Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 738 of 1767

Component Description

FUEL CUT SOLENOID VALVE

When the ignition switch is off, the ECM turns the fuel cut solenoid

valve OFF (under this condition, no current flows through the fuel

cut solenoid valve), shutting off fuel supply.

When the engine is not operating due to trouble, the fuel cut sole-

noid valve may or may not be OFF even when the ignition switch

is ON.

On Board Diagnosis Logic

DTC Malfunction is detected when ...Check Items

(Possible Cause)

P0125

0306IFuel cut solenoid valve circuit is malfunctioning.IHarness or connectors

(The solenoid valve circuit is open or shorted.)

IFuel cut solenoid valve

DTC Confirmation Procedure

NOTE:

If DTC P0115 or P0335 is displayed same time, perform trouble

diagnosis for P0115 or P0335 first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine. (If no start, circuit is open.)

4) Warm it up sufficiently.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

6) Start engine and rev it up to above 1,300 rpm. Release pedal

and wait at least 3 seconds.

WITHOUT CONSULT-II

1) Start engine. (If no start, circuit is open.)

2) Warm it up sufficiently.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds.

4) Start engine and rev it up to above 1,300 rpm. Release pedal

and wait at least 3 seconds.

5) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

6) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF667S

DTC P0215 FUEL CUT S/V 1TD27Ti

EC-376

Page 740 of 1767

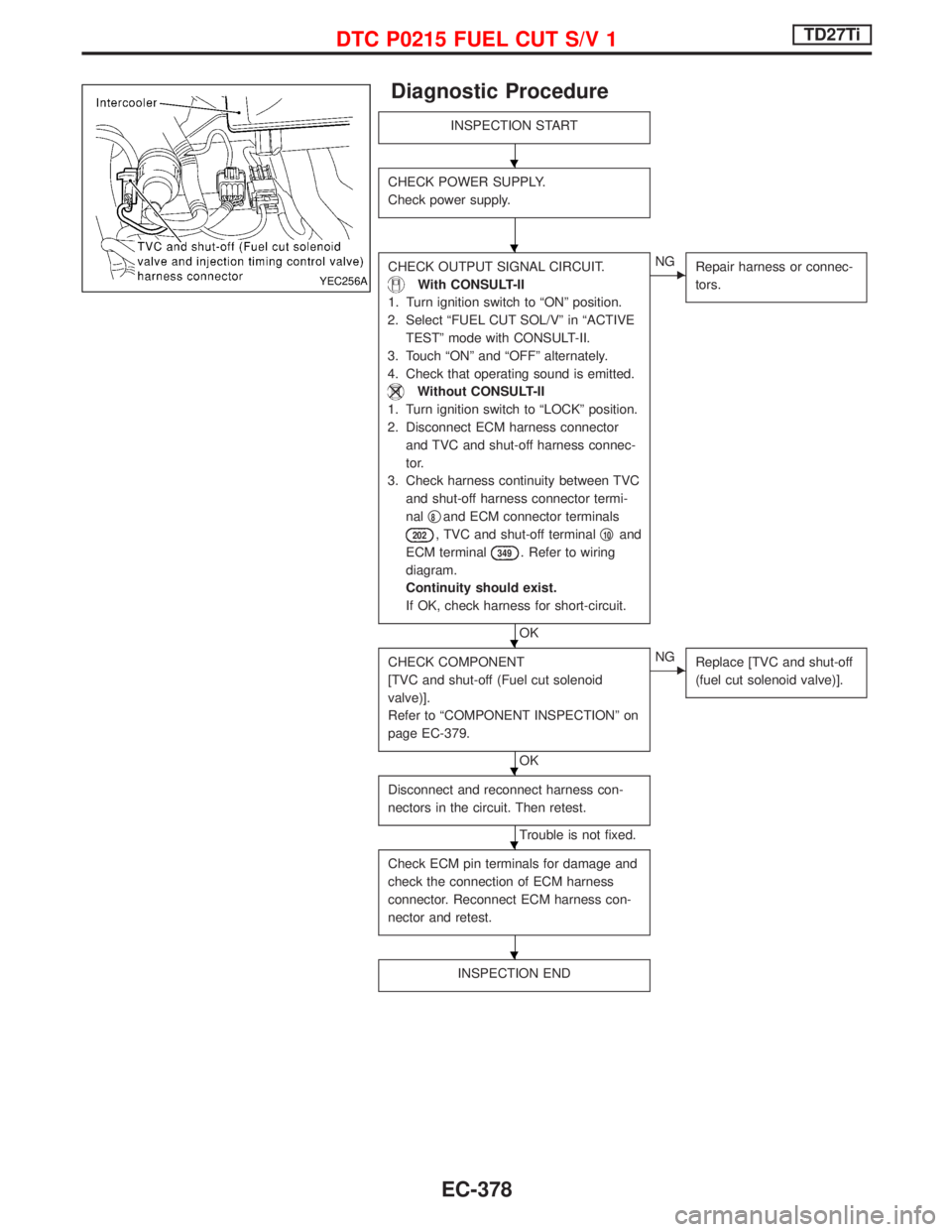

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

Check power supply.

CHECK OUTPUT SIGNAL CIRCUIT.

With CONSULT-II

1. Turn ignition switch to ªONº position.

2. Select ªFUEL CUT SOL/Vº in ªACTIVE

TESTº mode with CONSULT-II.

3. Touch ªONº and ªOFFº alternately.

4. Check that operating sound is emitted.

Without CONSULT-II

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector

and TVC and shut-off harness connec-

tor.

