NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 591 of 2267

4 CHECK HEATED OXYGEN SENSOR 1 HEATER (FRONT)

Refer to ªComponent Inspectionº, EC-QG-170.

OK or NG

OK©GO TO 5.

NG©Replace heated oxygen sensor 1 (front).

5 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-QG-149.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 1 (front).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

Refer to ªWiring Diagramº, EC-QG-135, for circuit.

©INSPECTION END

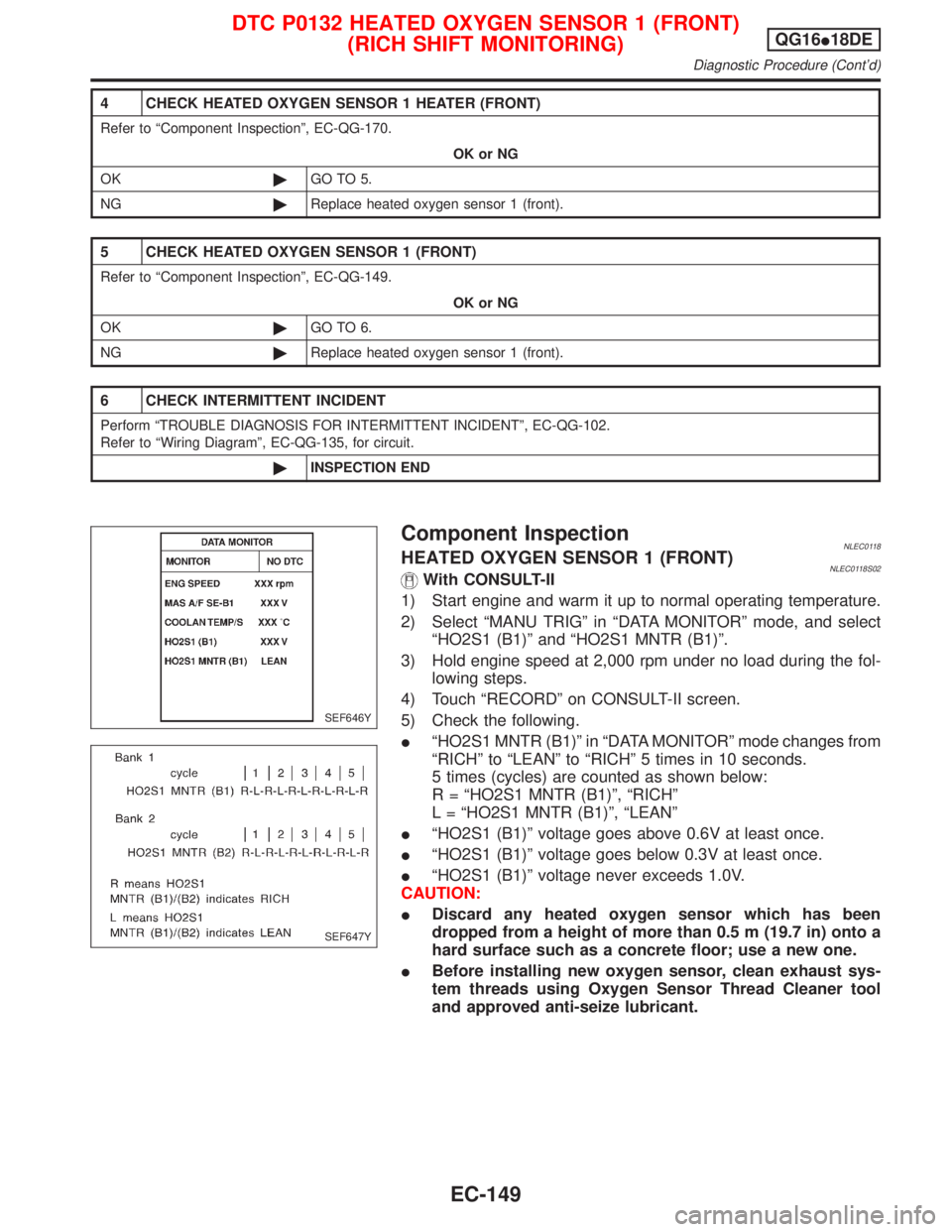

Component InspectionNLEC0118HEATED OXYGEN SENSOR 1 (FRONT)NLEC0118S02With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªMANU TRIGº in ªDATA MONITORº mode, and select

ªHO2S1 (B1)º and ªHO2S1 MNTR (B1)º.

