NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: charging, rims, spare tire, tailgate, clock, jump start, tire type

Page 131 of 1767

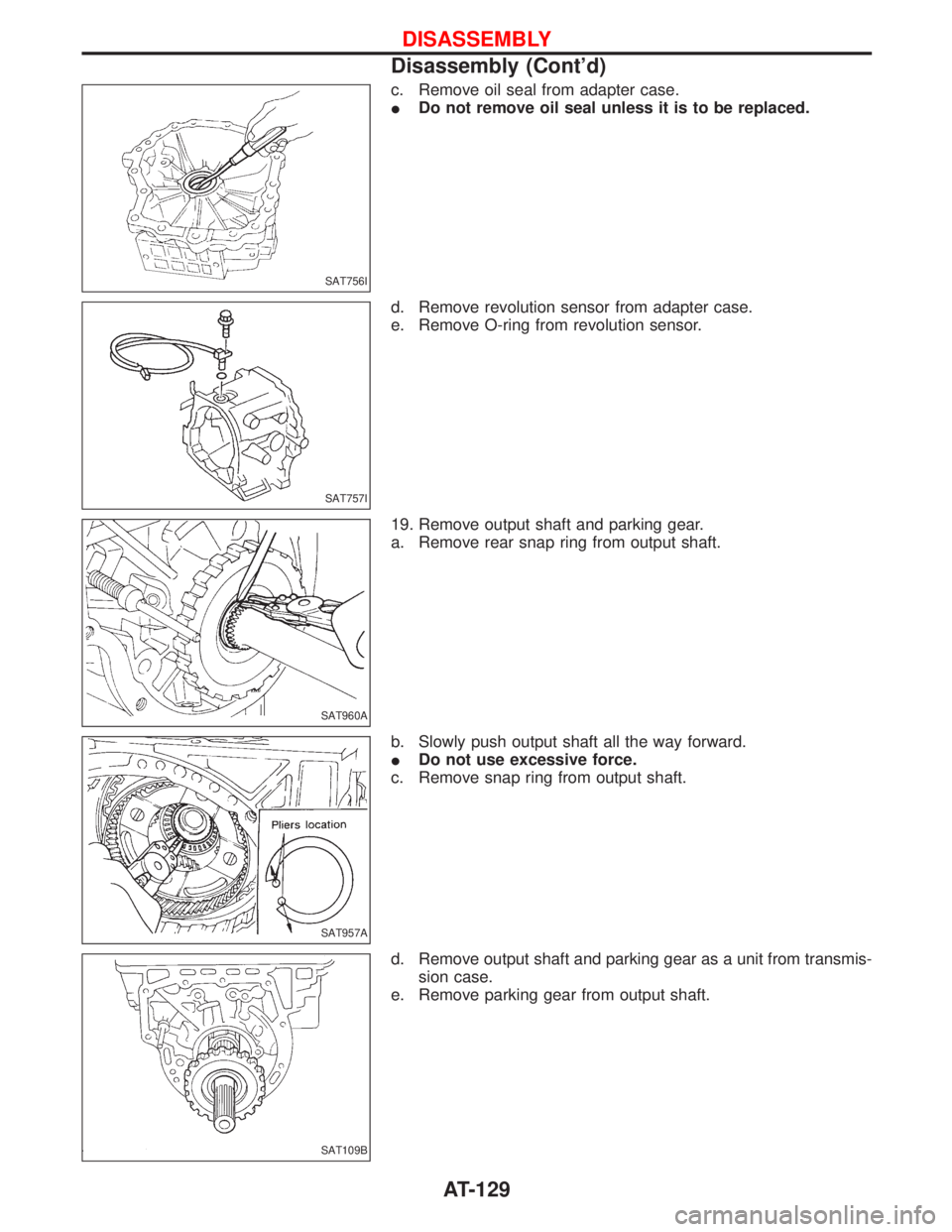

c. Remove oil seal from adapter case.

IDo not remove oil seal unless it is to be replaced.

d. Remove revolution sensor from adapter case.

e. Remove O-ring from revolution sensor.

19. Remove output shaft and parking gear.

a. Remove rear snap ring from output shaft.

b. Slowly push output shaft all the way forward.

IDo not use excessive force.

c. Remove snap ring from output shaft.

d. Remove output shaft and parking gear as a unit from transmis-

sion case.

e. Remove parking gear from output shaft.

SAT756I

SAT757I

SAT960A

SAT957A

SAT109B

DISASSEMBLY

Disassembly (Cont'd)

