NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4331 of 5883

MWI-24

< COMPONENT DIAGNOSIS >

DTC U1000 CAN COMMUNICATION

COMPONENT DIAGNOSIS

DTC U1000 CAN COMMUNICATION

DTC LogicINFOID:0000000001374683

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000001374684

Symptom: Displays “CAN COMM CIRC [U1000]” as a self-diagnosis result of combination meter.

1.CHECK CAN COMMUNICATION

Select “SELF-DIAG RESULTS” mode for “METER/M&A” with CONSULT-III.

>> Go to “LAN system”. Refer to LAN-22, "

Trouble Diagnosis Flow Chart".

DTC CONSULT-III display Detection condition

U1000CAN COMM CIRC

[U1000]When combination meter is not receiving CAN communication signals for 2 seconds or more.

Page 4332 of 5883

MWI

DTC B2205 VEHICLE SPEED CIRCUIT

MWI-25

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

DTC B2205 VEHICLE SPEED CIRCUIT

DescriptionINFOID:0000000001374685

The ABS actuator and electric unit (control unit) provides a vehicle speed signal to the combination meter via

CAN communication lines.

DTC LogicINFOID:0000000001374686

Diagnosis ProcedureINFOID:0000000001374687

Symptom: Displays “VEHICLE SPEED CIRC [B2205]” as a self-diagnosis result of combination meter.

1.CHECK COMBINATION METER INPUT SIGNAL

1. Start engine and select “METER/M&A” on CONSULT-III.

2. Using “SPEED METER” on “DATA MONITOR”, compare the value of DATA MONITOR with speedometer

pointer of combination meter. Speedometer and DATA MONITOR indications should be close.

Is the inspection result normal?

YES >> Perform ABS actuator and electric unit (control unit) self-diagnosis. Refer to BRC-25, "CONSULT-

III Function (ABS)" (with ABS) or BRC-105, "CONSULT-III Function (ABS)" (with ESP/TCS/ABS).

NO >> Replace combination meter. Refer to MWI-94, "

Removal and Installation".

DTC CONSULT-III display Detection condition

B2205VEHICLE SPEED CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input for 2 seconds or more.

