NISSAN TERRANO 2002 Service Repair Manual

TERRANO 2002

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57393/w960_57393-0.png

NISSAN TERRANO 2002 Service Repair Manual

Trending: manual radio set, fuel cap release, key, door lock, radiator, oil filter, check engine light

Page 661 of 1767

IIf MI illuminates or flashes irregularly while the engine is

running, water may have accumulated in fuel filter. Drain

water from fuel filter. If this does not correct the problem,

perform specified trouble diagnostic procedures.

IAfter performing each TROUBLE DIAGNOSIS, perform

ªOVERALL FUNCTION CHECKº or ªDTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is successful. The ªOVER-

ALL FUNCTION CHECKº should indicate a good result if

the repair is completed successfully.

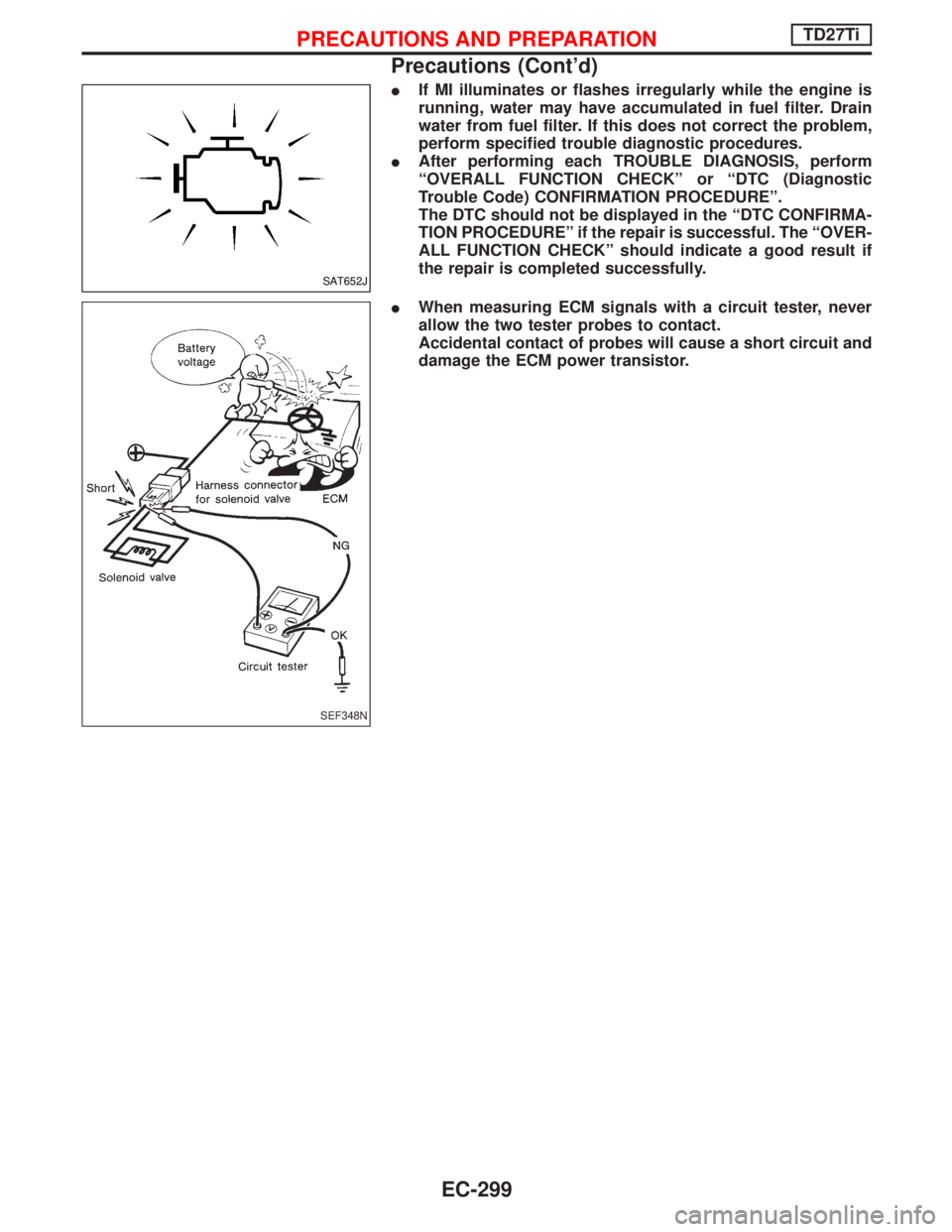

IWhen measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

SAT652J

SEF348N

PRECAUTIONS AND PREPARATIONTD27Ti

Precautions (Cont'd)