3. Check harness continuity between TVC

and shut-off harness connector termi-

nalq

8and ECM connector terminals

202, TVC and shut-off terminalq10and

ECM terminal

349. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT

[TVC and shut-off (Fuel cut solenoid

valve)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-379.

OK

ENG

Replace [TVC and shut-off

(fuel cut solenoid valve)].

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC256A

H

H

H

H

H

H

DTC P0215 FUEL CUT S/V 1TD27Ti

EC-378

Page 743 of 1767

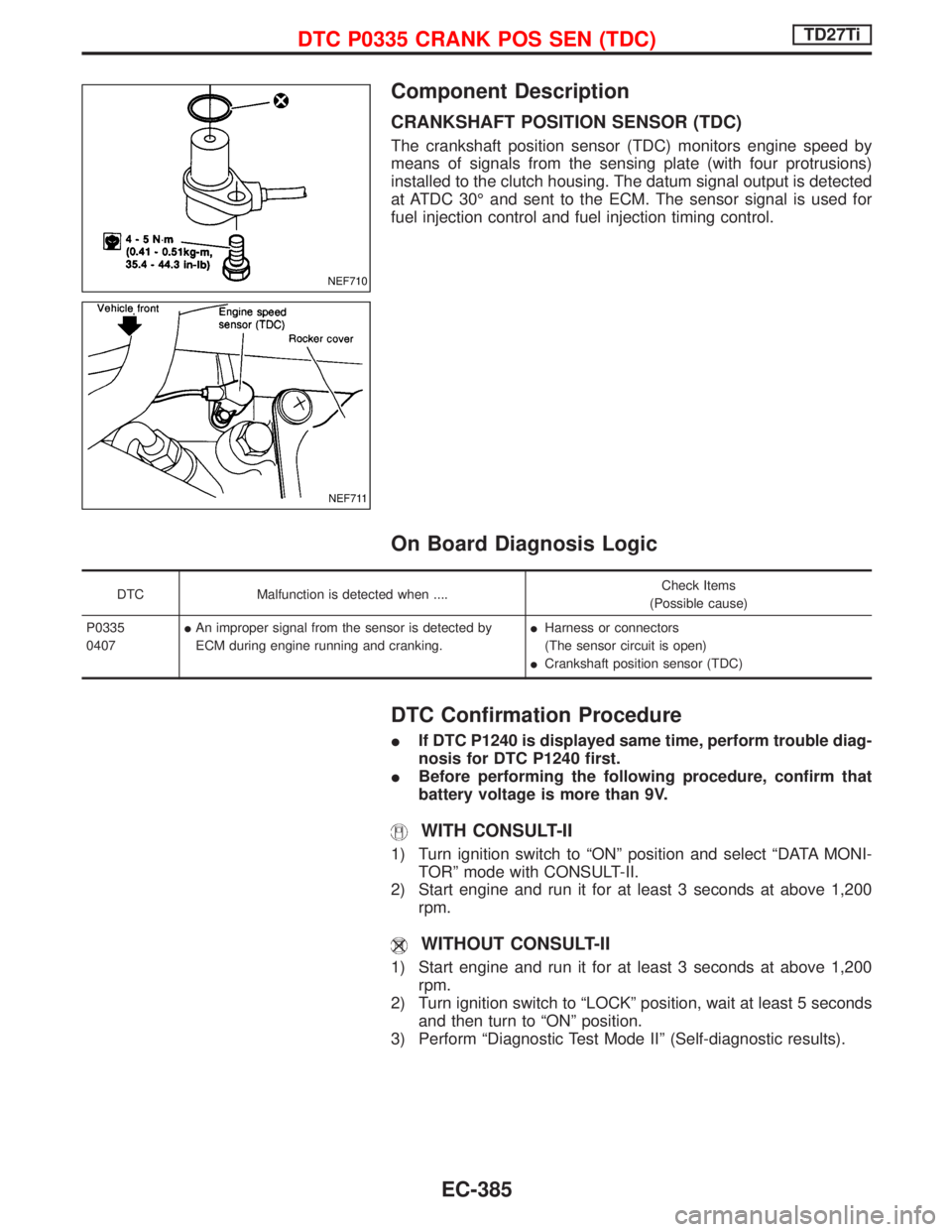

DTC P1246 Confirmation Procedure

NOTE:

If both DTC P1246 and P1240 or P0335 are displayed, perform

TROUBLE DIAGNOSIS FOR DTC P1240 or P0335. (See EC-427

or EC-385.)

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine. Run it for 10 seconds at idle.

WITHOUT CONSULT-II

1) Start engine. Run it for 10 seconds at idle.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NOTE:

If a malfunction occurs intermittently, conduct suitable driving

pattern for 10 minutes. This makes it possible to determine

DTC.

