NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: glove box, lights, ECO mode, handbrake, checking oil, radio antenna, fuel pump

Page 141 of 1767

DISASSEMBLY

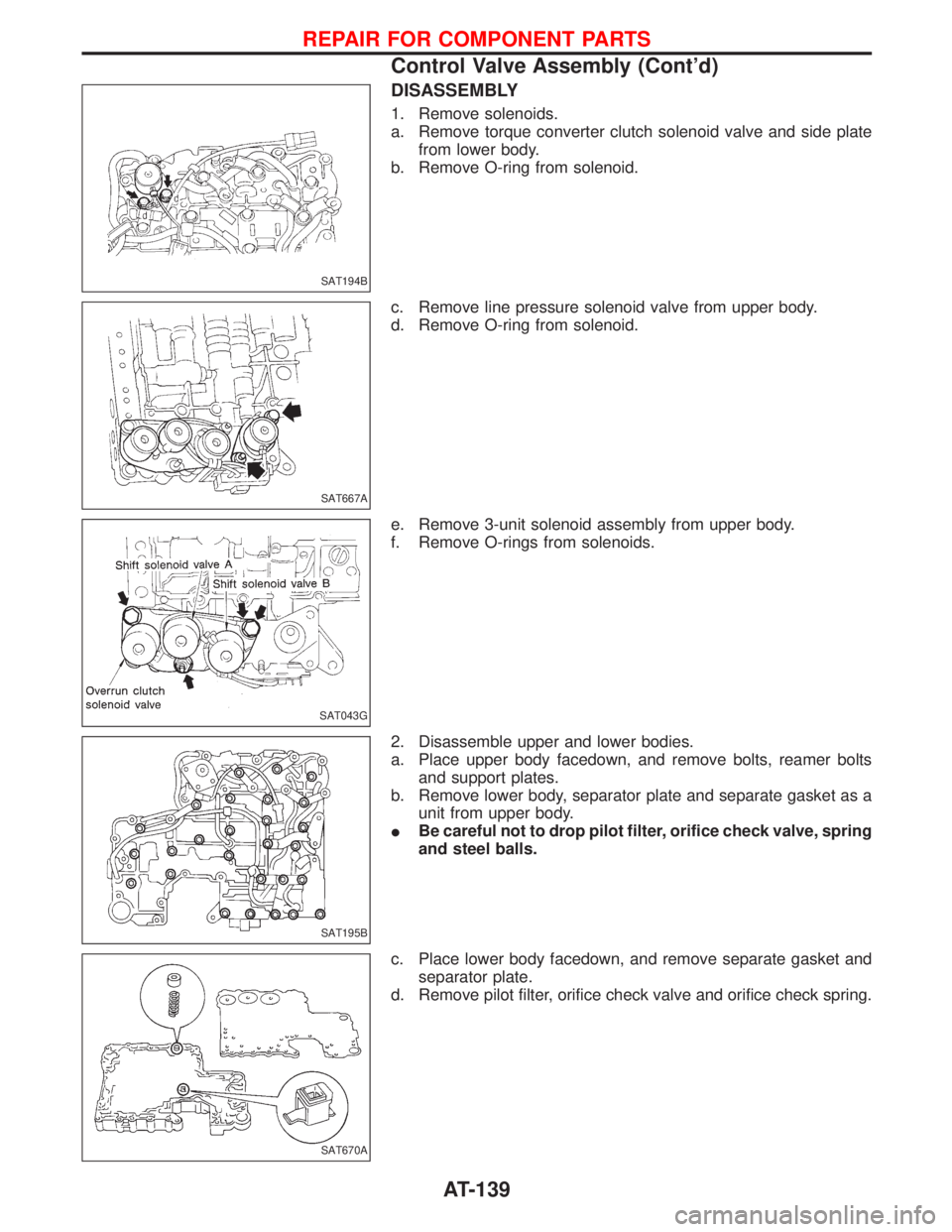

1. Remove solenoids.

a. Remove torque converter clutch solenoid valve and side plate

from lower body.

b. Remove O-ring from solenoid.

c. Remove line pressure solenoid valve from upper body.

d. Remove O-ring from solenoid.

e. Remove 3-unit solenoid assembly from upper body.

f. Remove O-rings from solenoids.

2. Disassemble upper and lower bodies.

a. Place upper body facedown, and remove bolts, reamer bolts

and support plates.

b. Remove lower body, separator plate and separate gasket as a

unit from upper body.

IBe careful not to drop pilot filter, orifice check valve, spring

and steel balls.

c. Place lower body facedown, and remove separate gasket and

separator plate.

d. Remove pilot filter, orifice check valve and orifice check spring.

