Start NISSAN TERRANO 2002 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 810 of 1767

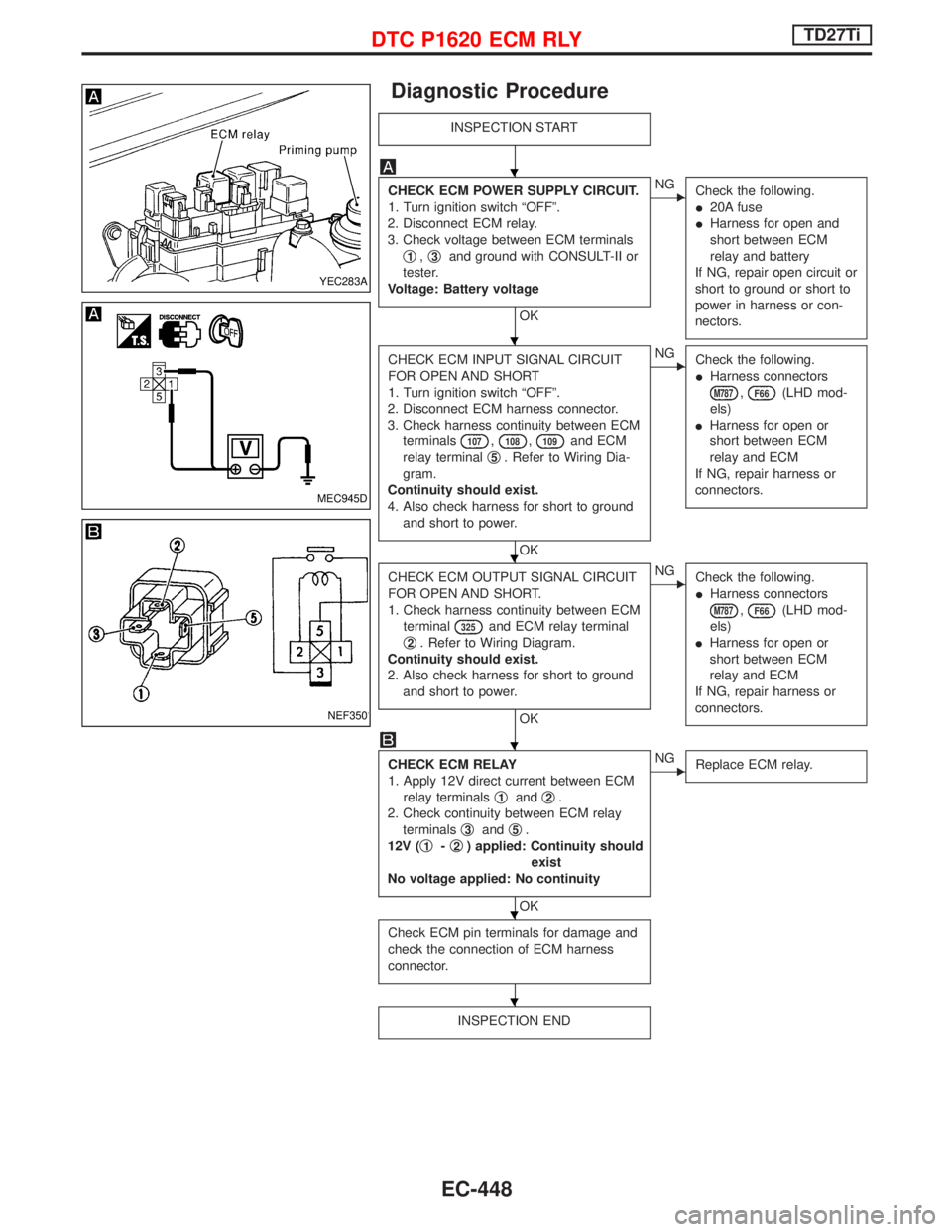

Diagnostic Procedure

INSPECTION START

CHECK ECM POWER SUPPLY CIRCUIT.

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

3. Check voltage between ECM terminals

q

1,q3and ground with CONSULT-II or

tester.

Voltage: Battery voltage

OK

ENG

Check the following.

I20A fuse

IHarness for open and

short between ECM

relay and battery

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

CHECK ECM INPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminals

107,108,109and ECM

relay terminalq

5. Refer to Wiring Dia-

gram.

Continuity should exist.

4. Also check harness for short to ground

and short to power.

OK

ENG

Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

IHarness for open or

short between ECM

relay and ECM

If NG, repair harness or

connectors.

CHECK ECM OUTPUT SIGNAL CIRCUIT

FOR OPEN AND SHORT.

1. Check harness continuity between ECM

terminal

325and ECM relay terminal

q

2. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground

and short to power.

OK

ENG

Check the following.

IHarness connectors

M787,F66(LHD mod-

els)

IHarness for open or

short between ECM

relay and ECM

If NG, repair harness or

connectors.

CHECK ECM RELAY

1. Apply 12V direct current between ECM

relay terminalsq

1andq2.

2. Check continuity between ECM relay

terminalsq

3andq5.

12V (q

1-q2) applied: Continuity should

exist

No voltage applied: No continuity

OK

ENG

Replace ECM relay.

Check ECM pin terminals for damage and

check the connection of ECM harness

connector.

