NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Page 604 of 1767

Diagnostic Procedure

1 INSPECTION START

Check fuel level, fuel supplying system, starter motor, etc.

OK or NG

OKEGO TO 2.

NGECorrect.

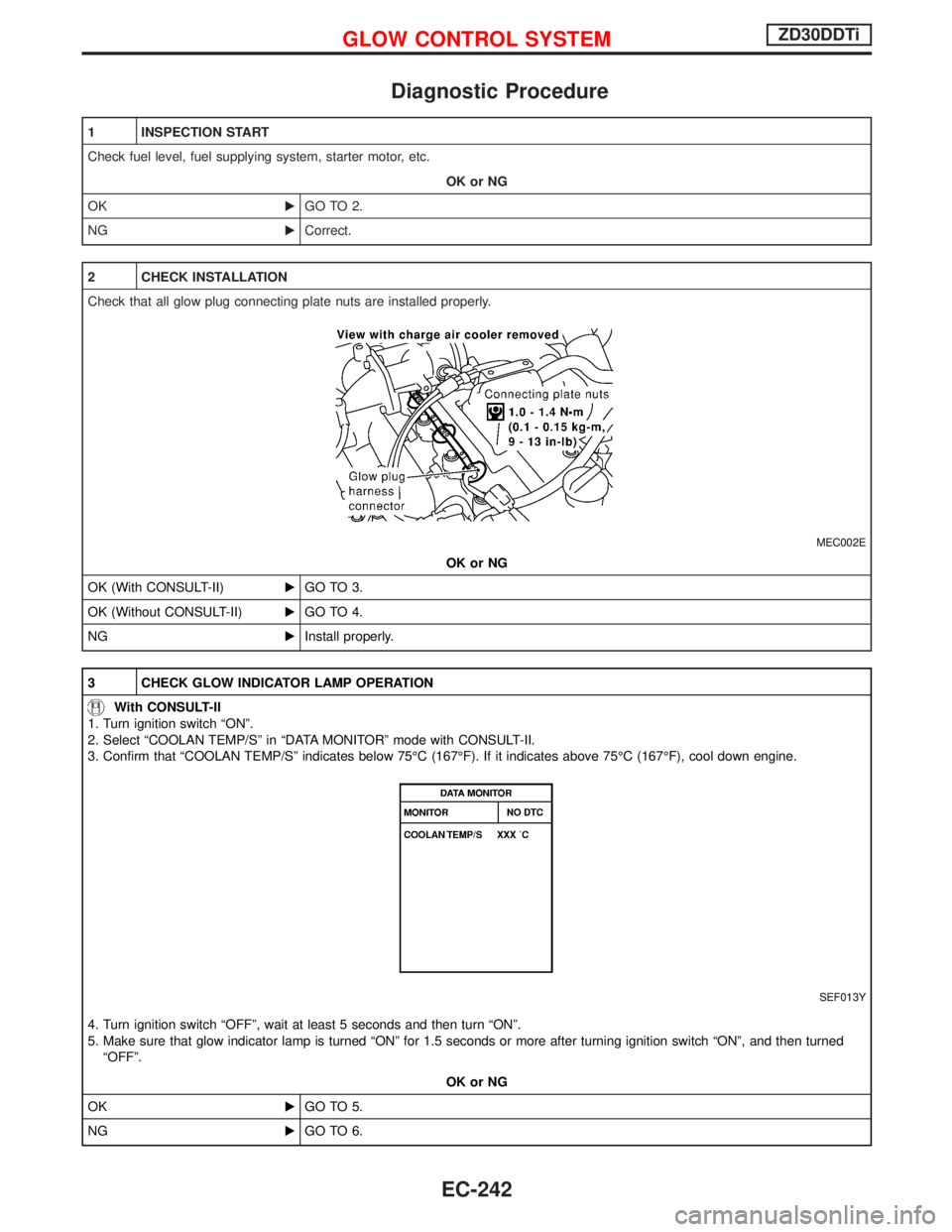

2 CHECK INSTALLATION

Check that all glow plug connecting plate nuts are installed properly.

MEC002E

OK or NG

OK (With CONSULT-II)EGO TO 3.

OK (Without CONSULT-II)EGO TO 4.

NGEInstall properly.

3 CHECK GLOW INDICATOR LAMP OPERATION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Confirm that ªCOOLAN TEMP/Sº indicates below 75ÉC (167ÉF). If it indicates above 75ÉC (167ÉF), cool down engine.

SEF013Y

4. Turn ignition switch ªOFFº, wait at least 5 seconds and then turn ªONº.

5. Make sure that glow indicator lamp is turned ªONº for 1.5 seconds or more after turning ignition switch ªONº, and then turned

ªOFFº.

OK or NG

OKEGO TO 5.

NGEGO TO 6.

