NISSAN PRIMERA 1999 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 991 of 2267

Diagnostic ProcedureNCEC0160

1 RETIGHTEN GROUND SCREWS

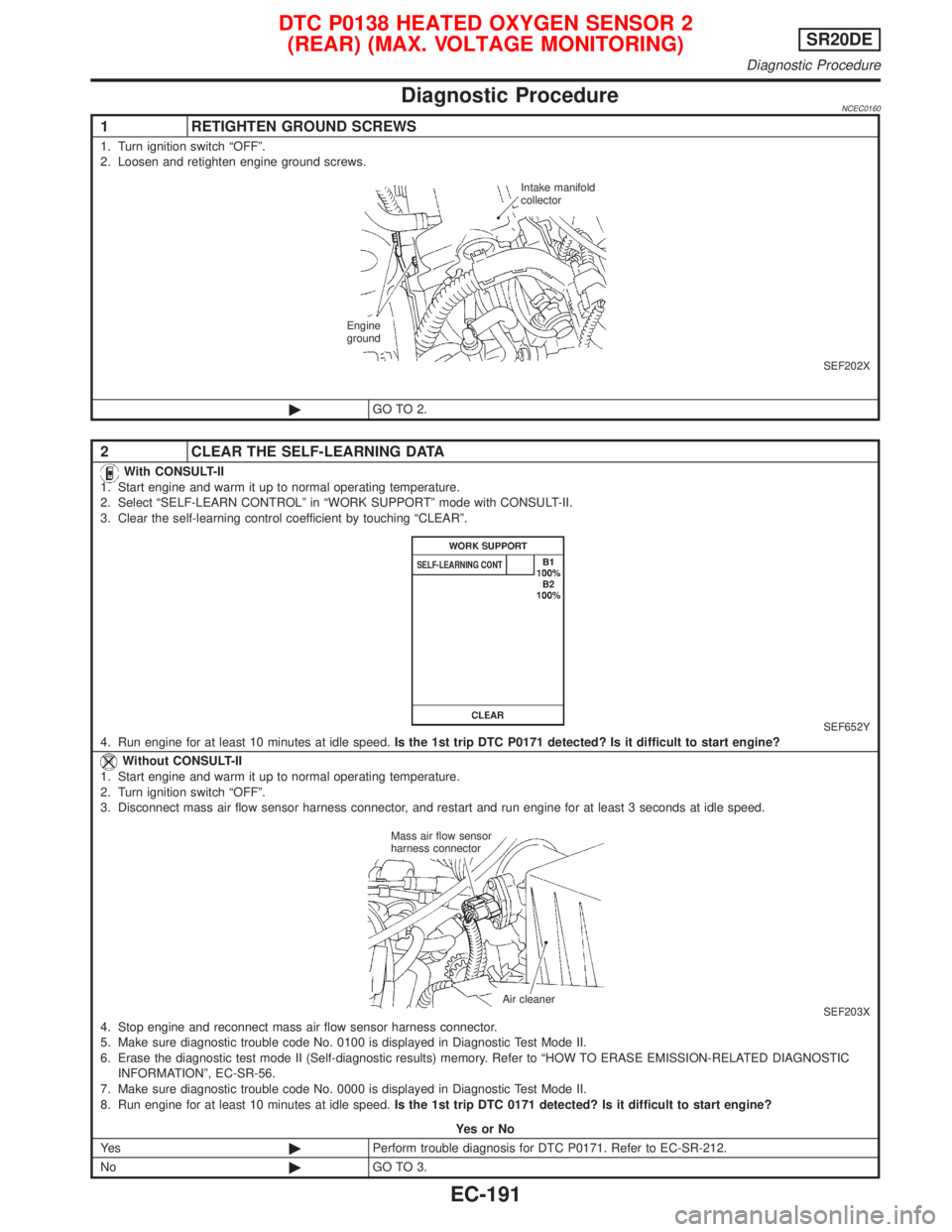

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 2.

2 CLEAR THE SELF-LEARNING DATA

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªSELF-LEARN CONTROLº in ªWORK SUPPORTº mode with CONSULT-II.

3. Clear the self-learning control coefficient by touching ªCLEARº.

SEF652Y4. Run engine for at least 10 minutes at idle speed.Is the 1st trip DTC P0171 detected? Is it difficult to start engine?

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Disconnect mass air flow sensor harness connector, and restart and run engine for at least 3 seconds at idle speed.

SEF203X4. Stop engine and reconnect mass air flow sensor harness connector.

5. Make sure diagnostic trouble code No. 0100 is displayed in Diagnostic Test Mode II.

6. Erase the diagnostic test mode II (Self-diagnostic results) memory. Refer to ªHOW TO ERASE EMISSION-RELATED DIAGNOSTIC

INFORMATIONº, EC-SR-56.

7. Make sure diagnostic trouble code No. 0000 is displayed in Diagnostic Test Mode II.

8. Run engine for at least 10 minutes at idle speed.Is the 1st trip DTC 0171 detected? Is it difficult to start engine?

YesorNo

Ye s©Perform trouble diagnosis for DTC P0171. Refer to EC-SR-212.

No©GO TO 3.

Intake manifold

collector

Engine

ground

Air cleaner Mass air flow sensor

harness connector

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING)SR20DE

Diagnostic Procedure

EC-191

Page 992 of 2267

3 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 2 (rear) harness connector and ECM harness connector.

2. Check harness continuity between ECM terminal 63 and heated oxygen sensor 2 (rear) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 63 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and heated oxygen sensor 2 (rear).

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK GROUND CIRCUIT

1. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 3 and engine ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-SR-193.

OK or NG

OK©GO TO 7.

NG©Replace heated oxygen sensor 2 (rear).

