Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 712 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant](/img/5/57393/w960_57393-711.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

347 LG/WEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant tempera-

ture

348 Y/B Fuel temperature sensor[Engine is running]0.6-5V

Output voltage varies with

fuel temperature.

349 G/RInjection timing control

valve ground[Ignition switch ªONº]Approximately 0V

403 G/R Air conditioner switch[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IBoth air conditioner switch and blower fan switch

are ªONº

(Compressor is operating)Approximately 0.1V

405 G/Y Stop lamp switch[Ignition switch ªONº]

IBrake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

IBrake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/RBrake pedal position

switch[Ignition switch ªONº]

IBrake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

IBrake pedal depressedApproximately 0V

415 OR

Data link connector for

CONSULT-II[Engine is running]

IIdle speed (CONSULT-II is connected and turned

on)Approximately 0V

420 OR/RBATTERY VOLTAGE

(11 - 14V)

417 Y/B Vehicle speed sensor[Engine is running]

ILift up the vehicle

IIn 1st gear position

IVehicle speed is 10 km/h (6 MPH)0 - Approximately 8V

SEF891Y

[Engine is running]

ILift up the vehicle

IIn 2nd gear position

IVehicle speed is 30 km/h (19 MPH)Approximately 6V

SEF892Y

422 PU Start signal[Ignition switch ªONº]Approximately 0V

[Ignition switch ªSTARTº]BATTERY VOLTAGE

(11 - 14V)

425 R/BAccelerator position sen-

sor ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-350

Page 715 of 1767

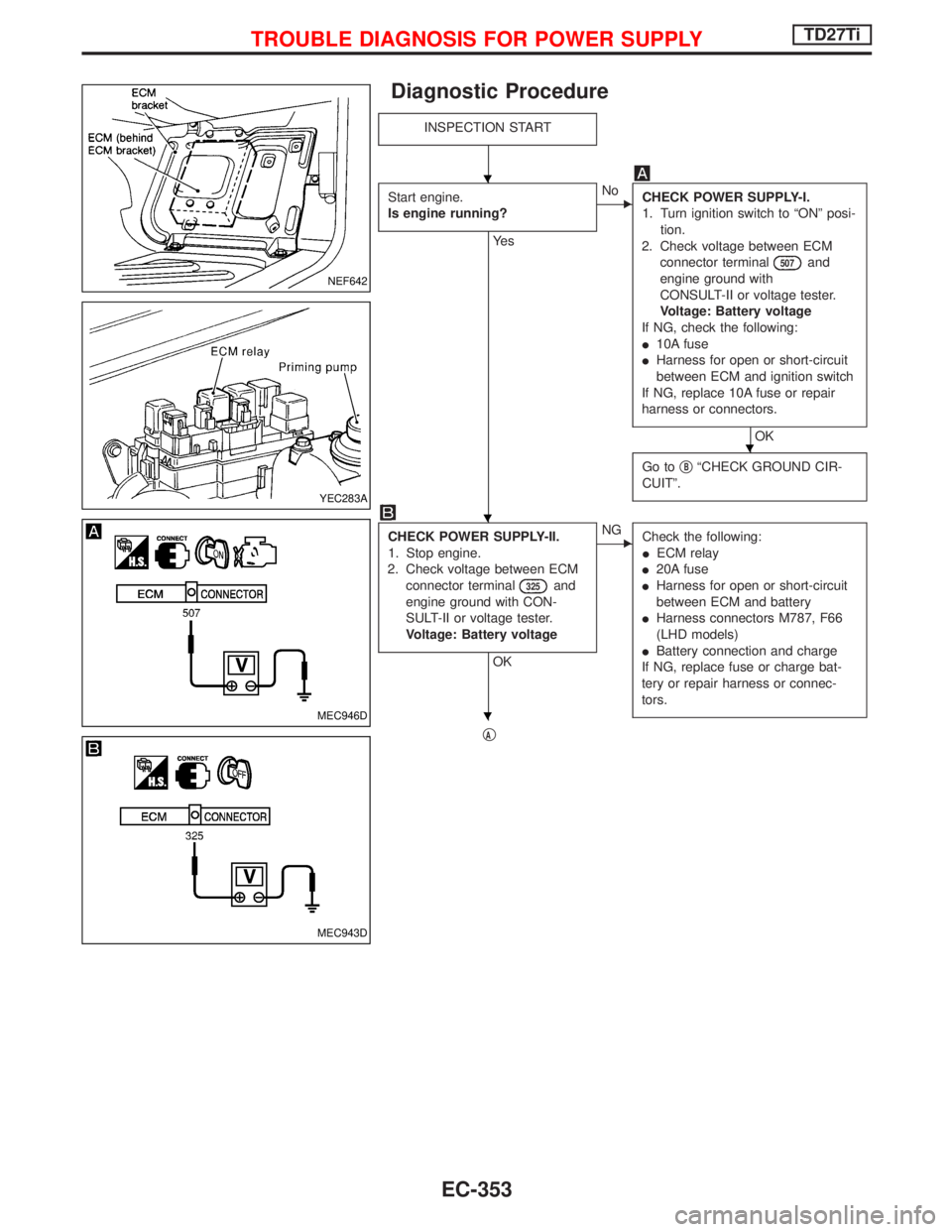

Diagnostic Procedure

INSPECTION START

Start engine.

