Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 637 of 1767

Diagnostic Procedure

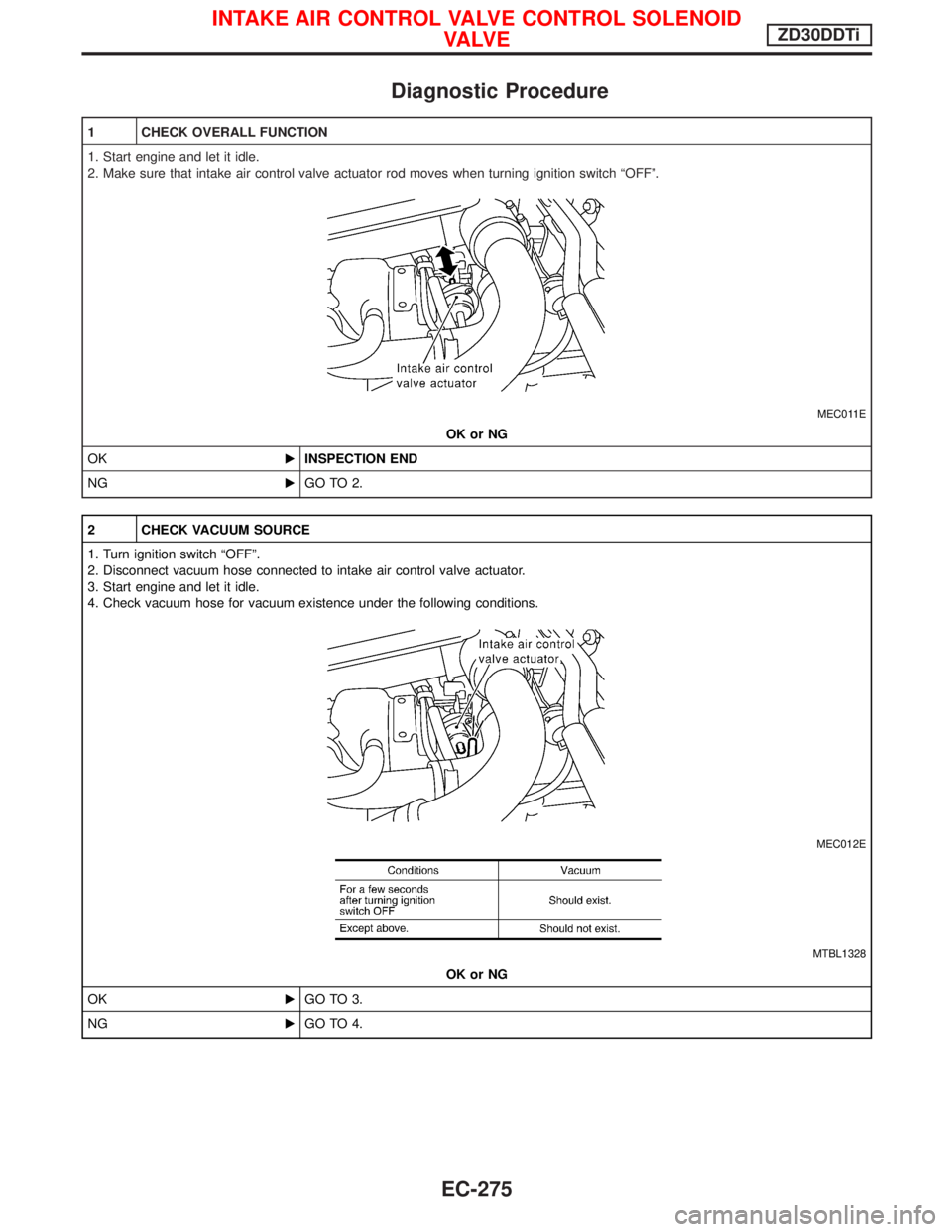

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that intake air control valve actuator rod moves when turning ignition switch ªOFFº.

MEC011E

OK or NG

OKEINSPECTION END

NGEGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to intake air control valve actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence under the following conditions.

MEC012E

MTBL1328

OK or NG

OKEGO TO 3.

NGEGO TO 4.