INSPECTION END

YEC283A

MEC945D

NEF350

H

H

H

H

H

H

DTC P1620 ECM RLYTD27Ti

EC-448

Page 811 of 1767

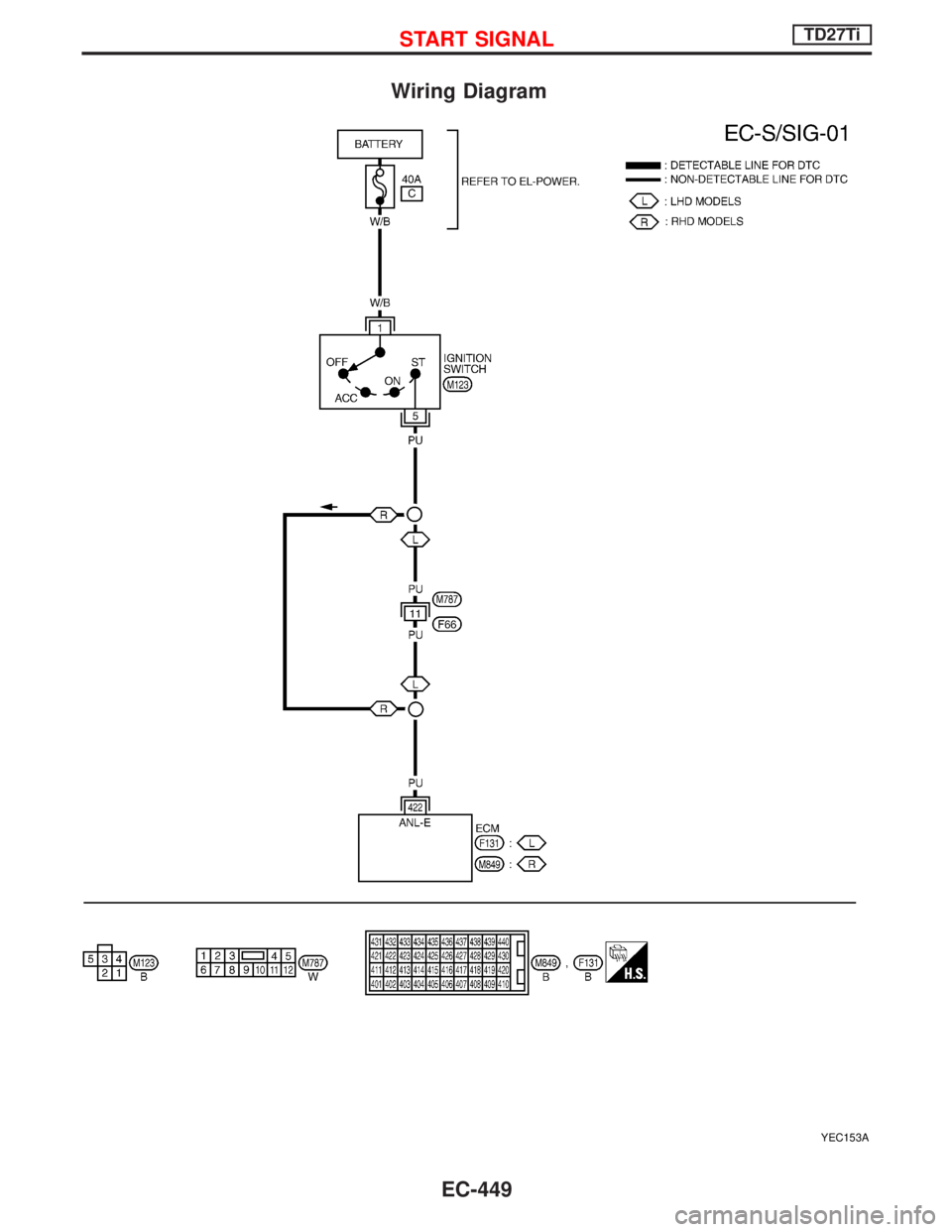

Wiring Diagram

YEC153A

START SIGNALTD27Ti

EC-449

Page 812 of 1767

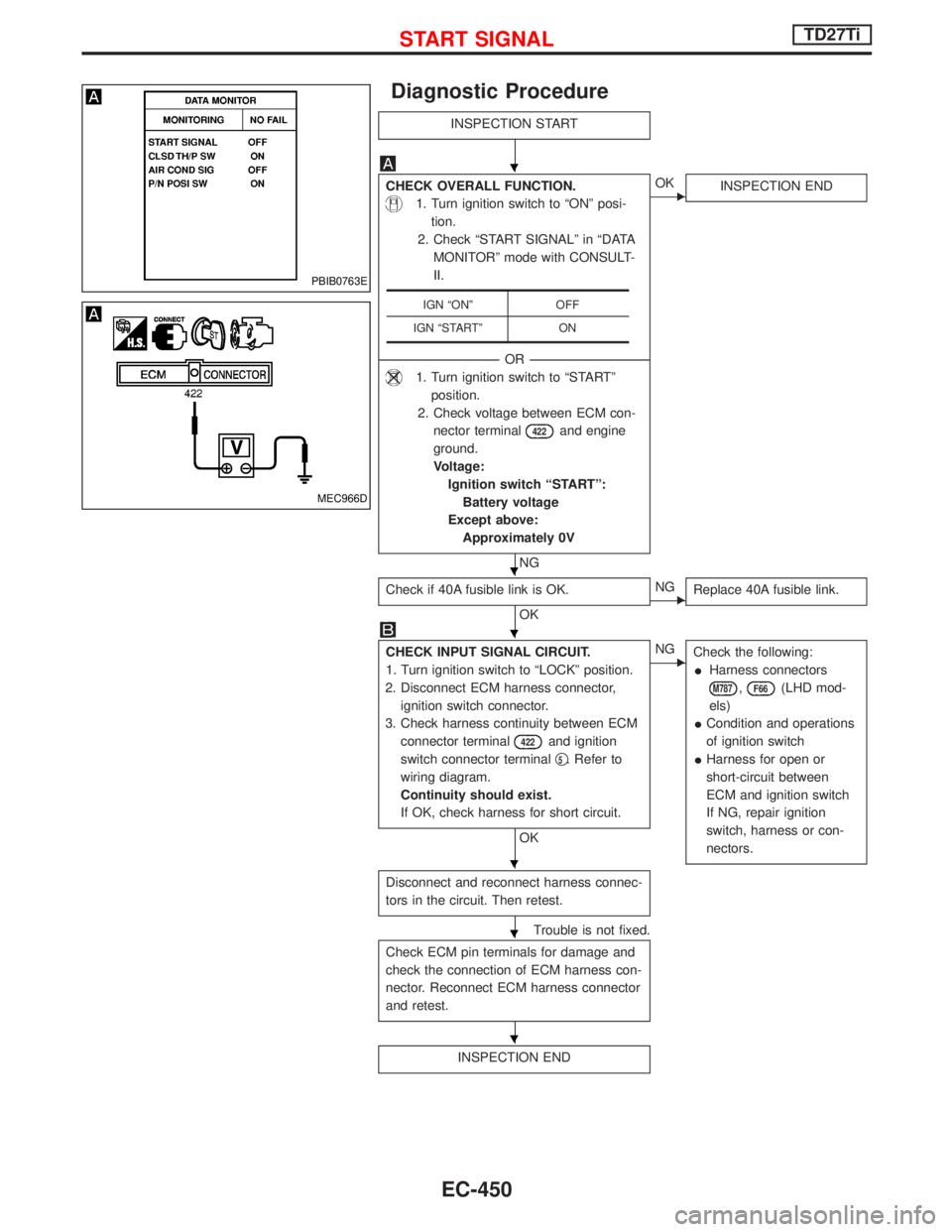

Diagnostic Procedure

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch to ªONº posi-

tion.

2. Check ªSTART SIGNALº in ªDATA

MONITORº mode with CONSULT-

II.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ªSTARTº

position.

2. Check voltage between ECM con-

nector terminal

422and engine

ground.

Voltage:

Ignition switch ªSTARTº:

Battery voltage

Except above:

Approximately 0V

NG

EOK

INSPECTION END

Check if 40A fusible link is OK.

OKENG

Replace 40A fusible link.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch to ªLOCKº position.

2. Disconnect ECM harness connector,

ignition switch connector.

3. Check harness continuity between ECM

connector terminal

422and ignition

switch connector terminalq

5. Refer to

wiring diagram.

Continuity should exist.

If OK, check harness for short circuit.