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING)SR20DE

Diagnostic Procedure (Cont'd)

EC-192

Page 993 of 2267

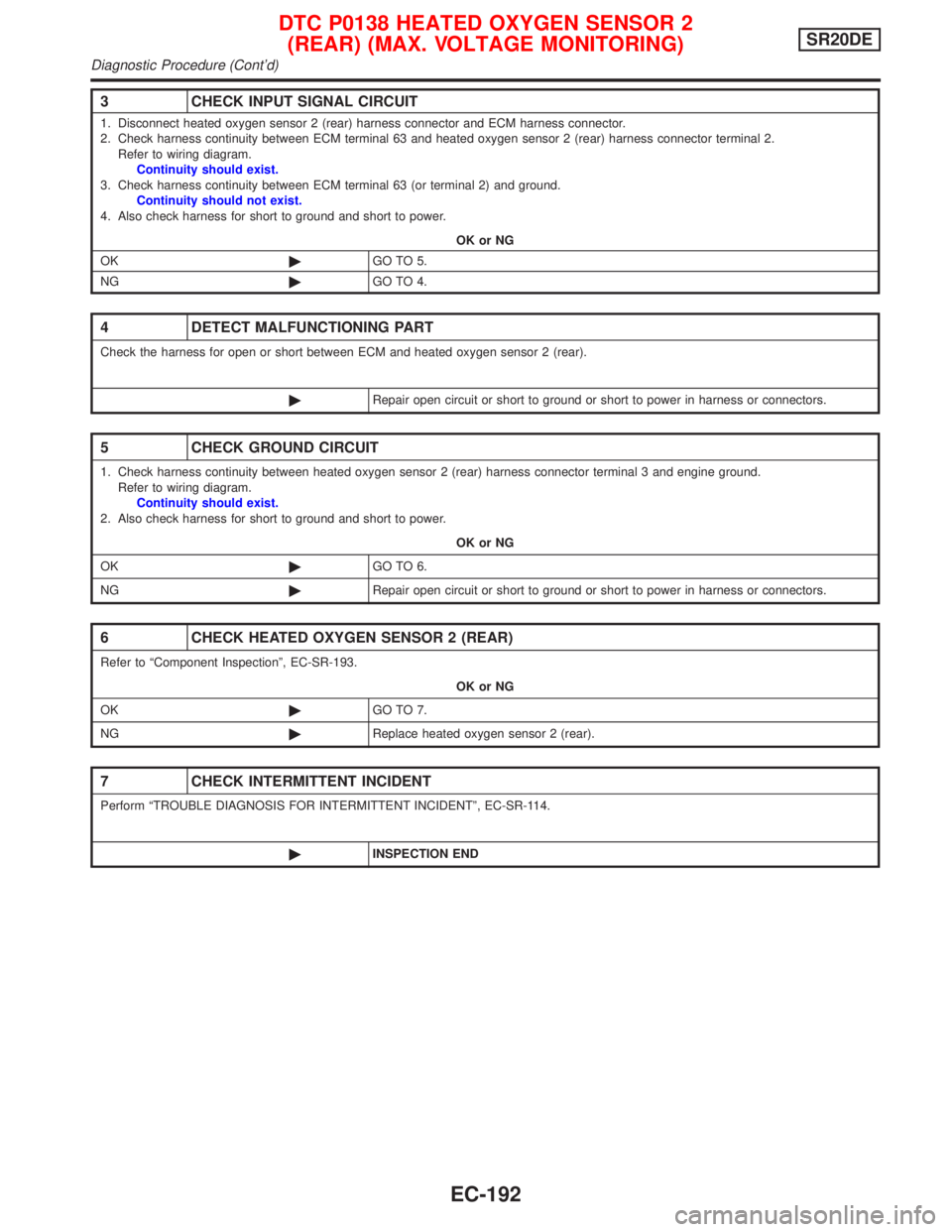

Component InspectionNCEC0161HEATED OXYGEN SENSOR 2 (REAR)NCEC0161S01With CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes..

2) Stop vehicle with engine running.

3) Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and

select ªHO2S2 (B1)º as the monitor item with CONSULT-II.

4) Check ªHO2S2 (B1)º at idle speed when adjusting ªFUEL

INJECTIONº to 25%.

ªHO2S2 (B1)º should be above 0.48V at least once when

the ªFUEL INJECTIONº is +25%.

ªHO2S2 (B1)º should be below 0.43V at least once when

the ªFUEL INJECTIONº is þ25%.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

