NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: Dash, open gas tank, wiring diagram, pairing phone, fuel cap, odometer, seat adjustment

Page 271 of 2267

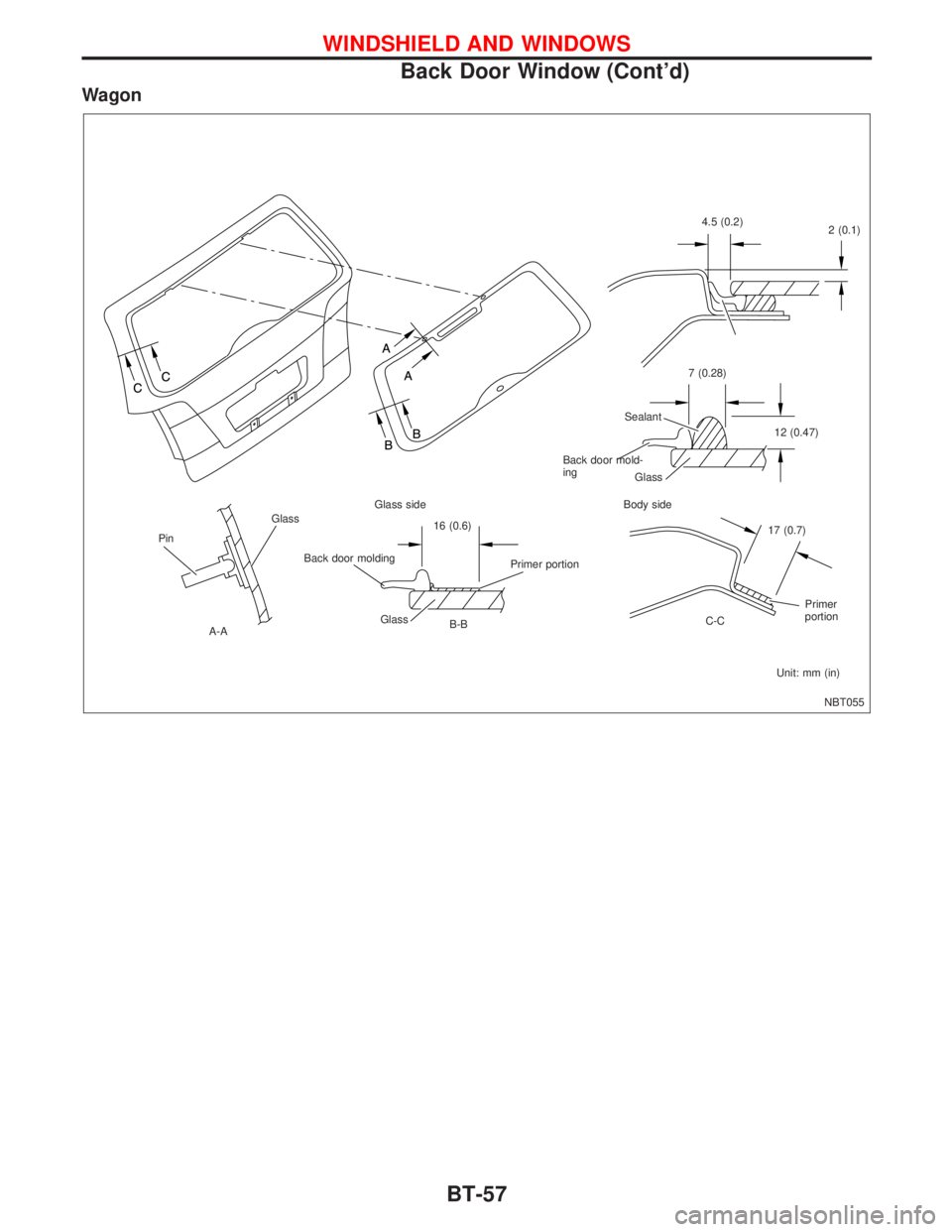

Wagon

NBT055

Glass

Pin

.A-AGlass side

16 (0.6)

Primer portion

Glass

B-BBody side

17 (0.7)

Primer

portion

C-C

Unit: mm (in) Glass Sealant7 (0.28)

12 (0.47) 4.5 (0.2)

2 (0.1)

Back door moldingBack door mold-

ing

WINDSHIELD AND WINDOWS

Back Door Window (Cont'd)

