NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: belt, fuel pressure, driver seat adjustment, keyless, brakes, coolant, service reset

Page 181 of 1767

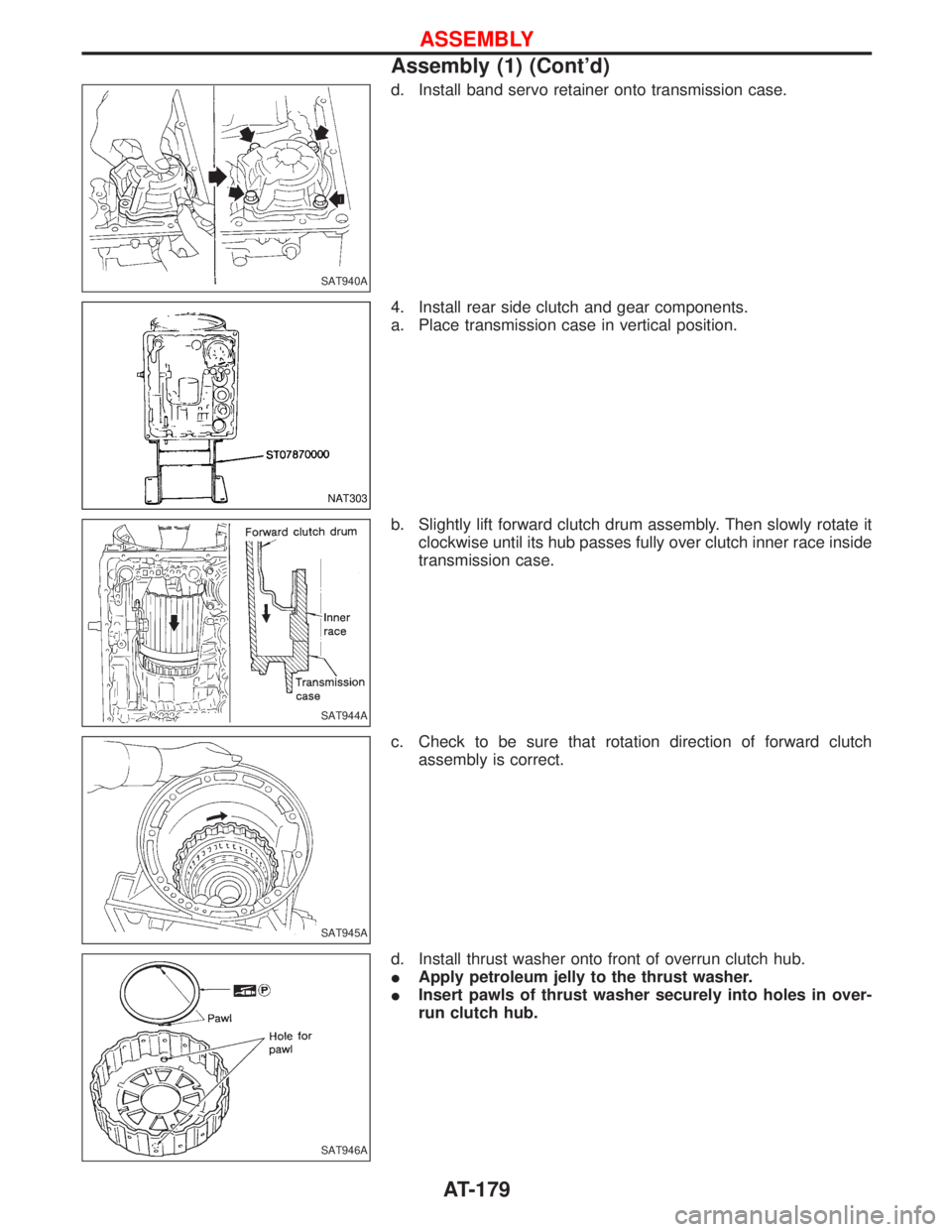

d. Install band servo retainer onto transmission case.

4. Install rear side clutch and gear components.

a. Place transmission case in vertical position.

b. Slightly lift forward clutch drum assembly. Then slowly rotate it

clockwise until its hub passes fully over clutch inner race inside

transmission case.

c. Check to be sure that rotation direction of forward clutch

assembly is correct.

d. Install thrust washer onto front of overrun clutch hub.

IApply petroleum jelly to the thrust washer.

IInsert pawls of thrust washer securely into holes in over-

run clutch hub.

SAT940A

NAT303

SAT944A

SAT945A

SAT946A

ASSEMBLY

Assembly (1) (Cont'd)