EC-299

Page 662 of 1767

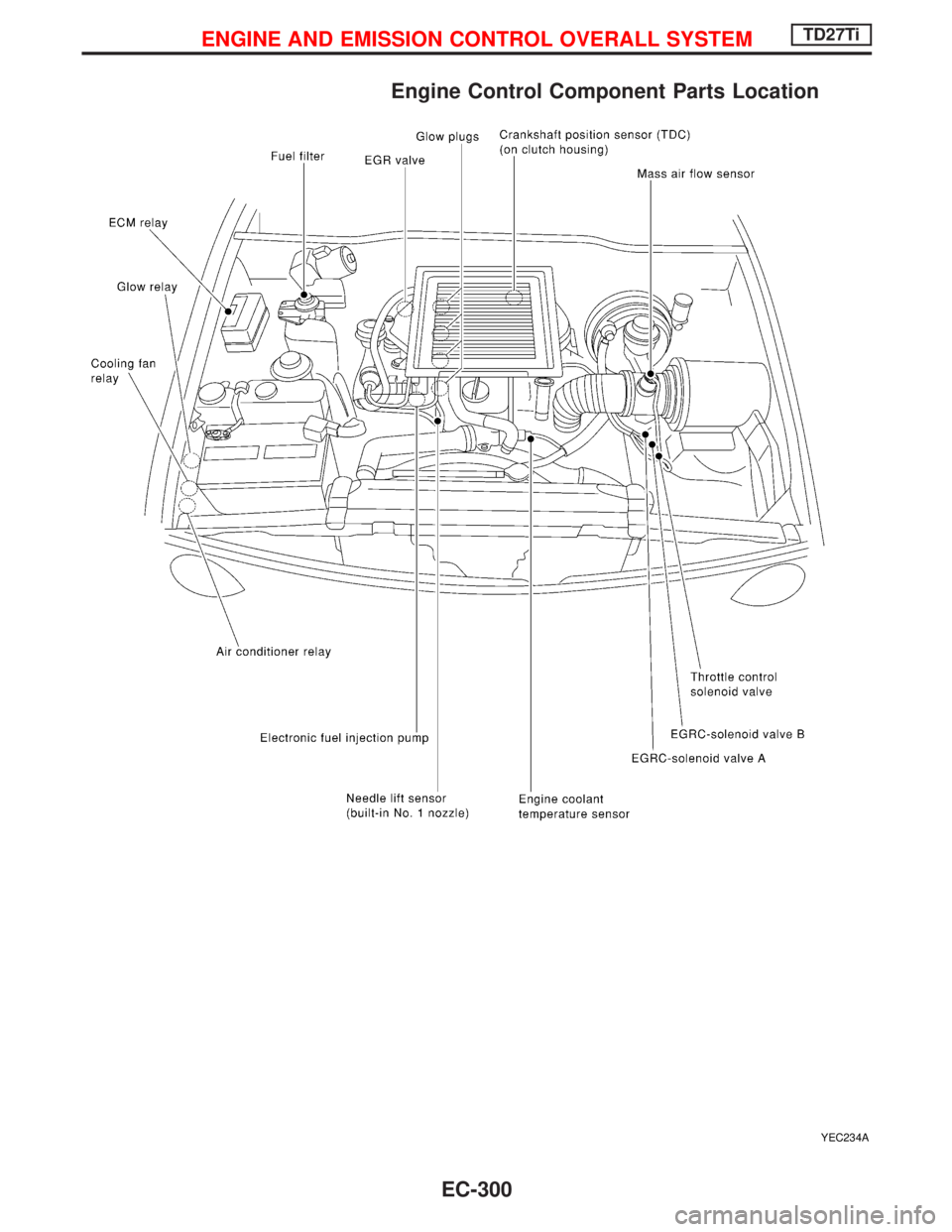

Engine Control Component Parts Location

YEC234A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-300

Page 663 of 1767

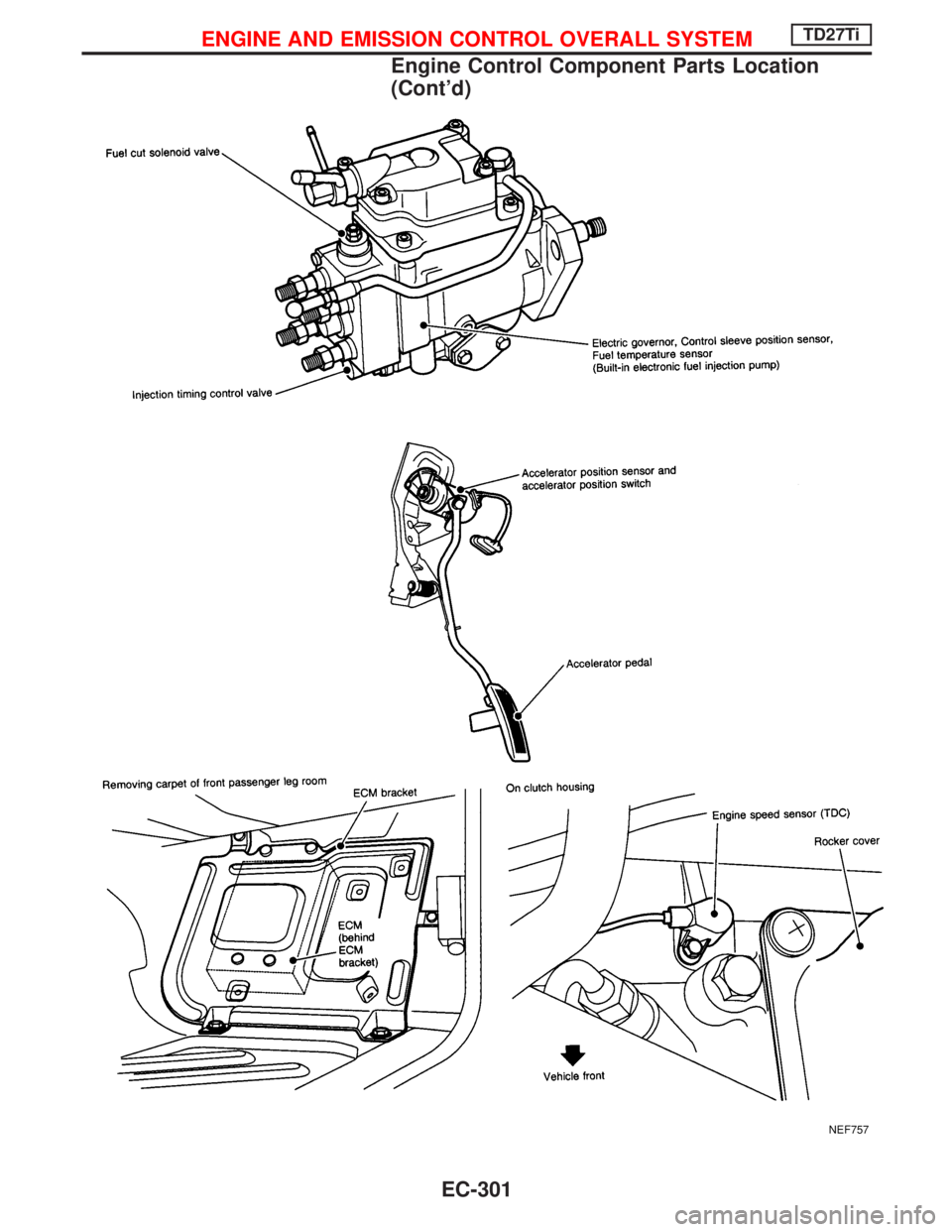

NEF757

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

Engine Control Component Parts Location

(Cont'd)

