Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 761 of 1767

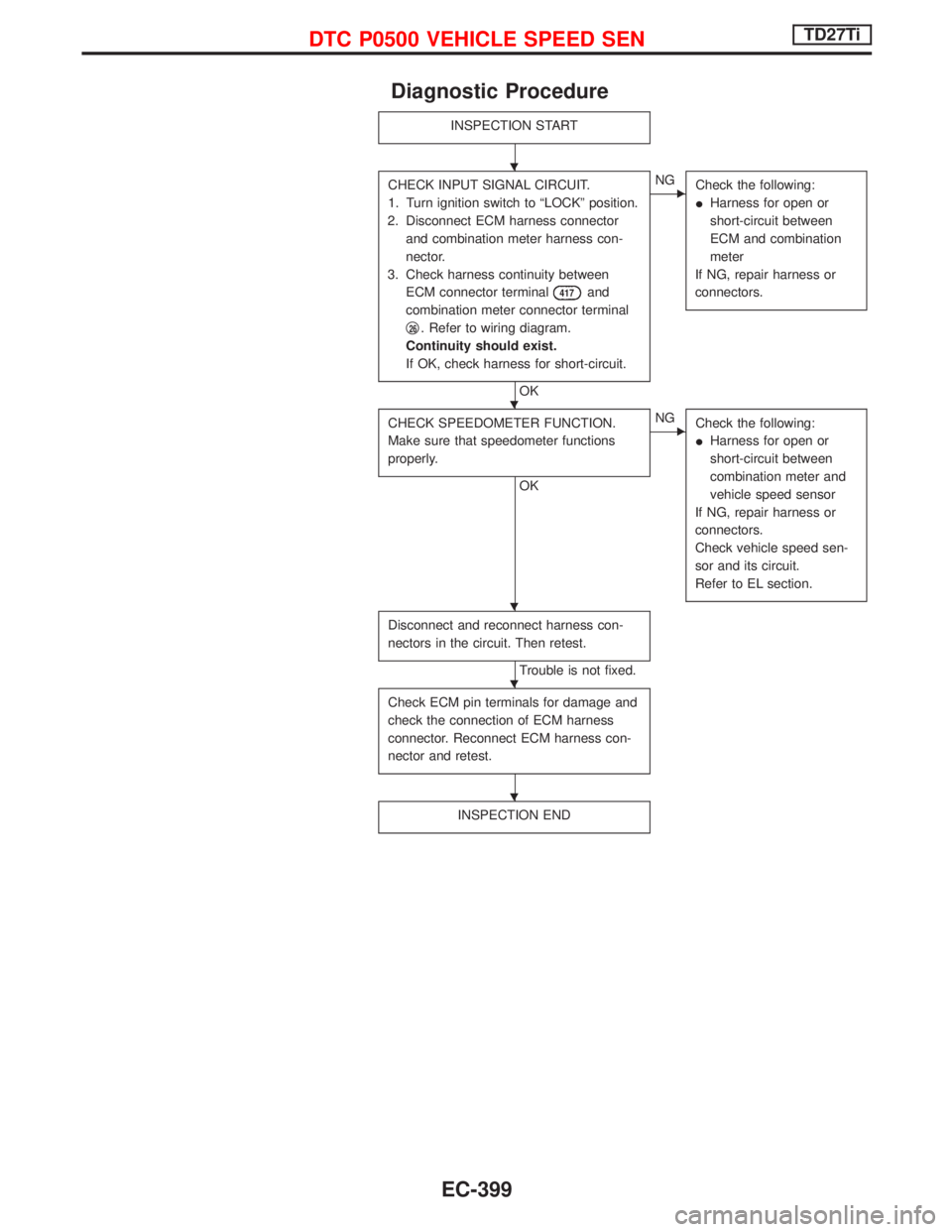

Diagnostic Procedure

INSPECTION START

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector

and combination meter harness con-

nector.

3. Check harness continuity between

ECM connector terminal

417and

combination meter connector terminal

q

26. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and combination

meter

If NG, repair harness or

connectors.

CHECK SPEEDOMETER FUNCTION.

Make sure that speedometer functions

properly.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

combination meter and

vehicle speed sensor

If NG, repair harness or

connectors.

Check vehicle speed sen-

sor and its circuit.

Refer to EL section.