Is engine running?

Ye s

ENo

CHECK POWER SUPPLY-I.

1. Turn ignition switch to ªONº posi-

tion.

2. Check voltage between ECM

connector terminal

507and

engine ground with

CONSULT-II or voltage tester.

Voltage: Battery voltage

If NG, check the following:

I10A fuse

IHarness for open or short-circuit

between ECM and ignition switch

If NG, replace 10A fuse or repair

harness or connectors.

OK

Go toq

BªCHECK GROUND CIR-

CUITº.

CHECK POWER SUPPLY-II.

1. Stop engine.

2. Check voltage between ECM

connector terminal

325and

engine ground with CON-

SULT-II or voltage tester.

Voltage: Battery voltage

OK

ENG

Check the following:

IECM relay

I20A fuse

IHarness for open or short-circuit

between ECM and battery

IHarness connectors M787, F66

(LHD models)

IBattery connection and charge

If NG, replace fuse or charge bat-

tery or repair harness or connec-

tors.

qA

NEF642

YEC283A

MEC946D

MEC943D

H

H

H

H

TROUBLE DIAGNOSIS FOR POWER SUPPLYTD27Ti

EC-353

Page 718 of 1767

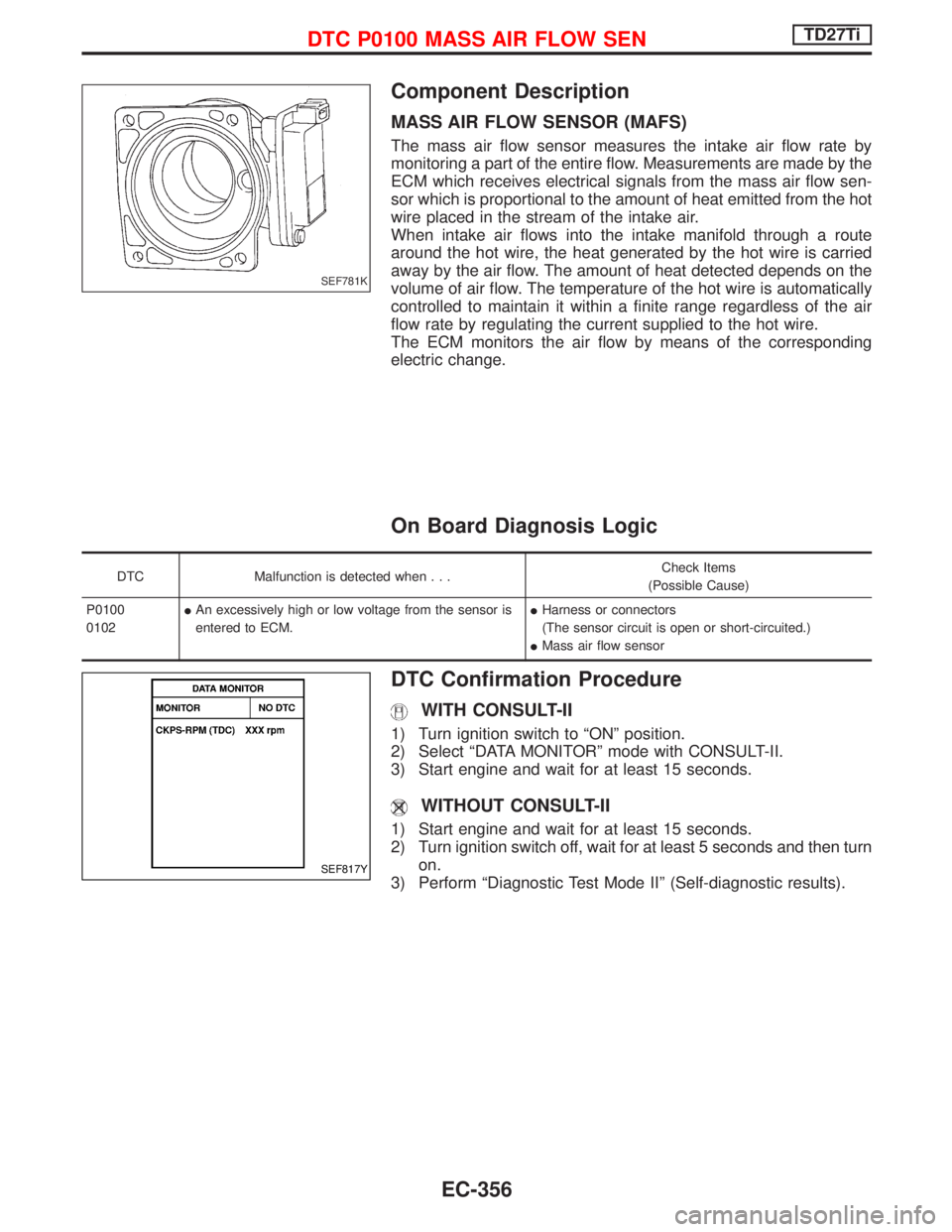

Component Description

MASS AIR FLOW SENSOR (MAFS)

The mass air flow sensor measures the intake air flow rate by

monitoring a part of the entire flow. Measurements are made by the

ECM which receives electrical signals from the mass air flow sen-

sor which is proportional to the amount of heat emitted from the hot

wire placed in the stream of the intake air.