GLOW CONTROL SYSTEMZD30DDTi

EC-242

Page 610 of 1767

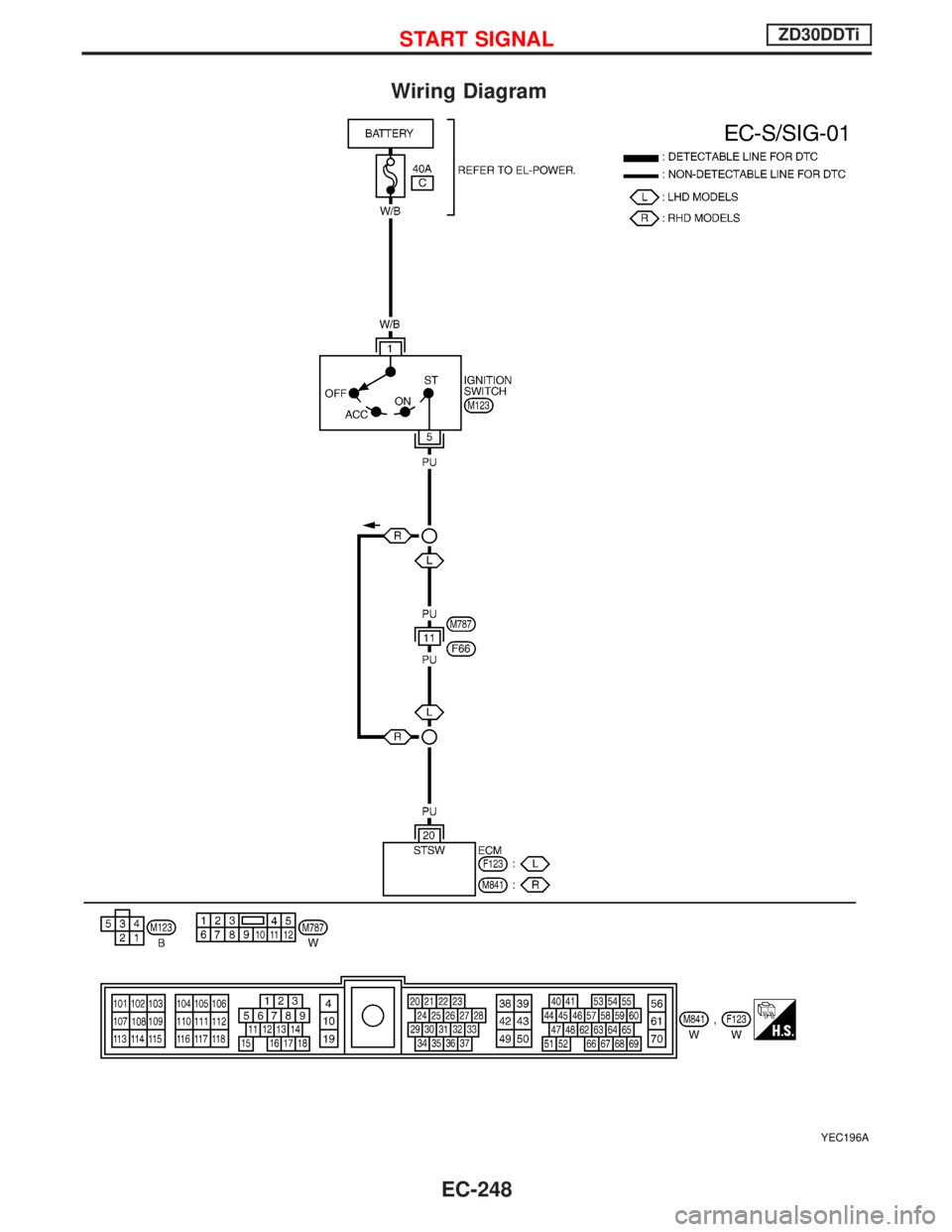

Wiring Diagram

YEC196A

START SIGNALZD30DDTi

EC-248

Page 611 of 1767

Diagnostic Procedure

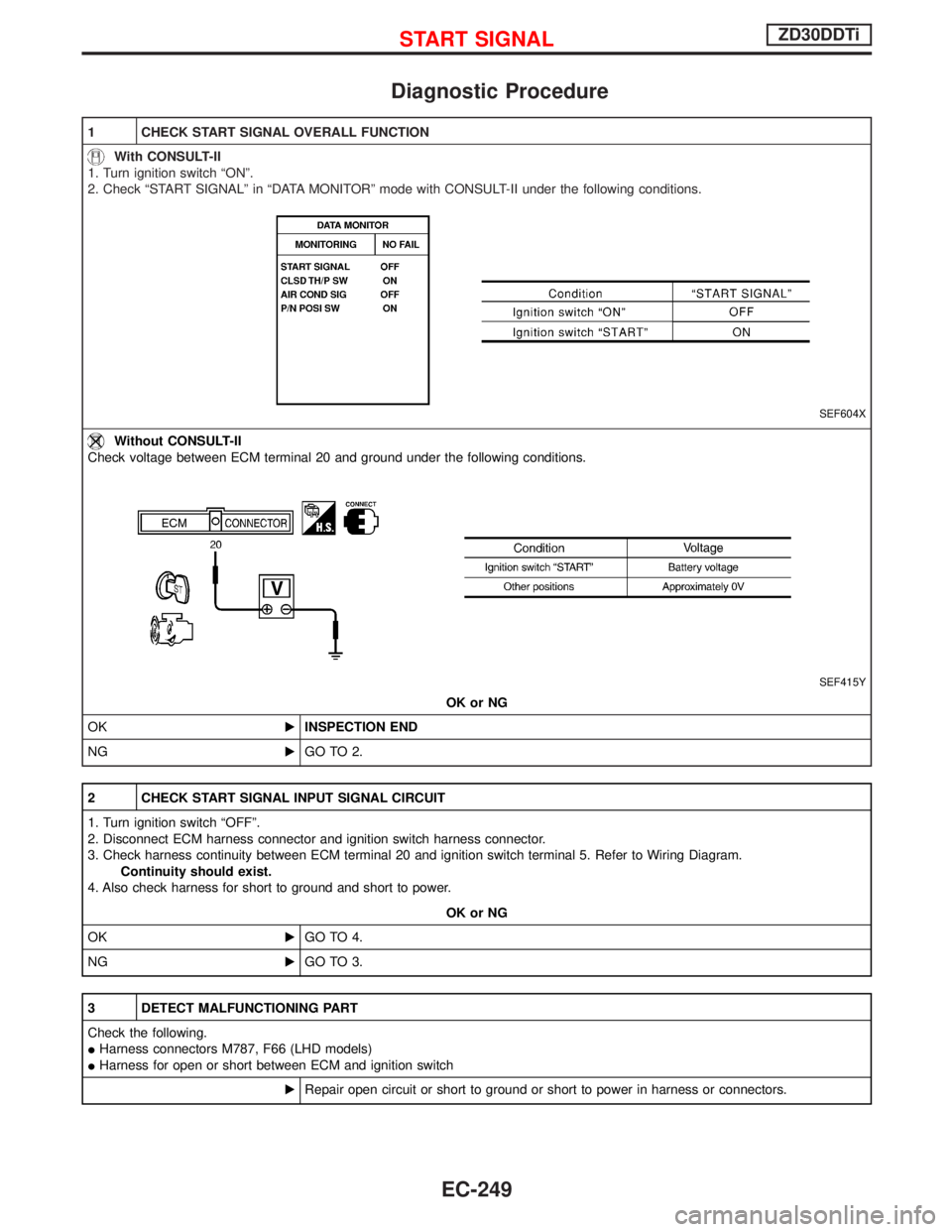

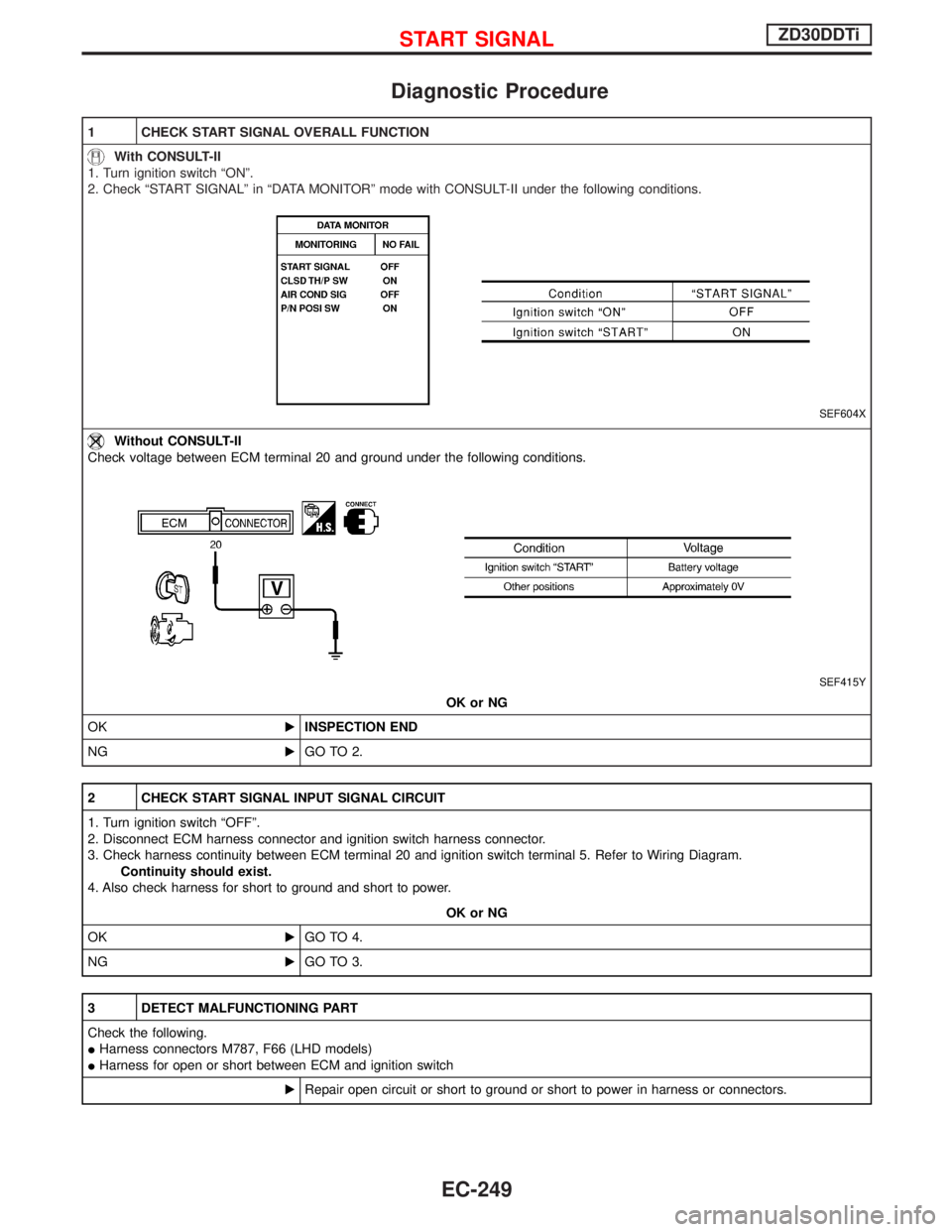

1 CHECK START SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªSTART SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF604X

Without CONSULT-II

Check voltage between ECM terminal 20 and ground under the following conditions.

SEF415Y

OK or NG

OKEINSPECTION END

NGEGO TO 2.

2 CHECK START SIGNAL INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and ignition switch harness connector.

3. Check harness continuity between ECM terminal 20 and ignition switch terminal 5. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKEGO TO 4.

NGEGO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M787, F66 (LHD models)

IHarness for open or short between ECM and ignition switch

ERepair open circuit or short to ground or short to power in harness or connectors.

START SIGNALZD30DDTi

EC-249

Page 612 of 1767

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-78.

EINSPECTION END

START SIGNALZD30DDTi

Diagnostic Procedure (Cont'd)

EC-250

Page 622 of 1767

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye sEGO TO 2.

NoEGO TO 3.