AT-129

Page 132 of 1767

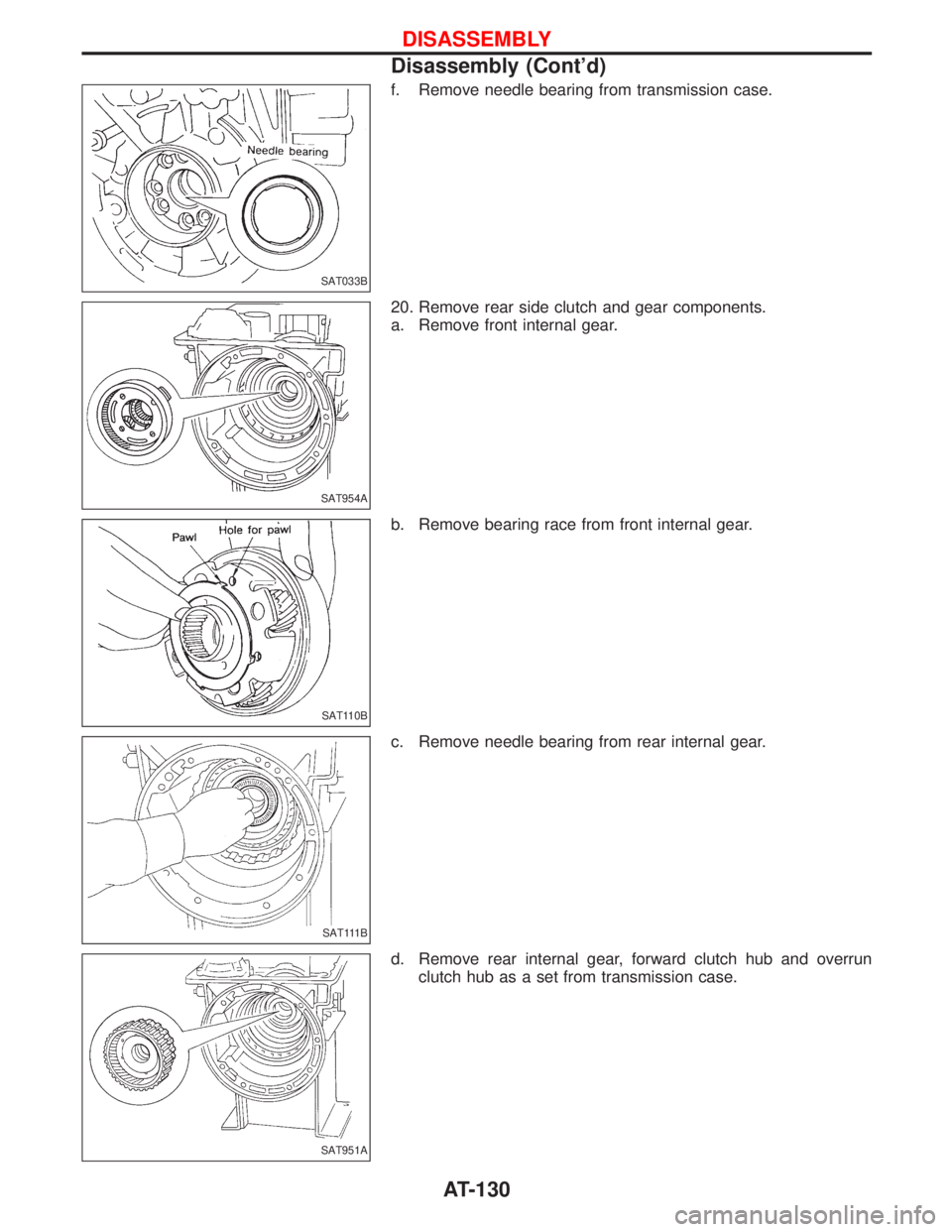

f. Remove needle bearing from transmission case.

20. Remove rear side clutch and gear components.

a. Remove front internal gear.

b. Remove bearing race from front internal gear.

c. Remove needle bearing from rear internal gear.

d. Remove rear internal gear, forward clutch hub and overrun

clutch hub as a set from transmission case.

SAT033B

SAT954A

SAT110B

SAT111B

SAT951A

DISASSEMBLY

Disassembly (Cont'd)

AT-130

Page 133 of 1767

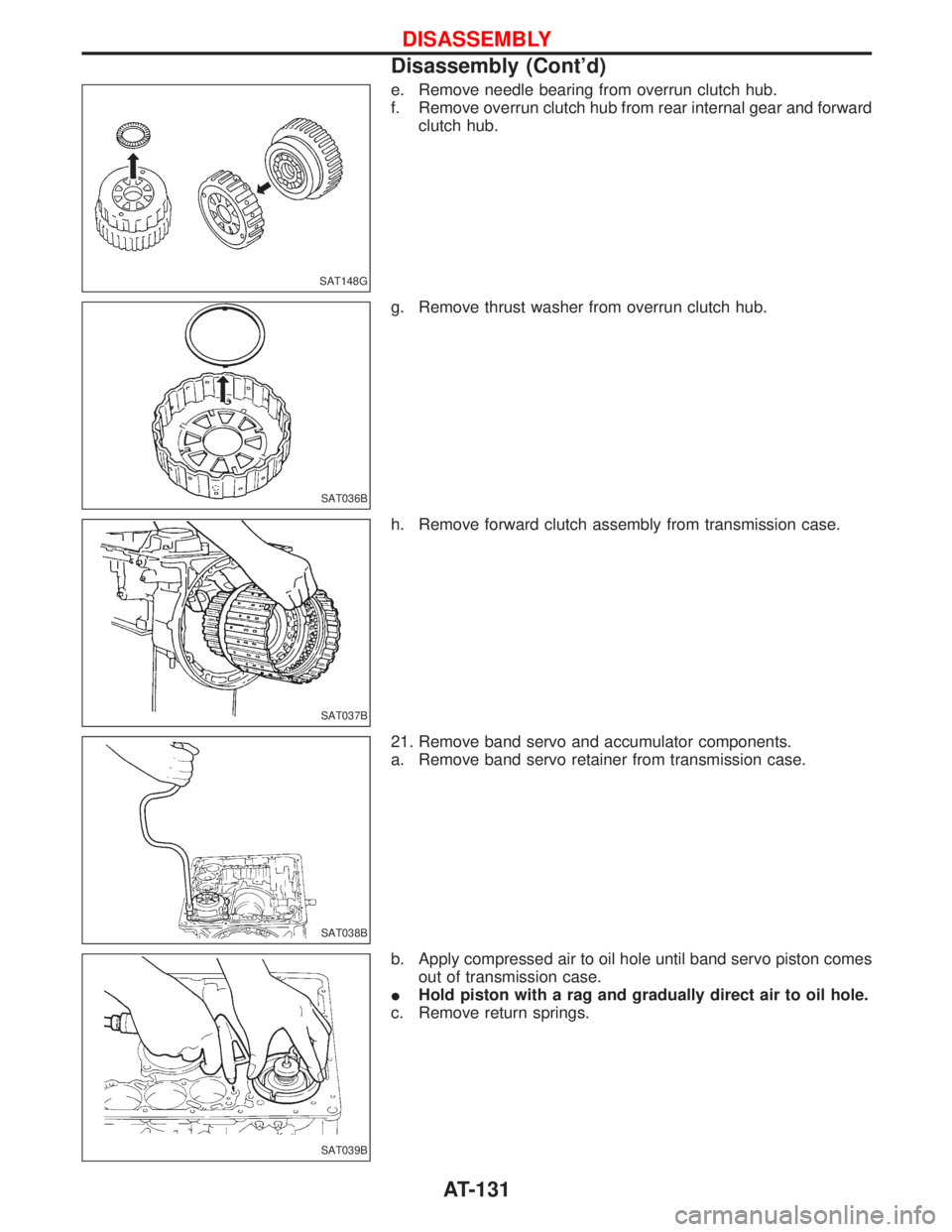

e. Remove needle bearing from overrun clutch hub.

f. Remove overrun clutch hub from rear internal gear and forward

clutch hub.

g. Remove thrust washer from overrun clutch hub.

h. Remove forward clutch assembly from transmission case.

