NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 281 of 2267

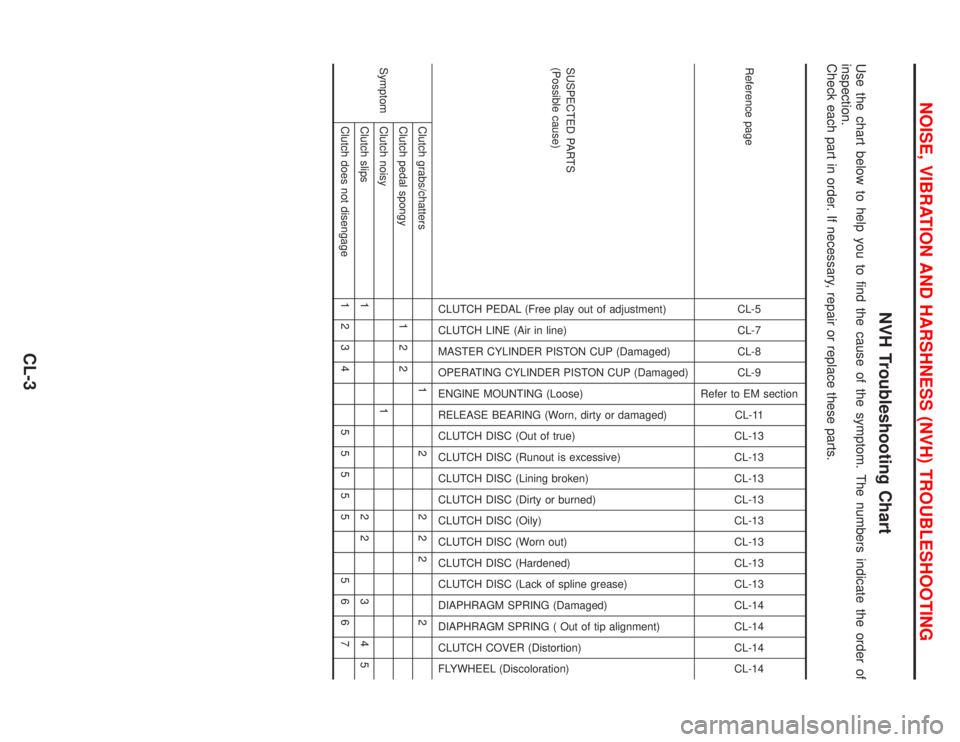

NVH Troubleshooting Chart

Use the chart below to help you to find the cause of the symptom. The numbers indicate the order of

inspection.

Check each part in order. If necessary, repair or replace these parts.

Reference pageCL-5

CL-7

CL-8

CL-9

Refer to EM section

CL-11

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-13

CL-14

CL-14

CL-14

CL-14

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING ( Out of tip alignment)

CLUTCH COVER (Distortion)

FLYWHEEL (Discoloration)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disengage 1 2 3 4 5 5 5 5 5 5 6 6 7