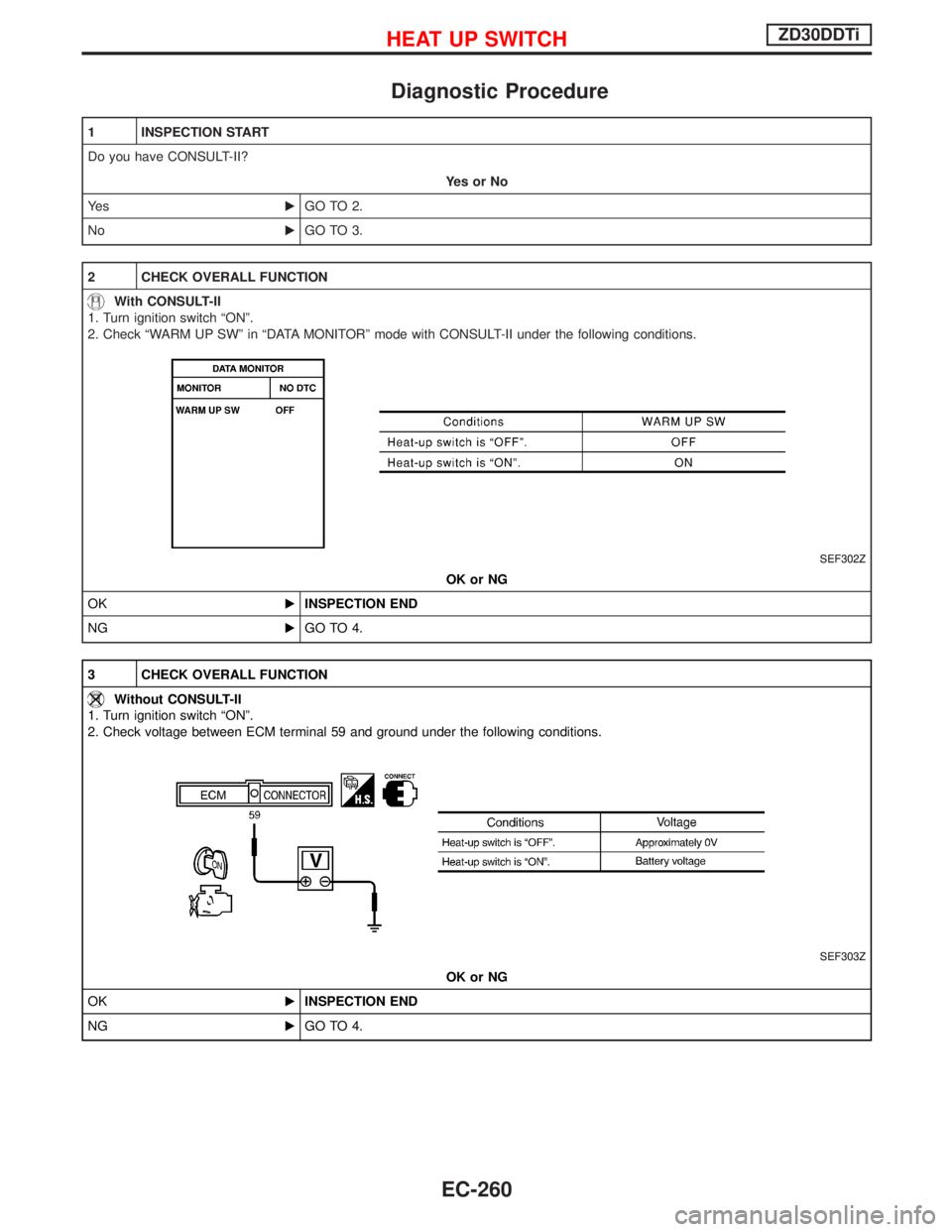

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Check ªWARM UP SWº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF302Z

OK or NG

OKEINSPECTION END

NGEGO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 59 and ground under the following conditions.

SEF303Z

OK or NG

OKEINSPECTION END

NGEGO TO 4.

