NISSAN PULSAR 1987 Workshop Manual

Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 201 of 238

Electrical System 201

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

Using a suitable drift, install the bearing into

the drive end bracket, install the retainer plate and

screws. Tighten the screws securely. Using a suitable press and press plates, install

the bearing to the slip ring end of the rotor shaft.

Ensure that pressure is ex erted only on the inner race

and that the stop ring groove is nearest to the sl i p

rings. Ensure that the rotor sh aft rear bearing stop

ring is positioned so that the protruding part of the

ring is located in the deepest part of the groove. Install the stator, diode pack and

regulator

assembly to the slip ring e nd bracket. Install the

retaining nuts and washers and tighten securely. Install the nut and insulator to the terminal

and tighten securely. Using a piece of wire, hold the brushes in a

retracted position. Hold the drive end bracket in a soft jawed

vice and install the rotor shaft assembly to the drive

end bracket. Install the pulley, retaining nut and washer to

the rotor shaft and tighten the retaining nut to the

specified torque. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the

installation of the rotor shaft rear bearing. Aligning the marks made on dismantling and

ensuring that the rotor sh aft rear bearing retaining

ring protrusion is located in the deepest part of its

groove, install the rotor/stator assembly to the slip ring

end bracket.

Remove the brush retr acting wire from the

alternator, ensure that the alternator component

marks are aligned, install the retaining through bolts

and tighten them securely. Check the alternator rotor for smooth oper-

ation and install the al ternator to the vehicle

as

previously described.

Check the alternator operation on the vehicle

as previously described.

8. STARTER MOTOR

Special Equipment Required:

To Renew Brushes — Soldering iron

To Renew Armature Bearings — Bearing puller

DESCRIPTION

Two types of starter motors are installed to the

range of vehicles covere d by this manual, either

Hitachi or Bosch.

The starter motor is the induced pole type with

four brushes and four pole shoes with field coils.

A solenoid switch is attached to the starter drive

end bracket. The solenoid plunger is connected to

the overrunning clutch and drive pinion assembly

through a lever and pivot arrangement.

When the solenoid windings are energized, the

plunger acting on the lever and pivot engages the drive

pinion with the flywheel ri ng gear and at the same

time closes the switch supplying power from the

positive lead of the battery to the starter motor field

coils and armature to operate the motor.

As the engine fires, the over-running clutch of the

drive pinion assembly prevents high speed rotation of.

and possible damage to, the starter armature if the

solenoid windings are not immediately de-energized

by releasing the ignition key.

The starter solenoid switch windings are energized

by the ignition switch.

TO TEST ON VEHICLE

Should the starter motor fail to operate when the

ignition switch is turned to the Start position, check

the following points:

Check the battery condition and state of

charge. Refer to the Battery heading for the correct

procedure.

Clean the battery terminals, taking particular

care to remove the scale from the positive ( + )

terminal post and terminal. Check the earth connection for tightness and

cleanliness.

Switch on the headlamps and turn the igni-

tion switch to Start. If the lamps dim but the starter

motor does not operate, it could indicate that a short

circuit has developed in the starting system. Check that the engine is not seized or that the

starter motor drive pinion and ring gear are not

locked as these conditions would -give the same

indications as above.

(5) If the lamps do not dim and the starter

motor does not operate, this would indicate an open

circuit such as a broken or disconnected wire or a

switch not operating.

If the vehicle is equipped with an automatic

transaxle, turn the ignition switch to Start and move

the selector lever through all the gear selection range.

If the starter motor operates in any position other

than N or P, the neutral safety switch is faulty.

(6) Check all the external wiring to ensure that

the fault is not external. If the external circuit proves

satisfactory, indicating that the problem is in the

starter motor, the unit will have to be removed and

tested.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Disconnect the wiring from the starter motor