21. Remove band servo and accumulator components.

a. Remove band servo retainer from transmission case.

b. Apply compressed air to oil hole until band servo piston comes

out of transmission case.

IHold piston with a rag and gradually direct air to oil hole.

c. Remove return springs.

SAT148G

SAT036B

SAT037B

SAT038B

SAT039B

DISASSEMBLY

Disassembly (Cont'd)

AT-131

Page 134 of 1767

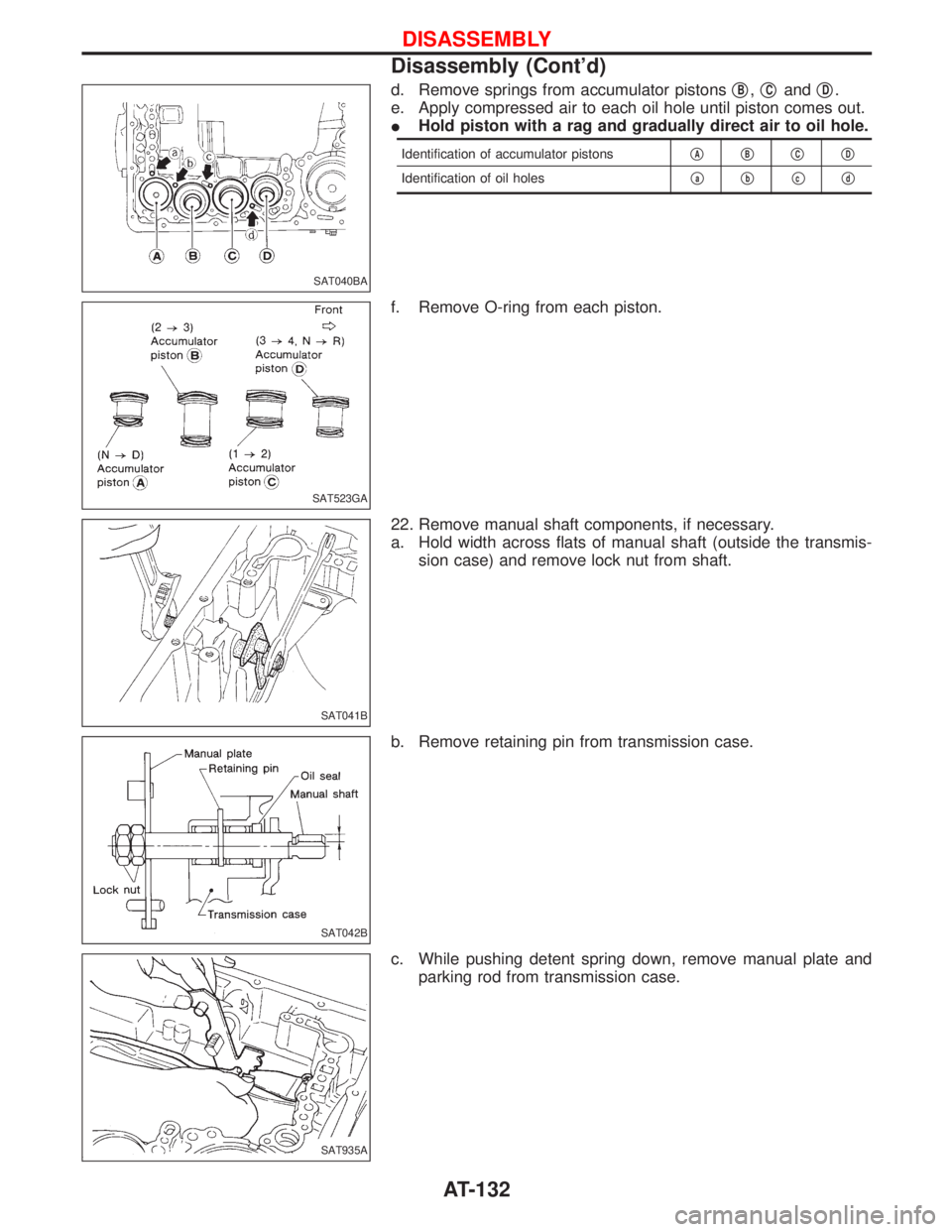

d. Remove springs from accumulator pistonsqB,qCandqD.

e. Apply compressed air to each oil hole until piston comes out.

IHold piston with a rag and gradually direct air to oil hole.

Identification of accumulator pistonsqAqBqCqD

Identification of oil holesqaqbqcqd

f. Remove O-ring from each piston.

22. Remove manual shaft components, if necessary.

a. Hold width across flats of manual shaft (outside the transmis-

sion case) and remove lock nut from shaft.

b. Remove retaining pin from transmission case.

c. While pushing detent spring down, remove manual plate and

parking rod from transmission case.