Page 4333 of 5883

MWI-26

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000001374688

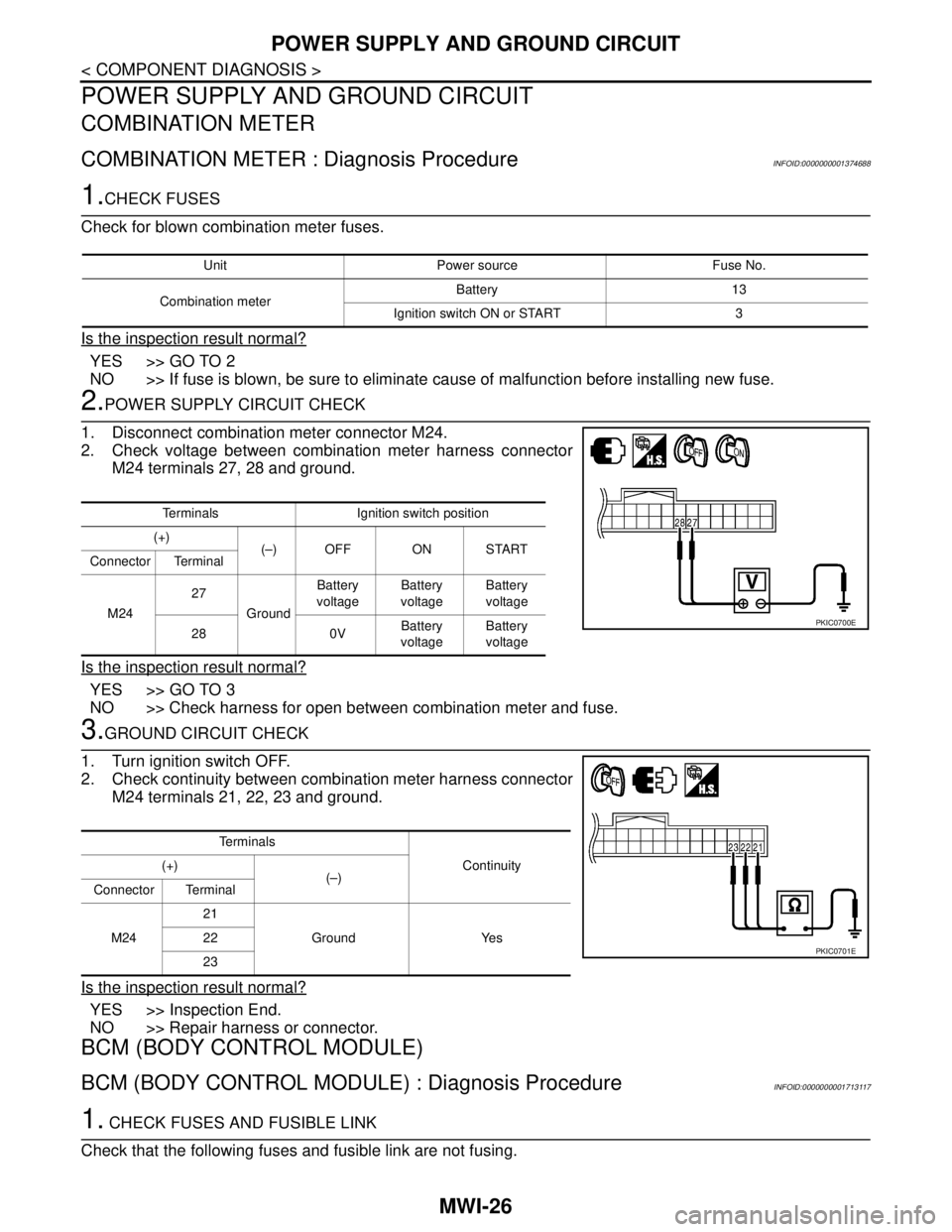

1.CHECK FUSES

Check for blown combination meter fuses.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector M24.

2. Check voltage between combination meter harness connector

M24 terminals 27, 28 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Check harness for open between combination meter and fuse.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Check continuity between combination meter harness connector

M24 terminals 21, 22, 23 and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000001713117

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not fusing.

Unit Power source Fuse No.

Combination meterBattery 13

Ignition switch ON or START 3

Terminals Ignition switch position

(+)

(–) OFF ON START

Connector Terminal

M2427

GroundBattery

voltageBattery

voltageBattery

voltage

28 0VBattery

voltageBattery

voltage

PKIC0700E

Te r m i n a l s

Continuity (+)

(–)

