NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 231 of 1767

PISTON

Check outside surface of piston for score, rust, wear, damage or

presence of foreign materials. Replace if any of the above condi-

tions are observed.

CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign materials are stuck to sliding

surface.

PIN, PIN BOLT AND PIN BOLT

Check for wear, cracks or other damage. Replace if any of the

above conditions are observed.

ROTOR

Rubbing surface

Check rotor for roughness, cracks or chips.

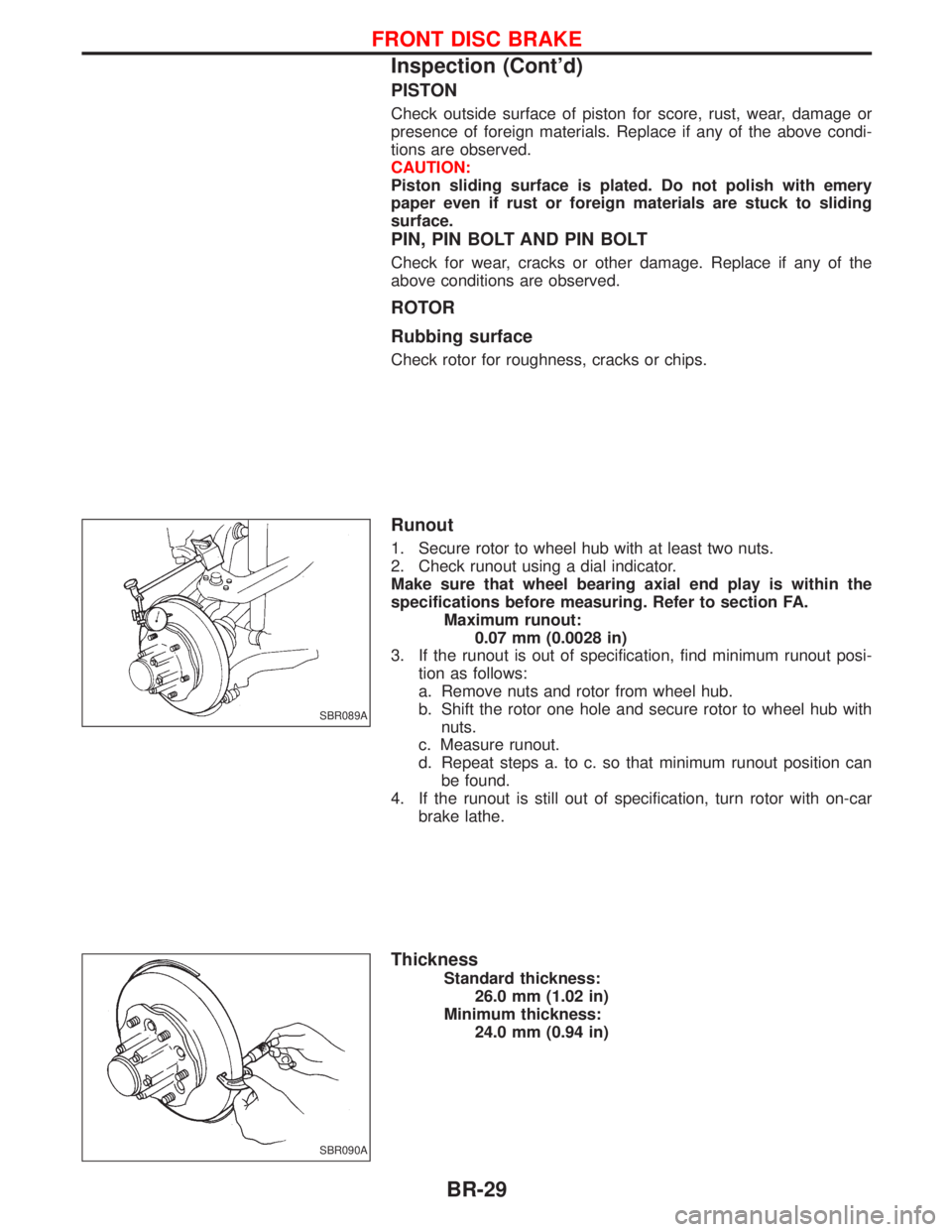

Runout

1. Secure rotor to wheel hub with at least two nuts.

2. Check runout using a dial indicator.

Make sure that wheel bearing axial end play is within the

specifications before measuring. Refer to section FA.

Maximum runout:

0.07 mm (0.0028 in)

3. If the runout is out of specification, find minimum runout posi-

tion as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub with

nuts.

c. Measure runout.

d. Repeat steps a. to c. so that minimum runout position can

be found.

4. If the runout is still out of specification, turn rotor with on-car

brake lathe.

Thickness

Standard thickness:

26.0 mm (1.02 in)

Minimum thickness:

24.0 mm (0.94 in)

SBR089A

SBR090A

FRONT DISC BRAKE

Inspection (Cont'd)