SAT040BA

SAT523GA

SAT041B

SAT042B

SAT935A

DISASSEMBLY

Disassembly (Cont'd)

AT-132

Page 135 of 1767

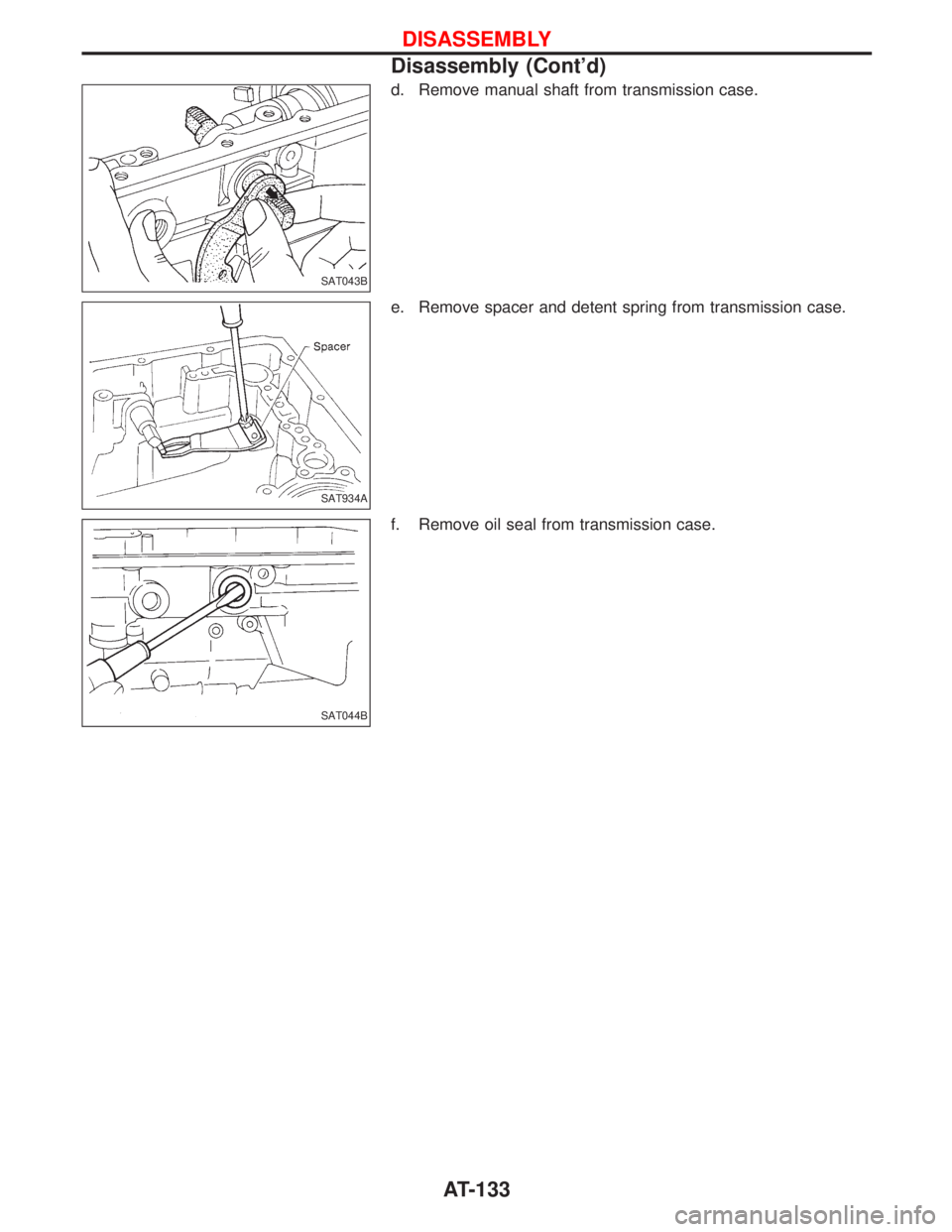

d. Remove manual shaft from transmission case.

e. Remove spacer and detent spring from transmission case.

f. Remove oil seal from transmission case.

SAT043B

SAT934A

SAT044B

DISASSEMBLY

Disassembly (Cont'd)