OK

ENG

Check the following:

IHarness connectors

M787,F66(LHD mod-

els)

ICondition and operations

of ignition switch

IHarness for open or

short-circuit between

ECM and ignition switch

If NG, repair ignition

switch, harness or con-

nectors.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not fixed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

IGN ªONº OFF

IGN ªSTARTº ON

PBIB0763E

MEC966D

H

H

H

H

H

H

START SIGNALTD27Ti

EC-450

Page 835 of 1767

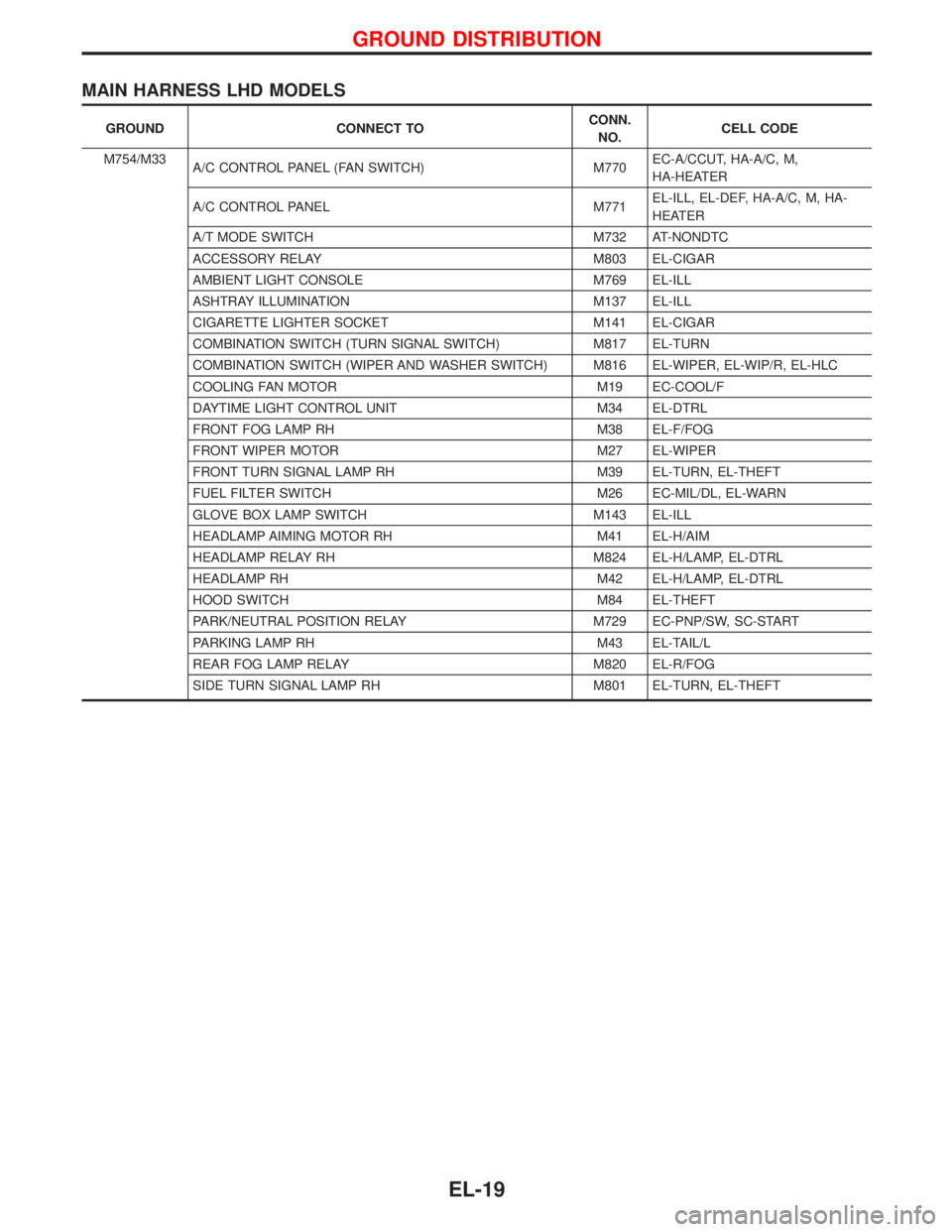

MAIN HARNESS LHD MODELS

GROUND CONNECT TOCONN.