HEAT UP SWITCHZD30DDTi

EC-260

Page 625 of 1767

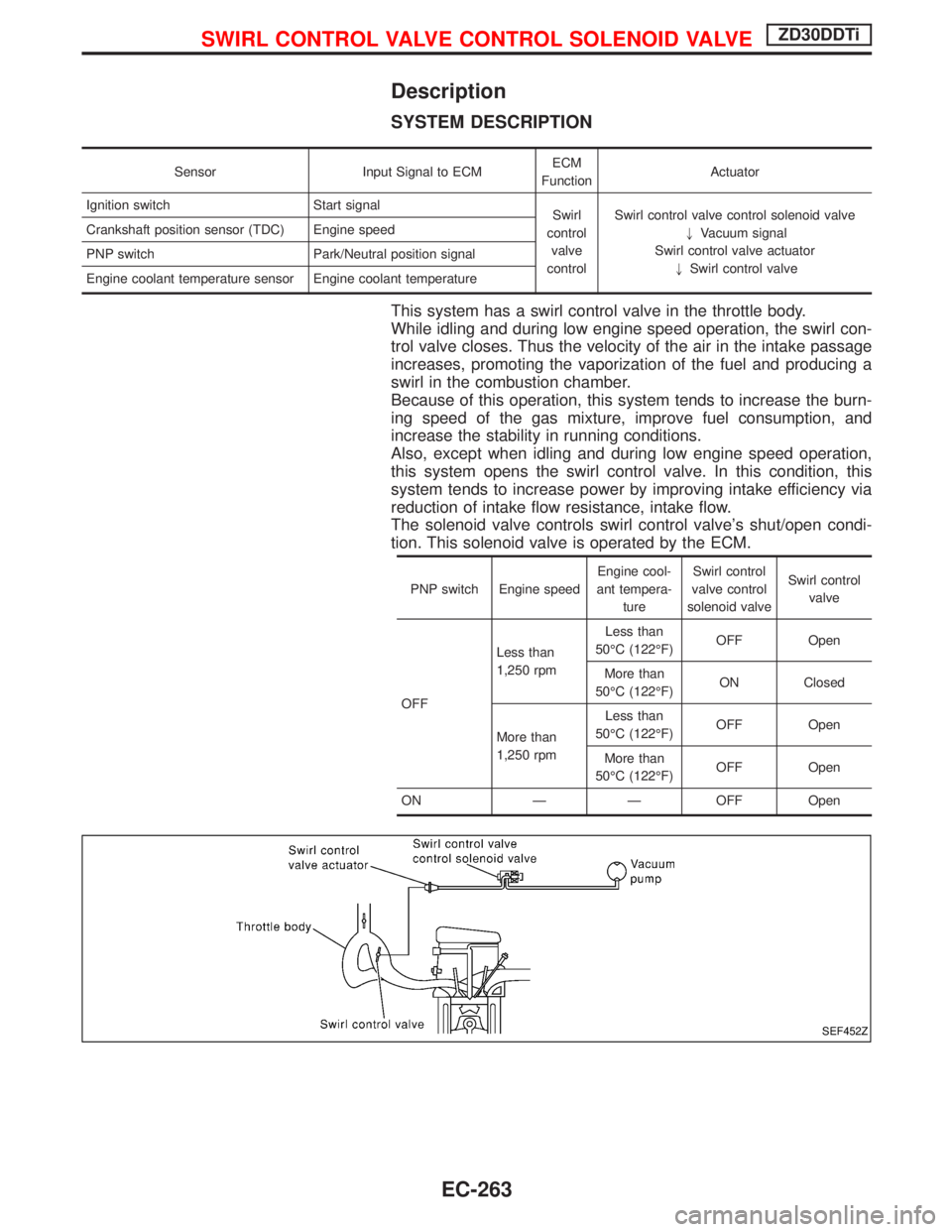

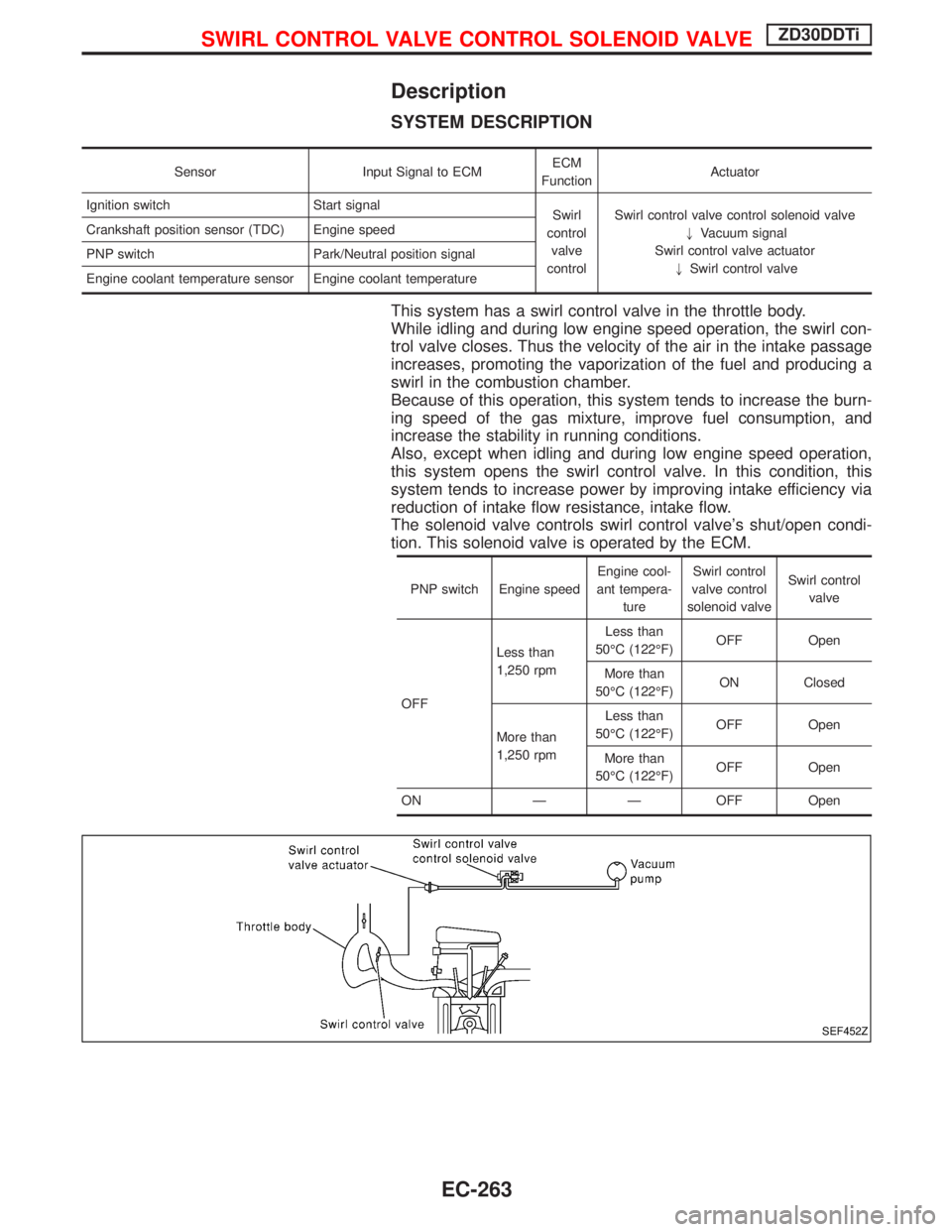

Description

SYSTEM DESCRIPTION

Sensor Input Signal to ECMECM

FunctionActuator

Ignition switch Start signal

Swirl

control

valve

controlSwirl control valve control solenoid valve

"Vacuum signal

Swirl control valve actuator

"Swirl control valve Crankshaft position sensor (TDC) Engine speed

PNP switch Park/Neutral position signal

Engine coolant temperature sensor Engine coolant temperature

This system has a swirl control valve in the throttle body.

While idling and during low engine speed operation, the swirl con-

trol valve closes. Thus the velocity of the air in the intake passage

increases, promoting the vaporization of the fuel and producing a

swirl in the combustion chamber.