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

H

H

H

H

H

DTC P0500 VEHICLE SPEED SENTD27Ti

EC-399

Page 764 of 1767

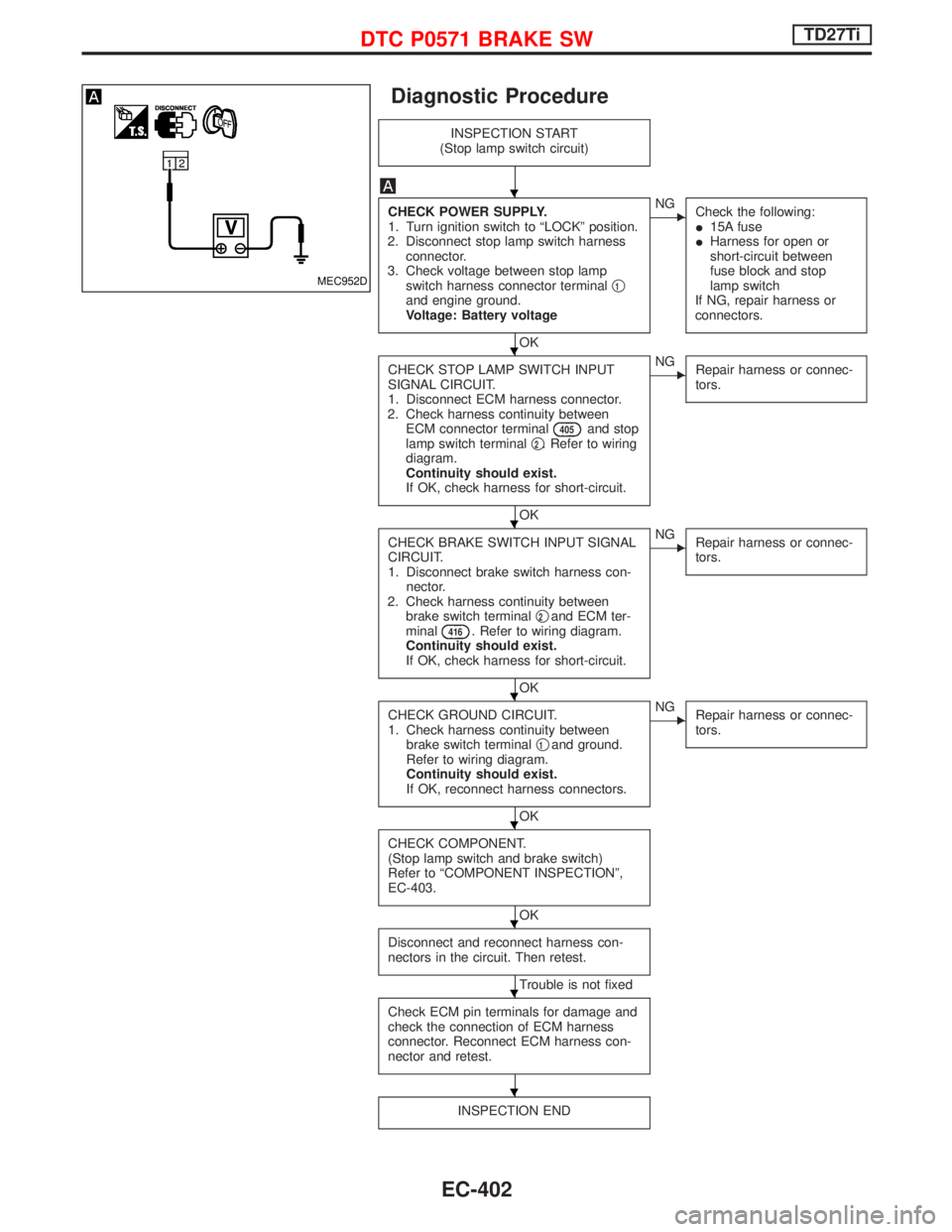

Diagnostic Procedure

INSPECTION START

(Stop lamp switch circuit)

CHECK POWER SUPPLY.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect stop lamp switch harness

connector.

3. Check voltage between stop lamp

switch harness connector terminalq

1and engine ground.

Voltage: Battery voltage

OK

ENG

Check the following:

I15A fuse

IHarness for open or

short-circuit between

fuse block and stop

lamp switch

If NG, repair harness or

connectors.

CHECK STOP LAMP SWITCH INPUT

SIGNAL CIRCUIT.

1. Disconnect ECM harness connector.

2. Check harness continuity between

ECM connector terminal

405and stop

lamp switch terminalq2. Refer to wiring

diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or connec-

tors.

CHECK BRAKE SWITCH INPUT SIGNAL

CIRCUIT.

1. Disconnect brake switch harness con-

nector.

2. Check harness continuity between

brake switch terminalq

2and ECM ter-

minal416. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or connec-

tors.

CHECK GROUND CIRCUIT.

1. Check harness continuity between

brake switch terminalq

1and ground.

Refer to wiring diagram.

Continuity should exist.

If OK, reconnect harness connectors.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT.

(Stop lamp switch and brake switch)

Refer to ªCOMPONENT INSPECTIONº,

EC-403.

OK

Disconnect and reconnect harness con-

nectors in the circuit. Then retest.

