NISSAN TERRANO 2002 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2002, Model line: TERRANO, Model: NISSAN TERRANO 2002Pages: 1767, PDF Size: 41.51 MB

Page 701 of 1767

qA

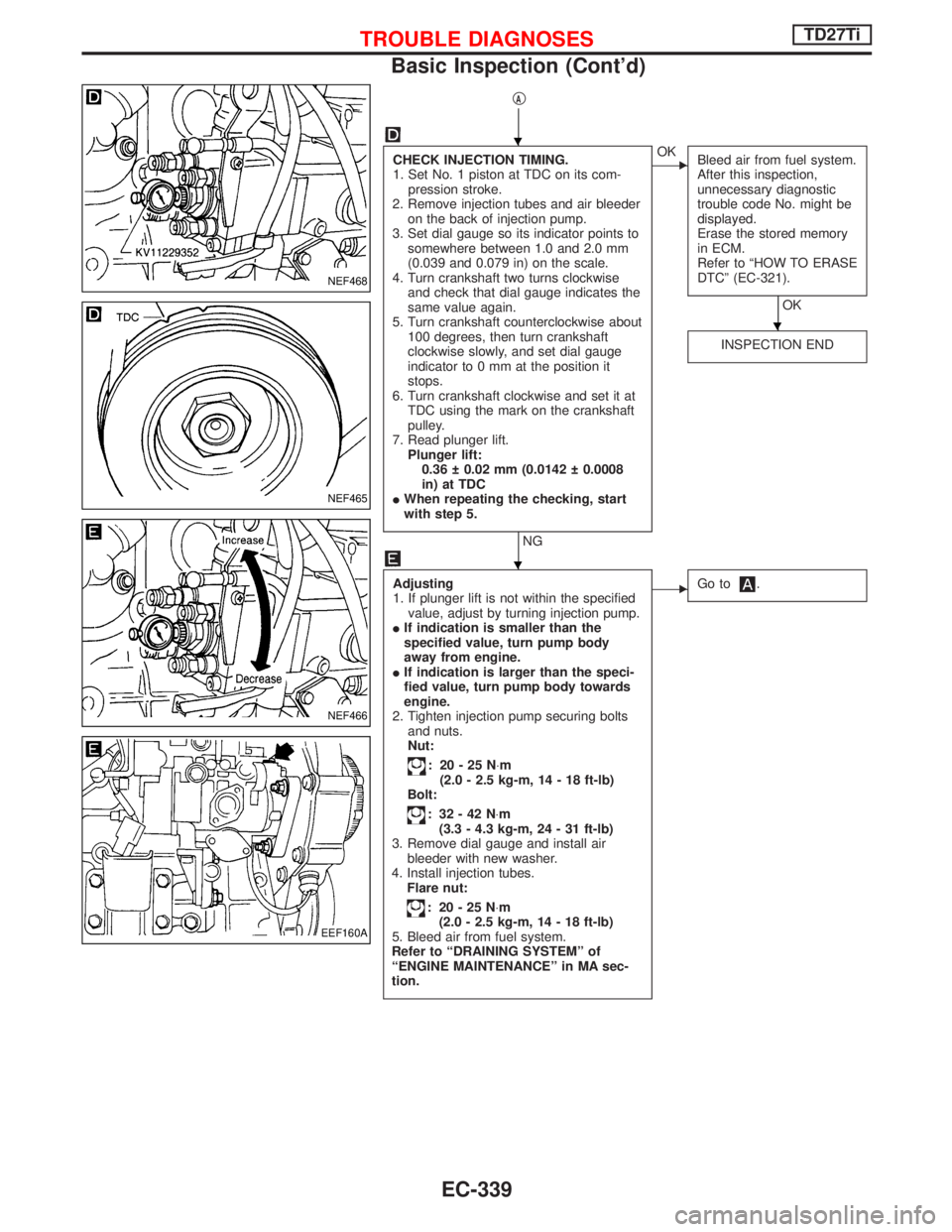

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft two turns clockwise

and check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set it at

TDC using the mark on the crankshaft

pulley.

7. Read plunger lift.

Plunger lift:

0.36 0.02 mm (0.0142 0.0008

in) at TDC

IWhen repeating the checking, start

with step 5.

NG

EOK

Bleed air from fuel system.

After this inspection,

unnecessary diagnostic

trouble code No. might be

displayed.

Erase the stored memory

in ECM.

Refer to ªHOW TO ERASE

DTCº (EC-321).

OK

INSPECTION END

Adjusting

1. If plunger lift is not within the specified

value, adjust by turning injection pump.

IIf indication is smaller than the

specified value, turn pump body

away from engine.

IIf indication is larger than the speci-

fied value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 20-25N×m

(2.0 - 2.5 kg-m, 14 - 18 ft-lb)

Bolt:

: 32-42N×m

(3.3 - 4.3 kg-m, 24 - 31 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 20-25N×m

(2.0 - 2.5 kg-m, 14 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ªDRAINING SYSTEMº of

ªENGINE MAINTENANCEº in MA sec-

tion.

EGo to.