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/INJ TIMG F/BTD27Ti

EC-381

Page 745 of 1767

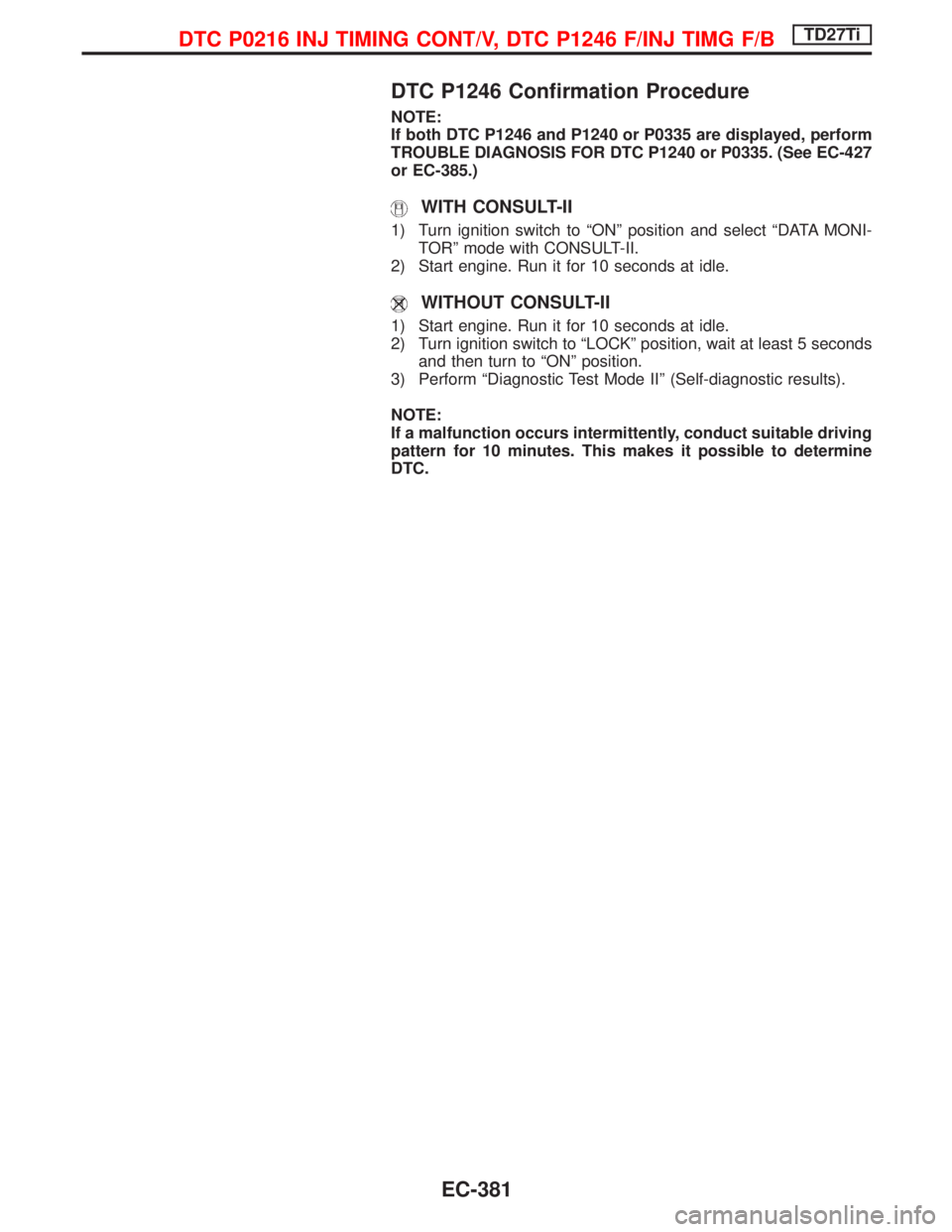

Diagnostic Procedure

INSPECTION START

CHECK FOR AIR IN FUEL FILTER.

1. Move priming pump up and down to

purge air from fuel filter.

2. Perform ªDIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCE-

DUREº.

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect TVC and shut-off (injection

timing control valve) harness connec-

tor.

3. Turn ignition switch to ªONº position.

4. Check voltage between TVC and shut-

off (injection timing control valve) con-

nector terminalq

9and engine ground

with CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following:

IHarness connector

M787,F66

I20A fuse

IECM relay

IHarness for open or

short-circuit between

TVC and shut-off (injec-

tion timing control valve)

harness connector and

fuse box.

If NG, replace 20A fuse or

ECM relay, harness or con-

nectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between TVC

and shut-off (injection timing control

valve) connector terminalq

8and ECM

terminals

202. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

TVC and shut-off (injec-

tion timing control valve)

and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM connector terminal

349and TVC

and shut-off (injection timing control

valve) connector terminalq

10. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness of short-circuit.