Because of this operation, this system tends to increase the burn-

ing speed of the gas mixture, improve fuel consumption, and

increase the stability in running conditions.

Also, except when idling and during low engine speed operation,

this system opens the swirl control valve. In this condition, this

system tends to increase power by improving intake efficiency via

reduction of intake flow resistance, intake flow.

The solenoid valve controls swirl control valve's shut/open condi-

tion. This solenoid valve is operated by the ECM.

PNP switch Engine speedEngine cool-

ant tempera-

tureSwirl control

valve control

solenoid valveSwirl control

valve

OFFLess than

1,250 rpmLess than

50ÉC (122ÉF)OFF Open

More than

50ÉC (122ÉF)ON Closed

More than

1,250 rpmLess than

50ÉC (122ÉF)OFF Open

More than

50ÉC (122ÉF)OFF Open

ON Ð Ð OFF Open

SEF452Z

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

EC-263

Page 628 of 1767

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye sEGO TO 2.

NoEGO TO 3.

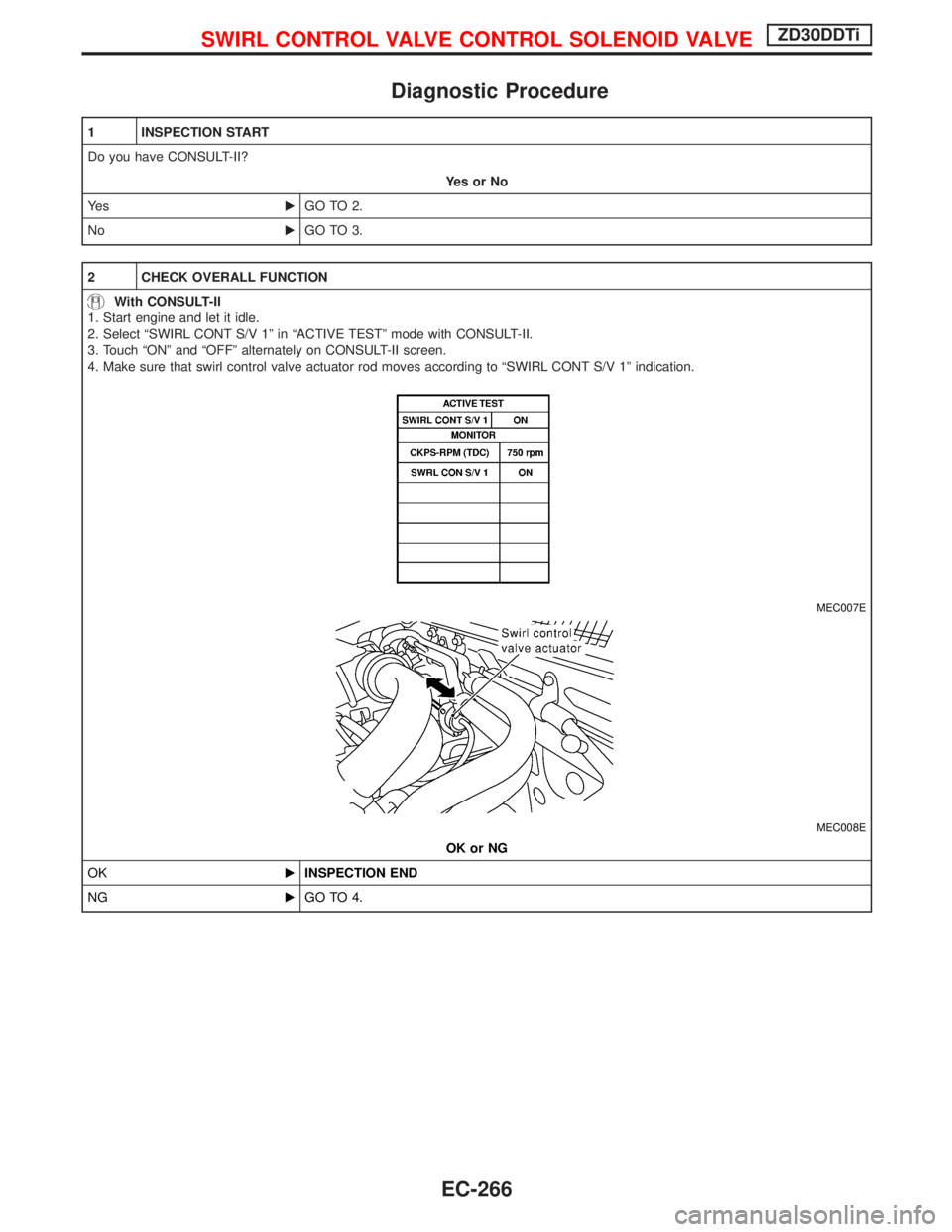

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine and let it idle.

2. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº alternately on CONSULT-II screen.