BR-29

Page 232 of 1767

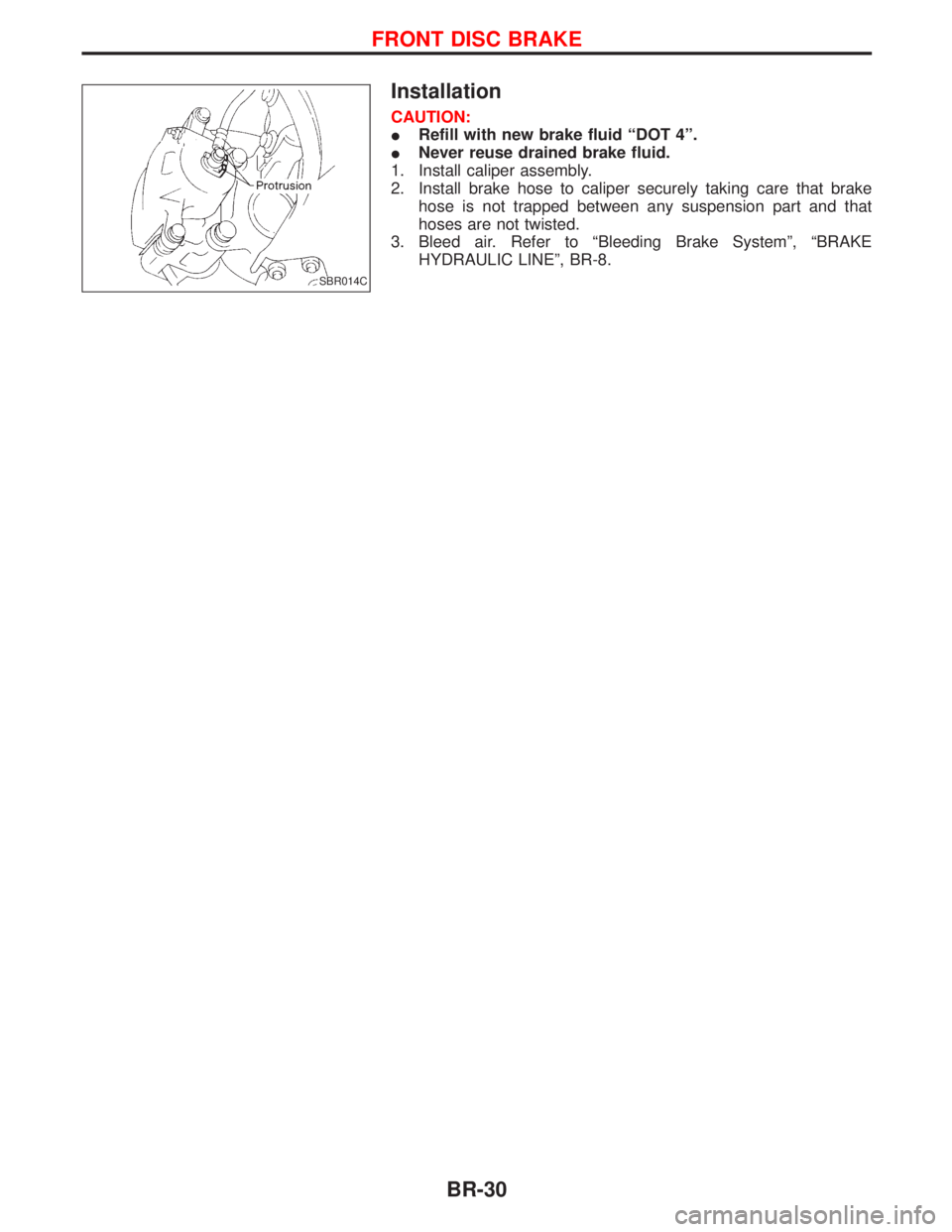

Installation

CAUTION:

IRefill with new brake fluid ªDOT 4º.

INever reuse drained brake fluid.

1. Install caliper assembly.

2. Install brake hose to caliper securely taking care that brake

hose is not trapped between any suspension part and that

hoses are not twisted.

3. Bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

SBR014C

FRONT DISC BRAKE

BR-30

Page 233 of 1767

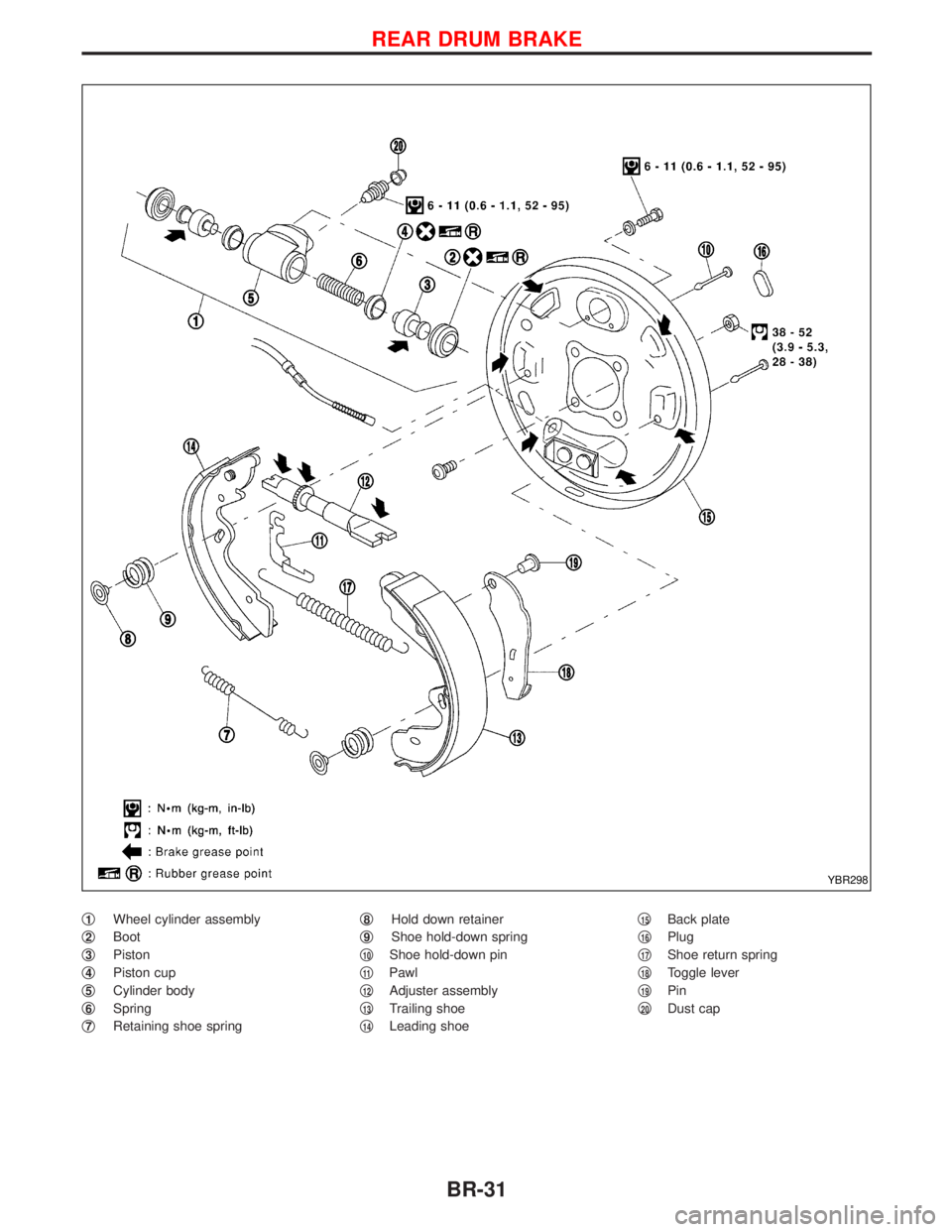

q1Wheel cylinder assembly

q

2Boot

q

3Piston

q

4Piston cup

q

5Cylinder body

q

6Spring

q

7Retaining shoe springq

8Hold down retainer

q

9Shoe hold-down spring

q

10Shoe hold-down pin

q

11Pawl

q

12Adjuster assembly

q

13Trailing shoe

q

14Leading shoeq

15Back plate

q

16Plug

q

17Shoe return spring

q

18Toggle lever

q

19Pin

q

20Dust cap

YBR298

REAR DRUM BRAKE

BR-31

Page 234 of 1767

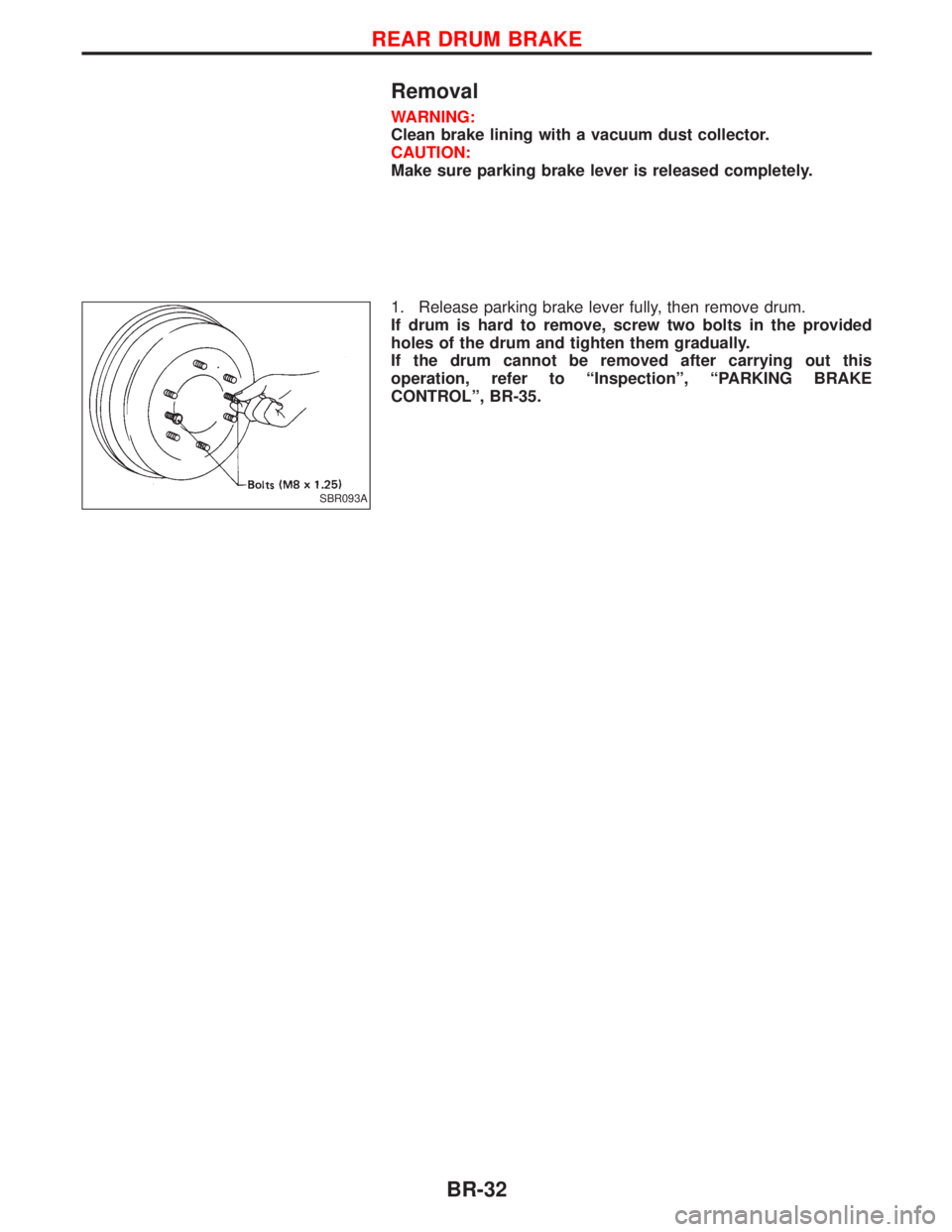

Removal

WARNING:

Clean brake lining with a vacuum dust collector.