INTAKE AIR CONTROL VALVE CONTROL SOLENOID

VA LV EZD30DDTi

EC-275

Page 646 of 1767

Diagnostic Procedure

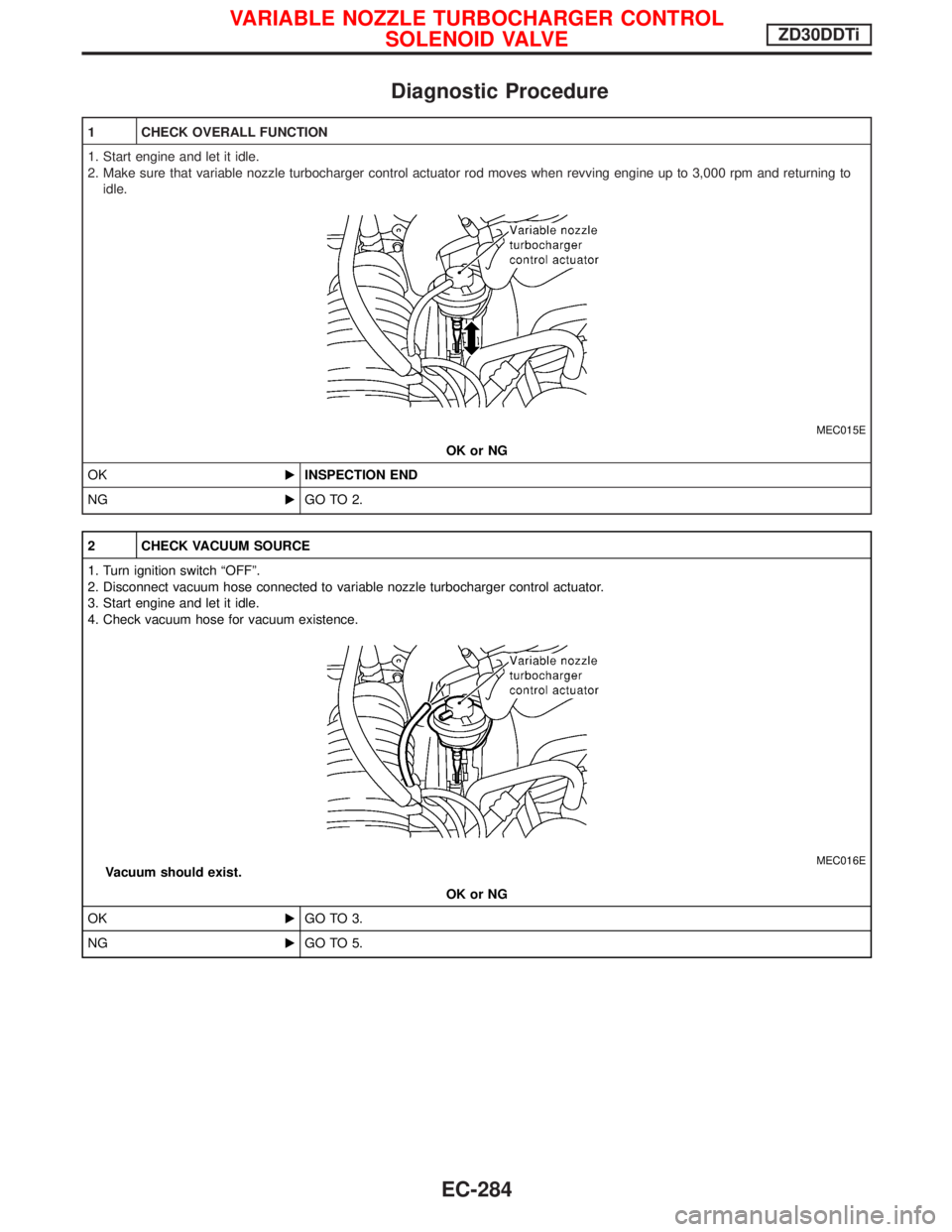

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that variable nozzle turbocharger control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

MEC015E

OK or NG

OKEINSPECTION END

NGEGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to variable nozzle turbocharger control actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

MEC016EVacuum should exist.

OK or NG

OKEGO TO 3.

NGEGO TO 5.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-284

Page 668 of 1767

Fuel Injection System

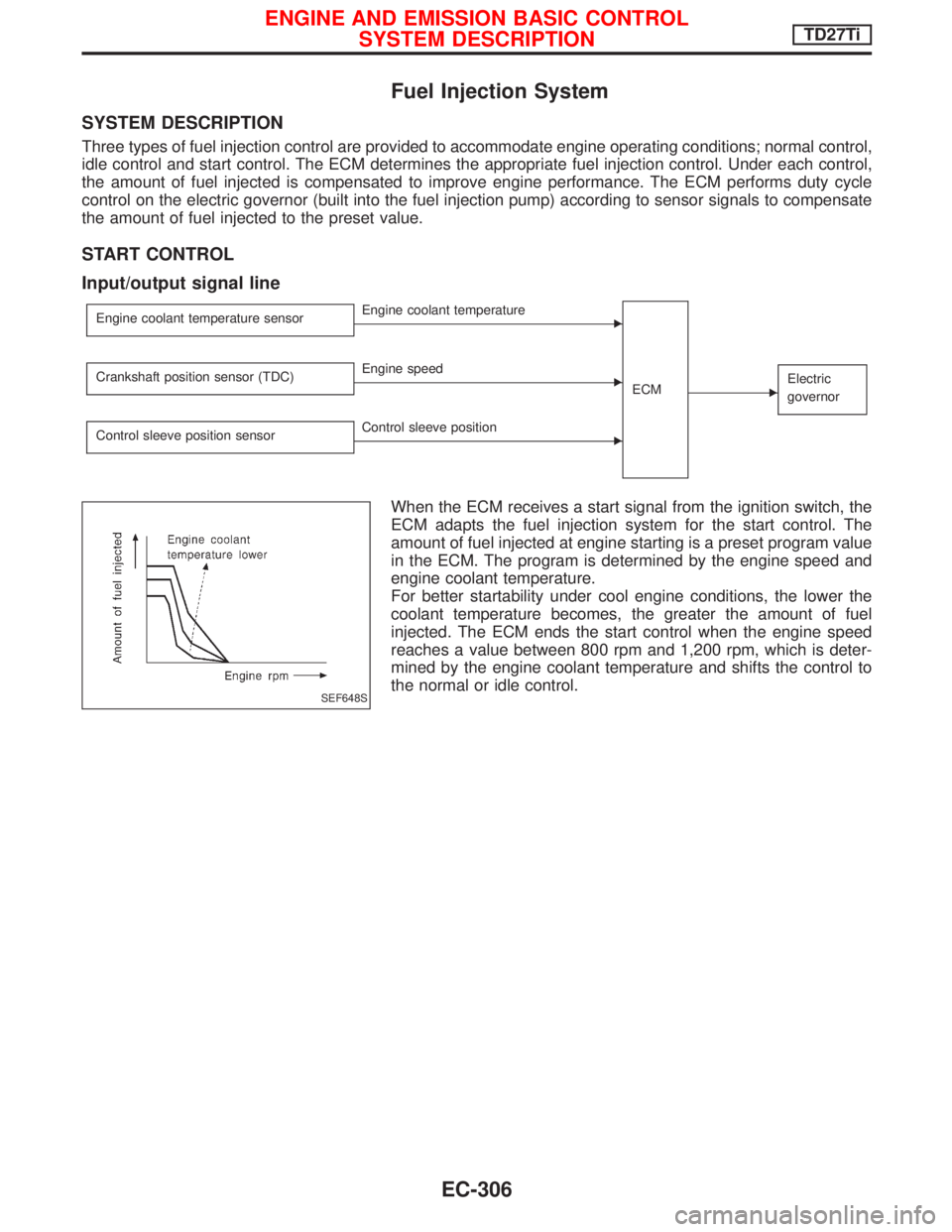

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance. The ECM performs duty cycle

control on the electric governor (built into the fuel injection pump) according to sensor signals to compensate

the amount of fuel injected to the preset value.