AT-133

Page 136 of 1767

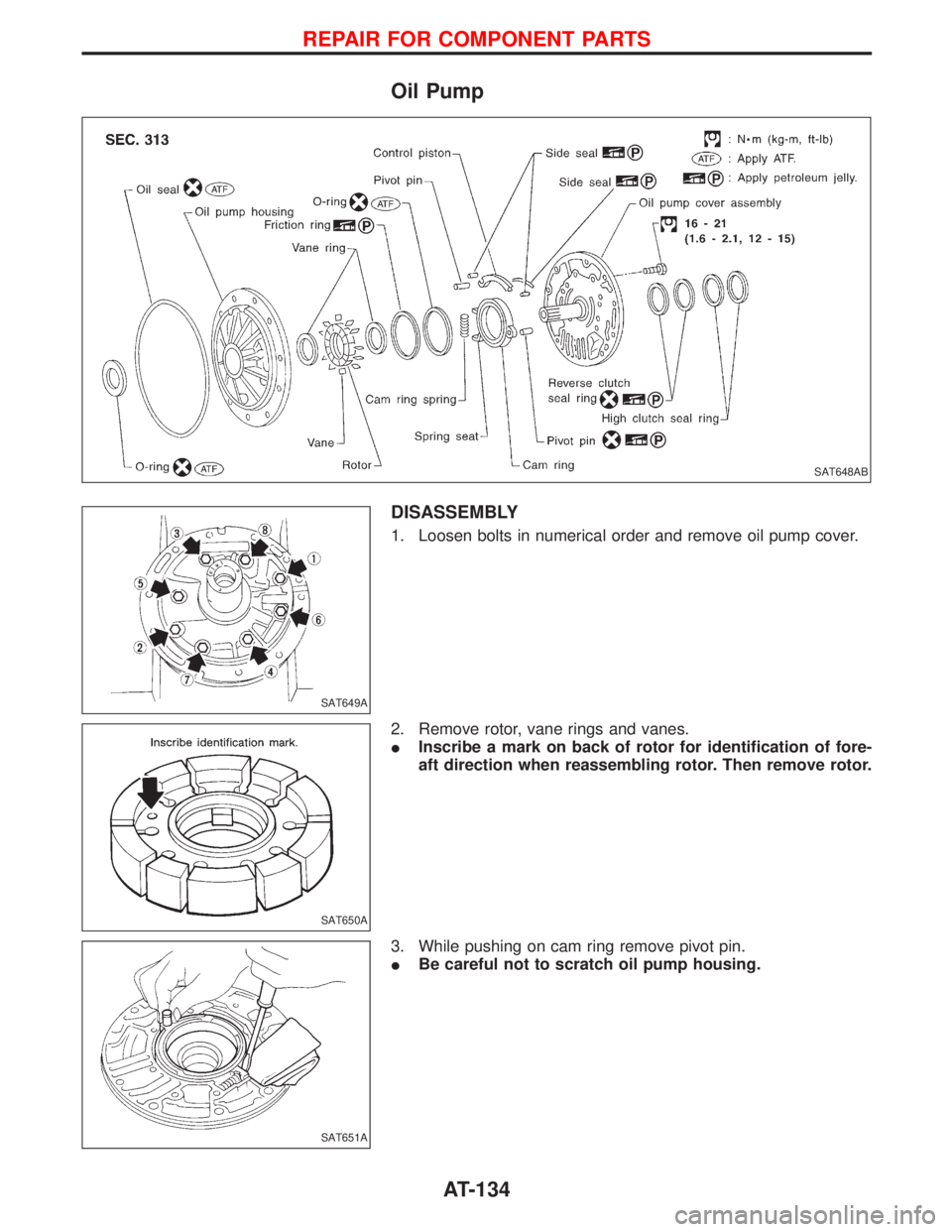

Oil Pump

DISASSEMBLY

1. Loosen bolts in numerical order and remove oil pump cover.

2. Remove rotor, vane rings and vanes.

IInscribe a mark on back of rotor for identification of fore-

aft direction when reassembling rotor. Then remove rotor.

3. While pushing on cam ring remove pivot pin.

IBe careful not to scratch oil pump housing.

SAT648AB

SAT649A

SAT650A

SAT651A

REPAIR FOR COMPONENT PARTS

AT-134

Page 137 of 1767

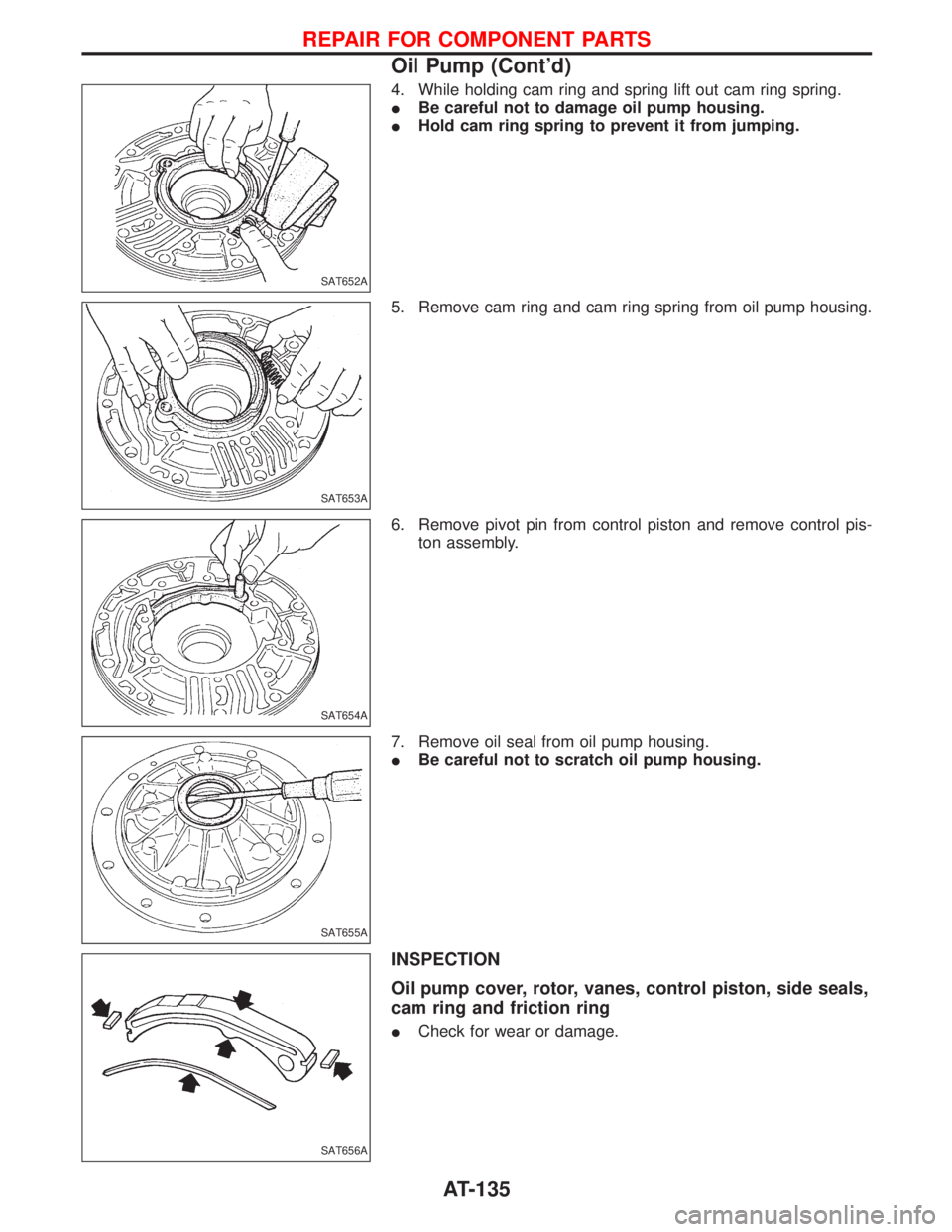

4. While holding cam ring and spring lift out cam ring spring.

IBe careful not to damage oil pump housing.

IHold cam ring spring to prevent it from jumping.