SAT194B

SAT667A

SAT043G

SAT195B

SAT670A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-139

Page 142 of 1767

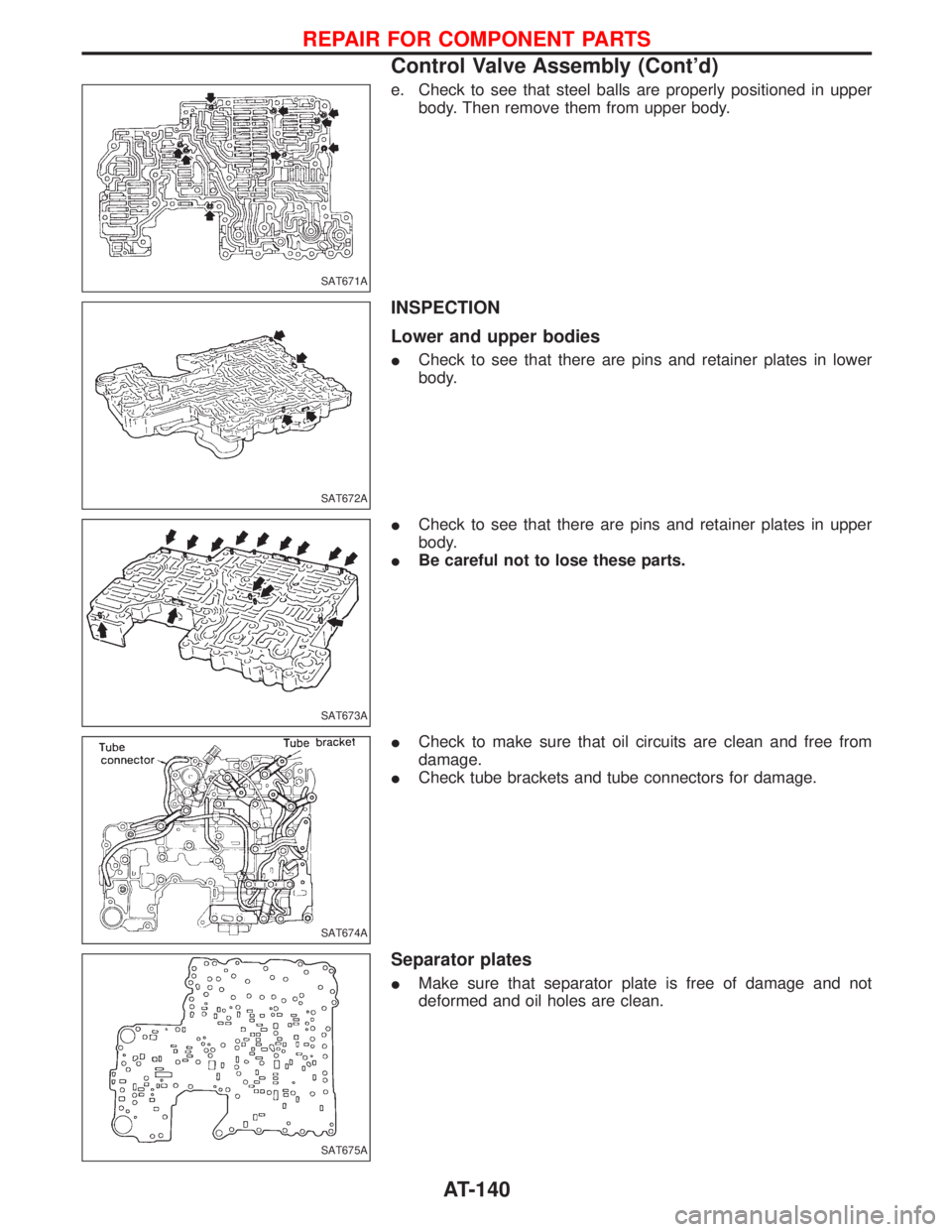

e. Check to see that steel balls are properly positioned in upper

body. Then remove them from upper body.

INSPECTION

Lower and upper bodies

ICheck to see that there are pins and retainer plates in lower

body.

ICheck to see that there are pins and retainer plates in upper

body.

IBe careful not to lose these parts.

ICheck to make sure that oil circuits are clean and free from

damage.

ICheck tube brackets and tube connectors for damage.

Separator plates

IMake sure that separator plate is free of damage and not

deformed and oil holes are clean.