OK

ENG

Repair harness or connec-

tors

qA

YEC256A

NEF463

MEC947D

H

H

H

H

H

DTC P0216 INJ TIMING CONT/V, DTC P1246 F/INJ TIMG F/BTD27Ti

EC-383

Page 747 of 1767

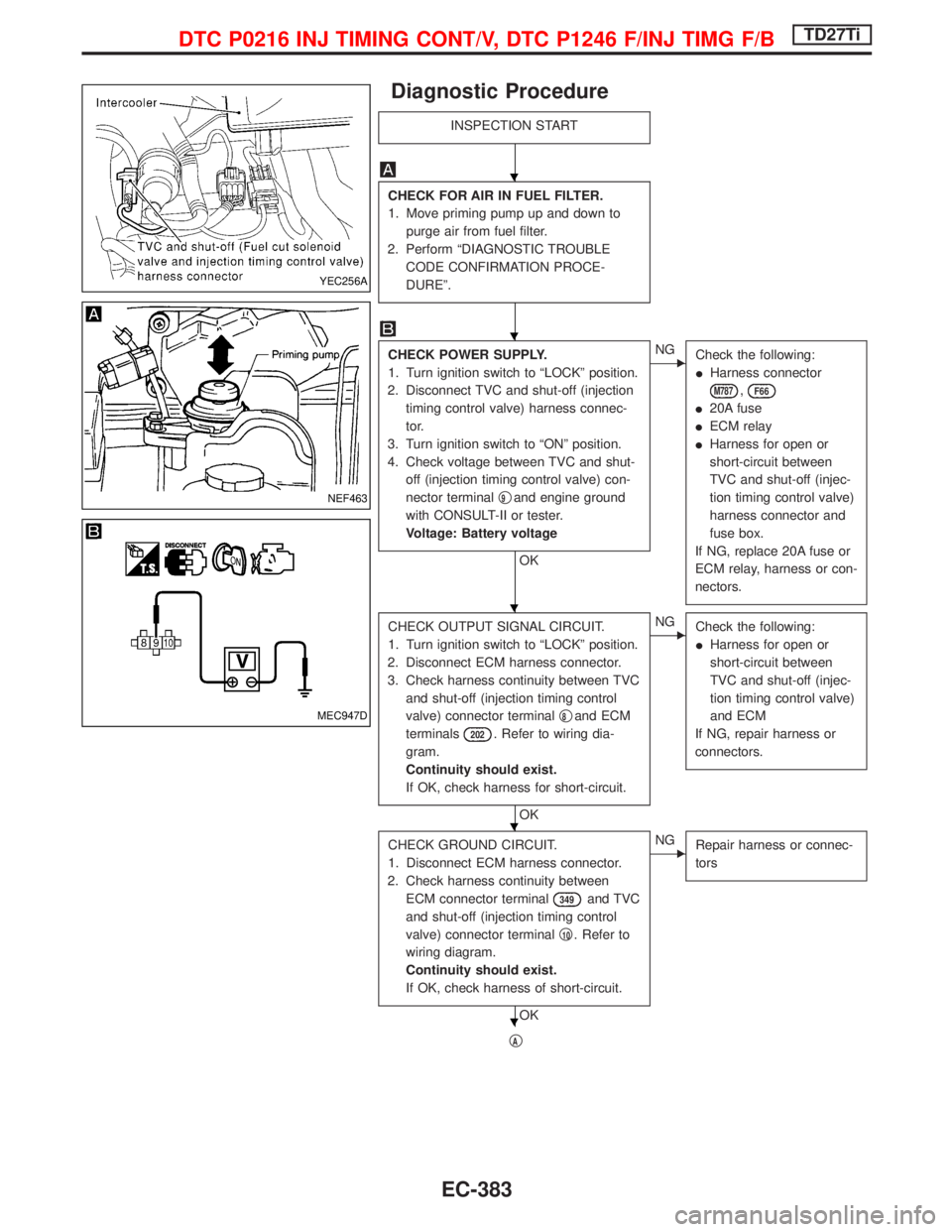

Component Description

CRANKSHAFT POSITION SENSOR (TDC)

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with four protrusions)

installed to the clutch housing. The datum signal output is detected

at ATDC 30É and sent to the ECM. The sensor signal is used for

fuel injection control and fuel injection timing control.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible cause)

P0335

0407IAn improper signal from the sensor is detected by

ECM during engine running and cranking.IHarness or connectors

(The sensor circuit is open)

ICrankshaft position sensor (TDC)

DTC Confirmation Procedure

IIf DTC P1240 is displayed same time, perform trouble diag-

nosis for DTC P1240 first.

IBefore performing the following procedure, confirm that

battery voltage is more than 9V.

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine and run it for at least 3 seconds at above 1,200

rpm.