NEF468

NEF465

NEF466

EEF160A

H

H

H

TROUBLE DIAGNOSESTD27Ti

Basic Inspection (Cont'd)

EC-339

Page 702 of 1767

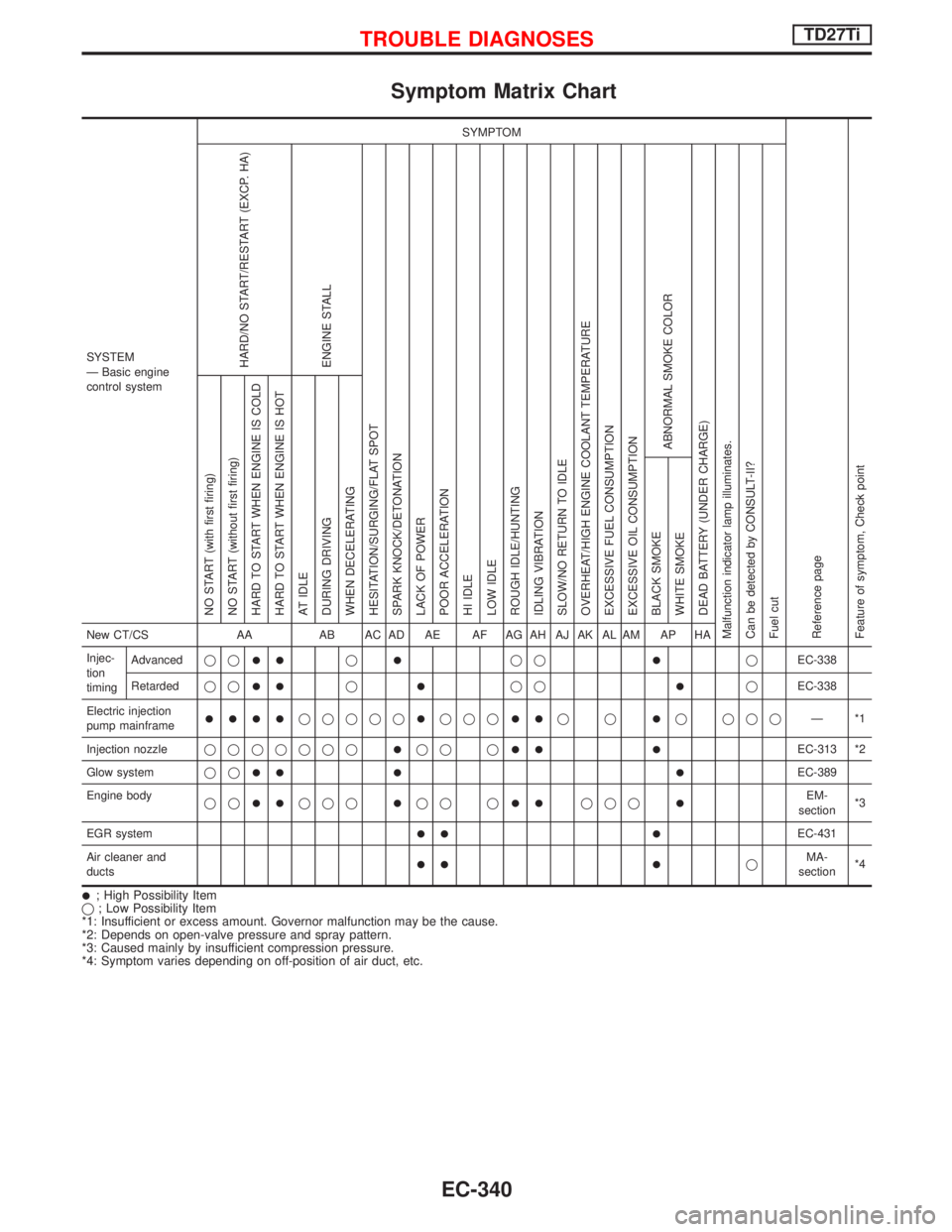

Symptom Matrix Chart

SYSTEM

Ð Basic engine

control systemSYMPTOM

Reference page

Feature of symptom, Check pointHARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE)

Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cutNO START (with first firing)

NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATING

BLACK SMOKE

WHITE SMOKENew CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Injec-

tion

timingAdvancedqq

IIqIqqIqEC-338

Retardedqq

IIqIqqIqEC-338

Electric injection

pump mainframe

IIIIqqqqqIqqqIIqqIq qqqÐ*1

Injection nozzleqqqqqqq

Iqq qII IEC-313 *2

Glow systemqq

II I IEC-389

Engine body

qq

IIqqqIqq qIIqqqIEM-

section*3

EGR system

II IEC-431

Air cleaner and

ducts

II IqMA-

section*4

I; High Possibility Item

q; Low Possibility Item

*1: Insufficient or excess amount. Governor malfunction may be the cause.

*2: Depends on open-valve pressure and spray pattern.

*3: Caused mainly by insufficient compression pressure.

*4: Symptom varies depending on off-position of air duct, etc.