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

CL-3

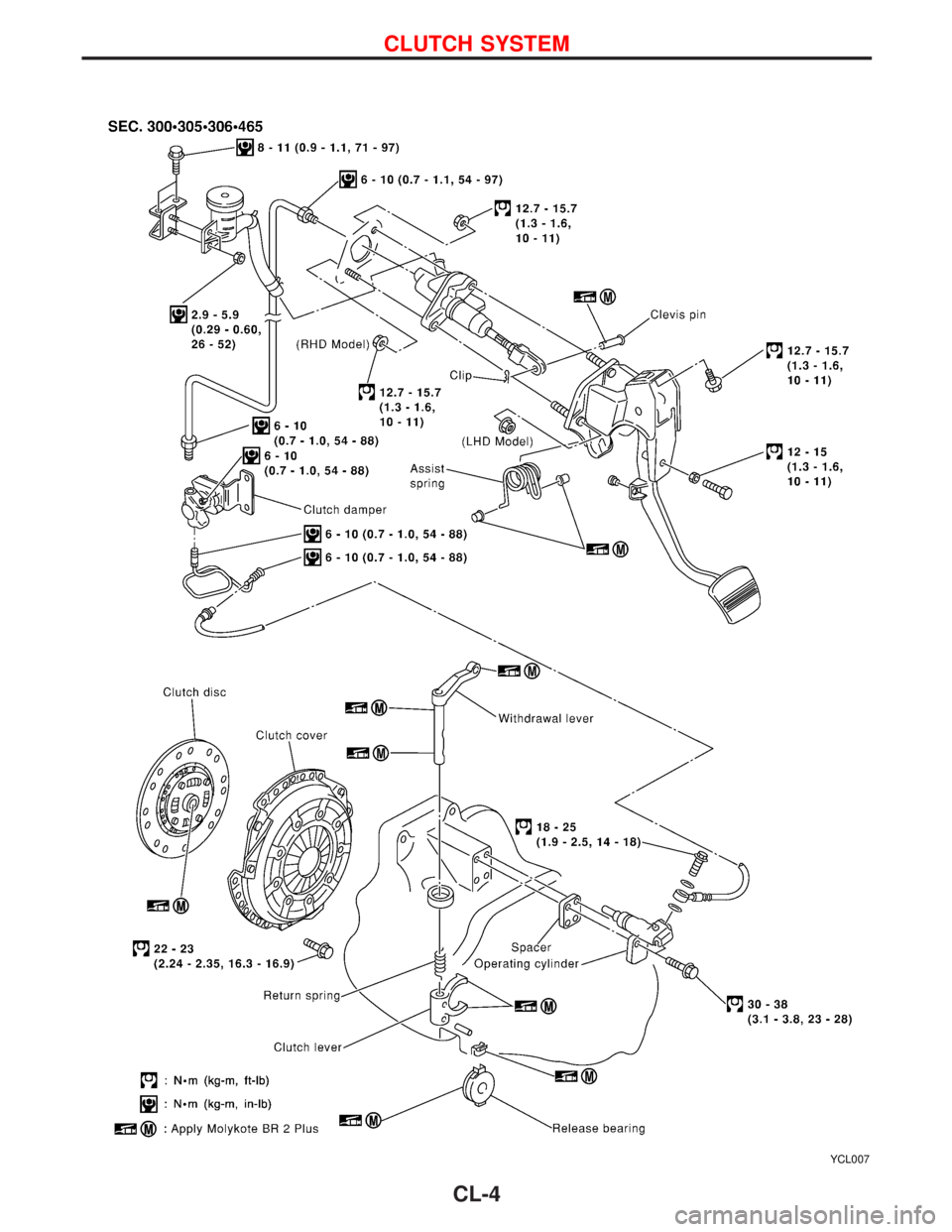

Page 282 of 2267

YCL007

CLUTCH SYSTEM

CL-4

Page 283 of 2267

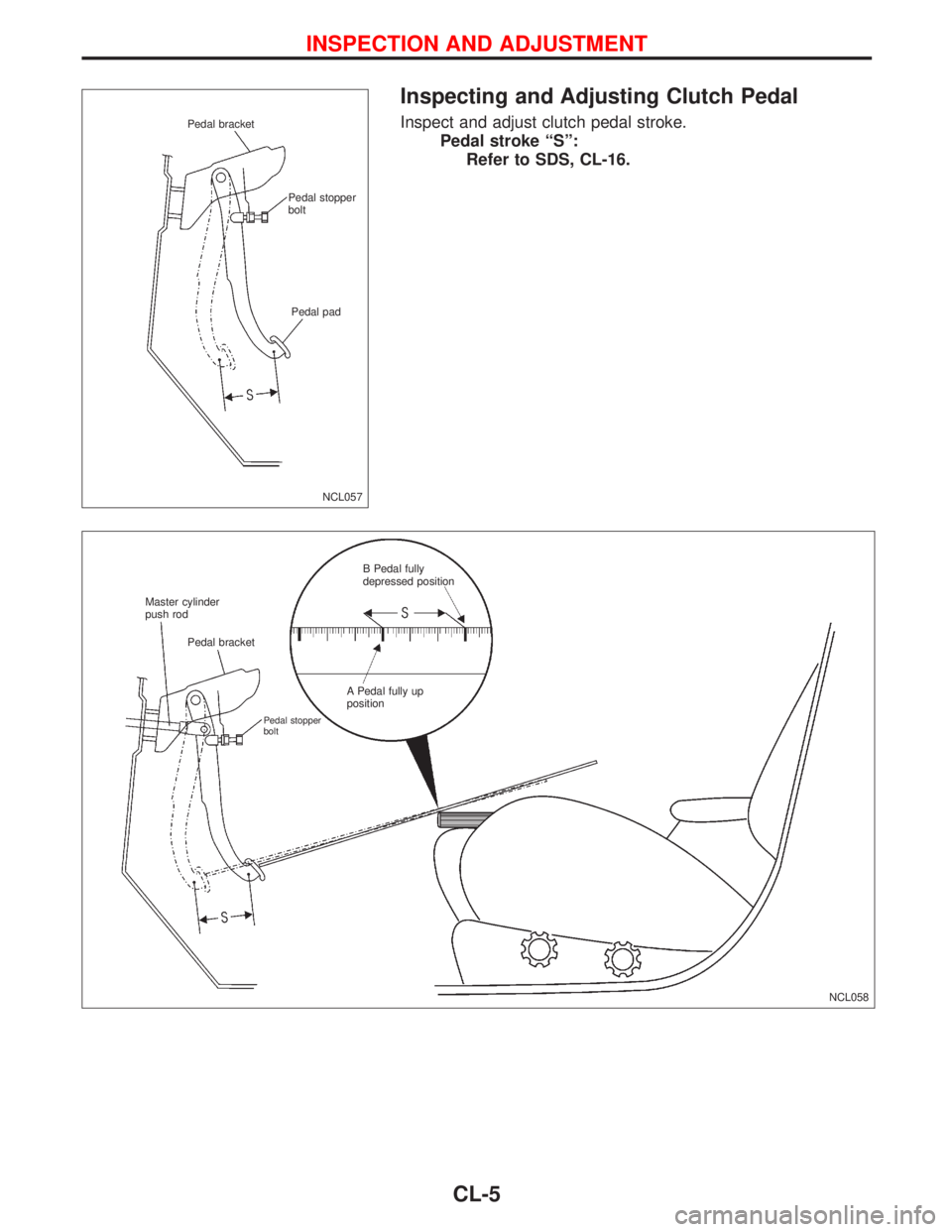

Inspecting and Adjusting Clutch Pedal

Inspect and adjust clutch pedal stroke.

Pedal stroke ªSº:

Refer to SDS, CL-16.