NO.CELL CODE

M754/M33

A/C CONTROL PANEL (FAN SWITCH) M770EC-A/CCUT, HA-A/C, M,

HA-HEATER

A/C CONTROL PANEL M771EL-ILL, EL-DEF, HA-A/C, M, HA-

HEATER

A/T MODE SWITCH M732 AT-NONDTC

ACCESSORY RELAY M803 EL-CIGAR

AMBIENT LIGHT CONSOLE M769 EL-ILL

ASHTRAY ILLUMINATION M137 EL-ILL

CIGARETTE LIGHTER SOCKET M141 EL-CIGAR

COMBINATION SWITCH (TURN SIGNAL SWITCH) M817 EL-TURN

COMBINATION SWITCH (WIPER AND WASHER SWITCH) M816 EL-WIPER, EL-WIP/R, EL-HLC

COOLING FAN MOTOR M19 EC-COOL/F

DAYTIME LIGHT CONTROL UNIT M34 EL-DTRL

FRONT FOG LAMP RH M38 EL-F/FOG

FRONT WIPER MOTOR M27 EL-WIPER

FRONT TURN SIGNAL LAMP RH M39 EL-TURN, EL-THEFT

FUEL FILTER SWITCH M26 EC-MIL/DL, EL-WARN

GLOVE BOX LAMP SWITCH M143 EL-ILL

HEADLAMP AIMING MOTOR RH M41 EL-H/AIM

HEADLAMP RELAY RH M824 EL-H/LAMP, EL-DTRL

HEADLAMP RH M42 EL-H/LAMP, EL-DTRL

HOOD SWITCH M84 EL-THEFT

PARK/NEUTRAL POSITION RELAY M729 EC-PNP/SW, SC-START

PARKING LAMP RH M43 EL-TAIL/L

REAR FOG LAMP RELAY M820 EL-R/FOG

SIDE TURN SIGNAL LAMP RH M801 EL-TURN, EL-THEFT

GROUND DISTRIBUTION

EL-19

Page 836 of 1767

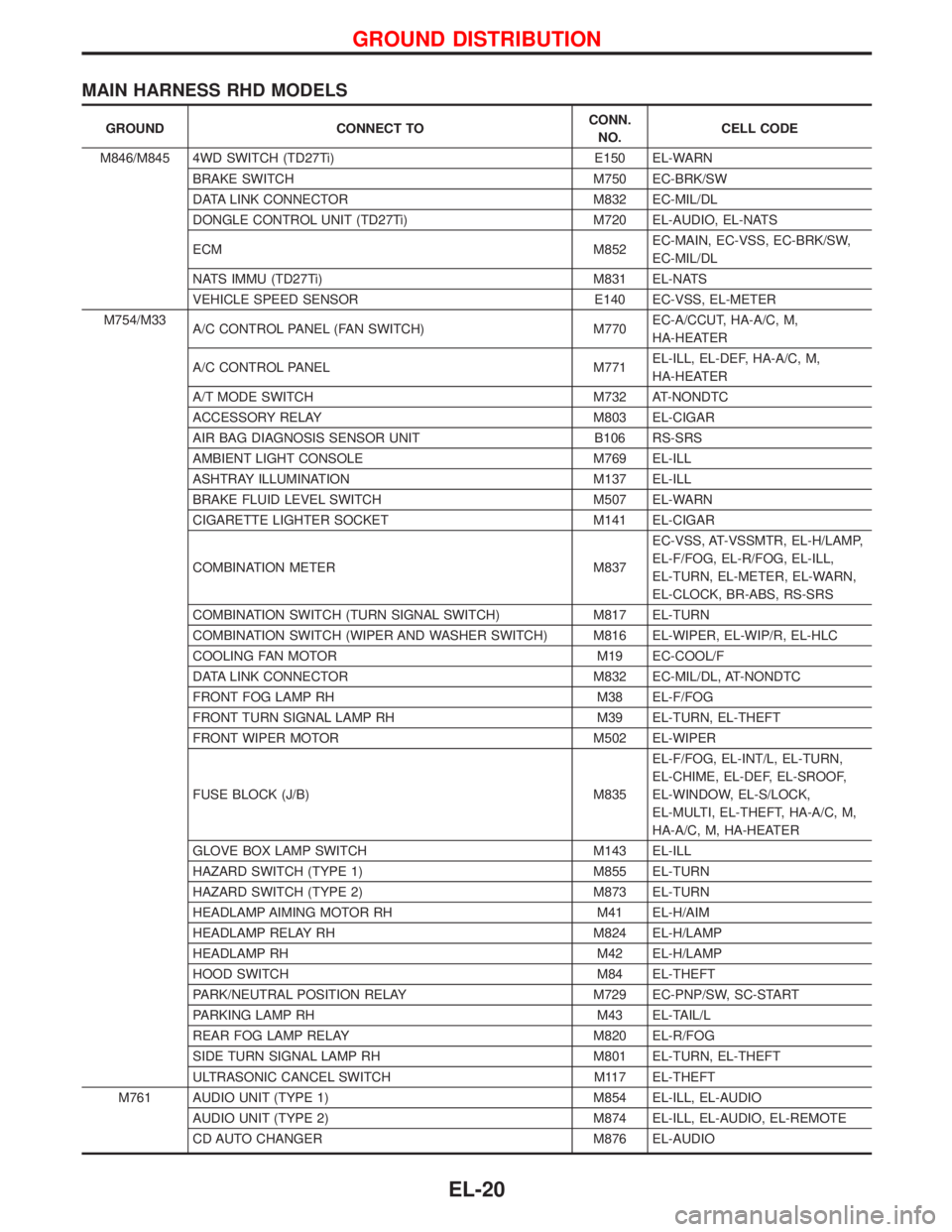

MAIN HARNESS RHD MODELS

GROUND CONNECT TOCONN.