WITHOUT CONSULT-II

1) Start engine and run it for at least 3 seconds at above 1,200

rpm.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NEF710

NEF711

DTC P0335 CRANK POS SEN (TDC)TD27Ti

EC-385

Page 749 of 1767

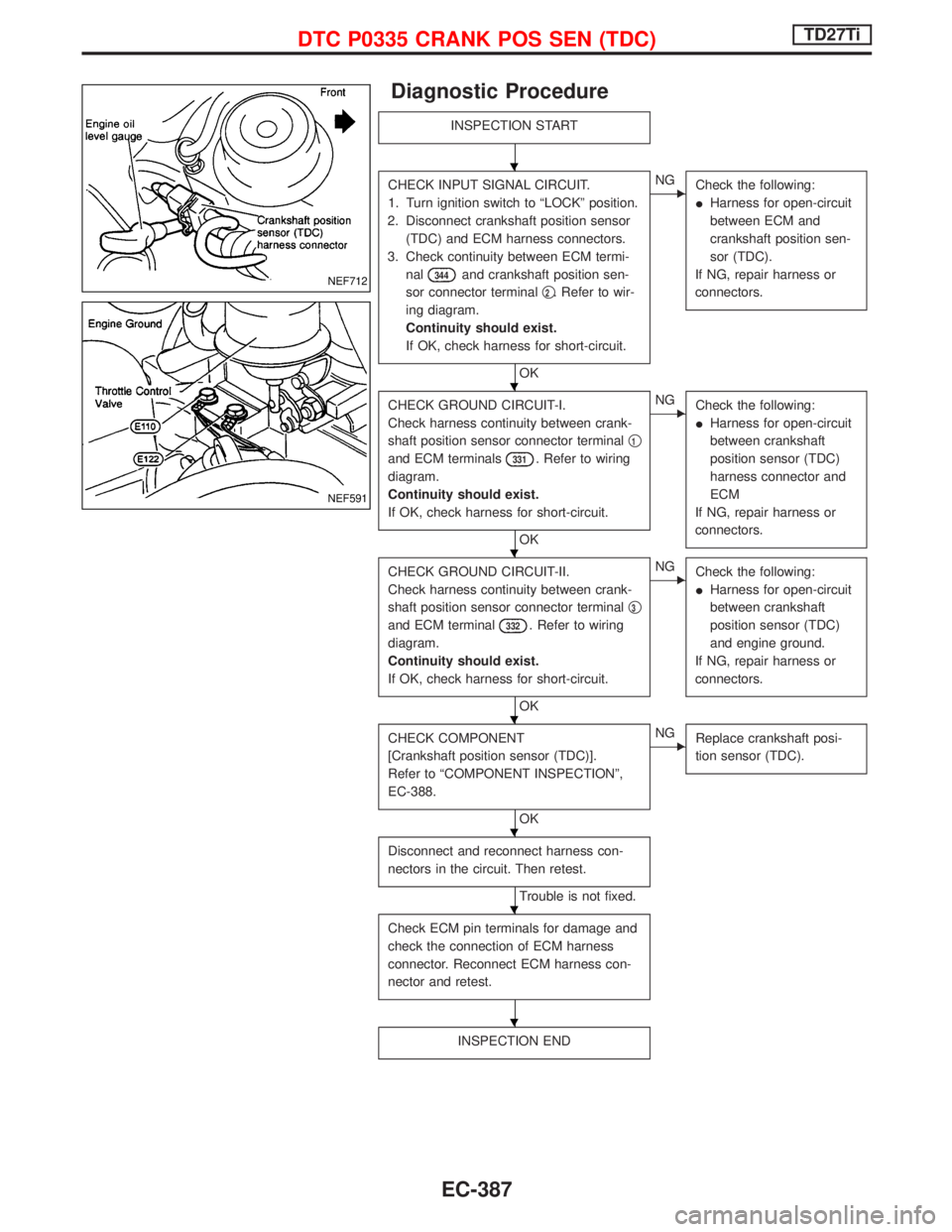

Diagnostic Procedure

INSPECTION START

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect crankshaft position sensor

(TDC) and ECM harness connectors.

3. Check continuity between ECM termi-

nal

344and crankshaft position sen-

sor connector terminalq

2. Refer to wir-

ing diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open-circuit

between ECM and

crankshaft position sen-

sor (TDC).

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between crank-

shaft position sensor connector terminalq

1

and ECM terminals331. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open-circuit

between crankshaft

position sensor (TDC)

harness connector and

ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-II.

Check harness continuity between crank-

shaft position sensor connector terminalq

3

and ECM terminal332. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open-circuit

between crankshaft

position sensor (TDC)

and engine ground.

If NG, repair harness or

connectors.

CHECK COMPONENT

[Crankshaft position sensor (TDC)].

Refer to ªCOMPONENT INSPECTIONº,

EC-388.

OK

ENG

Replace crankshaft posi-

tion sensor (TDC).