AT-179

Page 182 of 1767

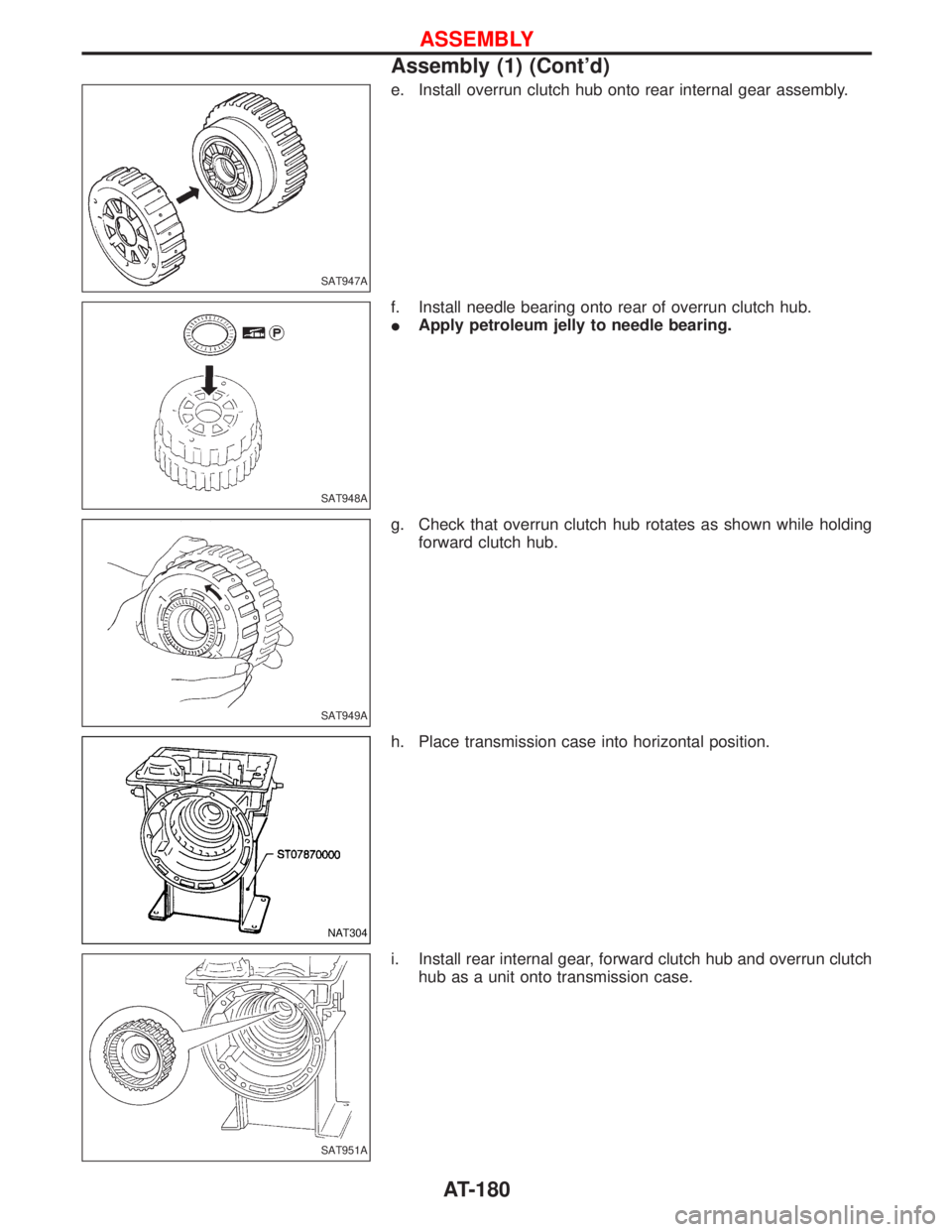

e. Install overrun clutch hub onto rear internal gear assembly.

f. Install needle bearing onto rear of overrun clutch hub.

IApply petroleum jelly to needle bearing.

g. Check that overrun clutch hub rotates as shown while holding

forward clutch hub.

h. Place transmission case into horizontal position.

i. Install rear internal gear, forward clutch hub and overrun clutch

hub as a unit onto transmission case.

SAT947A

SAT948A

SAT949A

NAT304

SAT951A

ASSEMBLY

Assembly (1) (Cont'd)