CAUTION:

Make sure parking brake lever is released completely.

1. Release parking brake lever fully, then remove drum.

If drum is hard to remove, screw two bolts in the provided

holes of the drum and tighten them gradually.

If the drum cannot be removed after carrying out this

operation, refer to ªInspectionº, ªPARKING BRAKE

CONTROLº, BR-35.

SBR093A

REAR DRUM BRAKE

BR-32

Page 235 of 1767

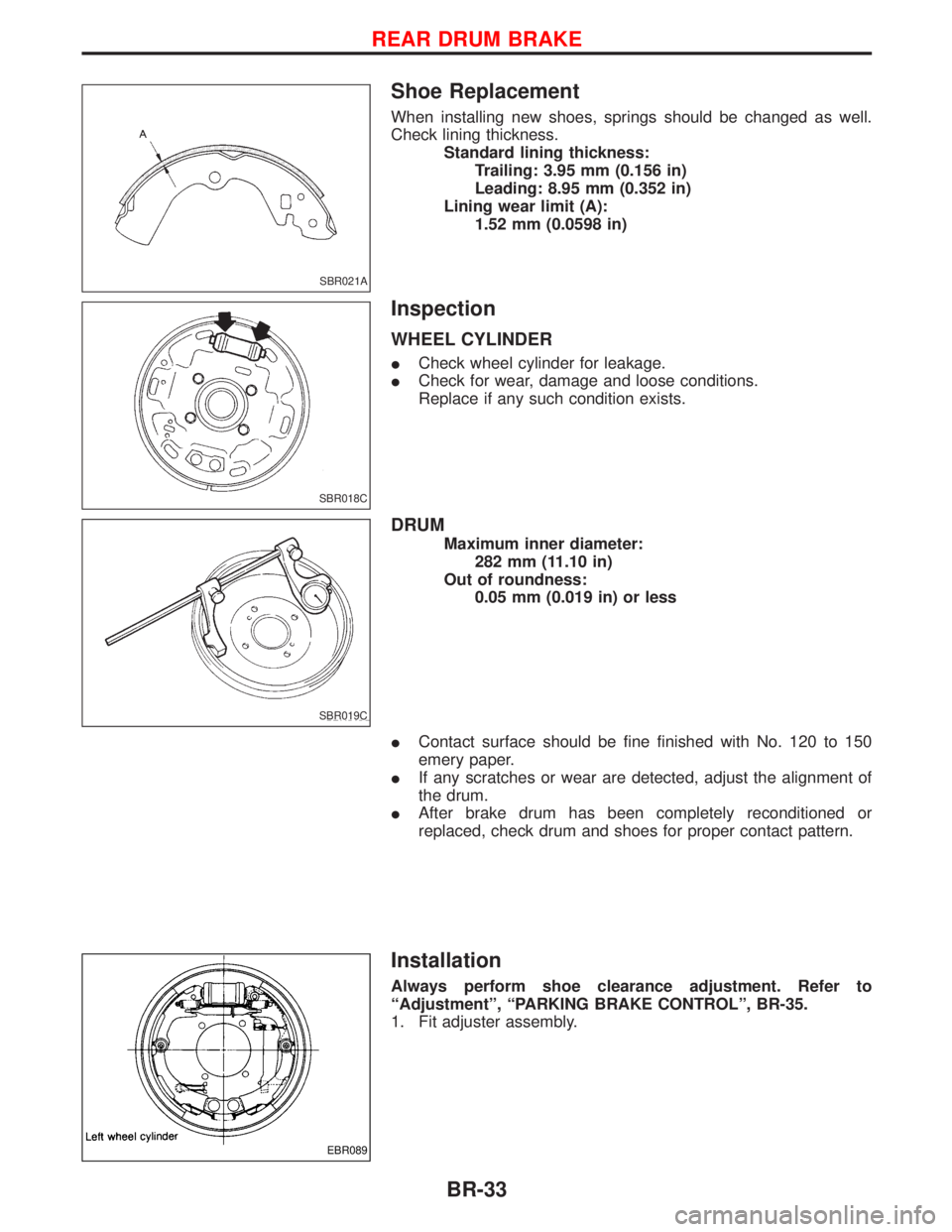

Shoe Replacement

When installing new shoes, springs should be changed as well.

Check lining thickness.

Standard lining thickness:

Trailing: 3.95 mm (0.156 in)

Leading: 8.95 mm (0.352 in)

Lining wear limit (A):

1.52 mm (0.0598 in)

Inspection

WHEEL CYLINDER

ICheck wheel cylinder for leakage.

ICheck for wear, damage and loose conditions.

Replace if any such condition exists.

DRUM

Maximum inner diameter:

282 mm (11.10 in)

Out of roundness:

0.05 mm (0.019 in) or less

IContact surface should be fine finished with No. 120 to 150

emery paper.

IIf any scratches or wear are detected, adjust the alignment of

the drum.

IAfter brake drum has been completely reconditioned or

replaced, check drum and shoes for proper contact pattern.