SAT671A

SAT672A

SAT673A

SAT674A

SAT675A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-140

Page 143 of 1767

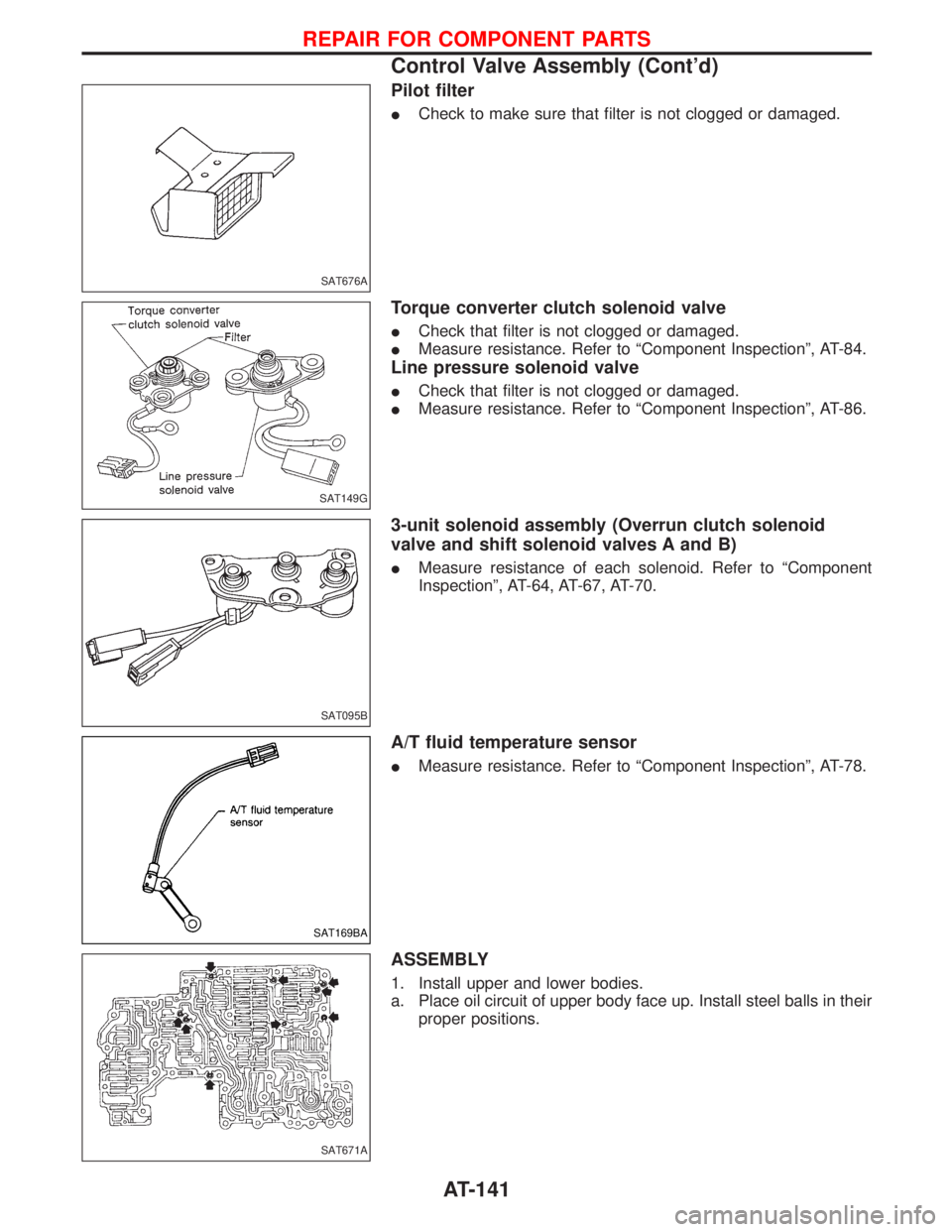

Pilot filter

ICheck to make sure that filter is not clogged or damaged.

Torque converter clutch solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-84.

Line pressure solenoid valve

ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-86.

3-unit solenoid assembly (Overrun clutch solenoid

valve and shift solenoid valves A and B)

IMeasure resistance of each solenoid. Refer to ªComponent

Inspectionº, AT-64, AT-67, AT-70.

A/T fluid temperature sensor

IMeasure resistance. Refer to ªComponent Inspectionº, AT-78.

ASSEMBLY

1. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

SAT676A

SAT149G

SAT095B

SAT169BA

SAT671A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-141

Page 144 of 1767

b. Install reamer bolts from bottom of upper body and install sepa-

rate gaskets.

c. Place oil circuit of lower body face up. Install orifice check

spring, orifice check valve and pilot filter.

d. Install lower separate gaskets and separator plates on lower

body.

e. Install and temporarily tighten support plates, fluid temperature

sensor and tube brackets.

f. Temporarily assemble lower and upper bodies, using reamer

bolt as a guide.

IBe careful not to dislocate or drop steel balls, orifice check

spring, orifice check valve and pilot filter.