Trouble is not fixed

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

MEC952D

H

H

H

H

H

H

H

H

DTC P0571 BRAKE SWTD27Ti

EC-402

Page 766 of 1767

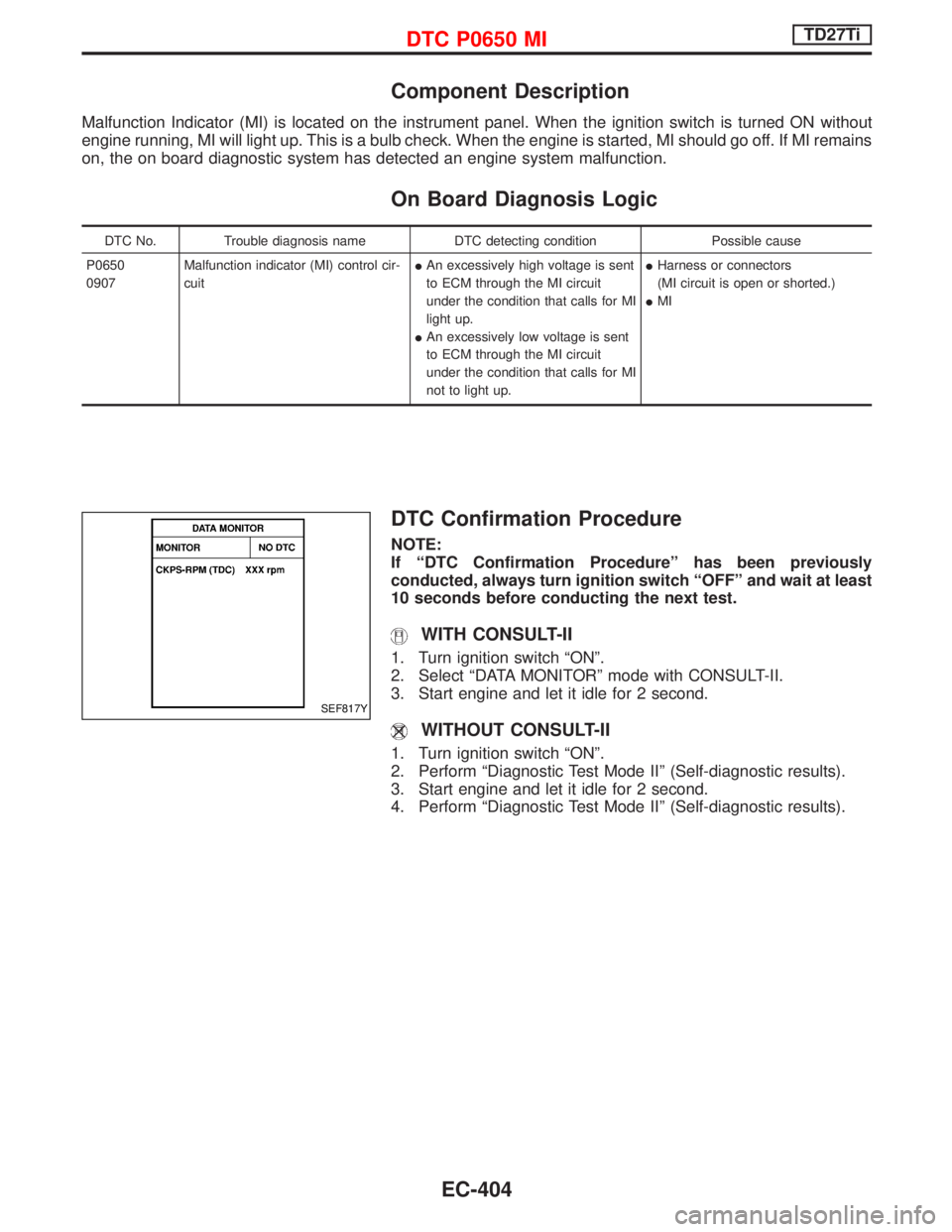

Component Description

Malfunction Indicator (MI) is located on the instrument panel. When the ignition switch is turned ON without

engine running, MI will light up. This is a bulb check. When the engine is started, MI should go off. If MI remains

on, the on board diagnostic system has detected an engine system malfunction.

On Board Diagnosis Logic

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0650

0907Malfunction indicator (MI) control cir-

cuitIAn excessively high voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

light up.

IAn excessively low voltage is sent

to ECM through the MI circuit

under the condition that calls for MI

not to light up.IHarness or connectors

(MI circuit is open or shorted.)

IMI

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Start engine and let it idle for 2 second.