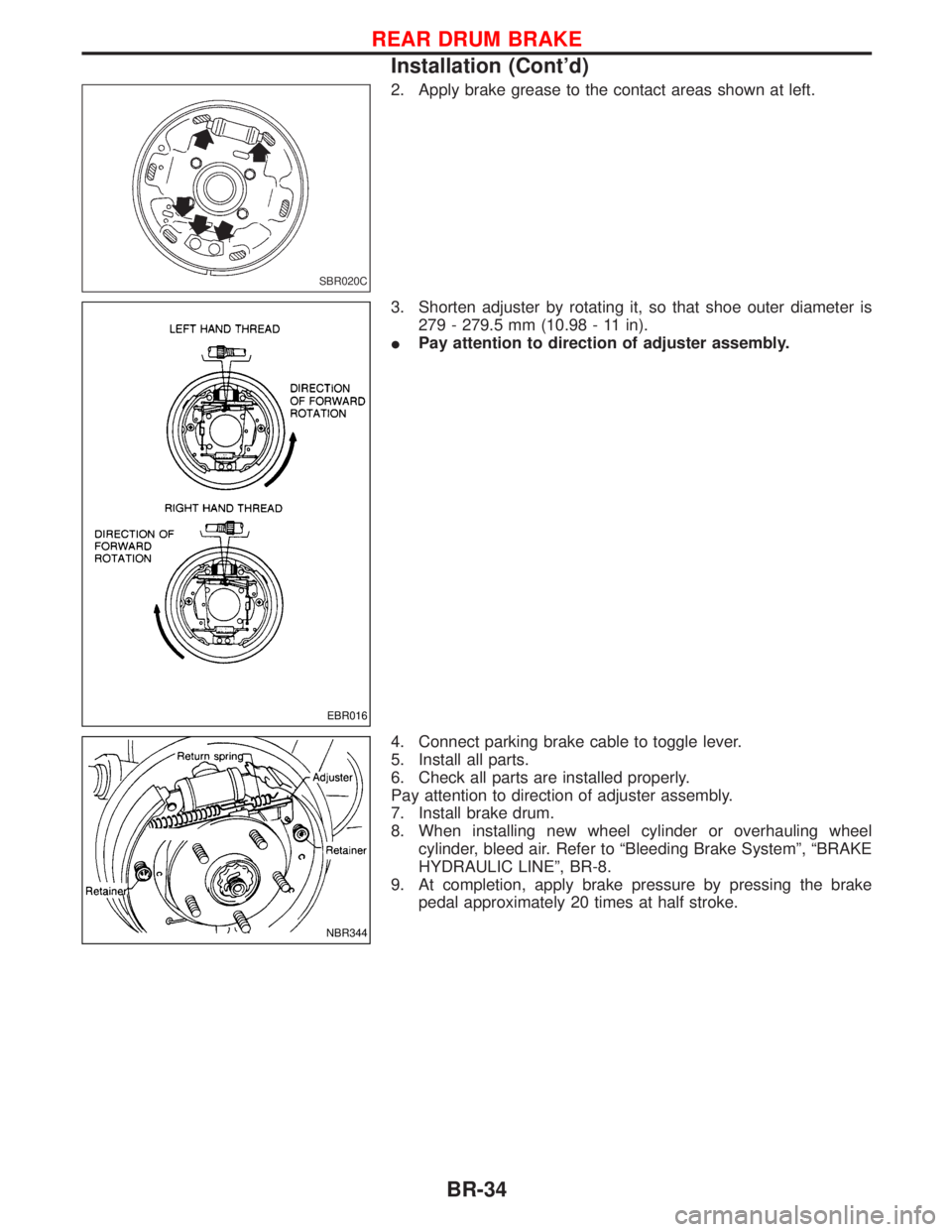

Installation

Always perform shoe clearance adjustment. Refer to

ªAdjustmentº, ªPARKING BRAKE CONTROLº, BR-35.

1. Fit adjuster assembly.

SBR021A

SBR018C

SBR019C

EBR089

REAR DRUM BRAKE

BR-33

Page 236 of 1767

2. Apply brake grease to the contact areas shown at left.

3. Shorten adjuster by rotating it, so that shoe outer diameter is

279 - 279.5 mm (10.98 - 11 in).

IPay attention to direction of adjuster assembly.

4. Connect parking brake cable to toggle lever.

5. Install all parts.

6. Check all parts are installed properly.

Pay attention to direction of adjuster assembly.

7. Install brake drum.

8. When installing new wheel cylinder or overhauling wheel

cylinder, bleed air. Refer to ªBleeding Brake Systemº, ªBRAKE

HYDRAULIC LINEº, BR-8.

9. At completion, apply brake pressure by pressing the brake

pedal approximately 20 times at half stroke.

SBR020C

EBR016

NBR344

REAR DRUM BRAKE

Installation (Cont'd)