5. Remove cam ring and cam ring spring from oil pump housing.

6. Remove pivot pin from control piston and remove control pis-

ton assembly.

7. Remove oil seal from oil pump housing.

IBe careful not to scratch oil pump housing.

INSPECTION

Oil pump cover, rotor, vanes, control piston, side seals,

cam ring and friction ring

ICheck for wear or damage.

SAT652A

SAT653A

SAT654A

SAT655A

SAT656A

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-135

Page 138 of 1767

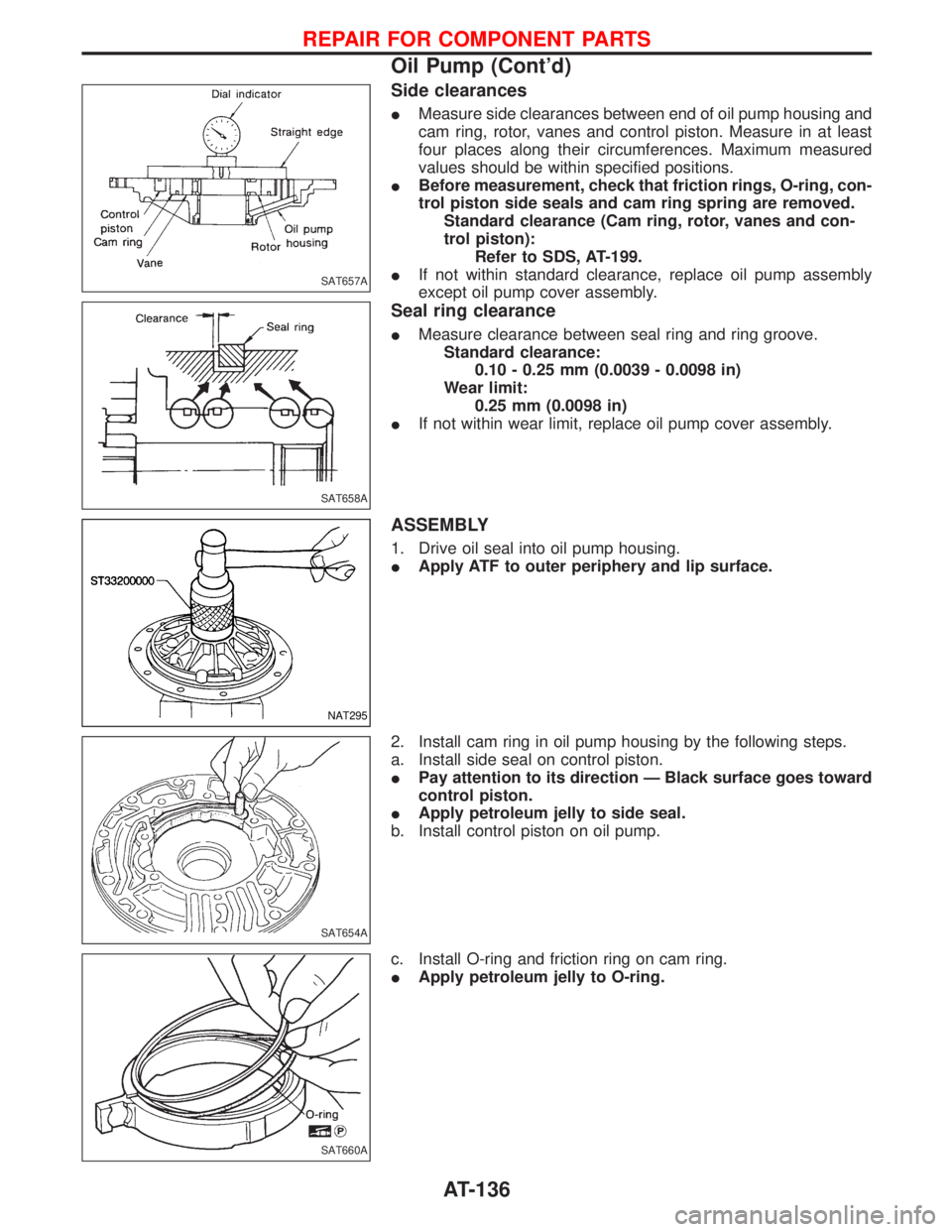

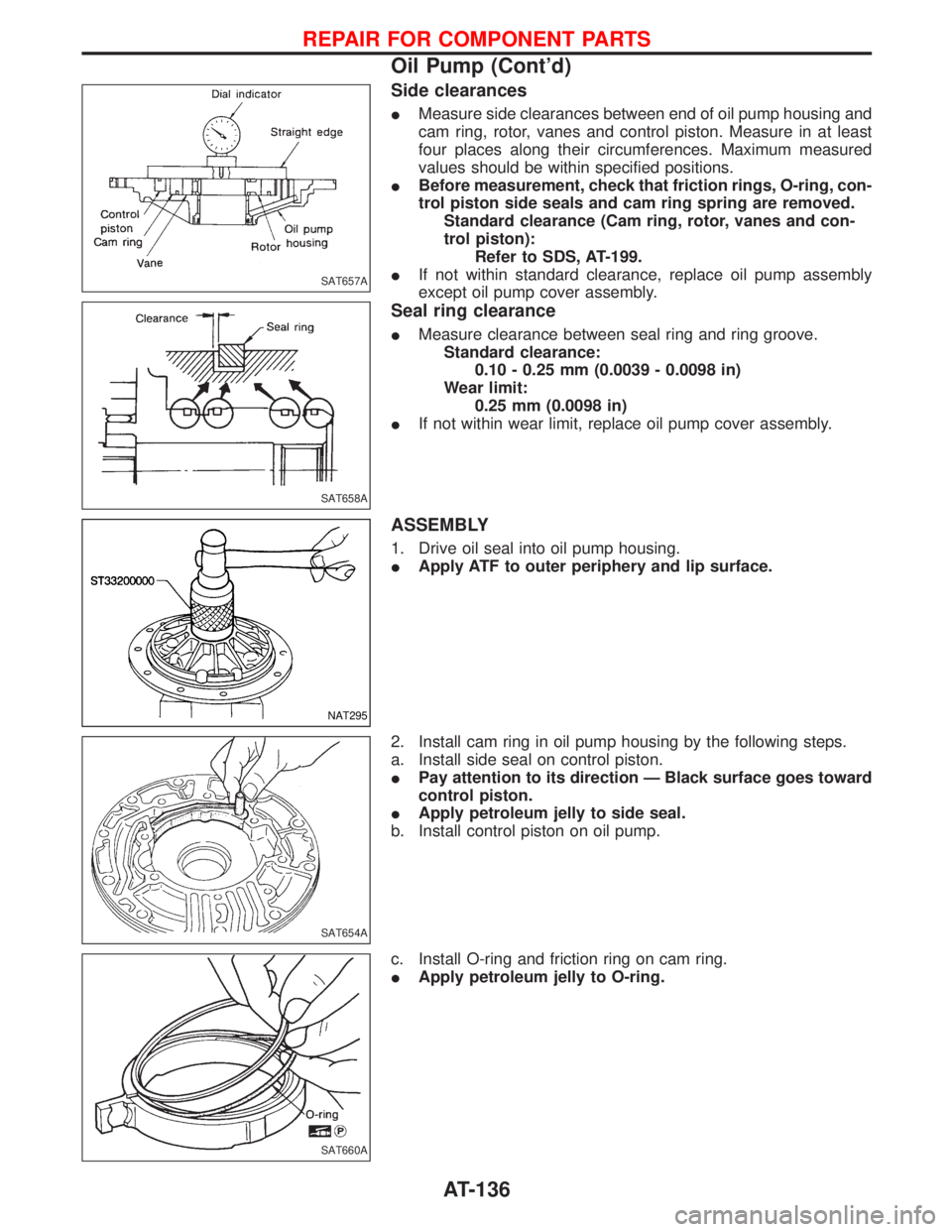

Side clearances

IMeasure side clearances between end of oil pump housing and

cam ring, rotor, vanes and control piston. Measure in at least

four places along their circumferences. Maximum measured

values should be within specified positions.

IBefore measurement, check that friction rings, O-ring, con-

trol piston side seals and cam ring spring are removed.

Standard clearance (Cam ring, rotor, vanes and con-

trol piston):

Refer to SDS, AT-199.

IIf not within standard clearance, replace oil pump assembly

except oil pump cover assembly.

Seal ring clearance

IMeasure clearance between seal ring and ring groove.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

IIf not within wear limit, replace oil pump cover assembly.

ASSEMBLY

1. Drive oil seal into oil pump housing.

IApply ATF to outer periphery and lip surface.

2. Install cam ring in oil pump housing by the following steps.

a. Install side seal on control piston.

IPay attention to its direction Ð Black surface goes toward

control piston.

IApply petroleum jelly to side seal.

b. Install control piston on oil pump.

c. Install O-ring and friction ring on cam ring.

IApply petroleum jelly to O-ring.