NO.CELL CODE

M846/M845 4WD SWITCH (TD27Ti) E150 EL-WARN

BRAKE SWITCH M750 EC-BRK/SW

DATA LINK CONNECTOR M832 EC-MIL/DL

DONGLE CONTROL UNIT (TD27Ti) M720 EL-AUDIO, EL-NATS

ECM M852EC-MAIN, EC-VSS, EC-BRK/SW,

EC-MIL/DL

NATS IMMU (TD27Ti) M831 EL-NATS

VEHICLE SPEED SENSOR E140 EC-VSS, EL-METER

M754/M33

A/C CONTROL PANEL (FAN SWITCH) M770EC-A/CCUT, HA-A/C, M,

HA-HEATER

A/C CONTROL PANEL M771EL-ILL, EL-DEF, HA-A/C, M,

HA-HEATER

A/T MODE SWITCH M732 AT-NONDTC

ACCESSORY RELAY M803 EL-CIGAR

AIR BAG DIAGNOSIS SENSOR UNIT B106 RS-SRS

AMBIENT LIGHT CONSOLE M769 EL-ILL

ASHTRAY ILLUMINATION M137 EL-ILL

BRAKE FLUID LEVEL SWITCH M507 EL-WARN

CIGARETTE LIGHTER SOCKET M141 EL-CIGAR

COMBINATION METER M837EC-VSS, AT-VSSMTR, EL-H/LAMP,

EL-F/FOG, EL-R/FOG, EL-ILL,

EL-TURN, EL-METER, EL-WARN,

EL-CLOCK, BR-ABS, RS-SRS

COMBINATION SWITCH (TURN SIGNAL SWITCH) M817 EL-TURN

COMBINATION SWITCH (WIPER AND WASHER SWITCH) M816 EL-WIPER, EL-WIP/R, EL-HLC

COOLING FAN MOTOR M19 EC-COOL/F

DATA LINK CONNECTOR M832 EC-MIL/DL, AT-NONDTC

FRONT FOG LAMP RH M38 EL-F/FOG

FRONT TURN SIGNAL LAMP RH M39 EL-TURN, EL-THEFT

FRONT WIPER MOTOR M502 EL-WIPER

FUSE BLOCK (J/B) M835EL-F/FOG, EL-INT/L, EL-TURN,

EL-CHIME, EL-DEF, EL-SROOF,

EL-WINDOW, EL-S/LOCK,

EL-MULTI, EL-THEFT, HA-A/C, M,

HA-A/C, M, HA-HEATER

GLOVE BOX LAMP SWITCH M143 EL-ILL

HAZARD SWITCH (TYPE 1) M855 EL-TURN

HAZARD SWITCH (TYPE 2) M873 EL-TURN

HEADLAMP AIMING MOTOR RH M41 EL-H/AIM

HEADLAMP RELAY RH M824 EL-H/LAMP

HEADLAMP RH M42 EL-H/LAMP

HOOD SWITCH M84 EL-THEFT

PARK/NEUTRAL POSITION RELAY M729 EC-PNP/SW, SC-START

PARKING LAMP RH M43 EL-TAIL/L

REAR FOG LAMP RELAY M820 EL-R/FOG

SIDE TURN SIGNAL LAMP RH M801 EL-TURN, EL-THEFT

ULTRASONIC CANCEL SWITCH M117 EL-THEFT

M761 AUDIO UNIT (TYPE 1) M854 EL-ILL, EL-AUDIO

AUDIO UNIT (TYPE 2) M874 EL-ILL, EL-AUDIO, EL-REMOTE

CD AUTO CHANGER M876 EL-AUDIO

GROUND DISTRIBUTION

EL-20

Page 845 of 1767

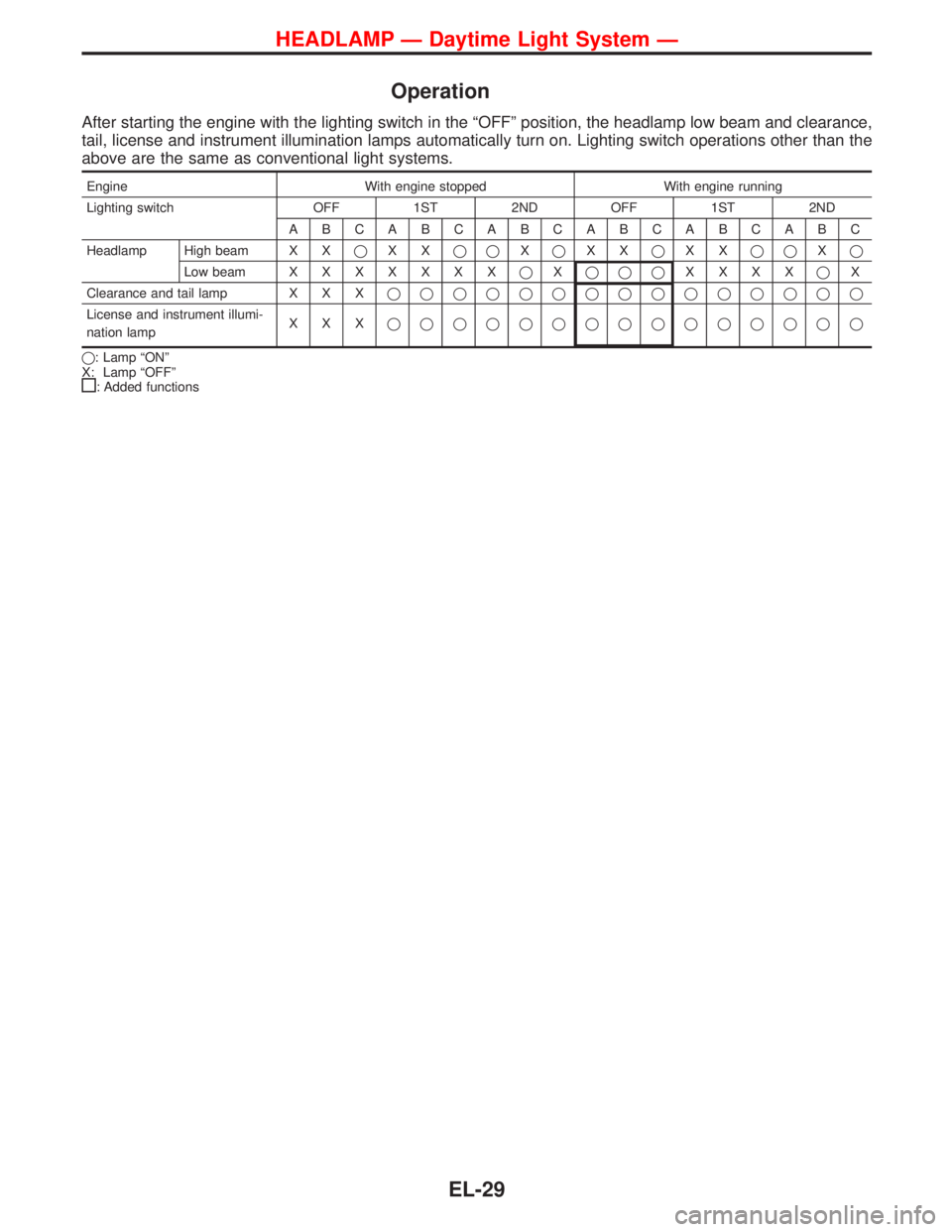

Operation

After starting the engine with the lighting switch in the ªOFFº position, the headlamp low beam and clearance,

tail, license and instrument illumination lamps automatically turn on. Lighting switch operations other than the

above are the same as conventional light systems.