SAT681A

SAT682A

SAT197B

SAT198B

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-142

Page 145 of 1767

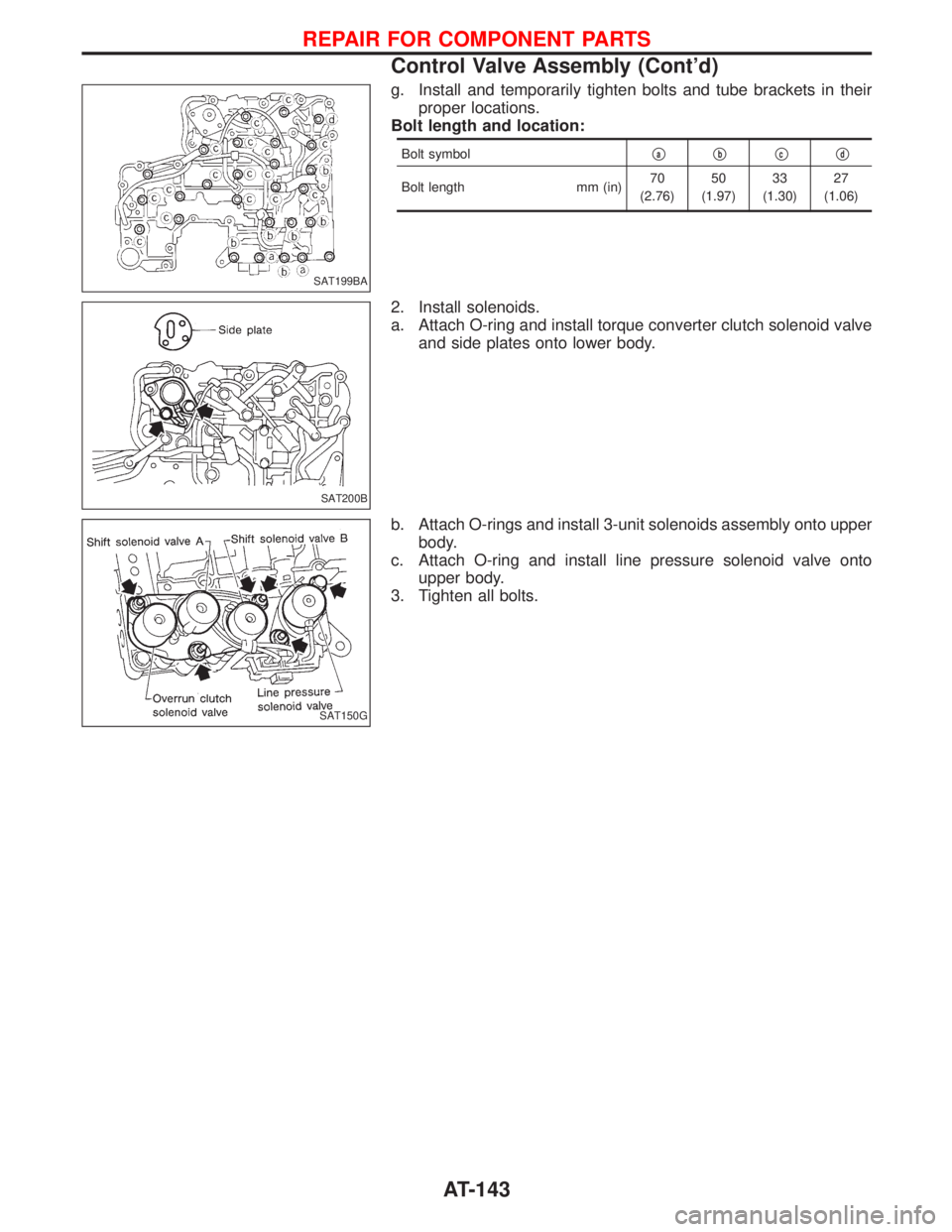

g. Install and temporarily tighten bolts and tube brackets in their

proper locations.

Bolt length and location:

Bolt symbolqaqbqcqd

Bolt length mm (in)70

(2.76)50

(1.97)33

(1.30)27

(1.06)

2. Install solenoids.

a. Attach O-ring and install torque converter clutch solenoid valve

and side plates onto lower body.

b. Attach O-rings and install 3-unit solenoids assembly onto upper

body.

c. Attach O-ring and install line pressure solenoid valve onto

upper body.

3. Tighten all bolts.

SAT199BA

SAT200B

SAT150G

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-143

Page 146 of 1767

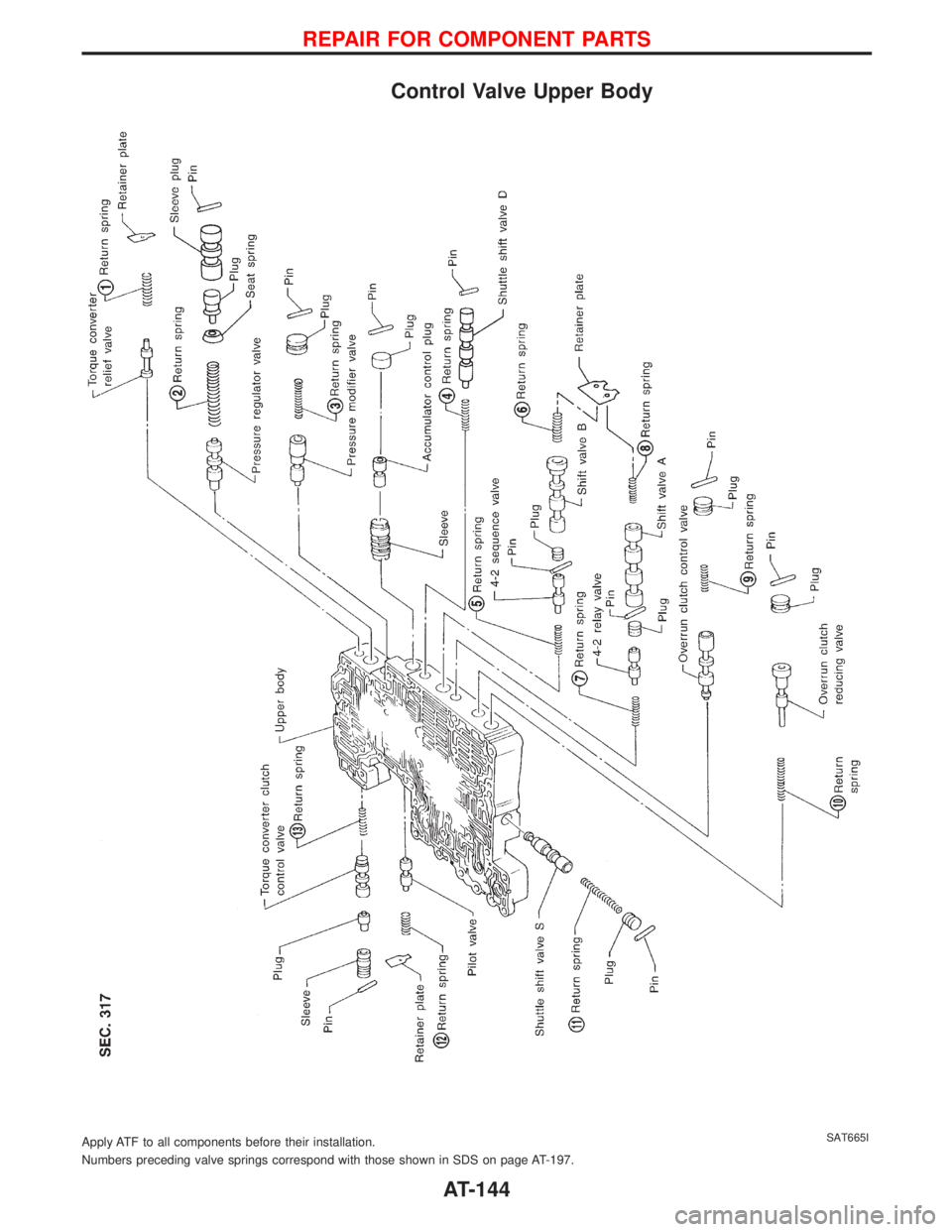

Control Valve Upper Body

Numbers preceding valve springs correspond with those shown in SDS on page AT-197. Apply ATF to all components before their installation.