When intake air flows into the intake manifold through a route

around the hot wire, the heat generated by the hot wire is carried

away by the air flow. The amount of heat detected depends on the

volume of air flow. The temperature of the hot wire is automatically

controlled to maintain it within a finite range regardless of the air

flow rate by regulating the current supplied to the hot wire.

The ECM monitors the air flow by means of the corresponding

electric change.

On Board Diagnosis Logic

DTC Malfunction is detected when...Check Items

(Possible Cause)

P0100

0102IAn excessively high or low voltage from the sensor is

entered to ECM.IHarness or connectors

(The sensor circuit is open or short-circuited.)

IMass air flow sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait for at least 15 seconds.

WITHOUT CONSULT-II

1) Start engine and wait for at least 15 seconds.

2) Turn ignition switch off, wait for at least 5 seconds and then turn

on.

3) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF781K

SEF817Y

DTC P0100 MASS AIR FLOW SENTD27Ti

EC-356

Page 721 of 1767

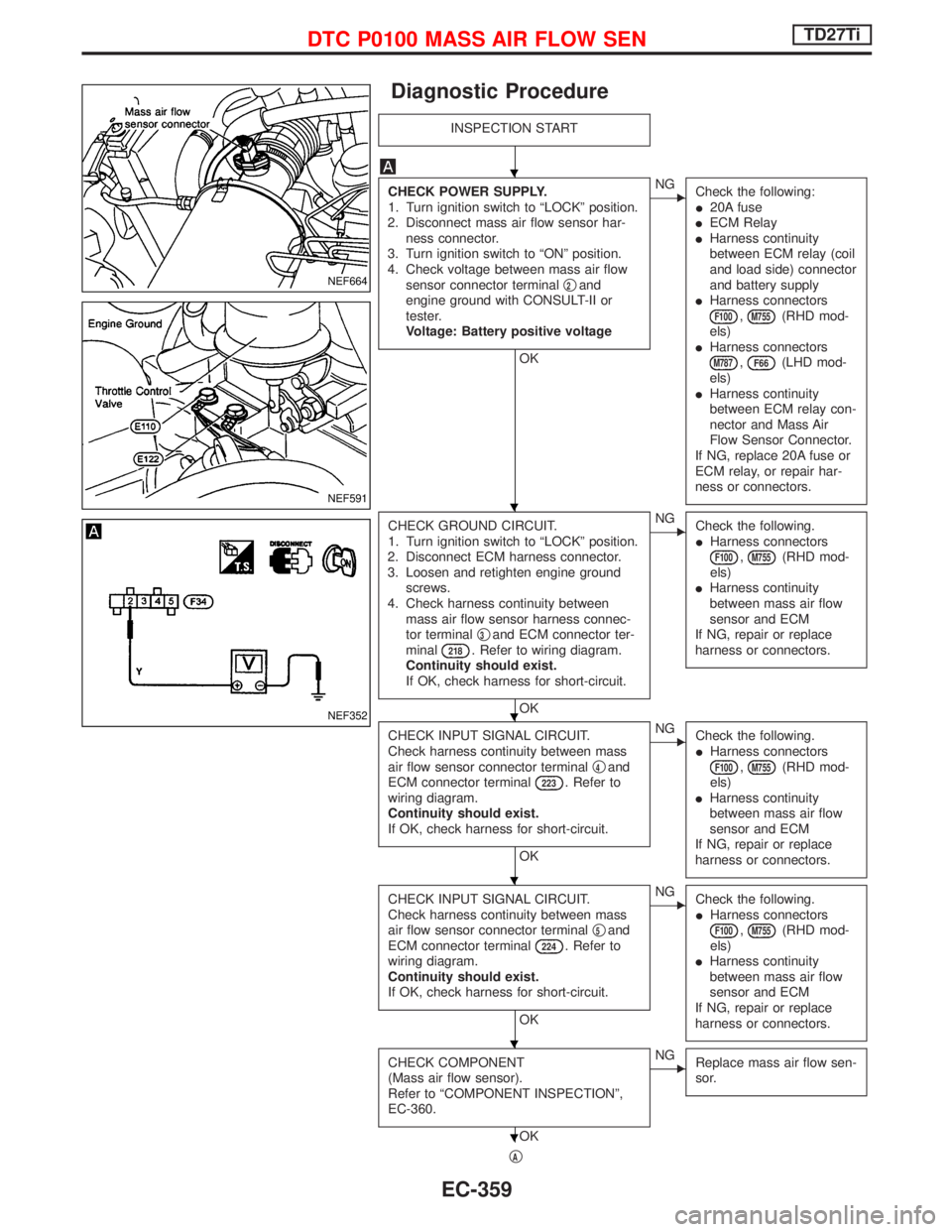

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect mass air flow sensor har-

ness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between mass air flow

sensor connector terminalq

2and

engine ground with CONSULT-II or

tester.