AT-180

Page 183 of 1767

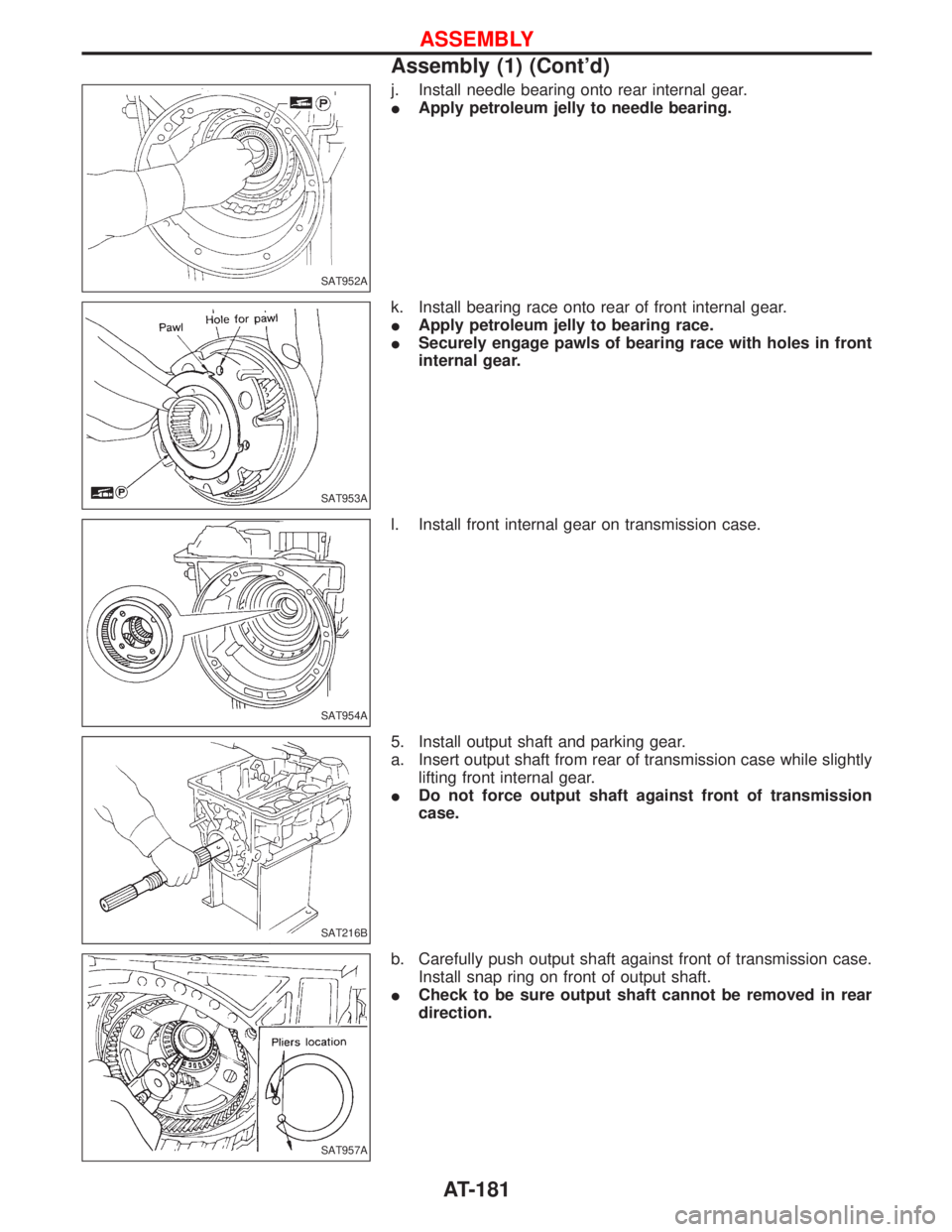

j. Install needle bearing onto rear internal gear.

IApply petroleum jelly to needle bearing.

k. Install bearing race onto rear of front internal gear.

IApply petroleum jelly to bearing race.

ISecurely engage pawls of bearing race with holes in front

internal gear.

l. Install front internal gear on transmission case.

5. Install output shaft and parking gear.

a. Insert output shaft from rear of transmission case while slightly

lifting front internal gear.

IDo not force output shaft against front of transmission

case.

b. Carefully push output shaft against front of transmission case.

Install snap ring on front of output shaft.

ICheck to be sure output shaft cannot be removed in rear

direction.

SAT952A

SAT953A

SAT954A

SAT216B

SAT957A

ASSEMBLY

Assembly (1) (Cont'd)

AT-181

Page 184 of 1767

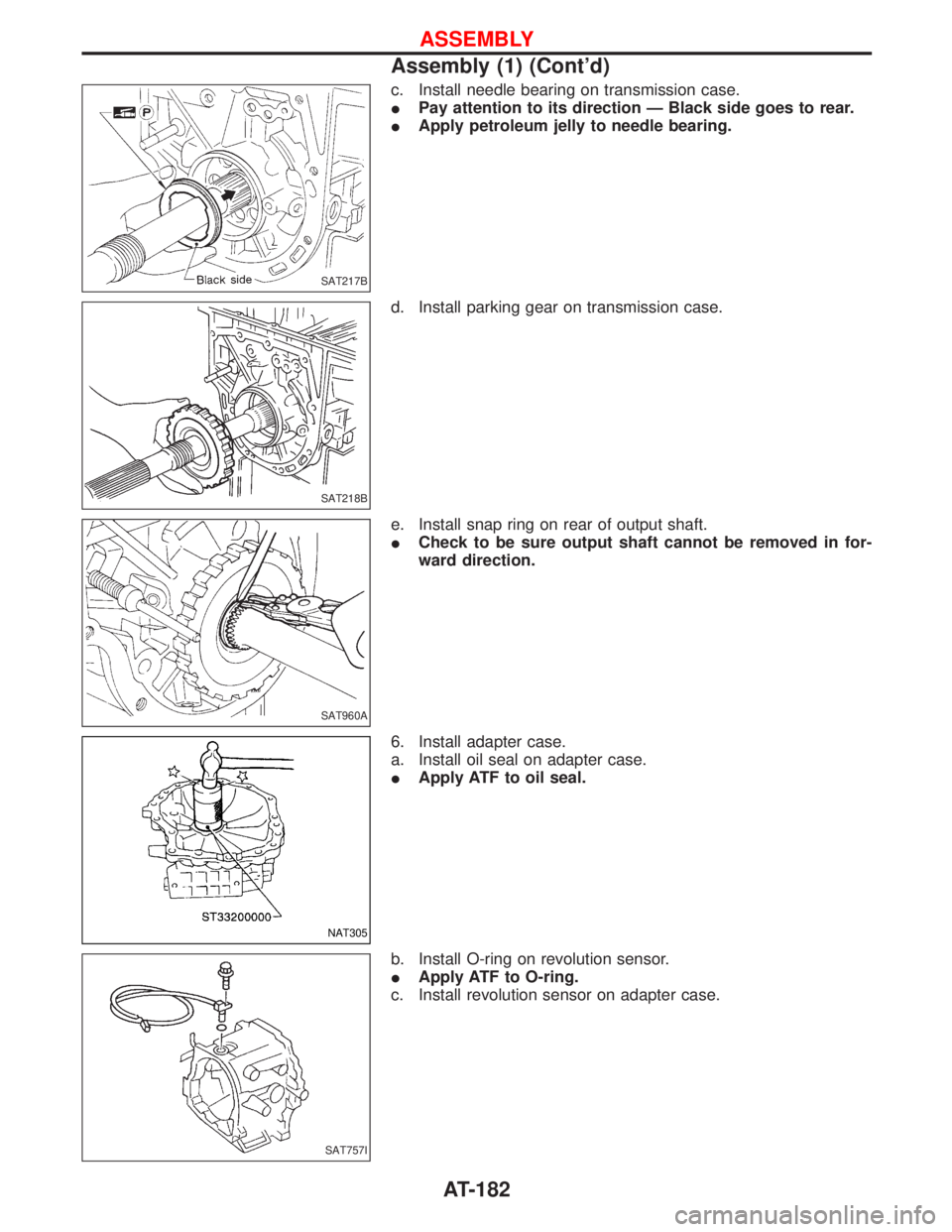

c. Install needle bearing on transmission case.