TROUBLE DIAGNOSESTD27Ti

EC-340

Page 703 of 1767

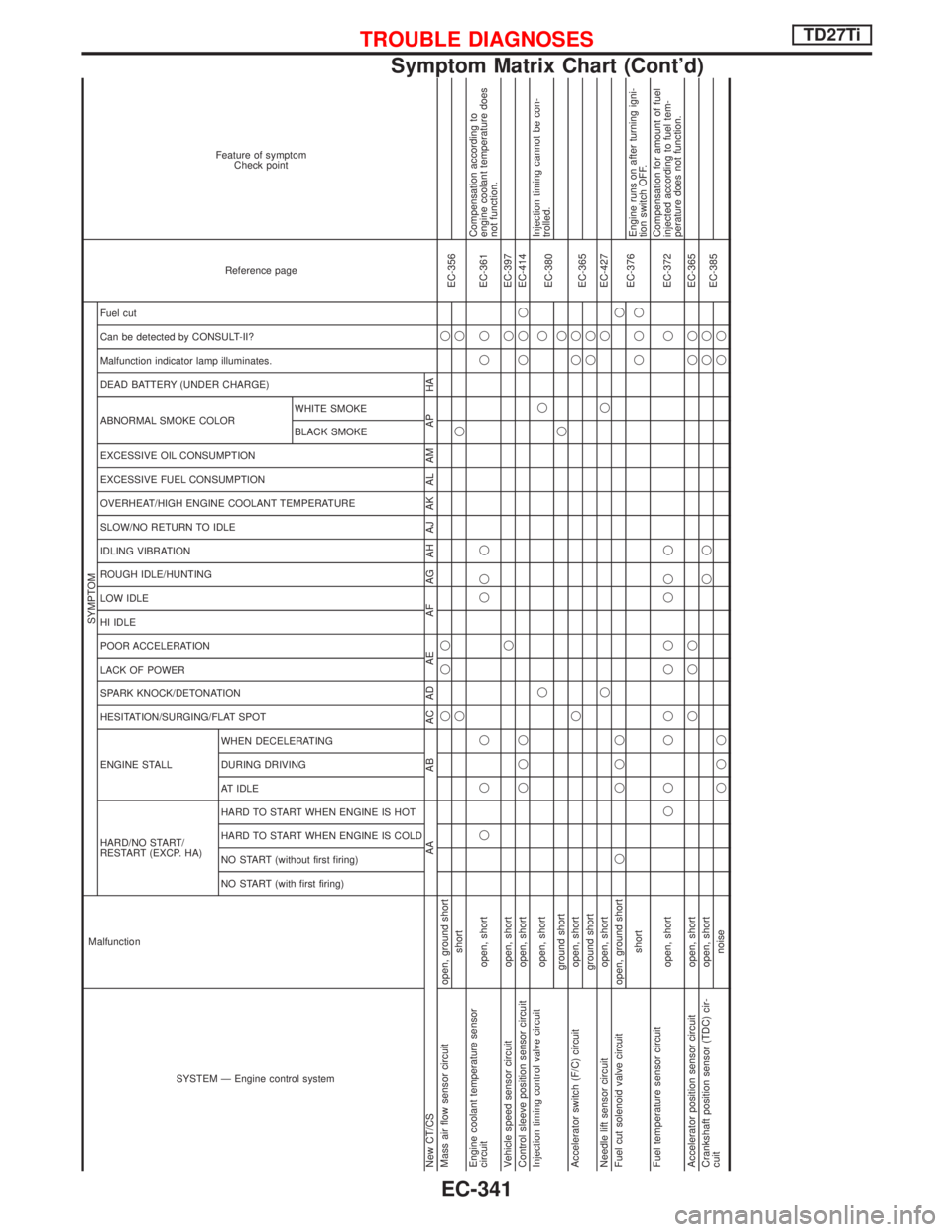

SYSTEM Ð Engine control system Malfunction

SYMPTOM

Reference page Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut

NO START (with first firing) NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

New CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Mass air flow sensor circuit open, ground shortqqq q

EC-356

shortqqq

Engine coolant temperature sensor

circuit open, shortqqq qqq qqEC-361Compensation according to

engine coolant temperature does

not function.

Vehicle speed sensor circuit open, shortqqEC-397

Control sleeve position sensor circuit open, shortqqqqqqEC-414

Injection timing control valve circuit

open, shortqqq

EC-380Injection timing cannot be con-

trolled.

ground shortqq

Accelerator switch (F/C) circuit open, shortqqq

EC-365

ground shortqq

Needle lift sensor circuit open, shortqqqEC-427

Fuel cut solenoid valve circuit open, ground shortq qqqq

EC-376

shortqqqEngine runs on after turning igni-

tion switch OFF.

Fuel temperature sensor circuit

open, shortqq qq qq qq q qEC-372Compensation for amount of fuel

injected according to fuel tem-

perature does not function.

Accelerator position sensor circuit open, shortqqq qqEC-365

Crankshaft position sensor (TDC) cir-

cuitopen, shortqq qq

EC-385

noiseqqqqq

TROUBLE DIAGNOSESTD27Ti

Symptom Matrix Chart (Cont'd)