EC-301

Page 664 of 1767

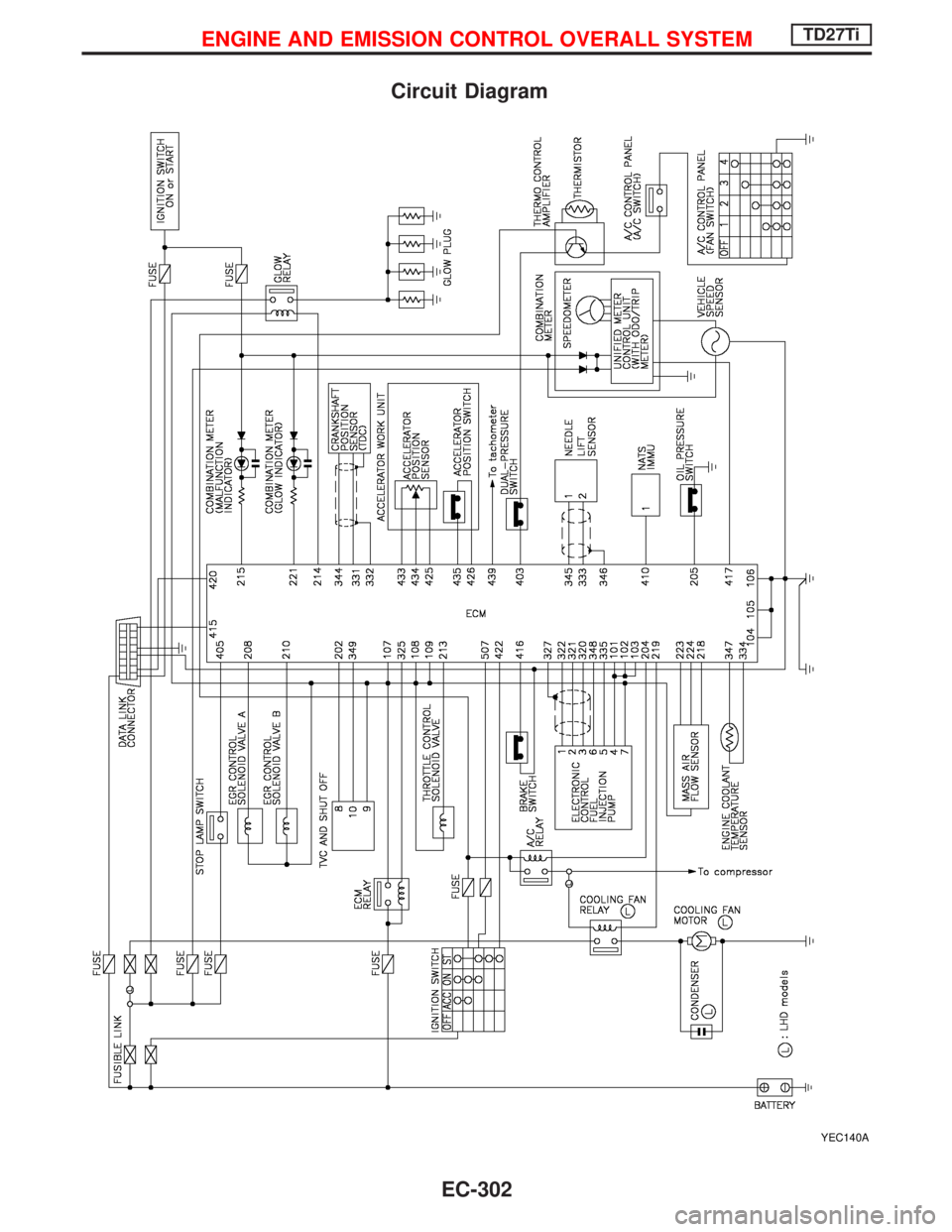

Circuit Diagram

YEC140A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-302

Page 665 of 1767

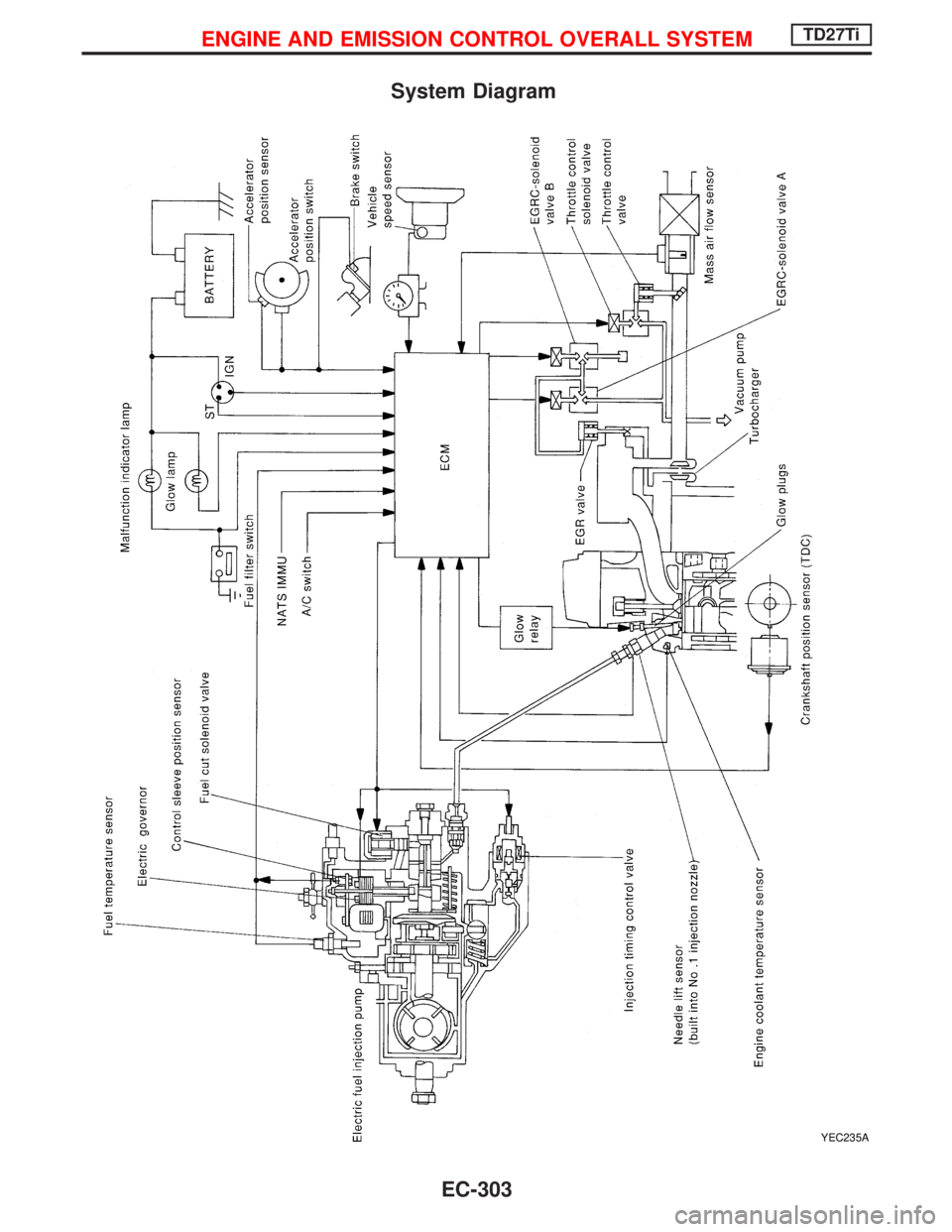

System Diagram

YEC235A

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-303

Page 666 of 1767

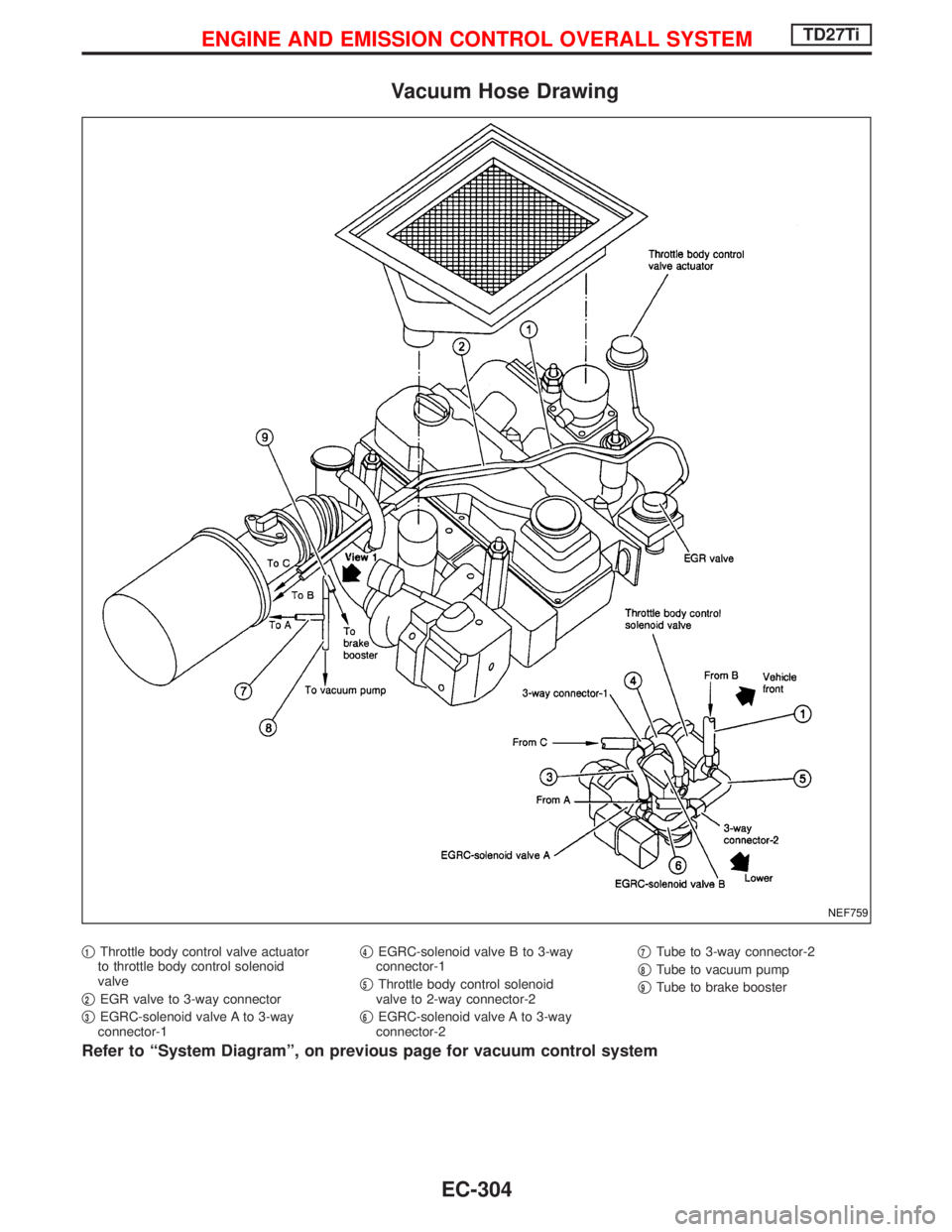

Vacuum Hose Drawing

q1Throttle body control valve actuator

to throttle body control solenoid

valve

q

2EGR valve to 3-way connector

q

3EGRC-solenoid valve A to 3-way

connector-1q

4EGRC-solenoid valve B to 3-way

connector-1

q

5Throttle body control solenoid