SAT657A

SAT658A

NAT295

SAT654A

SAT660A

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-136

Page 139 of 1767

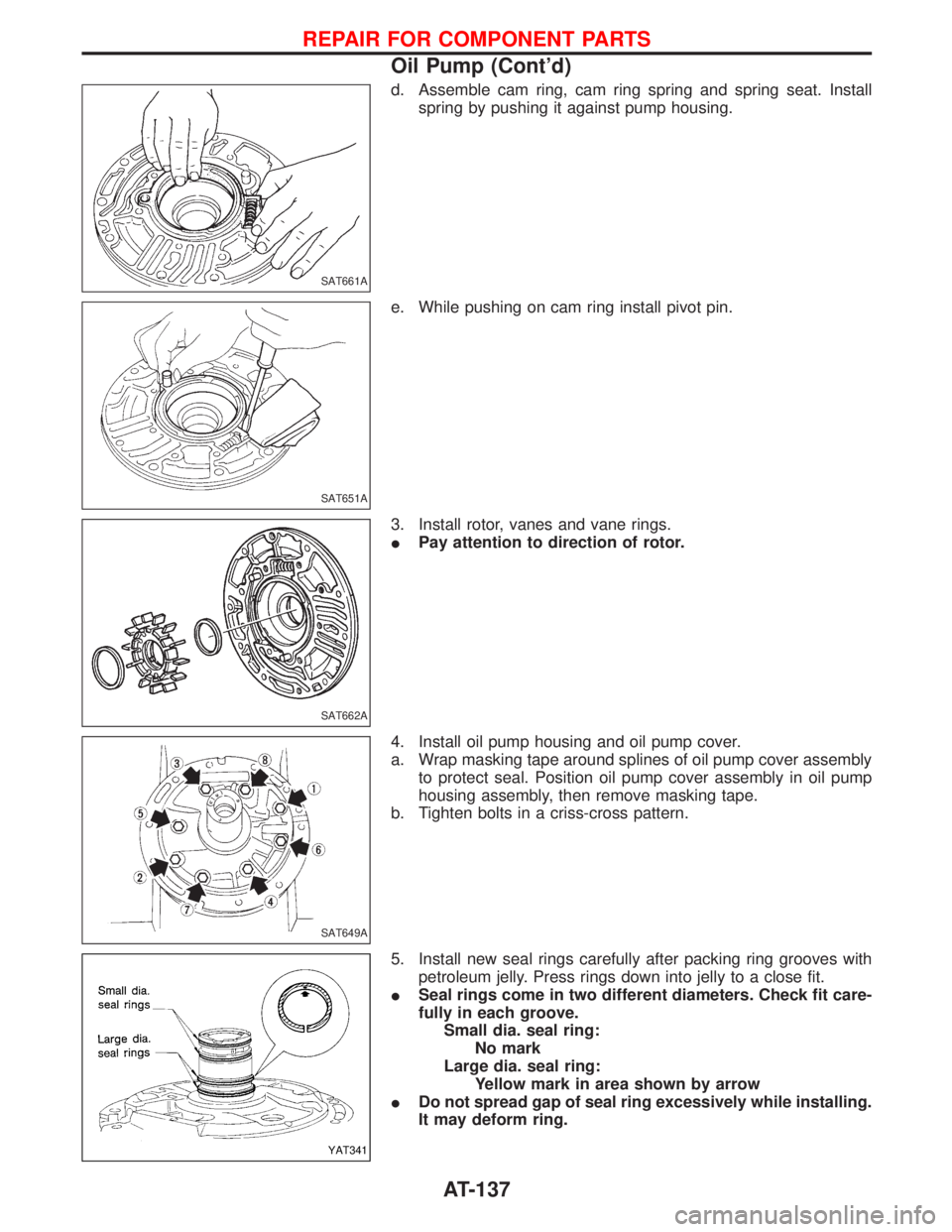

d. Assemble cam ring, cam ring spring and spring seat. Install

spring by pushing it against pump housing.

e. While pushing on cam ring install pivot pin.

3. Install rotor, vanes and vane rings.

IPay attention to direction of rotor.

4. Install oil pump housing and oil pump cover.

a. Wrap masking tape around splines of oil pump cover assembly

to protect seal. Position oil pump cover assembly in oil pump

housing assembly, then remove masking tape.

b. Tighten bolts in a criss-cross pattern.

5. Install new seal rings carefully after packing ring grooves with

petroleum jelly. Press rings down into jelly to a close fit.

ISeal rings come in two different diameters. Check fit care-

fully in each groove.

Small dia. seal ring:

No mark

Large dia. seal ring:

Yellow mark in area shown by arrow

IDo not spread gap of seal ring excessively while installing.

It may deform ring.

SAT661A

SAT651A

SAT662A

SAT649A

YAT341

REPAIR FOR COMPONENT PARTS

Oil Pump (Cont'd)

AT-137

Page 140 of 1767

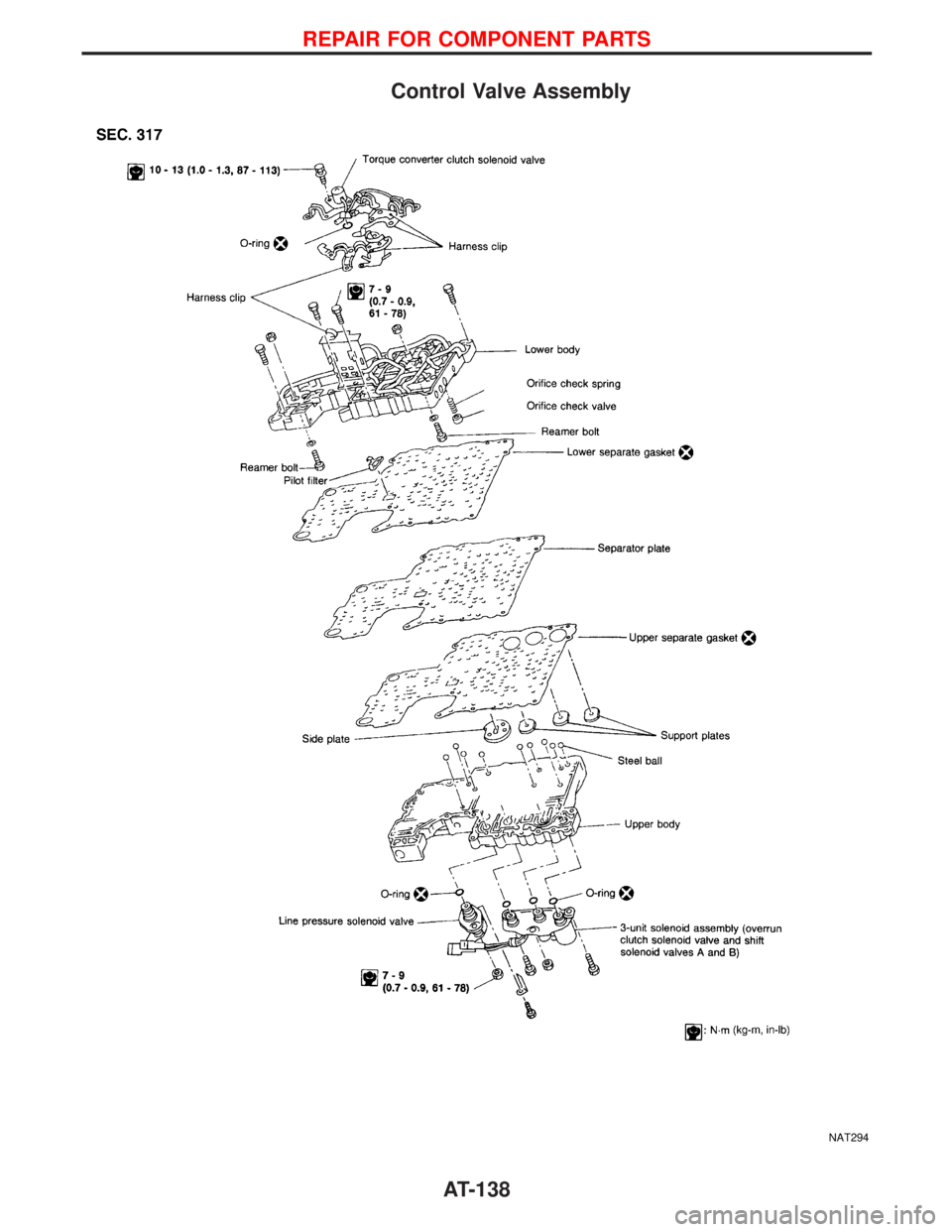

Control Valve Assembly

NAT294

REPAIR FOR COMPONENT PARTS

AT-138

Trending: pump, Ignition, steering wheel, dead battery, sport mode, cruise control, lock