solenoid. Remove the starter motor mounting bolts,

Page 202 of 238

202 Electrical System

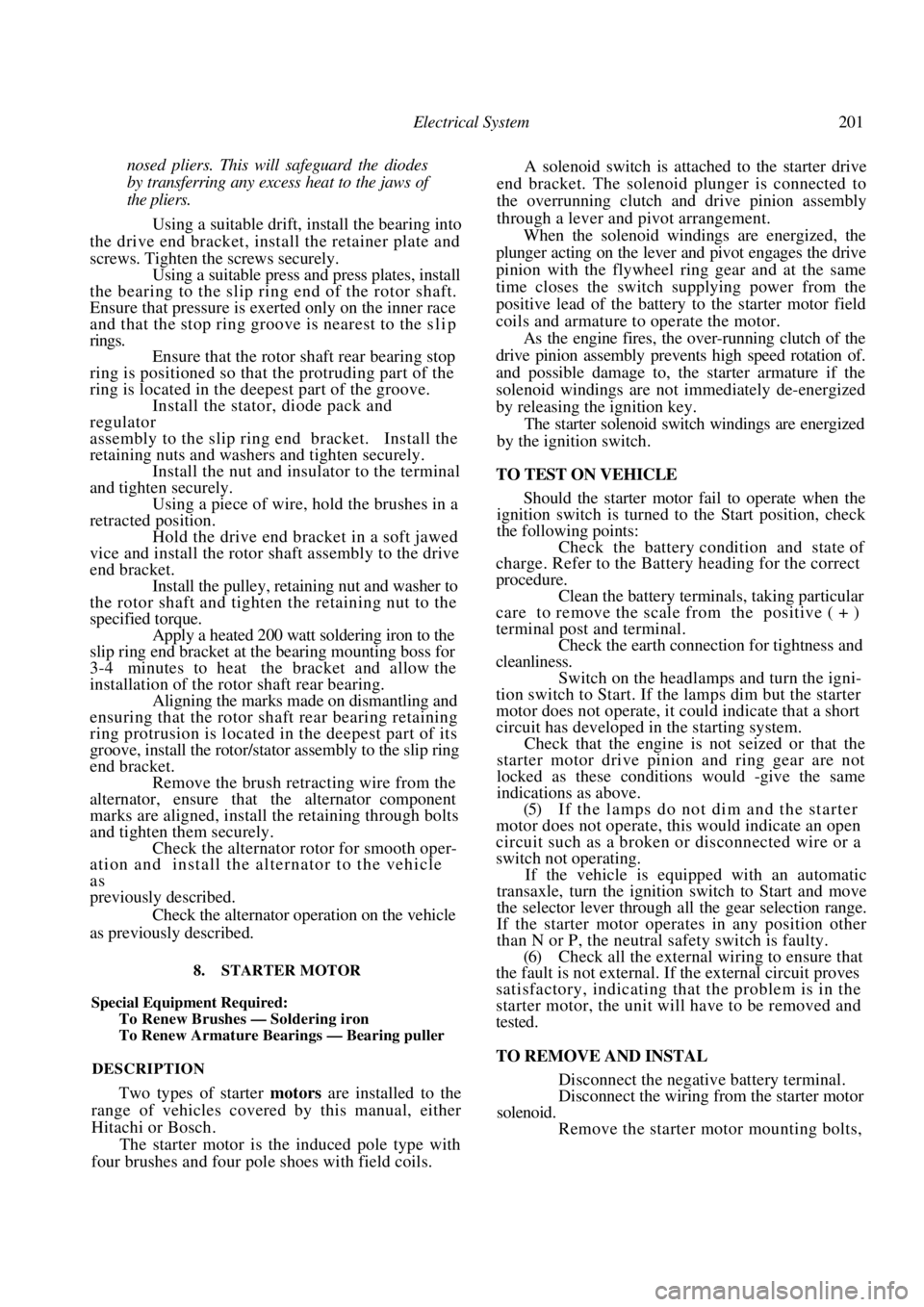

View of the Bosch starter motor removed from the

vehicle.

noting the position of the earth cable, and maneuver

the starter motor out of the engine compartment.

Installation is a reversal of the removal procedure

with attention to the following points:

Replace the earth cable to the position noted

on removal.

Tighten the starter motor mounting bolts

securely.

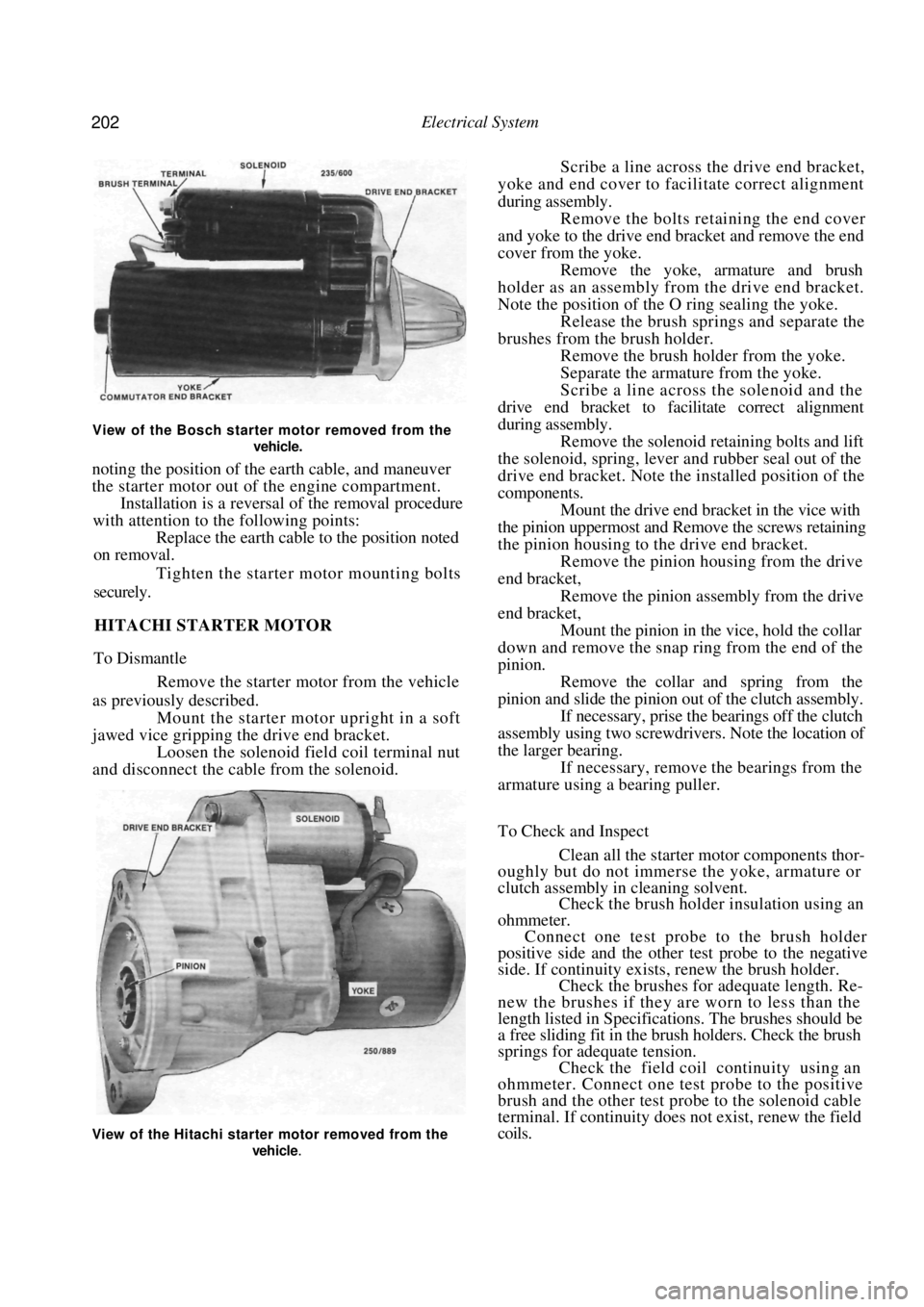

HITACHI STARTER MOTOR

To Dismantle

Remove the starter motor from the vehicle

as previously described. Mount the starter motor upright in a soft

jawed vice gripping the drive end bracket. Loosen the solenoid field coil terminal nut

and disconnect the cable from the solenoid.

Scribe a line across the drive end bracket,

yoke and end cover to facilitate correct alignment

during assembly. Remove the bolts retaining the end cover

and yoke to the drive end bracket and remove the end

cover from the yoke. Remove the yoke, armature and brush

holder as an assembly from the drive end bracket.

Note the position of the O ring sealing the yoke. Release the brush spri ngs and separate the

brushes from the brush holder. Remove the brush holder from the yoke.