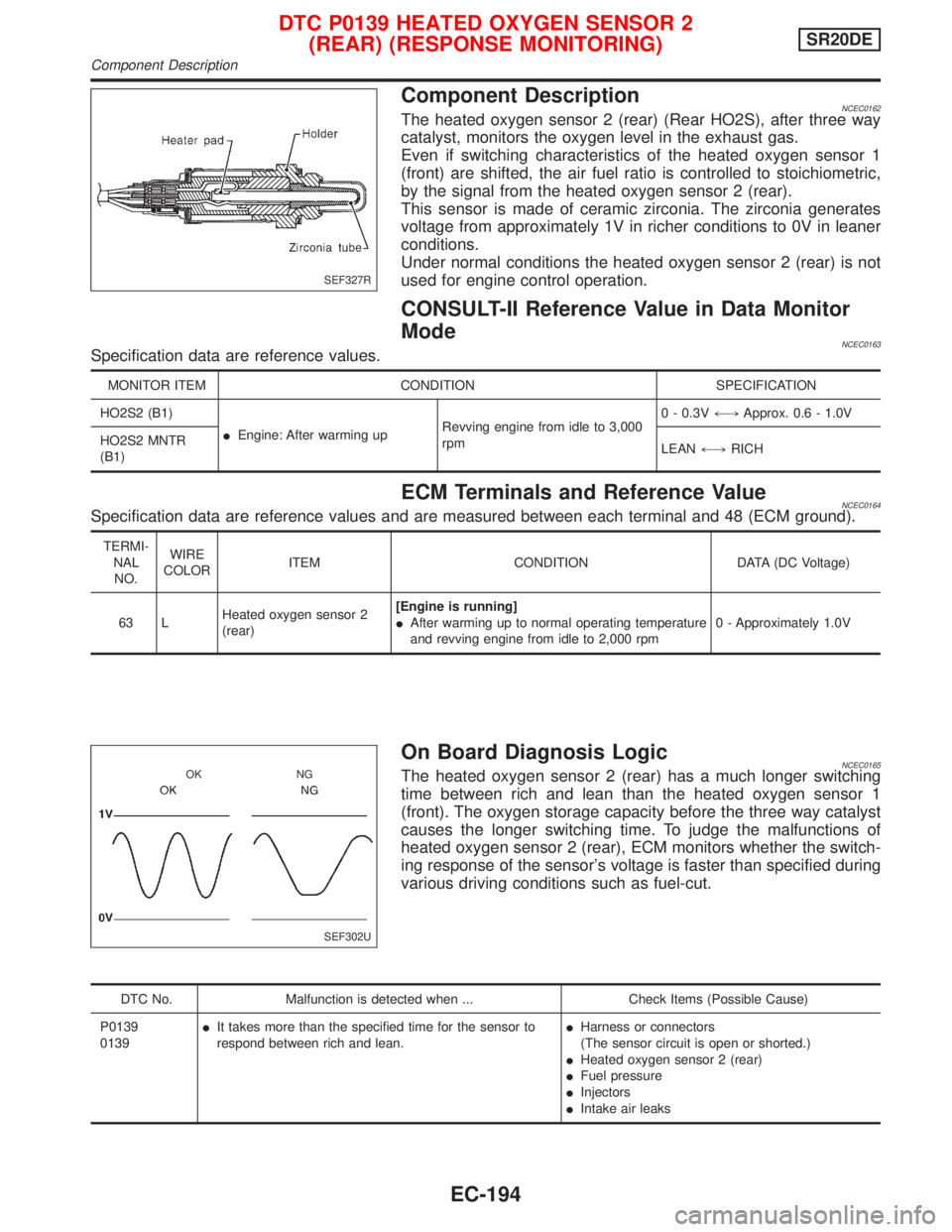

Without CONSULT-II

1) Start engine and drive vehicle at a speed of 70 km/h (43 MPH)

for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (Heated oxy-

gen sensor 2 (rear) signal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.48V at least once.

If the voltage is above 0.48V at step 4, step 5 is not nec-

essary.

5) Check the voltage when revving up to 6,000 rpm under no

load. Or keep vehicle at idling for 10 minutes, then check the

voltage. Or check the voltage when coasting from 80 km/h (50

MPH) in 3rd gear position (M/T), D position with ªSPORTS

MODE SWº OFF or without ªMANUAL MODEº (CVT).

The voltage should be below 0.43V at least once.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

NEF091A

SEF989R (Reference data)

The voltage should be above

0.48V at least one time.

The voltage should be below

0.43V at least one time.

x0.01V

SEF032X

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING)SR20DE

Component Inspection

EC-193

Page 994 of 2267

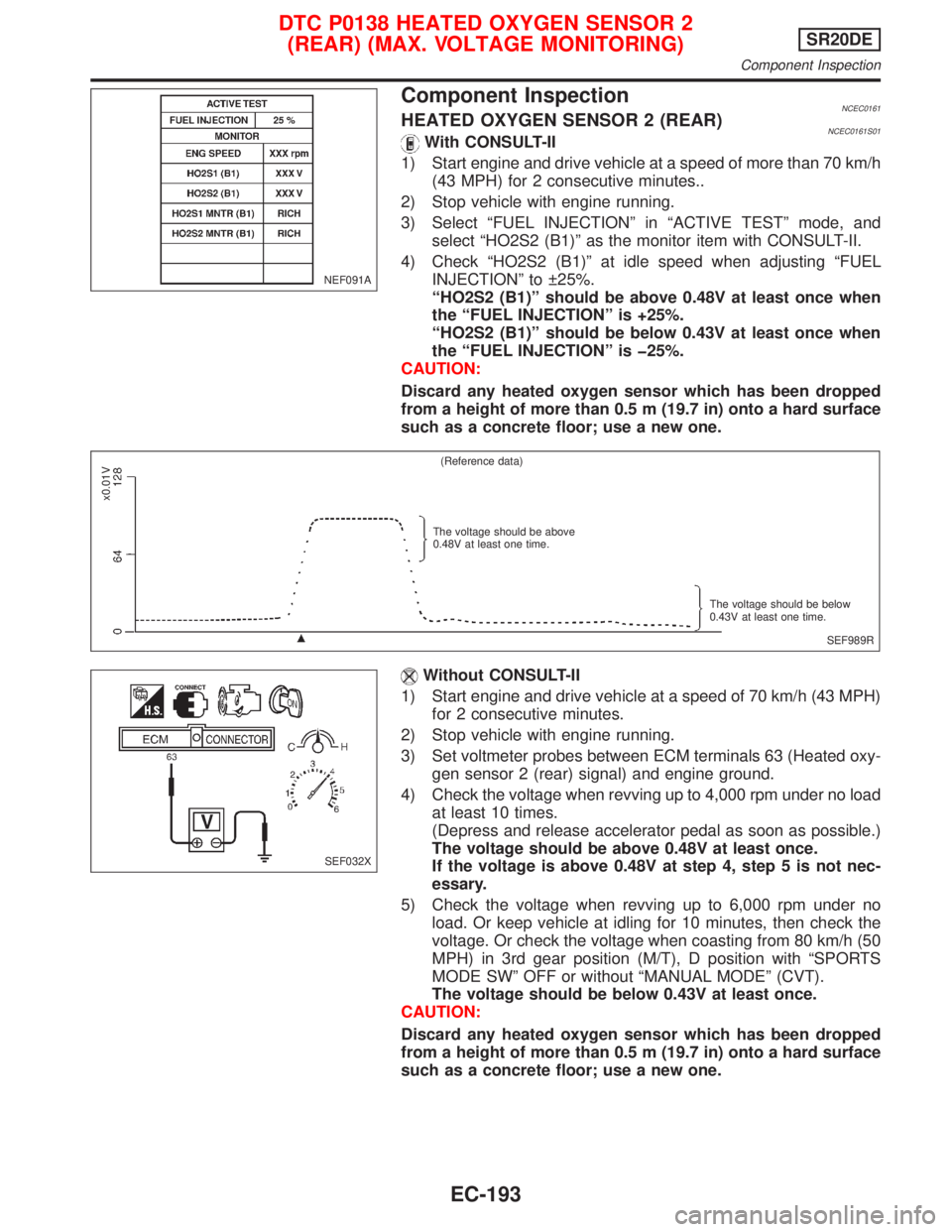

Component DescriptionNCEC0162The heated oxygen sensor 2 (rear) (Rear HO2S), after three way

catalyst, monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0163Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

IEngine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V+,Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN+,RICH

ECM Terminals and Reference ValueNCEC0164Specification data are reference values and are measured between each terminal and 48 (ECM ground).

