NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 191 of 1767

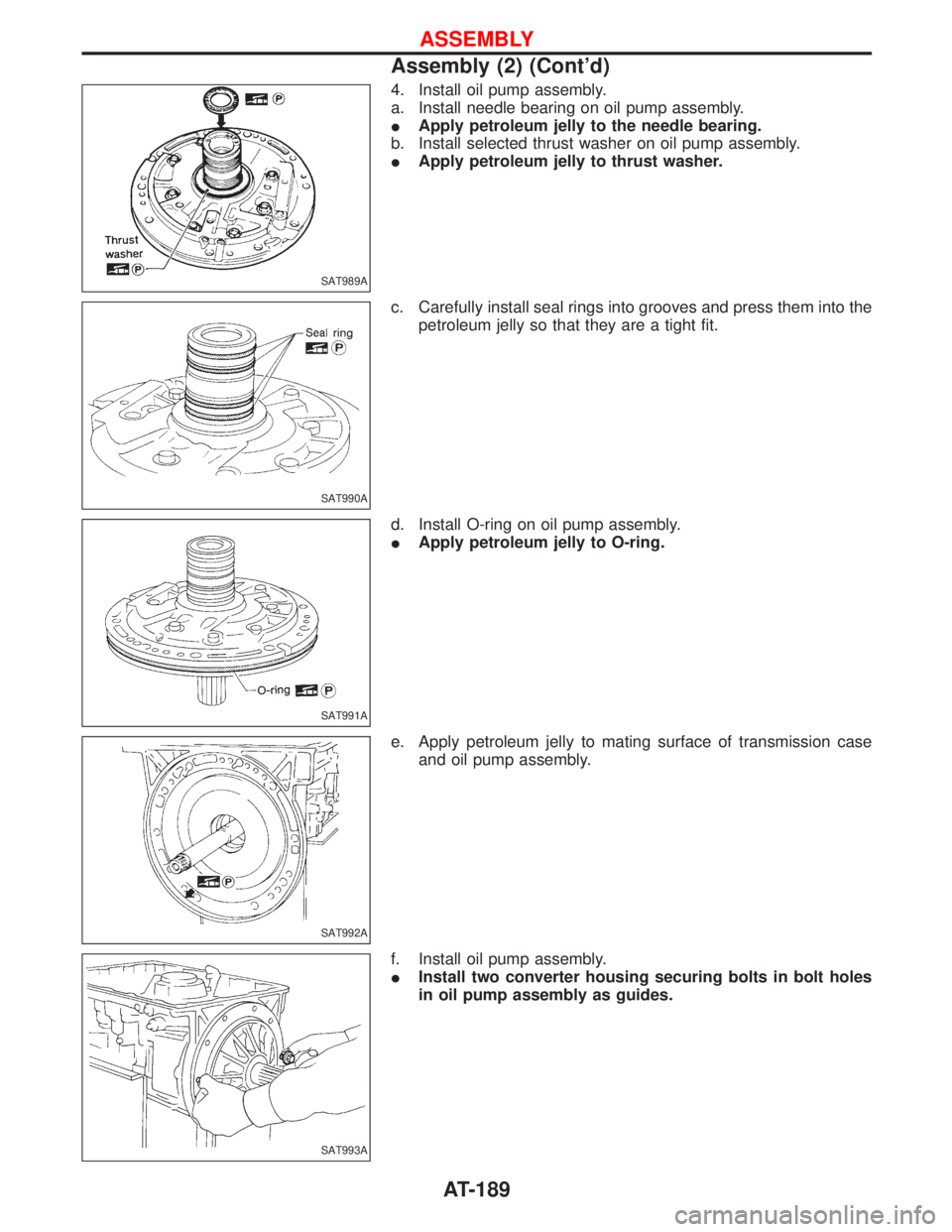

4. Install oil pump assembly.

a. Install needle bearing on oil pump assembly.

IApply petroleum jelly to the needle bearing.

b. Install selected thrust washer on oil pump assembly.

IApply petroleum jelly to thrust washer.

c. Carefully install seal rings into grooves and press them into the

petroleum jelly so that they are a tight fit.

d. Install O-ring on oil pump assembly.

IApply petroleum jelly to O-ring.

e. Apply petroleum jelly to mating surface of transmission case

and oil pump assembly.

f. Install oil pump assembly.

IInstall two converter housing securing bolts in bolt holes

in oil pump assembly as guides.

SAT989A

SAT990A

SAT991A

SAT992A

SAT993A

ASSEMBLY

Assembly (2) (Cont'd)

