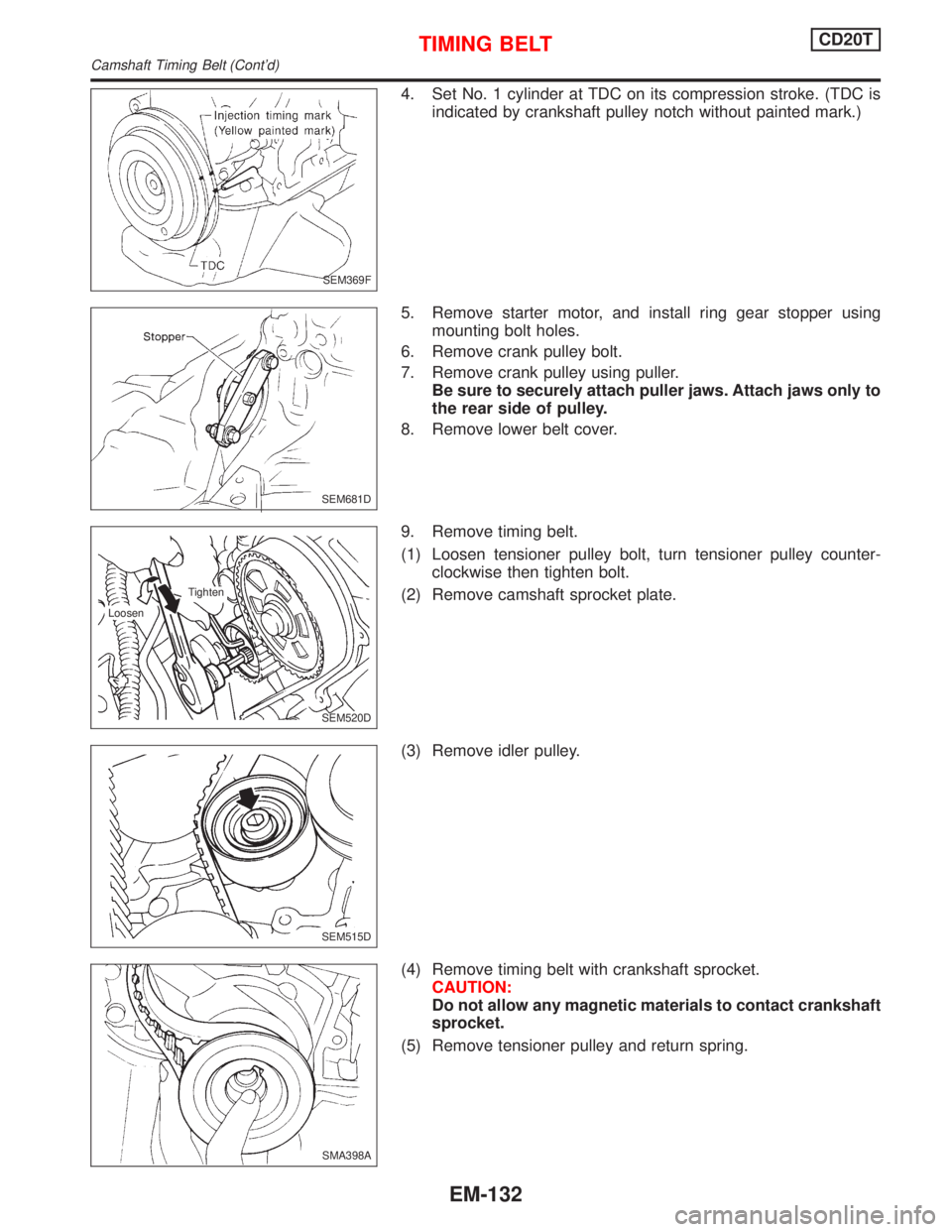

4. Set No. 1 cylinder at TDC on its compression stroke. (TDC is

indicated by crankshaft pulley notch without painted mark.)

5. Remove starter motor, and install ring gear stopper using

mounting bolt holes.

6. Remove crank pulley bolt.

7. Remove crank pulley using puller.

Be sure to securely attach puller jaws. Attach jaws only to

the rear side of pulley.

8. Remove lower belt cover.

9. Remove timing belt.

(1) Loosen tensioner pulley bolt, turn tensioner pulley counter-

clockwise then tighten bolt.

(2) Remove camshaft sprocket plate.

(3) Remove idler pulley.

(4) Remove timing belt with crankshaft sprocket.

CAUTION:

Do not allow any magnetic materials to contact crankshaft

sprocket.

(5) Remove tensioner pulley and return spring.

SEM369F

SEM681D

SEM520D LoosenTighten

SEM515D

SMA398A

TIMING BELTCD20T

Camshaft Timing Belt (Cont'd)