BT-57

Page 272 of 2267

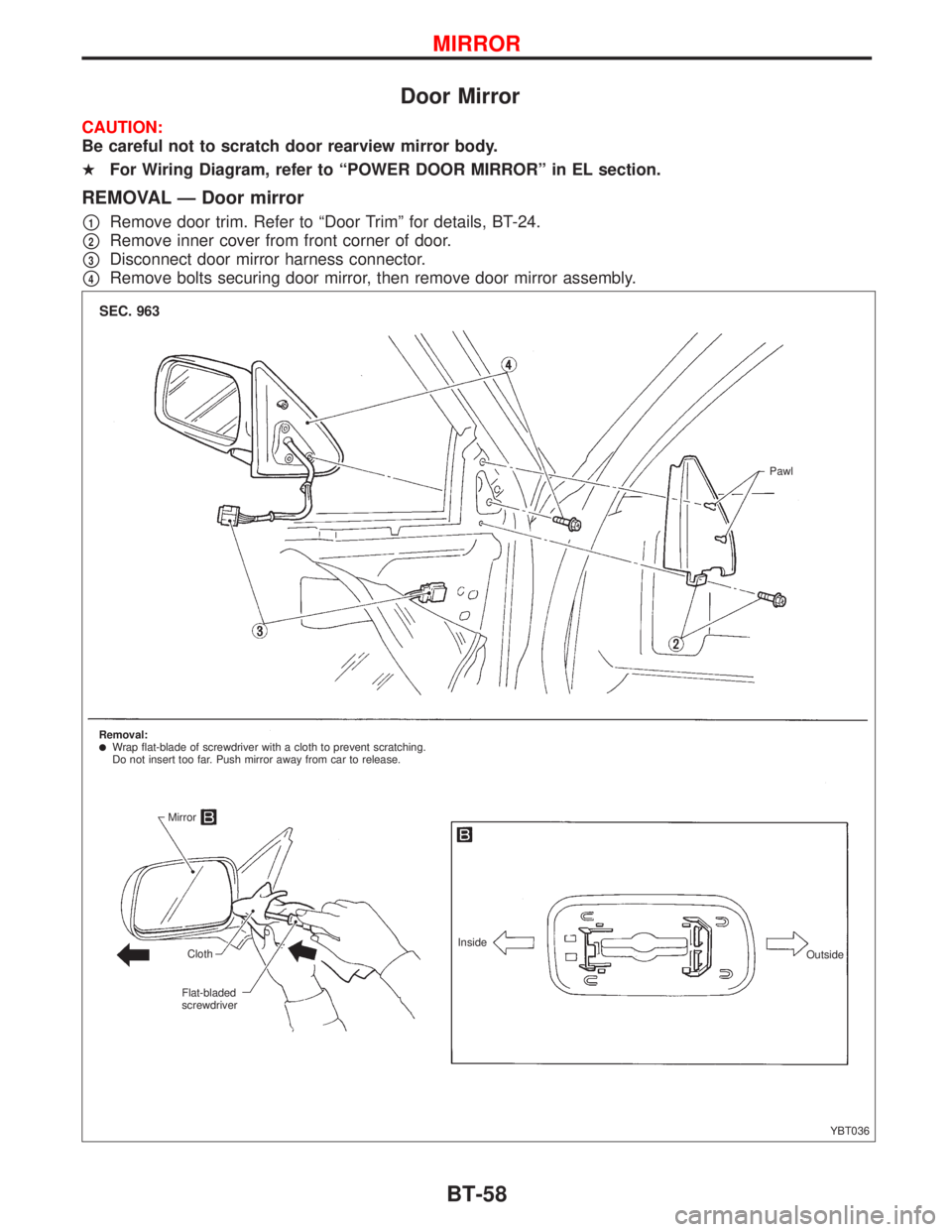

Door Mirror

CAUTION:

Be careful not to scratch door rearview mirror body.

HFor Wiring Diagram, refer to ªPOWER DOOR MIRRORº in EL section.

REMOVAL Ð Door mirror

p1Remove door trim. Refer to ªDoor Trimº for details, BT-24.

p2Remove inner cover from front corner of door.

p3Disconnect door mirror harness connector.

p4Remove bolts securing door mirror, then remove door mirror assembly.

YBT036

SEC. 963

Pawl

Removal:

lWrap flat-blade of screwdriver with a cloth to prevent scratching.

Do not insert too far. Push mirror away from car to release.