Separate the armature from the yoke.

Scribe a line across the solenoid and the

drive end bracket to facilitate correct alignment

during assembly. Remove the solenoid retaining bolts and lift

the solenoid, spring, lever an d rubber seal out of the

drive end bracket. Note the installed position of the

components. Mount the drive end bracket in the vice with

the pinion uppermost and Remove the screws retaining

the pinion housing to the drive end bracket. Remove the pinion housing from the drive

end bracket,

Remove the pinion assembly from the drive

end bracket, Mount the pinion in the vice, hold the collar

down and remove the snap ring from the end of the

pinion. Remove the collar and spring from the

pinion and slide the pinion out of the clutch assembly. If necessary, prise the bearings off the clutch

assembly using two screwdri vers. Note the location of

the larger bearing. If necessary, remove the bearings from the

armature using a bearing puller.

To Check and Inspect

Clean all the starter motor components thor-

oughly but do not immerse the yoke, armature or

clutch assembly in cleaning solvent.

Check the brush holder insulation using an

ohmmeter. Connect one test probe to the brush holder

positive side and the other test probe to the negative

side. If continuity exists , renew the brush holder.

Check the brushes for adequate length. Re-

new the brushes if they are worn to less than the

length listed in Specifications. The brushes should be

a free sliding fit in the brush holders. Check the brush

springs for adequate tension.

Check the field coil continuity using an

ohmmeter. Connect one test probe to the positive

brush and the other test probe to the solenoid cable

terminal. If continuity does not exist, renew the field

coils.

View of the Hitachi starter motor removed from the

vehicle

.

Page 203 of 238

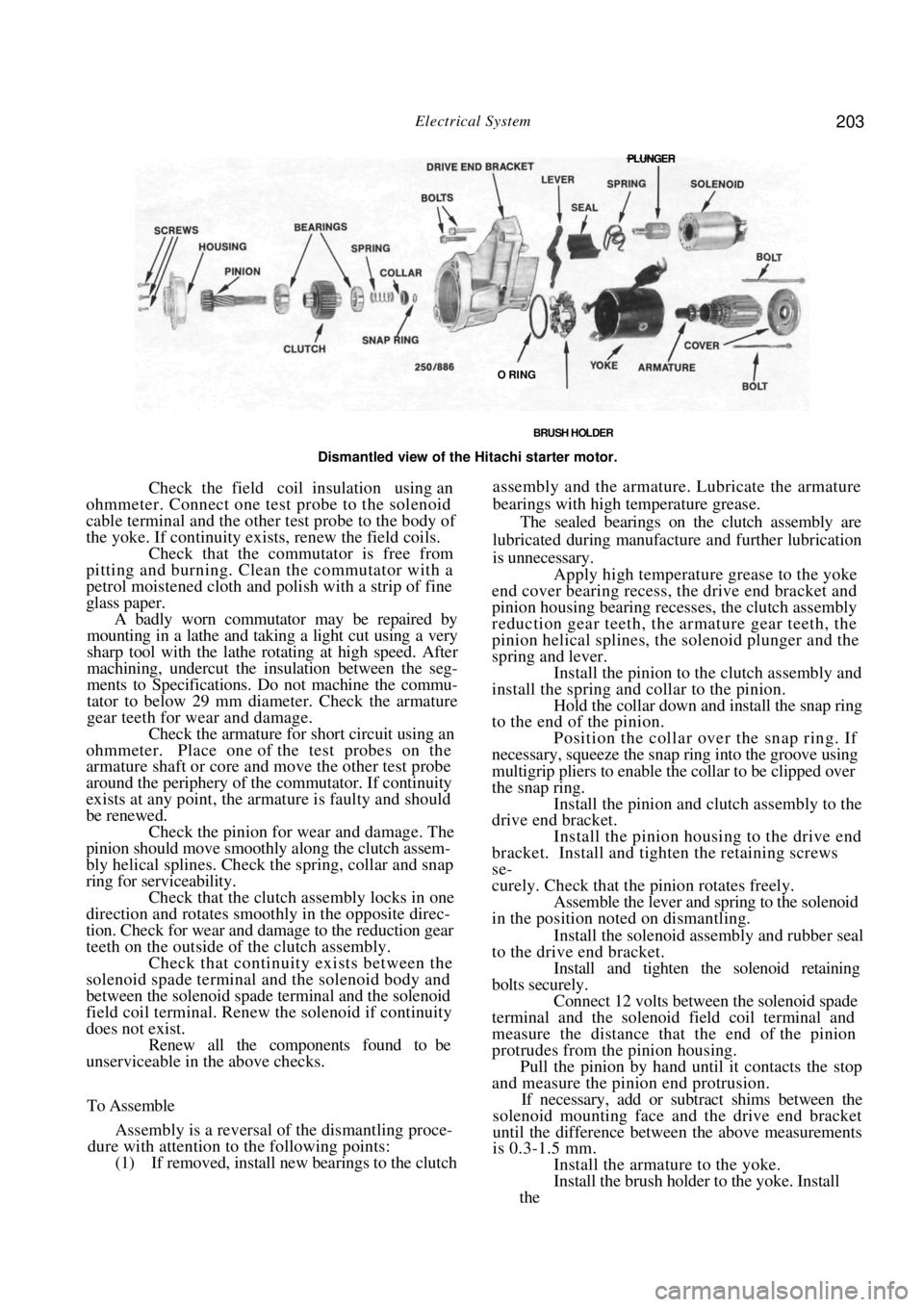

Electrical System 203

BRUSH HOLDER

Dismantled view of the Hitachi starter motor.

Check the field coil insulation using an

ohmmeter. Connect one test probe to the solenoid

cable terminal and the other test probe to the body of

the yoke. If continuity exists, renew the field coils. Check that the commutator is free from

pitting and burning. Clean the commutator with a

petrol moistened cloth and polish with a strip of fine

glass paper.

A badly worn commutator may be repaired by

mounting in a lathe and taking a light cut using a very

sharp tool with the lathe rotating at high speed. After

machining, undercut the insulation between the seg-

ments to Specifications. Do not machine the commu-

tator to below 29 mm diameter. Check the armature

gear teeth for wear and damage.