3) Hold engine speed at 2,000 rpm under no load during the fol-

lowing steps.

4) Touch ªRECORDº on CONSULT-II screen.

5) Check the following.

IªHO2S1 MNTR (B1)º in ªDATA MONITORº mode changes from

ªRICHº to ªLEANº to ªRICHº 5 times in 10 seconds.

5 times (cycles) are counted as shown below:

R = ªHO2S1 MNTR (B1)º, ªRICHº

L = ªHO2S1 MNTR (B1)º, ªLEANº

IªHO2S1 (B1)º voltage goes above 0.6V at least once.

IªHO2S1 (B1)º voltage goes below 0.3V at least once.

IªHO2S1 (B1)º voltage never exceeds 1.0V.

CAUTION:

IDiscard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

IBefore installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

SEF646Y

SEF647Y

DTC P0132 HEATED OXYGEN SENSOR 1 (FRONT)

(RICH SHIFT MONITORING)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-149

Page 592 of 2267

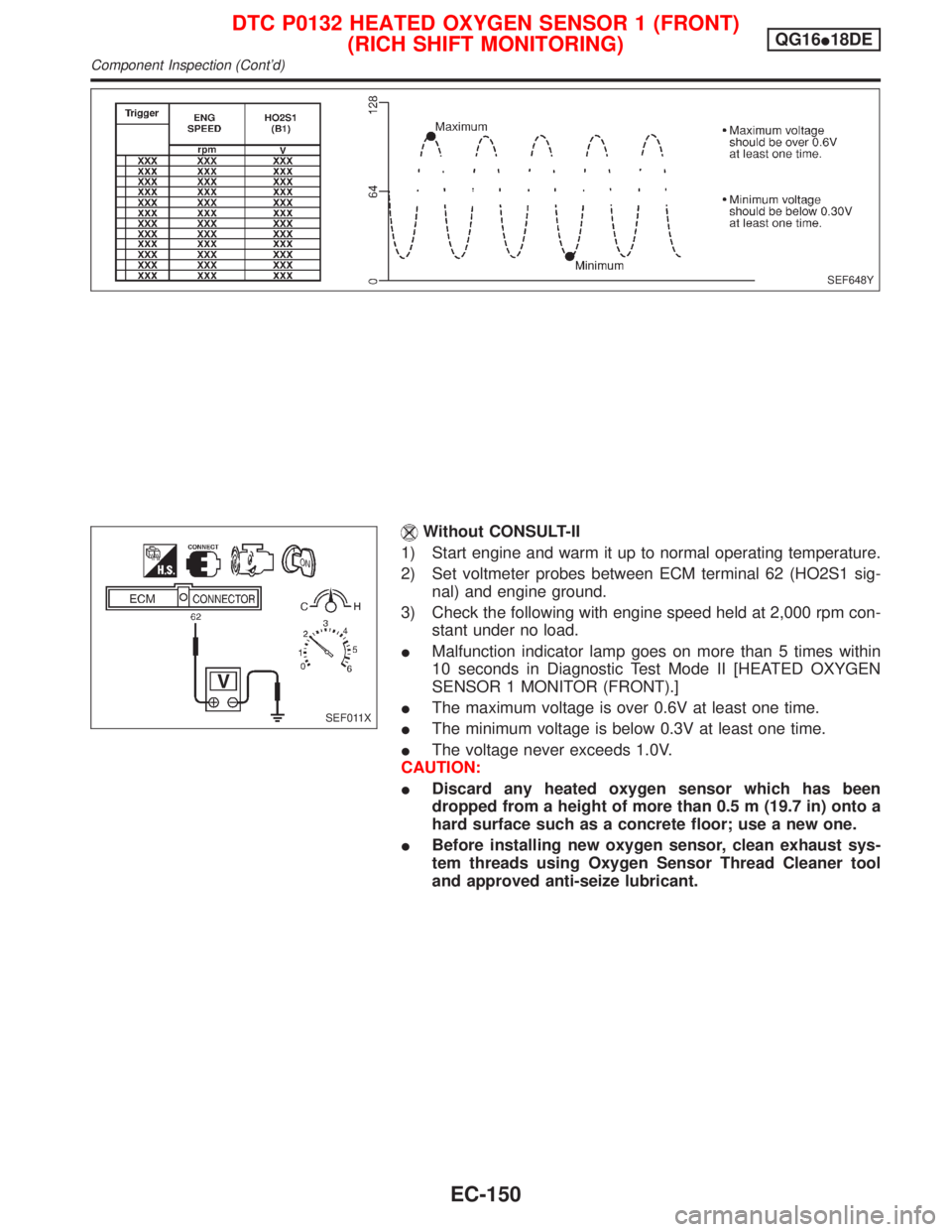

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (HO2S1 sig-

nal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IMalfunction indicator lamp goes on more than 5 times within

10 seconds in Diagnostic Test Mode II [HEATED OXYGEN

SENSOR 1 MONITOR (FRONT).]