Mirror

Cloth

Flat-bladed

screwdriverInside

Outside

MIRROR

BT-58

Page 273 of 2267

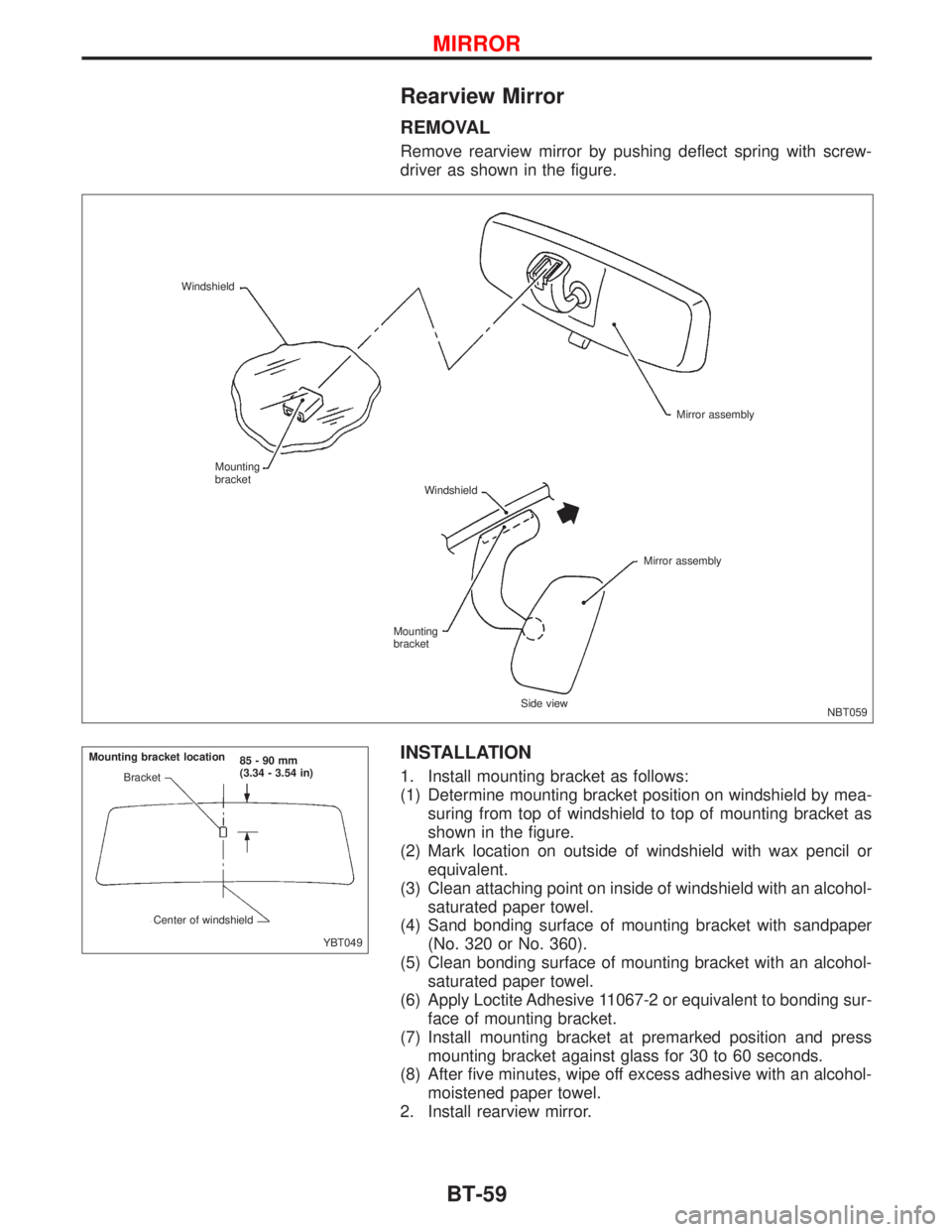

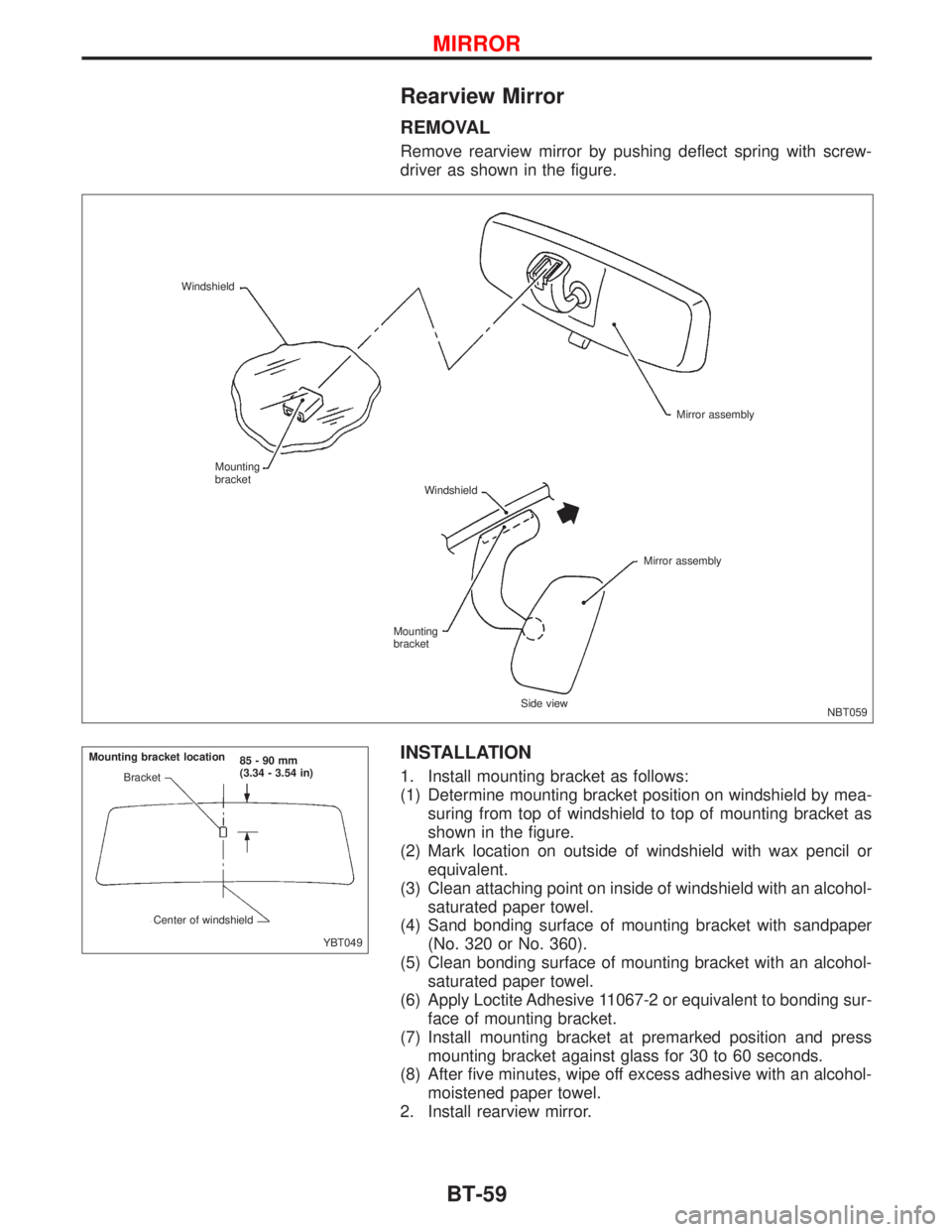

Rearview Mirror

REMOVAL

Remove rearview mirror by pushing deflect spring with screw-

driver as shown in the figure.

INSTALLATION

1. Install mounting bracket as follows:

(1) Determine mounting bracket position on windshield by mea-

suring from top of windshield to top of mounting bracket as

shown in the figure.

(2) Mark location on outside of windshield with wax pencil or

equivalent.

(3) Clean attaching point on inside of windshield with an alcohol-

saturated paper towel.

(4) Sand bonding surface of mounting bracket with sandpaper

(No. 320 or No. 360).

(5) Clean bonding surface of mounting bracket with an alcohol-

saturated paper towel.

(6) Apply Loctite Adhesive 11067-2 or equivalent to bonding sur-

face of mounting bracket.

(7) Install mounting bracket at premarked position and press

mounting bracket against glass for 30 to 60 seconds.

(8) After five minutes, wipe off excess adhesive with an alcohol-

moistened paper towel.