Voltage: Battery positive voltage

OK

ENG

Check the following:

I20A fuse

IECM Relay

IHarness continuity

between ECM relay (coil

and load side) connector

and battery supply

IHarness connectors

F100,M755(RHD mod-

els)

IHarness connectors

M787,F66(LHD mod-

els)

IHarness continuity

between ECM relay con-

nector and Mass Air

Flow Sensor Connector.

If NG, replace 20A fuse or

ECM relay, or repair har-

ness or connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector.

3. Loosen and retighten engine ground

screws.

4. Check harness continuity between

mass air flow sensor harness connec-

tor terminalq

3and ECM connector ter-

minal218. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

F100,M755(RHD mod-

els)

IHarness continuity

between mass air flow

sensor and ECM

If NG, repair or replace

harness or connectors.

CHECK INPUT SIGNAL CIRCUIT.

Check harness continuity between mass

air flow sensor connector terminalq

4and

ECM connector terminal223. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

F100,M755(RHD mod-

els)

IHarness continuity

between mass air flow

sensor and ECM

If NG, repair or replace

harness or connectors.

CHECK INPUT SIGNAL CIRCUIT.

Check harness continuity between mass

air flow sensor connector terminalq

5and

ECM connector terminal224. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connectors

F100,M755(RHD mod-

els)

IHarness continuity

between mass air flow

sensor and ECM

If NG, repair or replace

harness or connectors.

CHECK COMPONENT

(Mass air flow sensor).

Refer to ªCOMPONENT INSPECTIONº,

EC-360.

OK

ENG

Replace mass air flow sen-

sor.

qA

NEF664

NEF591

NEF352

H

H

H

H

H

H

DTC P0100 MASS AIR FLOW SENTD27Ti

EC-359

Page 722 of 1767

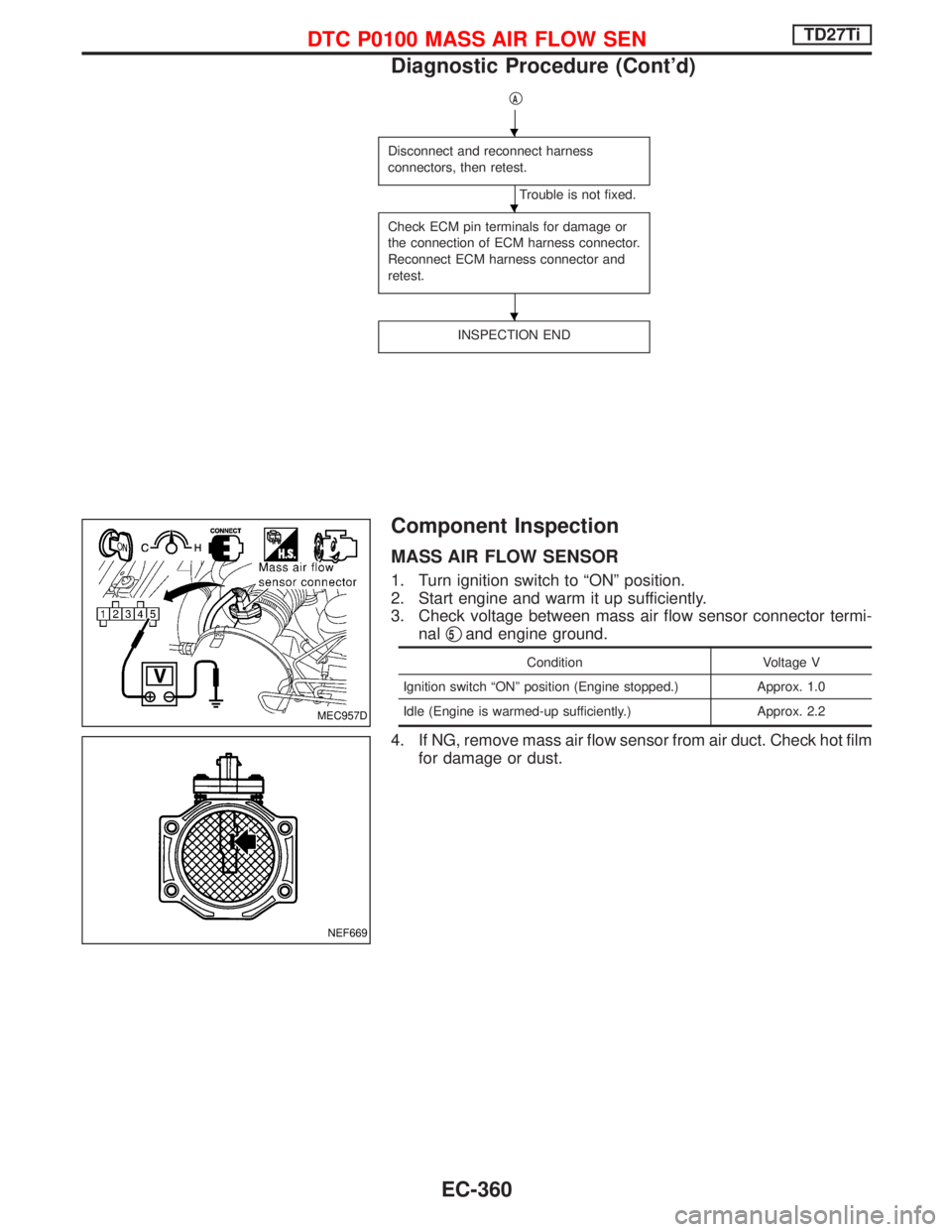

qA

Disconnect and reconnect harness

connectors, then retest.