EM-132

Page 1673 of 2267

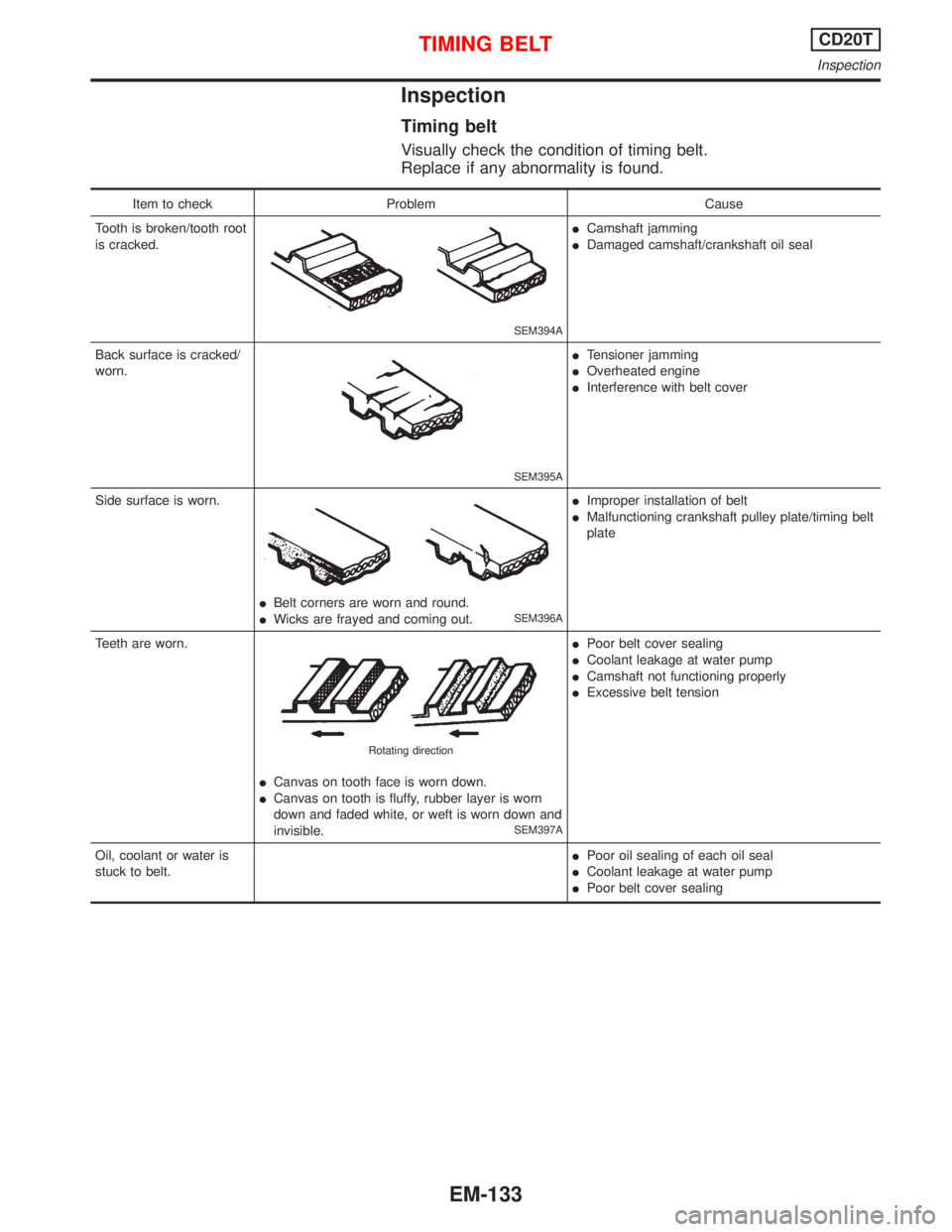

Inspection

Timing belt

Visually check the condition of timing belt.

Replace if any abnormality is found.

Item to check Problem Cause

Tooth is broken/tooth root

is cracked.

SEM394A

ICamshaft jamming

IDamaged camshaft/crankshaft oil seal

Back surface is cracked/

worn.

SEM395A

ITensioner jamming

IOverheated engine

IInterference with belt cover

Side surface is worn.

IBelt corners are worn and round.

IWicks are frayed and coming out.SEM396A

IImproper installation of belt

IMalfunctioning crankshaft pulley plate/timing belt

plate

Teeth are worn.

ICanvas on tooth face is worn down.

ICanvas on tooth is fluffy, rubber layer is worn

down and faded white, or weft is worn down and

invisible.