EC-341

Page 704 of 1767

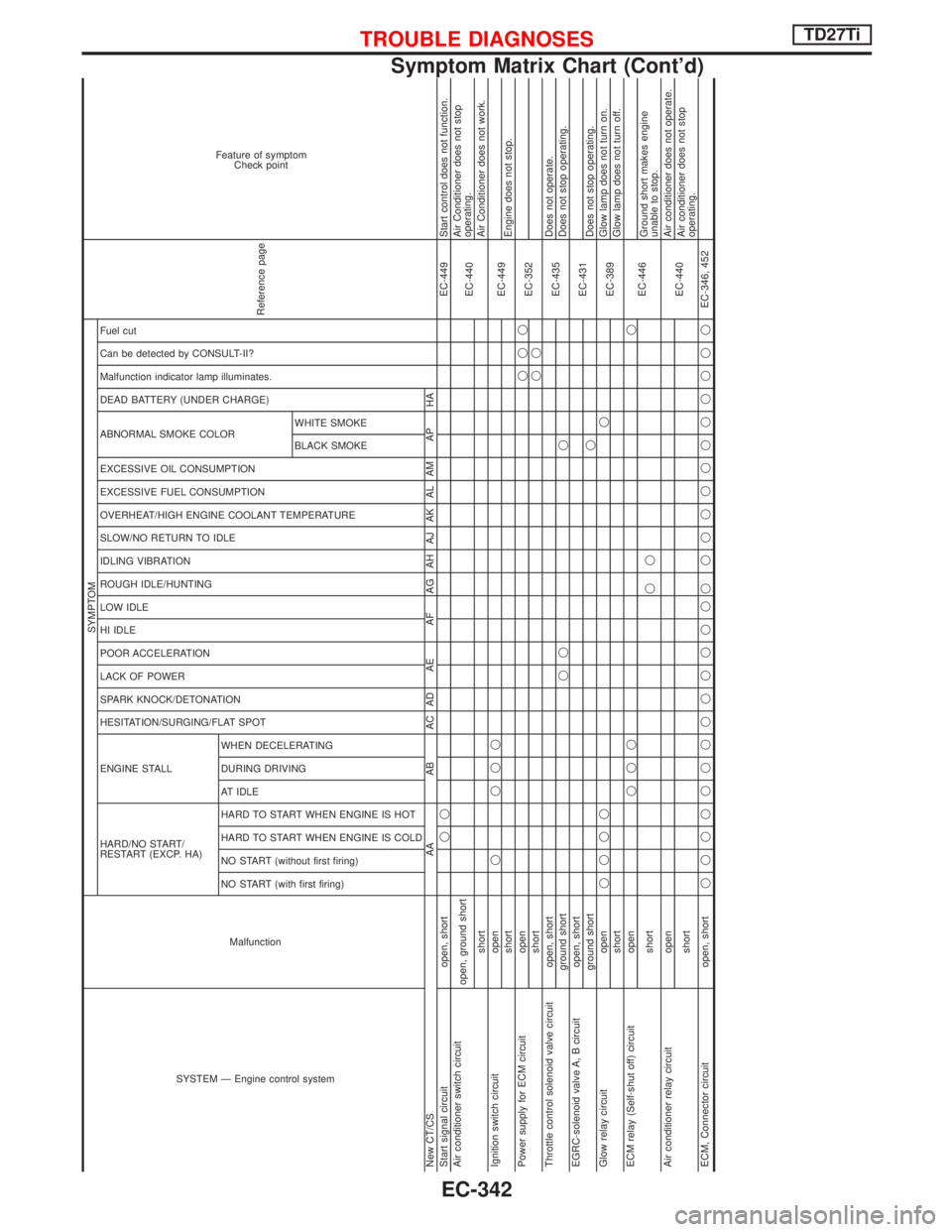

SYSTEM Ð Engine control systemMalfunction

SYMPTOM

Reference page

Feature of symptom

Check point

HARD/NO START/

RESTART (EXCP. HA) ENGINE STALL HESITATION/SURGING/FLAT SPOT SPARK KNOCK/DETONATION

LACK OF POWER

POOR ACCELERATION

HI IDLE

LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEAT/HIGH ENGINE COOLANT TEMPERATURE

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION ABNORMAL SMOKE COLOR

DEAD BATTERY (UNDER CHARGE) Malfunction indicator lamp illuminates.

Can be detected by CONSULT-II?

Fuel cut

NO START (with first firing) NO START (without first firing)

HARD TO START WHEN ENGINE IS COLD

HARD TO START WHEN ENGINE IS HOT

AT IDLE

DURING DRIVING

WHEN DECELERATINGBLACK SMOKE WHITE SMOKE

New CT/CS AA AB AC AD AE AF AG AH AJ AK AL AM AP HA

Start signal circuit open, shortqqEC-449 Start control does not function.

Air conditioner switch circuit

open, ground short

EC-440Air Conditioner does not stop

operating.

shortAir Conditioner does not work.

Ignition switch circuit openq qqq

EC-449

shortEngine does not stop.

Power supply for ECM circuit openqqq

EC-352

shortqq

Throttle control solenoid valve circuit open, short

EC-435Does not operate.

ground shortqq qDoes not stop operating.

EGRC-solenoid valve A, B circuit open, short

EC-431

ground shortqDoes not stop operating.

Glow relay circuit openqqqqq

EC-389Glow lamp does not turn on.

shortGlow lamp does not turn off.

ECM relay (Self-shut off) circuit openqqqq

EC-446

shortqqGround short makes engine

unable to stop.

Air conditioner relay circuit open

EC-440Air conditioner does not operate.

shortAir conditioner does not stop

operating.

ECM, Connector circuit open, shortqqqqqqqqqqqqqq qqqqqqqqqqqEC-346, 452

TROUBLE DIAGNOSESTD27Ti

Symptom Matrix Chart (Cont'd)