IThe maximum voltage is over 0.6V at least one time.

IThe minimum voltage is below 0.3V at least one time.

IThe voltage never exceeds 1.0V.

CAUTION:

IDiscard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

IBefore installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

SEF648Y

SEF011X

DTC P0132 HEATED OXYGEN SENSOR 1 (FRONT)

(RICH SHIFT MONITORING)QG16I18DE

Component Inspection (Cont'd)

EC-150

Page 593 of 2267

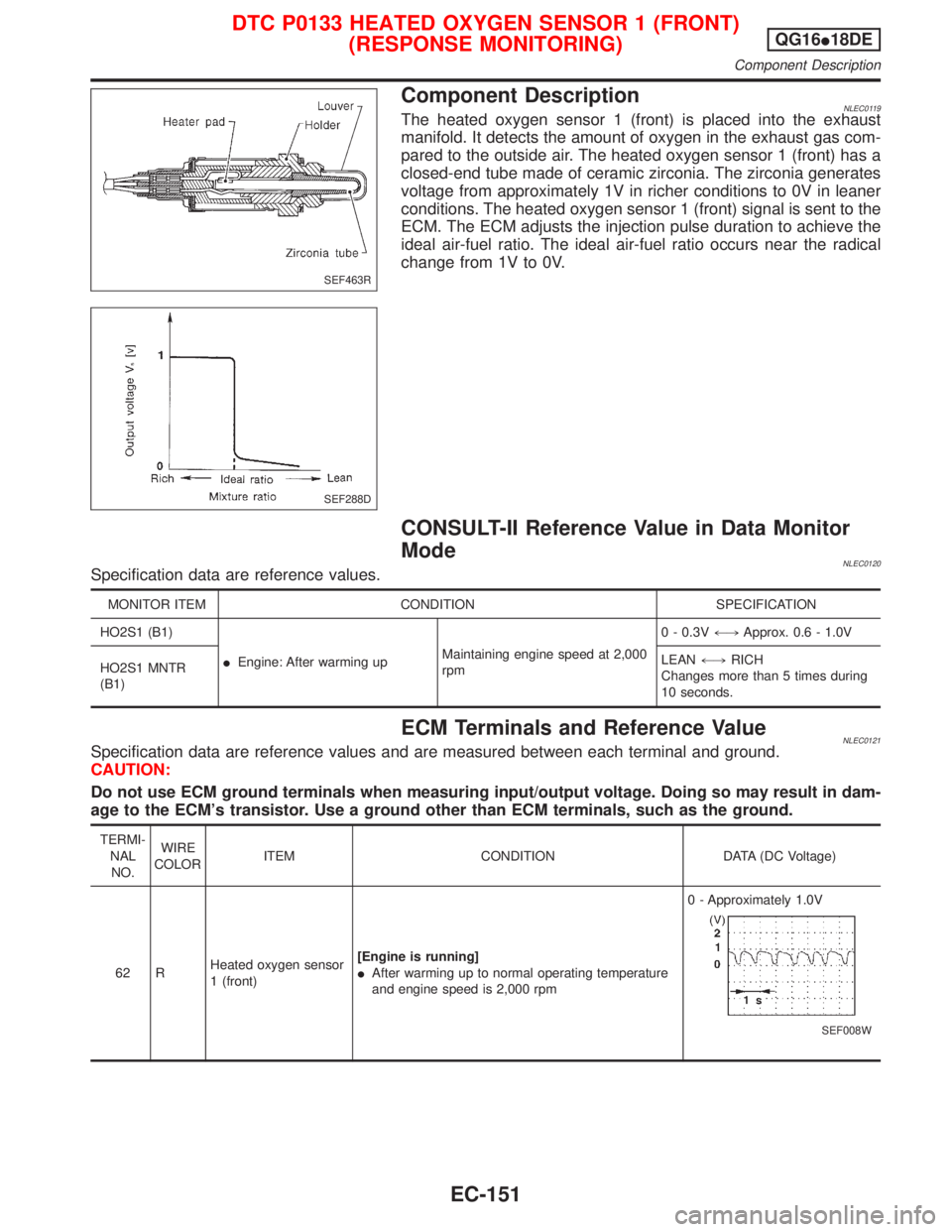

Component DescriptionNLEC0119The heated oxygen sensor 1 (front) is placed into the exhaust

manifold. It detects the amount of oxygen in the exhaust gas com-

pared to the outside air. The heated oxygen sensor 1 (front) has a

closed-end tube made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions. The heated oxygen sensor 1 (front) signal is sent to the