BR-34

Page 237 of 1767

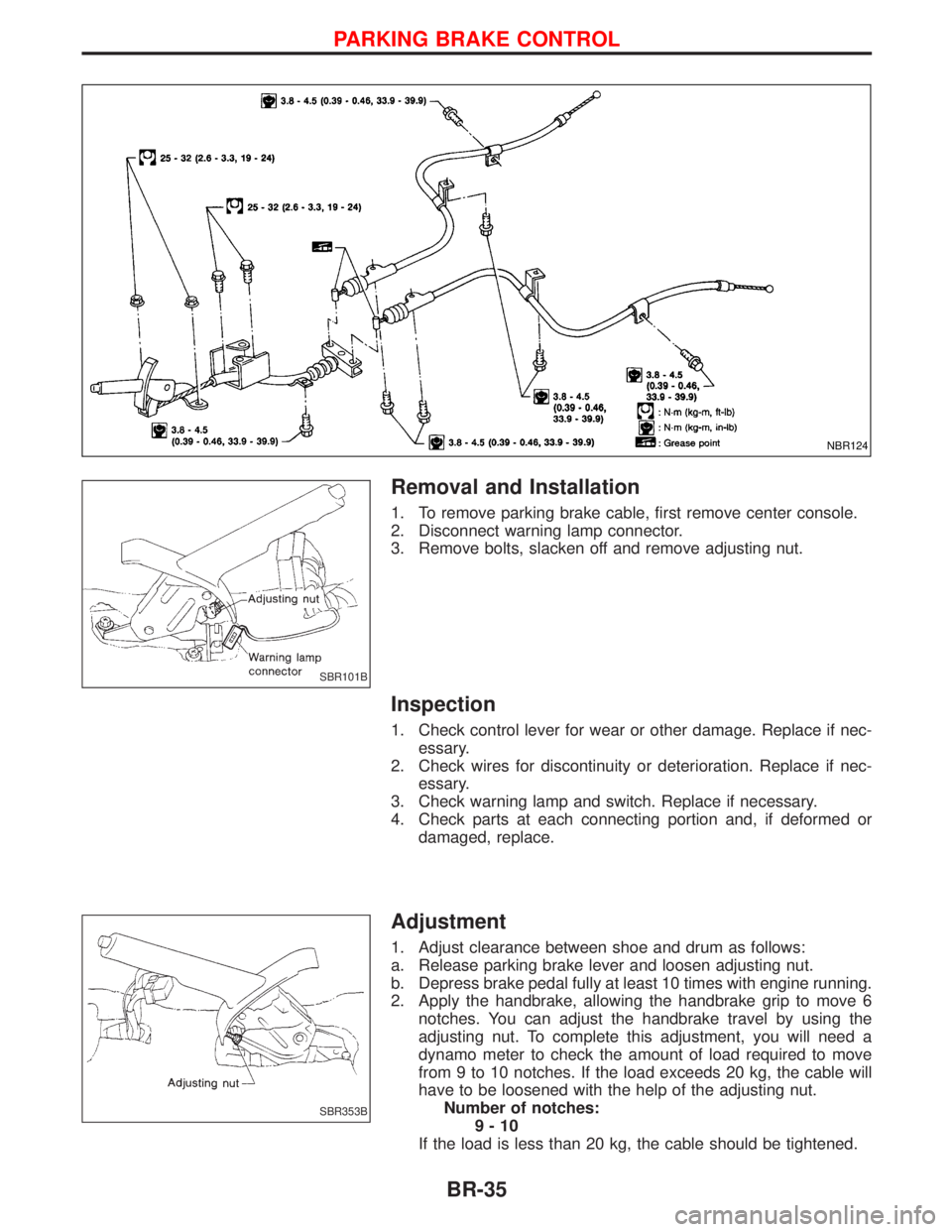

Removal and Installation

1. To remove parking brake cable, first remove center console.

2. Disconnect warning lamp connector.

3. Remove bolts, slacken off and remove adjusting nut.

Inspection

1. Check control lever for wear or other damage. Replace if nec-

essary.

2. Check wires for discontinuity or deterioration. Replace if nec-

essary.

3. Check warning lamp and switch. Replace if necessary.

4. Check parts at each connecting portion and, if deformed or

damaged, replace.

Adjustment

1. Adjust clearance between shoe and drum as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine running.

2. Apply the handbrake, allowing the handbrake grip to move 6

notches. You can adjust the handbrake travel by using the

adjusting nut. To complete this adjustment, you will need a

dynamo meter to check the amount of load required to move

from 9 to 10 notches. If the load exceeds 20 kg, the cable will

have to be loosened with the help of the adjusting nut.

Number of notches:

9-10

If the load is less than 20 kg, the cable should be tightened.