Engine With engine stopped With engine running

Lighting switch OFF 1ST 2ND OFF 1ST 2ND

ABCABCABCABCABCABC

Headlamp High beam X XqXXqqXqXXqXXqqXq

Low beamXXXXXXXqXqqqXXXXqX

Clearance and tail lamp X X Xqqqqqqqqqqqqqqq

License and instrument illumi-

nation lampXXXqqqqqqqqqqqqqqq

q: Lamp ªONº

X: Lamp ªOFFº

: Added functions

HEADLAMP Ð Daytime Light System Ð

EL-29

Page 892 of 1767

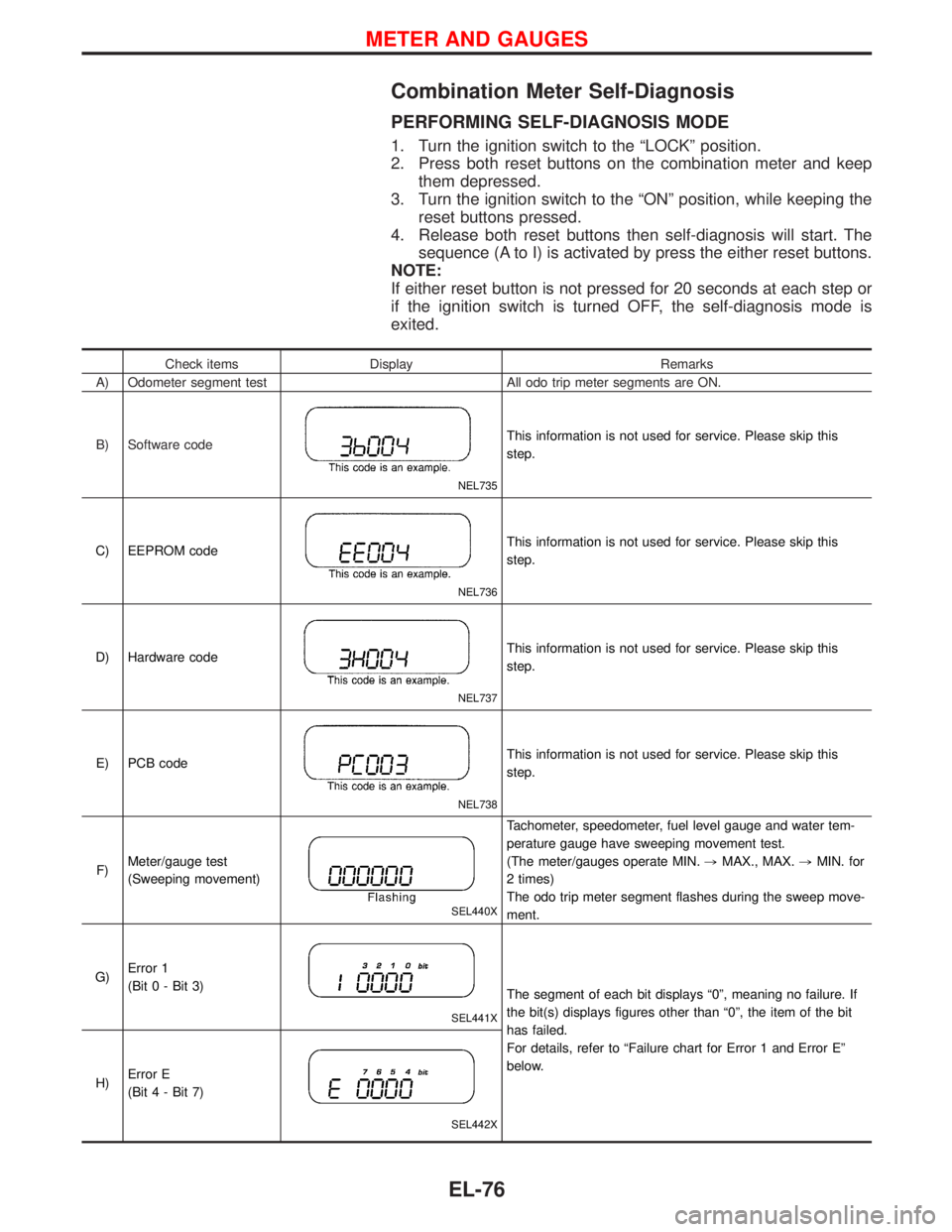

Combination Meter Self-Diagnosis

PERFORMING SELF-DIAGNOSIS MODE

1. Turn the ignition switch to the ªLOCKº position.

2. Press both reset buttons on the combination meter and keep

them depressed.

3. Turn the ignition switch to the ªONº position, while keeping the

reset buttons pressed.

4. Release both reset buttons then self-diagnosis will start. The

sequence (A to I) is activated by press the either reset buttons.

NOTE:

If either reset button is not pressed for 20 seconds at each step or

if the ignition switch is turned OFF, the self-diagnosis mode is

exited.

Check items Display Remarks

A) Odometer segment test All odo trip meter segments are ON.

B) Software code

NEL735

This information is not used for service. Please skip this

step.

C) EEPROM code

NEL736

This information is not used for service. Please skip this

step.

D) Hardware code

NEL737

This information is not used for service. Please skip this

step.

E) PCB code

NEL738

This information is not used for service. Please skip this

step.

F)Meter/gauge test

(Sweeping movement)

SEL440X

Tachometer, speedometer, fuel level gauge and water tem-

perature gauge have sweeping movement test.

(The meter/gauges operate MIN.,MAX., MAX.,MIN. for

2 times)

The odo trip meter segment flashes during the sweep move-

ment.

G)Error 1

(Bit 0 - Bit 3)

SEL441X

The segment of each bit displays ª0º, meaning no failure. If

the bit(s) displays figures other than ª0º, the item of the bit

has failed.

For details, refer to ªFailure chart for Error 1 and Error Eº

below.

H)Error E

(Bit 4 - Bit 7)

SEL442X

METER AND GAUGES

EL-76

Page 896 of 1767

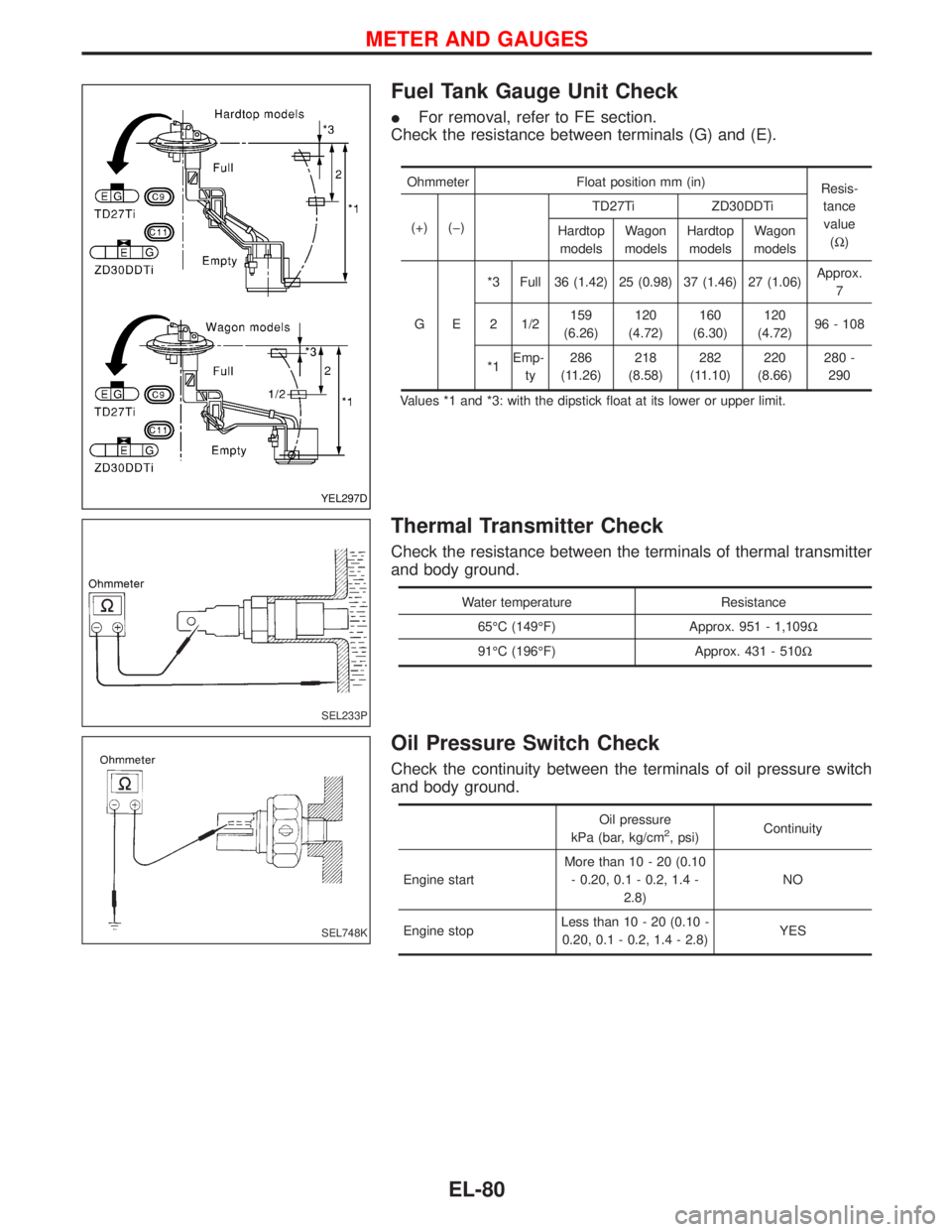

Fuel Tank Gauge Unit Check

IFor removal, refer to FE section.

Check the resistance between terminals (G) and (E).

Ohmmeter Float position mm (in)

Resis-

tance

value

(W) (+) (þ)TD27Ti ZD30DDTi

Hardtop

modelsWagon

modelsHardtop

modelsWagon

models

GE*3 Full 36 (1.42) 25 (0.98) 37 (1.46) 27 (1.06)Approx.

7

2 1/2159

(6.26)120

(4.72)160

(6.30)120

(4.72)96 - 108

*1Emp-

ty286

(11.26)218

(8.58)282

(11.10)220

(8.66)280 -

290

Values *1 and *3: with the dipstick float at its lower or upper limit.