EC-342

Page 705 of 1767

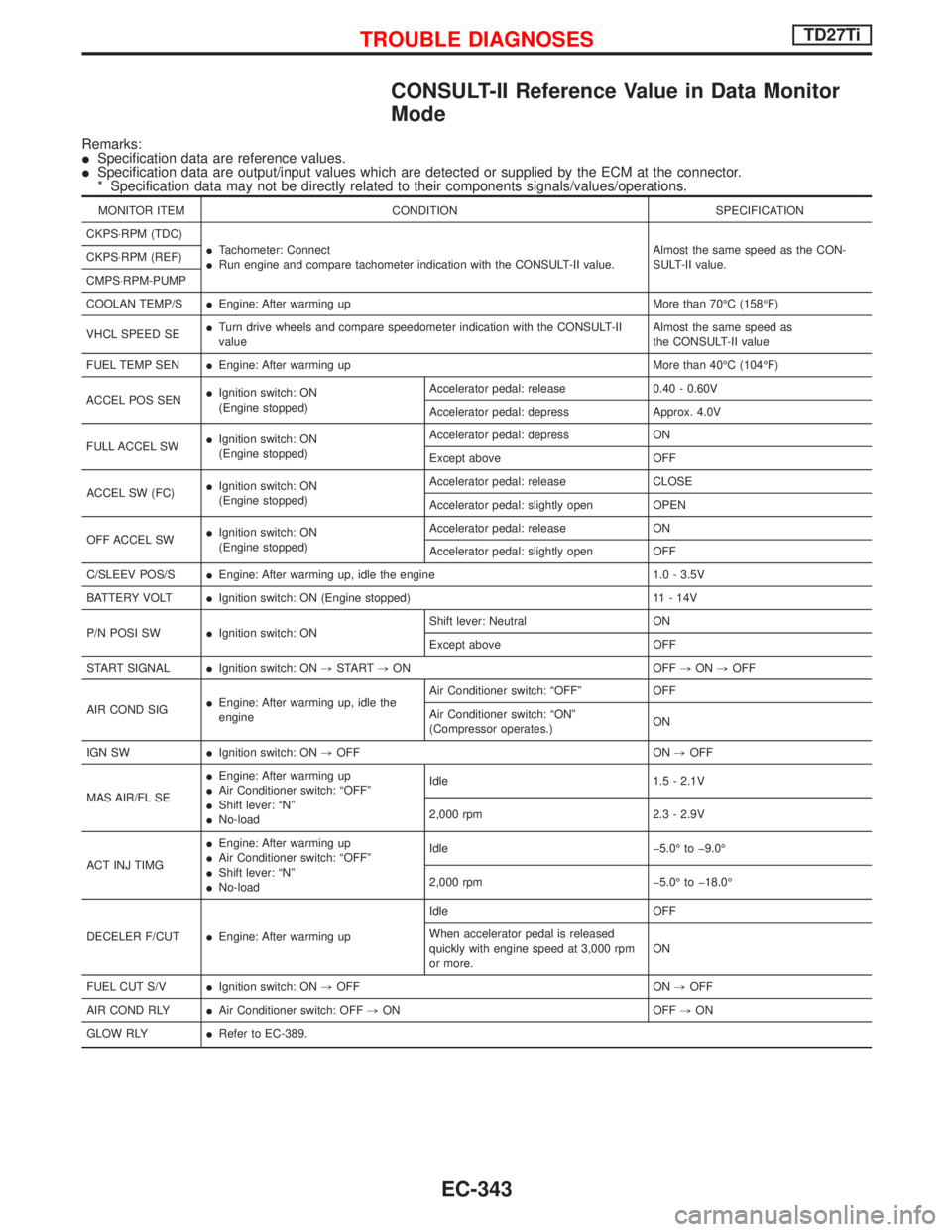

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS×RPM (TDC)

ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II value.Almost the same speed as the CON-

SULT-II value. CKPS×RPM (REF)

CMPS×RPM-PUMP

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CONSULT-II

valueAlmost the same speed as

the CONSULT-II value

FUEL TEMP SENIEngine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SENIIgnition switch: ON

(Engine stopped)Accelerator pedal: release 0.40 - 0.60V

Accelerator pedal: depress Approx. 4.0V

FULL ACCEL SWIIgnition switch: ON

(Engine stopped)Accelerator pedal: depress ON

Except above OFF

ACCEL SW (FC)IIgnition switch: ON

(Engine stopped)Accelerator pedal: release CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SWIIgnition switch: ON

(Engine stopped)Accelerator pedal: release ON

Accelerator pedal: slightly open OFF

C/SLEEV POS/SIEngine: After warming up, idle the engine 1.0 - 3.5V

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

P/N POSI SWIIgnition switch: ONShift lever: Neutral ON

Except above OFF

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

AIR COND SIGIEngine: After warming up, idle the

engineAir Conditioner switch: ªOFFº OFF

Air Conditioner switch: ªONº

(Compressor operates.)ON

IGN SWIIgnition switch: ON,OFF ON,OFF

MAS AIR/FL SEIEngine: After warming up

IAir Conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.5 - 2.1V

2,000 rpm 2.3 - 2.9V

ACT INJ TIMGIEngine: After warming up

IAir Conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle þ5.0É to þ9.0É

2,000 rpm þ5.0É to þ18.0É

DECELER F/CUTIEngine: After warming upIdle OFF

When accelerator pedal is released

quickly with engine speed at 3,000 rpm

or more.ON

FUEL CUT S/VIIgnition switch: ON,OFF ON,OFF

AIR COND RLYIAir Conditioner switch: OFF,ON OFF,ON

GLOW RLYIRefer to EC-389.

