NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 211 of 1767

Removal

CAUTION:

IUse suitable tool for assembly and disassembly of brake

lines and hoses.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately. DO

NOT RUB IT OFF.

IAll hoses must be free from excessive bending, twisting

and pulling.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve by depressing

brake pedal.

3. Remove flare nut securing brake tube to hose, then withdraw

lock spring.

4. Cover openings to prevent entrance of dirt whenever discon-

necting hydraulic line.

Inspection

Check brake lines (tubes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Tighten all flare nuts and connecting bolts.

Flare nut:

:9-11N×m (0.9 - 1.1 kg-m, 78 - 95 in-lb)

Connecting bolt:

:17-20N×m (1.7 - 2.0 kg-m, 12 - 14 ft-lb)

2. Refill until new brake fluid comes out of each air bleeder valve.

3. Bleed air. Refer to ªBleeding Brake Systemº, BR-8.

YBR293

YBR293

BRAKE HYDRAULIC LINE

BR-9

Page 212 of 1767

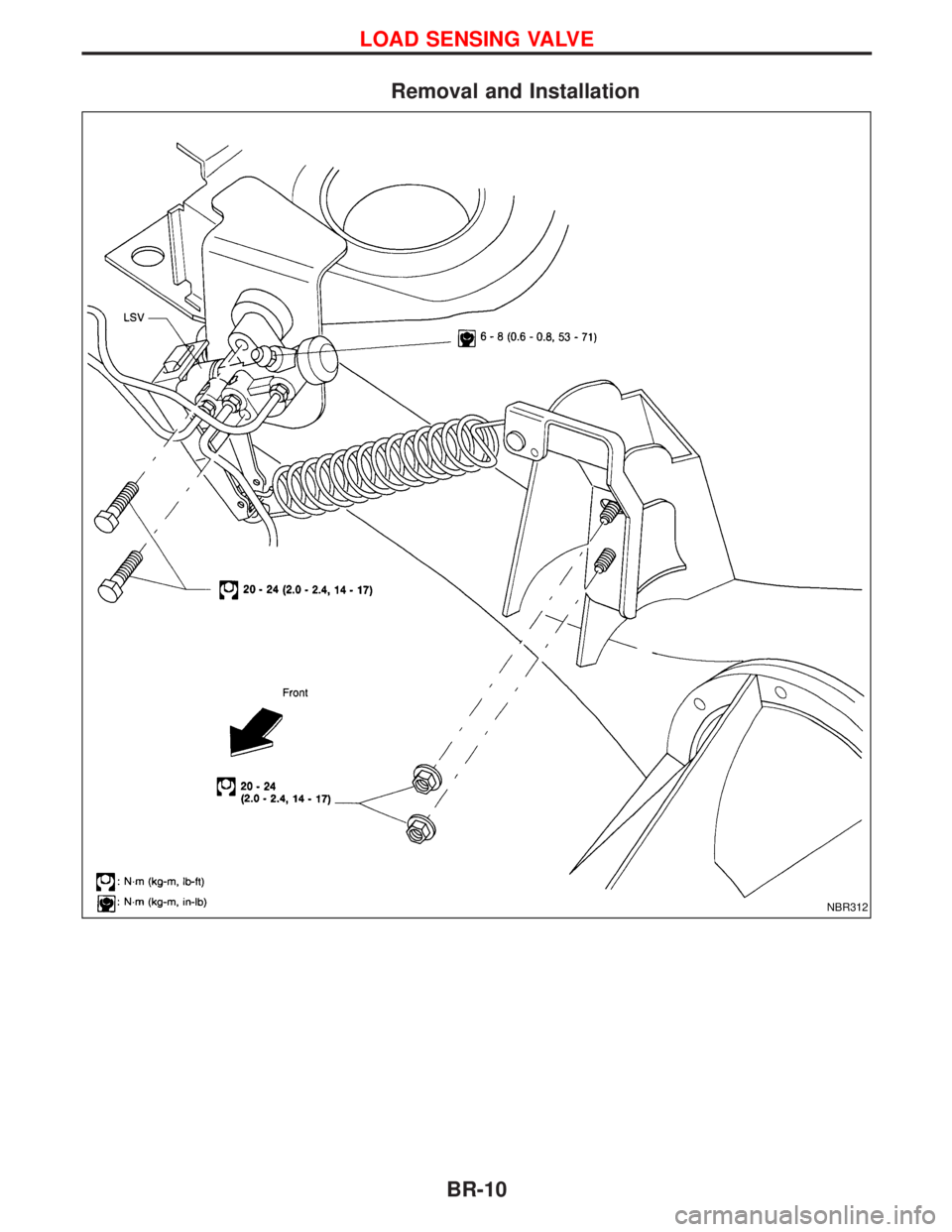

Removal and Installation

NBR312

LOAD SENSING VALVE

BR-10

Page 213 of 1767

Removal

CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately. DO

NOT RUB IT OFF.