SEM397A Rotating direction

IPoor belt cover sealing

ICoolant leakage at water pump

ICamshaft not functioning properly

IExcessive belt tension

Oil, coolant or water is

stuck to belt.IPoor oil sealing of each oil seal

ICoolant leakage at water pump

IPoor belt cover sealing

TIMING BELTCD20T

Inspection

EM-133

Page 1674 of 2267

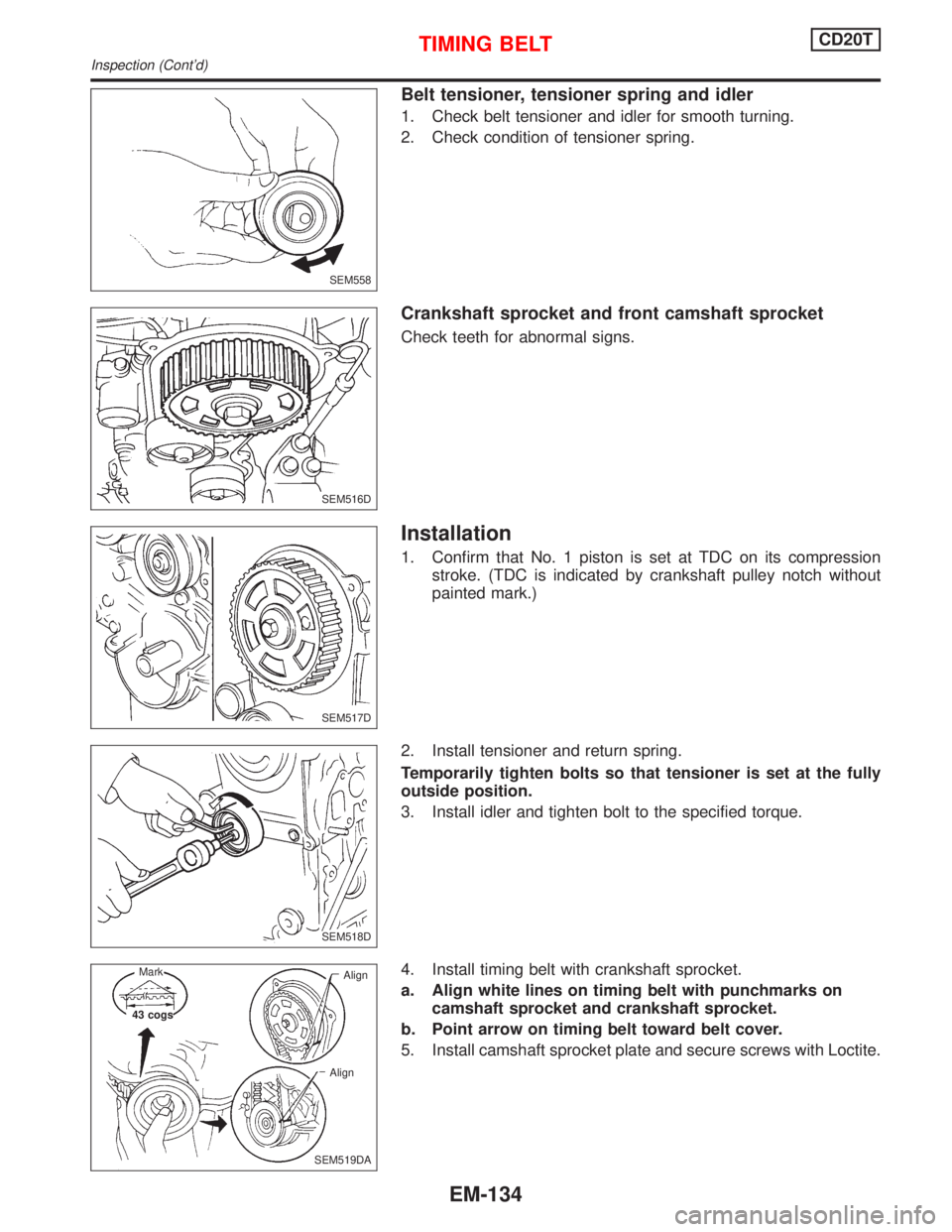

Belt tensioner, tensioner spring and idler

1. Check belt tensioner and idler for smooth turning.

2. Check condition of tensioner spring.

Crankshaft sprocket and front camshaft sprocket

Check teeth for abnormal signs.

Installation

1. Confirm that No. 1 piston is set at TDC on its compression

stroke. (TDC is indicated by crankshaft pulley notch without

painted mark.)

2. Install tensioner and return spring.

Temporarily tighten bolts so that tensioner is set at the fully

outside position.

3. Install idler and tighten bolt to the specified torque.

4. Install timing belt with crankshaft sprocket.

a. Align white lines on timing belt with punchmarks on

camshaft sprocket and crankshaft sprocket.

b. Point arrow on timing belt toward belt cover.

5. Install camshaft sprocket plate and secure screws with Loctite.

SEM558

SEM516D

SEM517D

SEM518D

Mark

43 cogsAlign

Align

SEM519DA

TIMING BELTCD20T

Inspection (Cont'd)