NCL057

Pedal bracket

Pedal stopper

bolt

Pedal pad

NCL058 Master cylinder

push rod

Pedal bracket

Pedal stopper

bolt

B Pedal fully

depressed position

A Pedal fully up

position

INSPECTION AND ADJUSTMENT

CL-5

Page 284 of 2267

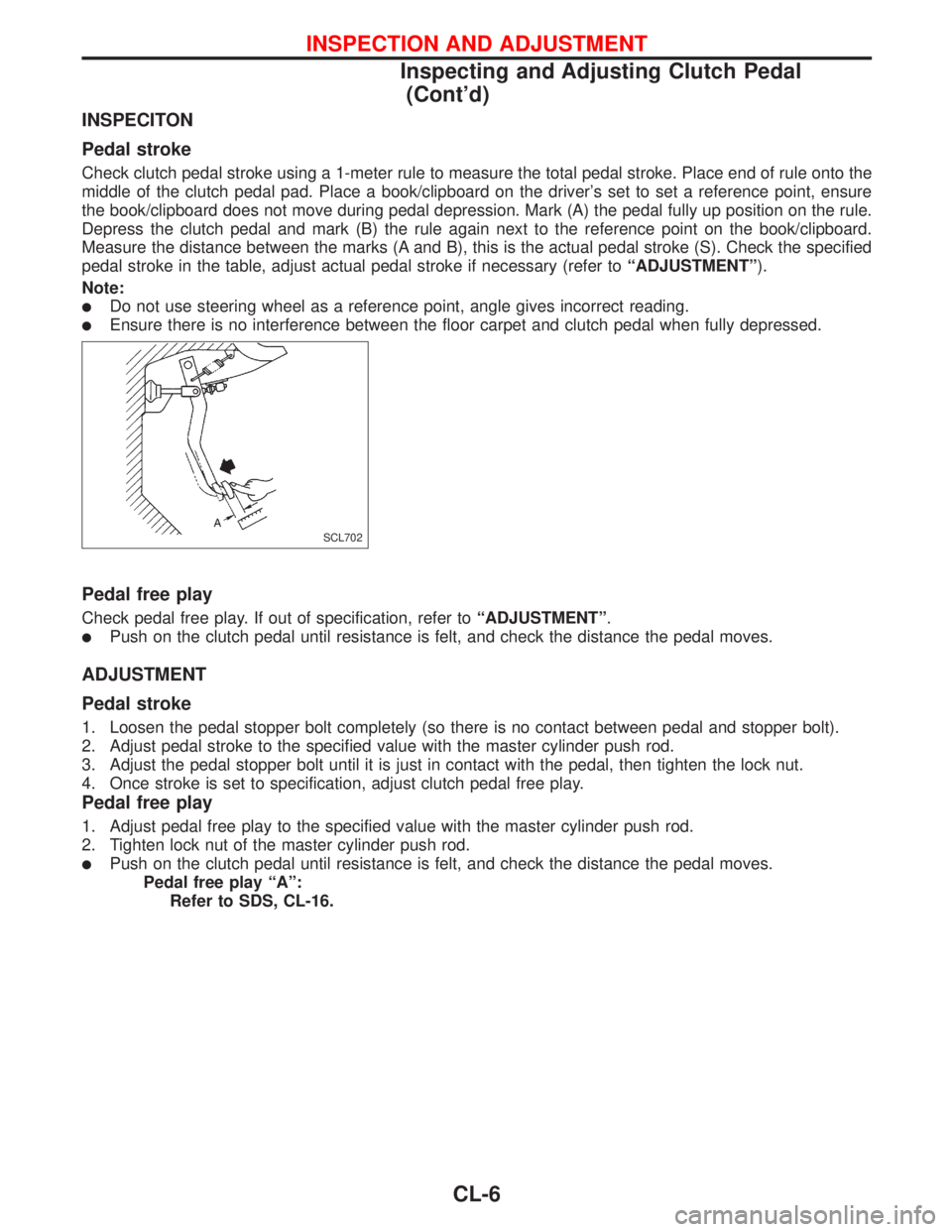

INSPECITON

Pedal stroke

Check clutch pedal stroke using a 1-meter rule to measure the total pedal stroke. Place end of rule onto the

middle of the clutch pedal pad. Place a book/clipboard on the driver's set to set a reference point, ensure

the book/clipboard does not move during pedal depression. Mark (A) the pedal fully up position on the rule.

Depress the clutch pedal and mark (B) the rule again next to the reference point on the book/clipboard.

Measure the distance between the marks (A and B), this is the actual pedal stroke (S). Check the specified

pedal stroke in the table, adjust actual pedal stroke if necessary (refer toªADJUSTMENTº).

Note:

lDo not use steering wheel as a reference point, angle gives incorrect reading.

lEnsure there is no interference between the floor carpet and clutch pedal when fully depressed.

Pedal free play

Check pedal free play. If out of specification, refer toªADJUSTMENTº.

lPush on the clutch pedal until resistance is felt, and check the distance the pedal moves.

ADJUSTMENT

Pedal stroke

1. Loosen the pedal stopper bolt completely (so there is no contact between pedal and stopper bolt).

2. Adjust pedal stroke to the specified value with the master cylinder push rod.

3. Adjust the pedal stopper bolt until it is just in contact with the pedal, then tighten the lock nut.

4. Once stroke is set to specification, adjust clutch pedal free play.

Pedal free play

1. Adjust pedal free play to the specified value with the master cylinder push rod.

2. Tighten lock nut of the master cylinder push rod.

lPush on the clutch pedal until resistance is felt, and check the distance the pedal moves.

Pedal free play ªAº:

Refer to SDS, CL-16.