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

IAfter warming up to normal operating temperature

and revving engine from idle to 2,000 rpm0 - Approximately 1.0V

On Board Diagnosis LogicNCEC0165The heated oxygen sensor 2 (rear) has a much longer switching

time between rich and lean than the heated oxygen sensor 1

(front). The oxygen storage capacity before the three way catalyst

causes the longer switching time. To judge the malfunctions of

heated oxygen sensor 2 (rear), ECM monitors whether the switch-

ing response of the sensor's voltage is faster than specified during

various driving conditions such as fuel-cut.

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0139

0139IIt takes more than the specified time for the sensor to

respond between rich and lean.IHarness or connectors

(The sensor circuit is open or shorted.)

IHeated oxygen sensor 2 (rear)

IFuel pressure

IInjectors

IIntake air leaks

SEF327R

SEF302U OK NG

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Component Description

EC-194

Page 995 of 2267

DTC Confirmation ProcedureNCEC0166CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedure º has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

IAlways perform at a temperature above þ10ÉC (14ÉF).

INever stop engine during this procedure. If the engine is

stopped, retry this procedure from step 2.

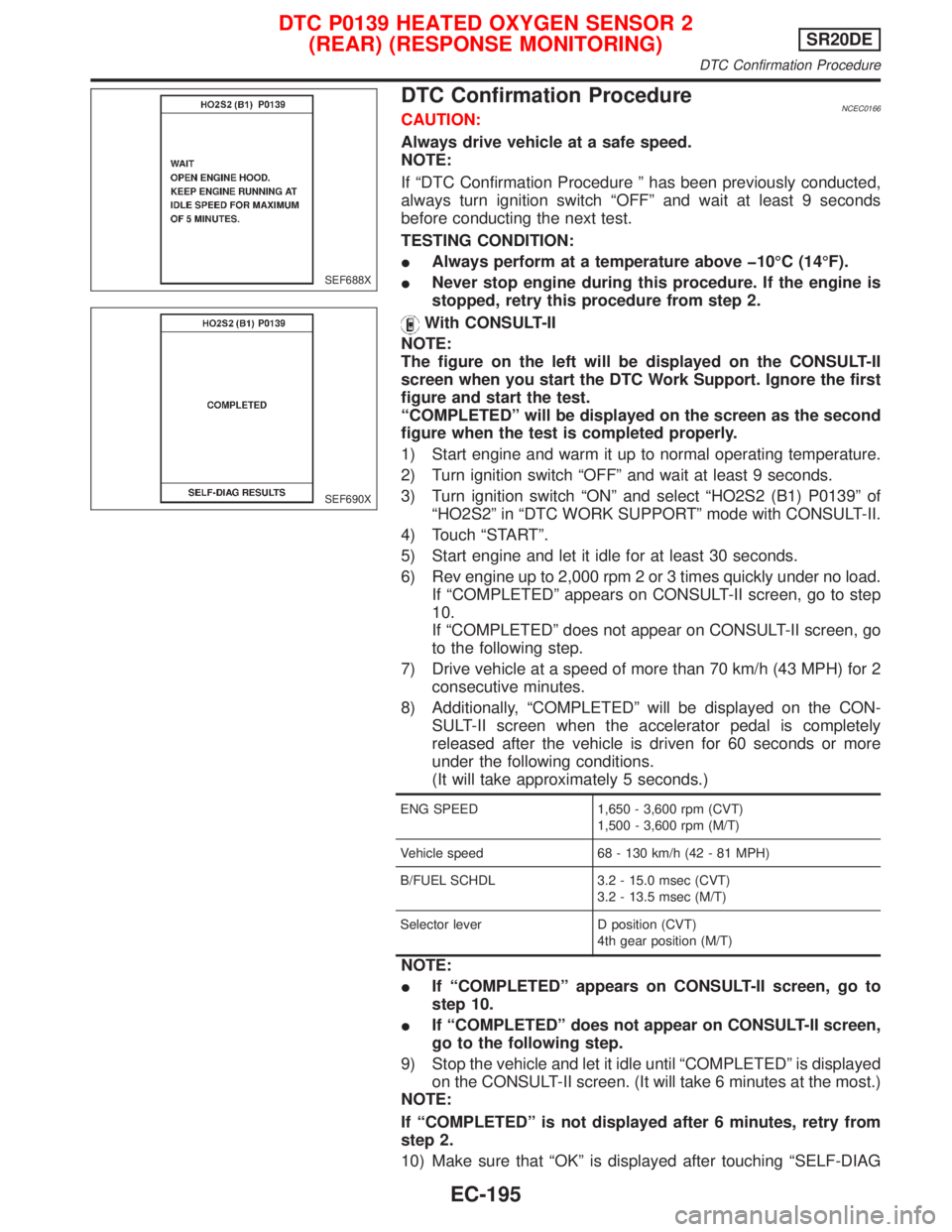

With CONSULT-II

NOTE:

The figure on the left will be displayed on the CONSULT-II

screen when you start the DTC Work Support. Ignore the first

figure and start the test.

ªCOMPLETEDº will be displayed on the screen as the second

figure when the test is completed properly.

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªHO2S2 (B1) P0139º of

ªHO2S2º in ªDTC WORK SUPPORTº mode with CONSULT-II.

4) Touch ªSTARTº.

5) Start engine and let it idle for at least 30 seconds.

6) Rev engine up to 2,000 rpm 2 or 3 times quickly under no load.

If ªCOMPLETEDº appears on CONSULT-II screen, go to step

10.

If ªCOMPLETEDº does not appear on CONSULT-II screen, go

to the following step.

7) Drive vehicle at a speed of more than 70 km/h (43 MPH) for 2

consecutive minutes.