IPay attention to its direction Ð Black side goes to rear.

IApply petroleum jelly to needle bearing.

d. Install parking gear on transmission case.

e. Install snap ring on rear of output shaft.

ICheck to be sure output shaft cannot be removed in for-

ward direction.

6. Install adapter case.

a. Install oil seal on adapter case.

IApply ATF to oil seal.

b. Install O-ring on revolution sensor.

IApply ATF to O-ring.

c. Install revolution sensor on adapter case.

SAT217B

SAT218B

SAT960A

NAT305

SAT757I

ASSEMBLY

Assembly (1) (Cont'd)

AT-182

Page 185 of 1767

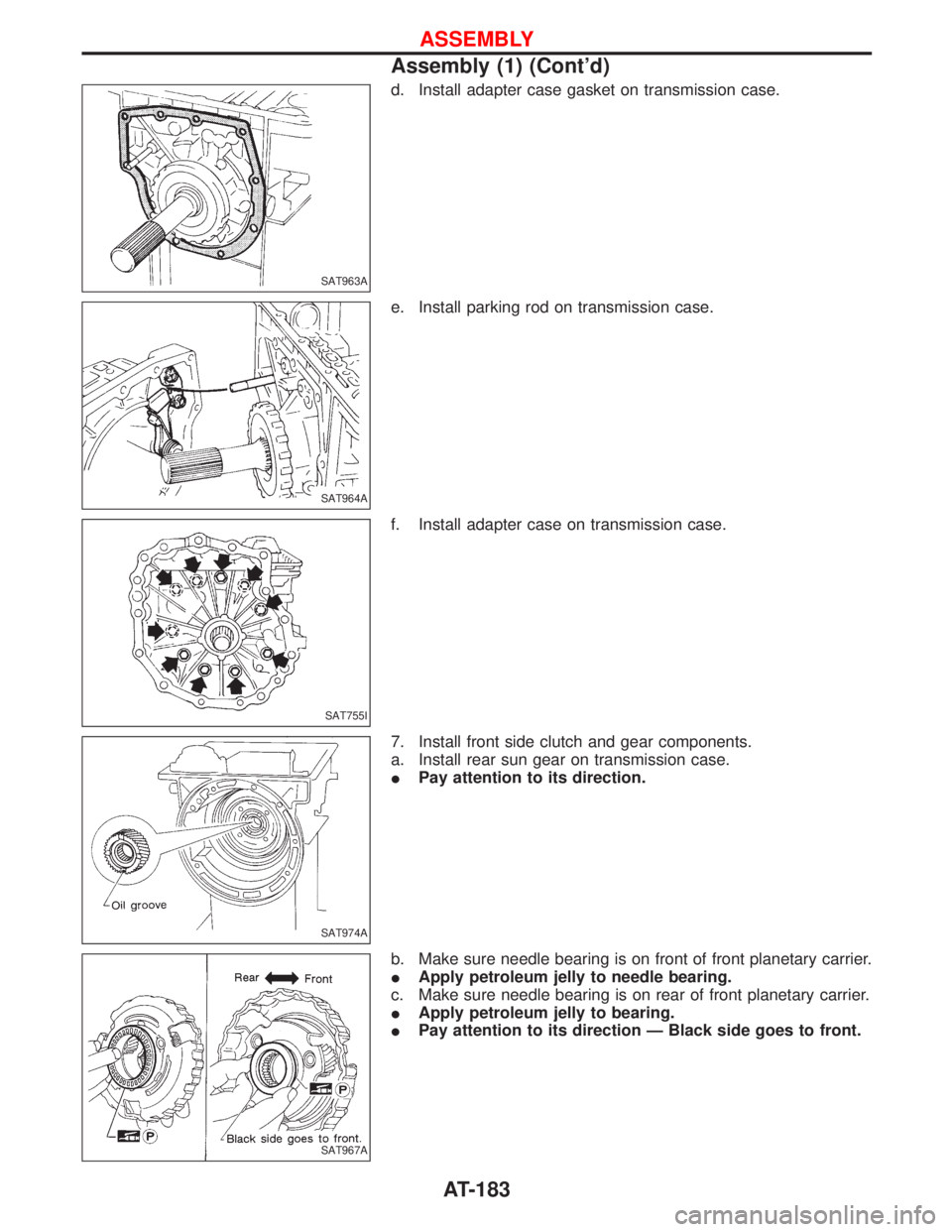

d. Install adapter case gasket on transmission case.

e. Install parking rod on transmission case.

f. Install adapter case on transmission case.