IRemove flare nuts and LSV bolts.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

ICheck level in brake fluid reservoir.

1. Tighten provisionally flare nuts.

2. Tighten LSV bolts.

:20-24N×m (2.0 - 2.4 kg-m, 14 - 17 ft-lb)

3. Tighten flare nuts.

:15-18N×m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

4. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

5. Adjust load sensing valve (LSV). Refer to ªInspection and

Adjustmentº, ªLOAD SENSING VALVEº, BR-12.

YBR293

LOAD SENSING VALVE

BR-11

Page 214 of 1767

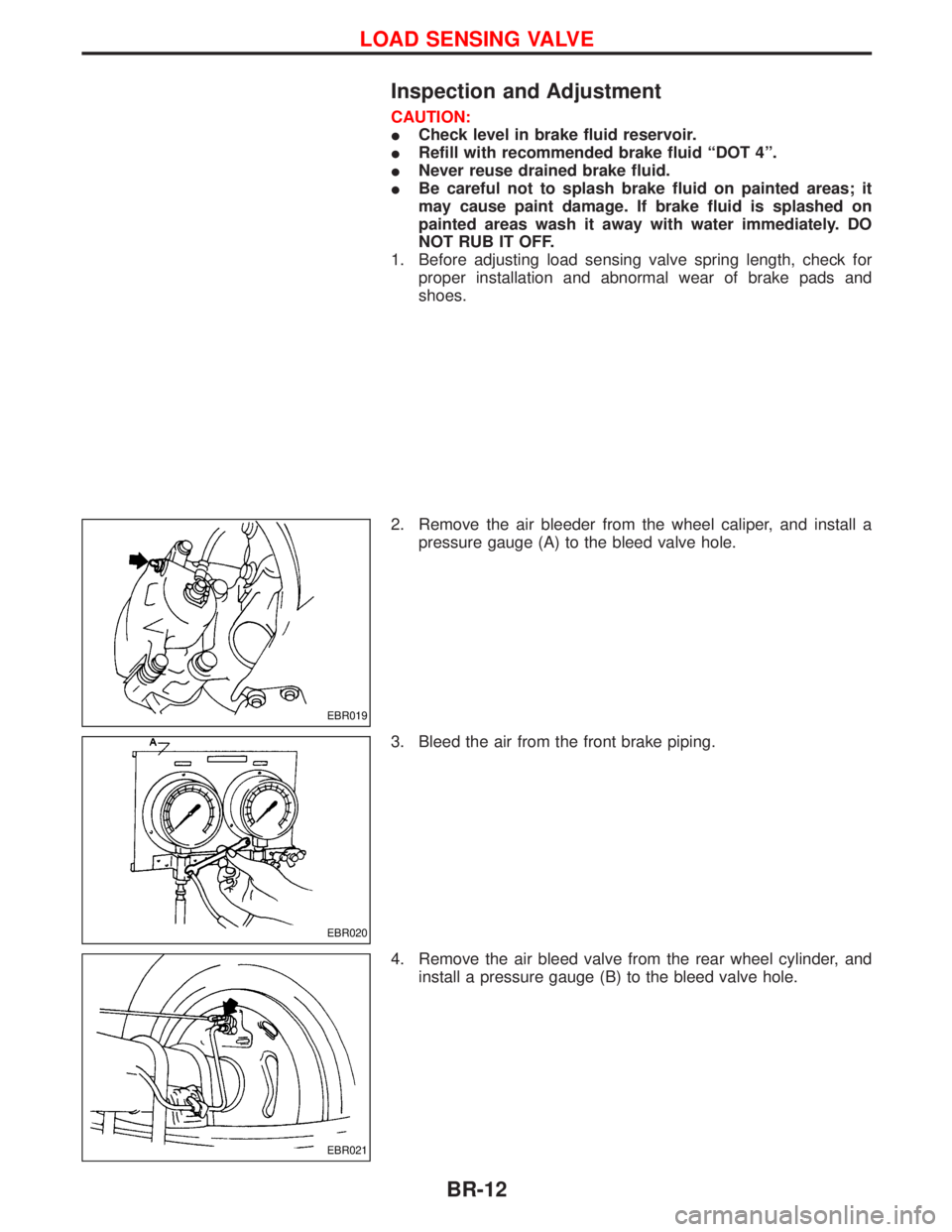

Inspection and Adjustment

CAUTION:

ICheck level in brake fluid reservoir.

IRefill with recommended brake fluid ªDOT 4º.

INever reuse drained brake fluid.

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas wash it away with water immediately. DO

NOT RUB IT OFF.