TROUBLE DIAGNOSESTD27Ti

EC-343

Page 706 of 1767

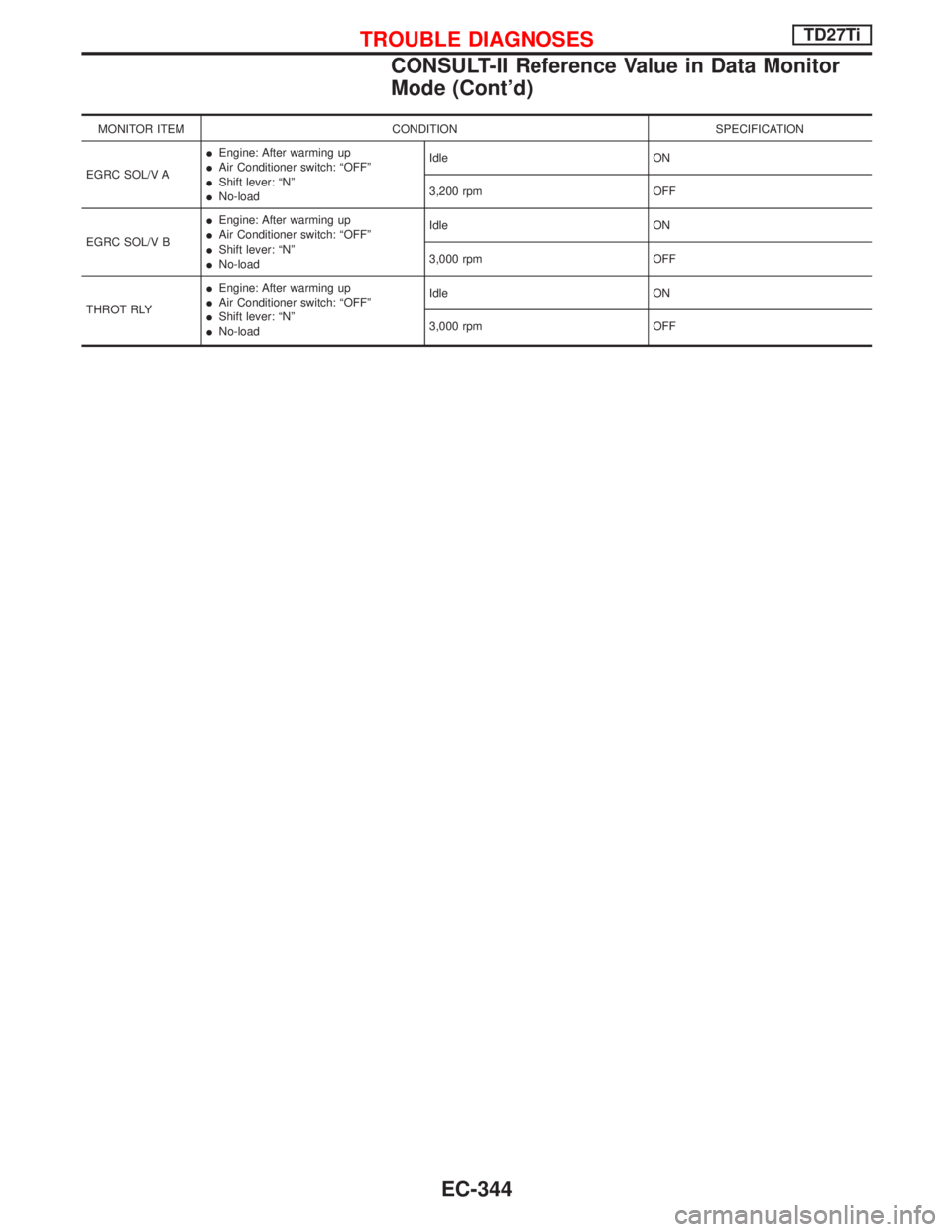

MONITOR ITEM CONDITION SPECIFICATION

EGRC SOL/V AIEngine: After warming up

IAir Conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle ON

3,200 rpm OFF

EGRC SOL/V BIEngine: After warming up

IAir Conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle ON

3,000 rpm OFF

THROT RLYIEngine: After warming up

IAir Conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle ON

3,000 rpm OFF

TROUBLE DIAGNOSESTD27Ti

CONSULT-II Reference Value in Data Monitor

Mode (Cont'd)

EC-344

Page 707 of 1767

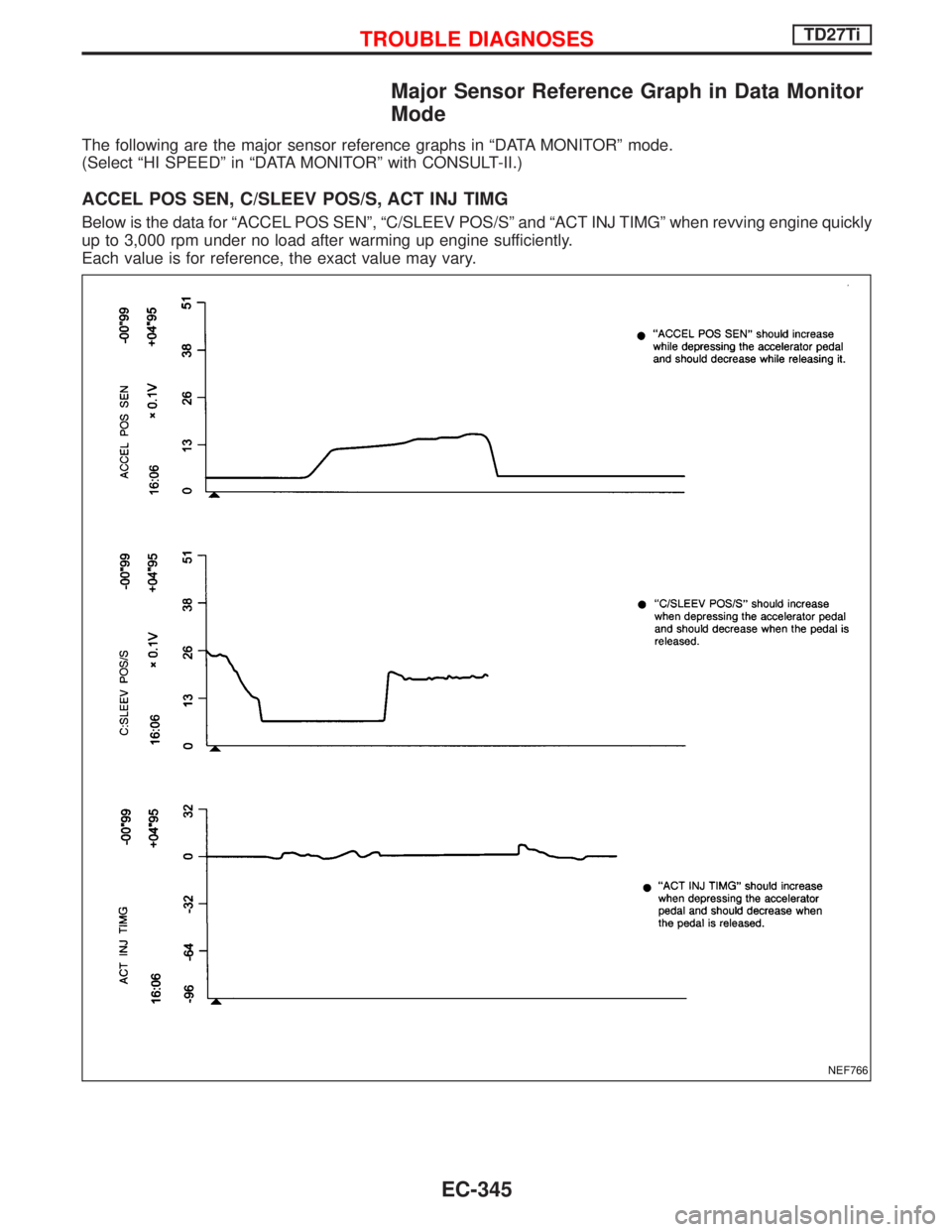

Major Sensor Reference Graph in Data Monitor

Mode

The following are the major sensor reference graphs in ªDATA MONITORº mode.