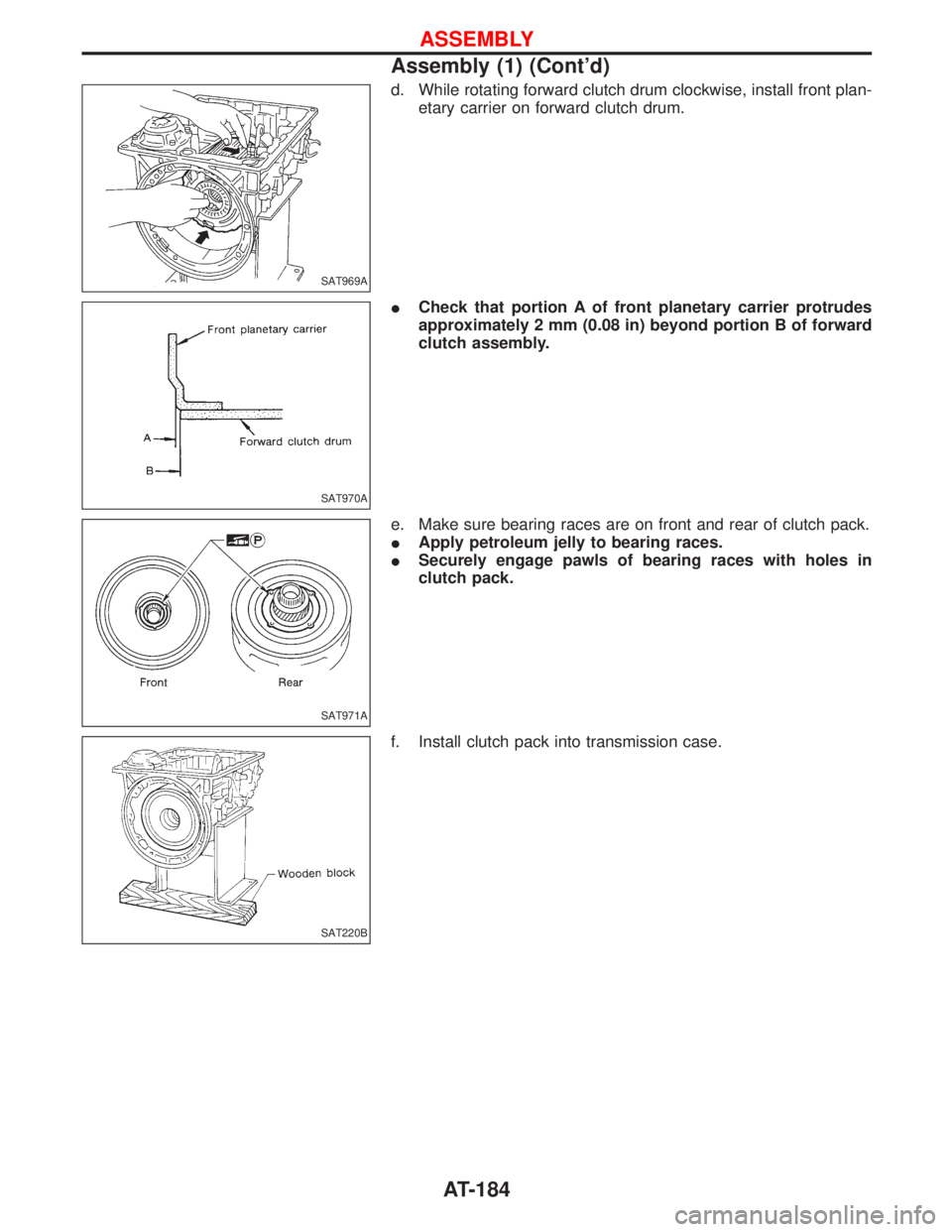

7. Install front side clutch and gear components.

a. Install rear sun gear on transmission case.

IPay attention to its direction.

b. Make sure needle bearing is on front of front planetary carrier.

IApply petroleum jelly to needle bearing.

c. Make sure needle bearing is on rear of front planetary carrier.

IApply petroleum jelly to bearing.

IPay attention to its direction Ð Black side goes to front.

SAT963A

SAT964A

SAT755I

SAT974A

SAT967A

ASSEMBLY

Assembly (1) (Cont'd)