NBR124

SBR101B

SBR353B

PARKING BRAKE CONTROL

BR-35

Page 238 of 1767

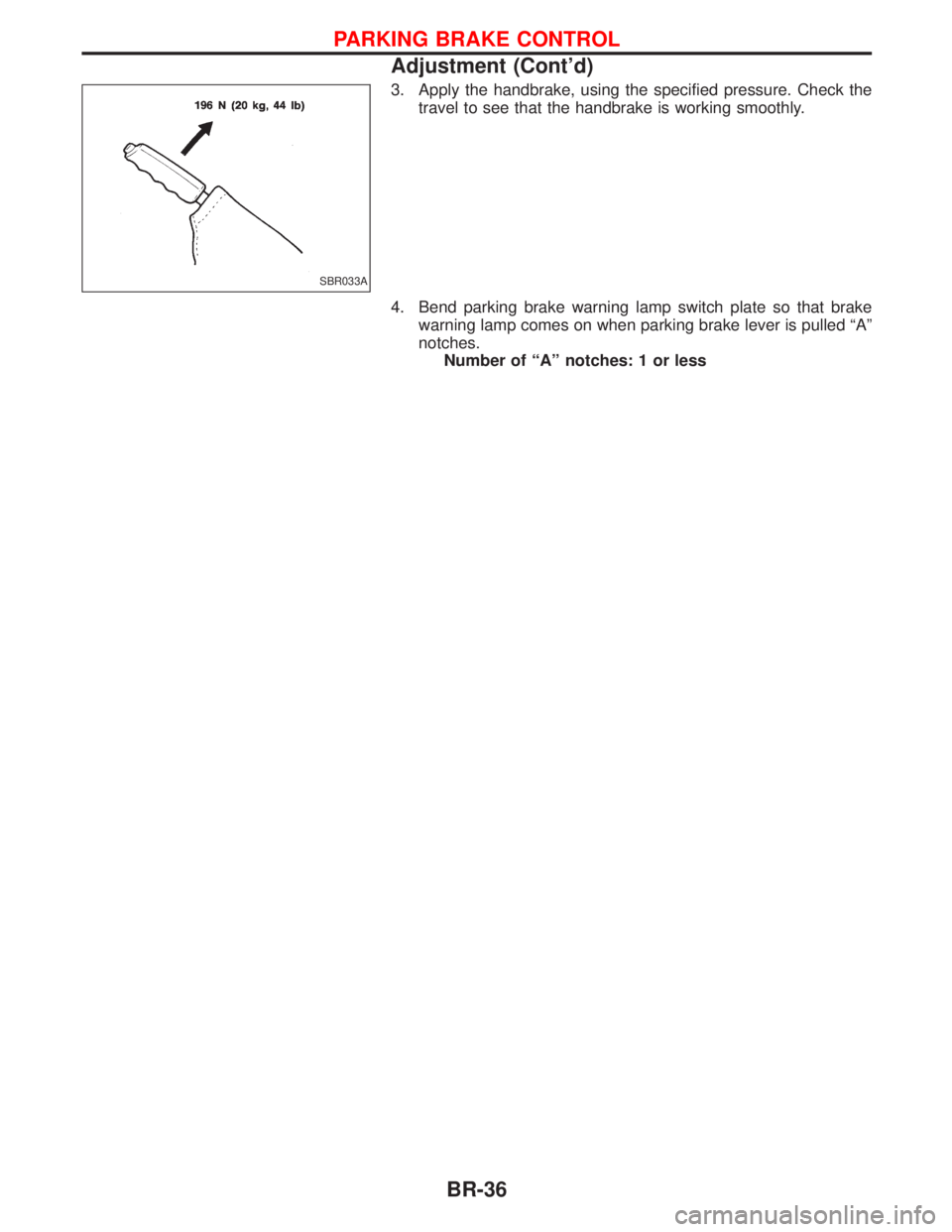

3. Apply the handbrake, using the specified pressure. Check the

travel to see that the handbrake is working smoothly.

4. Bend parking brake warning lamp switch plate so that brake

warning lamp comes on when parking brake lever is pulled ªAº

notches.

Number of ªAº notches: 1 or less

SBR033A

PARKING BRAKE CONTROL

Adjustment (Cont'd)

BR-36

Page 239 of 1767

Purpose

The Anti-lock Brake System (ABS) with an integrated Electronic Brake force Distribution (EBD) system con-

sists of electronic and hydraulic components. It allows you to control the braking force so that wheel lock can

be avoided during braking.

The advantages of ABS with EBD

1) Better tracking performance through improved steering wheel control.

2) Improved maneuverability and safer vehicle control.

3) Improved vehicle stability by preventing flat spins.

4) Shorter stopping distance and optimal utilisation of the rear brakes under many different circumstances.

Operation

IABS with EBD has self-test capabilities. The ABS warning lamp is illuminated for 1 second each time the

ignition switch is turned ªONº. After the engine is started, the ABS warning lamp turns off. An ABS self-test

is performed the first time the vehicle reaches 6 km/h (4 MPH) to ensure the system is operational. A

mechanical noise may be heard as the ABS performs this self-test and is a normal part of the self-test

feature. If a malfunction is detected during this check, the ABS warning lamp will stay on.

During the self-test, it also performs a EBD check when it detects a failure the ABS warning light will go

on simultaneously with the brake warning light and an audible sound will sound constantly.

IEBD system will only operate when the ABS is not in active status and it uses the inlet valves of ABS con-

trol unit to limit the pressure to the rear wheels when they tend to go into slip.

IWhen the vehicle speed is less than 10 km/h (6 MPH) the ABS system does not operate.

IWhile driving, a mechanical noise may be heard during ABS operation, this is a normal system condition.