WITHOUT CONSULT-II

1. Turn ignition switch ªONº.

2. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

3. Start engine and let it idle for 2 second.

4. Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

SEF817Y

DTC P0650 MITD27Ti

EC-404

Page 768 of 1767

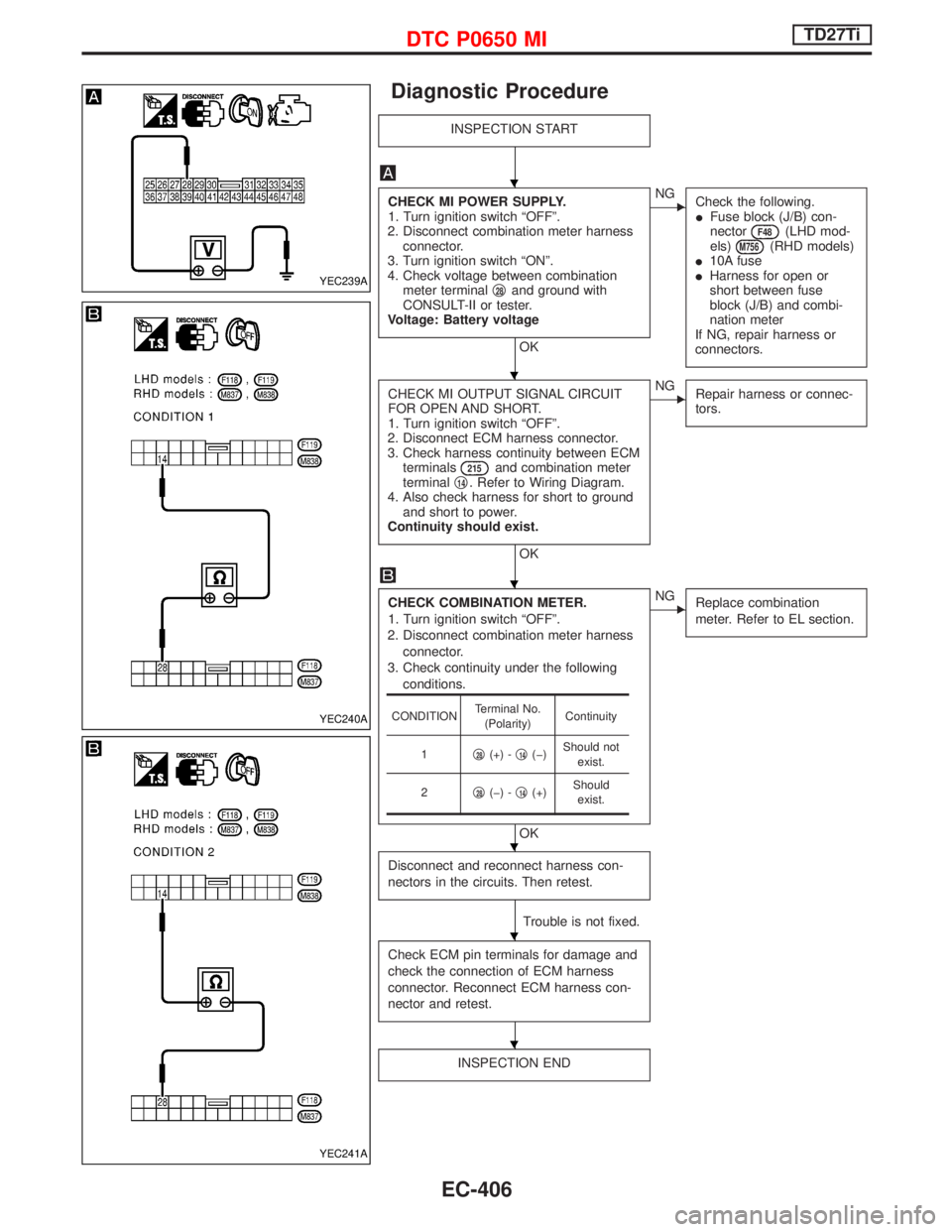

Diagnostic Procedure

INSPECTION START

CHECK MI POWER SUPPLY.

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness

connector.

3. Turn ignition switch ªONº.

4. Check voltage between combination

meter terminalq

28and ground with

CONSULT-II or tester.

Voltage: Battery voltage

OK

ENG

Check the following.

IFuse block (J/B) con-

nector

F48(LHD mod-

els)M756(RHD models)

I10A fuse

IHarness for open or

short between fuse

block (J/B) and combi-

nation meter

If NG, repair harness or

connectors.

CHECK MI OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT.

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminals

215and combination meter

terminalq14. Refer to Wiring Diagram.

4. Also check harness for short to ground

and short to power.

Continuity should exist.

OK

ENG

Repair harness or connec-

tors.

CHECK COMBINATION METER.

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness

connector.

3. Check continuity under the following

conditions.

OK

ENG

Replace combination

meter. Refer to EL section.

Disconnect and reconnect harness con-

nectors in the circuits. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector. Reconnect ECM harness con-

nector and retest.

INSPECTION END

CONDITIONTerminal No.

(Polarity)Continuity

1q

28(+) -q14(þ)Should not

exist.

2q

28(þ) -q14(+)Should

exist.