AT-183

Page 186 of 1767

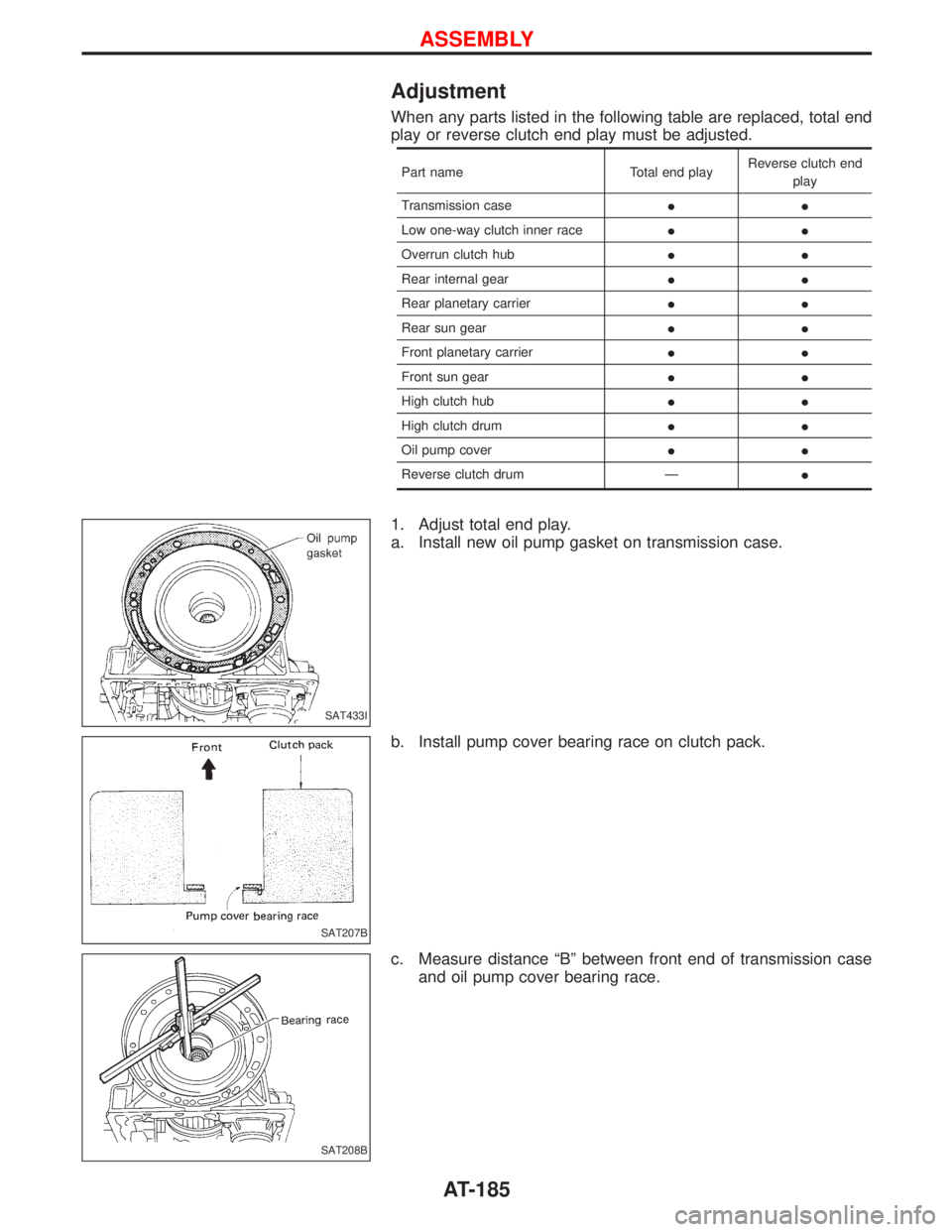

d. While rotating forward clutch drum clockwise, install front plan-

etary carrier on forward clutch drum.

ICheck that portion A of front planetary carrier protrudes

approximately 2 mm (0.08 in) beyond portion B of forward

clutch assembly.

e. Make sure bearing races are on front and rear of clutch pack.

IApply petroleum jelly to bearing races.

ISecurely engage pawls of bearing races with holes in

clutch pack.

f. Install clutch pack into transmission case.

SAT969A

SAT970A

SAT971A

SAT220B

ASSEMBLY

Assembly (1) (Cont'd)

AT-184

Page 187 of 1767

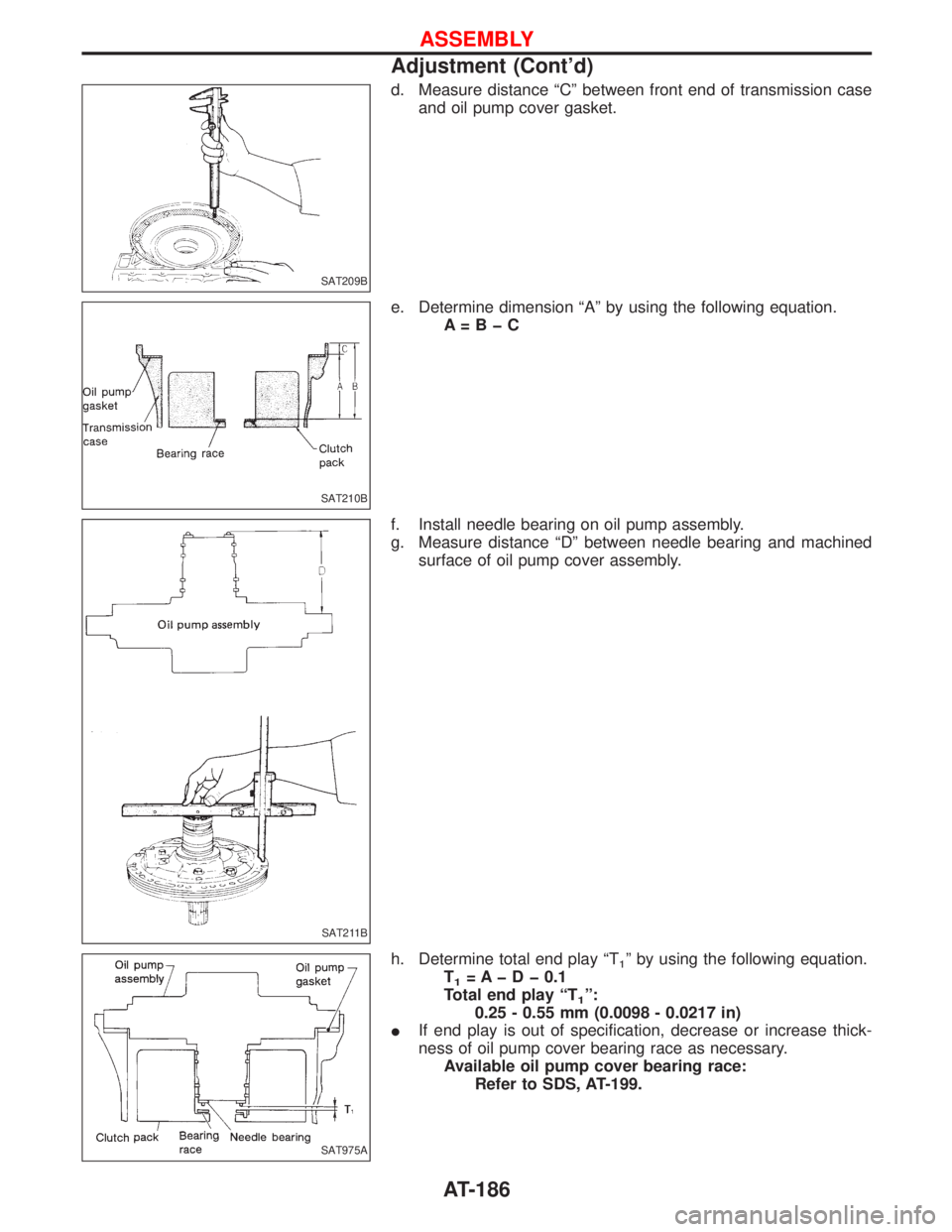

Adjustment

When any parts listed in the following table are replaced, total end

play or reverse clutch end play must be adjusted.