SCL702

INSPECTION AND ADJUSTMENT

Inspecting and Adjusting Clutch Pedal

(Cont'd)

CL-6

Page 285 of 2267

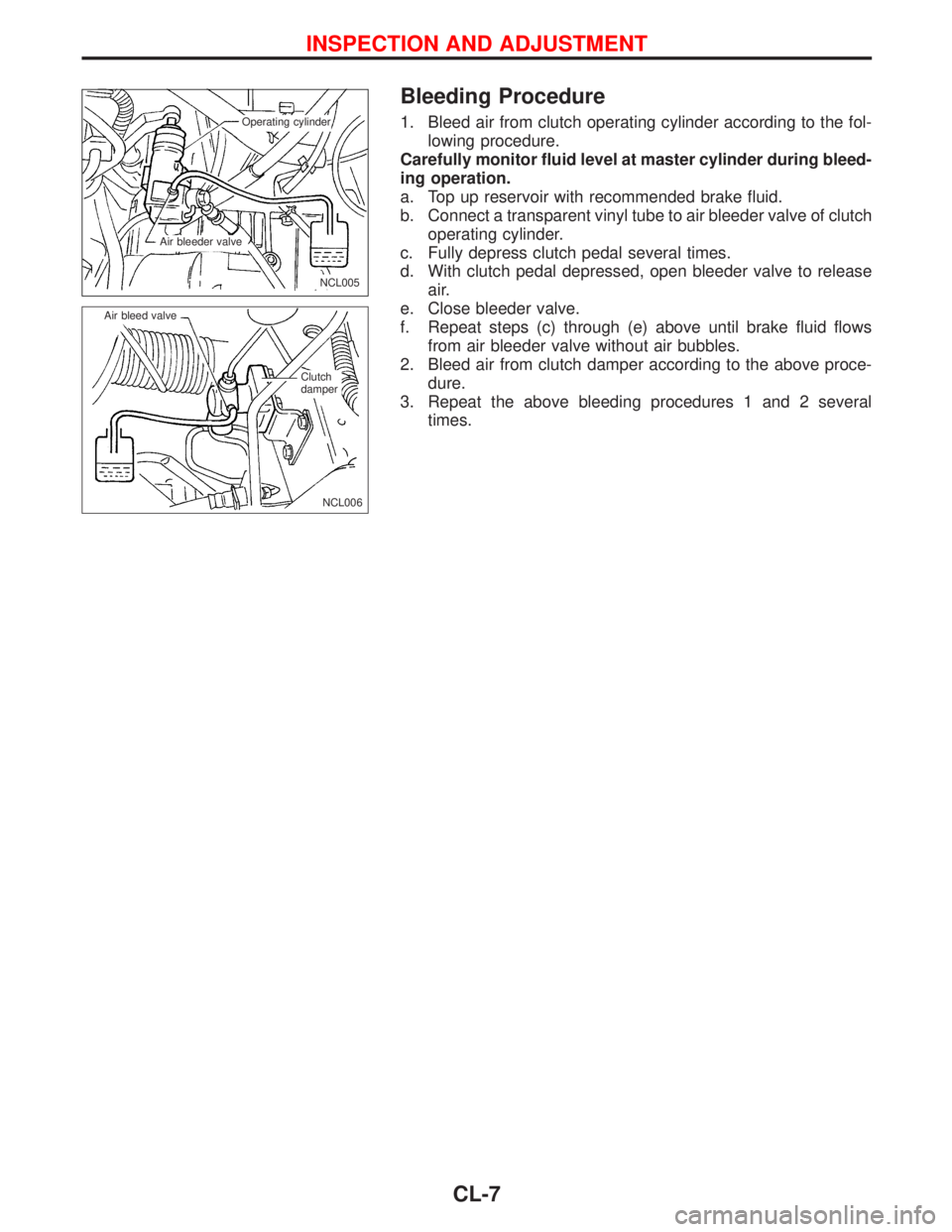

Bleeding Procedure

1. Bleed air from clutch operating cylinder according to the fol-

lowing procedure.

Carefully monitor fluid level at master cylinder during bleed-

ing operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve of clutch

operating cylinder.

c. Fully depress clutch pedal several times.

d. With clutch pedal depressed, open bleeder valve to release

air.

e. Close bleeder valve.

f. Repeat steps (c) through (e) above until brake fluid flows

from air bleeder valve without air bubbles.

2. Bleed air from clutch damper according to the above proce-

dure.

3. Repeat the above bleeding procedures 1 and 2 several

times.