START CONTROL

Input/output signal line

Engine coolant temperature sensorEEngine coolant temperature

ECM

EElectric

governorCrankshaft position sensor (TDC)EEngine speed

Control sleeve position sensor

EControl sleeve position

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches a value between 800 rpm and 1,200 rpm, which is deter-

mined by the engine coolant temperature and shifts the control to

the normal or idle control.

SEF648S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

EC-306

Page 672 of 1767

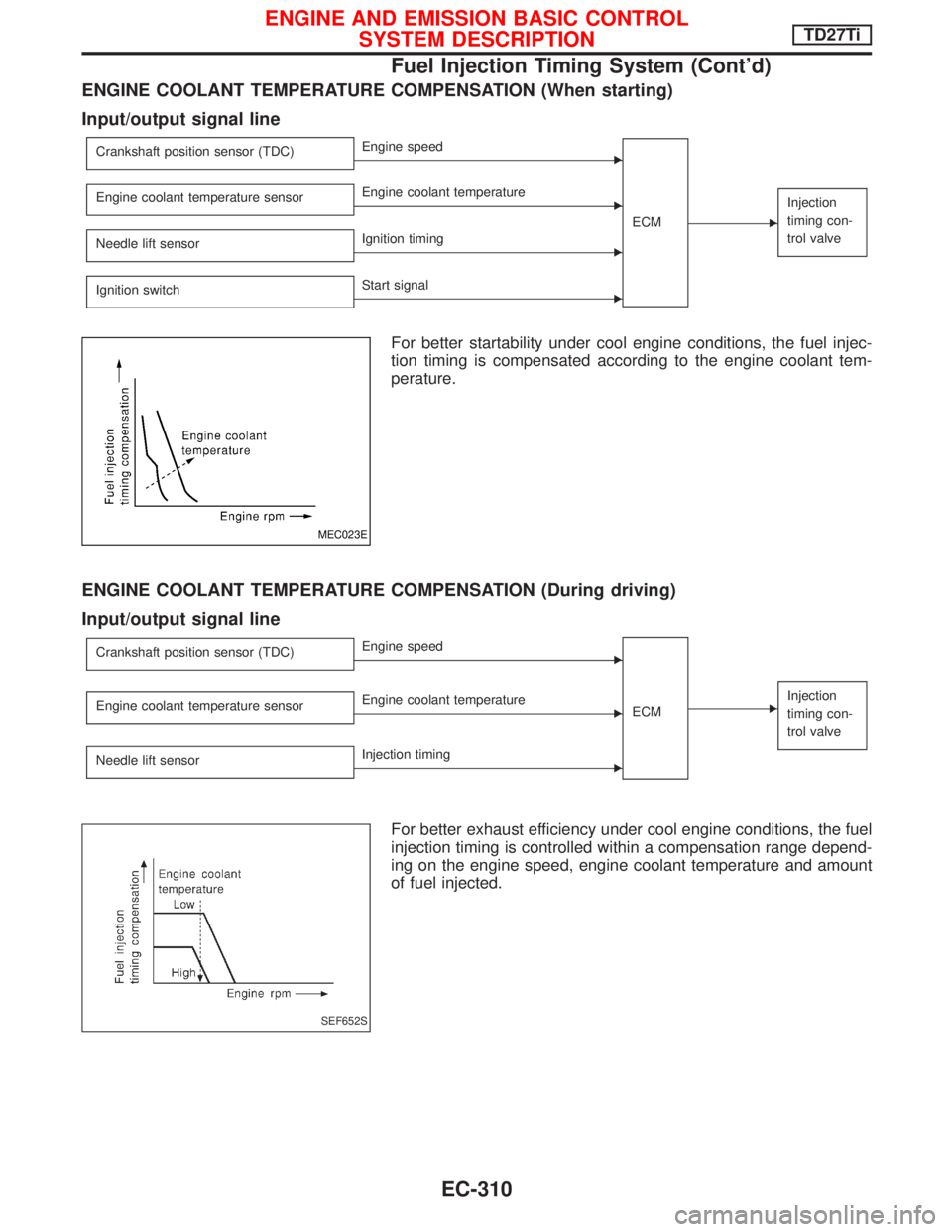

ENGINE COOLANT TEMPERATURE COMPENSATION (When starting)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

E

Injection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EIgnition timing

Ignition switch

EStart signal

For better startability under cool engine conditions, the fuel injec-

tion timing is compensated according to the engine coolant tem-

perature.

ENGINE COOLANT TEMPERATURE COMPENSATION (During driving)

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

EInjection

timing con-

trol valveEngine coolant temperature sensorEEngine coolant temperature

Needle lift sensor

EInjection timing

For better exhaust efficiency under cool engine conditions, the fuel

injection timing is controlled within a compensation range depend-

ing on the engine speed, engine coolant temperature and amount

of fuel injected.