Part name Total end playReverse clutch end

play

Transmission caseII

Low one-way clutch inner raceII

Overrun clutch hubII

Rear internal gearII

Rear planetary carrierII

Rear sun gearII

Front planetary carrierII

Front sun gearII

High clutch hubII

High clutch drumII

Oil pump coverII

Reverse clutch drum ÐI

1. Adjust total end play.

a. Install new oil pump gasket on transmission case.

b. Install pump cover bearing race on clutch pack.

c. Measure distance ªBº between front end of transmission case

and oil pump cover bearing race.

SAT433I

SAT207B

SAT208B

ASSEMBLY

AT-185

Page 188 of 1767

d. Measure distance ªCº between front end of transmission case

and oil pump cover gasket.

e. Determine dimension ªAº by using the following equation.

A=BþC

f. Install needle bearing on oil pump assembly.

g. Measure distance ªDº between needle bearing and machined

surface of oil pump cover assembly.

h. Determine total end play ªT

1º by using the following equation.

T

1=AþDþ0.1

Total end play ªT

1º:

0.25 - 0.55 mm (0.0098 - 0.0217 in)

IIf end play is out of specification, decrease or increase thick-

ness of oil pump cover bearing race as necessary.

Available oil pump cover bearing race:

Refer to SDS, AT-199.

SAT209B

SAT210B

SAT211B

SAT975A

ASSEMBLY

Adjustment (Cont'd)

AT-186

Page 189 of 1767

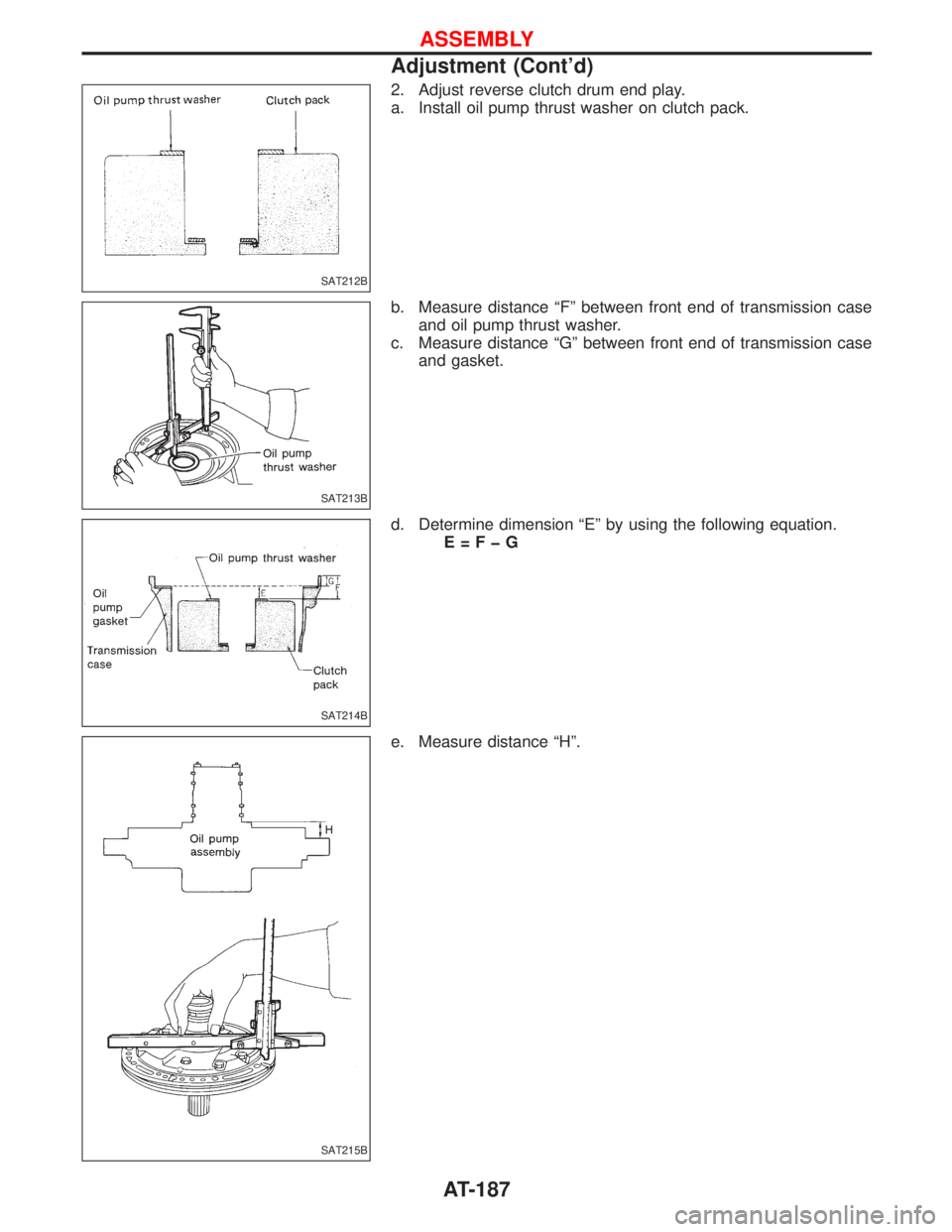

2. Adjust reverse clutch drum end play.

a. Install oil pump thrust washer on clutch pack.

b. Measure distance ªFº between front end of transmission case

and oil pump thrust washer.

c. Measure distance ªGº between front end of transmission case

and gasket.

d. Determine dimension ªEº by using the following equation.