8) Additionally, ªCOMPLETEDº will be displayed on the CON-

SULT-II screen when the accelerator pedal is completely

released after the vehicle is driven for 60 seconds or more

under the following conditions.

(It will take approximately 5 seconds.)

ENG SPEED 1,650 - 3,600 rpm (CVT)

1,500 - 3,600 rpm (M/T)

Vehicle speed 68 - 130 km/h (42 - 81 MPH)

B/FUEL SCHDL 3.2 - 15.0 msec (CVT)

3.2 - 13.5 msec (M/T)

Selector lever D position (CVT)

4th gear position (M/T)

NOTE:

IIf ªCOMPLETEDº appears on CONSULT-II screen, go to

step 10.

IIf ªCOMPLETEDº does not appear on CONSULT-II screen,

go to the following step.

9) Stop the vehicle and let it idle until ªCOMPLETEDº is displayed

on the CONSULT-II screen. (It will take 6 minutes at the most.)

NOTE:

If ªCOMPLETEDº is not displayed after 6 minutes, retry from

step 2.

10) Make sure that ªOKº is displayed after touching ªSELF-DIAG

SEF688X

SEF690X

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

DTC Confirmation Procedure

EC-195

Page 996 of 2267

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-SR-198.

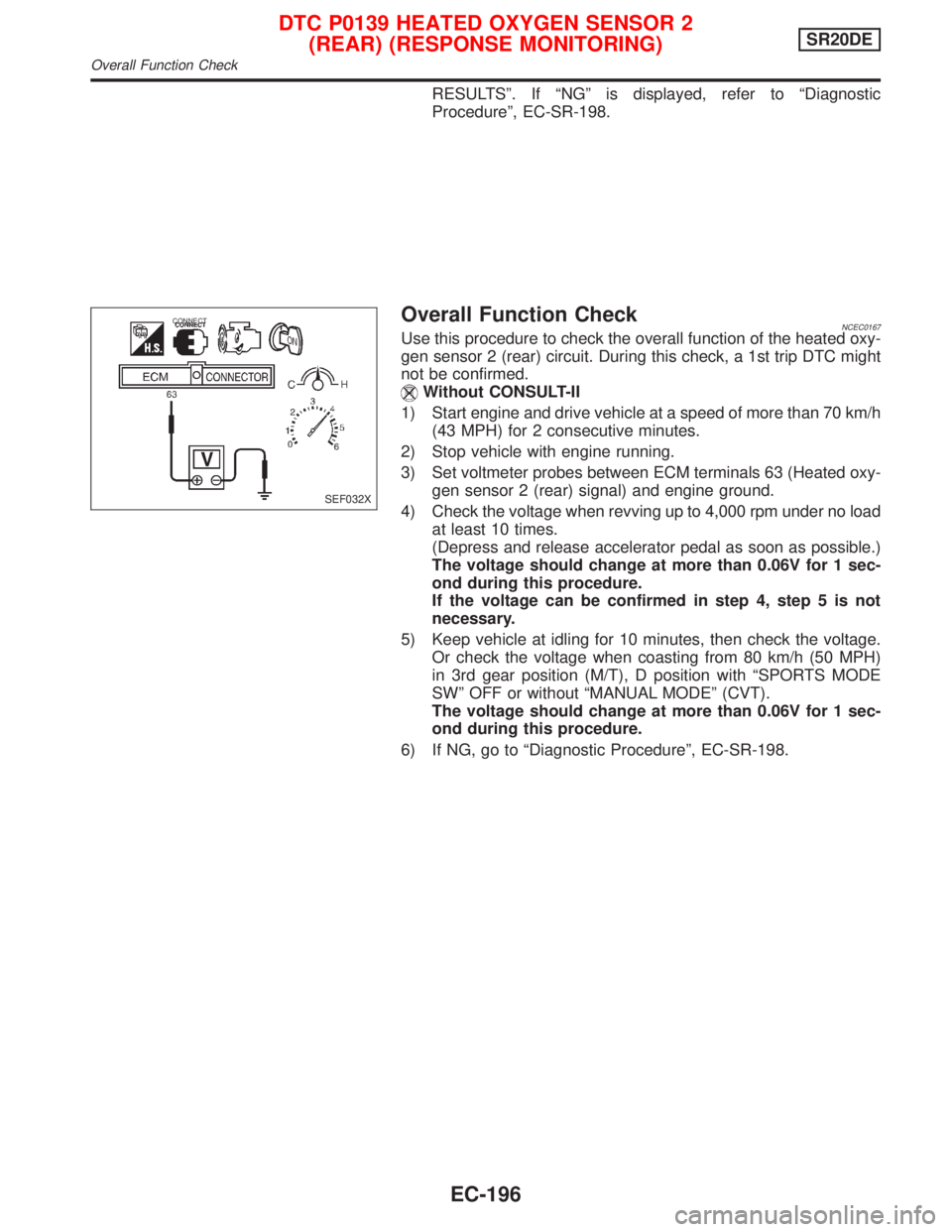

Overall Function CheckNCEC0167Use this procedure to check the overall function of the heated oxy-

gen sensor 2 (rear) circuit. During this check, a 1st trip DTC might

not be confirmed.

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (Heated oxy-

gen sensor 2 (rear) signal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should change at more than 0.06V for 1 sec-

ond during this procedure.

If the voltage can be confirmed in step 4, step 5 is not

necessary.

5) Keep vehicle at idling for 10 minutes, then check the voltage.

Or check the voltage when coasting from 80 km/h (50 MPH)

in 3rd gear position (M/T), D position with ªSPORTS MODE

SWº OFF or without ªMANUAL MODEº (CVT).

The voltage should change at more than 0.06V for 1 sec-

ond during this procedure.

6) If NG, go to ªDiagnostic Procedureº, EC-SR-198.