valve to 2-way connector-2

q

6EGRC-solenoid valve A to 3-way

connector-2q

7Tube to 3-way connector-2

q

8Tube to vacuum pump

q

9Tube to brake booster

Refer to ªSystem Diagramº, on previous page for vacuum control system

NEF759

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-304

Page 667 of 1767

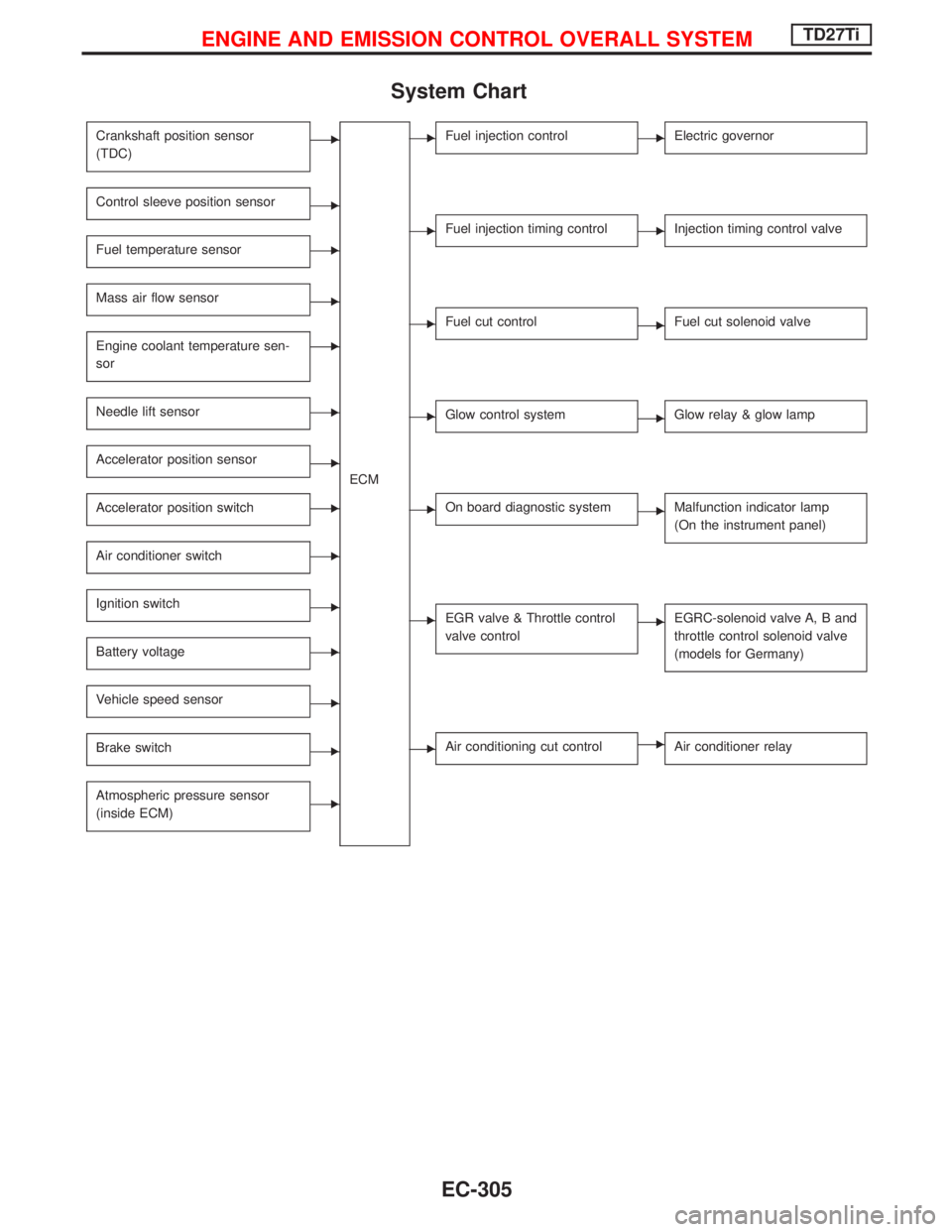

System Chart

Crankshaft position sensor

(TDC)E

ECM

Control sleeve position sensorE

Fuel temperature sensorE

Mass air flow sensorE

Engine coolant temperature sen-

sorE

Needle lift sensorE

Accelerator position sensorE

Accelerator position switchE

Air conditioner switchE

Ignition switchE

Battery voltageE

Vehicle speed sensorE

Brake switchE

Atmospheric pressure sensor

(inside ECM)E

EFuel injection controlEElectric governor

EFuel injection timing controlEInjection timing control valve

EFuel cut controlEFuel cut solenoid valve

EGlow control systemEGlow relay & glow lamp

EOn board diagnostic systemEMalfunction indicator lamp

(On the instrument panel)

EEGR valve & Throttle control

valve controlEEGRC-solenoid valve A, B and

throttle control solenoid valve

(models for Germany)

EAir conditioning cut controlEAir conditioner relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMTD27Ti