MEC023E

SEF652S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

Fuel Injection Timing System (Cont'd)

EC-310

Page 673 of 1767

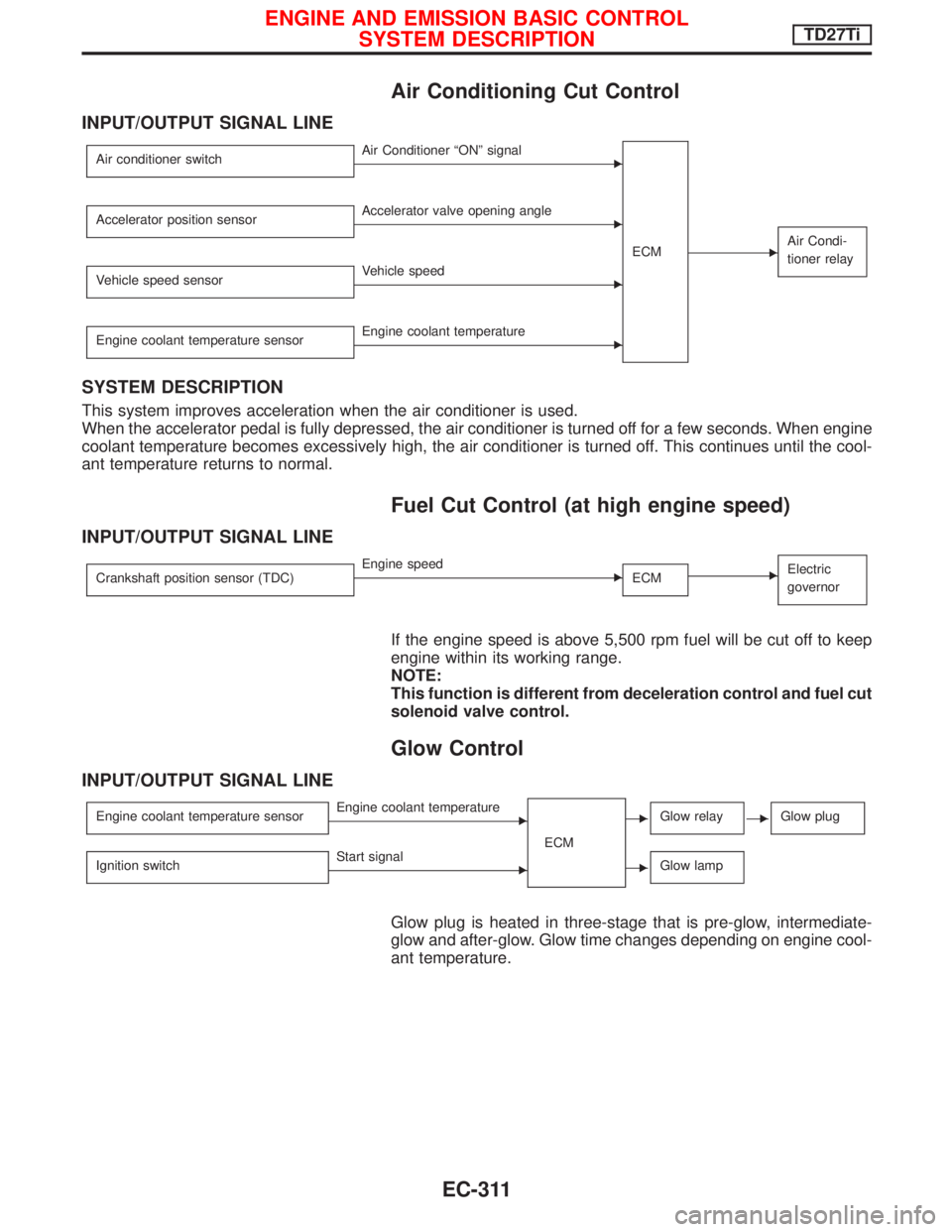

Air Conditioning Cut Control

INPUT/OUTPUT SIGNAL LINE

Air conditioner switchEAir Conditioner ªONº signal

ECM

EAir Condi-

tioner relay

Accelerator position sensorEAccelerator valve opening angle

Vehicle speed sensor

EVehicle speed

Engine coolant temperature sensor

EEngine coolant temperature

SYSTEM DESCRIPTION

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds. When engine

coolant temperature becomes excessively high, the air conditioner is turned off. This continues until the cool-

ant temperature returns to normal.

Fuel Cut Control (at high engine speed)

INPUT/OUTPUT SIGNAL LINE

Crankshaft position sensor (TDC)EEngine speed

ECMEElectric

governor

If the engine speed is above 5,500 rpm fuel will be cut off to keep

engine within its working range.

NOTE:

This function is different from deceleration control and fuel cut

solenoid valve control.

Glow Control

INPUT/OUTPUT SIGNAL LINE

Engine coolant temperature sensorEEngine coolant temperature

ECMEGlow relayEGlow plug

Ignition switchEStart signalEGlow lamp

Glow plug is heated in three-stage that is pre-glow, intermediate-

glow and after-glow. Glow time changes depending on engine cool-

ant temperature.