(Select ªHI SPEEDº in ªDATA MONITORº with CONSULT-II.)

ACCEL POS SEN, C/SLEEV POS/S, ACT INJ TIMG

Below is the data for ªACCEL POS SENº, ªC/SLEEV POS/Sº and ªACT INJ TIMGº when revving engine quickly

up to 3,000 rpm under no load after warming up engine sufficiently.

Each value is for reference, the exact value may vary.

NEF766

TROUBLE DIAGNOSESTD27Ti

EC-345

Page 708 of 1767

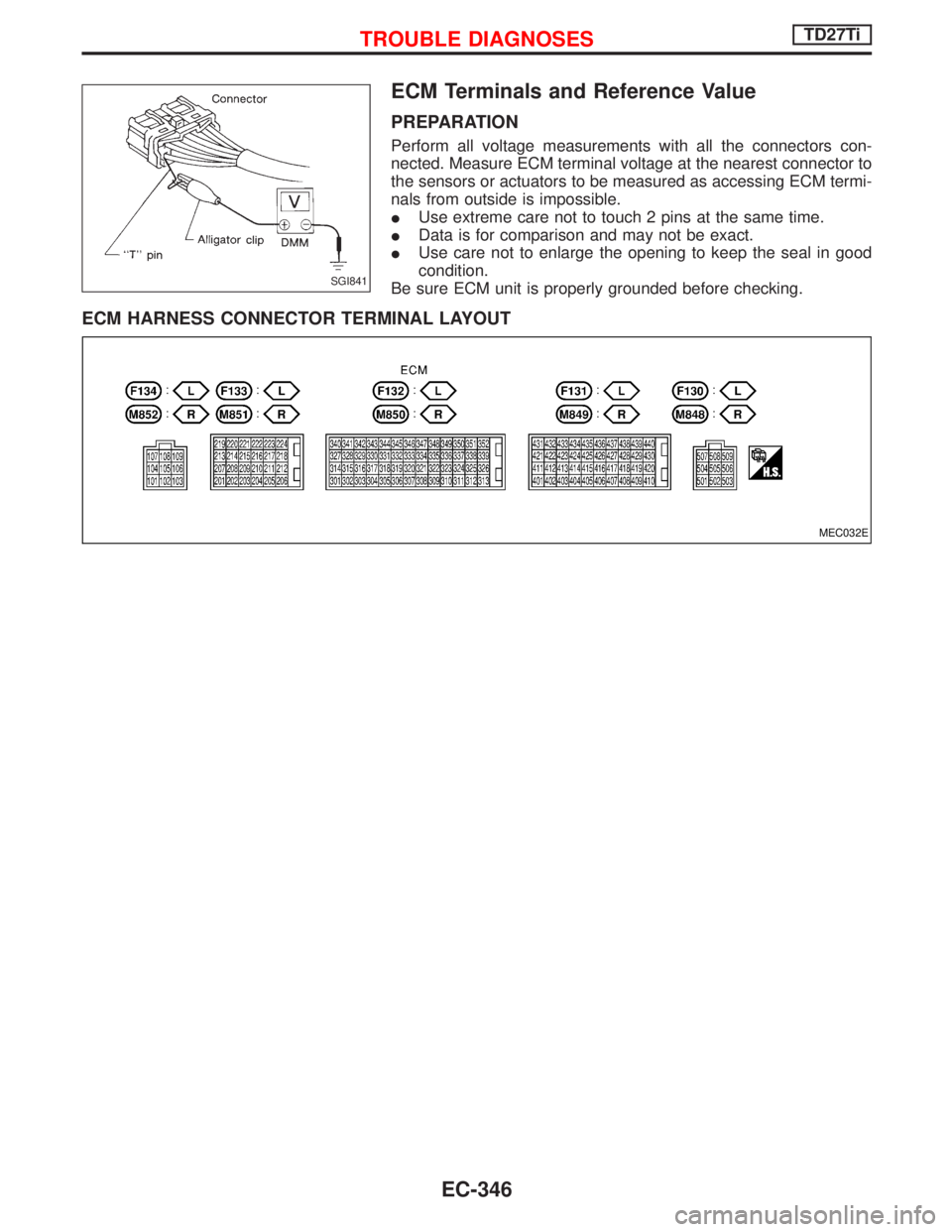

ECM Terminals and Reference Value

PREPARATION

Perform all voltage measurements with all the connectors con-

nected. Measure ECM terminal voltage at the nearest connector to

the sensors or actuators to be measured as accessing ECM termi-

nals from outside is impossible.

IUse extreme care not to touch 2 pins at the same time.

IData is for comparison and may not be exact.

IUse care not to enlarge the opening to keep the seal in good

condition.

Be sure ECM unit is properly grounded before checking.