AT-189

Page 192 of 1767

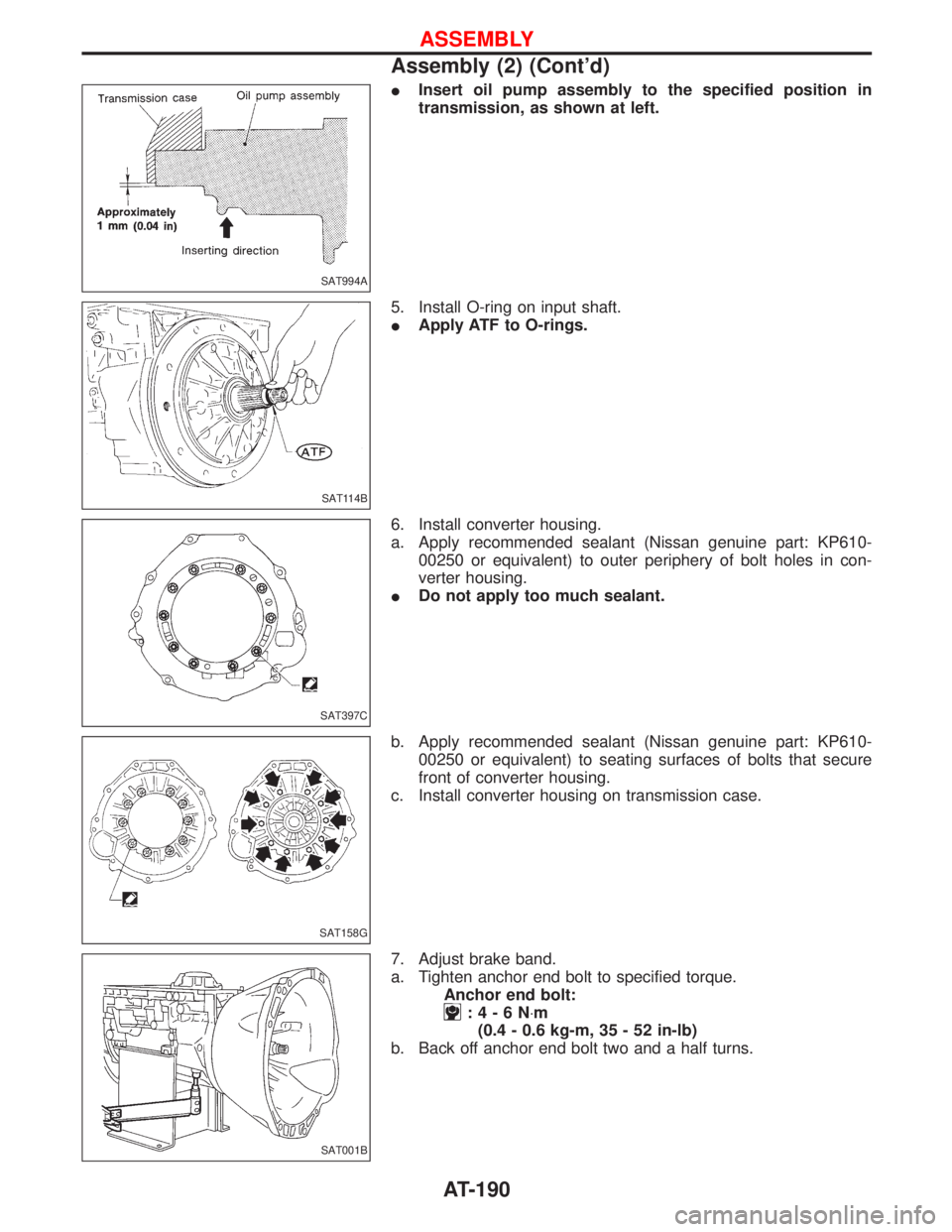

IInsert oil pump assembly to the specified position in

transmission, as shown at left.

5. Install O-ring on input shaft.

IApply ATF to O-rings.

6. Install converter housing.

a. Apply recommended sealant (Nissan genuine part: KP610-

00250 or equivalent) to outer periphery of bolt holes in con-

verter housing.

IDo not apply too much sealant.

b. Apply recommended sealant (Nissan genuine part: KP610-

00250 or equivalent) to seating surfaces of bolts that secure

front of converter housing.

c. Install converter housing on transmission case.

7. Adjust brake band.

a. Tighten anchor end bolt to specified torque.

Anchor end bolt:

:4-6N×m

(0.4 - 0.6 kg-m, 35 - 52 in-lb)

b. Back off anchor end bolt two and a half turns.

SAT994A

SAT114B

SAT397C

SAT158G

SAT001B

ASSEMBLY

Assembly (2) (Cont'd)

AT-190

Page 193 of 1767

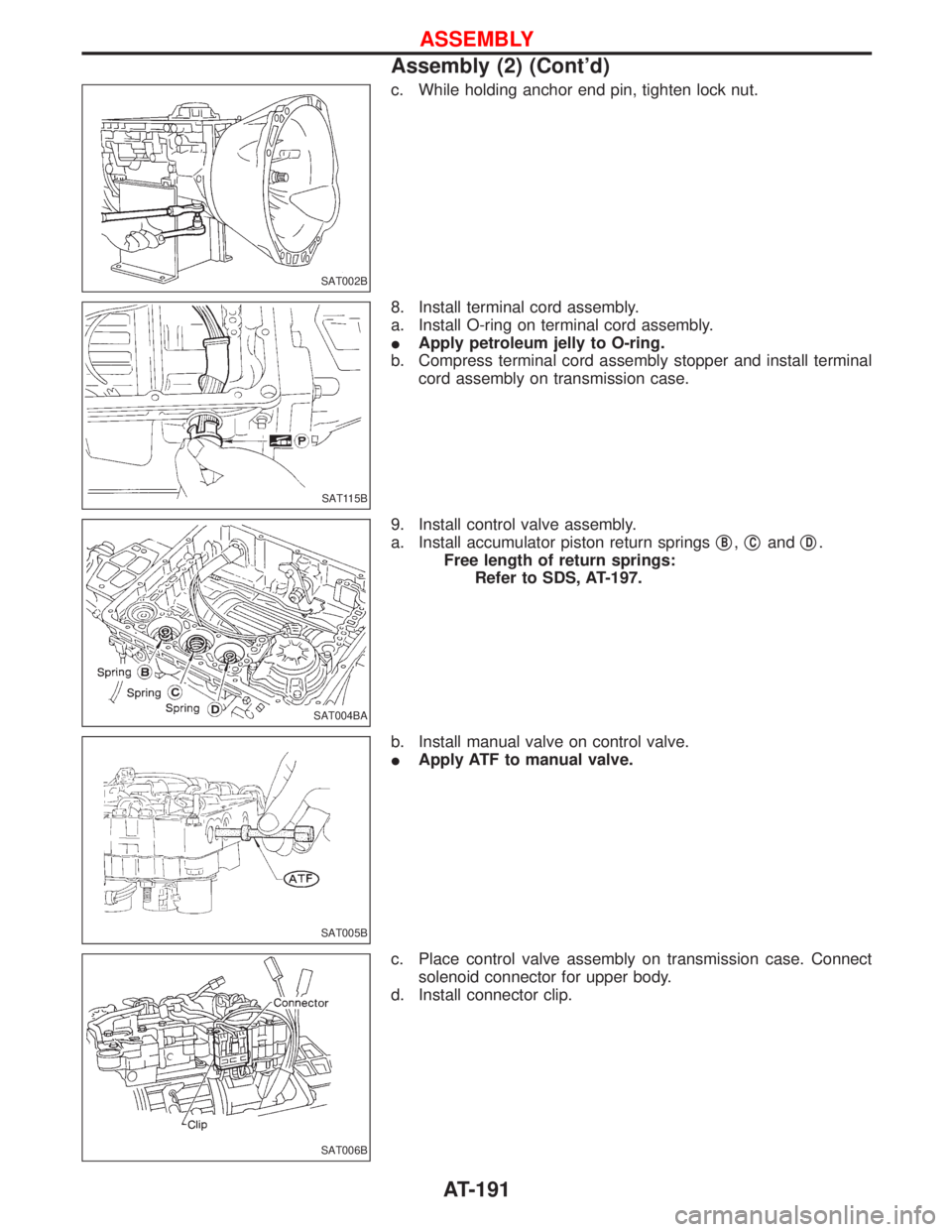

c. While holding anchor end pin, tighten lock nut.