2. Install rearview mirror.

NBT059 Windshield

Mirror assembly

Windshield Mounting

bracket

Mounting

bracket

Side viewMirror assembly

YBT049 Bracket

Center of windshield85-90mm

(3.34 - 3.54 in) Mounting bracket location

MIRROR

BT-59

Page 274 of 2267

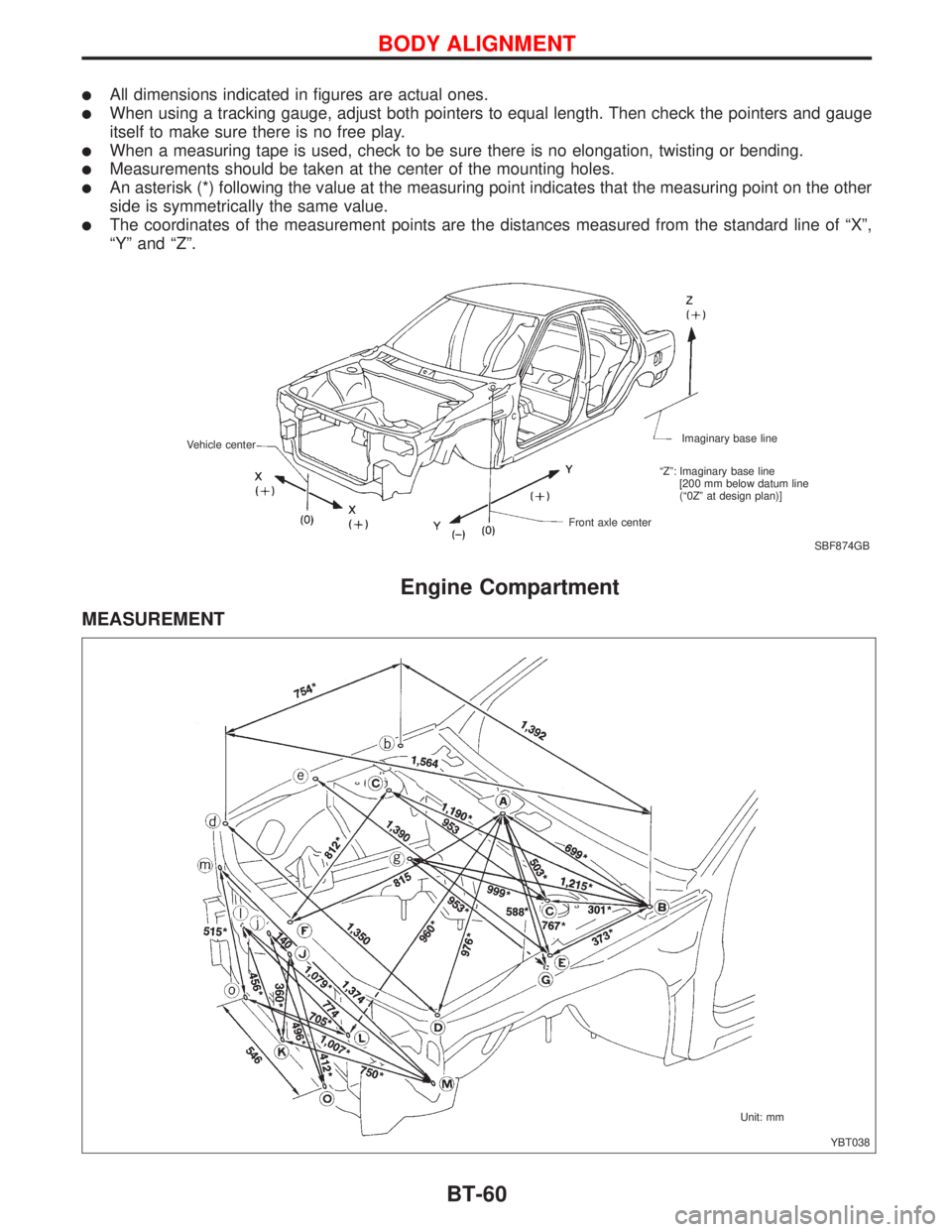

lAll dimensions indicated in figures are actual ones.

lWhen using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

lWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

lMeasurements should be taken at the center of the mounting holes.

lAn asterisk (*) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

lThe coordinates of the measurement points are the distances measured from the standard line of ªXº,

ªYº and ªZº.

Engine Compartment

MEASUREMENT

SBF874GB Imaginary base line

Front axle center Vehicle center

ªZº: Imaginary base line

[200 mm below datum line

(ª0Zº at design plan)]