YEC239A

YEC240A

YEC241A

H

H

H

H

H

H

DTC P0650 MITD27Ti

EC-406

Page 769 of 1767

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis Logic

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1107

0802IAn excessively high or low voltage from

the absolute pressure sensor (built-into

ECM) is sent to ECM.IECM

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then turn

ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

SEC220B

SEF817Y

DTC P1107 ECM 10TD27Ti

EC-407

Page 770 of 1767

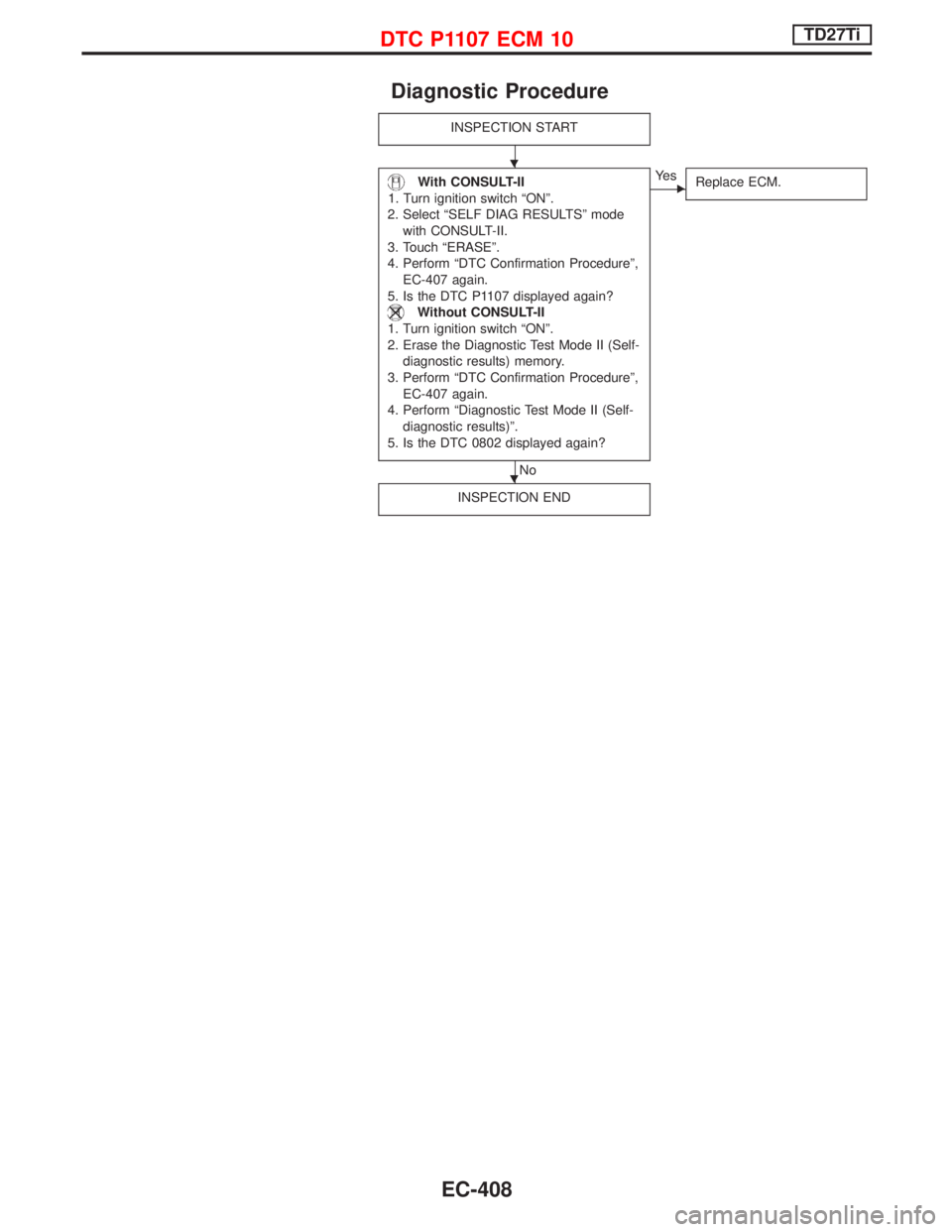

Diagnostic Procedure

INSPECTION START

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªSELF DIAG RESULTSº mode

with CONSULT-II.

3. Touch ªERASEº.

4. Perform ªDTC Confirmation Procedureº,

EC-407 again.

5. Is the DTC P1107 displayed again?

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Erase the Diagnostic Test Mode II (Self-

diagnostic results) memory.

3. Perform ªDTC Confirmation Procedureº,

EC-407 again.

4. Perform ªDiagnostic Test Mode II (Self-

diagnostic results)º.

5. Is the DTC 0802 displayed again?

No

EYe s

Replace ECM.

INSPECTION END

H

H

DTC P1107 ECM 10TD27Ti

EC-408

Page 772 of 1767

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine above 1,200 rpm.

3) Run it for 2 seconds above 1,200 rpm. Return engine speed to

idle.

WITHOUT CONSULT-II

1) Start engine above 1,200 rpm.

2) Run engine for 2 seconds above 1,200 rpm. Return engine

speed to idle.

3) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then turn to ªONº position.