SAT665I

REPAIR FOR COMPONENT PARTS

AT-144

Page 147 of 1767

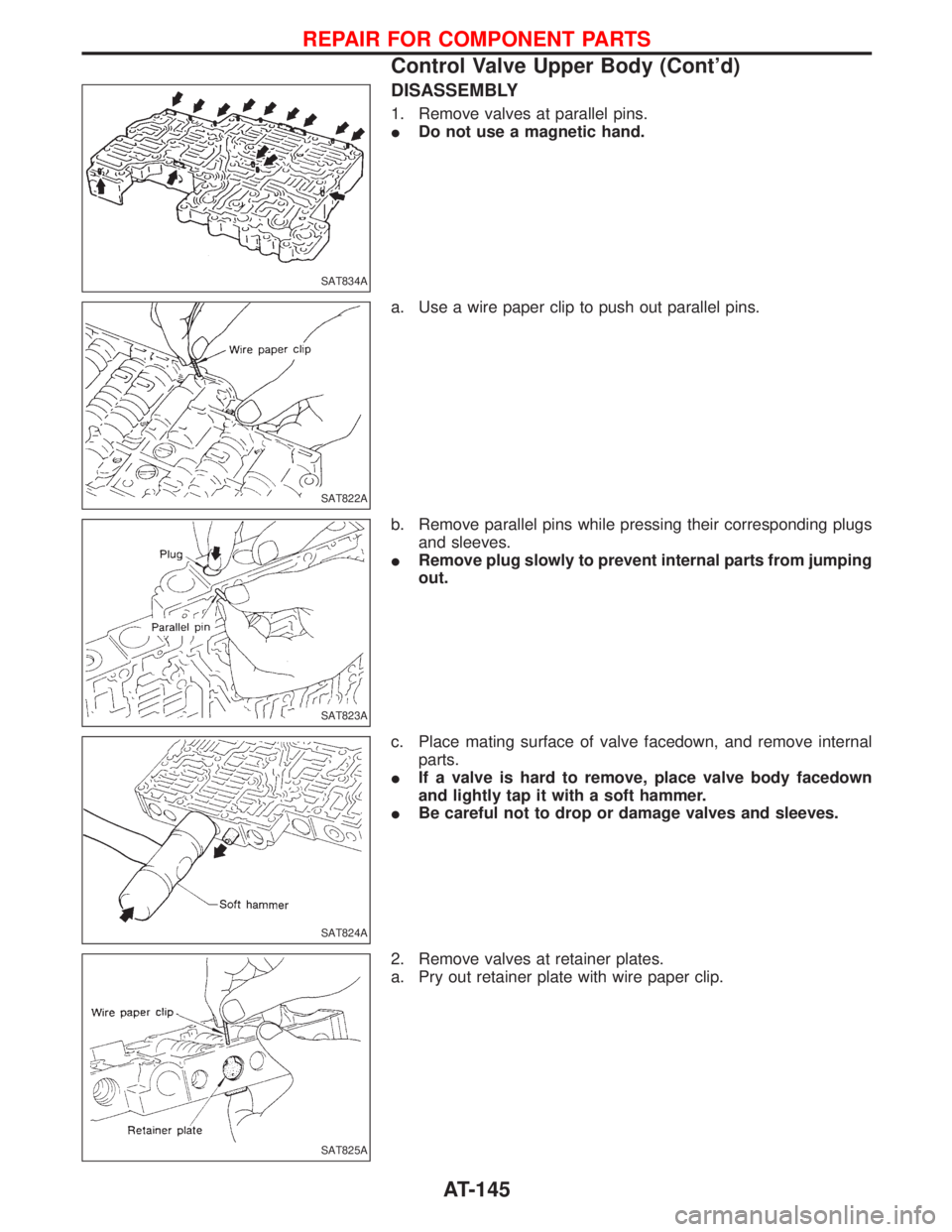

DISASSEMBLY

1. Remove valves at parallel pins.

IDo not use a magnetic hand.

a. Use a wire paper clip to push out parallel pins.

b. Remove parallel pins while pressing their corresponding plugs

and sleeves.

IRemove plug slowly to prevent internal parts from jumping

out.

c. Place mating surface of valve facedown, and remove internal

parts.

IIf a valve is hard to remove, place valve body facedown

and lightly tap it with a soft hammer.

IBe careful not to drop or damage valves and sleeves.

2. Remove valves at retainer plates.

a. Pry out retainer plate with wire paper clip.