Connector Terminal

M2421

Ground Yes 22

23

PKIC0701E

Page 4334 of 5883

MWI

POWER SUPPLY AND GROUND CIRCUIT

MWI-27

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

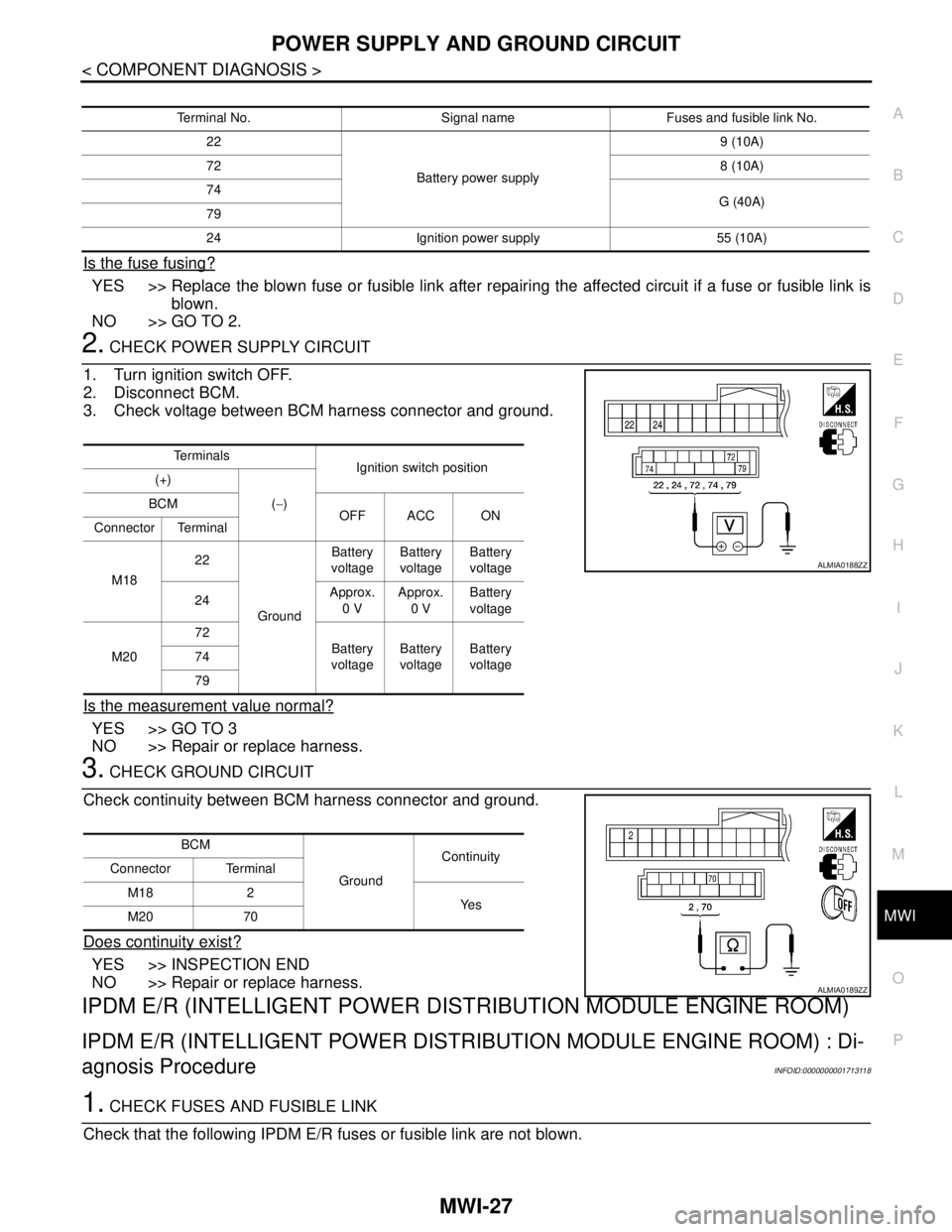

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000001713118

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Terminal No. Signal name Fuses and fusible link No.

22

Battery power supply9 (10A)

728 (10A)

74

G (40A)

79

24 Ignition power supply 55 (10A)

Te r m i n a l s

Ignition switch position

(+)

(−) BCM

OFF ACC ON

Connector Terminal

M1822

GroundBattery

voltageBattery

voltageBattery

voltage

24Approx.