Thermal Transmitter Check

Check the resistance between the terminals of thermal transmitter

and body ground.

Water temperature Resistance

65ÉC (149ÉF) Approx. 951 - 1,109W

91ÉC (196ÉF) Approx. 431 - 510W

Oil Pressure Switch Check

Check the continuity between the terminals of oil pressure switch

and body ground.

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20 (0.10

- 0.20, 0.1 - 0.2, 1.4 -

2.8)NO

Engine stopLess than 10 - 20 (0.10 -

0.20, 0.1 - 0.2, 1.4 - 2.8)YES

YEL297D

SEL233P

SEL748K

METER AND GAUGES

EL-80

Page 927 of 1767

System Description

Refer to Owner's Manual for audio system operating instructions.

NATS AUDIO LINK

Description

The link with the NATS IMMU implies that the audio unit can basically only be operated if connected to the

matching NATS IMMU to which the audio unit was initially fitted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the audio unit is basically

useless since special equipment is required to reset the audio unit.

Initialization process for audio units that are linked to the NATS IMMU

New audio units will be delivered to the factories in the ªNEWº state, i.e. ready to be linked with the vehicle's

NATS. When the audio unit in ªNEWº state is first switched on at the factory, it will start up communication

with the vehicle's immobiliser control unit (IMMU) and send a code (the ªaudio unit Codeº) to the IMMU. The

IMMU will then store this code, which is unique to each audio unit, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will confirm correct receipt of the audio unit code to the audio

unit. Hereafter, the audio unit will operate as normal.

During the initialisation process, ªNEWº is displayed on the audio unit display. Normally though, communica-

tion between audio unit and IMMU takes such a short time that the audio unit seems to switch on directly

without showing ªNEWº on its display.

Normal operation

Each time the audio unit is switched on afterwards, the audio unit code will be verified between the audio unit

and the NATS before the audio unit becomes operational. During the code verification process, ªWAITº is

shown on the audio unit display. Again, the communication takes such a short time that the audio unit seems

to switch on directly without showing ªWAITº on its display.

When the radio is locked

In case of a audio unit being linked with the vehicle's NATS (immobilizer system), disconnection of the link

between the audio unit and the IMMU will cause the audio unit to switch into the lock (ªSECUREº) mode in

which the audio unit is fully inoperative. Hence, repair of the audio unit is basically impossible, unless the audio

unit is reset to the ªNEWº state for which special decoding equipment is required.

Clarion has provided their authorized service representatives with so called ªdecoder boxesº which can bring

the audio unit back to the ªNEWº state, enabling the audio unit to be switched on after which repair can be

carried out. Subsequently, when the repaired audio unit is delivered to the final user again, it will be in the

ªNEWº state as to enable re-linking the audio unit to the vehicle's immobiliser system. As a result of the above,

repair of the audio unit can only be done by an authorized Clarion representative.

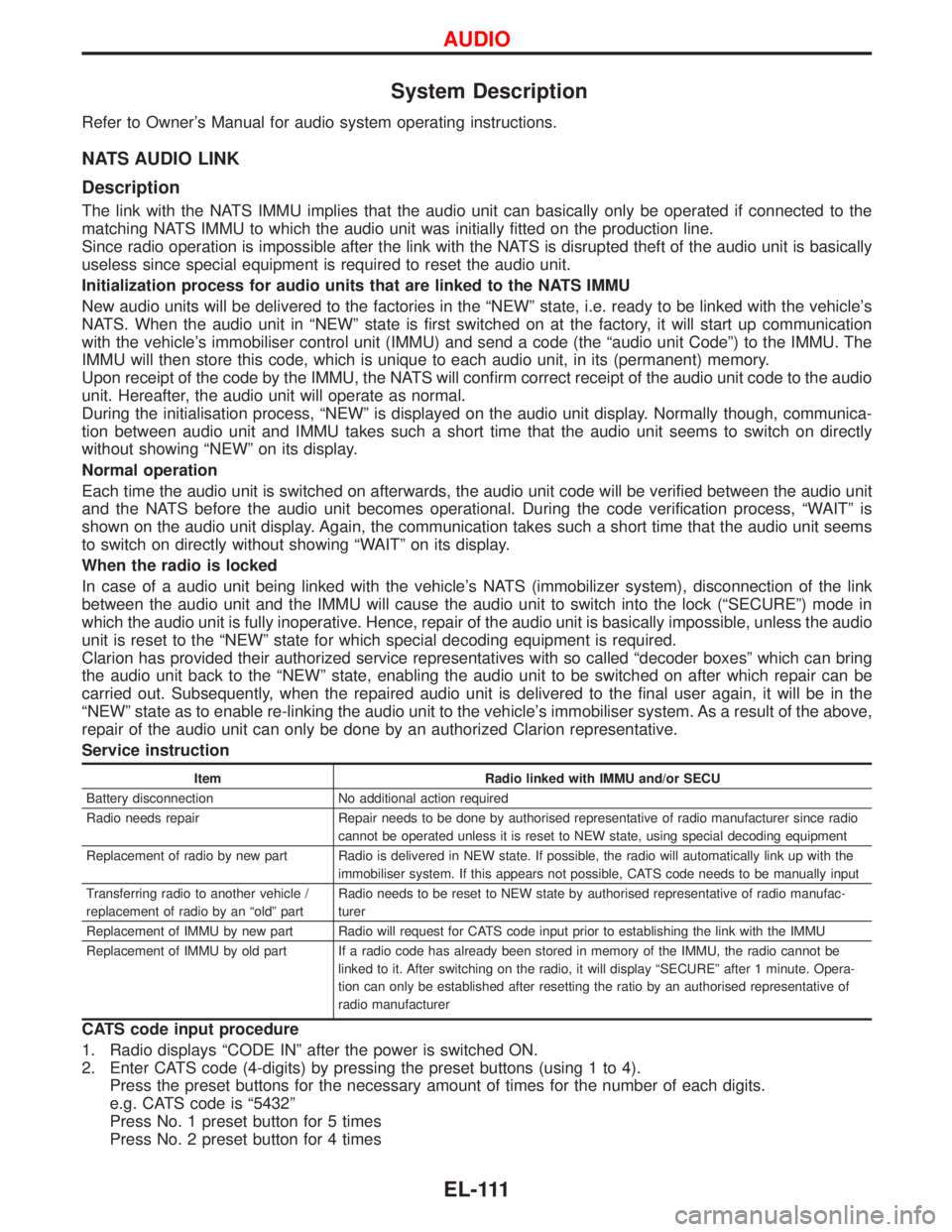

Service instruction

Item Radio linked with IMMU and/or SECU

Battery disconnection No additional action required

Radio needs repair Repair needs to be done by authorised representative of radio manufacturer since radio

cannot be operated unless it is reset to NEW state, using special decoding equipment

Replacement of radio by new part Radio is delivered in NEW state. If possible, the radio will automatically link up with the

immobiliser system. If this appears not possible, CATS code needs to be manually input