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

EC-311

Page 677 of 1767

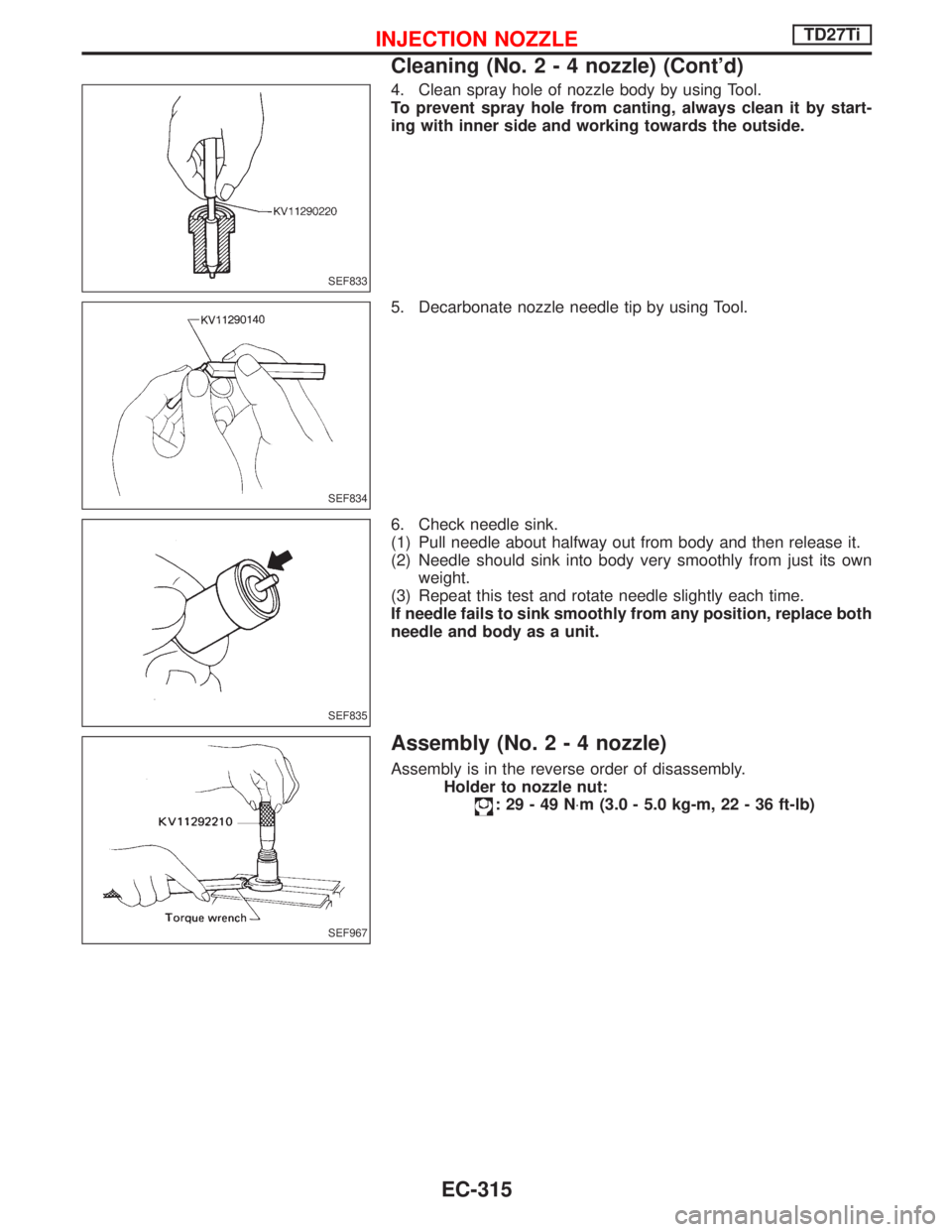

4. Clean spray hole of nozzle body by using Tool.

To prevent spray hole from canting, always clean it by start-

ing with inner side and working towards the outside.

5. Decarbonate nozzle needle tip by using Tool.

6. Check needle sink.

(1) Pull needle about halfway out from body and then release it.

(2) Needle should sink into body very smoothly from just its own

weight.

(3) Repeat this test and rotate needle slightly each time.

If needle fails to sink smoothly from any position, replace both

needle and body as a unit.

Assembly (No.2-4nozzle)

Assembly is in the reverse order of disassembly.

Holder to nozzle nut:

:29-49N×m (3.0 - 5.0 kg-m, 22 - 36 ft-lb)

SEF833

SEF834

SEF835

SEF967

INJECTION NOZZLETD27Ti

Cleaning (No.2-4nozzle) (Cont'd)