4) Perform ªDiagnostic Test Mode IIº (Self-diagnostic results).

NOTE:

If malfunction occurs intermittently, conduct suitable driving

pattern for 10 minutes. This makes it possible to determine

DTC.

DTC P1206 F/INJ F/B 2TD27Ti

EC-410

Page 774 of 1767

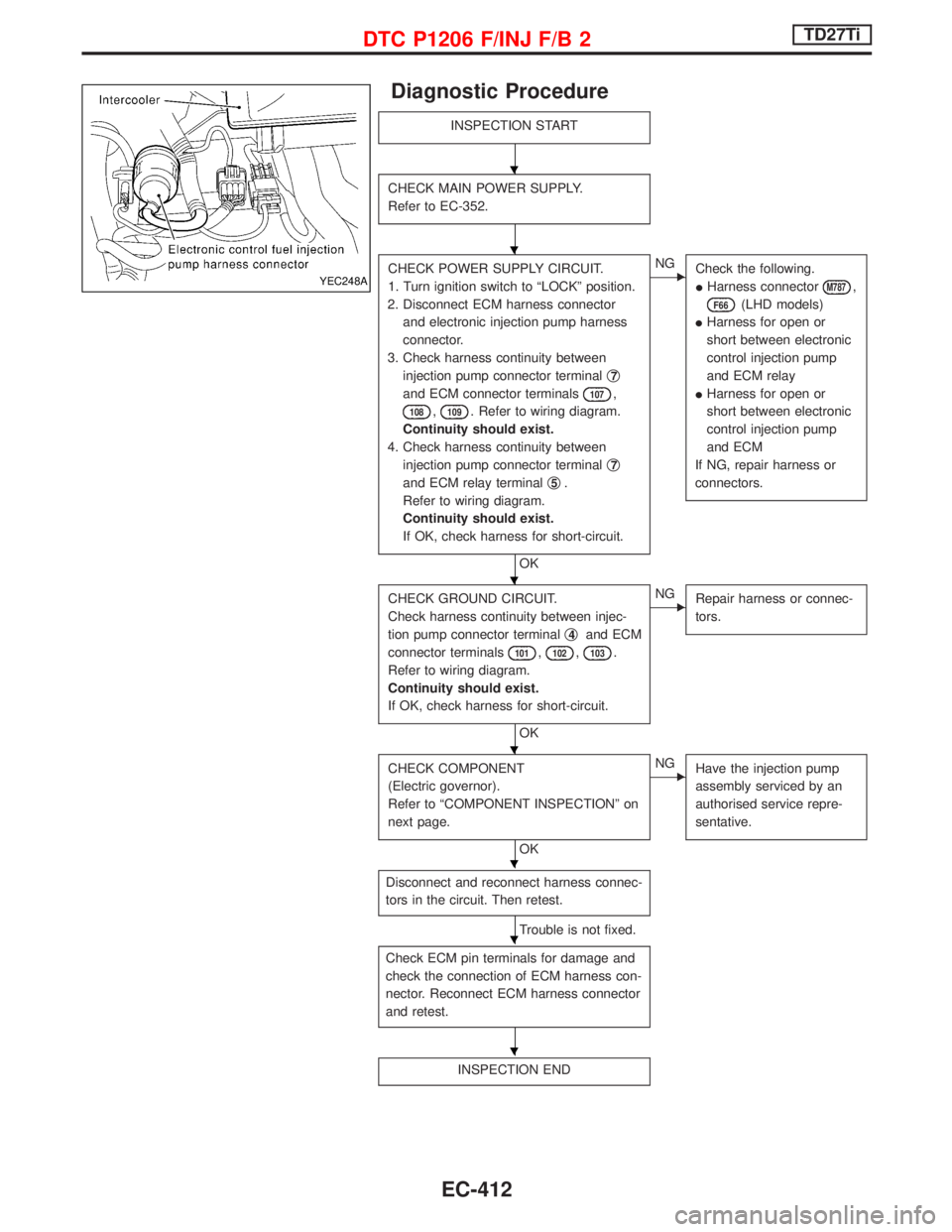

Diagnostic Procedure

INSPECTION START

CHECK MAIN POWER SUPPLY.

Refer to EC-352.

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector

and electronic injection pump harness

connector.

3. Check harness continuity between

injection pump connector terminalq

7

and ECM connector terminals107,

108,109. Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between

injection pump connector terminalq

7

and ECM relay terminalq5.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following.

IHarness connector

M787,

F66(LHD models)

IHarness for open or

short between electronic

control injection pump

and ECM relay

IHarness for open or

short between electronic

control injection pump

and ECM

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

Check harness continuity between injec-

tion pump connector terminalq

4and ECM

connector terminals

101,102,103.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Repair harness or connec-

tors.

CHECK COMPONENT

(Electric governor).

Refer to ªCOMPONENT INSPECTIONº on

next page.