SAT834A

SAT822A

SAT823A

SAT824A

SAT825A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-145

Page 148 of 1767

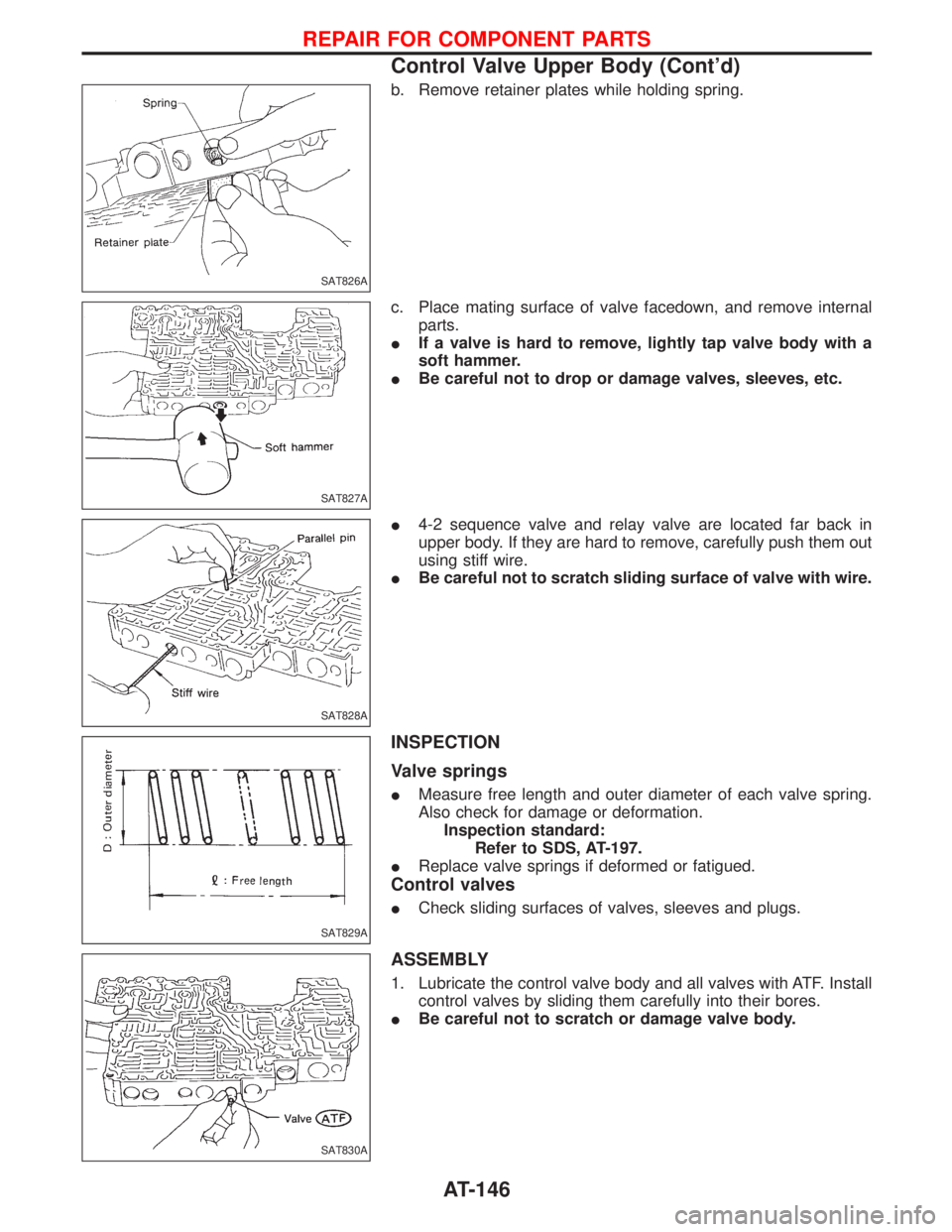

b. Remove retainer plates while holding spring.

c. Place mating surface of valve facedown, and remove internal

parts.

IIf a valve is hard to remove, lightly tap valve body with a

soft hammer.

IBe careful not to drop or damage valves, sleeves, etc.

I4-2 sequence valve and relay valve are located far back in

upper body. If they are hard to remove, carefully push them out

using stiff wire.

IBe careful not to scratch sliding surface of valve with wire.

INSPECTION

Valve springs

IMeasure free length and outer diameter of each valve spring.

Also check for damage or deformation.

Inspection standard:

Refer to SDS, AT-197.

IReplace valve springs if deformed or fatigued.

Control valves

ICheck sliding surfaces of valves, sleeves and plugs.

ASSEMBLY

1. Lubricate the control valve body and all valves with ATF. Install

control valves by sliding them carefully into their bores.

IBe careful not to scratch or damage valve body.

