NISSAN TERRANO 2004 Service Owner's Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 21 of 1833

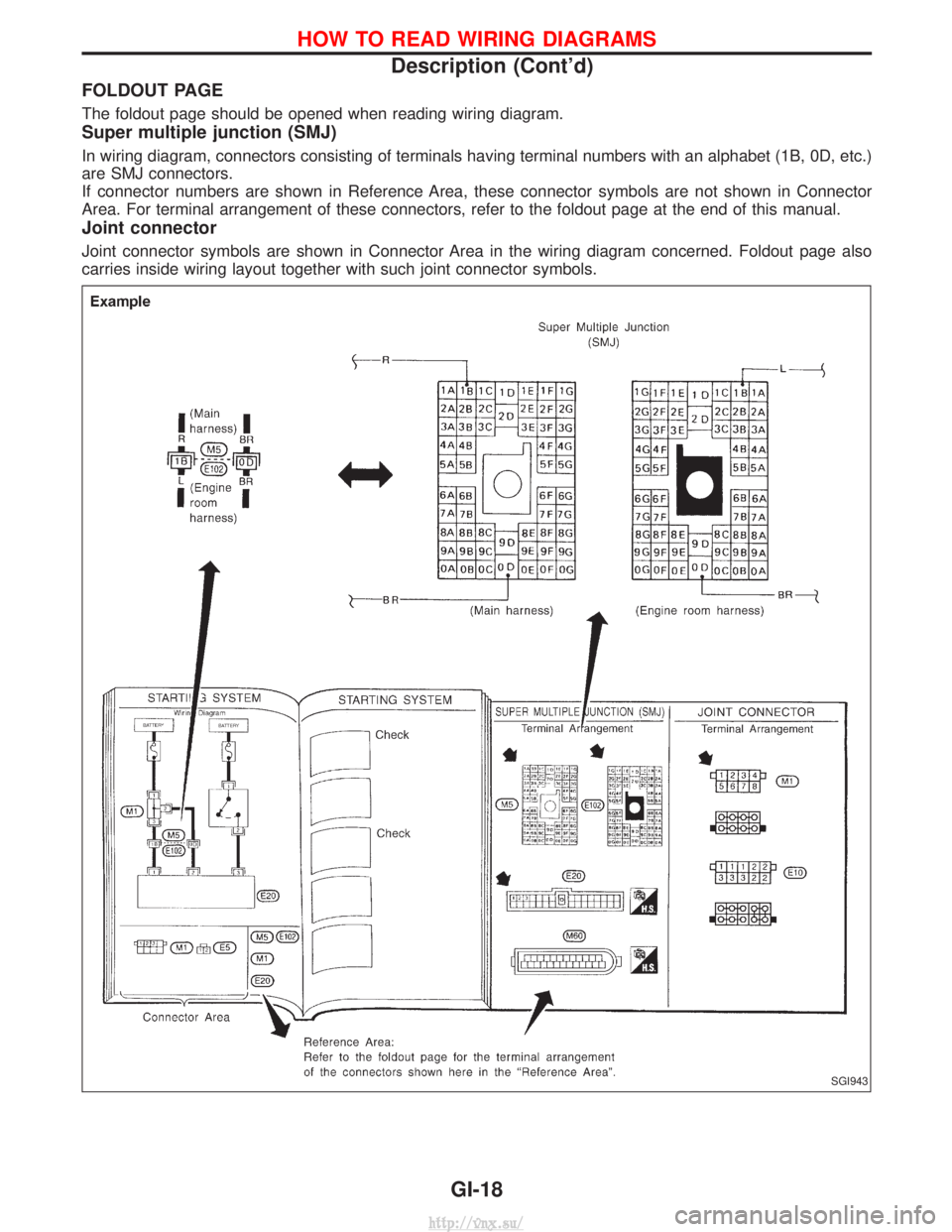

FOLDOUT PAGE

The foldout page should be opened when reading wiring diagram.

Super multiple junction (SMJ)

In wiring diagram, connectors consisting of terminals having terminal numbers with an alphabet (1B, 0D, etc.)

are SMJ connectors.

If connector numbers are shown in Reference Area, these connector symbols are not shown in Connector

Area. For terminal arrangement of these connectors, refer to the foldout page at the end of this manual.

Joint connector

Joint connector symbols are shown in Connector Area in the wiring diagram concerned. Foldout page also

carries inside wiring layout together with such joint connector symbols.