OK

ENG

Have the injection pump

assembly serviced by an

authorised service repre-

sentative.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

YEC248A

H

H

H

H

H

H

H

DTC P1206 F/INJ F/B 2TD27Ti

EC-412

Page 776 of 1767

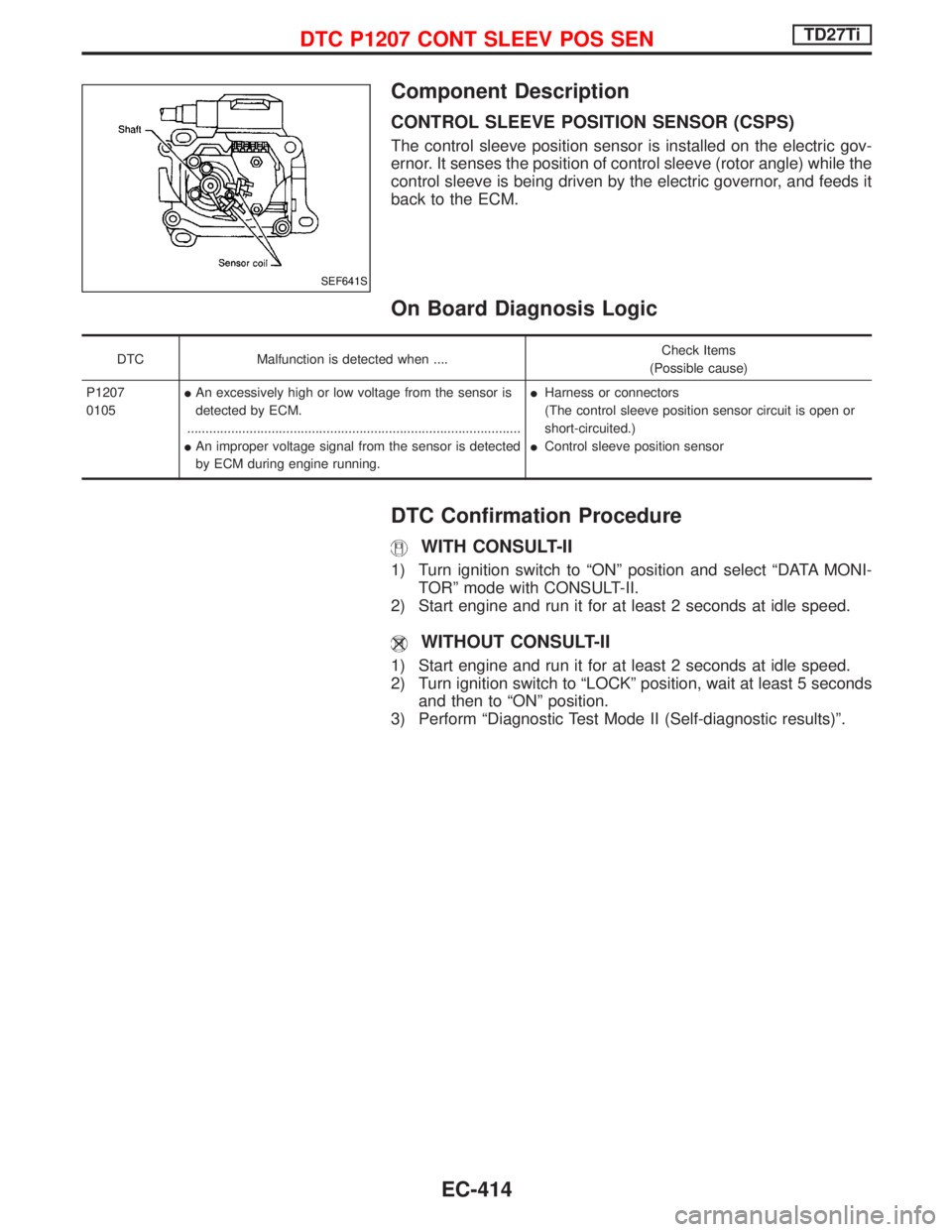

Component Description

CONTROL SLEEVE POSITION SENSOR (CSPS)

The control sleeve position sensor is installed on the electric gov-

ernor. It senses the position of control sleeve (rotor angle) while the

control sleeve is being driven by the electric governor, and feeds it

back to the ECM.

On Board Diagnosis Logic

DTC Malfunction is detected when ....Check Items

(Possible cause)

P1207

0105IAn excessively high or low voltage from the sensor is

detected by ECM.

...........................................................................................

IAn improper voltage signal from the sensor is detected

by ECM during engine running.IHarness or connectors

(The control sleeve position sensor circuit is open or

short-circuited.)

IControl sleeve position sensor

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch to ªONº position and select ªDATA MONI-

TORº mode with CONSULT-II.

2) Start engine and run it for at least 2 seconds at idle speed.

WITHOUT CONSULT-II

1) Start engine and run it for at least 2 seconds at idle speed.