EC-315

Page 678 of 1767

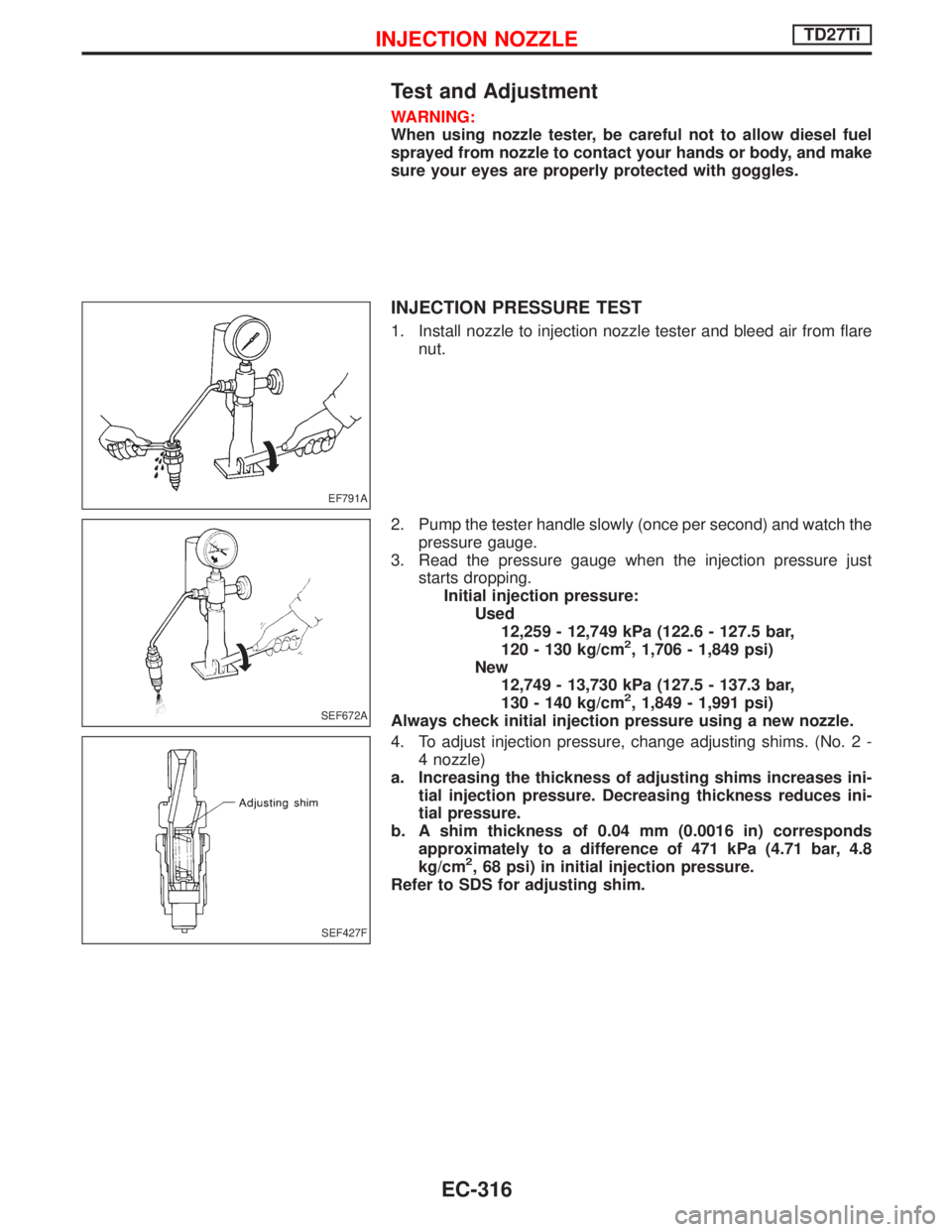

Test and Adjustment

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to contact your hands or body, and make

sure your eyes are properly protected with goggles.

INJECTION PRESSURE TEST

1. Install nozzle to injection nozzle tester and bleed air from flare

nut.

2. Pump the tester handle slowly (once per second) and watch the

pressure gauge.

3. Read the pressure gauge when the injection pressure just

starts dropping.

Initial injection pressure:

Used

12,259 - 12,749 kPa (122.6 - 127.5 bar,

120 - 130 kg/cm

2, 1,706 - 1,849 psi)

New

12,749 - 13,730 kPa (127.5 - 137.3 bar,

130 - 140 kg/cm

2, 1,849 - 1,991 psi)

Always check initial injection pressure using a new nozzle.

4. To adjust injection pressure, change adjusting shims. (No. 2 -

4 nozzle)

a. Increasing the thickness of adjusting shims increases ini-

tial injection pressure. Decreasing thickness reduces ini-

tial pressure.

b. A shim thickness of 0.04 mm (0.0016 in) corresponds

approximately to a difference of 471 kPa (4.71 bar, 4.8

kg/cm

2, 68 psi) in initial injection pressure.

Refer to SDS for adjusting shim.