EM-134

Page 1675 of 2267

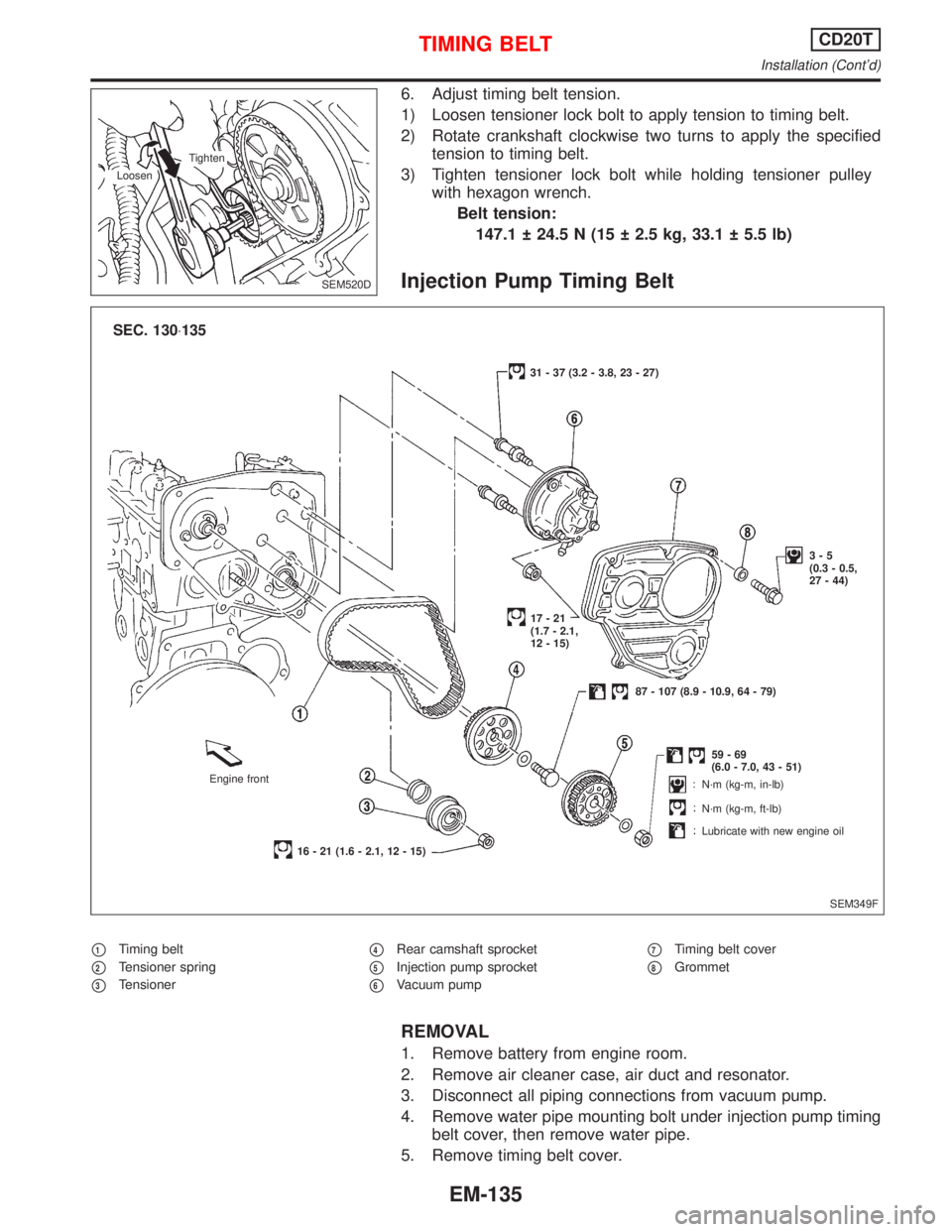

6. Adjust timing belt tension.

1) Loosen tensioner lock bolt to apply tension to timing belt.

2) Rotate crankshaft clockwise two turns to apply the specified

tension to timing belt.

3) Tighten tensioner lock bolt while holding tensioner pulley

with hexagon wrench.

Belt tension:

147.1 24.5 N (15 2.5 kg, 33.1 5.5 lb)

Injection Pump Timing Belt

p1Timing belt

p2Tensioner spring

p3Tensioner

p4Rear camshaft sprocket

p5Injection pump sprocket

p6Vacuum pump

p7Timing belt cover

p8Grommet

REMOVAL

1. Remove battery from engine room.

2. Remove air cleaner case, air duct and resonator.

3. Disconnect all piping connections from vacuum pump.

4. Remove water pipe mounting bolt under injection pump timing

belt cover, then remove water pipe.

5. Remove timing belt cover.

SEM520D Tighten

Loosen

SEM349F 31 - 37 (3.2 - 3.8, 23 - 27)

3-5

(0.3 - 0.5,

27 - 44)

59-69

(6.0 - 7.0, 43 - 51)

17-21

(1.7 - 2.1,

12 - 15)

Engine front

16 - 21 (1.6 - 2.1, 12 - 15)N´m (kg-m, in-lb)

N´m (kg-m, ft-lb)

Lubricate with new engine oil 87 - 107 (8.9 - 10.9, 64 - 79)

SEC. 130×135

TIMING BELTCD20T

Installation (Cont'd)