SGI943

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)GI-18

http://vnx.su/

Page 22 of 1833

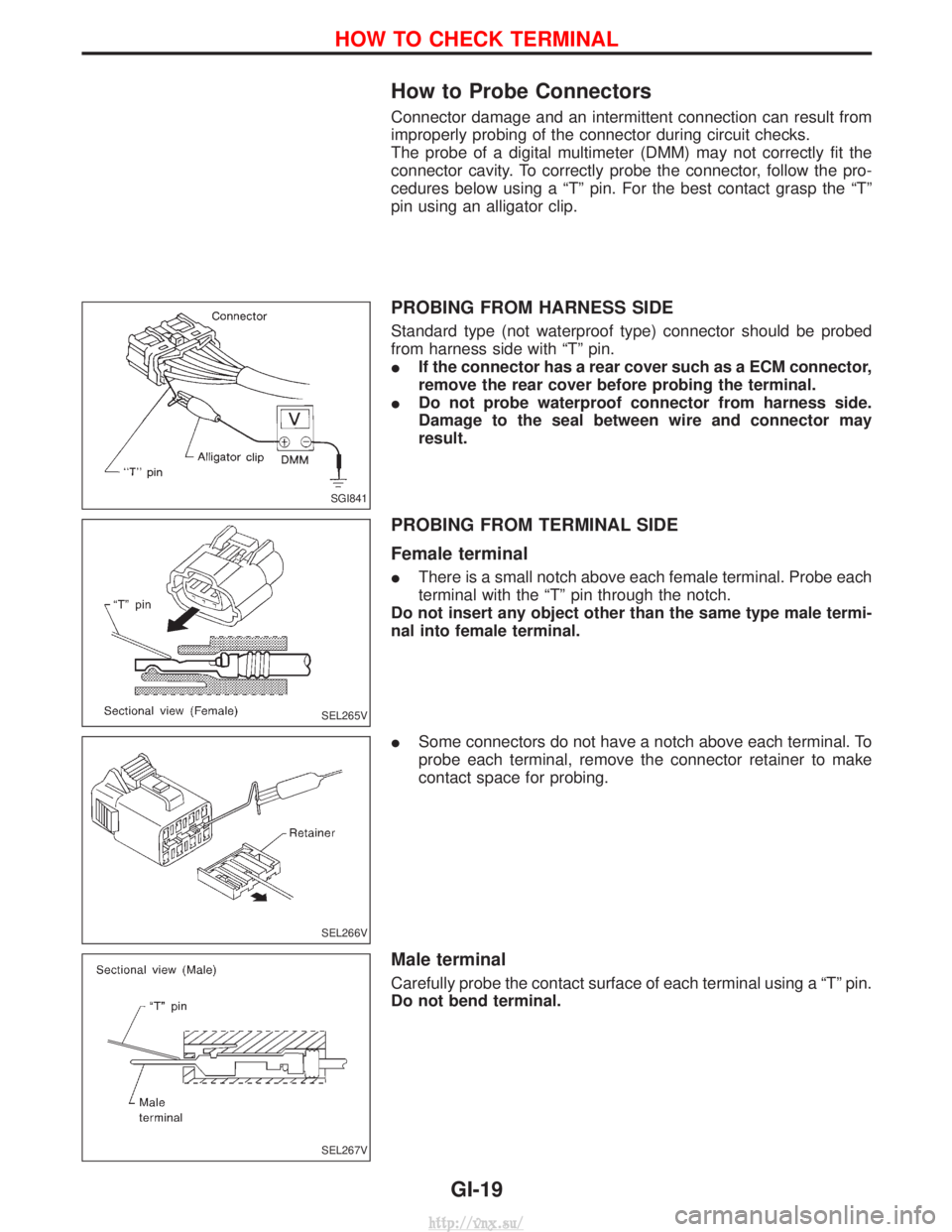

How to Probe Connectors

Connector damage and an intermittent connection can result from

improperly probing of the connector during circuit checks.

The probe of a digital multimeter (DMM) may not correctly fit the

connector cavity. To correctly probe the connector, follow the pro-

cedures below using a ªTº pin. For the best contact grasp the ªTº

pin using an alligator clip.

PROBING FROM HARNESS SIDE

Standard type (not waterproof type) connector should be probed

from harness side with ªTº pin.

IIf the connector has a rear cover such as a ECM connector,

remove the rear cover before probing the terminal.

I Do not probe waterproof connector from harness side.

Damage to the seal between wire and connector may

result.

PROBING FROM TERMINAL SIDE

Female terminal

IThere is a small notch above each female terminal. Probe each

terminal with the ªTº pin through the notch.

Do not insert any object other than the same type male termi-

nal into female terminal.

I Some connectors do not have a notch above each terminal. To

probe each terminal, remove the connector retainer to make

contact space for probing.

Male terminal

Carefully probe the contact surface of each terminal using a ªTº pin.

Do not bend terminal.