SEF032X

CONNECT

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Overall Function Check

EC-196

Page 997 of 2267

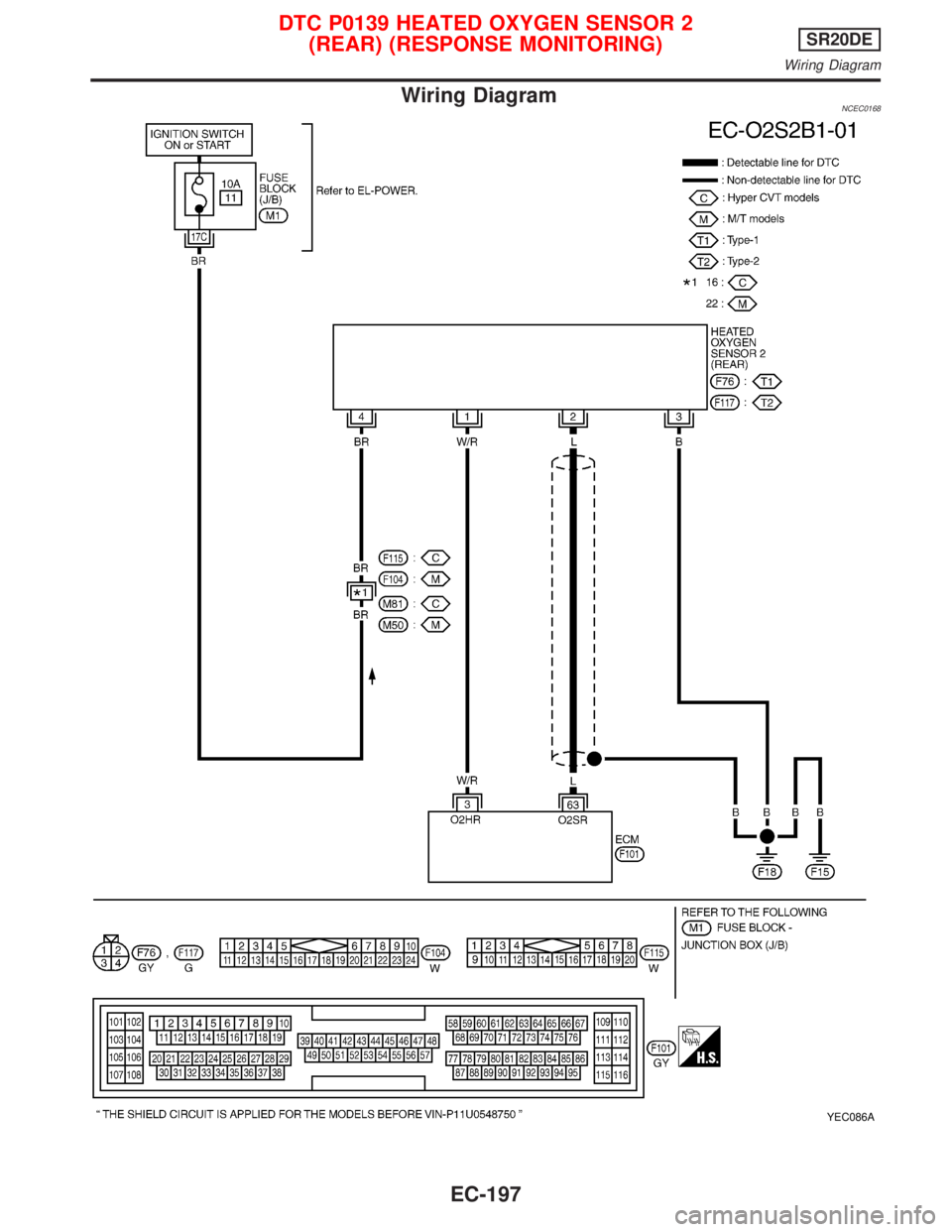

Wiring DiagramNCEC0168

YEC086A

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Wiring Diagram

EC-197

Page 998 of 2267

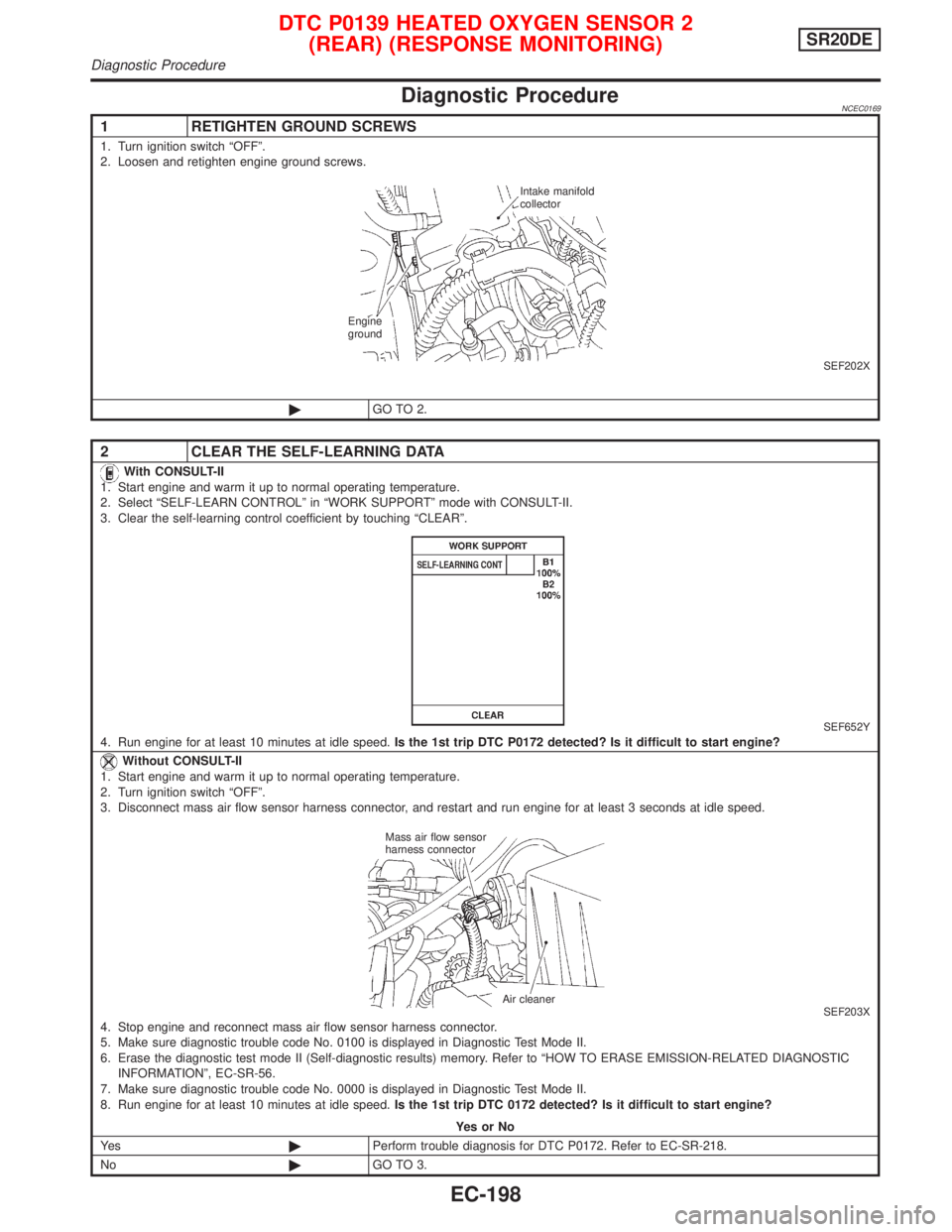

Diagnostic ProcedureNCEC0169

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF202X

©GO TO 2.

2 CLEAR THE SELF-LEARNING DATA

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªSELF-LEARN CONTROLº in ªWORK SUPPORTº mode with CONSULT-II.

3. Clear the self-learning control coefficient by touching ªCLEARº.

SEF652Y4. Run engine for at least 10 minutes at idle speed.Is the 1st trip DTC P0172 detected? Is it difficult to start engine?

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch ªOFFº.

3. Disconnect mass air flow sensor harness connector, and restart and run engine for at least 3 seconds at idle speed.