EM-135

Page 1676 of 2267

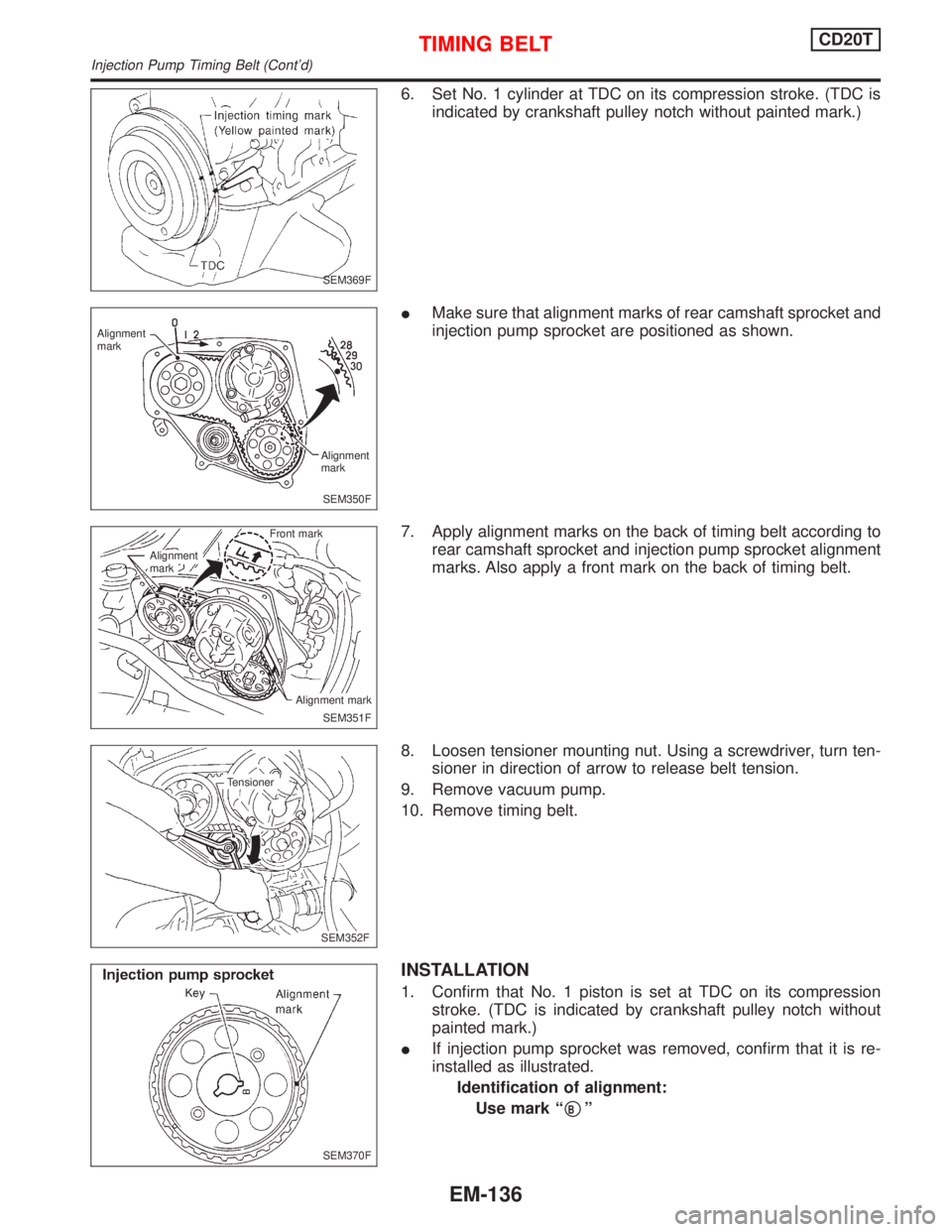

6. Set No. 1 cylinder at TDC on its compression stroke. (TDC is

indicated by crankshaft pulley notch without painted mark.)

IMake sure that alignment marks of rear camshaft sprocket and

injection pump sprocket are positioned as shown.

7. Apply alignment marks on the back of timing belt according to

rear camshaft sprocket and injection pump sprocket alignment

marks. Also apply a front mark on the back of timing belt.

8. Loosen tensioner mounting nut. Using a screwdriver, turn ten-

sioner in direction of arrow to release belt tension.

9. Remove vacuum pump.

10. Remove timing belt.

INSTALLATION

1. Confirm that No. 1 piston is set at TDC on its compression

stroke. (TDC is indicated by crankshaft pulley notch without

painted mark.)

IIf injection pump sprocket was removed, confirm that it is re-

installed as illustrated.

Identification of alignment:

Use mark ª

pBº

SEM369F

SEM350F Alignment

mark

Alignment

mark

SEM351F Alignment

markFront mark

Alignment mark

.SEM352F Tensioner

SEM370F

TIMING BELTCD20T

Injection Pump Timing Belt (Cont'd)