SAT826A

SAT827A

SAT828A

SAT829A

SAT830A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-146

Page 149 of 1767

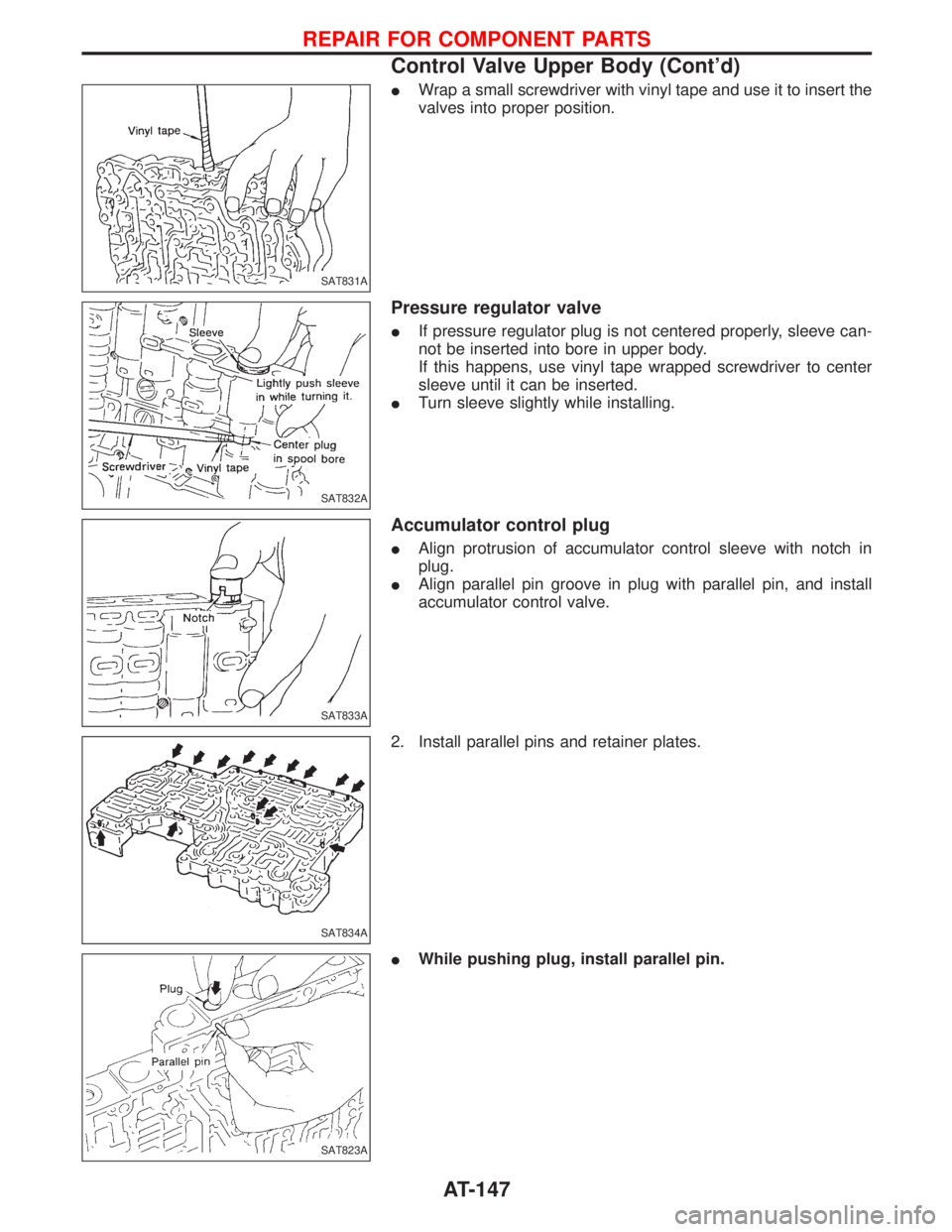

IWrap a small screwdriver with vinyl tape and use it to insert the

valves into proper position.

Pressure regulator valve

IIf pressure regulator plug is not centered properly, sleeve can-

not be inserted into bore in upper body.

If this happens, use vinyl tape wrapped screwdriver to center

sleeve until it can be inserted.

ITurn sleeve slightly while installing.

Accumulator control plug

IAlign protrusion of accumulator control sleeve with notch in

plug.

IAlign parallel pin groove in plug with parallel pin, and install

accumulator control valve.

2. Install parallel pins and retainer plates.

IWhile pushing plug, install parallel pin.