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF712

NEF591

H

H

H

H

H

H

H

DTC P0335 CRANK POS SEN (TDC)TD27Ti

EC-387

Page 751 of 1767

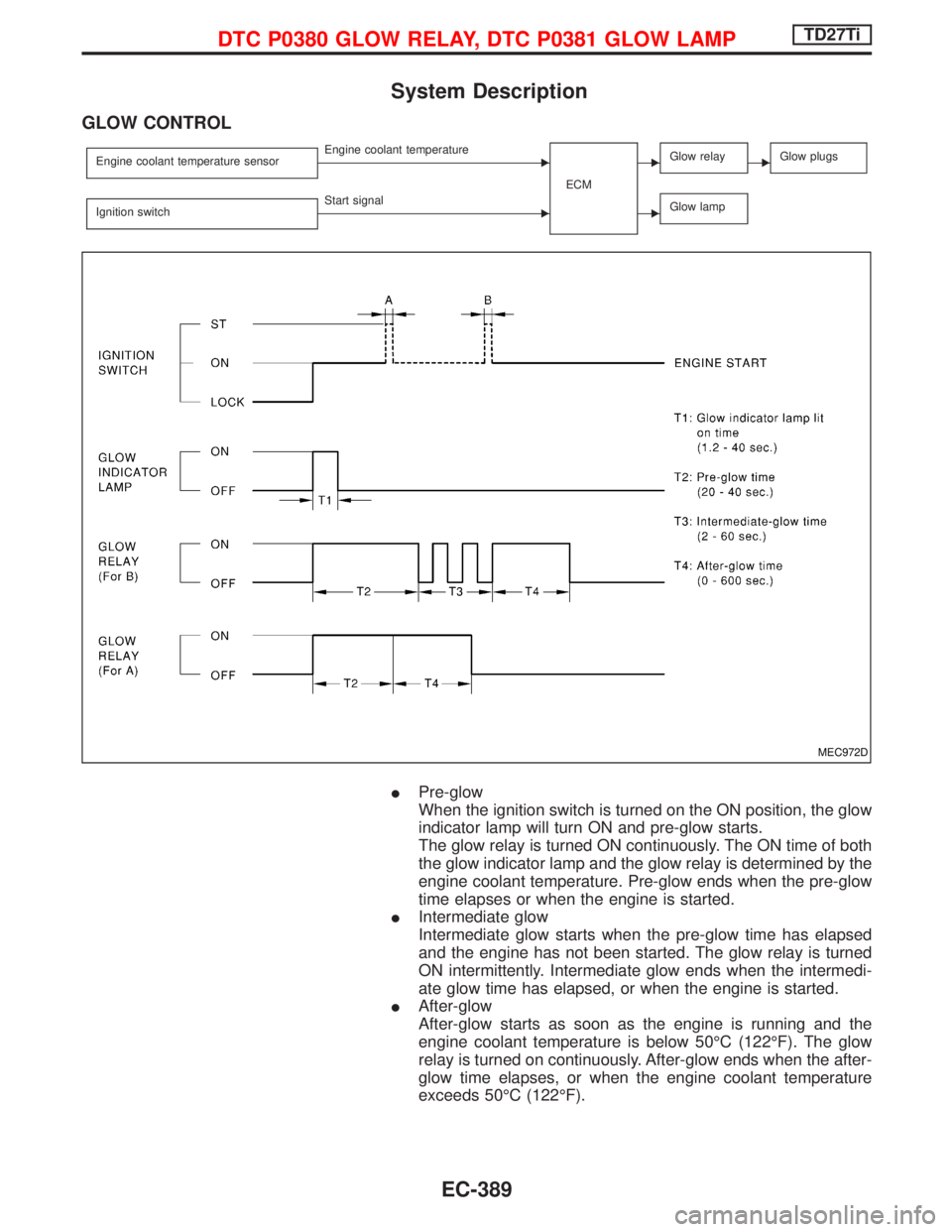

System Description

GLOW CONTROL

Engine coolant temperature sensorEEngine coolant temperature

ECMEGlow relayEGlow plugs

Ignition switchEStart signalEGlow lamp

IPre-glow

When the ignition switch is turned on the ON position, the glow

indicator lamp will turn ON and pre-glow starts.

The glow relay is turned ON continuously. The ON time of both

the glow indicator lamp and the glow relay is determined by the

engine coolant temperature. Pre-glow ends when the pre-glow

time elapses or when the engine is started.

IIntermediate glow

Intermediate glow starts when the pre-glow time has elapsed

and the engine has not been started. The glow relay is turned

ON intermittently. Intermediate glow ends when the intermedi-

ate glow time has elapsed, or when the engine is started.

IAfter-glow

After-glow starts as soon as the engine is running and the

engine coolant temperature is below 50ÉC (122ÉF). The glow

relay is turned on continuously. After-glow ends when the after-

glow time elapses, or when the engine coolant temperature

exceeds 50ÉC (122ÉF).

MEC972D

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-389

Page 755 of 1767

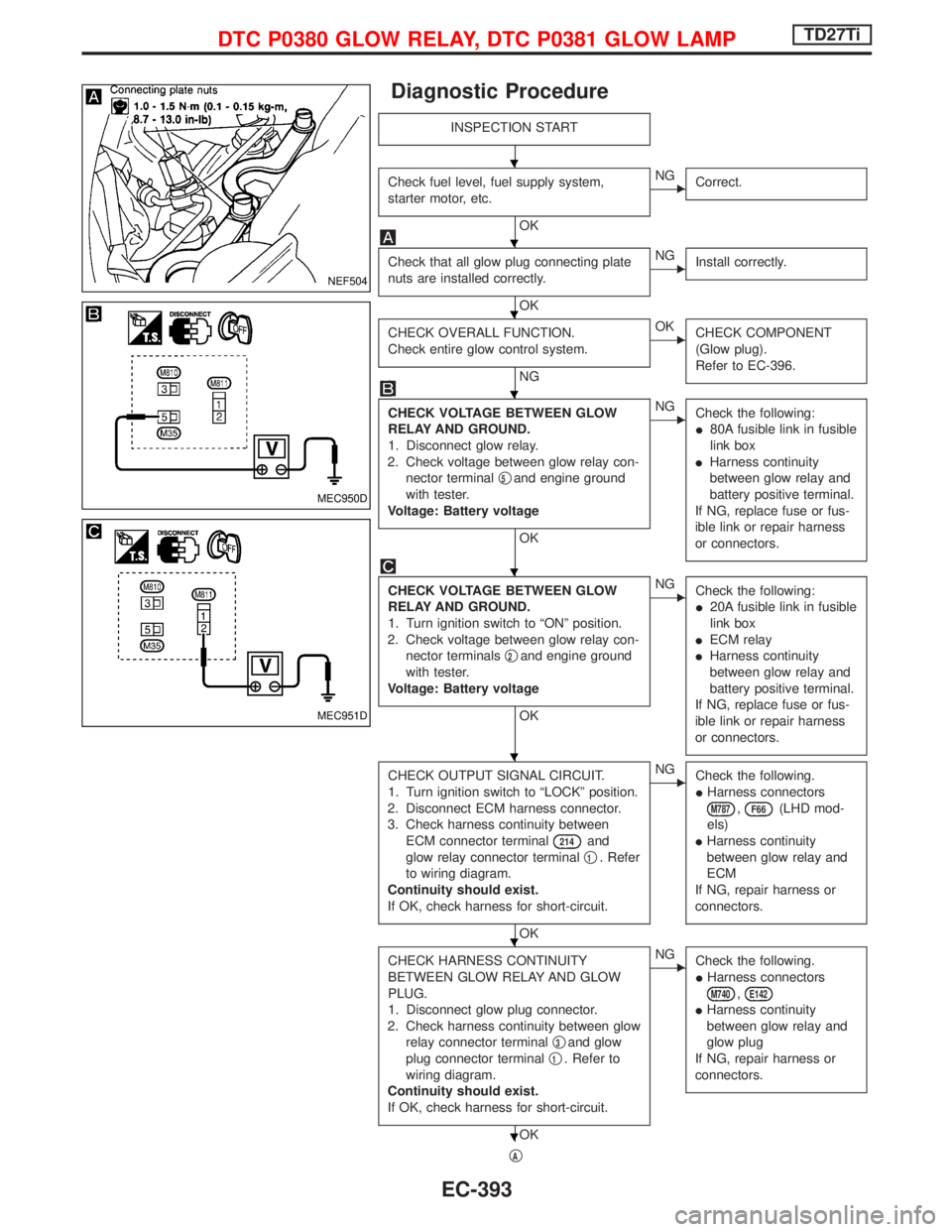

Diagnostic Procedure

INSPECTION START

Check fuel level, fuel supply system,

starter motor, etc.

OK

ENG

Correct.

Check that all glow plug connecting plate

nuts are installed correctly.

OK

ENG

Install correctly.

CHECK OVERALL FUNCTION.