EM-136

Page 1677 of 2267

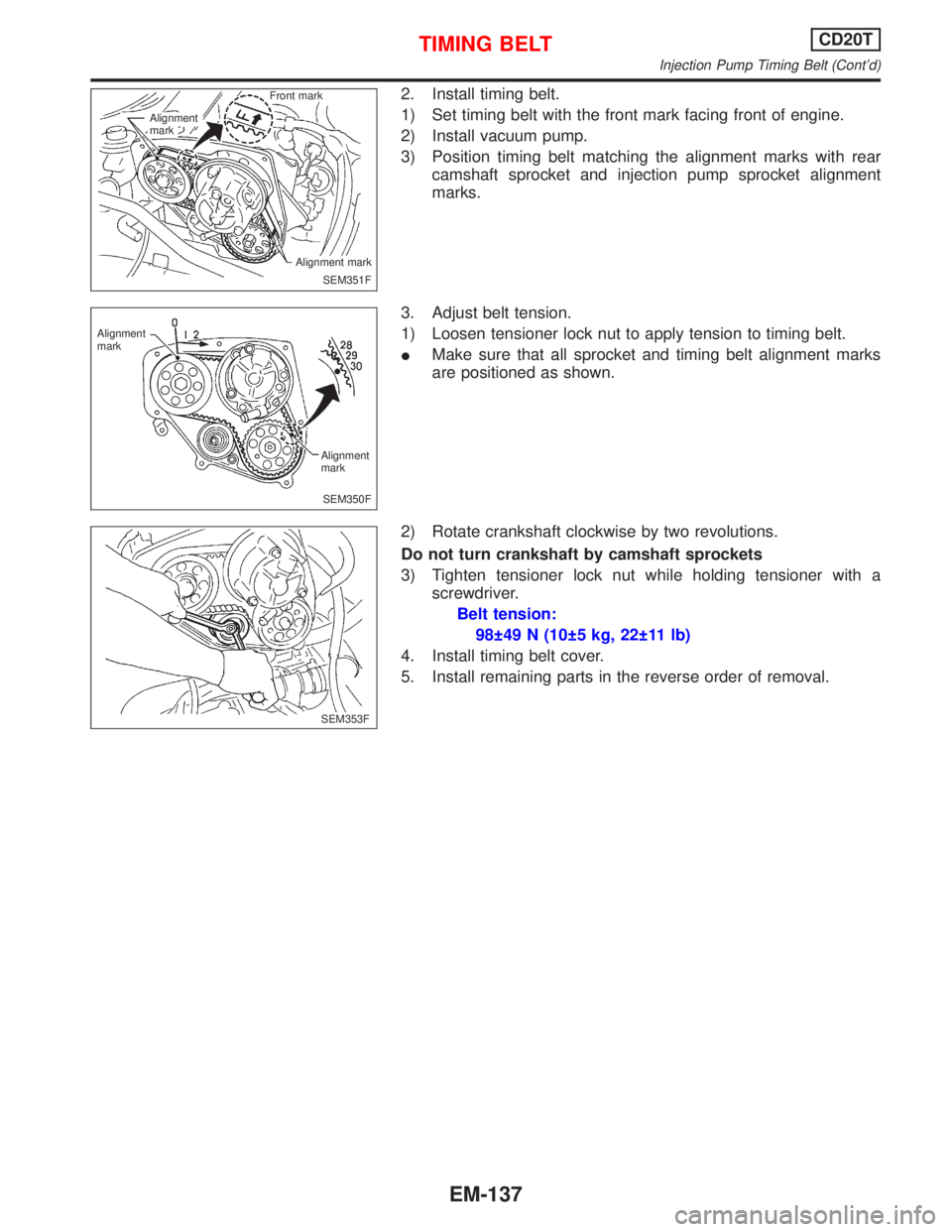

2. Install timing belt.

1) Set timing belt with the front mark facing front of engine.

2) Install vacuum pump.

3) Position timing belt matching the alignment marks with rear

camshaft sprocket and injection pump sprocket alignment

marks.

3. Adjust belt tension.

1) Loosen tensioner lock nut to apply tension to timing belt.

IMake sure that all sprocket and timing belt alignment marks

are positioned as shown.

2) Rotate crankshaft clockwise by two revolutions.

Do not turn crankshaft by camshaft sprockets

3) Tighten tensioner lock nut while holding tensioner with a

screwdriver.

Belt tension:

98 49 N (10 5 kg, 22 11 lb)

4. Install timing belt cover.

5. Install remaining parts in the reverse order of removal.

SEM351F Alignment

markFront mark

Alignment mark

SEM350F Alignment

mark

Alignment

mark

.SEM353F

TIMING BELTCD20T

Injection Pump Timing Belt (Cont'd)

EM-137

Page 1678 of 2267

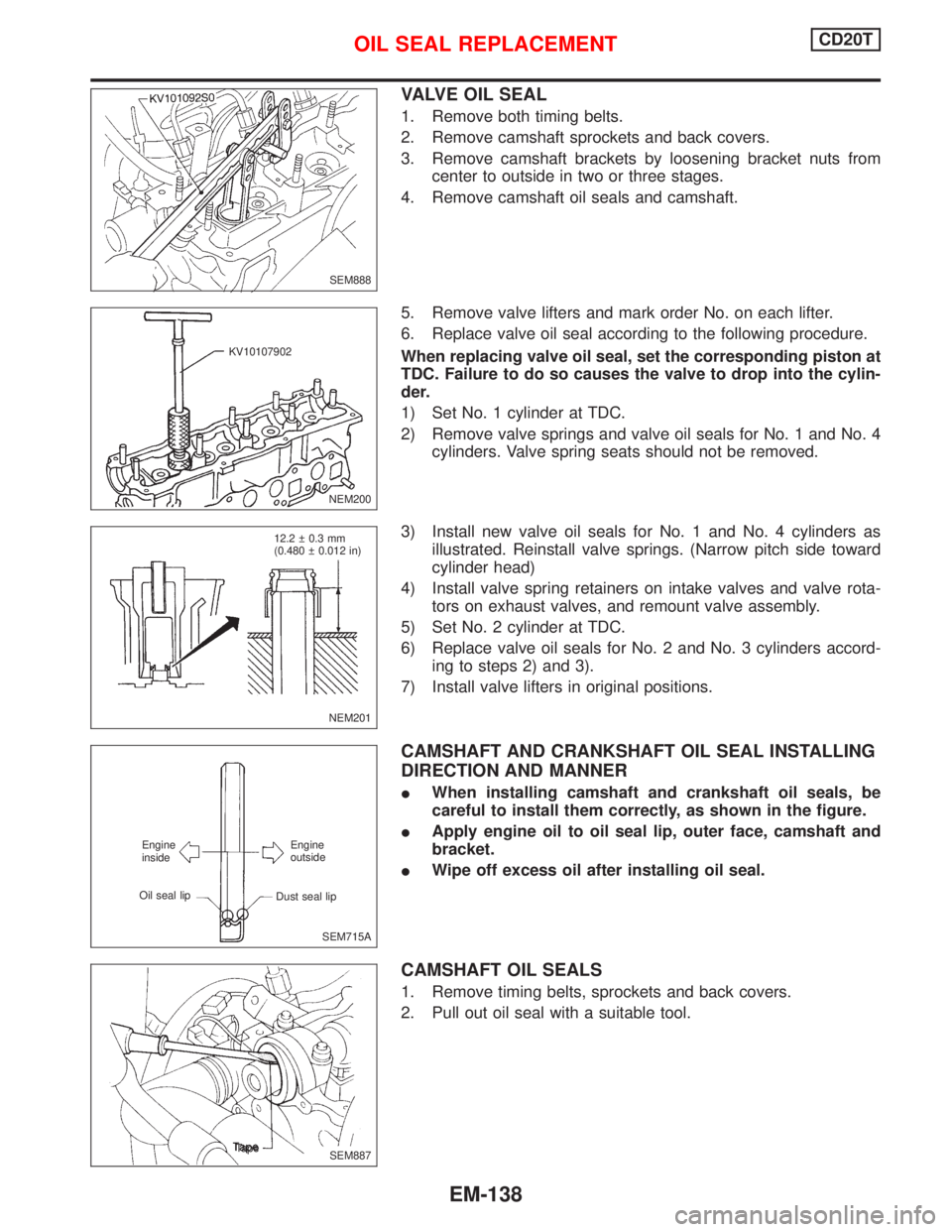

VALVE OIL SEAL

1. Remove both timing belts.

2. Remove camshaft sprockets and back covers.

3. Remove camshaft brackets by loosening bracket nuts from

center to outside in two or three stages.