YBT038 Unit: mm

BODY ALIGNMENT

BT-60

Page 275 of 2267

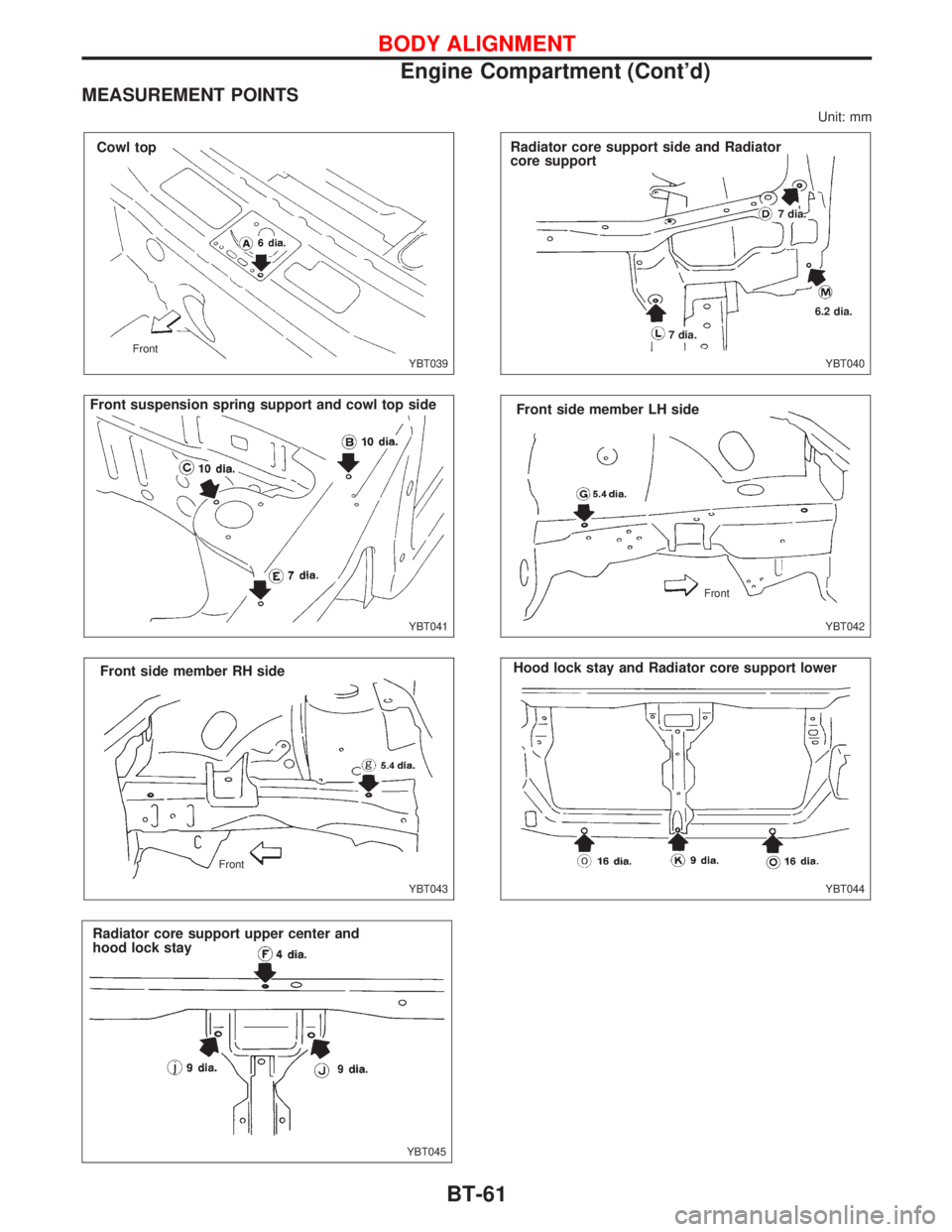

MEASUREMENT POINTS

Unit: mm

YBT039 Front

Cowl top

YBT041

.Front suspension spring support and cowl top side

.YBT043

Front side member RH side

Front

YBT045

Radiator core support upper center and

hood lock stay

YBT040

Radiator core support side and Radiator

core support

7 dia.

6.2 dia.

7 dia.

YBT042 Front

Front side member LH side

YBT044

Hood lock stay and Radiator core support lower

BODY ALIGNMENT

Engine Compartment (Cont'd)

BT-61

Page 276 of 2267

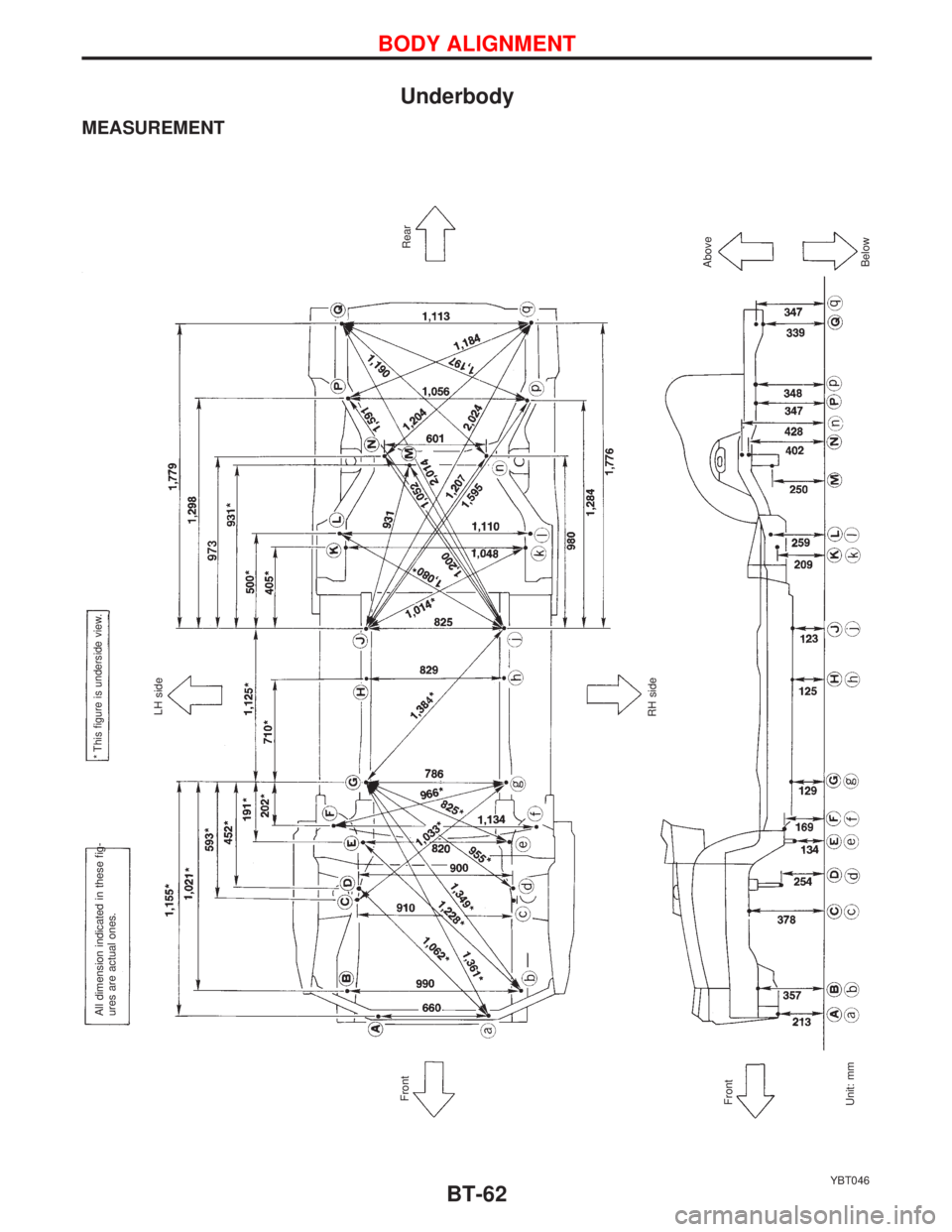

Underbody

MEASUREMENT

YBT046

Front

FrontRH sideLH side

Rear

Above All dimension indicated in these fig-

ures are actual ones.

* This figure is underside view.