1. Before adjusting load sensing valve spring length, check for

proper installation and abnormal wear of brake pads and

shoes.

2. Remove the air bleeder from the wheel caliper, and install a

pressure gauge (A) to the bleed valve hole.

3. Bleed the air from the front brake piping.

4. Remove the air bleed valve from the rear wheel cylinder, and

install a pressure gauge (B) to the bleed valve hole.

EBR019

EBR020

EBR021

LOAD SENSING VALVE

BR-12

Page 215 of 1767

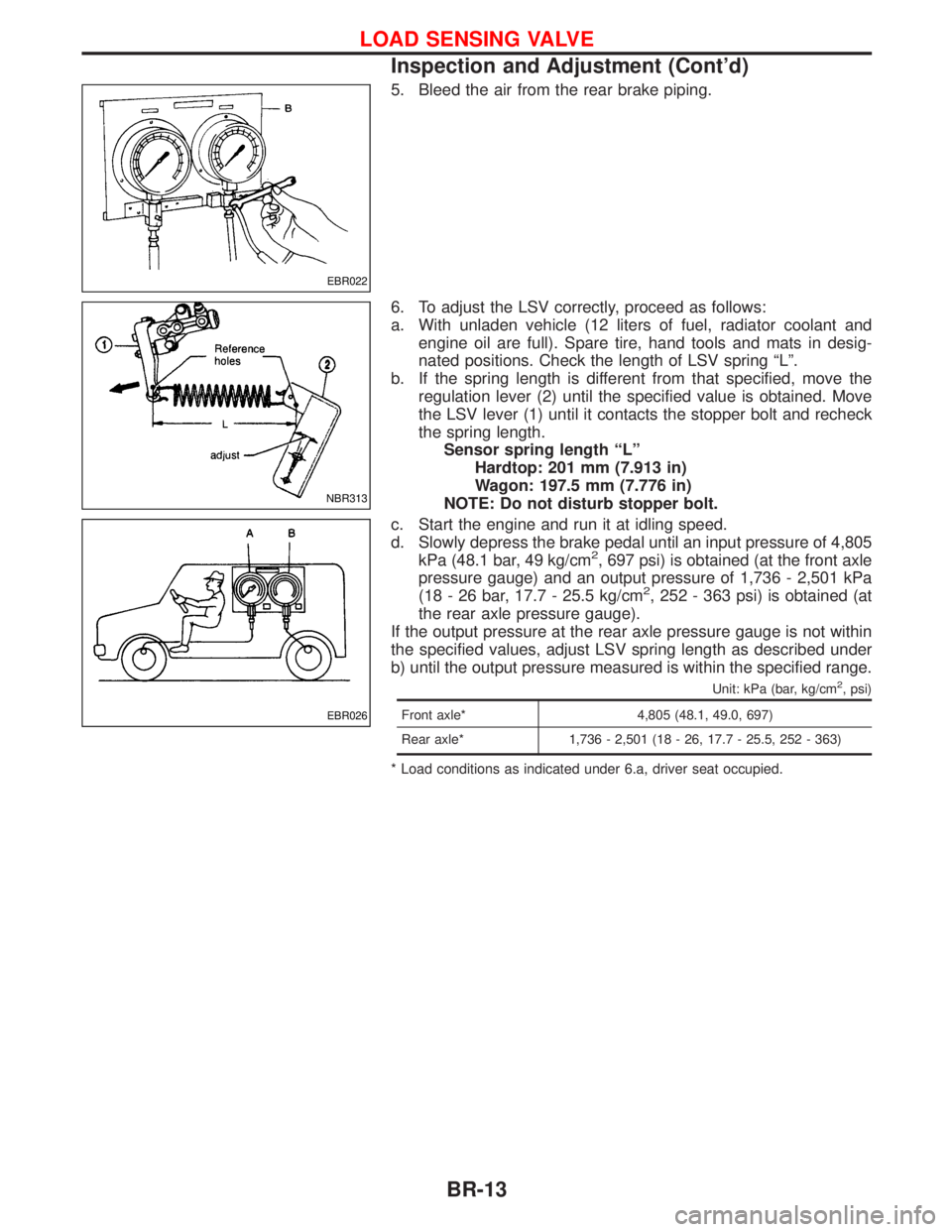

5. Bleed the air from the rear brake piping.

6. To adjust the LSV correctly, proceed as follows:

a. With unladen vehicle (12 liters of fuel, radiator coolant and

engine oil are full). Spare tire, hand tools and mats in desig-

nated positions. Check the length of LSV spring ªLº.

b. If the spring length is different from that specified, move the

regulation lever (2) until the specified value is obtained. Move

the LSV lever (1) until it contacts the stopper bolt and recheck

the spring length.