EC-305

Page 668 of 1767

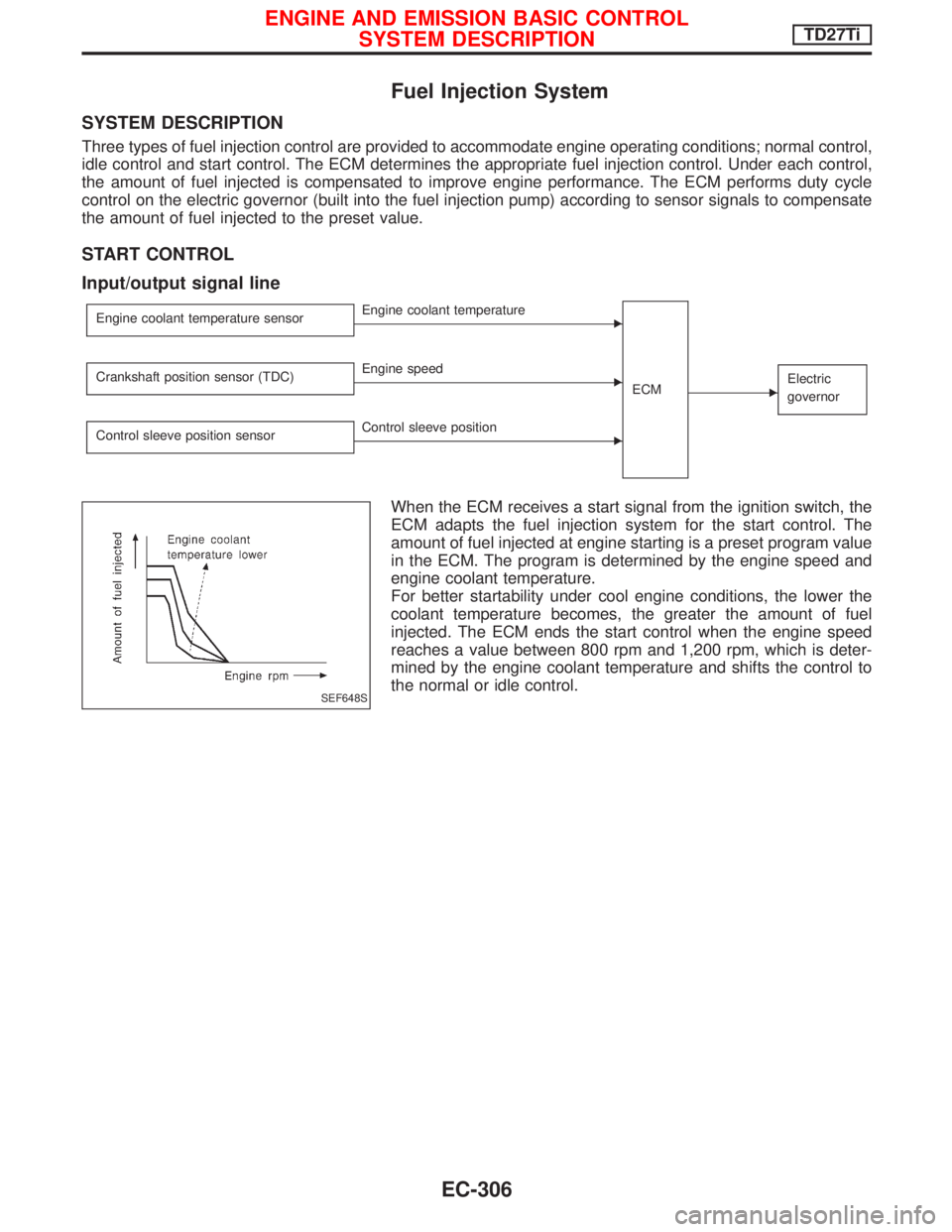

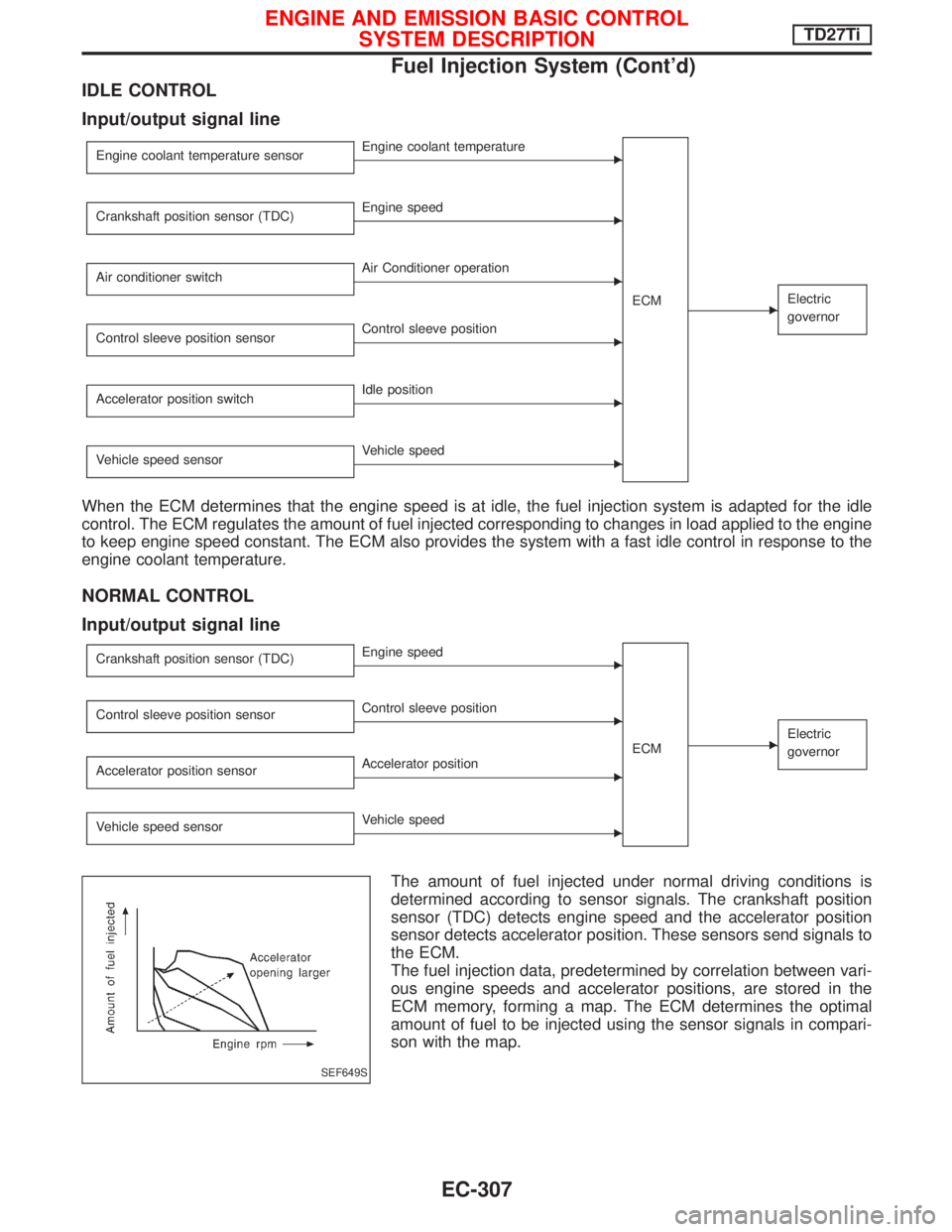

Fuel Injection System

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is compensated to improve engine performance. The ECM performs duty cycle

control on the electric governor (built into the fuel injection pump) according to sensor signals to compensate

the amount of fuel injected to the preset value.

START CONTROL

Input/output signal line

Engine coolant temperature sensorEEngine coolant temperature

ECM

EElectric

governorCrankshaft position sensor (TDC)EEngine speed

Control sleeve position sensor

EControl sleeve position

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed and

engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches a value between 800 rpm and 1,200 rpm, which is deter-

mined by the engine coolant temperature and shifts the control to

the normal or idle control.