Trouble is not fixed.

Check ECM pin terminals for damage or

the connection of ECM harness connector.

Reconnect ECM harness connector and

retest.

INSPECTION END

Component Inspection

MASS AIR FLOW SENSOR

1. Turn ignition switch to ªONº position.

2. Start engine and warm it up sufficiently.

3. Check voltage between mass air flow sensor connector termi-

nalq

5and engine ground.

Condition Voltage V

Ignition switch ªONº position (Engine stopped.) Approx. 1.0

Idle (Engine is warmed-up sufficiently.) Approx. 2.2

4. If NG, remove mass air flow sensor from air duct. Check hot film

for damage or dust.

MEC957D

NEF669

H

H

H

DTC P0100 MASS AIR FLOW SENTD27Ti

Diagnostic Procedure (Cont'd)

EC-360

Page 725 of 1767

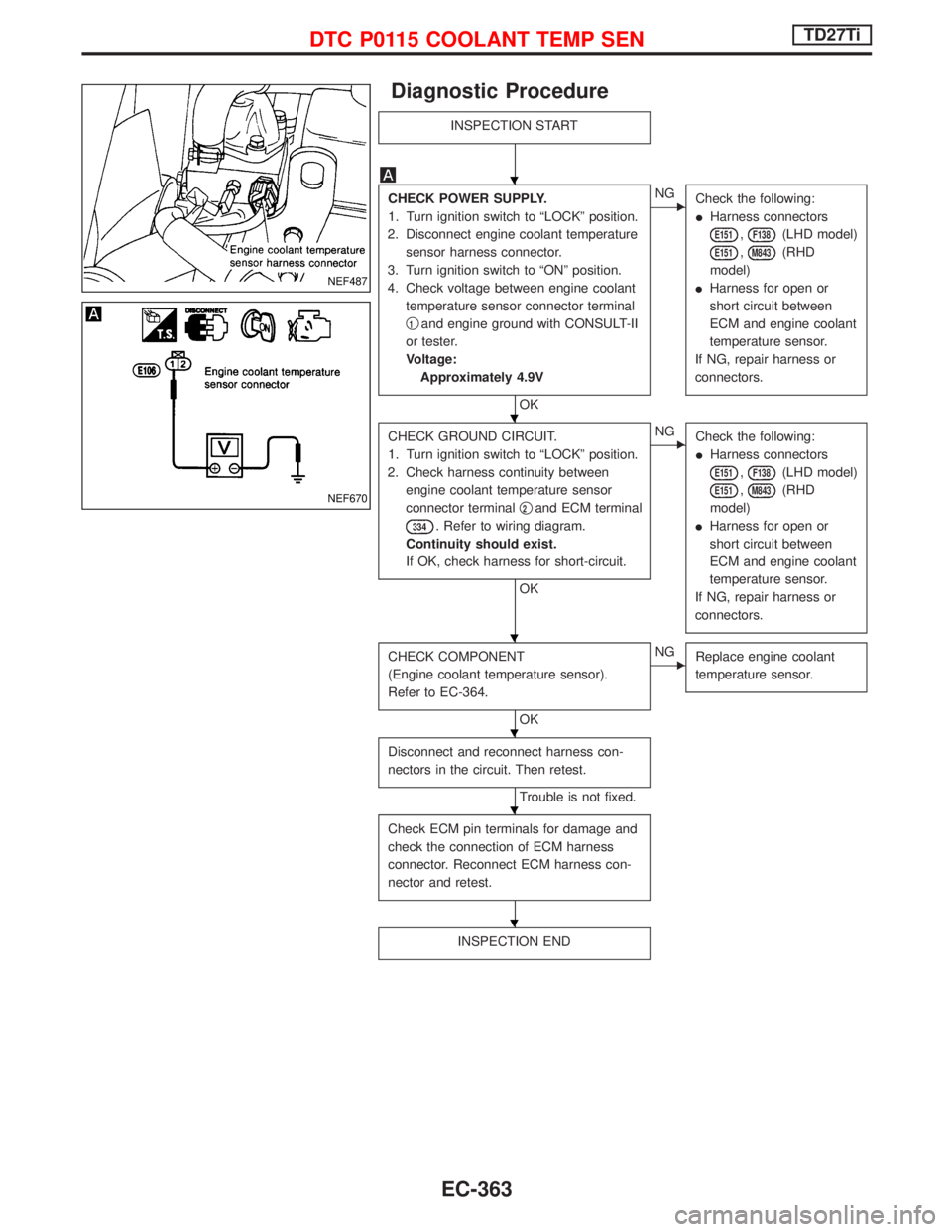

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect engine coolant temperature

sensor harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between engine coolant

temperature sensor connector terminal

q

1and engine ground with CONSULT-II

or tester.