Check entire glow control system.

NG

EOK

CHECK COMPONENT

(Glow plug).

Refer to EC-396.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Disconnect glow relay.

2. Check voltage between glow relay con-

nector terminalq

5and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I80A fusible link in fusible

link box

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK VOLTAGE BETWEEN GLOW

RELAY AND GROUND.

1. Turn ignition switch to ªONº position.

2. Check voltage between glow relay con-

nector terminalsq

2and engine ground

with tester.

Voltage: Battery voltage

OK

ENG

Check the following:

I20A fusible link in fusible

link box

IECM relay

IHarness continuity

between glow relay and

battery positive terminal.

If NG, replace fuse or fus-

ible link or repair harness

or connectors.

CHECK OUTPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Check harness continuity between

ECM connector terminal

214and

glow relay connector terminalq

1. Refer

to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

IHarness continuity

between glow relay and

ECM

If NG, repair harness or

connectors.

CHECK HARNESS CONTINUITY

BETWEEN GLOW RELAY AND GLOW

PLUG.

1. Disconnect glow plug connector.

2. Check harness continuity between glow

relay connector terminalq

3and glow

plug connector terminalq

1. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

M740,E142

IHarness continuity

between glow relay and

glow plug

If NG, repair harness or

connectors.

qA

NEF504

MEC950D

MEC951D

H

H

H

H

H

H

H

H

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-393

Page 757 of 1767

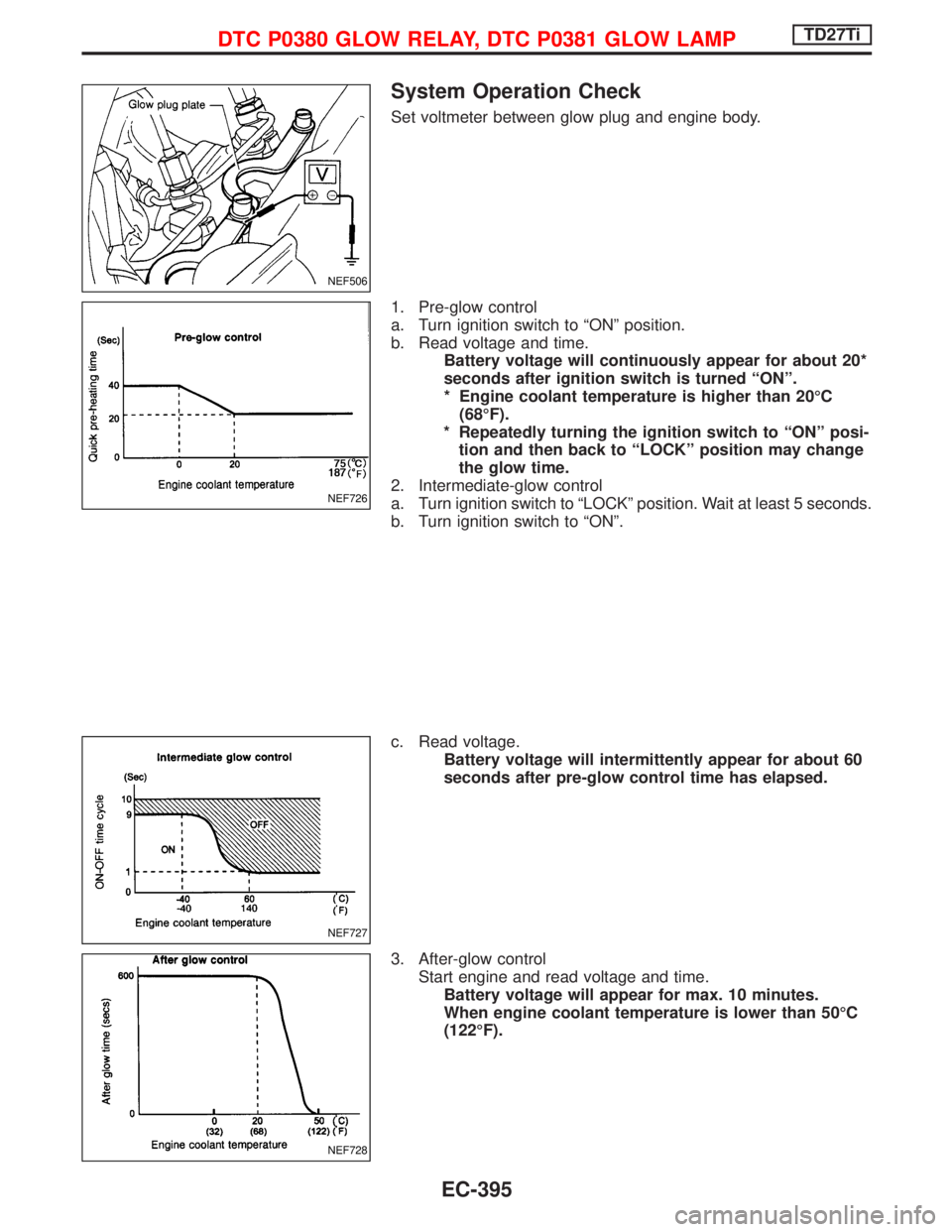

System Operation Check

Set voltmeter between glow plug and engine body.

1. Pre-glow control

a. Turn ignition switch to ªONº position.

b. Read voltage and time.

Battery voltage will continuously appear for about 20*

seconds after ignition switch is turned ªONº.

* Engine coolant temperature is higher than 20ÉC

(68ÉF).

* Repeatedly turning the ignition switch to ªONº posi-

tion and then back to ªLOCKº position may change

the glow time.