ECM. The ECM adjusts the injection pulse duration to achieve the

ideal air-fuel ratio. The ideal air-fuel ratio occurs near the radical

change from 1V to 0V.

CONSULT-II Reference Value in Data Monitor

Mode

NLEC0120Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S1 (B1)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 - 1.0V

HO2S1 MNTR

(B1)LEAN+,RICH

Changes more than 5 times during

10 seconds.

ECM Terminals and Reference ValueNLEC0121Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

62 RHeated oxygen sensor

1 (front)[Engine is running]

IAfter warming up to normal operating temperature

and engine speed is 2,000 rpm0 - Approximately 1.0V

SEF008W

SEF463R

SEF288D

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Component Description

EC-151

Page 594 of 2267

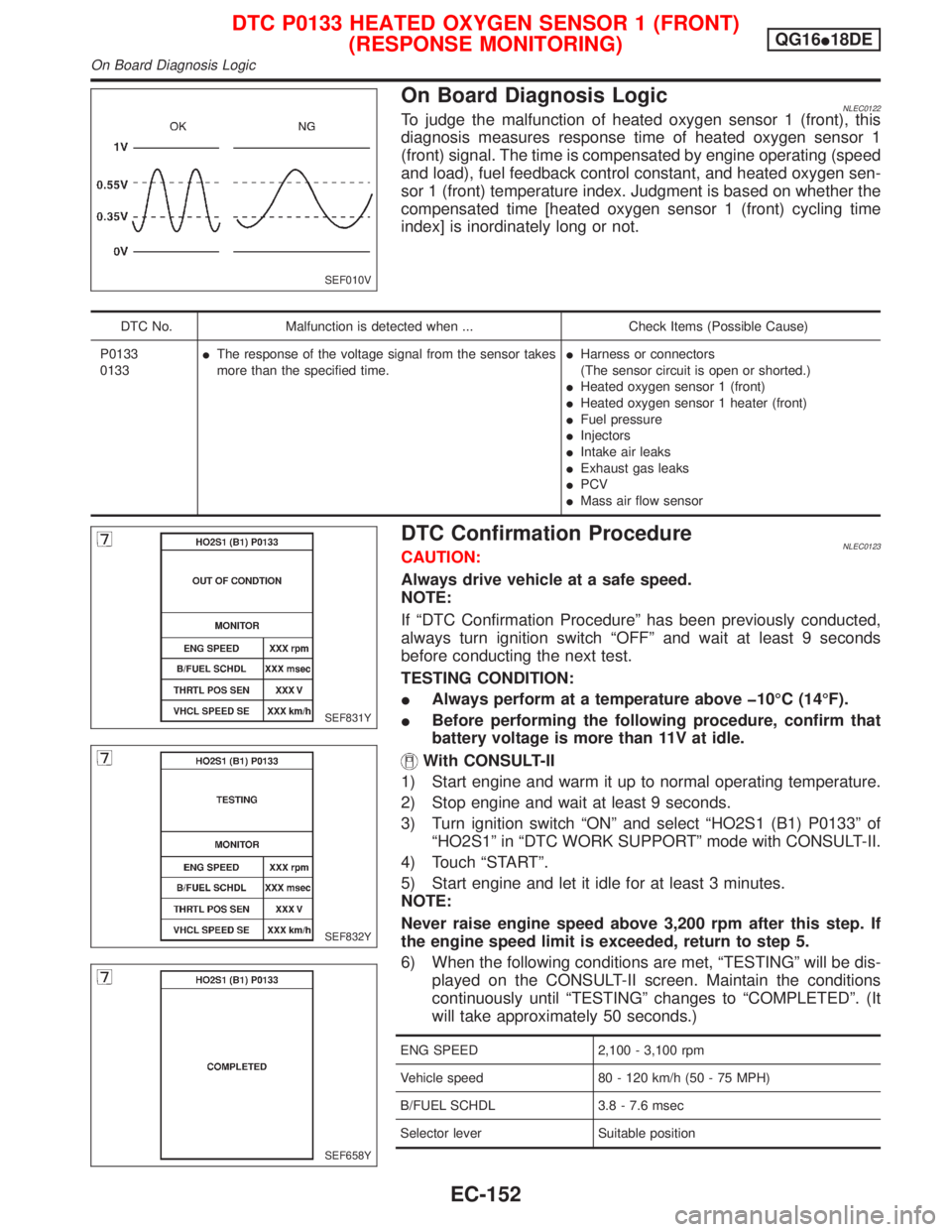

On Board Diagnosis LogicNLEC0122To judge the malfunction of heated oxygen sensor 1 (front), this