SGI841

SEL265V

SEL266V

SEL267V

HOW TO CHECK TERMINAL

GI-19

http://vnx.su/

Page 23 of 1833

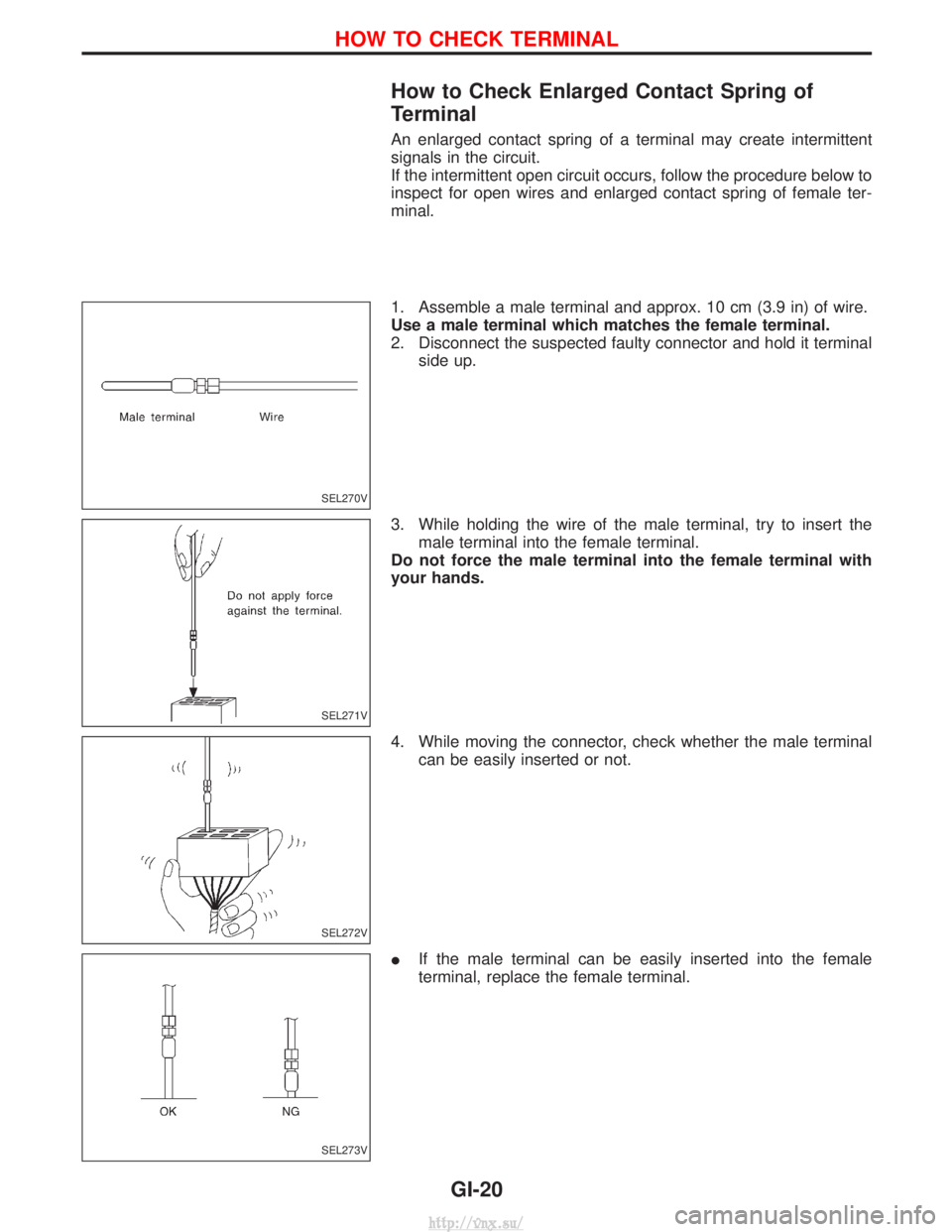

How to Check Enlarged Contact Spring of

Terminal

An enlarged contact spring of a terminal may create intermittent

signals in the circuit.

If the intermittent open circuit occurs, follow the procedure below to

inspect for open wires and enlarged contact spring of female ter-

minal.

1. Assemble a male terminal and approx. 10 cm (3.9 in) of wire.

Use a male terminal which matches the female terminal.

2. Disconnect the suspected faulty connector and hold it terminalside up.

3. While holding the wire of the male terminal, try to insert the male terminal into the female terminal.

Do not force the male terminal into the female terminal with

your hands.

4. While moving the connector, check whether the male terminal can be easily inserted or not.

I If the male terminal can be easily inserted into the female

terminal, replace the female terminal.