Voltage:

Approximately 4.9V

OK

ENG

Check the following:

IHarness connectors

E151,F138(LHD model)

E151,M843(RHD

model)

IHarness for open or

short circuit between

ECM and engine coolant

temperature sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between

engine coolant temperature sensor

connector terminalq

2and ECM terminal

334. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness connectors

E151,F138(LHD model)

E151,M843(RHD

model)

IHarness for open or

short circuit between

ECM and engine coolant

temperature sensor.

If NG, repair harness or

connectors.

CHECK COMPONENT

(Engine coolant temperature sensor).

Refer to EC-364.

OK

ENG

Replace engine coolant

temperature sensor.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF487

NEF670

H

H

H

H

H

H

DTC P0115 COOLANT TEMP SENTD27Ti

EC-363

Page 728 of 1767

DTC Confirmation Procedure B (For

Accelerator Sticking)

If DTC P0571 is displayed same time, cure it at first.

WITH CONSULT-II

1) Turn ignition switch to ªONº position.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and rev it up to above 1,300 rpm.

4) Depress brake pedal immediately after releasing accelerator

pedal and keep it at least 5 seconds.

WITHOUT CONSULT-II

1) Start engine and rev it up to above 1,300 rpm.

2) Depress brake pedal immediately after releasing accelerator

pedal and keep it at least 5 seconds.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

DTC P0120 ACCEL POS SENSORTD27Ti

EC-366

Page 730 of 1767

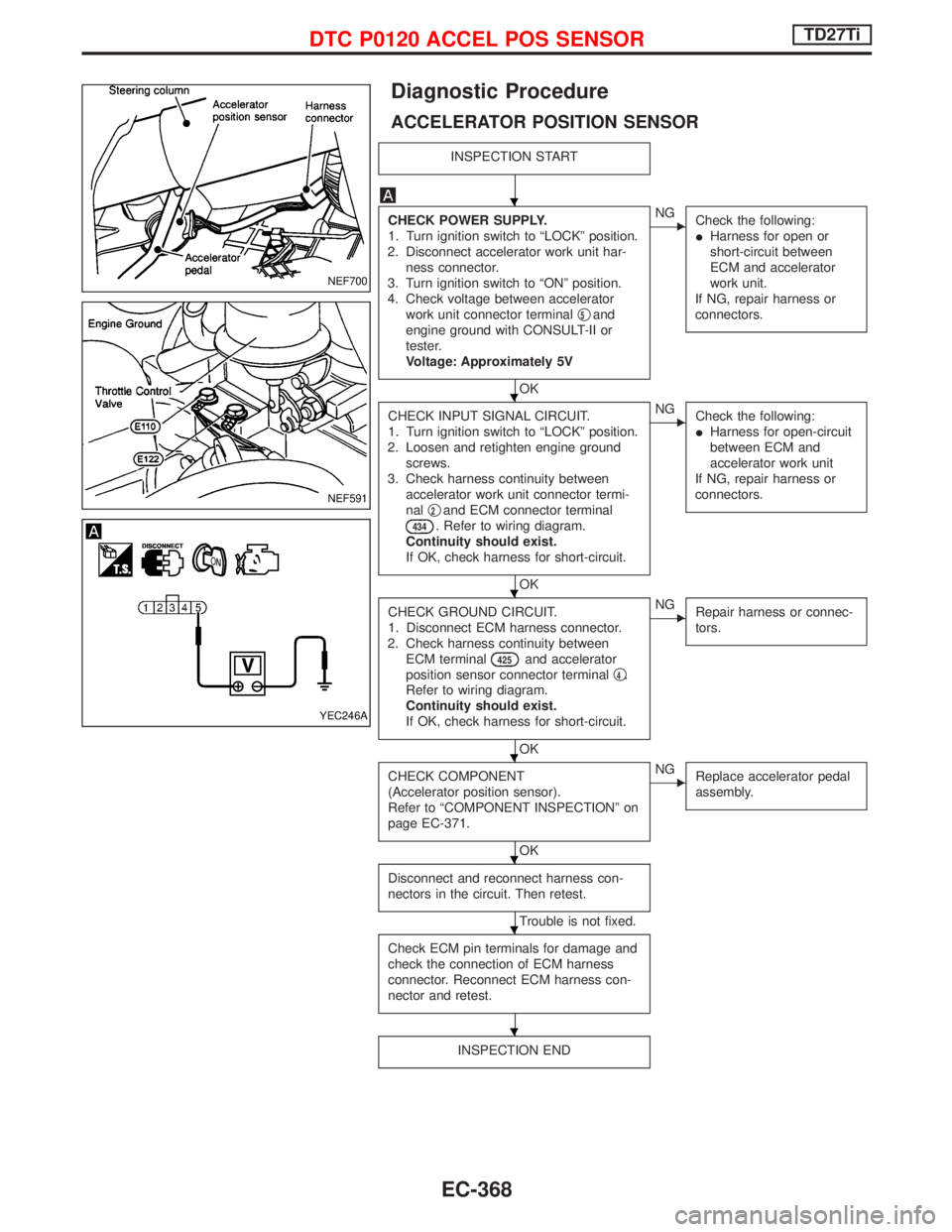

Diagnostic Procedure

ACCELERATOR POSITION SENSOR

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect accelerator work unit har-

ness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between accelerator

work unit connector terminalq

5and

engine ground with CONSULT-II or

tester.