diagnosis measures response time of heated oxygen sensor 1

(front) signal. The time is compensated by engine operating (speed

and load), fuel feedback control constant, and heated oxygen sen-

sor 1 (front) temperature index. Judgment is based on whether the

compensated time [heated oxygen sensor 1 (front) cycling time

index] is inordinately long or not.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0133

0133IThe response of the voltage signal from the sensor takes

more than the specified time.IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 1 (front)

IHeated oxygen sensor 1 heater (front)

IFuel pressure

IInjectors

IIntake air leaks

IExhaust gas leaks

IPCV

IMass air flow sensor

DTC Confirmation ProcedureNLEC0123CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Stop engine and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªHO2S1 (B1) P0133º of

ªHO2S1º in ªDTC WORK SUPPORTº mode with CONSULT-II.

4) Touch ªSTARTº.

5) Start engine and let it idle for at least 3 minutes.

NOTE:

Never raise engine speed above 3,200 rpm after this step. If

the engine speed limit is exceeded, return to step 5.

6) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take approximately 50 seconds.)

ENG SPEED 2,100 - 3,100 rpm

Vehicle speed 80 - 120 km/h (50 - 75 MPH)

B/FUEL SCHDL 3.8 - 7.6 msec

Selector lever Suitable position

SEF010V

SEF831Y

SEF832Y

SEF658Y

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

On Board Diagnosis Logic

EC-152

Page 595 of 2267

7) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-QG-155.

Overall Function CheckNLEC0124Use this procedure to check the overall function of the heated oxy-

gen sensor 1 (front) circuit. During this check, a 1st trip DTC might

not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set ECM in Diagnostic Test Mode II [HEATED OXYGEN SEN-

SOR 1 MONITOR (FRONT)].

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IMalfunction indicator goes on more than five times within 10

seconds in Diagnostic Test Mode II [HEATED OXYGEN SEN-

SOR 1 MONITOR (FRONT).]

4) If NG, go to ªDiagnostic Procedureº, EC-QG-155.