Check the armature for short circuit using an

ohmmeter. Place one of the test probes on the

armature shaft or core and move the other test probe

around the periphery of the commutator. If continuity

exists at any point, the armature is faulty and should

be renewed. Check the pinion for wear and damage. The

pinion should move smoothl y along the clutch assem-

bly helical splines. Check the spring, collar and snap

ring for serviceability.

Check that the clutch assembly locks in one

direction and rotates smoothly in the opposite direc-

tion. Check for wear and damage to the reduction gear

teeth on the outside of the clutch assembly.

Check that continuity exists between the

solenoid spade terminal and the solenoid body and

between the solenoid spade terminal and the solenoid

field coil terminal. Renew the solenoid if continuity

does not exist. Renew all the components found to be

unserviceable in the above checks.

To Assemble

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) If removed, install new bearings to the clutch

assembly and the armature. Lubricate the armature

bearings with high temperature grease.

The sealed bearings on the clutch assembly are

lubricated during manufacture and further lubrication

is unnecessary.

Apply high temperature grease to the yoke

end cover bearing recess, the drive end bracket and

pinion housing bearing recesses, the clutch assembly

reduction gear teeth, the armature gear teeth, the

pinion helical splines, th e solenoid plunger and the

spring and lever. Install the pinion to the clutch assembly and

install the spring and collar to the pinion. Hold the collar down and install the snap ring

to the end of the pinion.

Position the collar over the snap ring. If

necessary, squeeze the snap ring into the groove using

multigrip pliers to enable the collar to be clipped over

the snap ring. Install the pinion and clutch assembly to the

drive end bracket.

Install the pinion housing to the drive end

bracket. Install and tighten the retaining screws

se-

curely. Check that the pinion rotates freely.

Assemble the lever and spring to the solenoid

in the position noted on dismantling.

Install the solenoid assembly and rubber seal

to the drive end bracket.

Install and tighten the solenoid retaining

bolts securely. Connect 12 volts between the solenoid spade

terminal and the solenoid field coil terminal and

measure the distance that the end of the pinion

protrudes from the pinion housing. Pull the pinion by hand until it contacts the stop

and measure the pinion end protrusion.

If necessary, add or subt ract shims between the

solenoid mounting face and the drive end bracket

until the difference between the above measurements

is 0.3-1.5 mm.

Install the armature to the yoke.

Install the brush holder to the yoke. Install

the

PLUNGER

O RING

Page 204 of 238

204 Electrical System

brushes to the brush holder and position the springs

against the ends of the brushes.

Install the O ring to the yoke taking care

that

the O ring is not twisted. Install the yoke, armature and brush

holder

assembly to the drive end bracket, aligning the marks

made on dismantling. Install the end cover to the yoke. Install

and

tighten the retaining bolts securely. Connect the cable to the solenoid field coil

terminal and tighten the terminal nut securely. Install the starter motor to the vehicle

as

previously described.

BOSCH STARTER MOTOR

To Dismantle

Disconnect the brush connector strap from

the lower terminal on the solenoid switch.

Remove the screws retaining the solenoid to

the drive end bracket and remove the solenoid from

the drive end bracket.

Loosen, but do not remove the screws retain-

ing the armature end cover to the commutator end

bracket. Remove the through bolts retaining the drive

end bracket to the commutator end bracket.

Remove the yoke, armature and commutator

end bracket from the drive end bracket as an assem-

bly. Hold the rubber seal in place in the drive end

bracket to keep the engaging lever in position.

Remove the rubber seal from the drive end

bracket. Remove the cover plate from the planetary

gear set and remove the gear set, drive assembly and

engaging lever as an assembly. Remove the armature end cover and com-

mutator end bracket from the yoke. Remove the screws retaining the armature

end cover to the commutator end cover and remove

the armature end cover, C clip and shims from the

armature shaft. Remove the commutator end bracket

from the armature. Carefully remove the brush holder from the

armature. Support the gear set and drive assembly in a

vertical position with the drive assembly uppermost.

Using a suitable drift, tap the stop collar

towards the drive assembly and remove the snap ring

from the drive shaft. Remove any burrs from the drive shaft and

withdraw the drive assembly and stop ring from the

drive shaft.

Clean all parts thoroughly but do not im-

merse the armature, solenoid or drive assembly in

cleaning solvent.

To Check and Inspect

(1) With the starter motor dismantled, check the

brush holder insulation using an ohmmeter.

Connect one test lead to the brush holder positive

BRACKET

Dismantled view of the Bosch starter motor.

Page 205 of 238

Electrical System 205

Dismantled view of the brush holder assembly. Bosch

starter motor.

side and the other lead to the negative side. If there is

any indication of leakage the ohmmeter will show a

reading other than infinity. Repair or renew the brush

holder if leakage is evident.

(2) Check the brushes for adequate length.

Brushes should be renewed when their length is below

Specifications. They should be a free sliding fit in the

brush holders.

NOTE: Due to the difficulty involved in

removing and installing the brushes in the

Bosch starter motor, it is recommended that

the brush holder be renewed as an assembly.

(3) Check that the commutator is free from

pitting and burning. Clean with a petrol moistened

cloth and polish with a strip of fine glass paper.

A badly worn commutator may be repaired by

mounting in a lathe, spi nning at high speed, and

taking a light cut with a very sharp tool. After turning,

undercut the insulation between the segments.

(4) Check the armature for short circuit using an

ohmmeter.

Place one of the test lead s on the armature shaft

or core and move the other lead around the circum-

ference of the commutator. If the ohmmeter shows a

reading at any point the armature is faulty and should

be renewed.

Check the drive assembly clutch pinion teeth

for wear, scoring or chipping. A clutch in good

condition should take up the drive in one direction

only. It should rotate easily and smoothly in the

non-drive direction and the assembly should move

smoothly along the armature or drive shaft helical

splines.

Check the armature shaft bushes for wear

and renew as necessary. The old bushes must be

removed and the new ones pressed into the end

brackets using a polished mandrel of the exact diam-

eter of the armature shaft. NOTE: The new bushes must not be reamed

to size, as reaming will impair the porosity

of the bushes and cause early failure. New

bushes should be allowed to stand immersed

in clean light engine oil for one hour before

installation.