Sensor spring length ªLº

Hardtop: 201 mm (7.913 in)

Wagon: 197.5 mm (7.776 in)

NOTE: Do not disturb stopper bolt.

c. Start the engine and run it at idling speed.

d. Slowly depress the brake pedal until an input pressure of 4,805

kPa (48.1 bar, 49 kg/cm

2, 697 psi) is obtained (at the front axle

pressure gauge) and an output pressure of 1,736 - 2,501 kPa

(18 - 26 bar, 17.7 - 25.5 kg/cm

2, 252 - 363 psi) is obtained (at

the rear axle pressure gauge).

If the output pressure at the rear axle pressure gauge is not within

the specified values, adjust LSV spring length as described under

b) until the output pressure measured is within the specified range.

Unit: kPa (bar, kg/cm2, psi)

Front axle* 4,805 (48.1, 49.0, 697)

Rear axle* 1,736 - 2,501 (18 - 26, 17.7 - 25.5, 252 - 363)

* Load conditions as indicated under 6.a, driver seat occupied.

EBR022

NBR313

EBR026

LOAD SENSING VALVE

Inspection and Adjustment (Cont'd)

BR-13

Page 216 of 1767

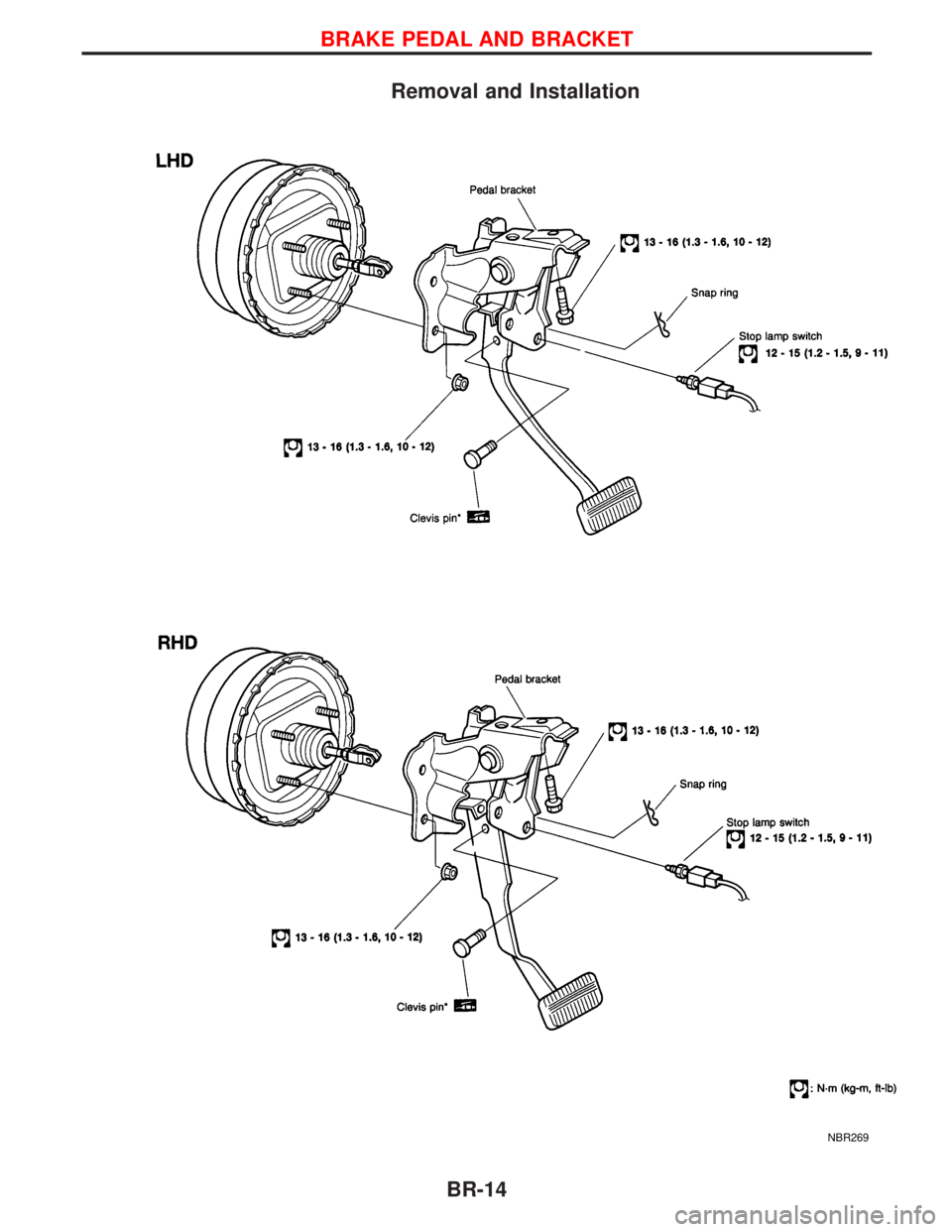

Removal and Installation

NBR269

BRAKE PEDAL AND BRACKET

BR-14

Page 217 of 1767

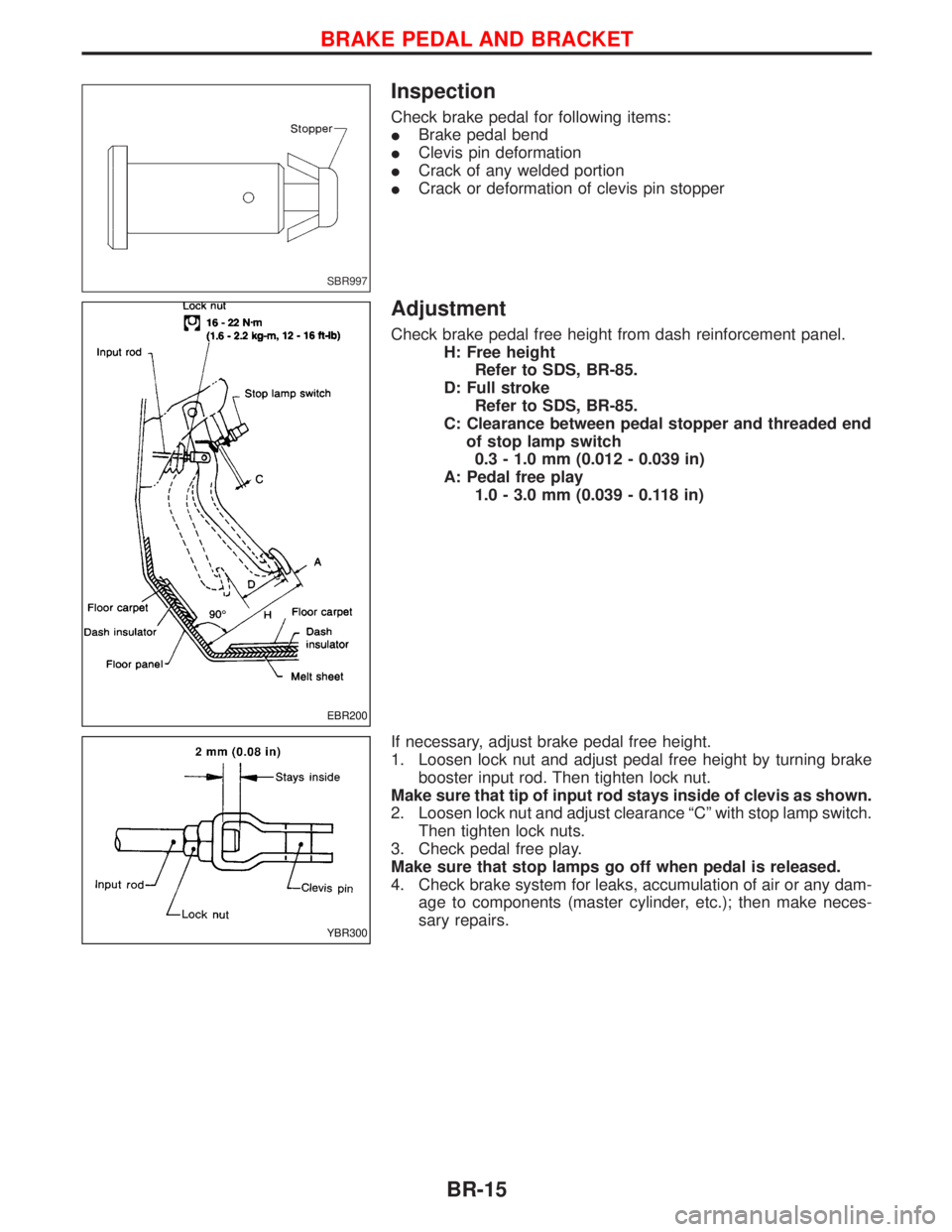

Inspection

Check brake pedal for following items:

IBrake pedal bend

IClevis pin deformation

ICrack of any welded portion

ICrack or deformation of clevis pin stopper

Adjustment

Check brake pedal free height from dash reinforcement panel.

H: Free height

Refer to SDS, BR-85.

D: Full stroke

Refer to SDS, BR-85.

C: Clearance between pedal stopper and threaded end

of stop lamp switch

0.3 - 1.0 mm (0.012 - 0.039 in)

A: Pedal free play

1.0 - 3.0 mm (0.039 - 0.118 in)

If necessary, adjust brake pedal free height.

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside of clevis as shown.

2. Loosen lock nut and adjust clearance ªCº with stop lamp switch.

Then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamps go off when pedal is released.