SEL270V

SEL271V

SEL272V

SEL273V

HOW TO CHECK TERMINAL

GI-20

http://vnx.su/

Page 24 of 1833

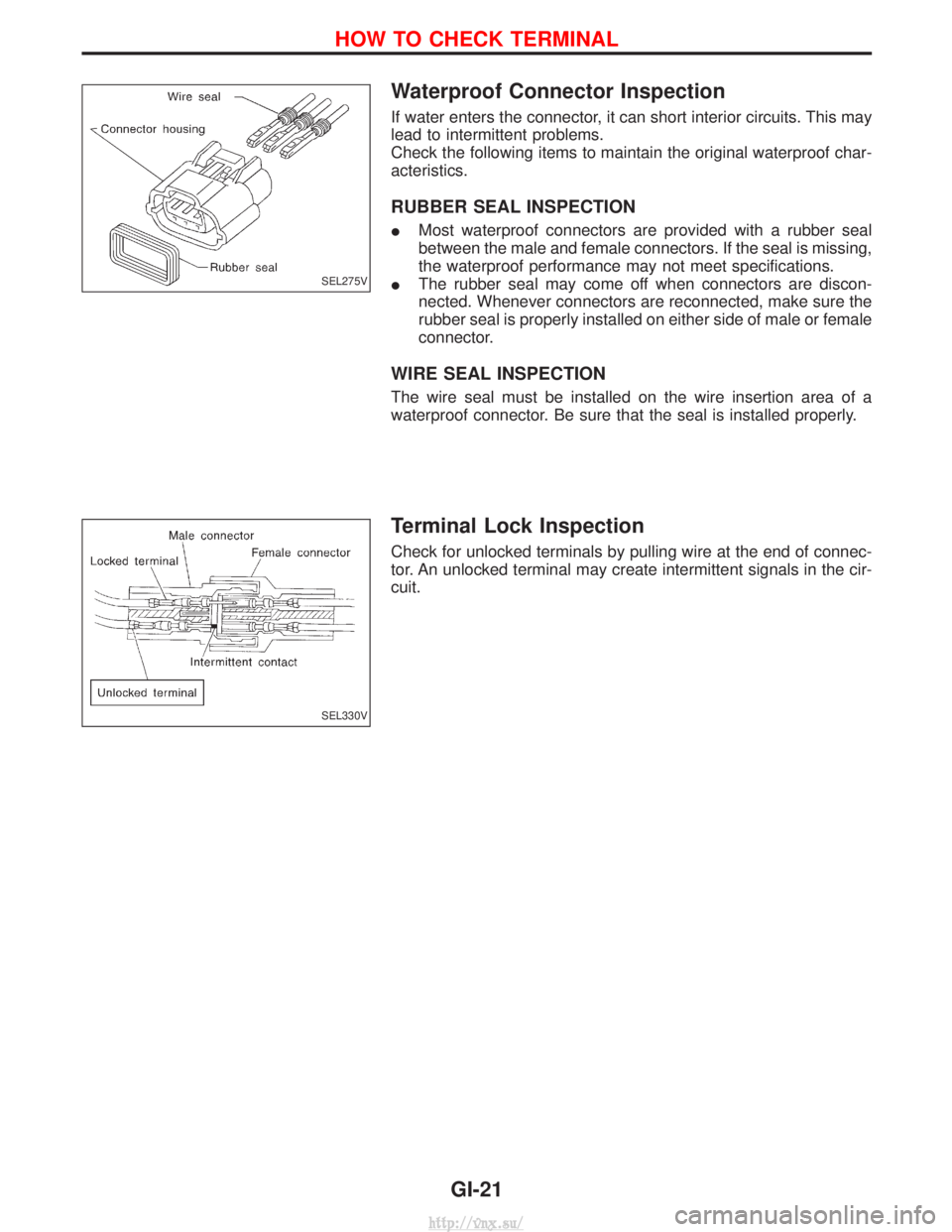

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may

lead to intermittent problems.

Check the following items to maintain the original waterproof char-

acteristics.

RUBBER SEAL INSPECTION

IMost waterproof connectors are provided with a rubber seal

between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

I The rubber seal may come off when connectors are discon-

nected. Whenever connectors are reconnected, make sure the

rubber seal is properly installed on either side of male or female

connector.

WIRE SEAL INSPECTION

The wire seal must be installed on the wire insertion area of a

waterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connec-

tor. An unlocked terminal may create intermittent signals in the cir-

cuit.

SEL275V

SEL330V

HOW TO CHECK TERMINAL

GI-21

http://vnx.su/

Page 25 of 1833

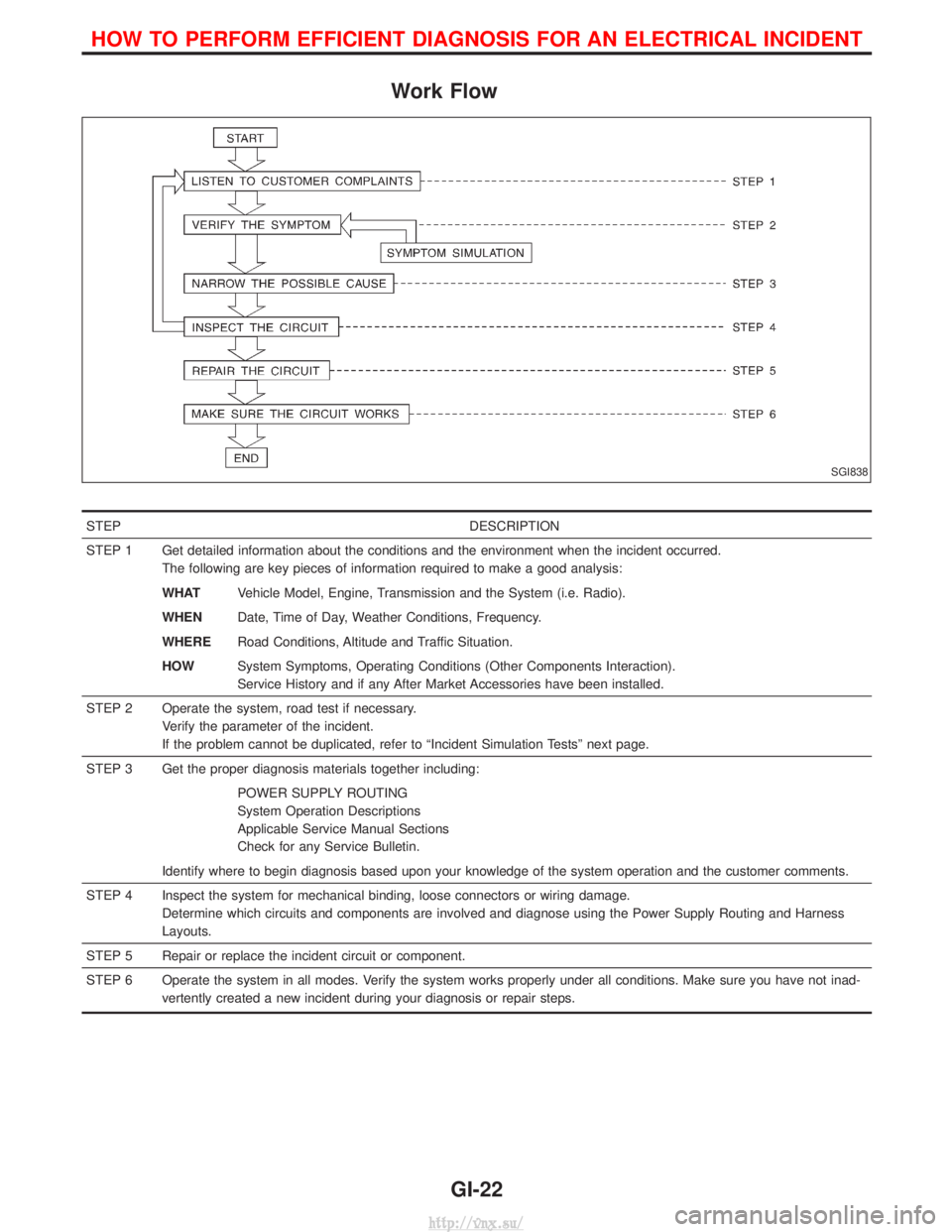

Work Flow

STEPDESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred. The following are key pieces of information required to make a good analysis:

WHATVehicle Model, Engine, Transmission and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions (Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary. Verify the parameter of the incident.