To Assemble

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Lubricate the helix of the drive shaft lightly

with graphite grease and install the drive assembly

to

the drive shaft. Install the stop collar and snap ring, slide the

stop collar over the snap ring to lock the snap ring in

position.

Lubricate the bushes in both end brackets

sparingly with engine oil. Install the engaging lever and gear set into the

drive end bracket. Install the centre rear bracket and the engag-

ing lever seal into the drive end bracket.

Slide the brush holder assembly into position

on the commutator ensuring that the brush holders

are correctly positioned in the anchor points. Install the commutator end bracket to

the

armature, install the shims and C clip. Check that the armature end float is satisfac-

tory and adjust as necessary using shims of the correct

thickness.

Align the slot in the commutator end bracket

with the cut out on the wiring seal and install the

armature end cover to the commutator end bracket.

Install the cover retaini ng screws but do not tighten.

Ensure that the permanent magnets in the

yoke have not picked up any debris and slide the yoke

over the armature ensuring that the wiring seal locates

correctly in the slot in the yoke.

View showing the planetary gear set. Bosch starter

motor.

Page 206 of 238

206 Electrical System

Install the armature and yoke to the drive end

bracket rotating the drive to align the reduction gears.

Do not use force.

Install the retaining through bolts to the

commutator end bracket and lighten the through bolts

and armature end cover retaining screws securely. Install the solenoid to the drive end bracket,

install the retaining screws and tighten them securely.

Install the brush connector strap and

install

the retaining nut and washer and tighten securely.

9 . IGNITION SYSTEM

The testing and repair procedures for the ignition

system are fully covered in the Fuel and Engine

Management section.

10. STEERING WHEEL

The removal and installation procedures for the

steering wheel and horn pad are fully covered in the

Steering section.

11. SWITCHES AND CONTROLS

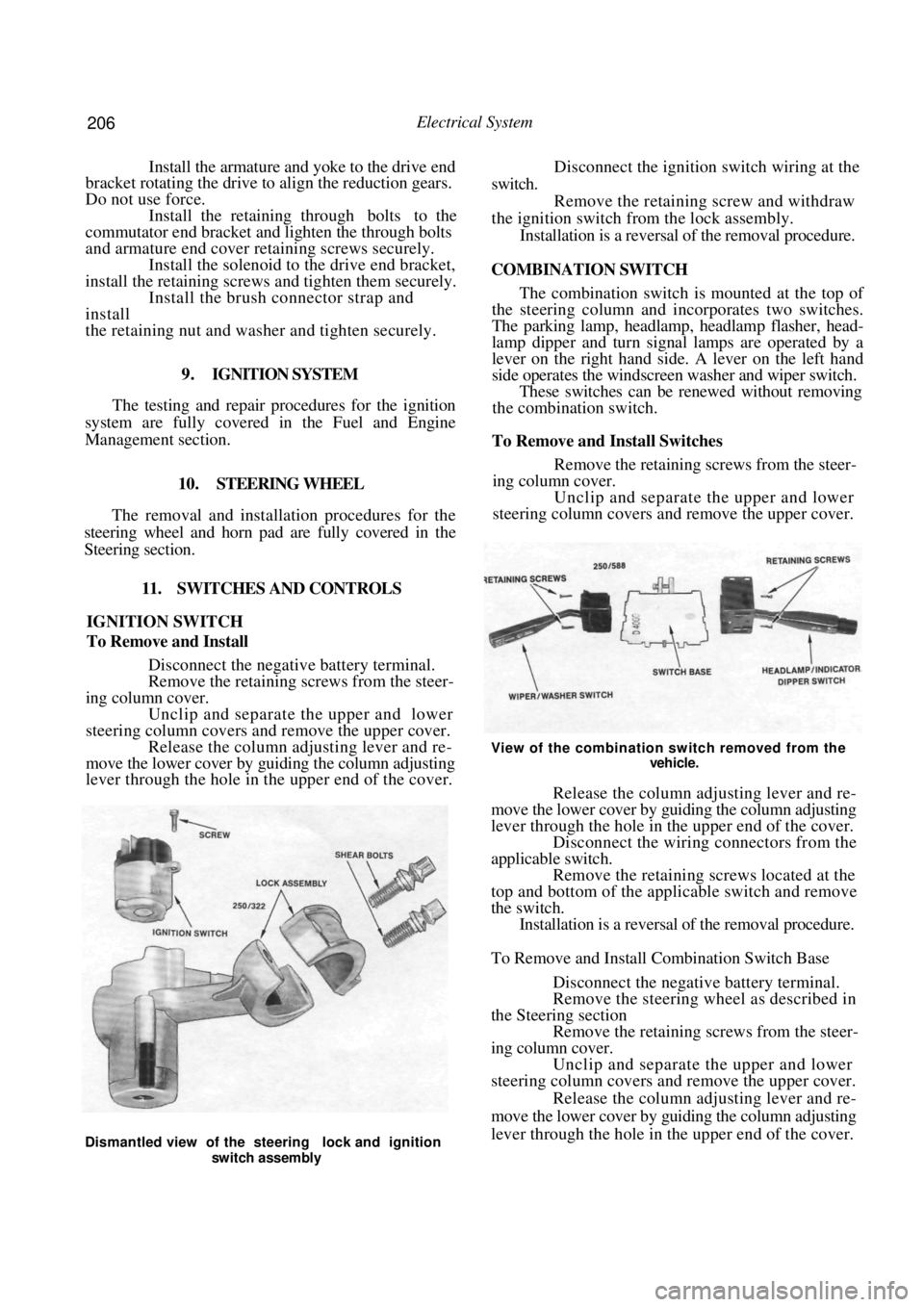

IGNITION SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover. Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Disconnect the ignition switch wiring at the

switch. Remove the retaining screw and withdraw

the ignition switch fr om the lock assembly.

Installation is a reversal of the removal procedure.

COMBINATION SWITCH

The combination switch is mounted at the top of

the steering column and incorporates two switches.

The parking lamp, headlamp, headlamp flasher, head-

lamp dipper and turn signal lamps are operated by a

lever on the right hand side. A lever on the left hand

side operates the windscreen washer and wiper switch.

These switches can be re newed without removing

the combination switch.

To Remove and Install Switches

Remove the retaining screws from the steer-

ing column cover.

Unclip and separate the upper and lower

steering column covers and remove the upper cover.