SEF203X4. Stop engine and reconnect mass air flow sensor harness connector.

5. Make sure diagnostic trouble code No. 0100 is displayed in Diagnostic Test Mode II.

6. Erase the diagnostic test mode II (Self-diagnostic results) memory. Refer to ªHOW TO ERASE EMISSION-RELATED DIAGNOSTIC

INFORMATIONº, EC-SR-56.

7. Make sure diagnostic trouble code No. 0000 is displayed in Diagnostic Test Mode II.

8. Run engine for at least 10 minutes at idle speed.Is the 1st trip DTC 0172 detected? Is it difficult to start engine?

YesorNo

Ye s©Perform trouble diagnosis for DTC P0172. Refer to EC-SR-218.

No©GO TO 3.

Intake manifold

collector

Engine

ground

Mass air flow sensor

harness connector

Air cleaner

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Diagnostic Procedure

EC-198

Page 999 of 2267

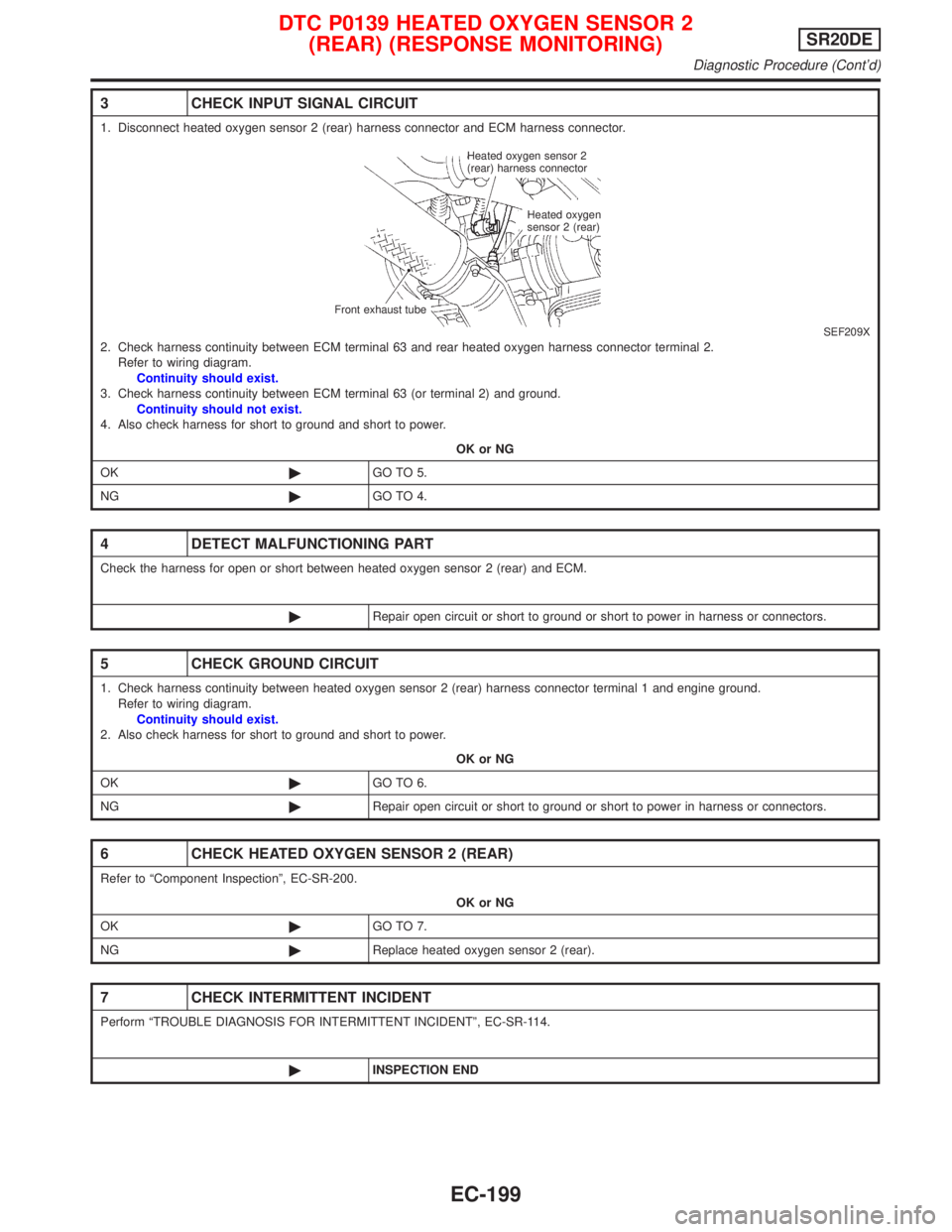

3 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 2 (rear) harness connector and ECM harness connector.