4. Check brake system for leaks, accumulation of air or any dam-

age to components (master cylinder, etc.); then make neces-

sary repairs.

SBR997

EBR200

YBR300

BRAKE PEDAL AND BRACKET

BR-15

Page 218 of 1767

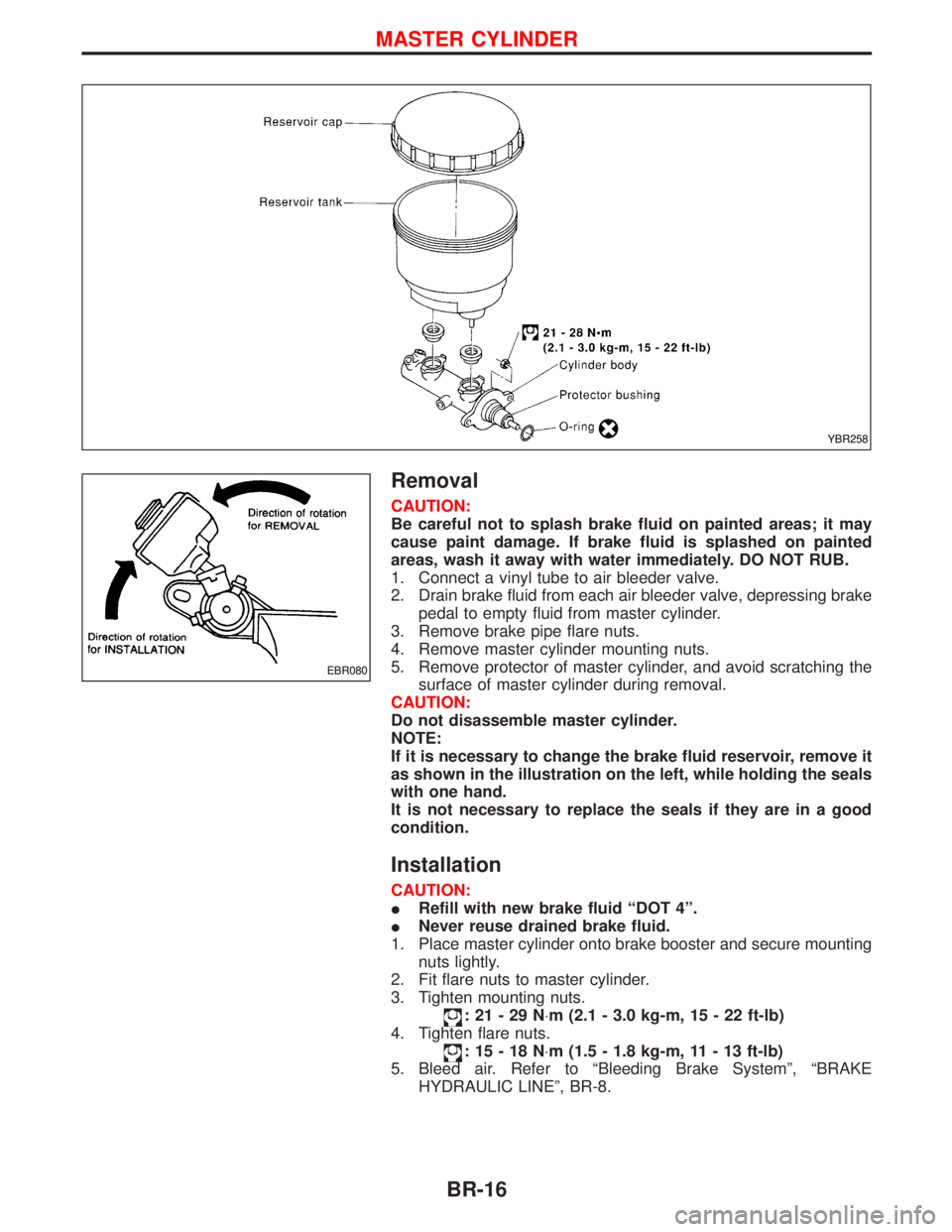

Removal

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately. DO NOT RUB.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve, depressing brake

pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

5. Remove protector of master cylinder, and avoid scratching the

surface of master cylinder during removal.

CAUTION:

Do not disassemble master cylinder.

NOTE:

If it is necessary to change the brake fluid reservoir, remove it

as shown in the illustration on the left, while holding the seals

with one hand.

It is not necessary to replace the seals if they are in a good

condition.

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mounting

nuts lightly.