.NCL005

.Operating cylinder

.Air bleeder valve

NCL006 Air bleed valve

.Clutch

damper

INSPECTION AND ADJUSTMENT

CL-7

Page 286 of 2267

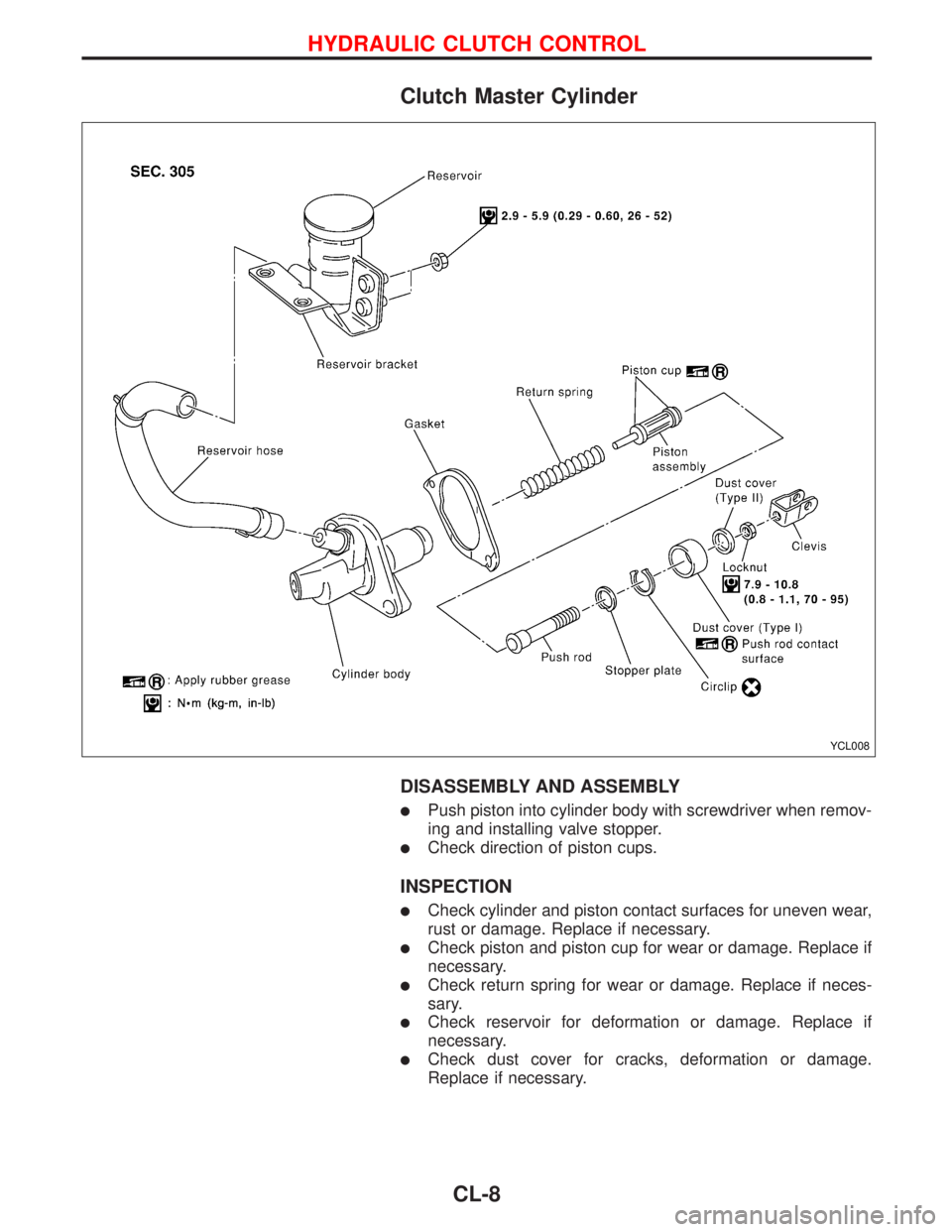

Clutch Master Cylinder

DISASSEMBLY AND ASSEMBLY

lPush piston into cylinder body with screwdriver when remov-

ing and installing valve stopper.

lCheck direction of piston cups.

INSPECTION

lCheck cylinder and piston contact surfaces for uneven wear,

rust or damage. Replace if necessary.

lCheck piston and piston cup for wear or damage. Replace if

necessary.

lCheck return spring for wear or damage. Replace if neces-

sary.

lCheck reservoir for deformation or damage. Replace if

necessary.

lCheck dust cover for cracks, deformation or damage.

Replace if necessary.