4. Remove camshaft oil seals and camshaft.

5. Remove valve lifters and mark order No. on each lifter.

6. Replace valve oil seal according to the following procedure.

When replacing valve oil seal, set the corresponding piston at

TDC. Failure to do so causes the valve to drop into the cylin-

der.

1) Set No. 1 cylinder at TDC.

2) Remove valve springs and valve oil seals for No. 1 and No. 4

cylinders. Valve spring seats should not be removed.

3) Install new valve oil seals for No. 1 and No. 4 cylinders as

illustrated. Reinstall valve springs. (Narrow pitch side toward

cylinder head)

4) Install valve spring retainers on intake valves and valve rota-

tors on exhaust valves, and remount valve assembly.

5) Set No. 2 cylinder at TDC.

6) Replace valve oil seals for No. 2 and No. 3 cylinders accord-

ing to steps 2) and 3).

7) Install valve lifters in original positions.

CAMSHAFT AND CRANKSHAFT OIL SEAL INSTALLING

DIRECTION AND MANNER

IWhen installing camshaft and crankshaft oil seals, be

careful to install them correctly, as shown in the figure.

IApply engine oil to oil seal lip, outer face, camshaft and

bracket.

IWipe off excess oil after installing oil seal.

CAMSHAFT OIL SEALS

1. Remove timing belts, sprockets and back covers.

2. Pull out oil seal with a suitable tool.

SEM888

NEM200 KV10107902

NEM201 12.2 0.3 mm

(0.480 0.012 in)

SEM715A Engine

inside

Oil seal lipEngine

outside

Dust seal lip

.SEM887 Tape

OIL SEAL REPLACEMENTCD20T

EM-138

Page 1679 of 2267

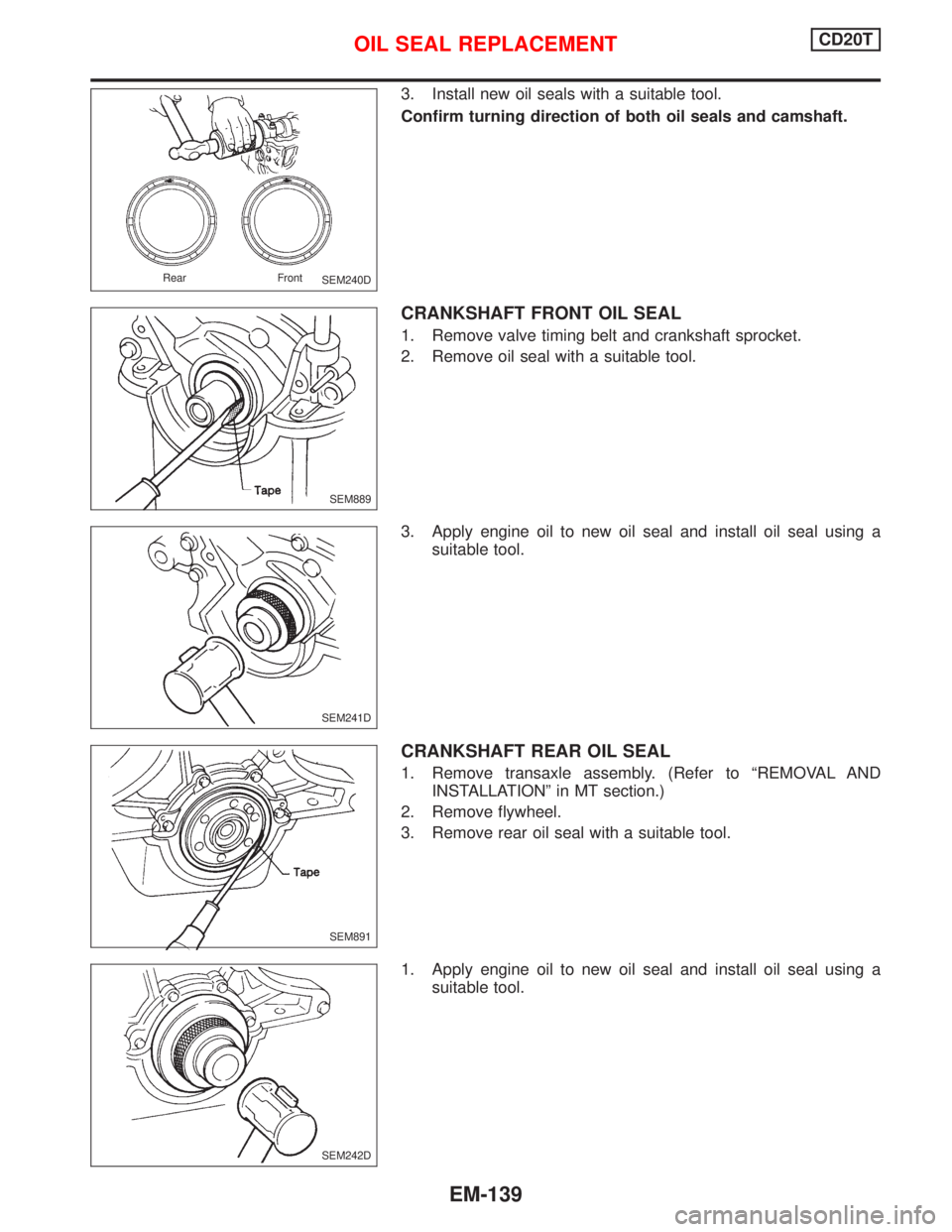

3. Install new oil seals with a suitable tool.

Confirm turning direction of both oil seals and camshaft.