If the problem cannot be duplicated, refer to ªIncident Simulation Testsº next page.

STEP 3 Get the proper diagnosis materials together including: POWER SUPPLY ROUTING

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletin.

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage. Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness

Layouts.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad- vertently created a new incident during your diagnosis or repair steps.

SGI838

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-22

http://vnx.su/

Page 26 of 1833

Incident Simulation Tests

INTRODUCTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doing so may help avoid a No Trouble Found Diagnosis. The

following section illustrates ways to simulate the conditions/environment under which the owner experiences

an electrical incident.

The section is broken into the six following topics:

IVehicle vibration

I Heat sensitive

I Freezing

I Water intrusion

I Electrical load

I Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of

the problem.

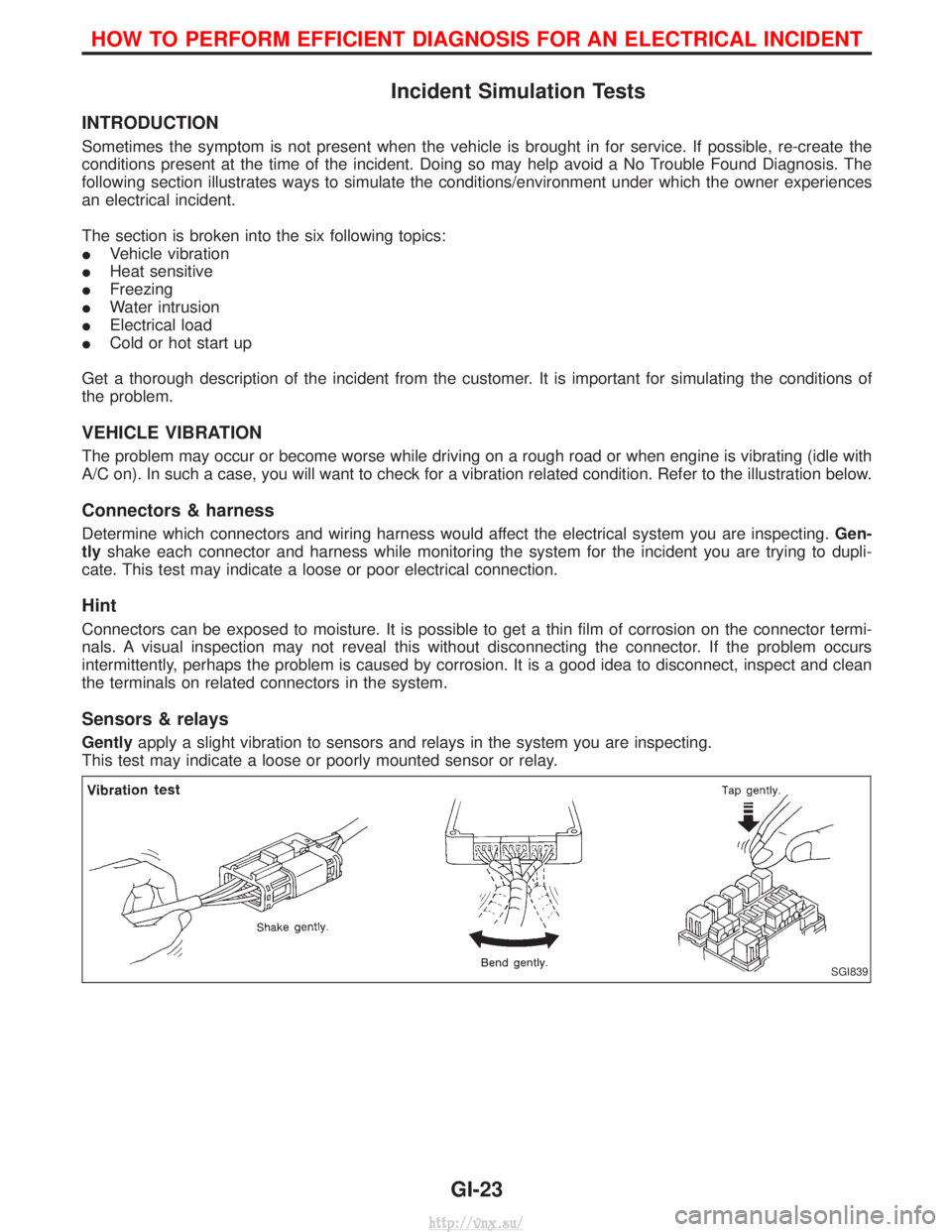

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the illustration below.

Connectors & harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gen-

tly shake each connector and harness while monitoring the system for the incident you are trying to dupli-

cate. This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs

intermittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean

the terminals on related connectors in the system.

Sensors & relays

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

SGI839

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

GI-23

http://vnx.su/

Page 27 of 1833

Engine compartment

There are several reasons a vehicle or engine vibration could

cause an electrical complaint. Some of the things to check for are:

IConnectors not fully seated.

I Wiring harness not long enough and is being stressed due to

engine vibrations or rocking.

I Wires laying across brackets or moving components.

I Loose, dirty or corroded ground wires.

I Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integ-

rity of ground connections. (Refer to GROUND INSPECTION

described later.) First check that the system is properly grounded.

Then check for loose connection by gently shakingthe wiring or

components as previously explained. Using the wiring diagrams

inspect the wiring for continuity.