SAT652J

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Overall Function Check

EC-153

Page 596 of 2267

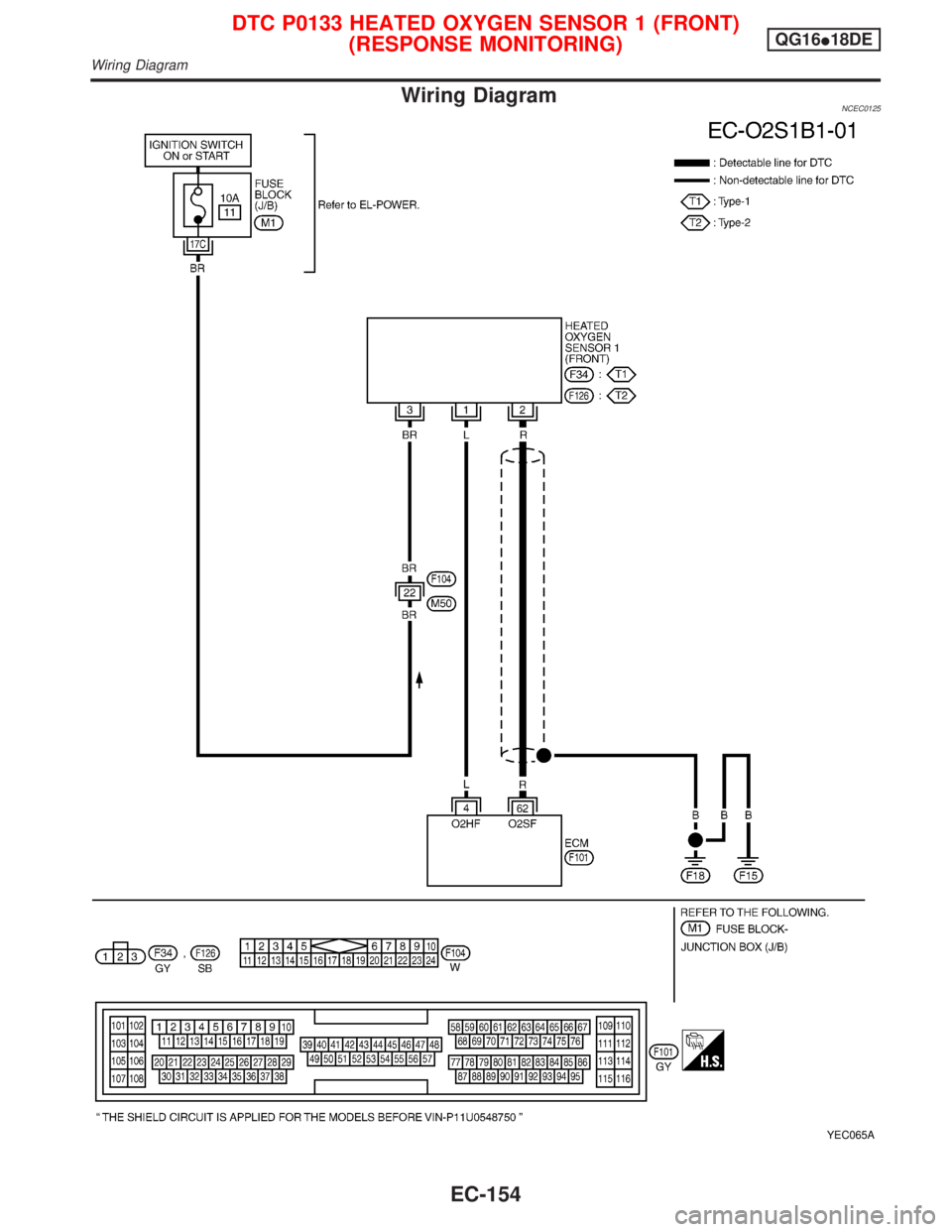

Wiring DiagramNCEC0125

YEC065A

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Wiring Diagram

EC-154

Page 597 of 2267

Diagnostic ProcedureNLEC0126

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF994W

©GO TO 2.

2 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40-60N×m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 3.

3 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before three way catalyst.

SEF099P

OK or NG

OK©GO TO 4.

NG©Repair or replace.

4 CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 5.

NG©Repair or replace.