8. Install terminal cord assembly.

a. Install O-ring on terminal cord assembly.

IApply petroleum jelly to O-ring.

b. Compress terminal cord assembly stopper and install terminal

cord assembly on transmission case.

9. Install control valve assembly.

a. Install accumulator piston return springsq

B,qCandqD.

Free length of return springs:

Refer to SDS, AT-197.

b. Install manual valve on control valve.

IApply ATF to manual valve.

c. Place control valve assembly on transmission case. Connect

solenoid connector for upper body.

d. Install connector clip.

SAT002B

SAT115B

SAT004BA

SAT005B

SAT006B

ASSEMBLY

Assembly (2) (Cont'd)

AT-191

Page 194 of 1767

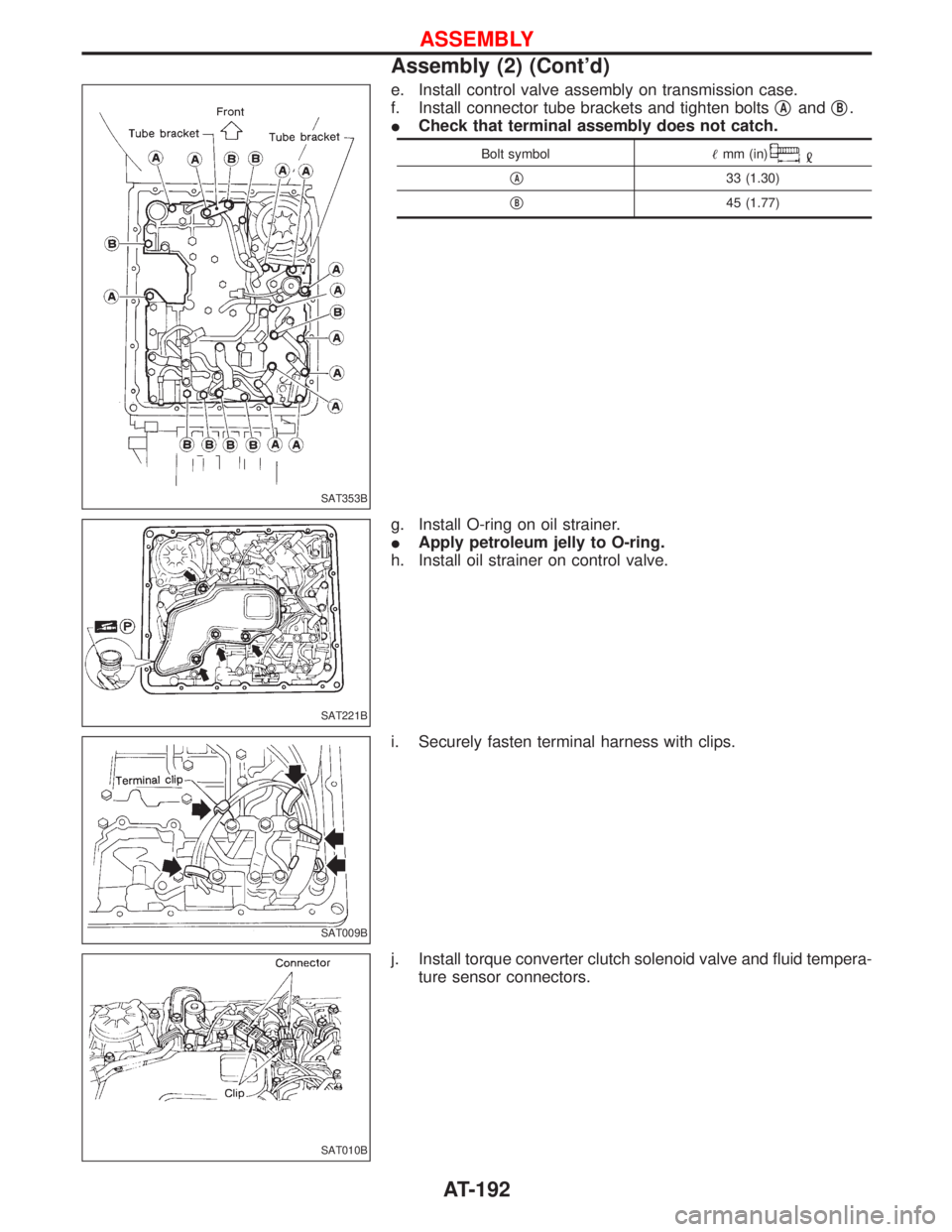

e. Install control valve assembly on transmission case.

f. Install connector tube brackets and tighten boltsq

AandqB.

ICheck that terminal assembly does not catch.

Bolt symbolmm (in)

qA33 (1.30)

q

B45 (1.77)

g. Install O-ring on oil strainer.

IApply petroleum jelly to O-ring.

h. Install oil strainer on control valve.

i. Securely fasten terminal harness with clips.

j. Install torque converter clutch solenoid valve and fluid tempera-

ture sensor connectors.