EF791A

SEF672A

SEF427F

INJECTION NOZZLETD27Ti

EC-316

Page 684 of 1767

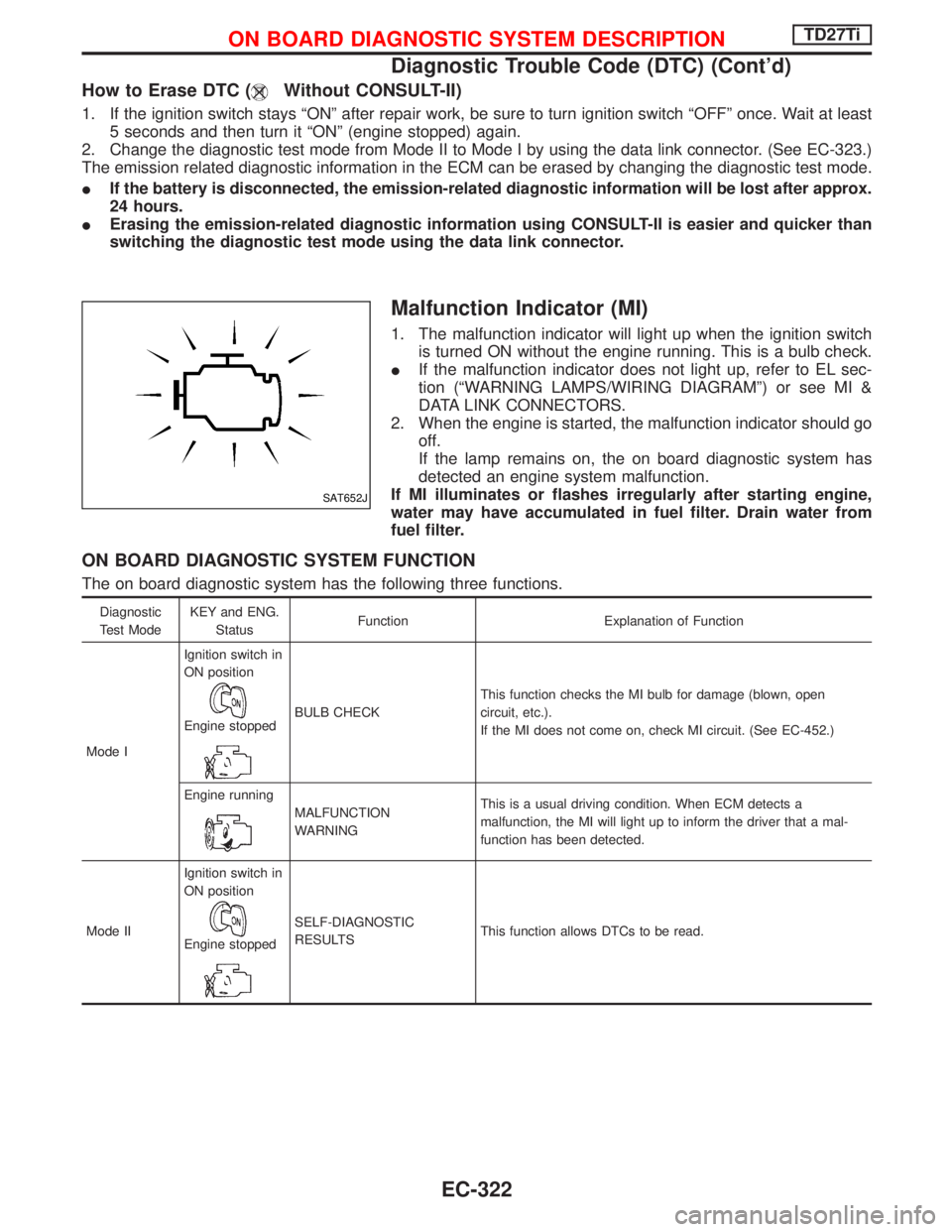

How to Erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-323.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

IErasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

Malfunction Indicator (MI)

1. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is a bulb check.

IIf the malfunction indicator does not light up, refer to EL sec-

tion (ªWARNING LAMPS/WIRING DIAGRAMº) or see MI &

DATA LINK CONNECTORS.

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or flashes irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

Diagnostic

Test ModeKEY and ENG.

StatusFunction Explanation of Function

Mode IIgnition switch in

ON position

Engine stoppedBULB CHECKThis function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit. (See EC-452.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM detects a

malfunction, the MI will light up to inform the driver that a mal-

function has been detected.

Mode IIIgnition switch in

ON position

Engine stopped

SELF-DIAGNOSTIC

RESULTSThis function allows DTCs to be read.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Diagnostic Trouble Code (DTC) (Cont'd)

EC-322

Page 686 of 1767

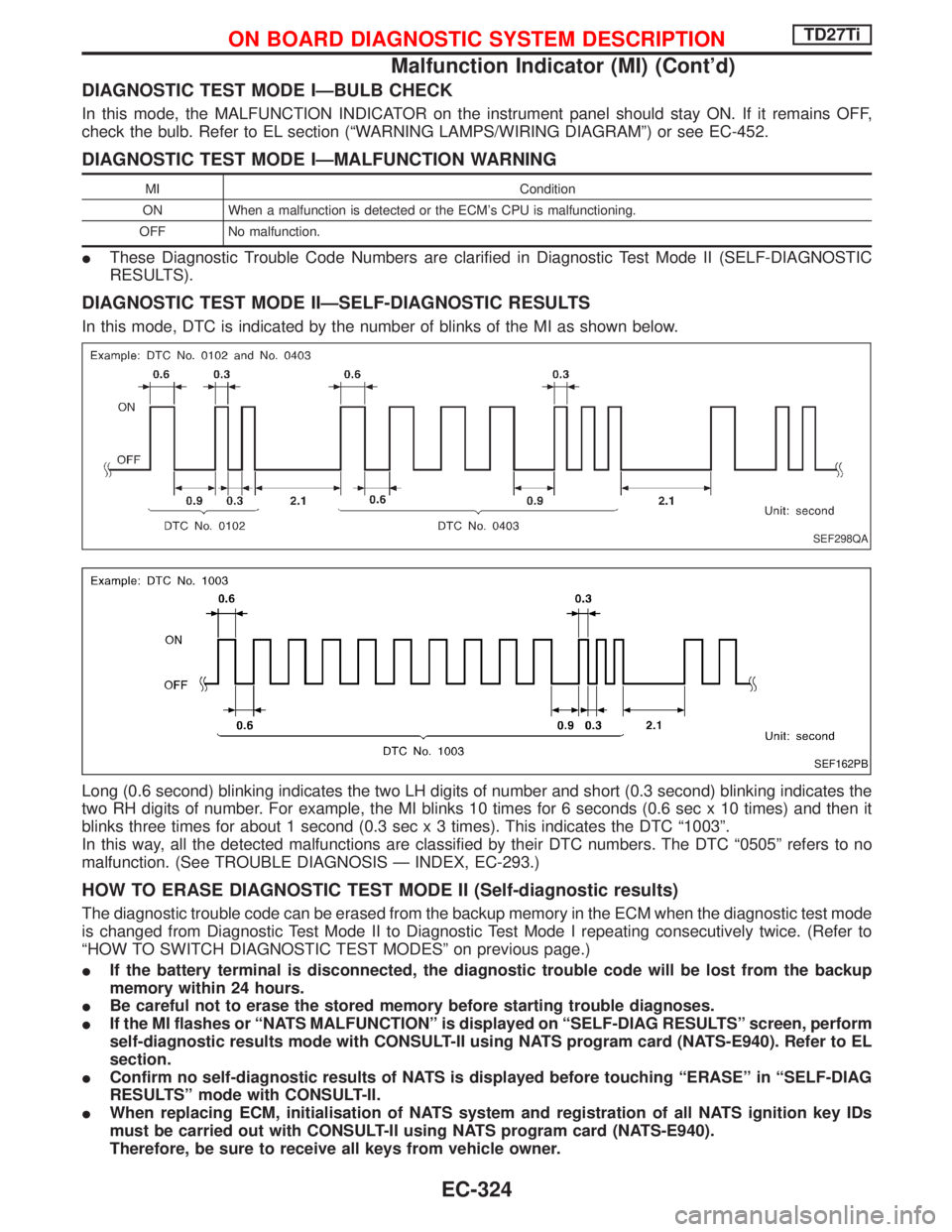

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR on the instrument panel should stay ON. If it remains OFF,

check the bulb. Refer to EL section (ªWARNING LAMPS/WIRING DIAGRAMº) or see EC-452.