Below Unit: mm

BODY ALIGNMENT

BT-62

Page 277 of 2267

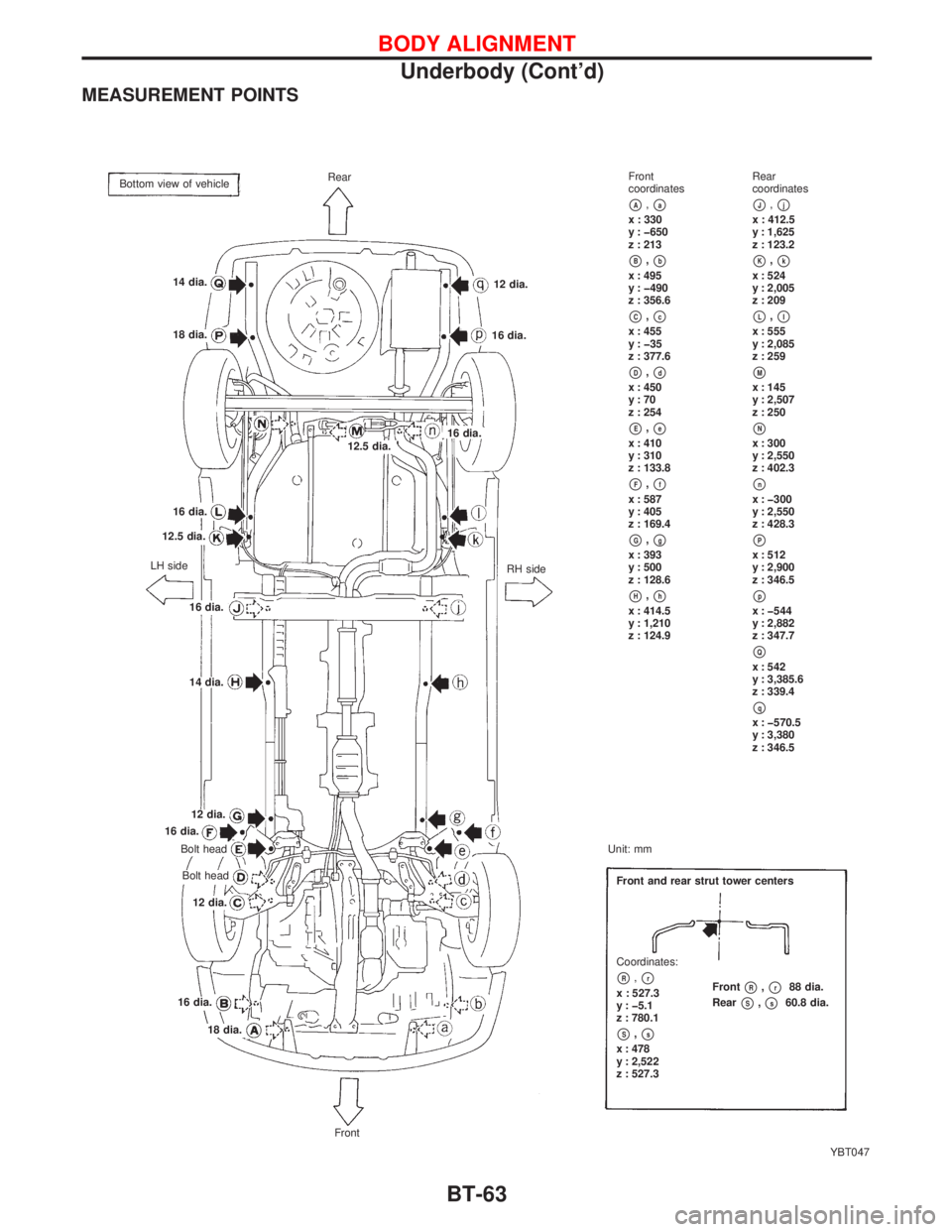

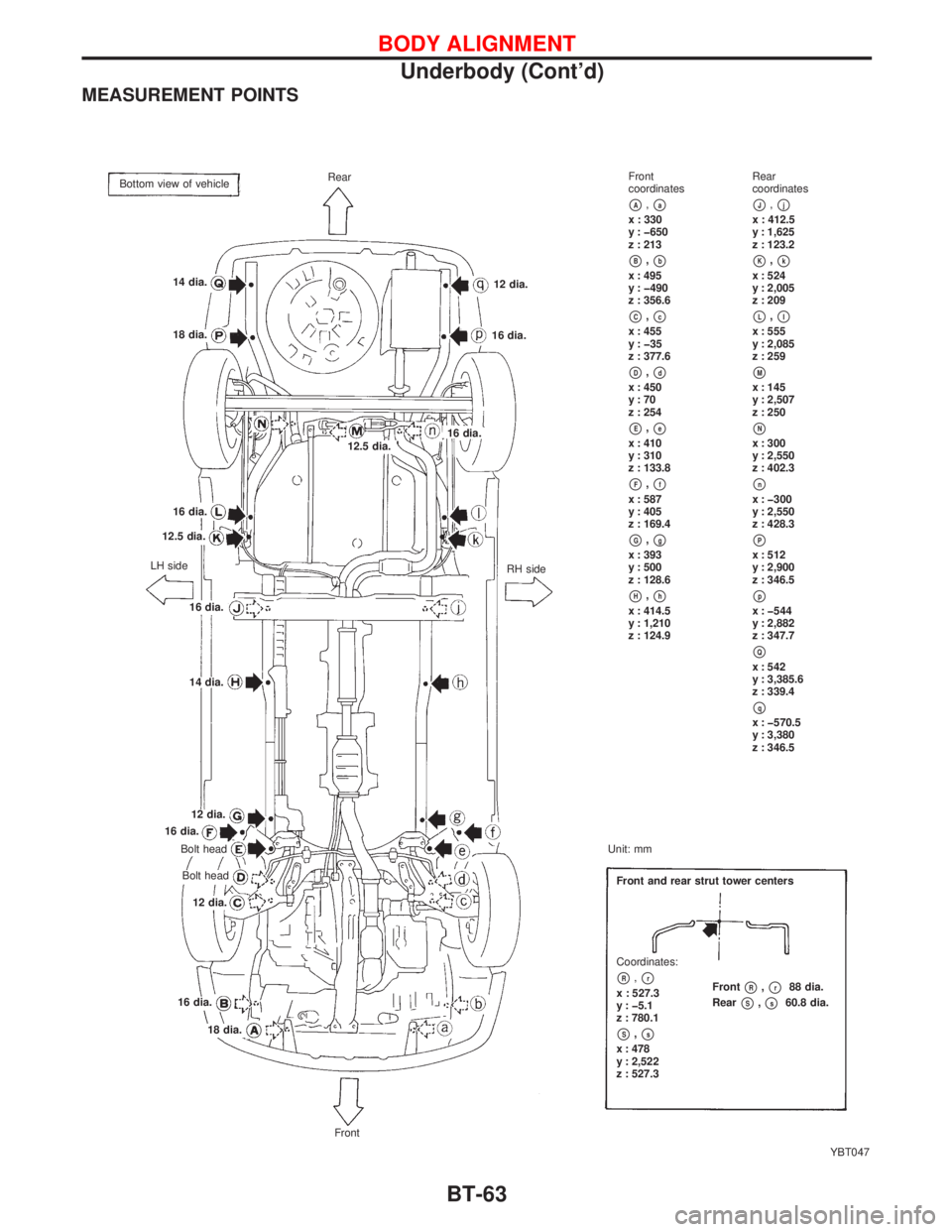

MEASUREMENT POINTS

YBT047 Rear

14 dia.