SAT353B

SAT221B

SAT009B

SAT010B

ASSEMBLY

Assembly (2) (Cont'd)

AT-192

Page 195 of 1767

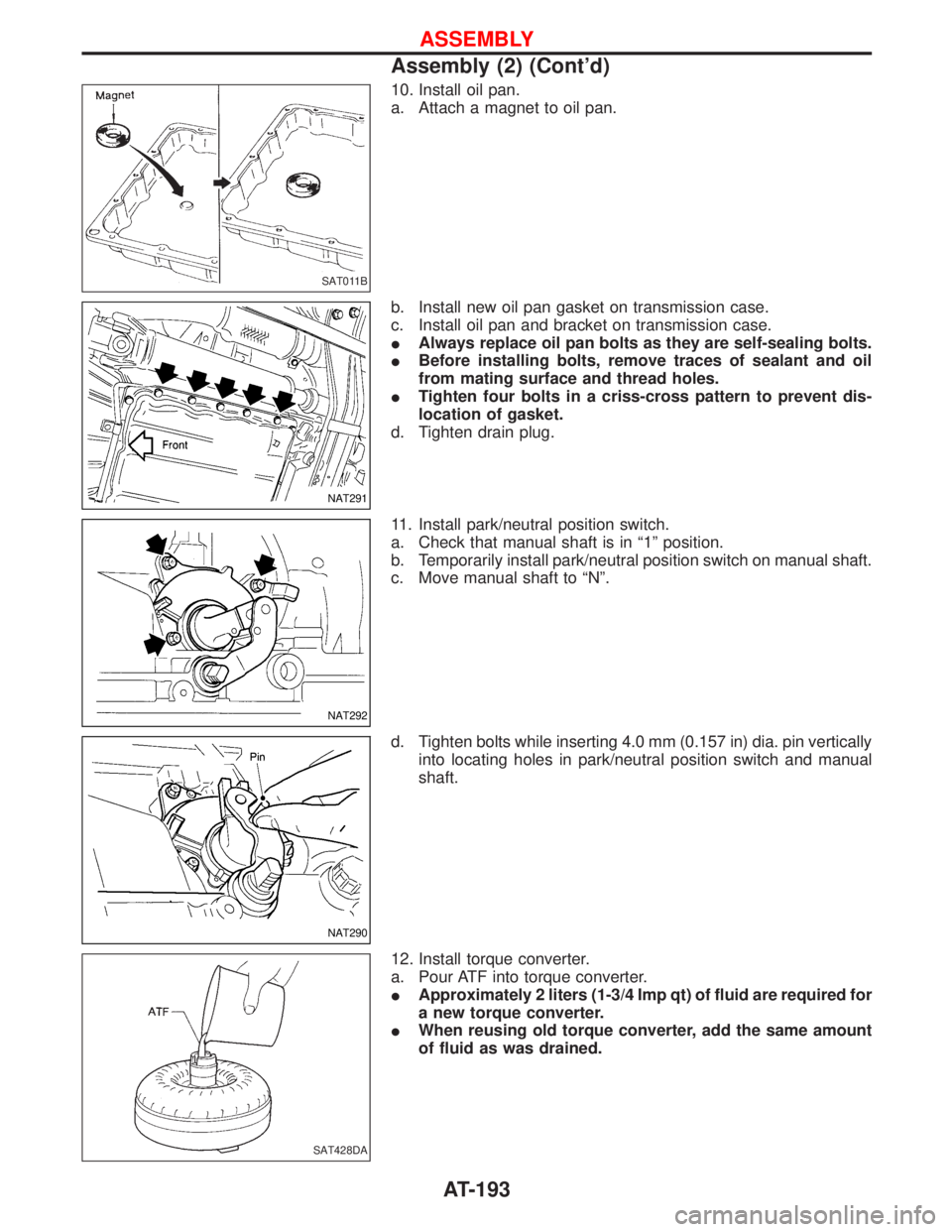

10. Install oil pan.

a. Attach a magnet to oil pan.

b. Install new oil pan gasket on transmission case.

c. Install oil pan and bracket on transmission case.

IAlways replace oil pan bolts as they are self-sealing bolts.

IBefore installing bolts, remove traces of sealant and oil

from mating surface and thread holes.

ITighten four bolts in a criss-cross pattern to prevent dis-

location of gasket.

d. Tighten drain plug.

11. Install park/neutral position switch.

a. Check that manual shaft is in ª1º position.

b. Temporarily install park/neutral position switch on manual shaft.

c. Move manual shaft to ªNº.

d. Tighten bolts while inserting 4.0 mm (0.157 in) dia. pin vertically

into locating holes in park/neutral position switch and manual

shaft.

12. Install torque converter.

a. Pour ATF into torque converter.

IApproximately 2 liters (1-3/4 Imp qt) of fluid are required for

a new torque converter.

IWhen reusing old torque converter, add the same amount

of fluid as was drained.

SAT011B

NAT291

NAT292

NAT290

SAT428DA

ASSEMBLY

Assembly (2) (Cont'd)