YCL008

HYDRAULIC CLUTCH CONTROL

CL-8

Page 287 of 2267

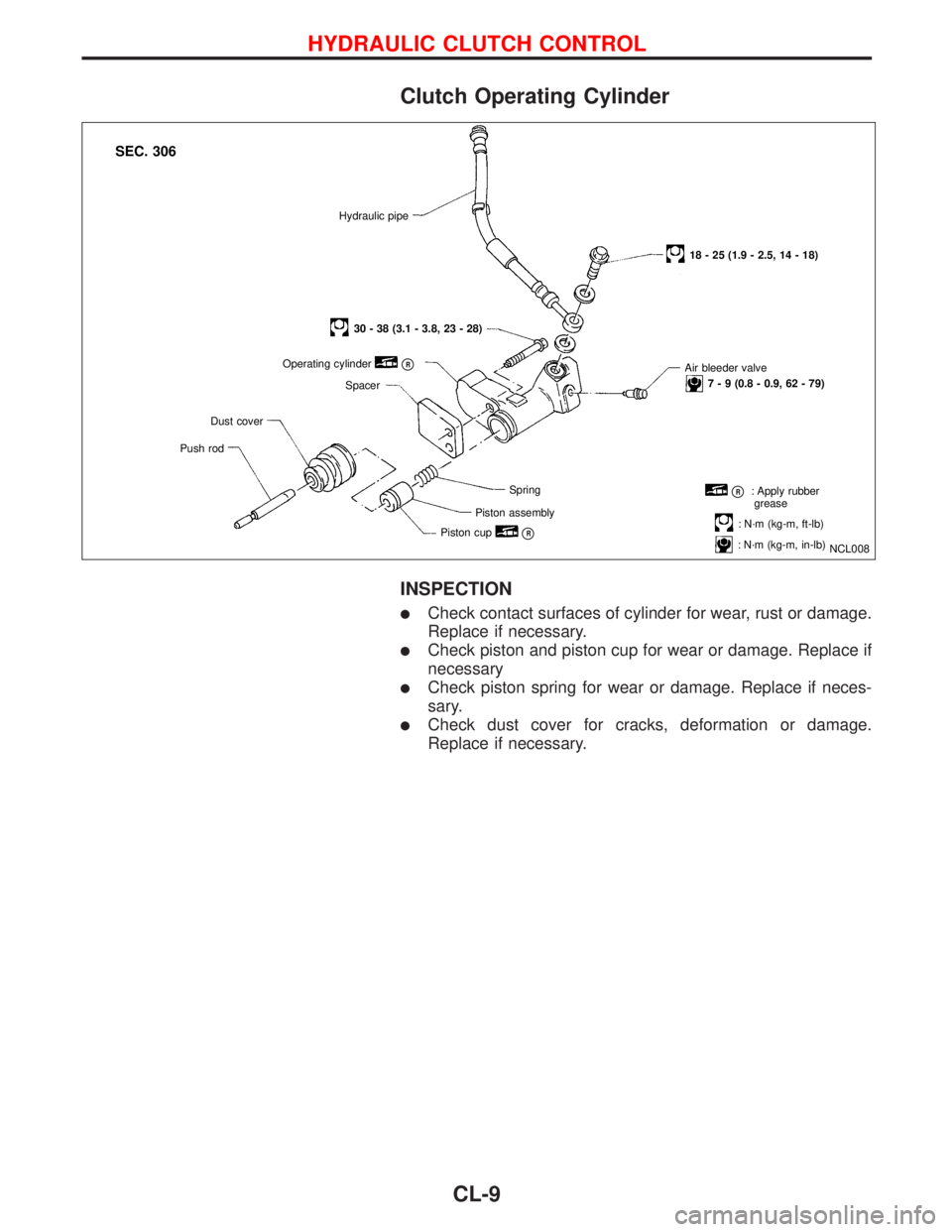

Clutch Operating Cylinder

INSPECTION

lCheck contact surfaces of cylinder for wear, rust or damage.

Replace if necessary.

lCheck piston and piston cup for wear or damage. Replace if

necessary

lCheck piston spring for wear or damage. Replace if neces-

sary.

lCheck dust cover for cracks, deformation or damage.

Replace if necessary.

NCL008

18 - 25 (1.9 - 2.5, 14 - 18) Hydraulic pipe

Air bleeder valve

7 - 9 (0.8 - 0.9, 62 - 79)

30 - 38 (3.1 - 3.8, 23 - 28)

Operating cylinder

pR

Spacer

Dust cover

Push rod

Spring

Piston assembly

Piston cup

pR

pR: Apply rubber

grease

: N´m (kg-m, ft-lb)

: N´m (kg-m, in-lb)