18 dia.12 dia.

16 dia.

12.5 dia.16 dia.

RH side 16 dia.

12.5 dia.

LH side

16 dia.

14 dia.

12 dia.

16 dia.

Bolt head

Bolt head

12 dia.

16 dia.

18 dia.Front and rear strut tower centers

Front

pR,pr88 dia.

Rear

pS,ps60.8 dia. Coordinates:

pR,prx : 527.3

y : þ5.1

z : 780.1

pS,psx : 478

y : 2,522

z : 527.3

FrontUnit: mmFront

coordinates

pA,pax : 330

y : þ650

z : 213

pB,pbx : 495

y : þ490

z : 356.6

pC,pcx : 455

y : þ35

z : 377.6

pD,pdx : 450

y:70

z : 254

pE,pex : 410

y : 310

z : 133.8

pF,pfx : 587

y : 405

z : 169.4

pG,pgx : 393

y : 500

z : 128.6

pH,phx : 414.5

y : 1,210

z : 124.9Rear

coordinates

pJ,pjx : 412.5

y : 1,625

z : 123.2

pK,pkx : 524

y : 2,005

z : 209

pL,plx : 555

y : 2,085

z : 259

pMx : 145

y : 2,507

z : 250

pNx : 300

y : 2,550

z : 402.3

pnx : þ300

y : 2,550

z : 428.3

pPx : 512

y : 2,900

z : 346.5

ppx : þ544

y : 2,882

z : 347.7

pQx : 542

y : 3,385.6

z : 339.4

pqx : þ570.5

y : 3,380

z : 346.5 Bottom view of vehicle

BODY ALIGNMENT

Underbody (Cont'd)

BT-63

Page 278 of 2267

NOTE

BODY ALIGNMENT

BT-64

Page 279 of 2267

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS AND PREPARATION.......................... 2

Precautions ................................................................ 2

Preparation ................................................................ 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING................................................... 3

NVH Troubleshooting Chart....................................... 3

CLUTCH SYSTEM......................................................... 4

INSPECTION AND ADJUSTMENT............................... 5

Inspecting and Adjusting Clutch Pedal ...................... 5

Bleeding Procedure ................................................... 7HYDRAULIC CLUTCH CONTROL............................... 8