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Diagnostic Procedure

EC-155

Page 598 of 2267

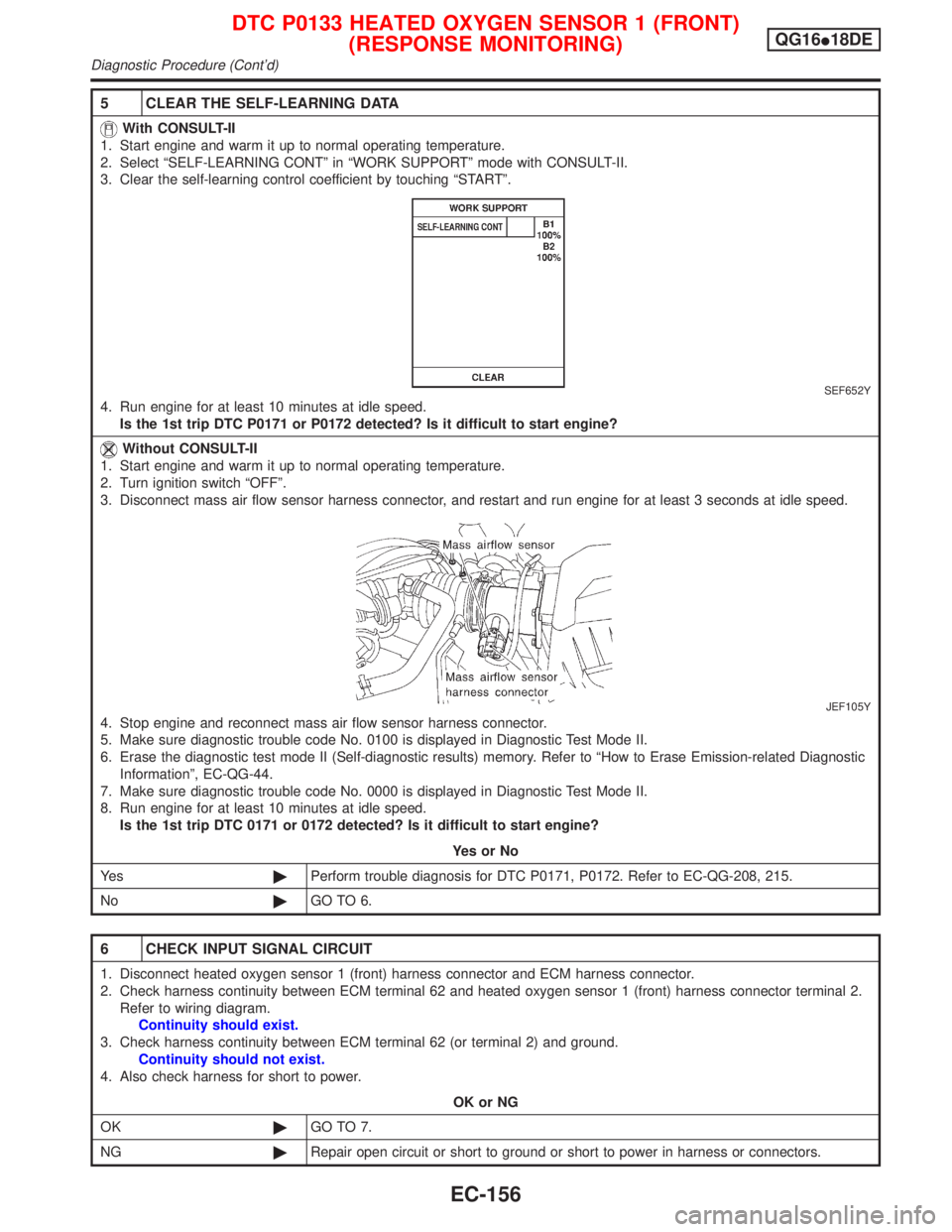

5 CLEAR THE SELF-LEARNING DATA

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªSELF-LEARNING CONTº in ªWORK SUPPORTº mode with CONSULT-II.

3. Clear the self-learning control coefficient by touching ªSTARTº.

SEF652Y

4. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171 or P0172 detected? Is it difficult to start engine?

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Disconnect mass air flow sensor harness connector, and restart and run engine for at least 3 seconds at idle speed.

JEF105Y

4. Stop engine and reconnect mass air flow sensor harness connector.

5. Make sure diagnostic trouble code No. 0100 is displayed in Diagnostic Test Mode II.

6. Erase the diagnostic test mode II (Self-diagnostic results) memory. Refer to ªHow to Erase Emission-related Diagnostic

Informationº, EC-QG-44.

7. Make sure diagnostic trouble code No. 0000 is displayed in Diagnostic Test Mode II.

8. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC 0171 or 0172 detected? Is it difficult to start engine?

YesorNo

Ye s©Perform trouble diagnosis for DTC P0171, P0172. Refer to EC-QG-208, 215.

No©GO TO 6.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-156

Page 599 of 2267

7 CHECK HEATED OXYGEN SENSOR 1 HEATER (FRONT)

Refer to ªComponent Inspectionº, EC-QG-170.

OK or NG

OK©GO TO 8.

NG©Replace heated oxygen sensor 1 (front).

8 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-QG-158.

OK or NG

OK©GO TO 9.

NG©Replace heated oxygen sensor 1 (front).

9 CHECK MASS AIR FLOW SENSOR

Refer to ªComponent Inspectionº, EC-QG-115.

OK or NG

OK©GO TO 10.

NG©Replace mass air flow sensor.

10 CHECK PCV VALVE

Refer to ªPositive Crankcase Ventilationº, EC-QG-28.

OK or NG

OK©GO TO 11.

NG©Repair or replace PCV valve.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-157