View of the combination switch removed from the

vehicle.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover. Disconnect the wiring connectors from the

applicable switch. Remove the retaining screws located at the

top and bottom of the applicable switch and remove

the switch. Installation is a reversal of the removal procedure.

To Remove and Install Combination Switch Base

Disconnect the negative battery terminal.

Remove the steering wheel as described in

the Steering section Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Dismantled view of the steering lock and ignition

switch assembly

Page 207 of 238

Electrical System 207

Disconnect the wiring connectors from the

rear of the combination switch.

Loosen the clamping screw located at the left

hand side of the combination switch. Push, turn and slide the combination switch

from the steering column. Installation is a reversal of the removal procedure.

REAR WINDOW DEMISTER

SWITCH/HAZARD WARNING LAMP SWITCH

To Remove and Install

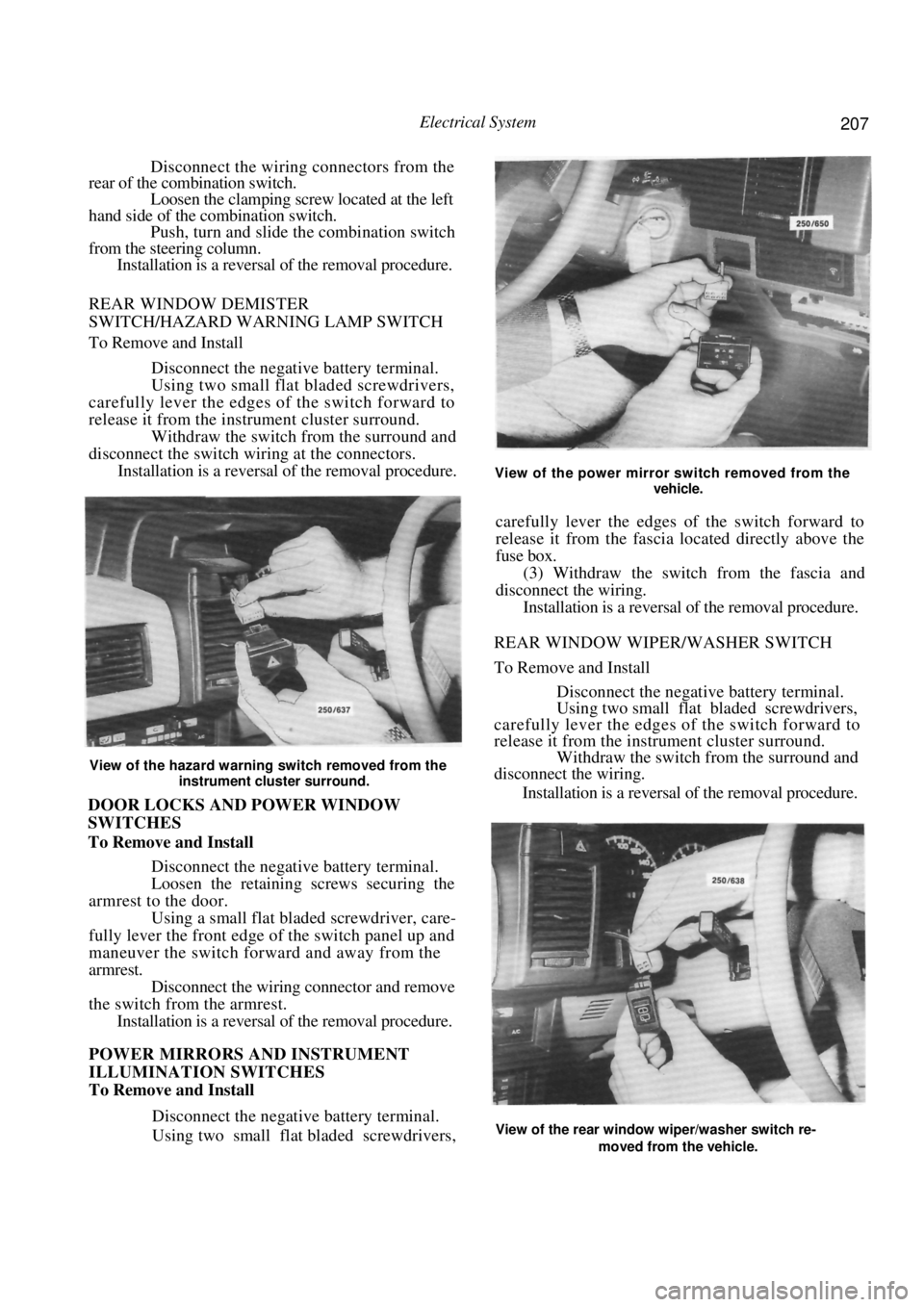

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround.

Withdraw the switch from the surround and

disconnect the switch wiri ng at the connectors.

Installation is a reversal of the removal procedure.

View of the hazard warning switch removed from the

instrument cluster surround.

DOOR LOCKS AND POWER WINDOW

SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Loosen the retaining screws securing the

armrest to the door. Using a small flat bladed screwdriver, care-

fully lever the front edge of the switch panel up and

maneuver the switch forward and away from the

armrest. Disconnect the wiring connector and remove

the switch from the armrest. Installation is a reversal of the removal procedure.

POWER MIRRORS AND INSTRUMENT

ILLUMINATION SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

View of the power mirror switch removed from the

vehicle.

carefully lever the edges of the switch forward to

release it from the fascia lo cated directly above the

fuse box.

(3) Withdraw the switch from the fascia and

disconnect the wiring.

Installation is a reversal of the removal procedure.

REAR WINDOW WIPER/WASHER SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround. Withdraw the switch from the surround and

disconnect the wiring.

Installation is a reversal of the removal procedure.

View of the rear window wiper/washer switch re-

moved from the vehicle.