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MI Condition

ON When a malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

IThese Diagnostic Trouble Code Numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates the

two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and then it

blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-293.)

HOW TO ERASE DIAGNOSTIC TEST MODE II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test mode

is changed from Diagnostic Test Mode II to Diagnostic Test Mode I repeating consecutively twice. (Refer to

ªHOW TO SWITCH DIAGNOSTIC TEST MODESº on previous page.)

IIf the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

IBe careful not to erase the stored memory before starting trouble diagnoses.

IIf the MI flashes or ªNATS MALFUNCTIONº is displayed on ªSELF-DIAG RESULTSº screen, perform

self-diagnostic results mode with CONSULT-II using NATS program card (NATS-E940). Refer to EL

section.

IConfirm no self-diagnostic results of NATS is displayed before touching ªERASEº in ªSELF-DIAG

RESULTSº mode with CONSULT-II.

IWhen replacing ECM, initialisation of NATS system and registration of all NATS ignition key IDs

must be carried out with CONSULT-II using NATS program card (NATS-E940).

Therefore, be sure to receive all keys from vehicle owner.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

Malfunction Indicator (MI) (Cont'd)

EC-324

Page 689 of 1767

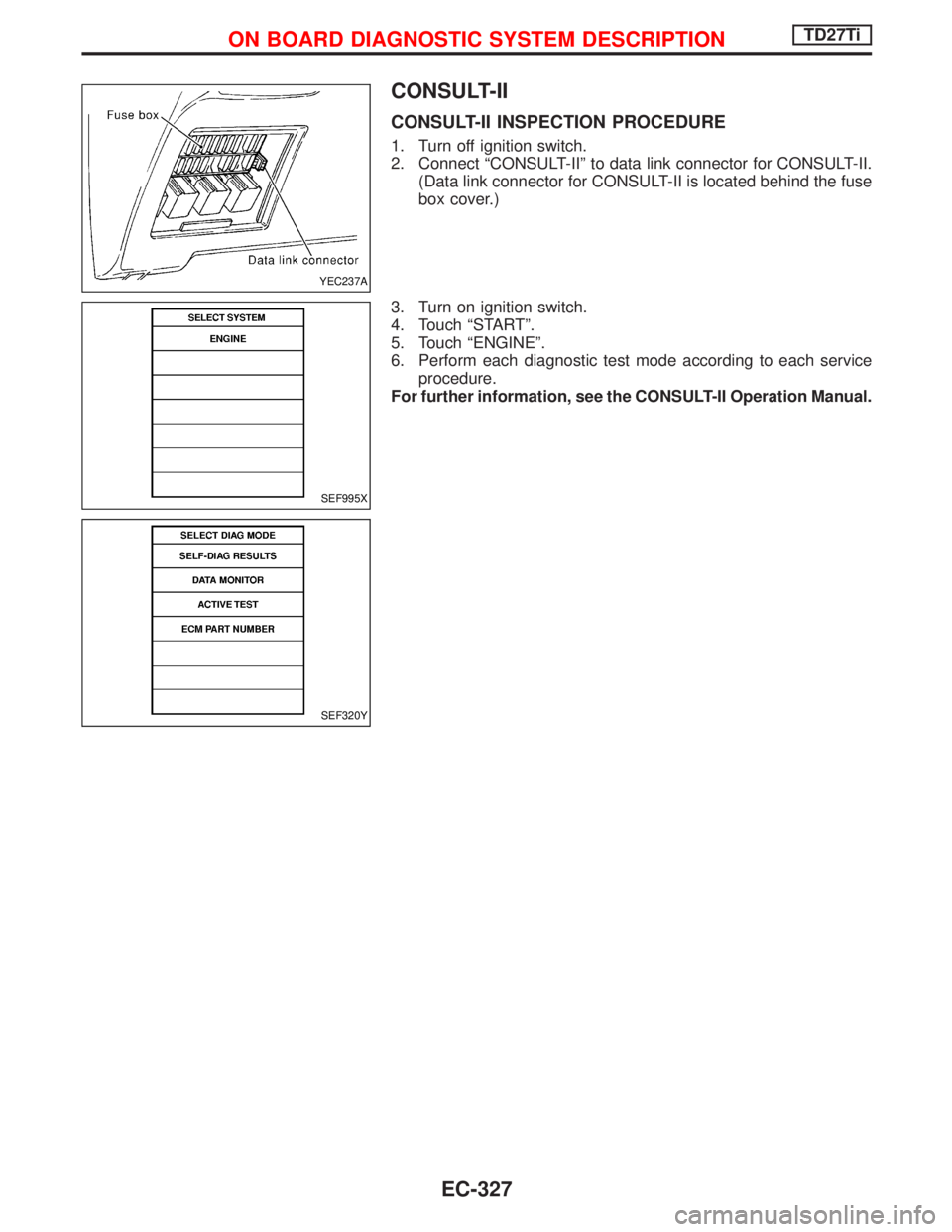

CONSULT-II

CONSULT-II INSPECTION PROCEDURE

1. Turn off ignition switch.

2. Connect ªCONSULT-IIº to data link connector for CONSULT-II.

(Data link connector for CONSULT-II is located behind the fuse

box cover.)

3. Turn on ignition switch.

4. Touch ªSTARTº.

5. Touch ªENGINEº.

6. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT-II Operation Manual.

YEC237A

SEF995X

SEF320Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONTD27Ti

EC-327