Voltage: Approximately 5V

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and accelerator

work unit.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Loosen and retighten engine ground

screws.

3. Check harness continuity between

accelerator work unit connector termi-

nalq

2and ECM connector terminal

434. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open-circuit

between ECM and

accelerator work unit

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM terminal

425and accelerator

position sensor connector terminalq

4.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT

(Accelerator position sensor).

Refer to ªCOMPONENT INSPECTIONº on

page EC-371.

OK

ENG

Replace accelerator pedal

assembly.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

NEF700

NEF591

YEC246A

H

H

H

H

H

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

EC-368

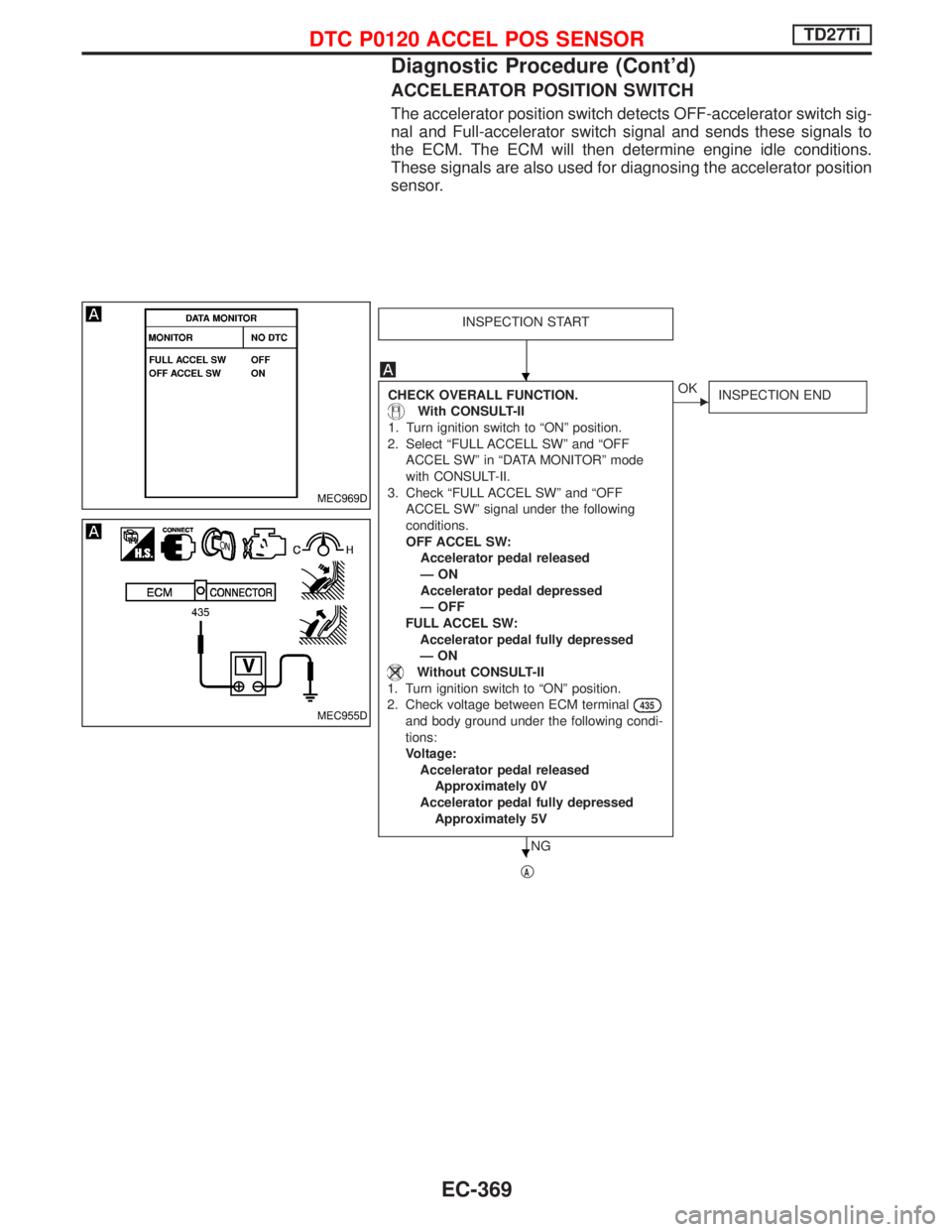

Page 731 of 1767

ACCELERATOR POSITION SWITCH

The accelerator position switch detects OFF-accelerator switch sig-

nal and Full-accelerator switch signal and sends these signals to

the ECM. The ECM will then determine engine idle conditions.

These signals are also used for diagnosing the accelerator position

sensor.

INSPECTION START

CHECK OVERALL FUNCTION.

With CONSULT-II

1. Turn ignition switch to ªONº position.

2. Select ªFULL ACCELL SWº and ªOFF

ACCEL SWº in ªDATA MONITORº mode

with CONSULT-II.

3. Check ªFULL ACCEL SWº and ªOFF

ACCEL SWº signal under the following

conditions.