Behind the instrument panel

An improperly routed or improperly clamped harness can become

pinched during accessory installation. Vehicle vibration can aggra-

vate a harness which is routed along a bracket or near a screw.

Under seating areas

An unclamped or loose harness can cause wiring to be pinched by

seat components (such as slide guides) during vehicle vibration. If

the wiring runs under seating areas, inspect wire routing for pos-

sible damage or pinching.

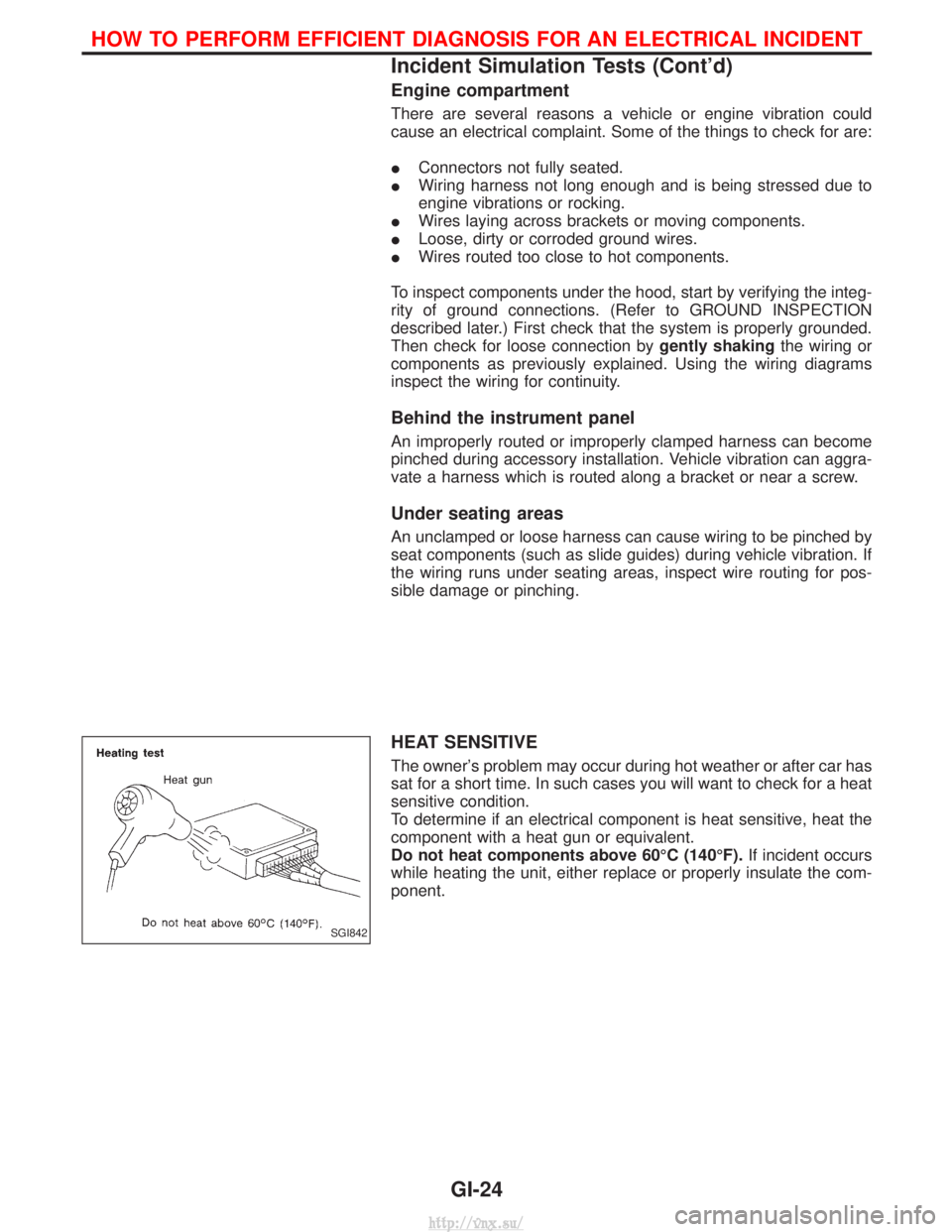

HEAT SENSITIVE

The owner's problem may occur during hot weather or after car has

sat for a short time. In such cases you will want to check for a heat

sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

Do not heat components above 60ÉC (140ÉF). If incident occurs

while heating the unit, either replace or properly insulate the com-

ponent.