SAT831A

SAT832A

SAT833A

SAT834A

SAT823A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-147

Page 150 of 1767

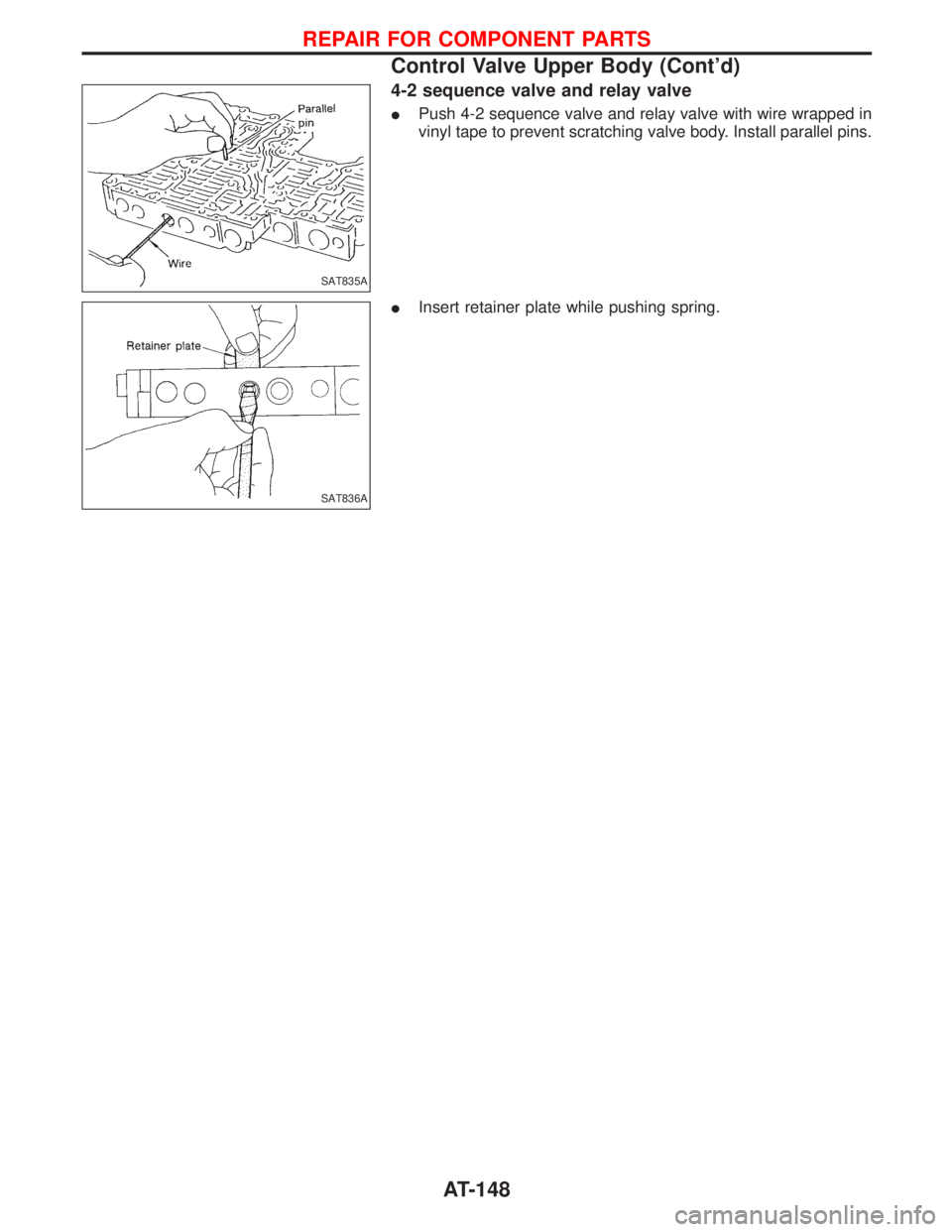

4-2 sequence valve and relay valve

IPush 4-2 sequence valve and relay valve with wire wrapped in

vinyl tape to prevent scratching valve body. Install parallel pins.

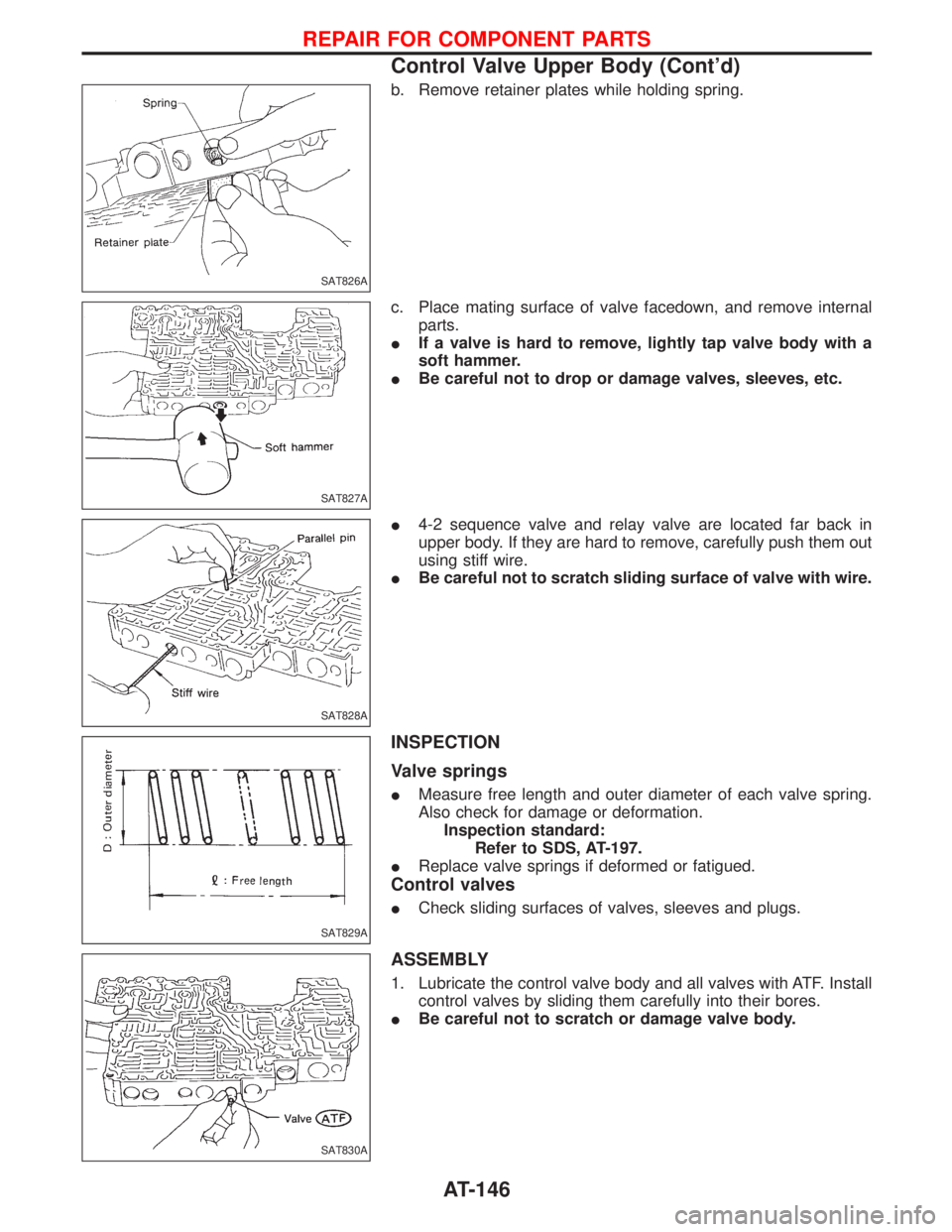

IInsert retainer plate while pushing spring.

SAT835A

SAT836A

REPAIR FOR COMPONENT PARTS

Control Valve Upper Body (Cont'd)

AT-148

Trending: wiper, compression ratio, oil, tire type, wiper relay, buttons, ESP