Transferring radio to another vehicle /

replacement of radio by an ªoldº partRadio needs to be reset to NEW state by authorised representative of radio manufac-

turer

Replacement of IMMU by new part Radio will request for CATS code input prior to establishing the link with the IMMU

Replacement of IMMU by old part If a radio code has already been stored in memory of the IMMU, the radio cannot be

linked to it. After switching on the radio, it will display ªSECUREº after 1 minute. Opera-

tion can only be established after resetting the ratio by an authorised representative of

radio manufacturer

CATS code input procedure

1. Radio displays ªCODE INº after the power is switched ON.

2. Enter CATS code (4-digits) by pressing the preset buttons (using 1 to 4).

Press the preset buttons for the necessary amount of times for the number of each digits.

e.g. CATS code is ª5432º

Press No. 1 preset button for 5 times

Press No. 2 preset button for 4 times

AUDIO

EL-111

Page 941 of 1767

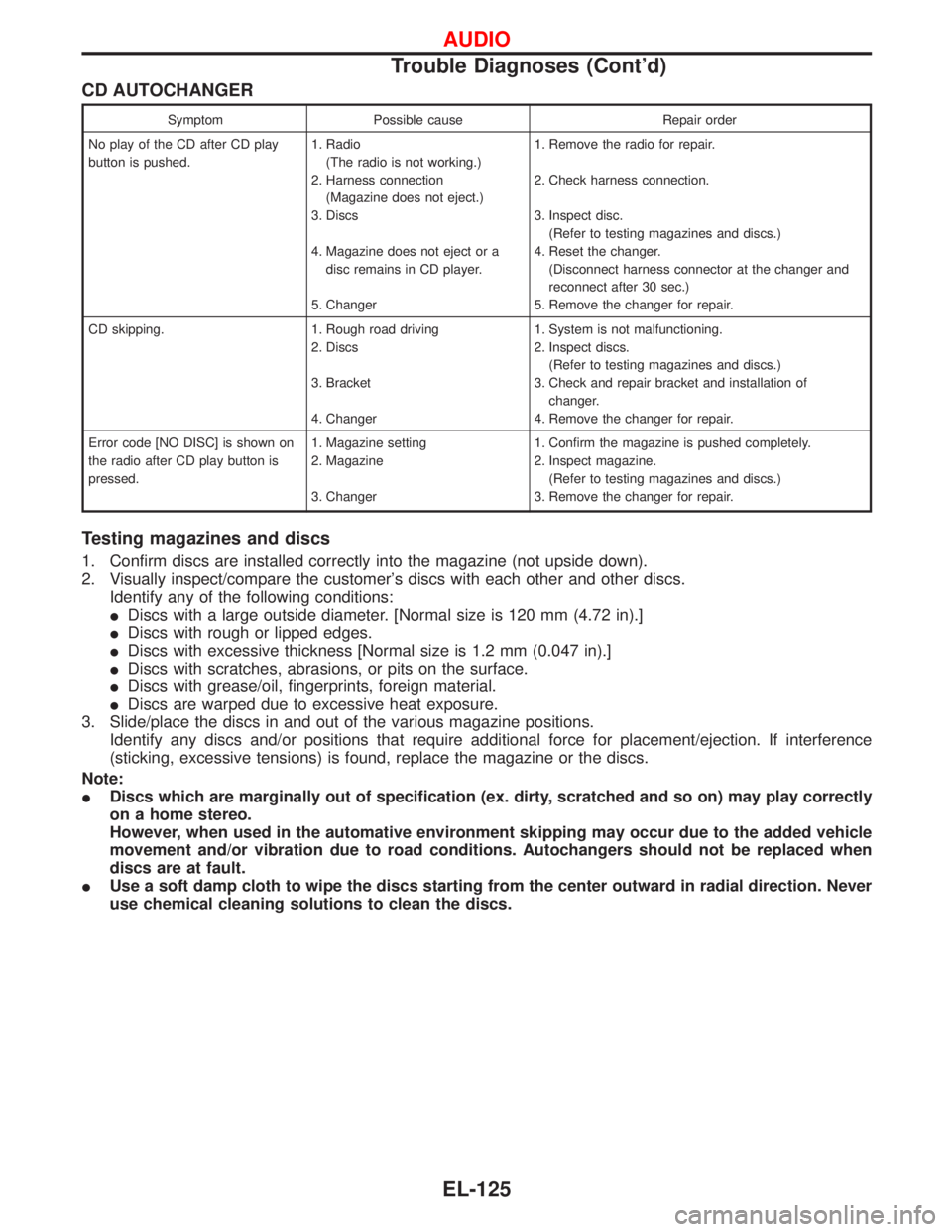

CD AUTOCHANGER

Symptom Possible cause Repair order

No play of the CD after CD play

button is pushed.1. Radio

(The radio is not working.)

2. Harness connection

(Magazine does not eject.)

3. Discs

4. Magazine does not eject or a

disc remains in CD player.

5. Changer1. Remove the radio for repair.

2. Check harness connection.

3. Inspect disc.

(Refer to testing magazines and discs.)

4. Reset the changer.

(Disconnect harness connector at the changer and

reconnect after 30 sec.)

5. Remove the changer for repair.

CD skipping. 1. Rough road driving

2. Discs

3. Bracket

4. Changer1. System is not malfunctioning.

2. Inspect discs.

(Refer to testing magazines and discs.)

3. Check and repair bracket and installation of

changer.

4. Remove the changer for repair.

Error code [NO DISC] is shown on

the radio after CD play button is

pressed.1. Magazine setting

2. Magazine

3. Changer1. Confirm the magazine is pushed completely.

2. Inspect magazine.

(Refer to testing magazines and discs.)

3. Remove the changer for repair.

Testing magazines and discs

1. Confirm discs are installed correctly into the magazine (not upside down).

2. Visually inspect/compare the customer's discs with each other and other discs.

Identify any of the following conditions:

IDiscs with a large outside diameter. [Normal size is 120 mm (4.72 in).]

IDiscs with rough or lipped edges.

IDiscs with excessive thickness [Normal size is 1.2 mm (0.047 in).]

IDiscs with scratches, abrasions, or pits on the surface.

IDiscs with grease/oil, fingerprints, foreign material.

IDiscs are warped due to excessive heat exposure.

3. Slide/place the discs in and out of the various magazine positions.

Identify any discs and/or positions that require additional force for placement/ejection. If interference

(sticking, excessive tensions) is found, replace the magazine or the discs.

Note:

IDiscs which are marginally out of specification (ex. dirty, scratched and so on) may play correctly

on a home stereo.

However, when used in the automative environment skipping may occur due to the added vehicle

movement and/or vibration due to road conditions. Autochangers should not be replaced when

discs are at fault.

IUse a soft damp cloth to wipe the discs starting from the center outward in radial direction. Never

use chemical cleaning solutions to clean the discs.

AUDIO

Trouble Diagnoses (Cont'd)

EL-125