SGI842

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-24

http://vnx.su/

Page 28 of 1833

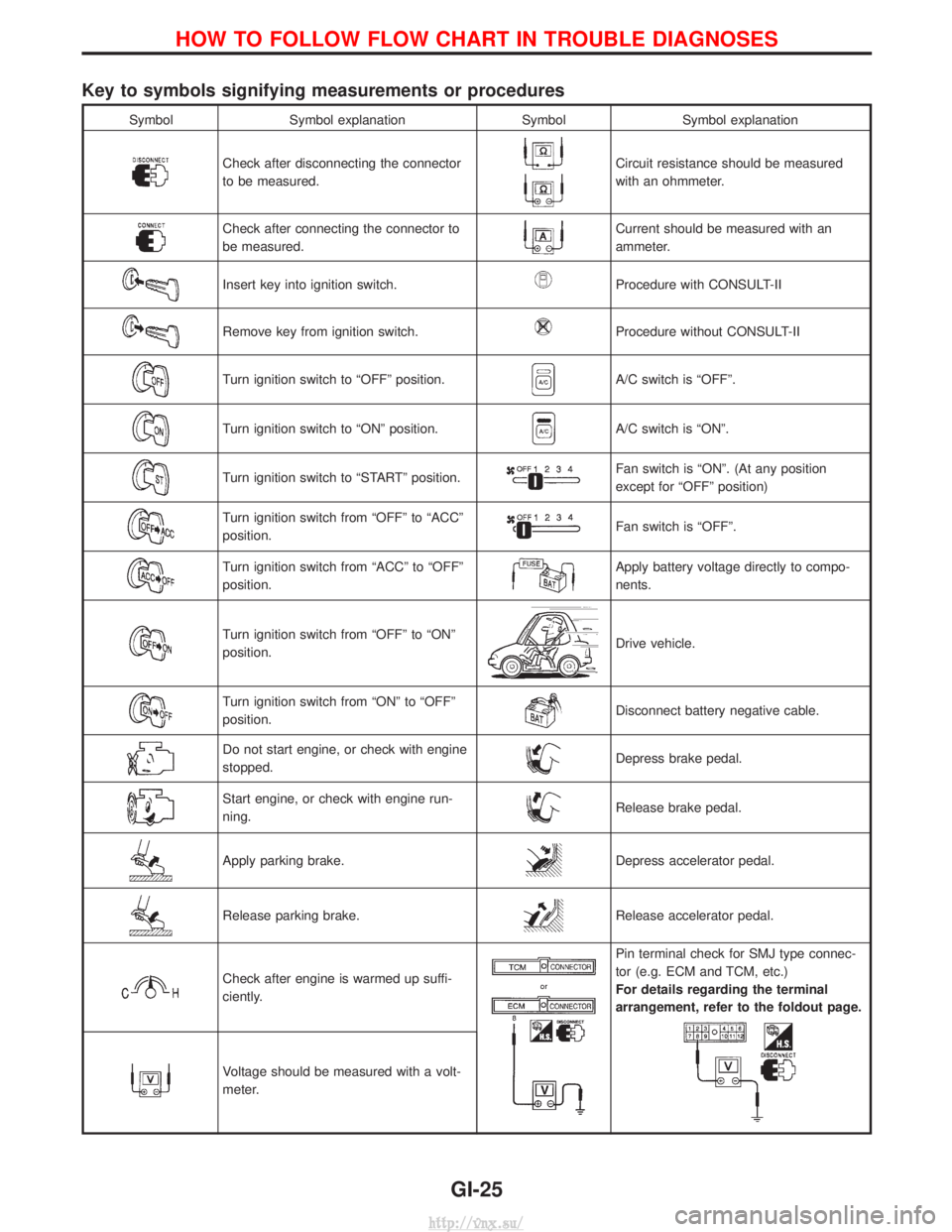

Key to symbols signifying measurements or procedures

SymbolSymbol explanation SymbolSymbol explanation

Check after disconnecting the connector

to be measured.Circuit resistance should be measured

with an ohmmeter.

Check after connecting the connector to

be measured.Current should be measured with an

ammeter.

Insert key into ignition switch.Procedure with CONSULT-II

Remove key from ignition switch.Procedure without CONSULT-II

Turn ignition switch to ªOFFº position.A/C switch is ªOFFº.

Turn ignition switch to ªONº position.A/C switch is ªONº.

Turn ignition switch to ªSTARTº position.Fan switch is ªONº. (At any position

except for ªOFFº position)

Turn ignition switch from ªOFFº to ªACCº

position.Fan switch is ªOFFº.

Turn ignition switch from ªACCº to ªOFFº

position.Apply battery voltage directly to compo-

nents.

Turn ignition switch from ªOFFº to ªONº

position.Drive vehicle.

Turn ignition switch from ªONº to ªOFFº

position.Disconnect battery negative cable.

Do not start engine, or check with engine

stopped.Depress brake pedal.

Start engine, or check with engine run-

ning.Release brake pedal.

Apply parking brake.Depress accelerator pedal.

Release parking brake.Release accelerator pedal.

Check after engine is warmed up suffi-

ciently.

Pin terminal check for SMJ type connec-

tor (e.g. ECM and TCM, etc.)

For details regarding the terminal

arrangement, refer to the foldout page.

Voltage should be measured with a volt-

meter.

HOW TO FOLLOW FLOW CHART IN TROUBLE DIAGNOSES

GI-25

http://vnx.su/

Page 29 of 1833

Function and System Application

Diagnostictest mode Function ENGINE A/T Air bag ABS NATS*1

Self-diagnostic results Self-diagnostic results can be read and erased quickly. xxxxx

ECU discriminated No. Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being installed. ÐÐxÐÐ

Data monitor Input/Output data in the ECM can be read. x xÐxÐ

Active test Diagnostic Test Mode in which CONSULT-II drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range. xÐÐxÐ

ECU (ECM) part number ECU (ECM) part number can be read. x xÐxÐ

Control unit initialisation All registered ignition key IDs in NATS components can

be initialised and new IDs can be registered. ÐÐÐÐ x

Self-function check ECM checks its own NATS communication interface. ÐÐÐÐ x

x: Applicable

*1: NATS: Nissan Anti-Theft System

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with genuine CONSULT-II battery only. Use of another battery

may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mis-

treated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering this equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT-II

q

1CONSULT-II unit and acces-

sories

q

2Program card

AED03E for diagnosis,

AEN02C-1 for NATS

To confirm the best combination

of these softwares, refer to

CONSULT-II Operation Manual.

YGI004

NOTE:

I The CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialisation) procedure.

I Be sure the CONSULT-II is turned off before installing or removing a program card.