2. Fit flare nuts to master cylinder.

3. Tighten mounting nuts.

:21-29N×m (2.1 - 3.0 kg-m, 15 - 22 ft-lb)

4. Tighten flare nuts.

:15-18N×m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

5. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR258

EBR080

MASTER CYLINDER

BR-16

Page 219 of 1767

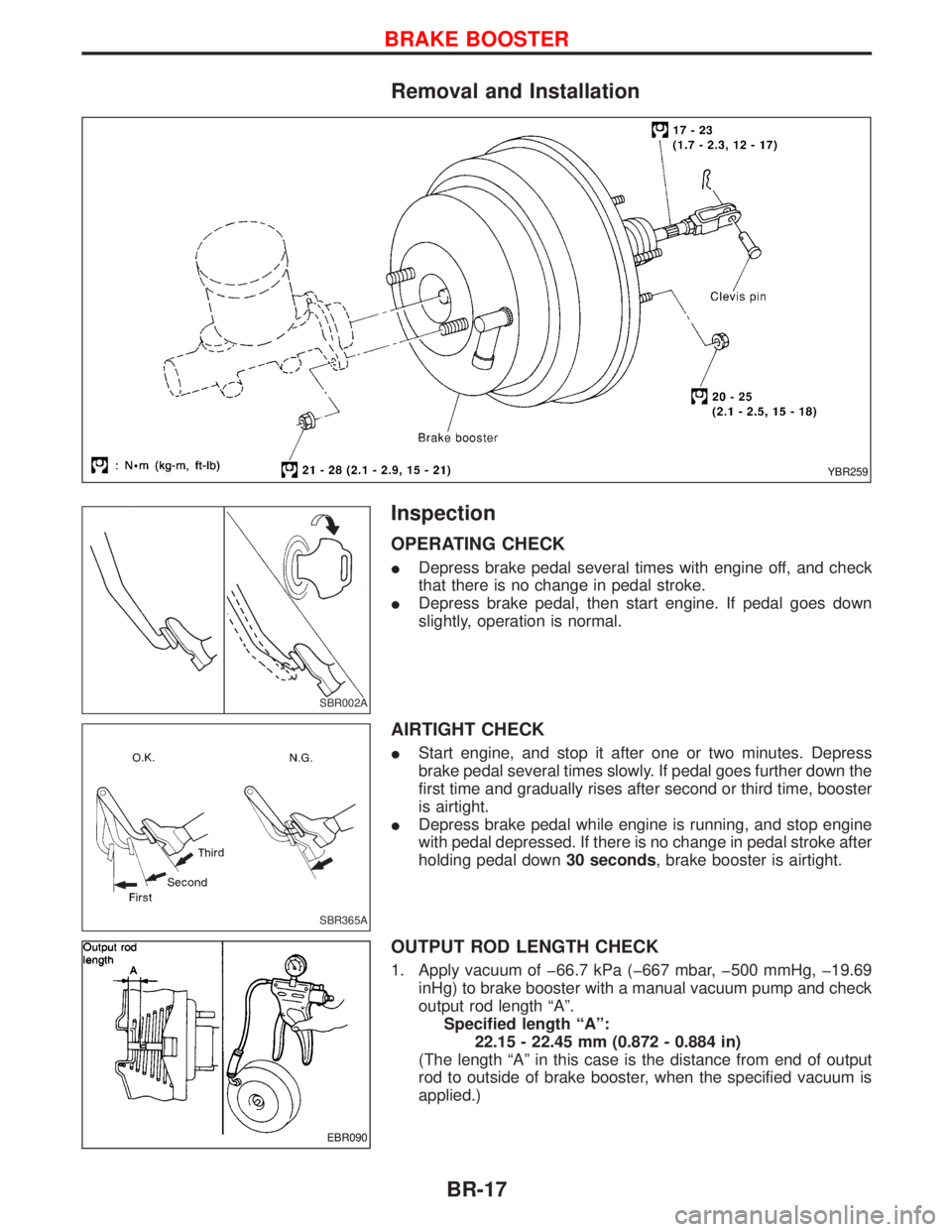

Removal and Installation

Inspection

OPERATING CHECK

IDepress brake pedal several times with engine off, and check

that there is no change in pedal stroke.

IDepress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECK

IStart engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. If pedal goes further down the

first time and gradually rises after second or third time, booster

is airtight.

IDepress brake pedal while engine is running, and stop engine

with pedal depressed. If there is no change in pedal stroke after

holding pedal down30 seconds, brake booster is airtight.

OUTPUT ROD LENGTH CHECK

1. Apply vacuum of þ66.7 kPa (þ667 mbar, þ500 mmHg, þ19.69

inHg) to brake booster with a manual vacuum pump and check

output rod length ªAº.

Specified length ªAº:

22.15 - 22.45 mm (0.872 - 0.884 in)

(The length ªAº in this case is the distance from end of output

rod to outside of brake booster, when the specified vacuum is

applied.)