AT-193

Page 196 of 1767

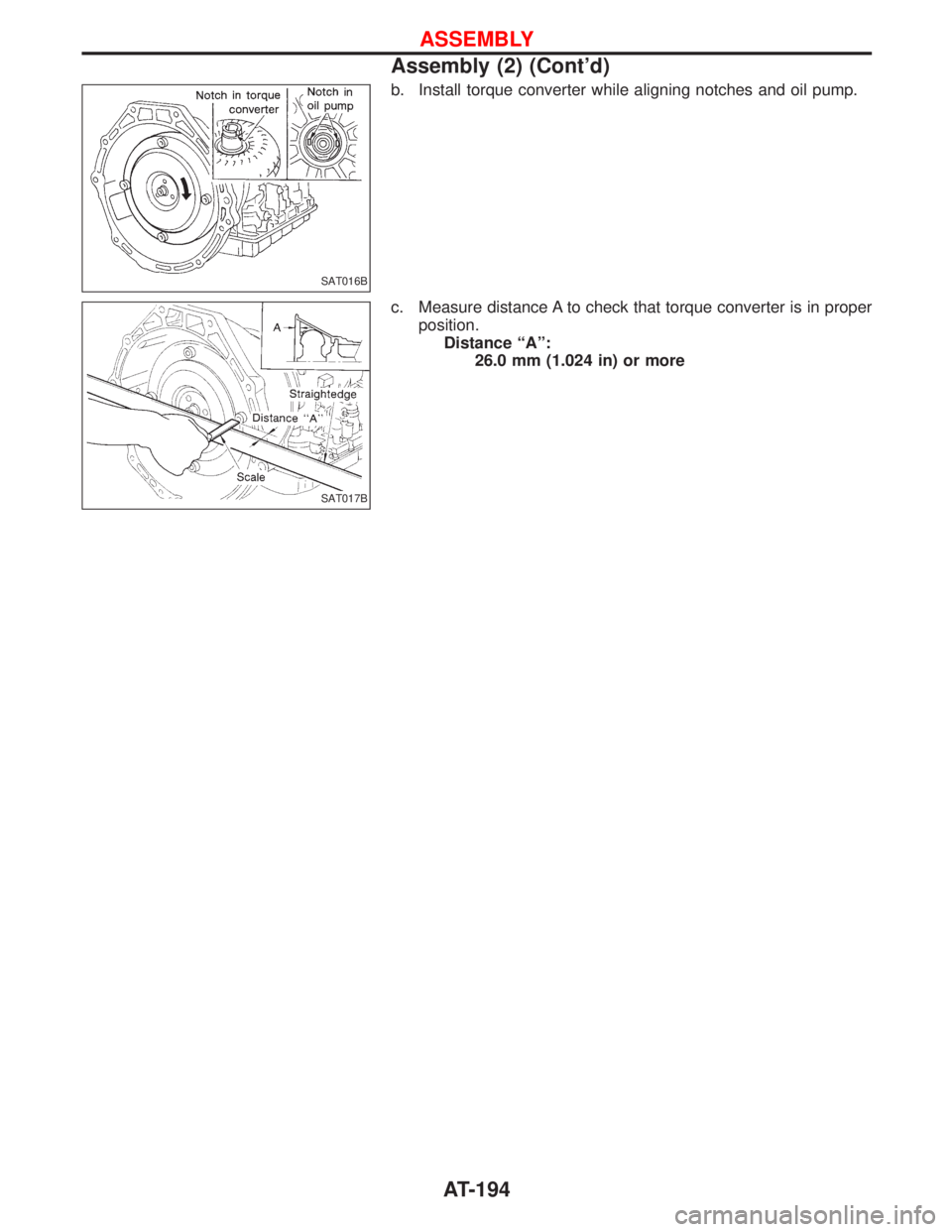

b. Install torque converter while aligning notches and oil pump.

c. Measure distance A to check that torque converter is in proper

position.

Distance ªAº:

26.0 mm (1.024 in) or more

SAT016B

SAT017B

ASSEMBLY

Assembly (2) (Cont'd)

AT-194

Page 197 of 1767

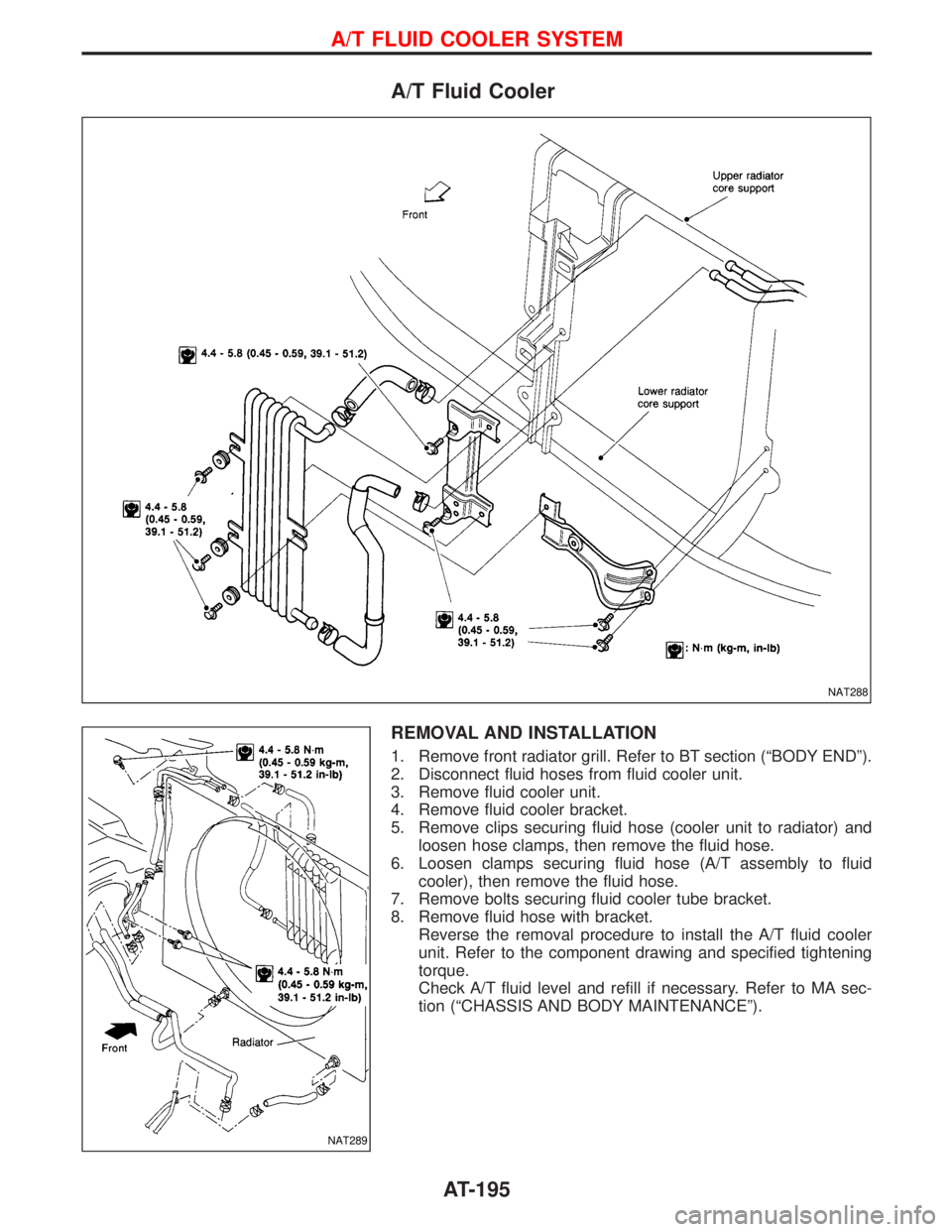

A/T Fluid Cooler

REMOVAL AND INSTALLATION

1. Remove front radiator grill. Refer to BT section (ªBODY ENDº).

2. Disconnect fluid hoses from fluid cooler unit.

3. Remove fluid cooler unit.

4. Remove fluid cooler bracket.

5. Remove clips securing fluid hose (cooler unit to radiator) and

loosen hose clamps, then remove the fluid hose.