SEC. 306

HYDRAULIC CLUTCH CONTROL

CL-9

Page 288 of 2267

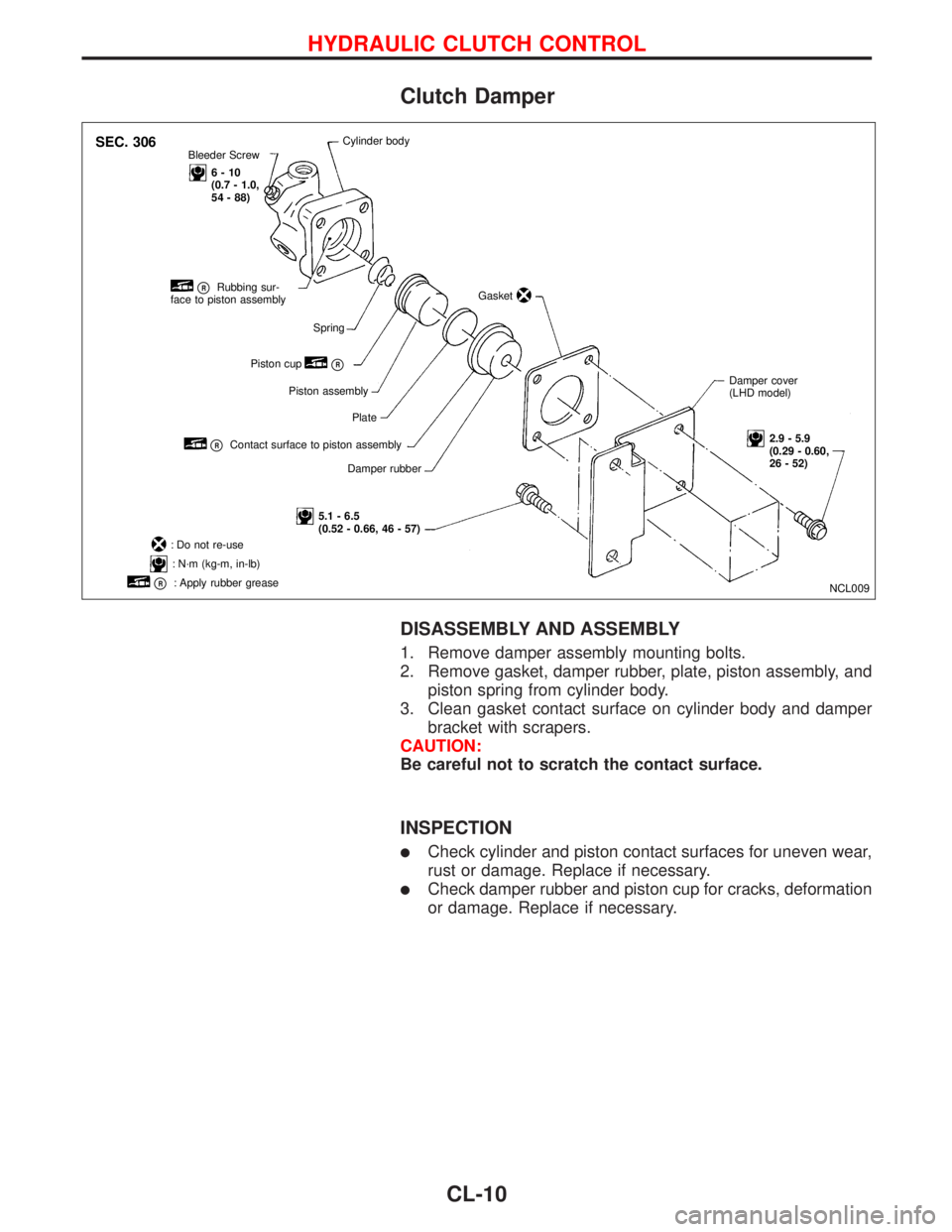

Clutch Damper

DISASSEMBLY AND ASSEMBLY

1. Remove damper assembly mounting bolts.

2. Remove gasket, damper rubber, plate, piston assembly, and

piston spring from cylinder body.

3. Clean gasket contact surface on cylinder body and damper

bracket with scrapers.

CAUTION:

Be careful not to scratch the contact surface.

INSPECTION

lCheck cylinder and piston contact surfaces for uneven wear,

rust or damage. Replace if necessary.

lCheck damper rubber and piston cup for cracks, deformation

or damage. Replace if necessary.

NCL009 Bleeder Screw

6-10

(0.7 - 1.0,

54 - 88)Cylinder body

Gasket

Damper cover

(LHD model)

2.9 - 5.9

(0.29 - 0.60,

26 - 52)

5.1 - 6.5

(0.52 - 0.66, 46 - 57)Damper rubber

pRContact surface to piston assemblyPlate Piston assembly Piston cup

pR

pRRubbing sur-

face to piston assembly

Spring

: Do not re-use

: N´m (kg-m, in-lb)

pR: Apply rubber grease

SEC. 306

HYDRAULIC CLUTCH CONTROL

CL-10

Page 289 of 2267

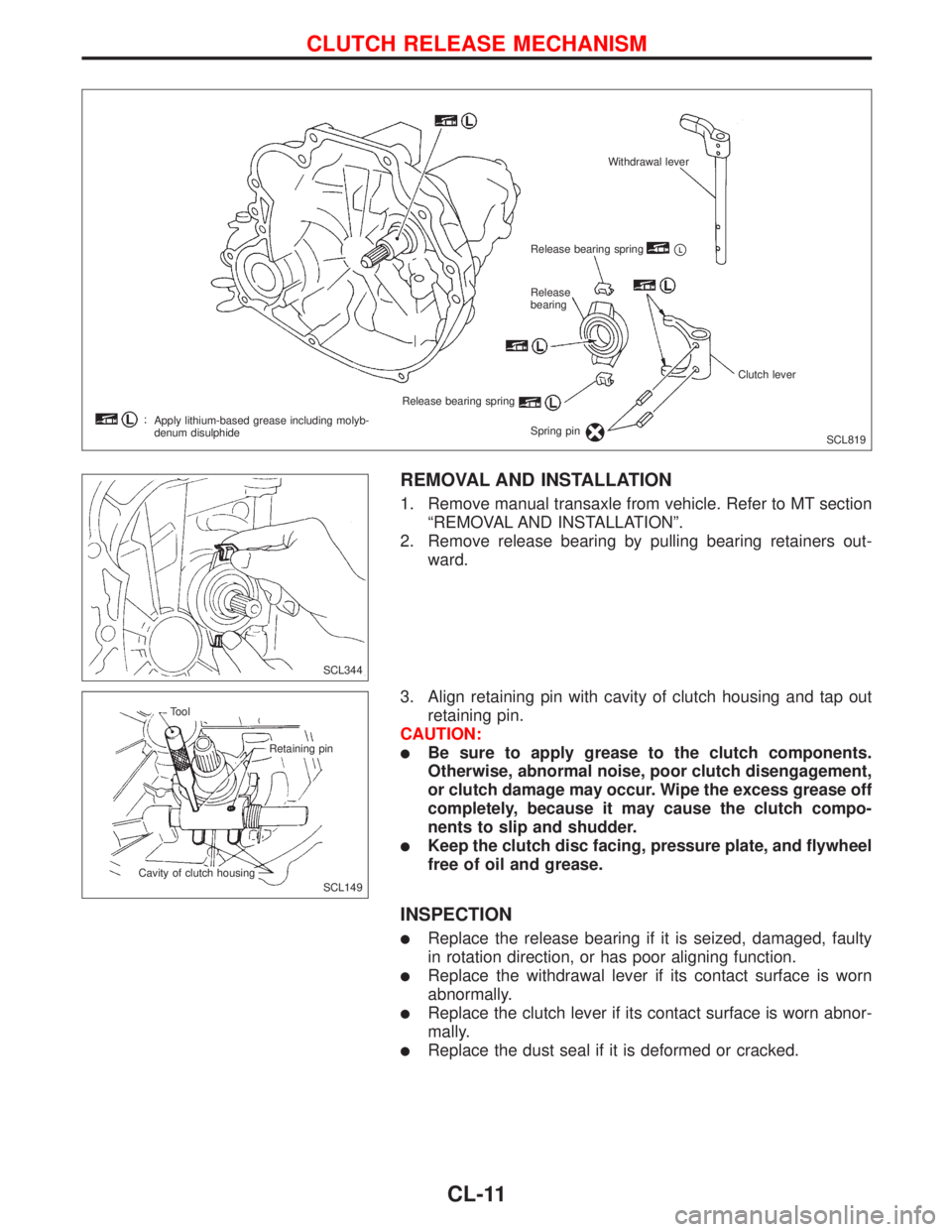

REMOVAL AND INSTALLATION

1. Remove manual transaxle from vehicle. Refer to MT section

ªREMOVAL AND INSTALLATIONº.