YBR259

SBR002A

SBR365A

EBR090

BRAKE BOOSTER

BR-17

Page 220 of 1767

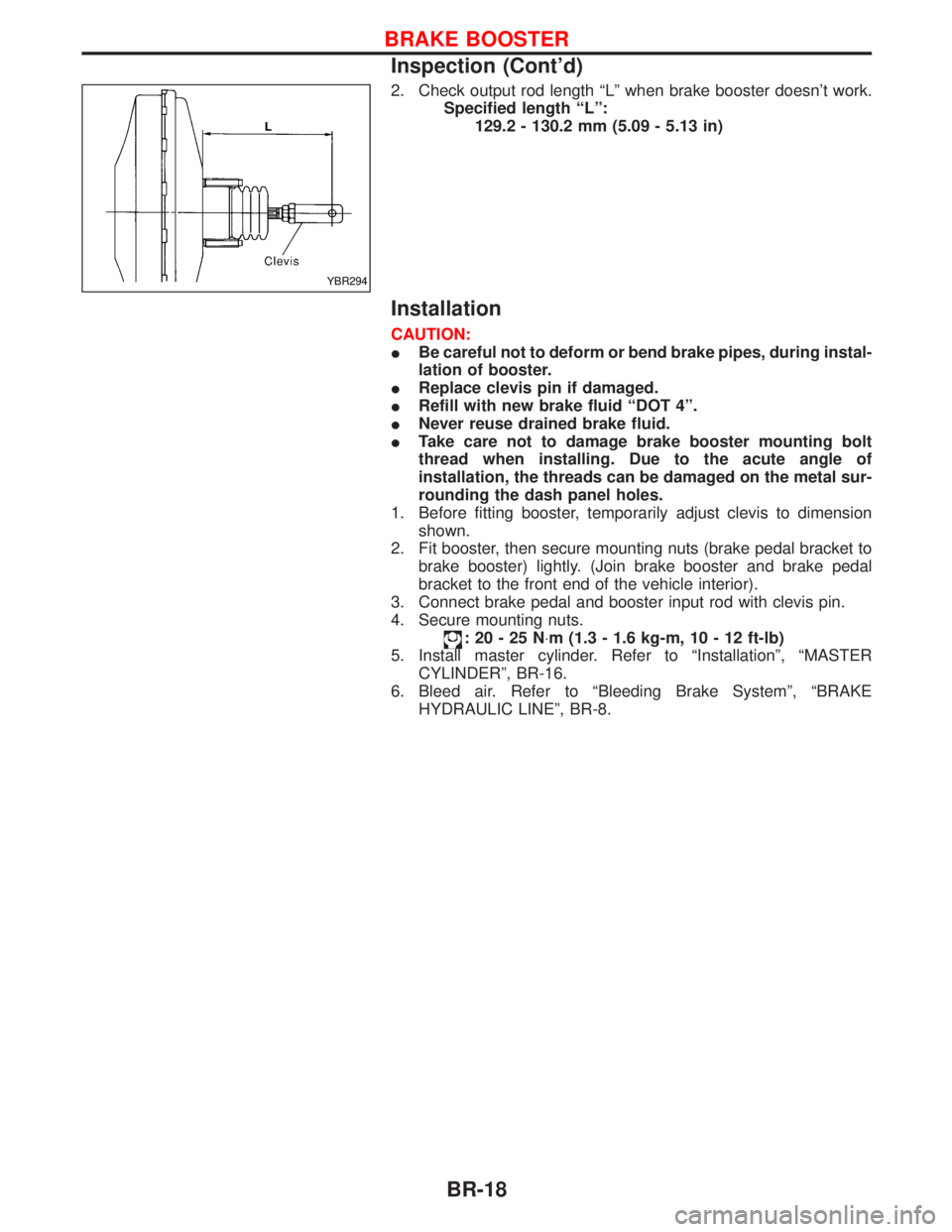

2. Check output rod length ªLº when brake booster doesn't work.

Specified length ªLº:

129.2 - 130.2 mm (5.09 - 5.13 in)

Installation

CAUTION:

IBe careful not to deform or bend brake pipes, during instal-

lation of booster.

IReplace clevis pin if damaged.

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

ITake care not to damage brake booster mounting bolt

thread when installing. Due to the acute angle of

installation, the threads can be damaged on the metal sur-

rounding the dash panel holes.

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

2. Fit booster, then secure mounting nuts (brake pedal bracket to

brake booster) lightly. (Join brake booster and brake pedal

bracket to the front end of the vehicle interior).

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure mounting nuts.

:20-25N×m (1.3 - 1.6 kg-m, 10 - 12 ft-lb)

5. Install master cylinder. Refer to ªInstallationº, ªMASTER

CYLINDERº, BR-16.

6. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

YBR294

BRAKE BOOSTER

Inspection (Cont'd)

BR-18