2. Intermediate-glow control

a. Turn ignition switch to ªLOCKº position. Wait at least 5 seconds.

b. Turn ignition switch to ªONº.

c. Read voltage.

Battery voltage will intermittently appear for about 60

seconds after pre-glow control time has elapsed.

3. After-glow control

Start engine and read voltage and time.

Battery voltage will appear for max. 10 minutes.

When engine coolant temperature is lower than 50ÉC

(122ÉF).

NEF506

NEF726

NEF727

NEF728

DTC P0380 GLOW RELAY, DTC P0381 GLOW LAMPTD27Ti

EC-395

Page 759 of 1767

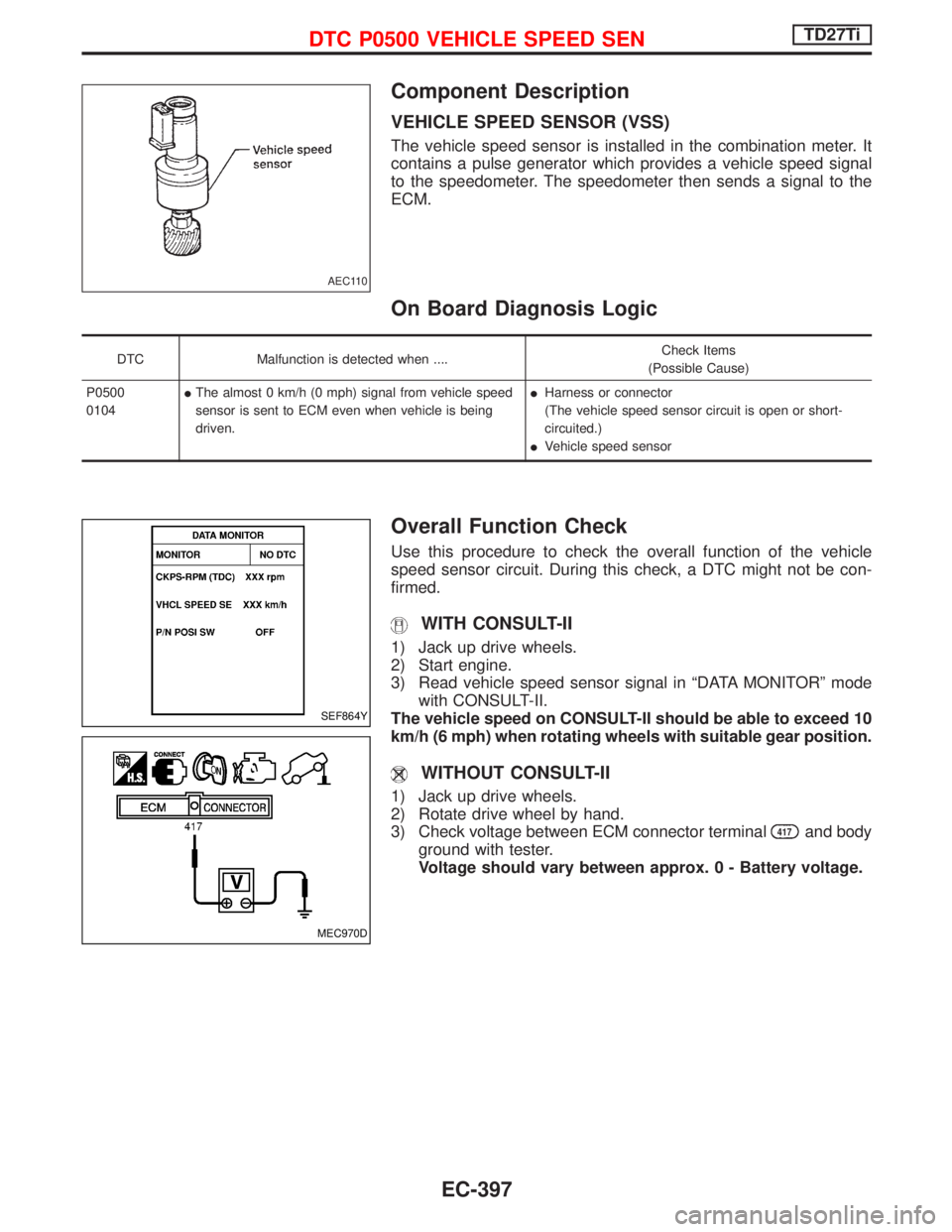

Component Description

VEHICLE SPEED SENSOR (VSS)

The vehicle speed sensor is installed in the combination meter. It

contains a pulse generator which provides a vehicle speed signal

to the speedometer. The speedometer then sends a signal to the

ECM.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible Cause)

P0500

0104IThe almost 0 km/h (0 mph) signal from vehicle speed

sensor is sent to ECM even when vehicle is being

driven.IHarness or connector

(The vehicle speed sensor circuit is open or short-

circuited.)

IVehicle speed sensor

Overall Function Check

Use this procedure to check the overall function of the vehicle

speed sensor circuit. During this check, a DTC might not be con-

firmed.

WITH CONSULT-II

1) Jack up drive wheels.

2) Start engine.

3) Read vehicle speed sensor signal in ªDATA MONITORº mode

with CONSULT-II.

The vehicle speed on CONSULT-II should be able to exceed 10

km/h (6 mph) when rotating wheels with suitable gear position.

WITHOUT CONSULT-II

1) Jack up drive wheels.

2) Rotate drive wheel by hand.

3) Check voltage between ECM connector terminal

417and body

ground with tester.

Voltage should vary between approx. 0 - Battery voltage.

AEC110

SEF864Y

MEC970D

DTC P0500 VEHICLE SPEED SENTD27Ti

EC-397