2. Remove release bearing by pulling bearing retainers out-

ward.

3. Align retaining pin with cavity of clutch housing and tap out

retaining pin.

CAUTION:

lBe sure to apply grease to the clutch components.

Otherwise, abnormal noise, poor clutch disengagement,

or clutch damage may occur. Wipe the excess grease off

completely, because it may cause the clutch compo-

nents to slip and shudder.

lKeep the clutch disc facing, pressure plate, and flywheel

free of oil and grease.

INSPECTION

lReplace the release bearing if it is seized, damaged, faulty

in rotation direction, or has poor aligning function.

lReplace the withdrawal lever if its contact surface is worn

abnormally.

lReplace the clutch lever if its contact surface is worn abnor-

mally.

lReplace the dust seal if it is deformed or cracked.

SCL819 Withdrawal lever

Release bearing spring

pL

Release

bearing

Release bearing spring

Spring pinClutch lever

Apply lithium-based grease including molyb-

denum disulphide

SCL344

SCL149 Tool

Retaining pin

Cavity of clutch housing

CLUTCH RELEASE MECHANISM

CL-11

Page 290 of 2267

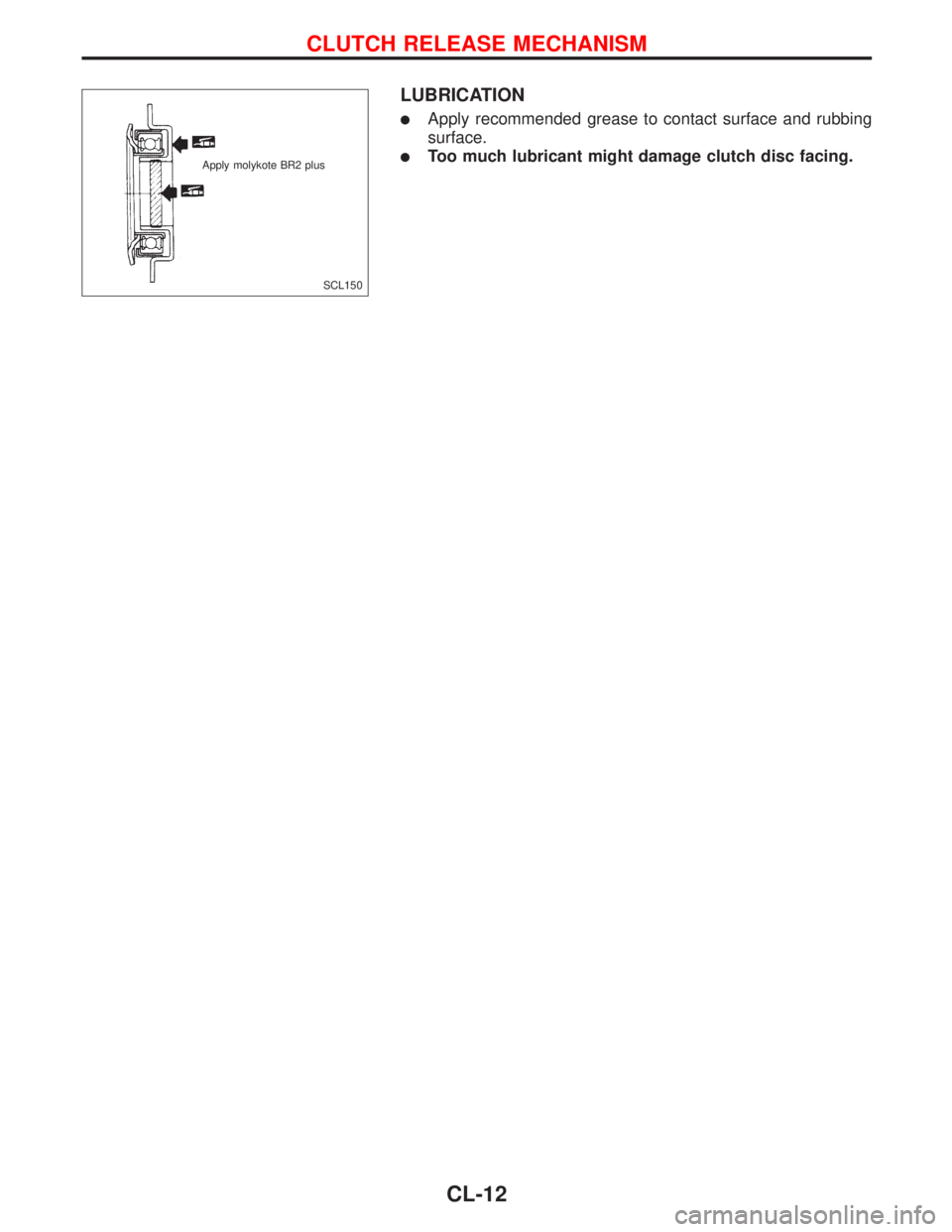

LUBRICATION

lApply recommended grease to contact surface and rubbing

surface.

lToo much lubricant might damage clutch disc facing.

SCL150 Apply molykote BR2 plus

CLUTCH RELEASE MECHANISM

CL-12