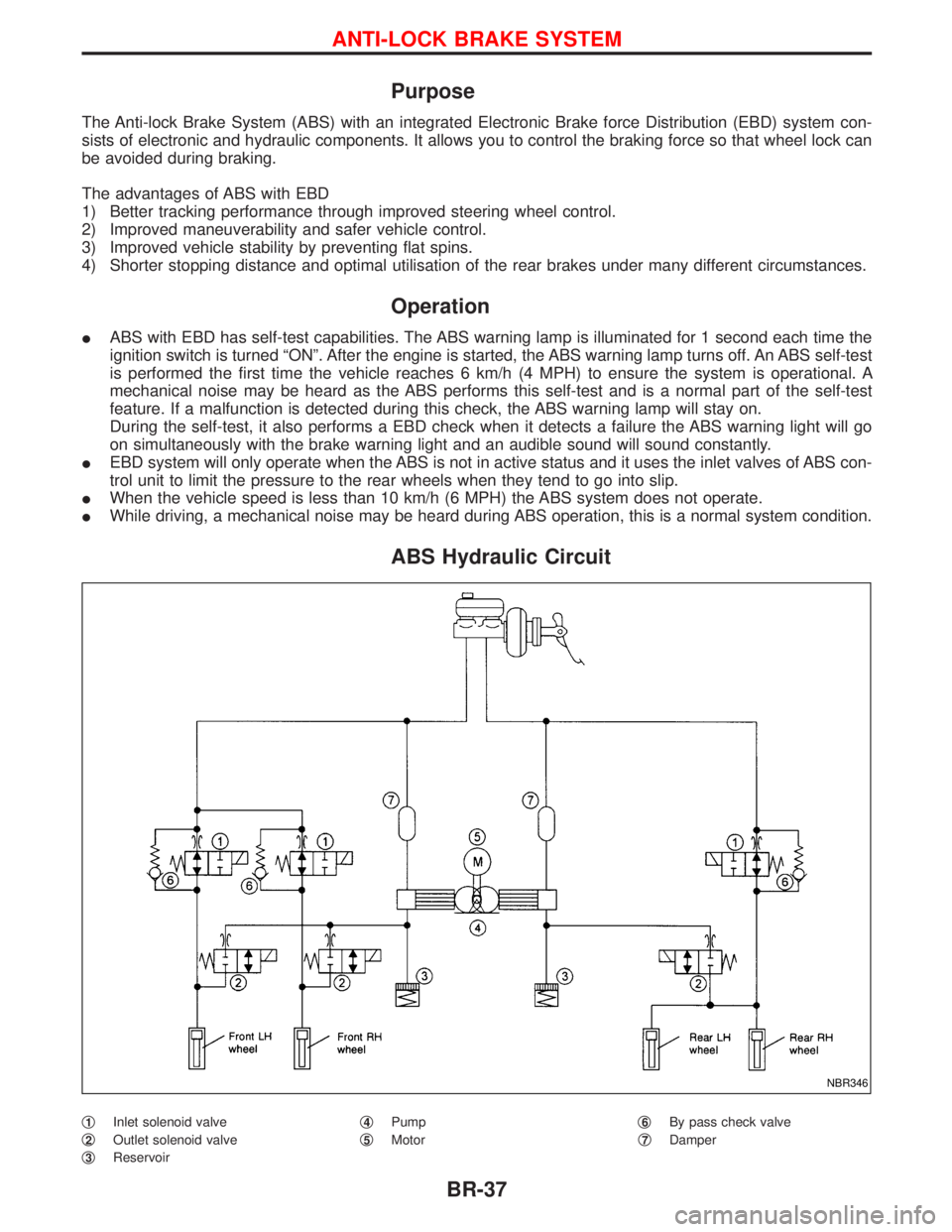

ABS Hydraulic Circuit

q1Inlet solenoid valve

q

2Outlet solenoid valve

q

3Reservoirq

4Pump

q

5Motorq

6By pass check valve

q

7Damper

NBR346

ANTI-LOCK BRAKE SYSTEM

BR-37

Page 240 of 1767

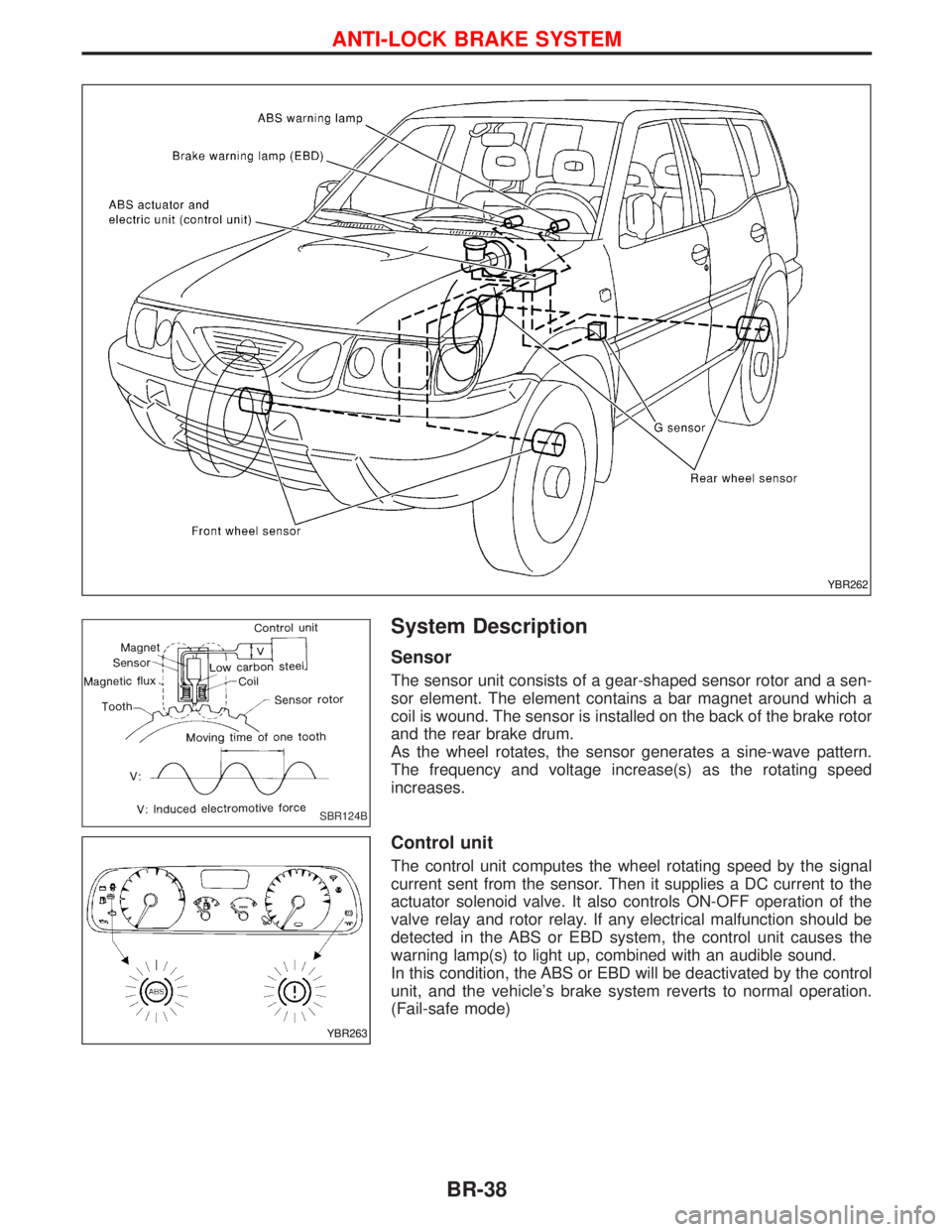

System Description

Sensor

The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back of the brake rotor

and the rear brake drum.

As the wheel rotates, the sensor generates a sine-wave pattern.

The frequency and voltage increase(s) as the rotating speed

increases.

Control unit

The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and rotor relay. If any electrical malfunction should be

detected in the ABS or EBD system, the control unit causes the

warning lamp(s) to light up, combined with an audible sound.

In this condition, the ABS or EBD will be deactivated by the control

unit, and the vehicle's brake system reverts to normal operation.

(Fail-safe mode)

YBR262

SBR124B

YBR263

ANTI-LOCK BRAKE SYSTEM

BR-38