4. Make sure that swirl control valve actuator rod moves according to ªSWIRL CONT S/V 1º indication.

MEC007E

MEC008E

OK or NG

OKEINSPECTION END

NGEGO TO 4.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

EC-266

Page 629 of 1767

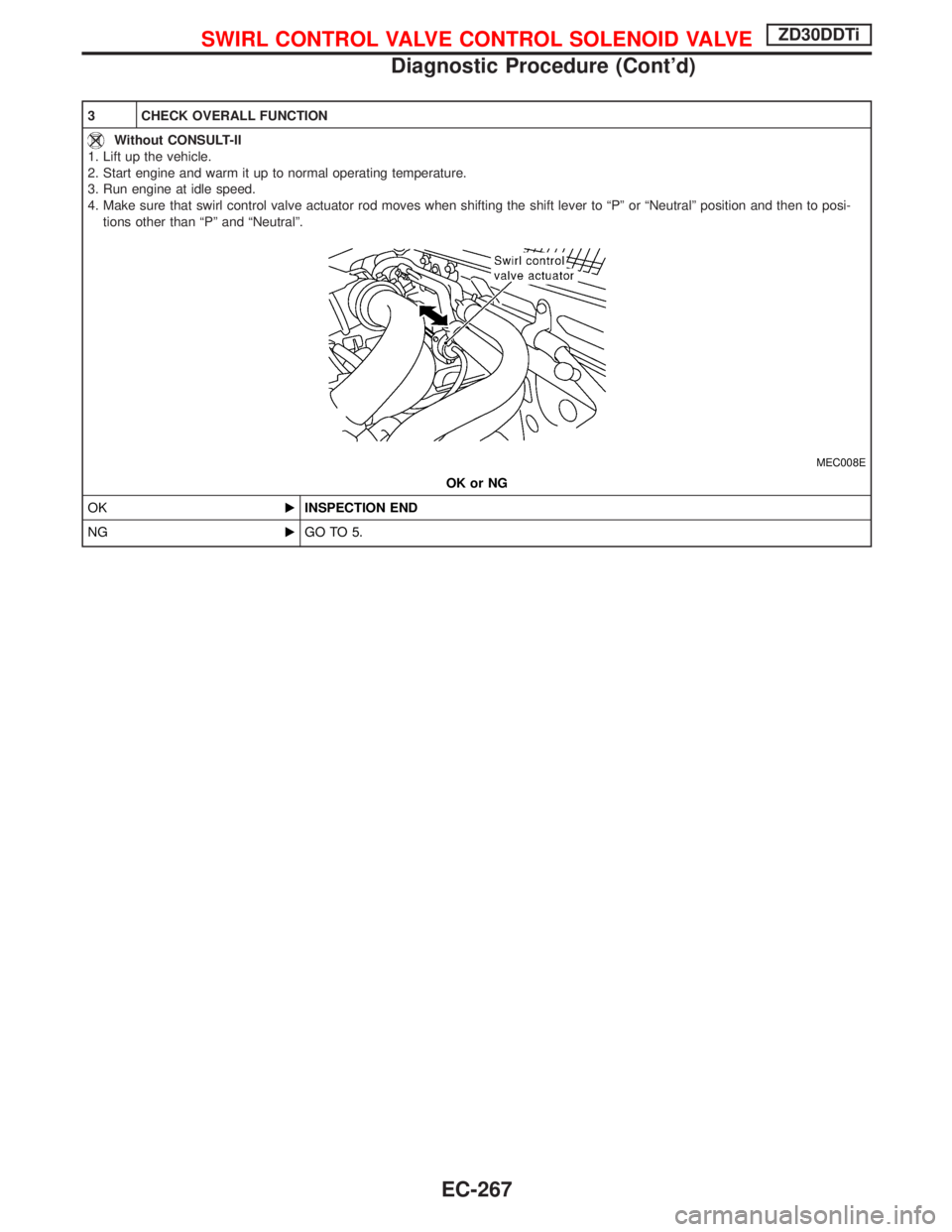

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Lift up the vehicle.

2. Start engine and warm it up to normal operating temperature.

3. Run engine at idle speed.

4. Make sure that swirl control valve actuator rod moves when shifting the shift lever to ªPº or ªNeutralº position and then to posi-

tions other than ªPº and ªNeutralº.