CRANKSHAFT FRONT OIL SEAL

1. Remove valve timing belt and crankshaft sprocket.

2. Remove oil seal with a suitable tool.

3. Apply engine oil to new oil seal and install oil seal using a

suitable tool.

CRANKSHAFT REAR OIL SEAL

1. Remove transaxle assembly. (Refer to ªREMOVAL AND

INSTALLATIONº in MT section.)

2. Remove flywheel.

3. Remove rear oil seal with a suitable tool.

1. Apply engine oil to new oil seal and install oil seal using a

suitable tool.

SEM240D Rear Front

SEM889

SEM241D

SEM891

SEM242D

OIL SEAL REPLACEMENTCD20T

EM-139

Page 1680 of 2267

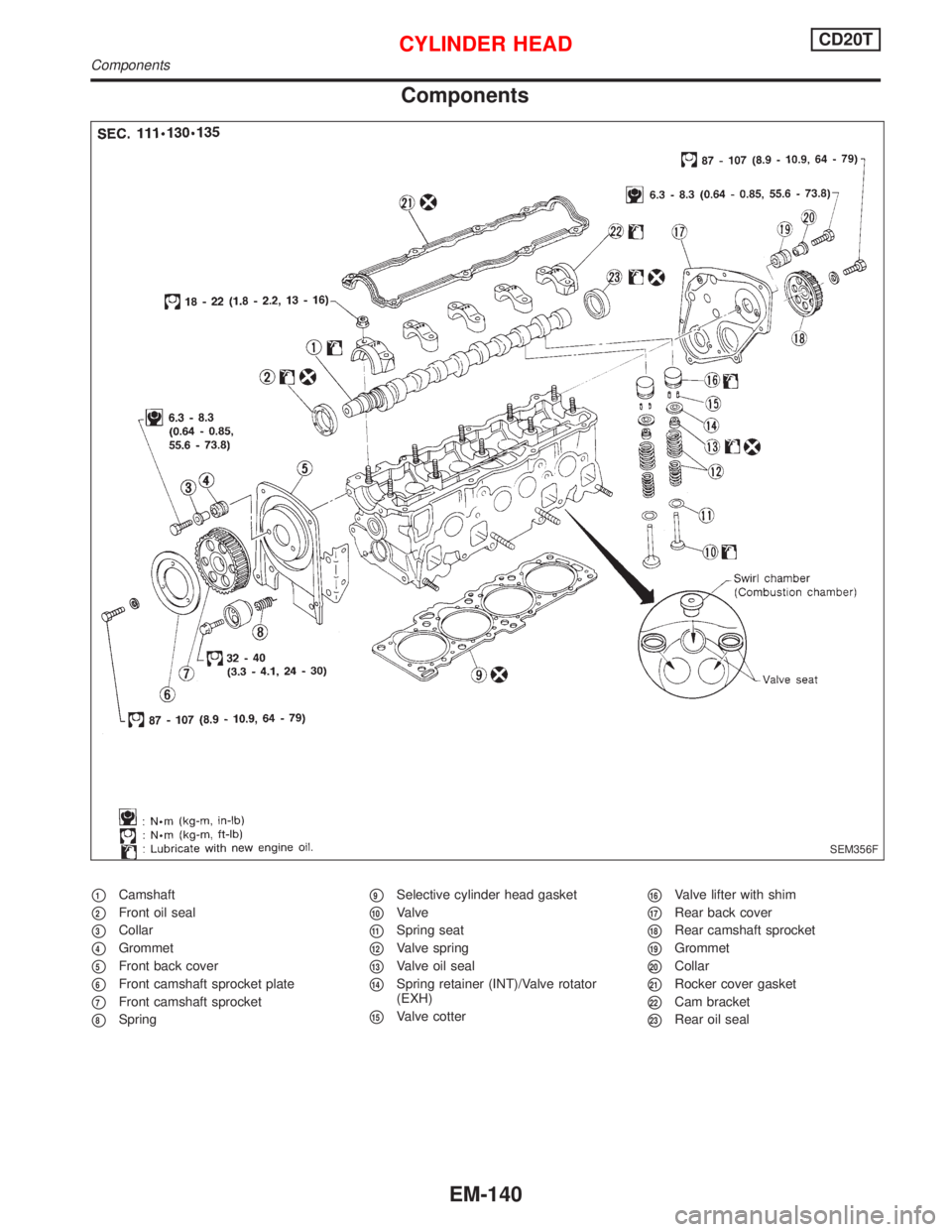

Components

p1Camshaft

p2Front oil seal

p3Collar

p4Grommet

p5Front back cover

p6Front camshaft sprocket plate

p7Front camshaft sprocket

p8Spring

p9Selective cylinder head gasket

p10Valve

p11Spring seat

p12Valve spring

p13Valve oil seal

p14Spring retainer (INT)/Valve rotator

(EXH)

p15Valve cotter

p16Valve lifter with shim

p17Rear back cover

p18Rear camshaft sprocket

p19Grommet

p20Collar

p21Rocker cover gasket

p22Cam bracket

p23Rear oil seal

SEM356F

CYLINDER HEADCD20T

Components

EM-140