6. Loosen clamps securing fluid hose (A/T assembly to fluid

cooler), then remove the fluid hose.

7. Remove bolts securing fluid cooler tube bracket.

8. Remove fluid hose with bracket.

Reverse the removal procedure to install the A/T fluid cooler

unit. Refer to the component drawing and specified tightening

torque.

Check A/T fluid level and refill if necessary. Refer to MA sec-

tion (ªCHASSIS AND BODY MAINTENANCEº).

NAT288

NAT289

A/T FLUID COOLER SYSTEM

AT-195

Page 198 of 1767

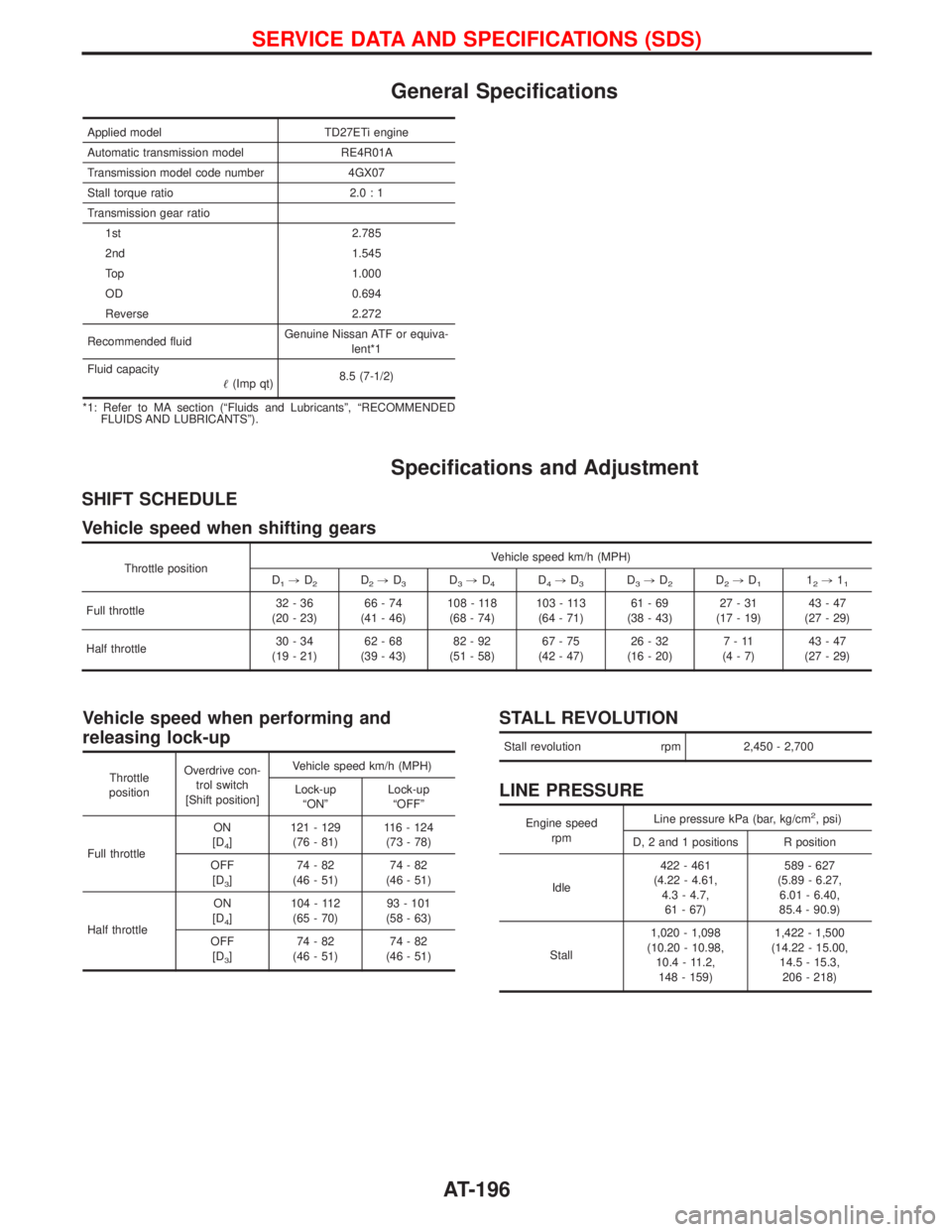

General Specifications

Applied model TD27ETi engine

Automatic transmission model RE4R01A

Transmission model code number 4GX07

Stall torque ratio 2.0 : 1

Transmission gear ratio

1st 2.785

2nd 1.545

Top 1.000

OD 0.694

Reverse 2.272

Recommended fluidGenuine Nissan ATF or equiva-

lent*1

Fluid capacity

(Imp qt)8.5 (7-1/2)

*1: Refer to MA section (ªFluids and Lubricantsº, ªRECOMMENDED

FLUIDS AND LUBRICANTSº).