2) Turn ignition switch to ªLOCKº position, wait at least 5 seconds

and then to ªONº position.

3) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º.

SEF641S

DTC P1207 CONT SLEEV POS SENTD27Ti

EC-414

Page 778 of 1767

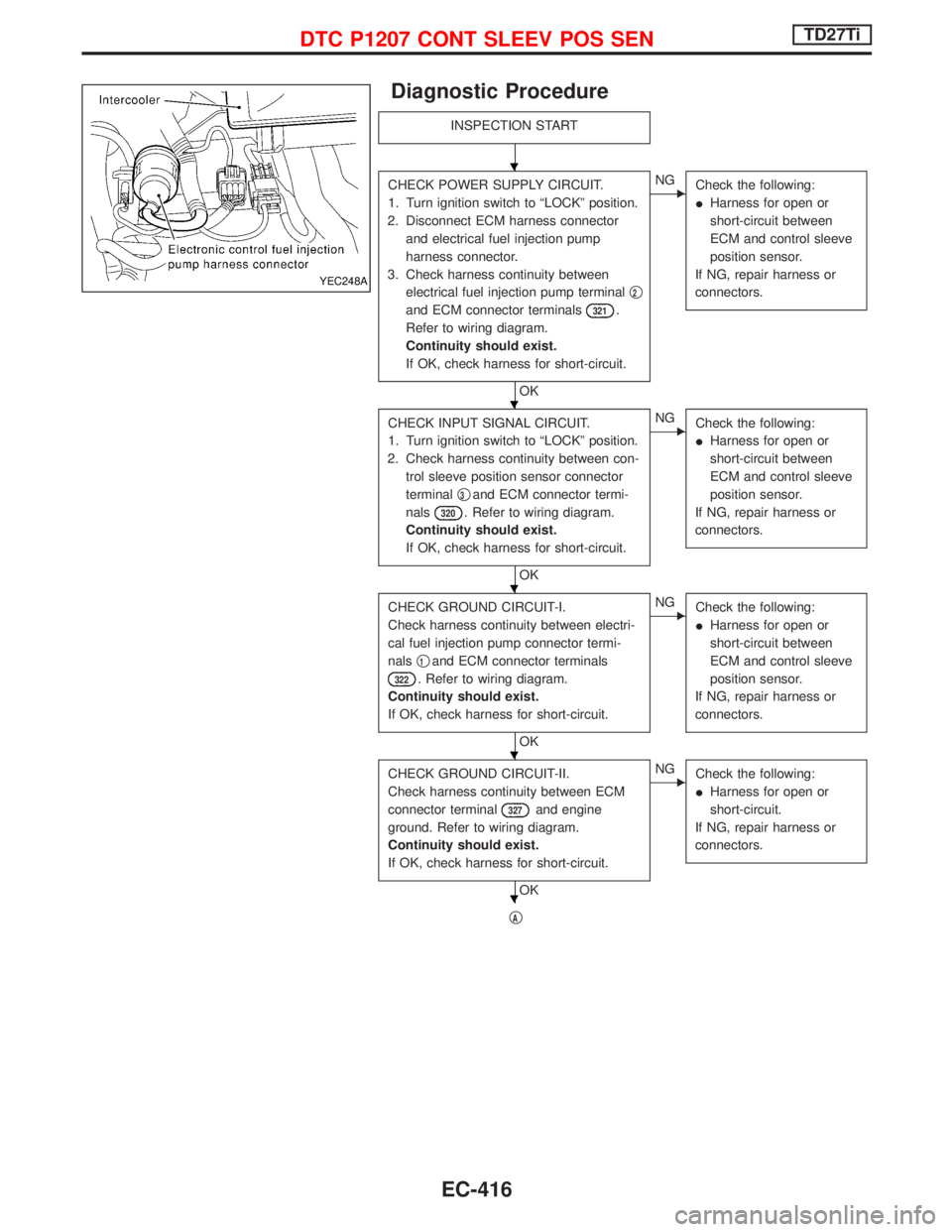

Diagnostic Procedure

INSPECTION START

CHECK POWER SUPPLY CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector

and electrical fuel injection pump

harness connector.

3. Check harness continuity between

electrical fuel injection pump terminalq

2

and ECM connector terminals321.

Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Check harness continuity between con-

trol sleeve position sensor connector

terminalq

3and ECM connector termi-

nals

320. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-I.

Check harness continuity between electri-

cal fuel injection pump connector termi-

nalsq

1and ECM connector terminals

322. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit between

ECM and control sleeve

position sensor.

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT-II.

Check harness continuity between ECM

connector terminal

327and engine

ground. Refer to wiring diagram.

Continuity should exist.

If OK, check harness for short-circuit.

OK

ENG

Check the following:

IHarness for open or

short-circuit.

If NG, repair harness or

connectors.

qA

YEC248A

H

H

H

H

H

DTC P1207 CONT SLEEV POS SENTD27Ti

EC-416