Page 208 of 238

208 Electrical System

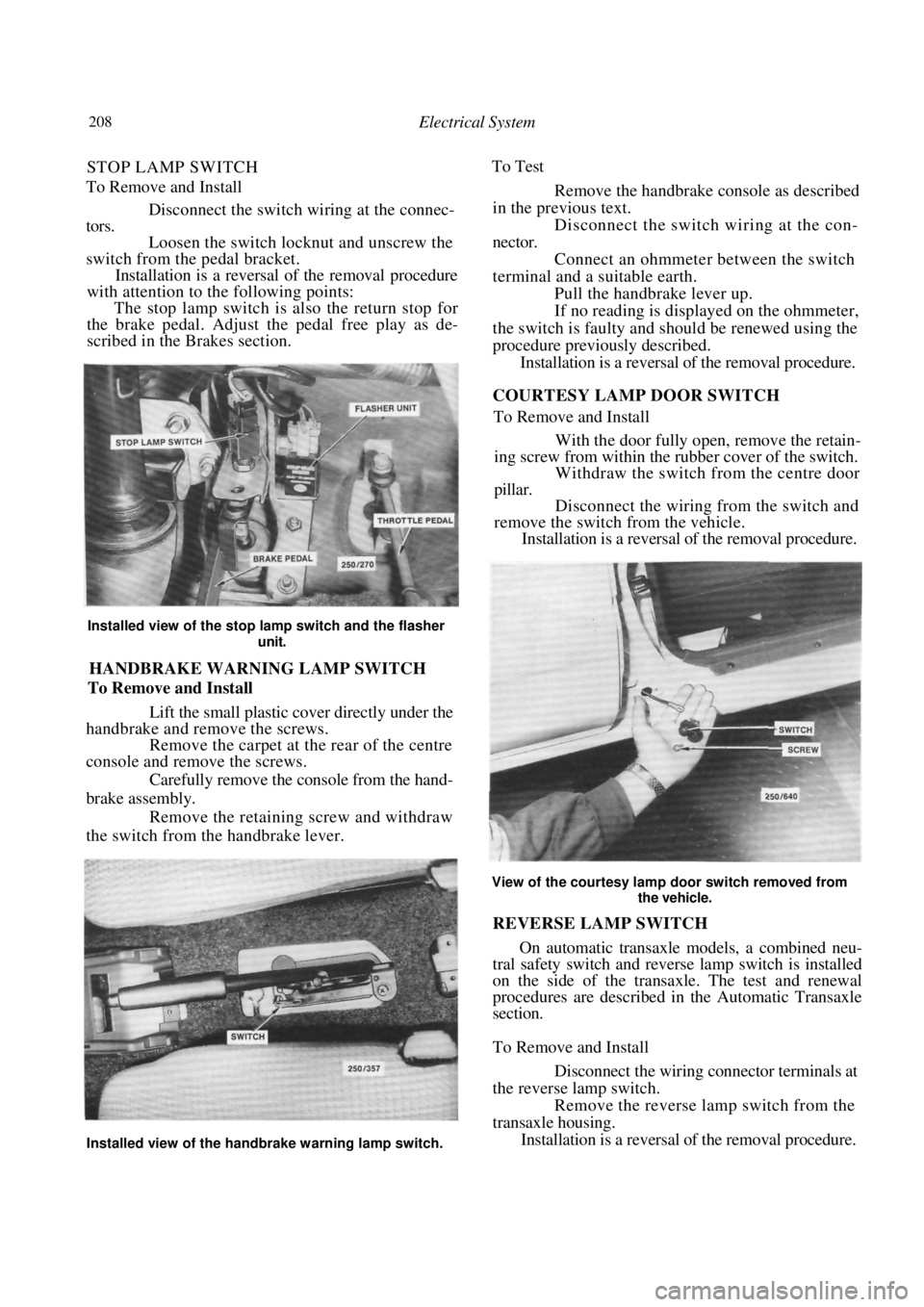

STOP LAMP SWITCH

To Remove and Install

Disconnect the switch wi ring at the connec-

tors.

Loosen the switch locknut and unscrew the

switch from the pedal bracket.

Installation is a reversal of the removal procedure

with attention to the following points:

The stop lamp switch is also the return stop for

the brake pedal. Adjust the pedal free play as de-

scribed in the Brakes section.

Installed view of the stop lamp switch and the flasher

unit.

HANDBRAKE WARNING LAMP SWITCH

To Remove and Install

Lift the small plastic cover directly under the

handbrake and remove the screws.

Remove the carpet at the rear of the centre

console and remove the screws.

Carefully remove the console from the hand-

brake assembly. Remove the retaining screw and withdraw

the switch from the handbrake lever. To Test

Remove the handbrake console as described

in the previous text.

Disconnect the switch wiring at the con-

nector. Connect an ohmmeter between the switch

terminal and a suitable earth. Pull the handbrake lever up.

If no reading is displayed on the ohmmeter,

the switch is faulty and should be renewed using the

procedure previously described. Installation is a reversal of the removal procedure.

COURTESY LAMP DOOR SWITCH

To Remove and Install

With the door fully open, remove the retain-

ing screw from within the rubber cover of the switch. Withdraw the switch from the centre door

pillar.

Disconnect the wiring from the switch and

remove the switch from the vehicle. Installation is a reversal of the removal procedure.

View of the courtesy lamp door switch removed from

the vehicle.

REVERSE LAMP SWITCH

On automatic transaxle models, a combined neu-

tral safety switch and reverse lamp switch is installed

on the side of the transaxle. The test and renewal

procedures are described in the Automatic Transaxle

section.

To Remove and Install

Disconnect the wiring connector terminals at

the reverse lamp switch. Remove the reverse lamp switch from the

transaxle housing. Installation is a reversal of the removal procedure.

Installed view of the handbrake warning lamp switch.

Page 209 of 238

Electrical System 209

12. INSTRUMENT CLUSTER

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the retaining screws from the instru-

ment cluster surround. Carefully withdraw the instrument cluster

surround from the instrument panel sufficiently to

enable the wiring to be disconnected. Remove the

surround from the vehicle.

.

FLEXIBLE PRINTED

CIRCUIT

Rear view of the instrument cluster removed from the

vehicle.

(4) Remove the instrument cluster assembly

retaining screws and gently ease the assembly from the

instrument panel sufficiently to enable the wiring to be

disconnected.

If necessary, remove the instruments as follows:

Carefully depress the retaining clips on the

front lens and remove the front lens. On models equipped with a tachometer, slide

the plastic rib from between the speedometer and the

tachometer. Remove the screws retaining the speedome-

ter and the tachometer or fuel/temperature gauges

from the rear of the instrument cluster.