SEF648S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

EC-306

Page 669 of 1767

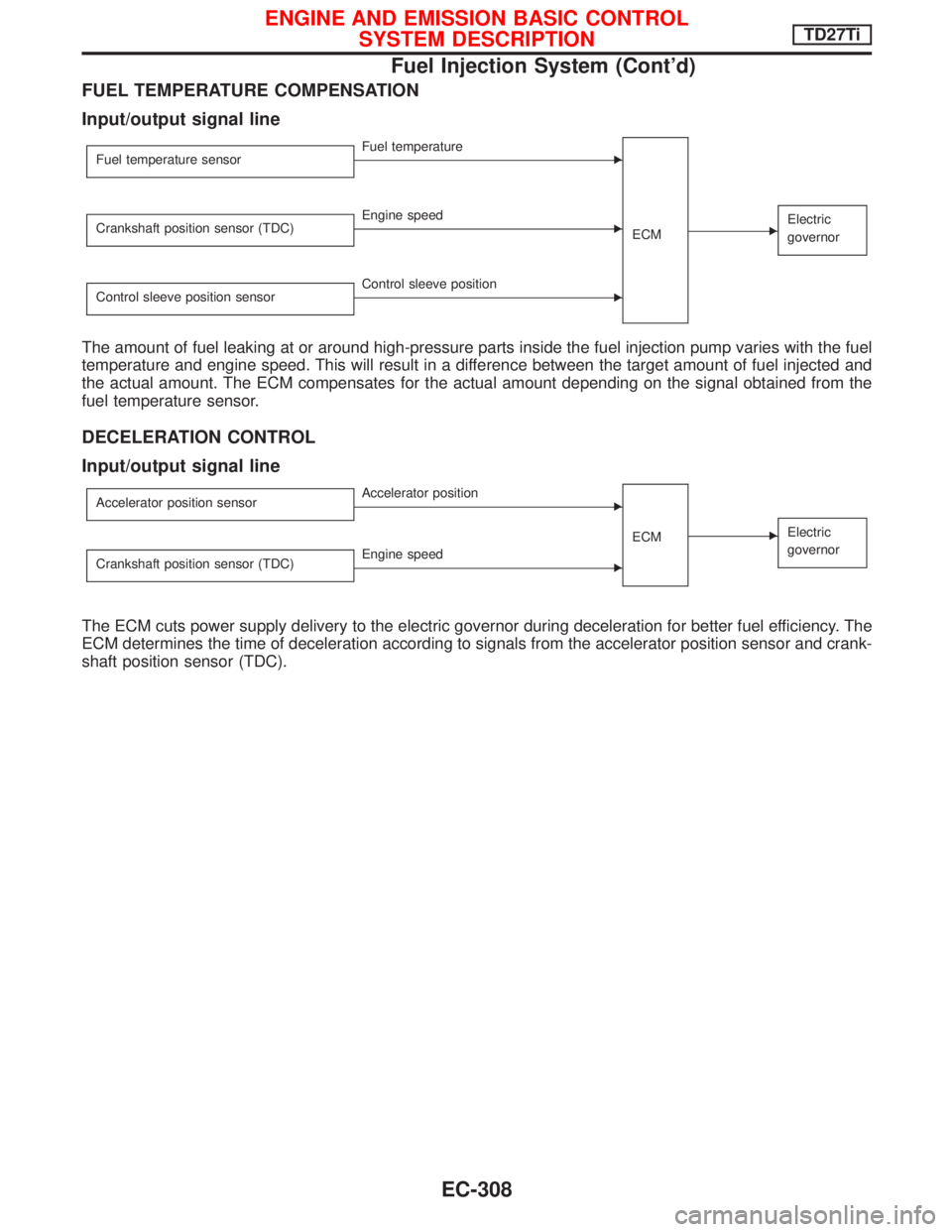

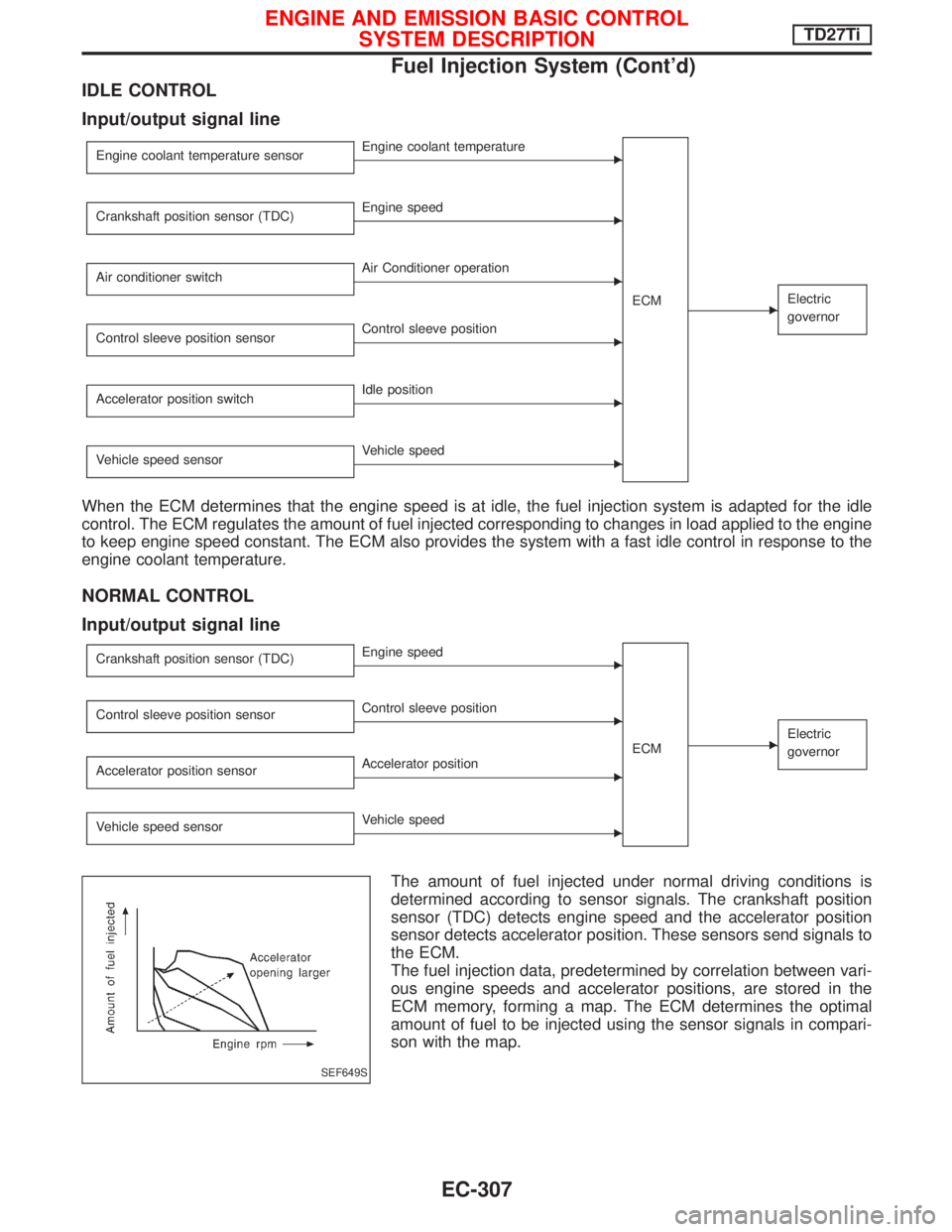

IDLE CONTROL

Input/output signal line

Engine coolant temperature sensorEEngine coolant temperature

ECM

EElectric

governor

Crankshaft position sensor (TDC)EEngine speed

Air conditioner switch

EAir Conditioner operation

Control sleeve position sensor

EControl sleeve position

Accelerator position switch

EIdle position

Vehicle speed sensor

EVehicle speed

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the engine

to keep engine speed constant. The ECM also provides the system with a fast idle control in response to the

engine coolant temperature.

NORMAL CONTROL

Input/output signal line

Crankshaft position sensor (TDC)EEngine speed

ECM

EElectric

governor

Control sleeve position sensorEControl sleeve position

Accelerator position sensor

EAccelerator position

Vehicle speed sensor

EVehicle speed

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals to

the ECM.

The fuel injection data, predetermined by correlation between vari-

ous engine speeds and accelerator positions, are stored in the

ECM memory, forming a map. The ECM determines the optimal

amount of fuel to be injected using the sensor signals in compari-

son with the map.

SEF649S

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

Fuel Injection System (Cont'd)