Specifications and Adjustment

SHIFT SCHEDULE

Vehicle speed when shifting gears

Throttle positionVehicle speed km/h (MPH)

D1,D2D2,D3D3,D4D4,D3D3,D2D2,D112,11

Full throttle32-36

(20 - 23)66-74

(41 - 46)108 - 118

(68 - 74)103 - 113

(64 - 71)61-69

(38 - 43)27-31

(17 - 19)43-47

(27 - 29)

Half throttle30-34

(19 - 21)62-68

(39 - 43)82-92

(51 - 58)67-75

(42 - 47)26-32

(16 - 20)7-11

(4-7)43-47

(27 - 29)

Vehicle speed when performing and

releasing lock-up

Throttle

positionOverdrive con-

trol switch

[Shift position]Vehicle speed km/h (MPH)

Lock-up

ªONºLock-up

ªOFFº

Full throttleON

[D

4]121 - 129

(76 - 81)116 - 124

(73 - 78)

OFF

[D

3]74-82

(46 - 51)74-82

(46 - 51)

Half throttleON

[D

4]104 - 112

(65 - 70)93 - 101

(58 - 63)

OFF

[D

3]74-82

(46 - 51)74-82

(46 - 51)

STALL REVOLUTION

Stall revolution rpm 2,450 - 2,700

LINE PRESSURE

Engine speed

rpmLine pressure kPa (bar, kg/cm2, psi)

D, 2 and 1 positions R position

Idle422 - 461

(4.22 - 4.61,

4.3 - 4.7,

61 - 67)589 - 627

(5.89 - 6.27,

6.01 - 6.40,

85.4 - 90.9)

Stall1,020 - 1,098

(10.20 - 10.98,

10.4 - 11.2,

148 - 159)1,422 - 1,500

(14.22 - 15.00,

14.5 - 15.3,

206 - 218)

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-196

Page 199 of 1767

RETURN SPRINGSUnit: mm (in)

PartsItem

Part No. Free length Outer diameter

Control

valveUpper

bodyTorque converter relief valve

springq

131742-41X23 38.0 (1.496) 9.0 (0.354)

Pressure regulator valve

springq

231742-41X24 44.02 (1.7331) 14.0 (0.551)

Pressure modifier valve

springq

331742-41X19 31.95 (1.2579) 6.8 (0.268)

Accumulator control valve

springÐÐÐÐ

Shuttle shift valve D springq

431762-41X01 25.0 (0.984) 7.0 (0.276)

4-2 sequence valve springq

531756-41X00 29.1 (1.146) 6.95 (0.2736)

Shift valve B springq

631762-41X01 25.0 (0.984) 7.0 (0.276)

4-2 relay valve springq

731756-41X00 29.1 (1.146) 6.95 (0.2736)

Shift valve A springq

831762-41X01 25.0 (0.984) 7.0 (0.276)

Overrun clutch control valve

springq

931762-41X03 23.6 (0.929) 7.0 (0.276)

Overrun clutch reducing

valve springq

1031742-41X20 32.5 (1.280) 7.0 (0.276)

Shuttle shift valve S springq

1131762-41X04 51.0 (2.008) 5.65 (0.2224)

Pilot valve springq

1231742-41X13 25.7 (1.012) 9.0 (0.354)

Torque converter clutch con-

trol valve springq

1331742-41X22 18.5 (0.728) 13.0 (0.512)

Lower

bodyModifier accumulator

piston springq

131742-27X70 31.4 (1.236) 9.8 (0.386)

1st reducing valve springq

231756-41X05 25.4 (1.000) 6.75 (0.2657)

3-2 timing valve springq

331742-41X06 23.0 (0.906) 6.7 (0.264)

Servo charger valve springq

431742-41X06 23.0 (0.906) 6.7 (0.264)

Reverse clutch 16 pcs 31521-41X02 (Assembly) 19.69 (0.7752) 11.6 (0.457)

High clutch 10 pcs 31521-41X03 (Assembly) 24.2 (0.953) 11.6 (0.457)

Forward clutch

(Overrun clutch)20 pcs 32521-41X00 (Assembly) 35.77 (1.4083) 9.7 (0.382)

Low & reverse

brake18 pcs 31655-41X00 (Assembly) 22.3 (0.878) 11.2 (0.441)

Band servoSpringq

A31605-41X05 45.6 (1.795) 34.3 (1.350)

Springq

B31605-41X00 53.8 (2.118) 40.3 (1.587)

Springq

C31605-41X01 29.7 (1.169) 27.6 (1.087)

AccumulatorAccumulatorq

A31605-41X02 43.0 (1.693) 18.0 (0.709)

Accumulatorq

B31605-41X10 66.0 (2.598) 20.0 (0.787)

Accumulatorq

C31605-41X09 45.0 (1.772) 29.3 (1.154)

Accumulatorq

D31605-41X06 58.4 (2.299) 17.3 (0.681)

ACCUMULATOR O-RING

AccumulatorDiameter mm (in)

qAqBqCqD

Small diameter end 29 (1.14) 32 (1.26) 45 (1.77) 29 (1.14)

Large diameter end 45 (1.77) 50 (1.97) 50 (1.97) 45 (1.77)

SERVICE DATA AND SPECIFICATIONS (SDS)

Specifications and Adjustment (Cont'd)