CLUSTER ASSEMBLY

(d) Withdraw both instruments from the front of

the instrument cluster being careful as these instru-

ments are held by protruding pin terminals.

NOTE: Do not touch the faces of the instru-

ment dials as they mark easily.

(e) On models equipped with a tachometer,

remove the retaining nuts and remove the tempera-

ture and/or the fuel gauge from the cluster assembly.

Installation is a reversal of the removal procedure

ensuring that all electrical connectors are correctly

installed.

13. BLOWER FAN

The removal and installation procedure for the

blower fan is described in the Cooling and Heating

Systems section.

14. RADIO/CASSETTE

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the release hole covers on each side

of the radio/cassette.

Dismantled view of the instrument cluster.

Illustration of the radio/cass ette removal tool showing

the required dimensions.

BULB HOLDERS

BULB HOLDERS

Removing the release hole covers from the radio/cas-

sette.

Page 210 of 238

210 Electrical System

Using the radio/cassette removal tools during removal of the unit.

Construct the special tools as illustrated,

insert both tools into the release holes on the radio/

cassette and carefully withdraw the radio/cassette

from the mounting bracket.

Disconnect the wiring harness terminal plug

and remove the radio/cassette.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the special tools from the radio/

cassette, connect the wiring harness terminal and push

the radio/cassette into the mounting bracket. Install the release hole covers on each side

of

the radio/cassette.

15. LAMP UNITS

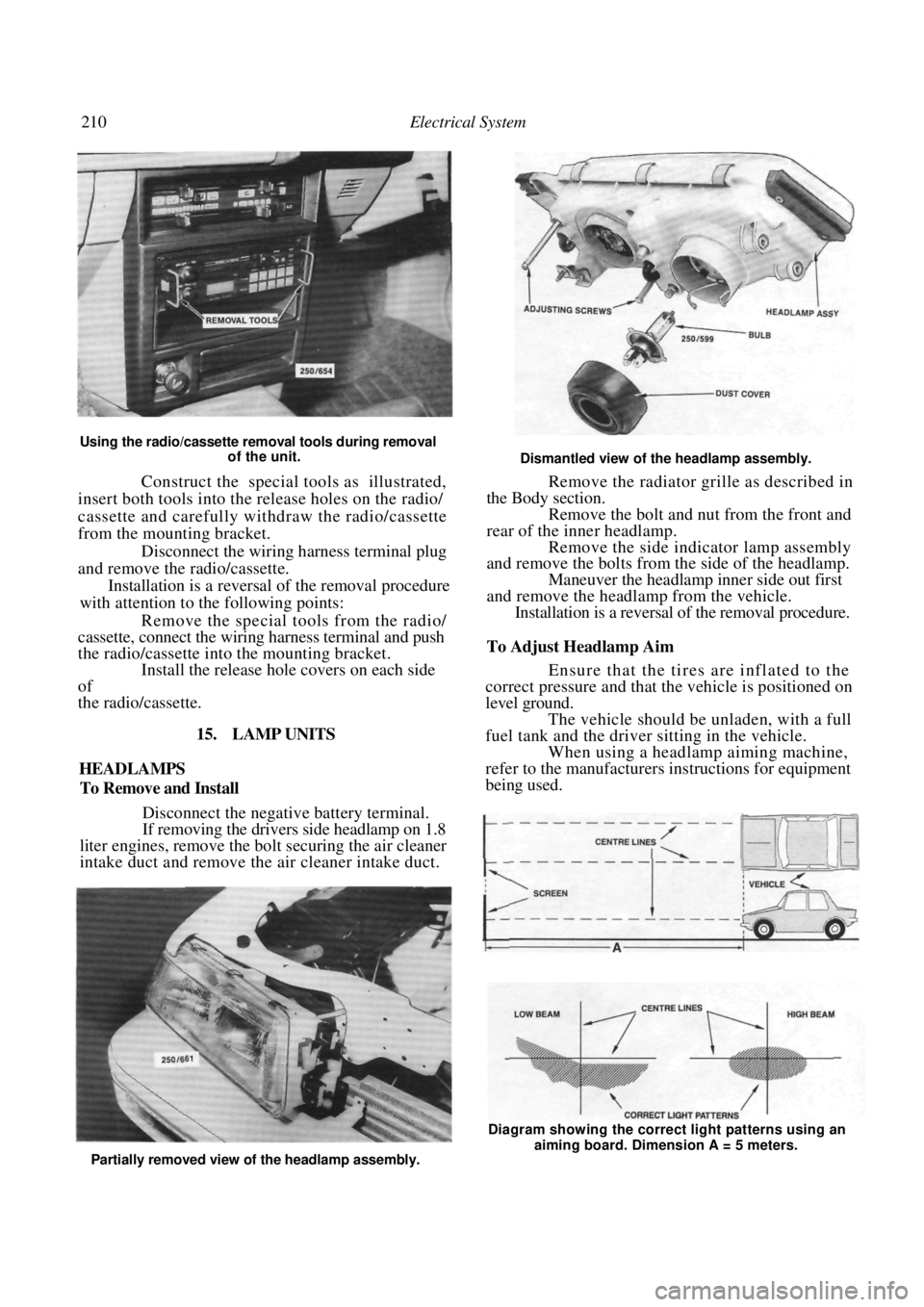

HEADLAMPS

To Remove and Install

Disconnect the negative battery terminal.

If removing the drivers side headlamp on 1.8

liter engines, remove the bo lt securing the air cleaner

intake duct and remove the air cleaner intake duct.

Dismantled view of the headlamp assembly.

Remove the radiator grille as described in

the Body section. Remove the bolt and nut from the front and

rear of the inner headlamp. Remove the side indicator lamp assembly

and remove the bolts from the side of the headlamp.

Maneuver the headlamp inner side out first

and remove the headlamp from the vehicle. Installation is a reversal of the removal procedure.

To Adjust Headlamp Aim

Ensure that the tires are inflated to the

correct pressure and that the vehicle is positioned on

level ground.

The vehicle should be unladen, with a full

fuel tank and the driver sitting in the vehicle. When using a headlamp aiming machine,

refer to the manufacturers instructions for equipment

being used.

Partially removed view of the headlamp assembly. Diagram showing the correct light patterns using an

aiming board. Dimension A = 5 meters.