Page 600 of 2267

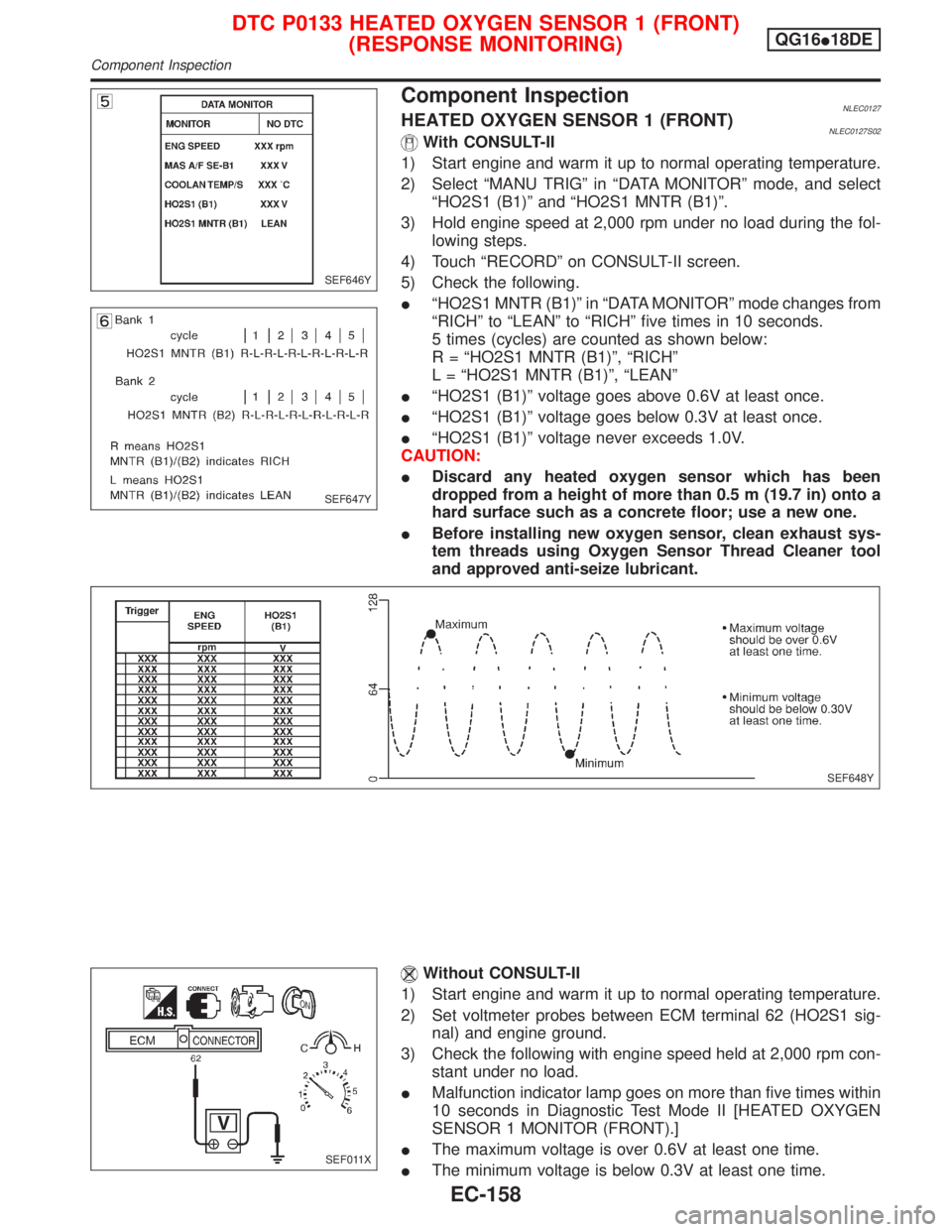

Component InspectionNLEC0127HEATED OXYGEN SENSOR 1 (FRONT)NLEC0127S02With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªMANU TRIGº in ªDATA MONITORº mode, and select

ªHO2S1 (B1)º and ªHO2S1 MNTR (B1)º.

3) Hold engine speed at 2,000 rpm under no load during the fol-

lowing steps.

4) Touch ªRECORDº on CONSULT-II screen.

5) Check the following.

IªHO2S1 MNTR (B1)º in ªDATA MONITORº mode changes from

ªRICHº to ªLEANº to ªRICHº five times in 10 seconds.

5 times (cycles) are counted as shown below:

R = ªHO2S1 MNTR (B1)º, ªRICHº

L = ªHO2S1 MNTR (B1)º, ªLEANº

IªHO2S1 (B1)º voltage goes above 0.6V at least once.

IªHO2S1 (B1)º voltage goes below 0.3V at least once.

IªHO2S1 (B1)º voltage never exceeds 1.0V.

CAUTION:

IDiscard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

IBefore installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (HO2S1 sig-

nal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

IMalfunction indicator lamp goes on more than five times within

10 seconds in Diagnostic Test Mode II [HEATED OXYGEN

SENSOR 1 MONITOR (FRONT).]

IThe maximum voltage is over 0.6V at least one time.

IThe minimum voltage is below 0.3V at least one time.

SEF646Y

SEF647Y

SEF648Y

SEF011X

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)QG16I18DE

Component Inspection

EC-158