CONSULT-II CHECKING SYSTEM

GI-26

http://vnx.su/

Page 30 of 1833

Model Variation

BodyGrade Engine Transmission Group A (RHD) Group B (South)

Group C (Cen- tral) Group D (North)

H/T SE

ªLuxury/

Eleganceº TD27Ti FS5R30A KVPNRVF-UED KVPNLVF-UGD KVPNLVF-USD

ZD30DDTi FS5R30A KWSNRVF-UED KWSNLVF-UGD KWSNLVF-USD

RE4R01A KWSNRVA-UED KWSNLVA-UGD KWSNLVA-USD

SR

ªSportº TD27Ti FS5R30A KVPNRUF-UED KVPNLUF-UGD KVPNLUF-USD

Wagon SE

ªLuxury/

Eleganceº TD27Ti FS5R30A TVPURVF-UED TVPULVF-UGD TVPULVF-USD

ZD30DDTi FS5R30A TWSURVF-UED TWSULVF-UGD TWSULVF-USD

RE4R01A TWSURVA-UED TWSULVA-UGD TWSULVA-USD

SR

ªSportº TD27Ti FS5R30A TVPURUF-UED TVPULUF-UGD TVPULUF-USD

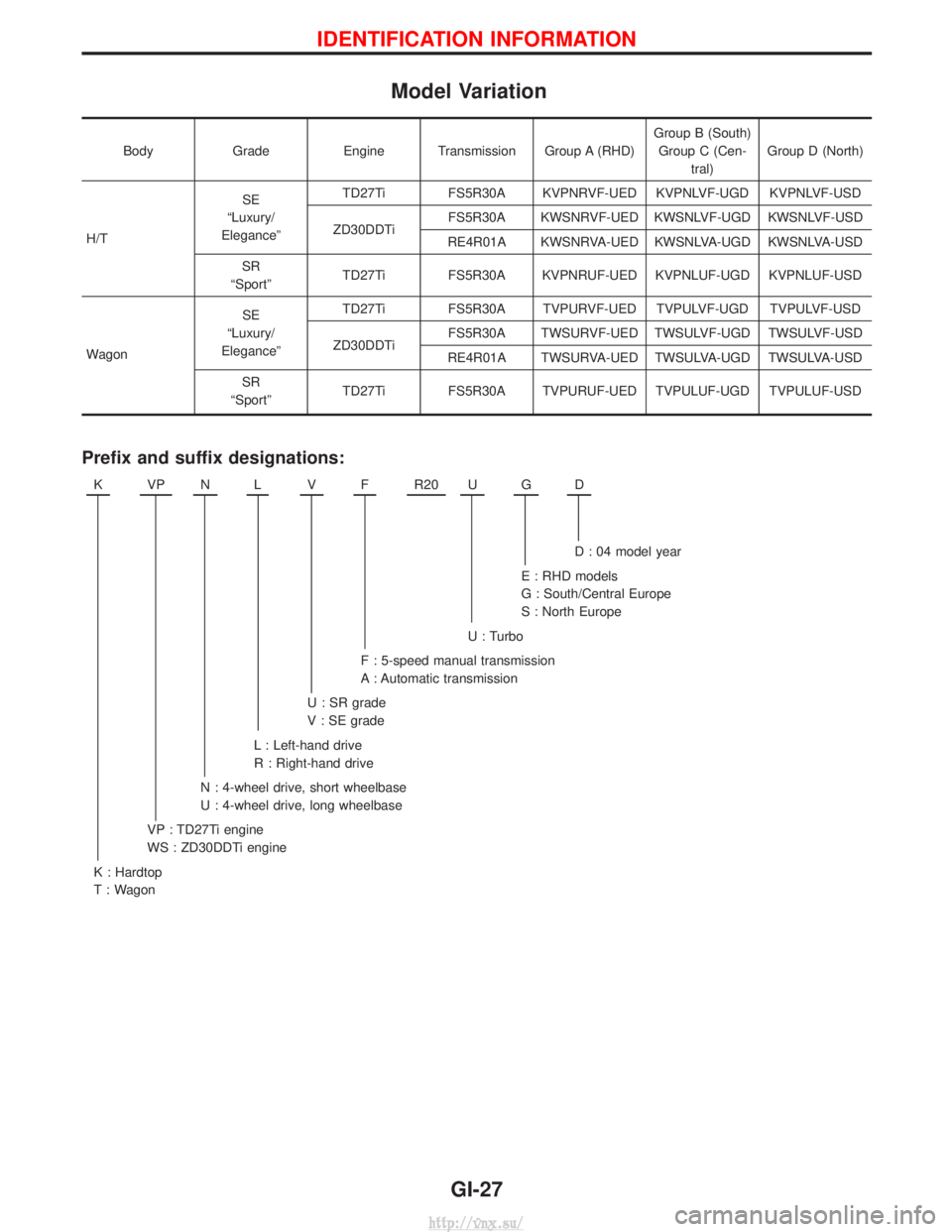

Prefix and suffix designations:

KVPNLVFR20UGD

D : 04 model year

E : RHD models

G : South/Central Europe

S : North Europe

U : Turbo

F : 5-speed manual transmission

A : Automatic transmission

U : SR grade

V : SE grade

L : Left-hand drive

R : Right-hand drive

N : 4-wheel drive, short wheelbase

U : 4-wheel drive, long wheelbase

VP : TD27Ti engine

WS : ZD30DDTi engine

K : Hardtop

T : Wagon

IDENTIFICATION INFORMATION

GI-27

http://vnx.su/