Clutch Master Cylinder .............................................. 8

Clutch Operating Cylinder ......................................... 9

Clutch Damper ......................................................... 10

CLUTCH RELEASE MECHANISM.............................. 11

CLUTCH DISC AND CLUTCH COVER...................... 13

Clutch Disc............................................................... 13

Clutch Cover and Flywheel ..................................... 14

SERVICE DATA AND SPECIFICATIONS (SDS)........ 15

General Specifications ............................................. 15

Inspection and Adjustment ...................................... 16

CL

Page 280 of 2267

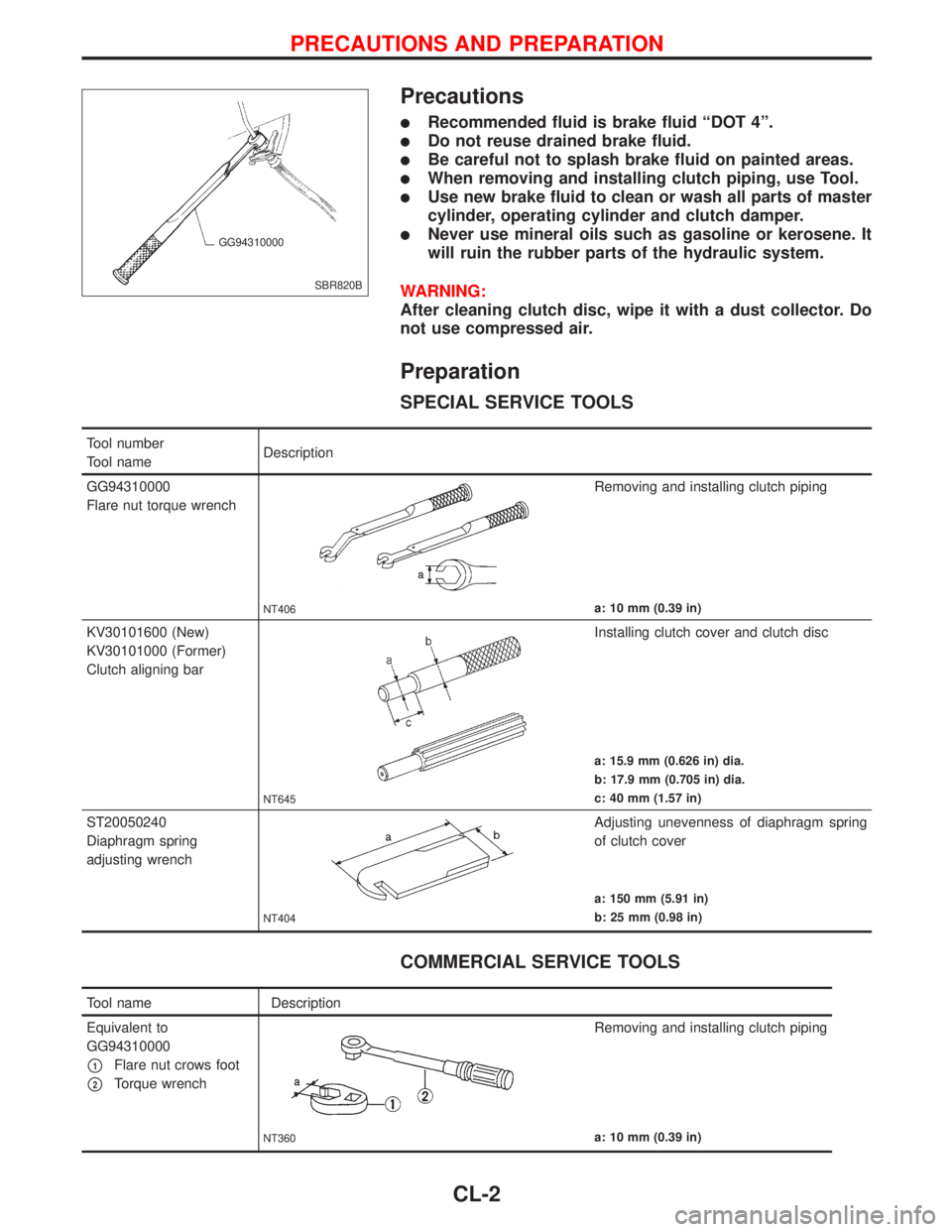

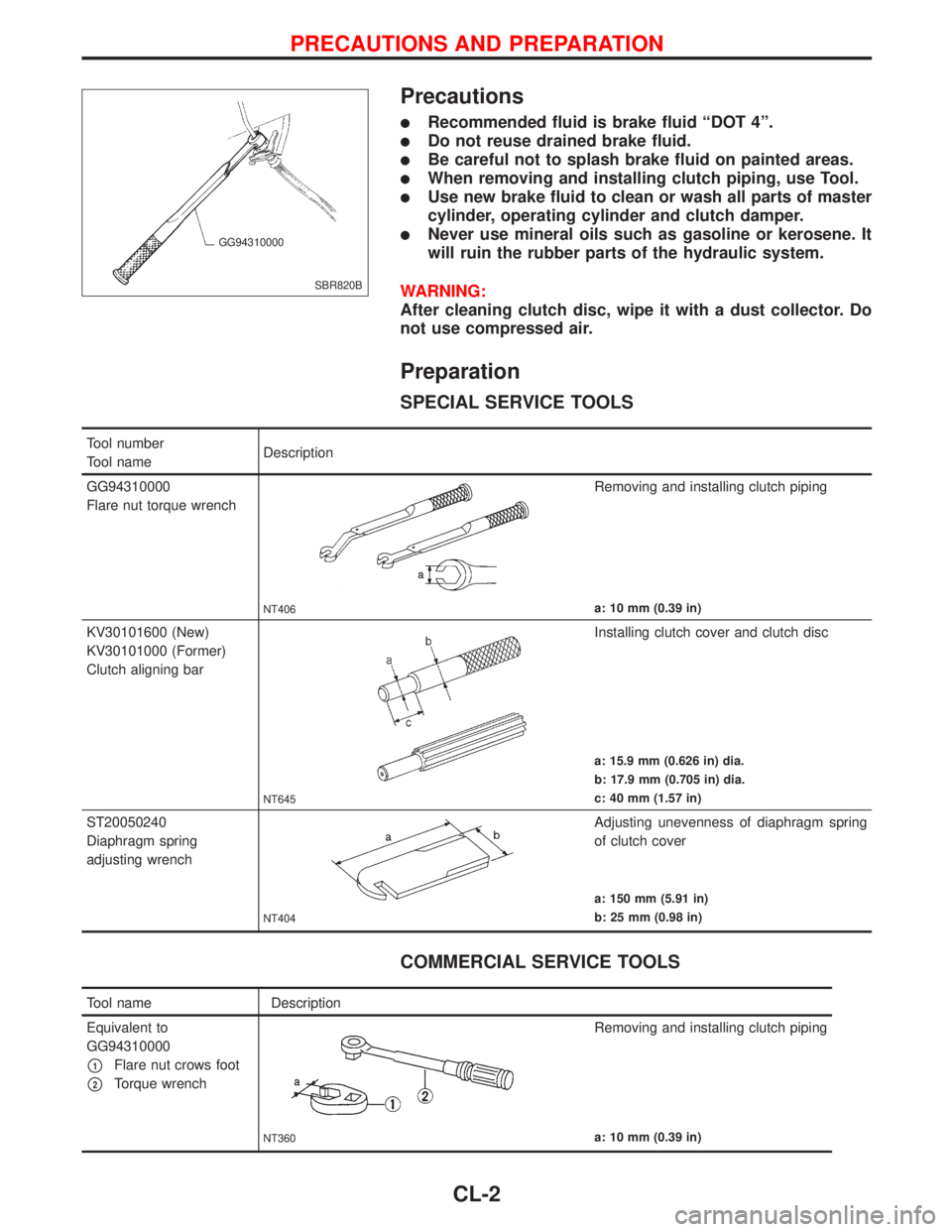

Precautions

lRecommended fluid is brake fluid ªDOT 4º.

lDo not reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lWhen removing and installing clutch piping, use Tool.

lUse new brake fluid to clean or wash all parts of master

cylinder, operating cylinder and clutch damper.

lNever use mineral oils such as gasoline or kerosene. It

will ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do

not use compressed air.

Preparation

SPECIAL SERVICE TOOLS

COMMERCIAL SERVICE TOOLS

SBR820B GG94310000

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing clutch piping

a: 10 mm (0.39 in)

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

NT645

Installing clutch cover and clutch disc

a: 15.9 mm (0.626 in) dia.

b: 17.9 mm (0.705 in) dia.

c: 40 mm (1.57 in)

ST20050240

Diaphragm spring

adjusting wrench

NT404

Adjusting unevenness of diaphragm spring

of clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

Tool name Description

Equivalent to

GG94310000

p1Flare nut crows foot

p2Torque wrench

NT360

Removing and installing clutch piping

a: 10 mm (0.39 in)

PRECAUTIONS AND PREPARATION

CL-2

Trending: maintenance schedule, change wheel, rear view mirror, sr20de, transmission oil, fuel filter, hood release