OFF ACCEL SW:

Accelerator pedal released

ÐON

Accelerator pedal depressed

Ð OFF

FULL ACCEL SW:

Accelerator pedal fully depressed

ÐON

Without CONSULT-II

1. Turn ignition switch to ªONº position.

2. Check voltage between ECM terminal

435

and body ground under the following condi-

tions:

Voltage:

Accelerator pedal released

Approximately 0V

Accelerator pedal fully depressed

Approximately 5V

NG

EOK

INSPECTION END

qA

MEC969D

MEC955D

H

H

DTC P0120 ACCEL POS SENSORTD27Ti

Diagnostic Procedure (Cont'd)

EC-369

Page 736 of 1767

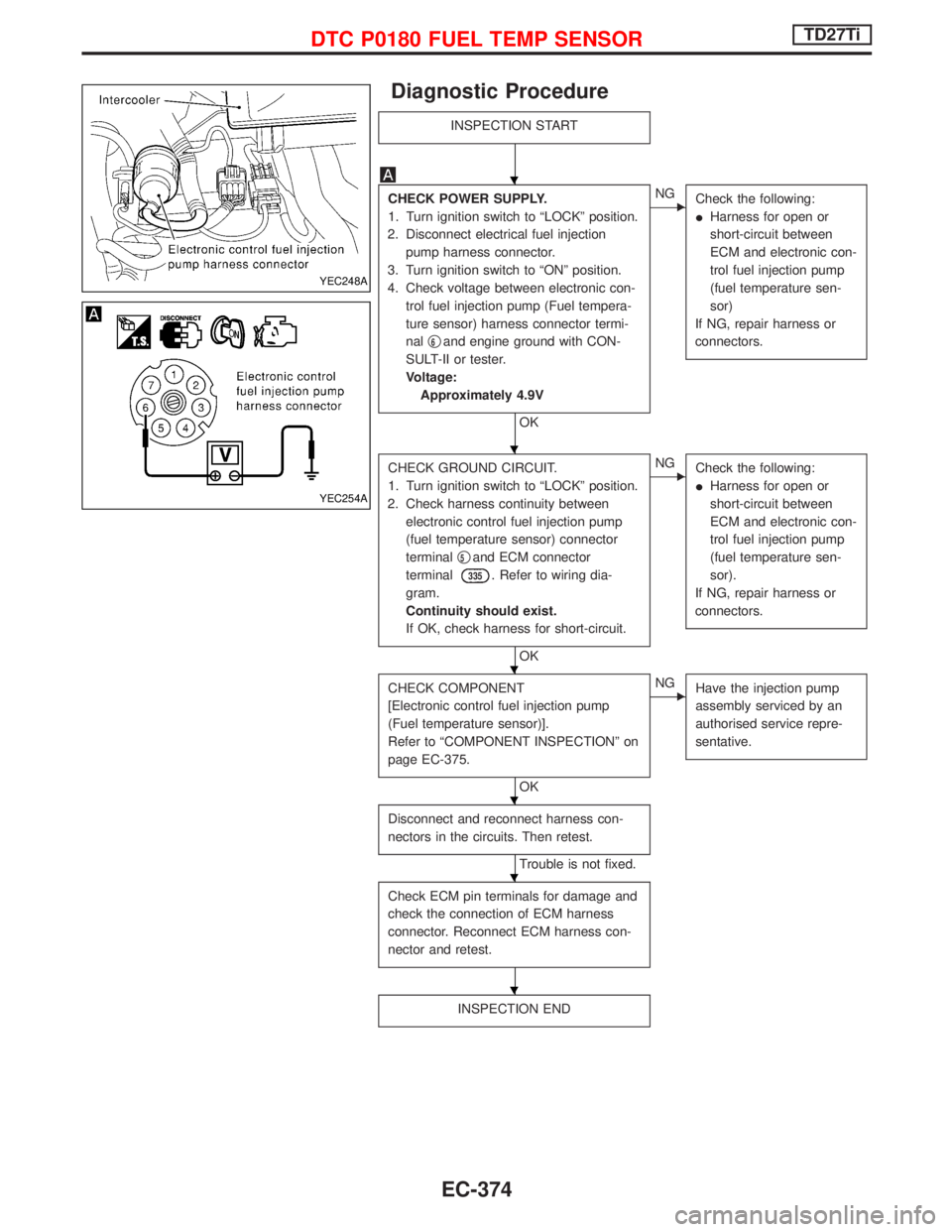

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect electrical fuel injection

pump harness connector.

3. Turn ignition switch to ªONº position.

4. Check voltage between electronic con-

trol fuel injection pump (Fuel tempera-

ture sensor) harness connector termi-

nalq

6and engine ground with CON-

SULT-II or tester.

Voltage:

Approximately 4.9V

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor)

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between

electronic control fuel injection pump

(fuel temperature sensor) connector

terminalq

5and ECM connector

terminal

335. Refer to wiring dia-

gram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and electronic con-

trol fuel injection pump

(fuel temperature sen-

sor).

If NG, repair harness or

connectors.

CHECK COMPONENT

[Electronic control fuel injection pump

(Fuel temperature sensor)].

Refer to ªCOMPONENT INSPECTIONº on

page EC-375.

OK

ENG

Have the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

YEC248A

YEC254A

H

H

H

H

H

H

DTC P0180 FUEL TEMP SENSORTD27Ti

EC-374