EC-307

Page 670 of 1767

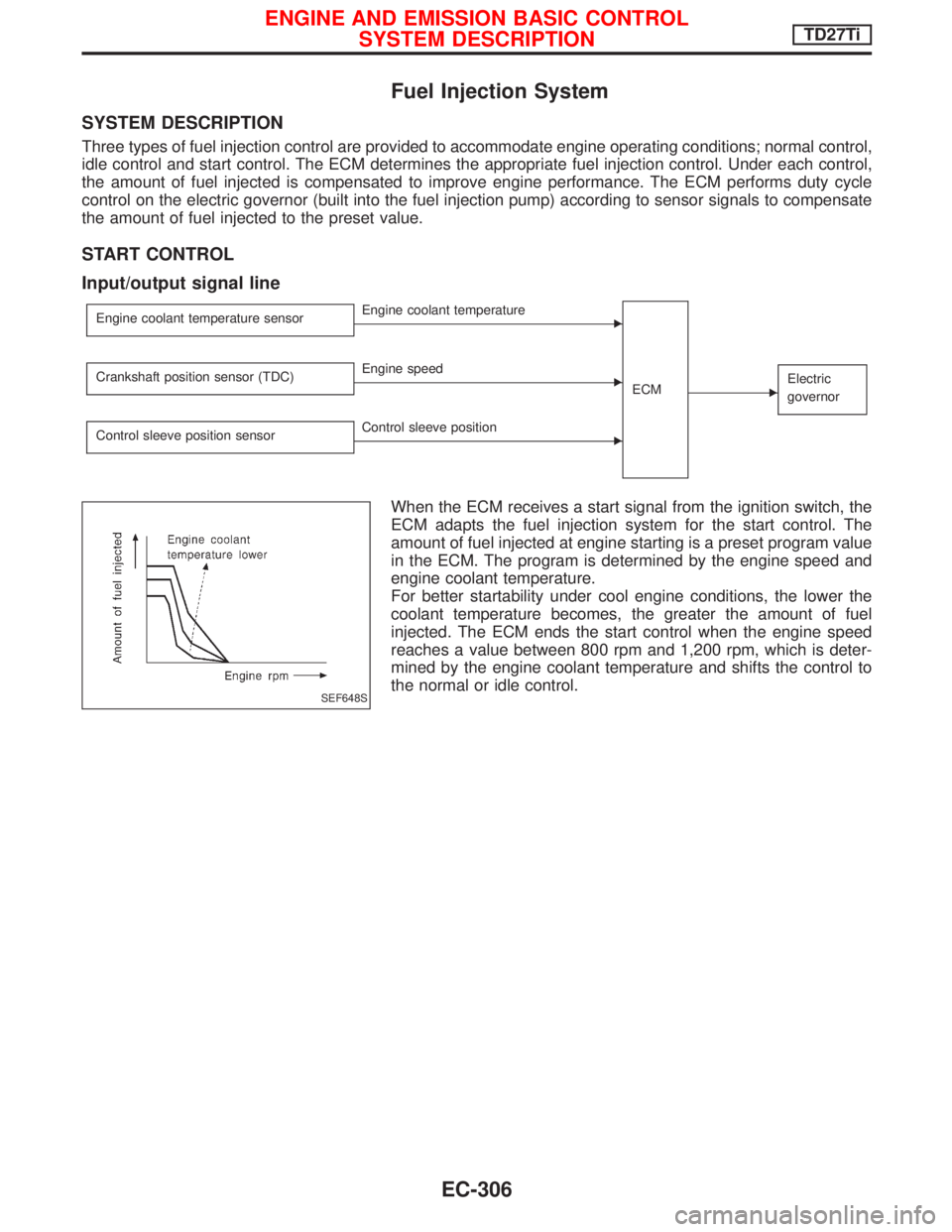

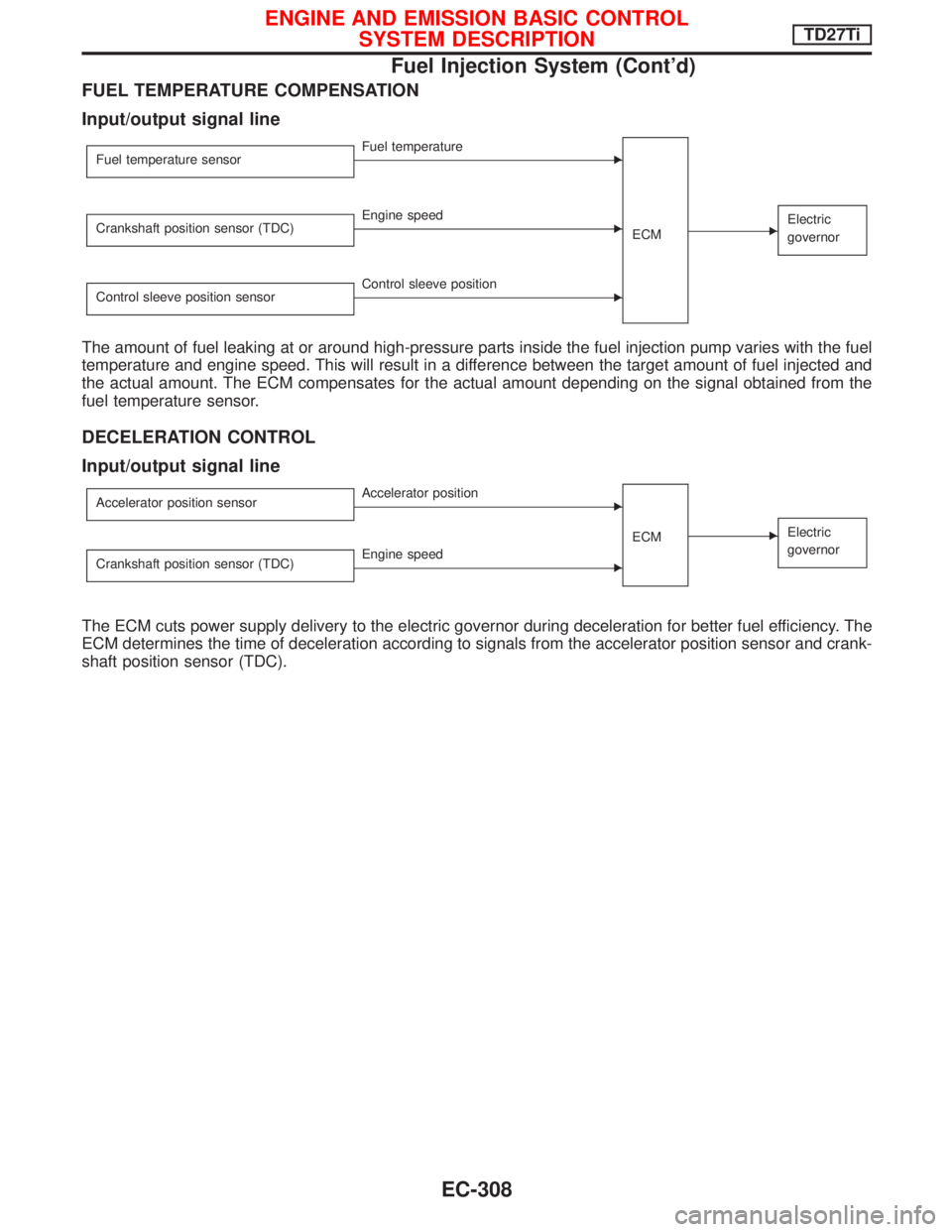

FUEL TEMPERATURE COMPENSATION

Input/output signal line

Fuel temperature sensorEFuel temperature

ECM

EElectric

governorCrankshaft position sensor (TDC)EEngine speed

Control sleeve position sensor

EControl sleeve position

The amount of fuel leaking at or around high-pressure parts inside the fuel injection pump varies with the fuel

temperature and engine speed. This will result in a difference between the target amount of fuel injected and

the actual amount. The ECM compensates for the actual amount depending on the signal obtained from the

fuel temperature sensor.

DECELERATION CONTROL

Input/output signal line

Accelerator position sensorEAccelerator position

ECM

EElectric

governor

Crankshaft position sensor (TDC)EEngine speed

The ECM cuts power supply delivery to the electric governor during deceleration for better fuel efficiency. The

ECM determines the time of deceleration according to signals from the accelerator position sensor and crank-

shaft position sensor (TDC).

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONTD27Ti

Fuel Injection System (Cont'd)

EC-308

Trending: cruise control, fuse box, heater, steering wheel, low beam, fog light, Full system