AT-197

Page 200 of 1767

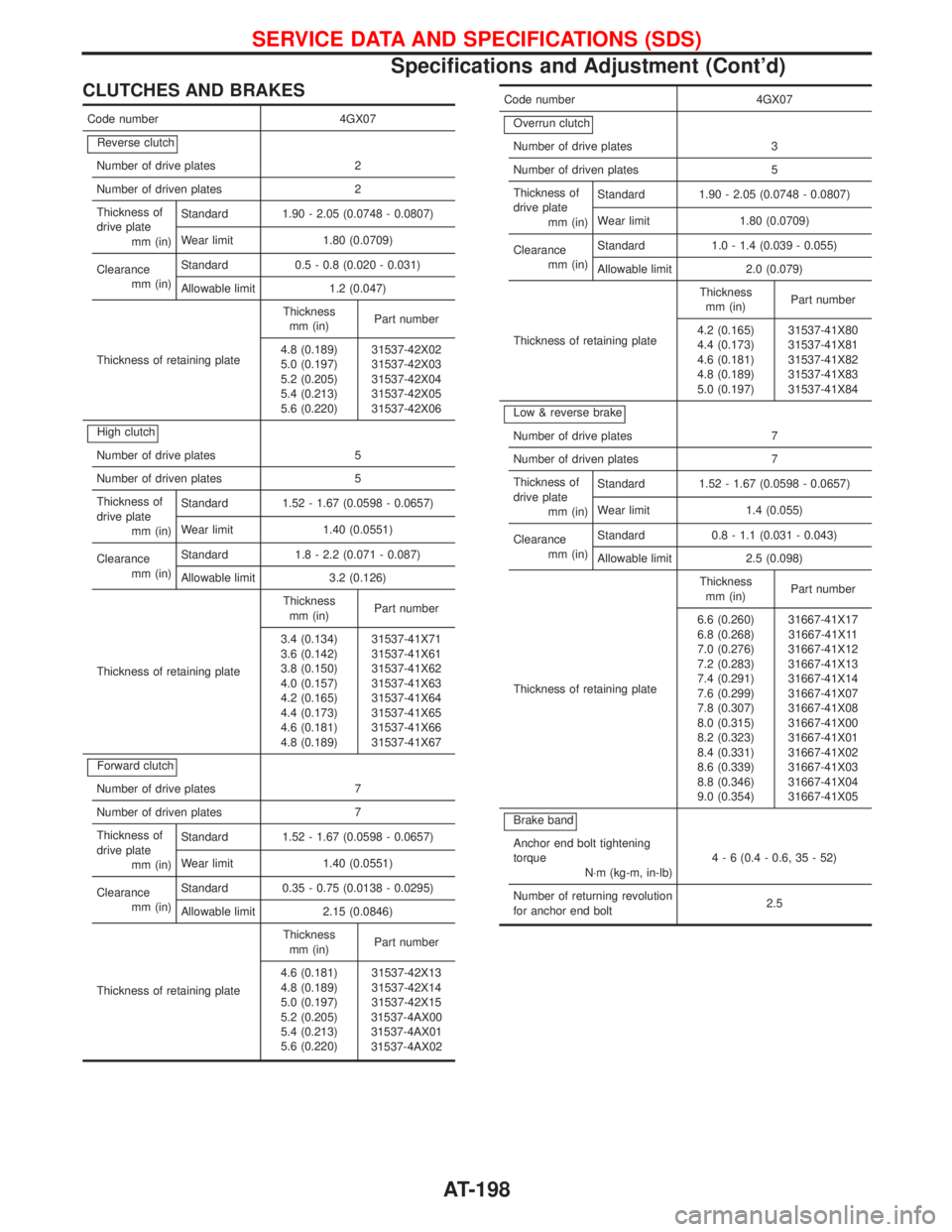

CLUTCHES AND BRAKES

Code number 4GX07

Reverse clutch

Number of drive plates 2

Number of driven plates 2

Thickness of

drive plate

mm (in)Standard 1.90 - 2.05 (0.0748 - 0.0807)

Wear limit 1.80 (0.0709)

Clearance

mm (in)Standard 0.5 - 0.8 (0.020 - 0.031)

Allowable limit 1.2 (0.047)

Thickness of retaining plateThickness

mm (in)Part number

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)31537-42X02

31537-42X03

31537-42X04

31537-42X05

31537-42X06

High clutch

Number of drive plates 5

Number of driven plates 5

Thickness of

drive plate

mm (in)Standard 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.40 (0.0551)

Clearance

mm (in)Standard 1.8 - 2.2 (0.071 - 0.087)

Allowable limit 3.2 (0.126)

Thickness of retaining plateThickness

mm (in)Part number

3.4 (0.134)

3.6 (0.142)

3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)31537-41X71

31537-41X61

31537-41X62

31537-41X63

31537-41X64

31537-41X65

31537-41X66

31537-41X67

Forward clutch

Number of drive plates 7

Number of driven plates 7

Thickness of

drive plate

mm (in)Standard 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.40 (0.0551)

Clearance

mm (in)Standard 0.35 - 0.75 (0.0138 - 0.0295)

Allowable limit 2.15 (0.0846)

Thickness of retaining plateThickness

mm (in)Part number

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)

5.4 (0.213)

5.6 (0.220)31537-42X13

31537-42X14

31537-42X15

31537-4AX00

31537-4AX01

31537-4AX02

Code number 4GX07

Overrun clutch

Number of drive plates 3

Number of driven plates 5

Thickness of

drive plate

mm (in)Standard 1.90 - 2.05 (0.0748 - 0.0807)

Wear limit 1.80 (0.0709)

Clearance

mm (in)Standard 1.0 - 1.4 (0.039 - 0.055)

Allowable limit 2.0 (0.079)

Thickness of retaining plateThickness

mm (in)Part number

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)31537-41X80

31537-41X81

31537-41X82

31537-41X83

31537-41X84

Low & reverse brake

Number of drive plates 7

Number of driven plates 7

Thickness of

drive plate

mm (in)Standard 1.52 - 1.67 (0.0598 - 0.0657)

Wear limit 1.4 (0.055)

Clearance

mm (in)Standard 0.8 - 1.1 (0.031 - 0.043)

Allowable limit 2.5 (0.098)

Thickness of retaining plateThickness

mm (in)Part number

6.6 (0.260)

6.8 (0.268)

7.0 (0.276)

7.2 (0.283)

7.4 (0.291)

7.6 (0.299)

7.8 (0.307)

8.0 (0.315)

8.2 (0.323)

8.4 (0.331)

8.6 (0.339)

8.8 (0.346)

9.0 (0.354)31667-41X17

31667-41X11

31667-41X12

31667-41X13

31667-41X14

31667-41X07

31667-41X08

31667-41X00

31667-41X01

31667-41X02

31667-41X03

31667-41X04

31667-41X05

Brake band

Anchor end bolt tightening

torque

N×m (kg-m, in-lb)4 - 6 (0.4 - 0.6, 35 - 52)

Number of returning revolution

for anchor end bolt2.5

SERVICE DATA AND SPECIFICATIONS (SDS)

Specifications and Adjustment (Cont'd)

AT-198