ECM HARNESS CONNECTOR TERMINAL LAYOUT

SGI841

MEC032E

TROUBLE DIAGNOSESTD27Ti

EC-346

Page 709 of 1767

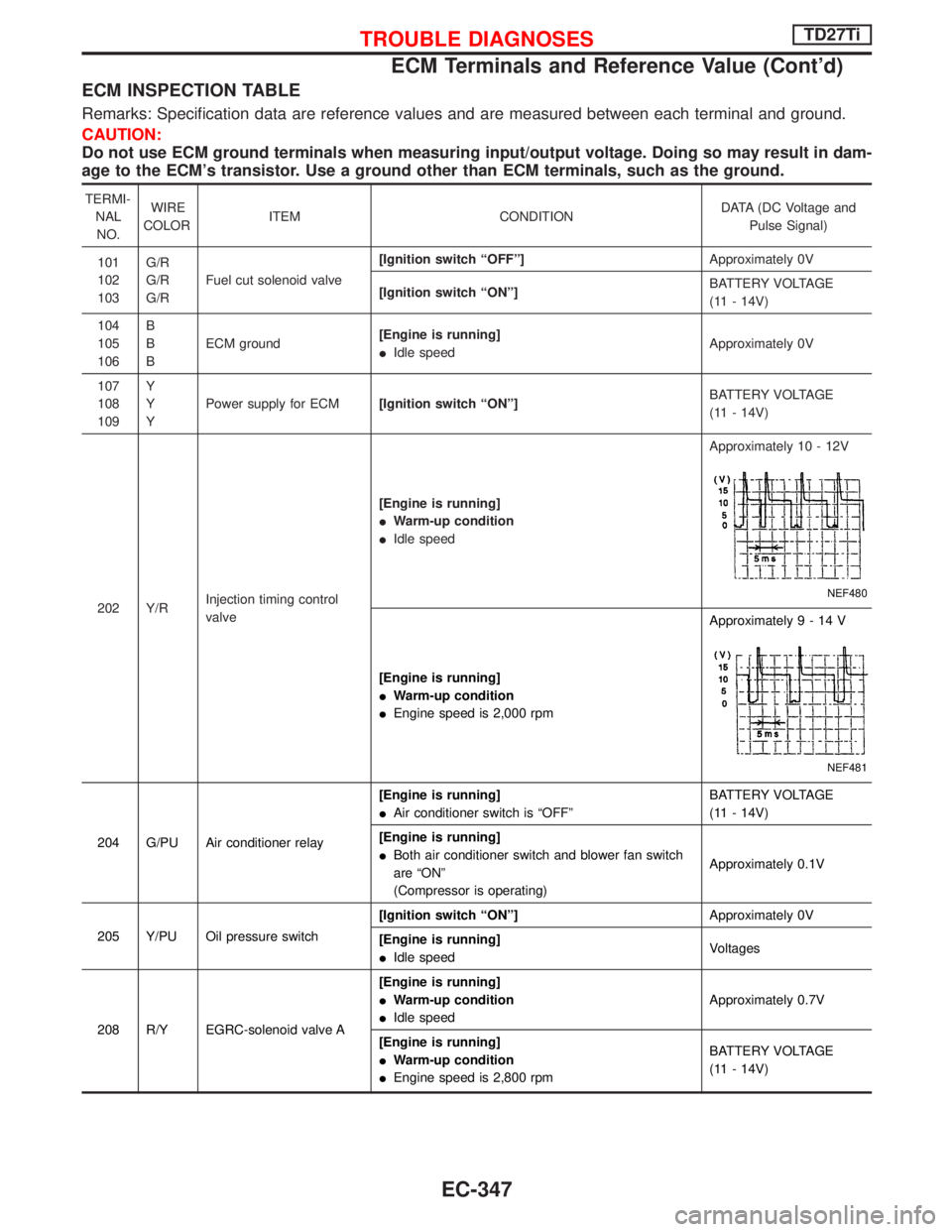

ECM INSPECTION TABLE

Remarks: Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

101

102

103G/R

G/R

G/RFuel cut solenoid valve[Ignition switch ªOFFº]Approximately 0V

[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

104

105

106B

B

BECM ground[Engine is running]

IIdle speedApproximately 0V

107

108

109Y

Y

YPower supply for ECM[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

202 Y/RInjection timing control

valve[Engine is running]

IWarm-up condition

IIdle speedApproximately 10 - 12V

NEF480

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpmApproximately9-14V

NEF481

204 G/PU Air conditioner relay[Engine is running]

IAir conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IBoth air conditioner switch and blower fan switch

are ªONº

(Compressor is operating)Approximately 0.1V

205 Y/PU Oil pressure switch[Ignition switch ªONº]Approximately 0V

[Engine is running]

IIdle speedVoltages

208 R/Y EGRC-solenoid valve A[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.7V

[Engine is running]

IWarm-up condition

IEngine speed is 2,800 rpmBATTERY VOLTAGE

(11 - 14V)

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-347

Page 710 of 1767

![NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up NISSAN TERRANO 2002 Service Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up](/img/5/57393/w960_57393-709.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

210 Y/B EGRC-solenoid valve B[Engine is running]

IWarm-up condition

IIdle speedApproximately 0.4V

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpmBATTERY VOLTAGE

(11 - 14V)

213 G/YThrottle control solenoid

valve[Engine is running]

IWarm-up condition

ILow loadApproximately 0V

Except above condition Battery voltage (12 - 14V)

214 LG Glow relay Refer to ªGlow Control Systemº, EC-389.

215 L Malfunction indicator (MI)[Ignition switch ªONº]Approximately 1.0V

[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

218 G/R Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

219 LG/R Cooling fan relay[Engine is running]

ICooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

ICooling fan is operatingApproximately 0.1V

221 G/W Glow lamp[Ignition switch ªONº]

IGlow lamp is ªONºApproximately 1V

[Ignition switch ªONº]

IGlow lamp is ªOFFºBATTERY VOLTAGE

(11 - 14V)

223 R/LMass air flow sensor

power supply[Ignition switch ªONº]Approximately 5V

224 L/W Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.5 - 2.0V

320 WControl sleeve position

sensor[Engine is running]

IIdle speedApproximately 2.6V

NEF477

321 RControl sleeve position

sensor power supply[Engine is running]

IIdle speedApproximately 2.6V

NEF476

TROUBLE DIAGNOSESTD27Ti

ECM Terminals and Reference Value (Cont'd)

EC-348