E=FþG

e. Measure distance ªHº.

SAT212B

SAT213B

SAT214B

SAT215B

ASSEMBLY

Adjustment (Cont'd)

AT-187

Page 190 of 1767

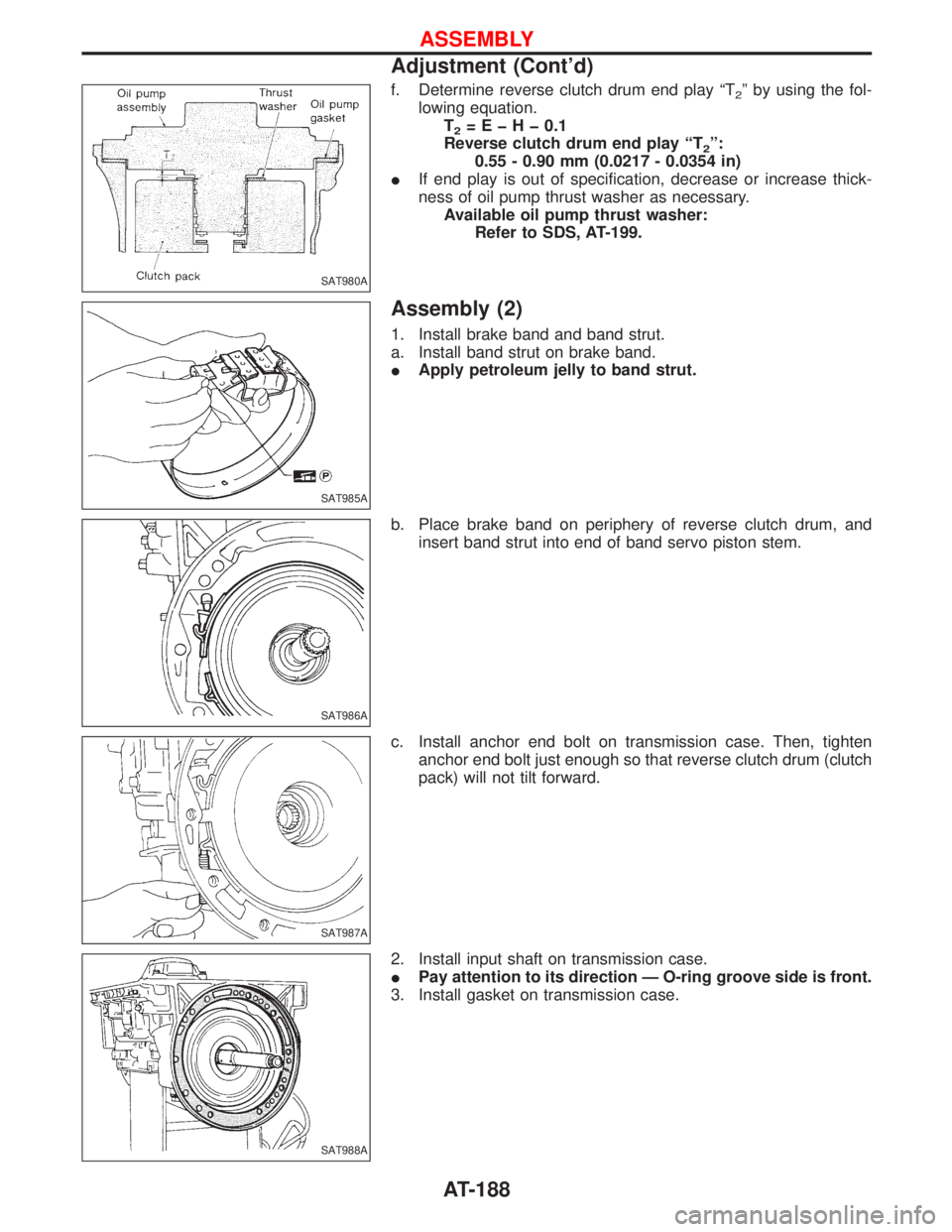

f. Determine reverse clutch drum end play ªT2º by using the fol-

lowing equation.

T

2=EþHþ0.1

Reverse clutch drum end play ªT

2º:

0.55 - 0.90 mm (0.0217 - 0.0354 in)

IIf end play is out of specification, decrease or increase thick-

ness of oil pump thrust washer as necessary.

Available oil pump thrust washer:

Refer to SDS, AT-199.

Assembly (2)

1. Install brake band and band strut.

a. Install band strut on brake band.

IApply petroleum jelly to band strut.

b. Place brake band on periphery of reverse clutch drum, and

insert band strut into end of band servo piston stem.

c. Install anchor end bolt on transmission case. Then, tighten

anchor end bolt just enough so that reverse clutch drum (clutch

pack) will not tilt forward.

2. Install input shaft on transmission case.

IPay attention to its direction Ð O-ring groove side is front.

3. Install gasket on transmission case.

SAT980A

SAT985A

SAT986A

SAT987A

SAT988A

ASSEMBLY

Adjustment (Cont'd)

AT-188

Trending: brake rotor, service reset, relay, warning light, automatic transmission, center console, adding oil