SEF209X2. Check harness continuity between ECM terminal 63 and rear heated oxygen harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 63 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK GROUND CIRCUIT

1. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-SR-200.

OK or NG

OK©GO TO 7.

NG©Replace heated oxygen sensor 2 (rear).

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-SR-114.

©INSPECTION END

Heated oxygen sensor 2

(rear) harness connector

Heated oxygen

sensor 2 (rear)

Front exhaust tube

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Diagnostic Procedure (Cont'd)

EC-199

Page 1000 of 2267

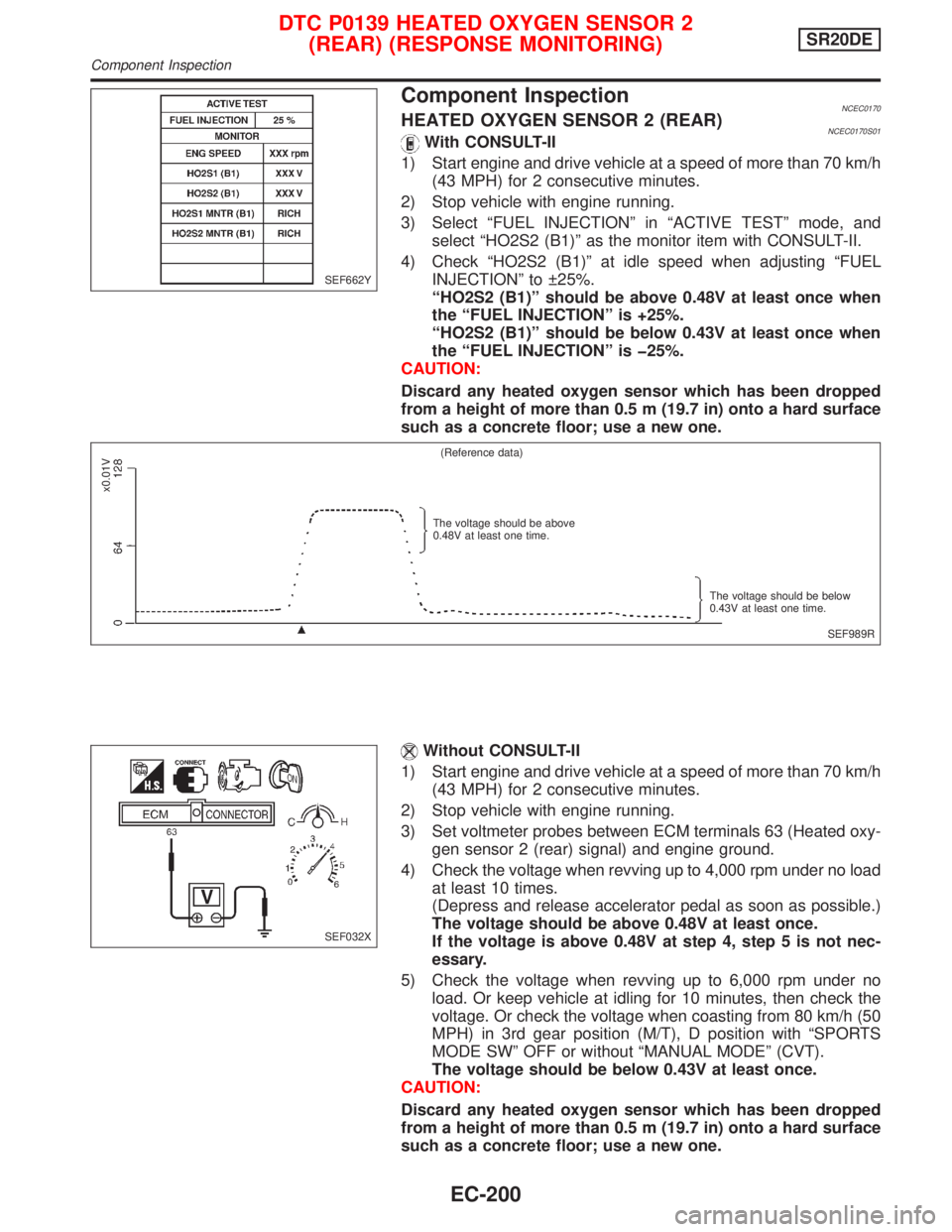

Component InspectionNCEC0170HEATED OXYGEN SENSOR 2 (REAR)NCEC0170S01With CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and

select ªHO2S2 (B1)º as the monitor item with CONSULT-II.

4) Check ªHO2S2 (B1)º at idle speed when adjusting ªFUEL

INJECTIONº to 25%.

ªHO2S2 (B1)º should be above 0.48V at least once when

the ªFUEL INJECTIONº is +25%.

ªHO2S2 (B1)º should be below 0.43V at least once when

the ªFUEL INJECTIONº is þ25%.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (Heated oxy-

gen sensor 2 (rear) signal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.48V at least once.

If the voltage is above 0.48V at step 4, step 5 is not nec-

essary.

5) Check the voltage when revving up to 6,000 rpm under no

load. Or keep vehicle at idling for 10 minutes, then check the

voltage. Or check the voltage when coasting from 80 km/h (50

MPH) in 3rd gear position (M/T), D position with ªSPORTS

MODE SWº OFF or without ªMANUAL MODEº (CVT).

The voltage should be below 0.43V at least once.

CAUTION:

Discard any heated oxygen sensor which has been dropped

from a height of more than 0.5 m (19.7 in) onto a hard surface

such as a concrete floor; use a new one.

SEF662Y

SEF989R (Reference data)

The voltage should be above

0.48V at least one time.

The voltage should be below

0.43V at least one time.

x0.01V

SEF032X

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING)SR20DE

Component Inspection

EC-200