MEC008E

OK or NG

OKEINSPECTION END

NGEGO TO 5.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-267

Page 630 of 1767

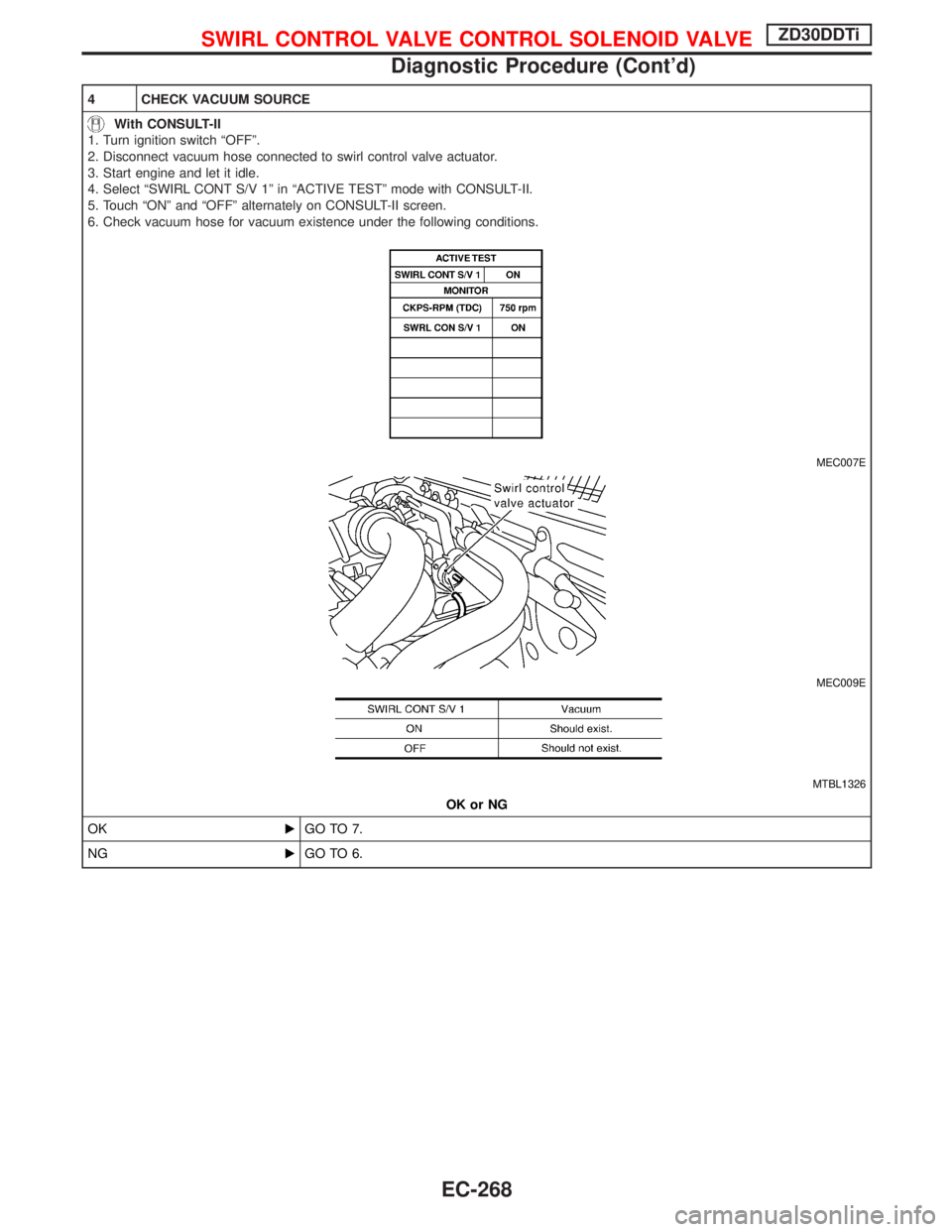

4 CHECK VACUUM SOURCE

With CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to swirl control valve actuator.

3. Start engine and let it idle.

4. Select ªSWIRL CONT S/V 1º in ªACTIVE TESTº mode with CONSULT-II.

5. Touch ªONº and ªOFFº alternately on CONSULT-II screen.

6. Check vacuum hose for vacuum existence under the following conditions.

MEC007E

MEC009E

MTBL1326

OK or NG

OKEGO TO 7.

NGEGO TO 6.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-268

Page 631 of 1767

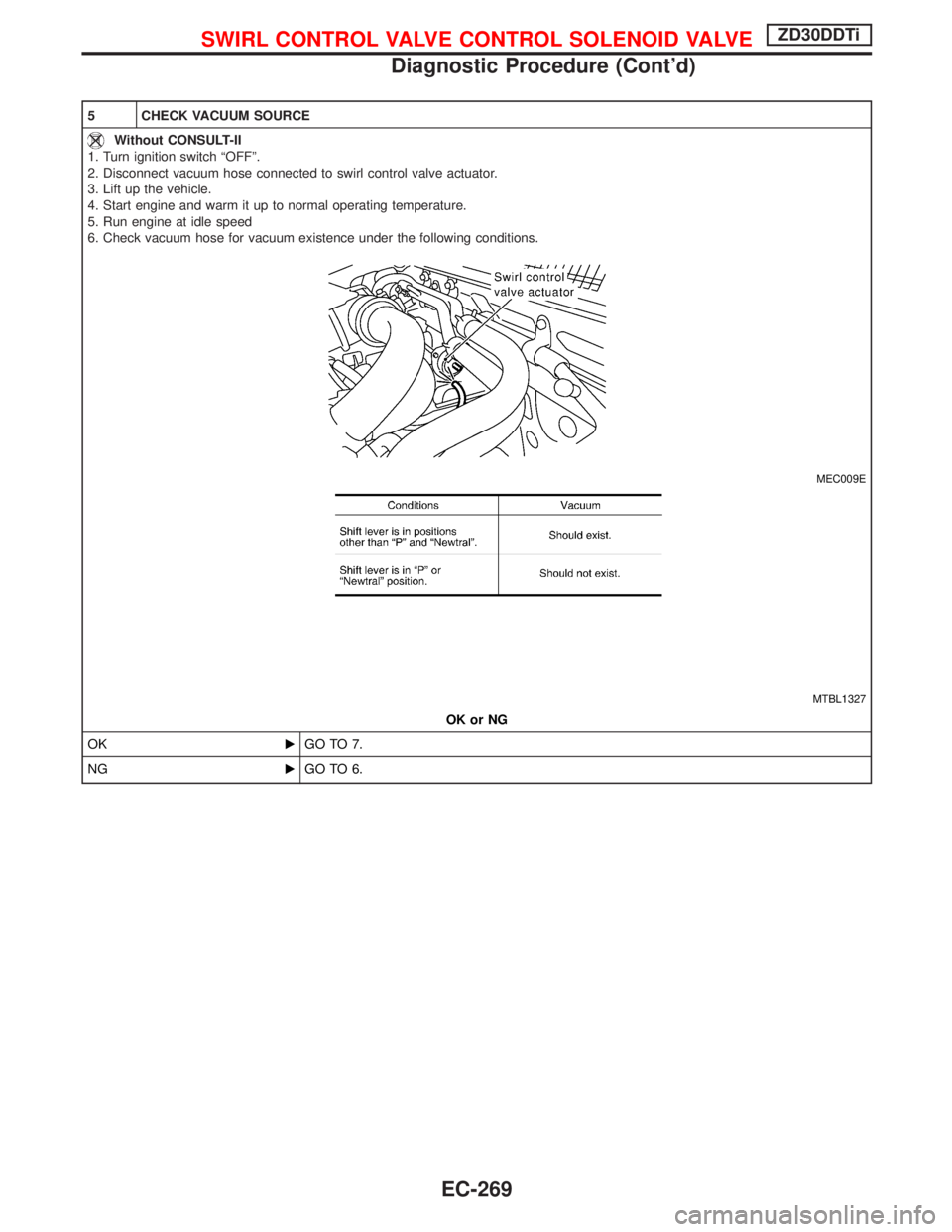

5 CHECK VACUUM SOURCE

Without CONSULT-II

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to swirl control valve actuator.

3. Lift up the vehicle.

4. Start engine and warm it up to normal operating temperature.

5. Run engine at idle speed

6. Check vacuum hose for vacuum existence under the following conditions.

MEC009E

MTBL1327

OK or NG

OKEGO TO 7.

NGEGO TO 6.

SWIRL CONTROL VALVE CONTROL SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-269