0 VApprox.

0 VBattery

voltage

M2072

Battery

voltageBattery

voltageBattery

voltage 74

79

ALMIA0188ZZ

BCM

GroundContinuity

Connector Terminal

M18 2

Ye s

M20 70

ALMIA0189ZZ

Page 4335 of 5883

MWI-28

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

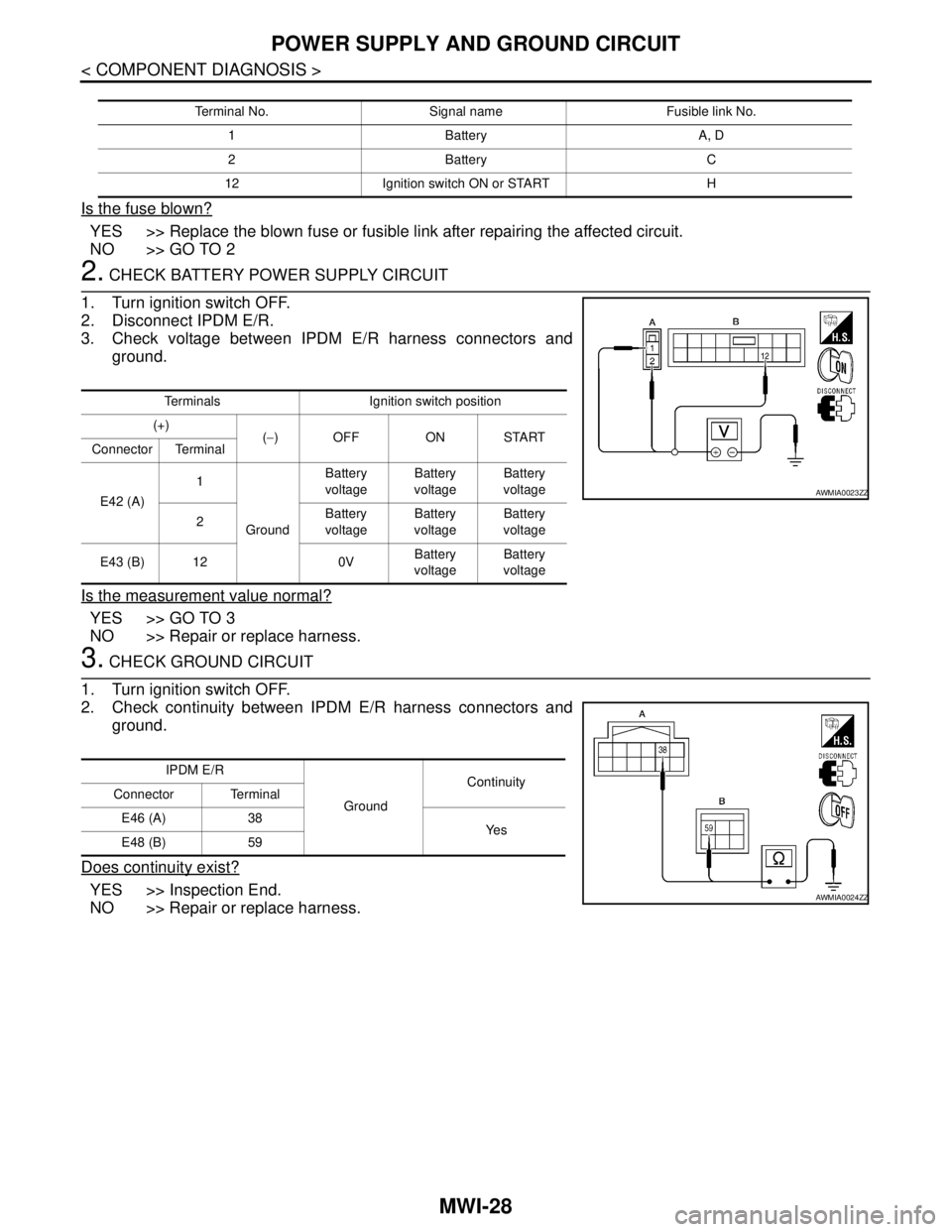

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and

ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

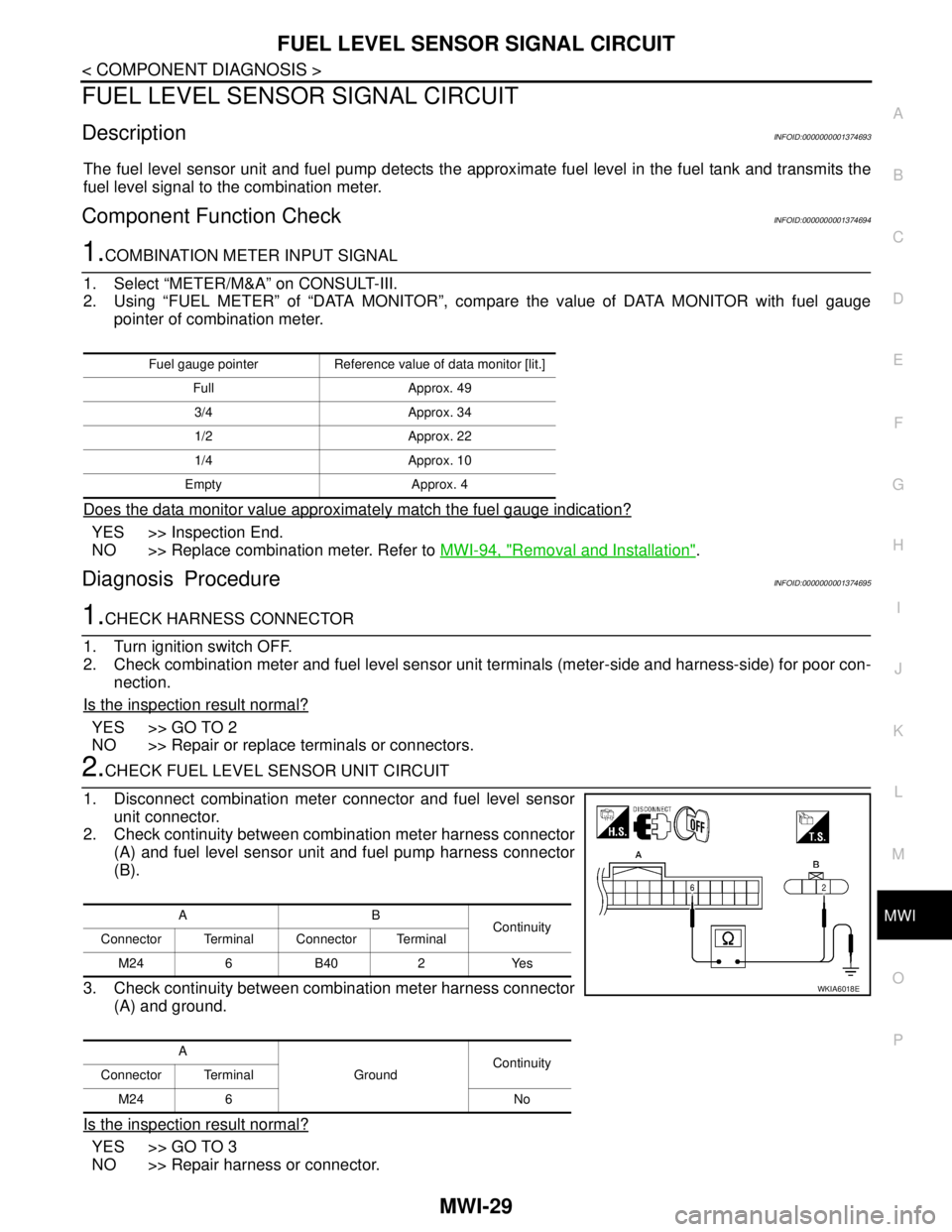

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between IPDM E/R harness connectors and

ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

Terminal No. Signal name Fusible link No.

1 Battery A, D

2 Battery C

12 Ignition switch ON or START H

Terminals Ignition switch position

(+)

(−) OFF ON START

Connector Terminal

E42 (A)1

GroundBattery

voltageBattery

voltageBattery

voltage

2Battery

voltageBattery

voltageBattery

voltage

E43 (B) 12 0VBattery

voltageBattery

voltage

AWMIA0023ZZ

IPDM E/R

GroundContinuity

Connector Terminal

E46 (A) 38

Ye s

E48 (B) 59

AWMIA0024ZZ

Page 4336 of 5883

MWI

FUEL LEVEL SENSOR SIGNAL CIRCUIT

MWI-29

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUEL LEVEL SENSOR SIGNAL CIRCUIT

DescriptionINFOID:0000000001374693

The fuel level sensor unit and fuel pump detects the approximate fuel level in the fuel tank and transmits the

fuel level signal to the combination meter.

Component Function CheckINFOID:0000000001374694

1.COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Using “FUEL METER” of “DATA MONITOR”, compare the value of DATA MONITOR with fuel gauge

pointer of combination meter.

Does the data monitor value approximately match the fuel gauge indication?

YES >> Inspection End.

NO >> Replace combination meter. Refer to MWI-94, "

Removal and Installation".

Diagnosis ProcedureINFOID:0000000001374695

1.CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

2. Check combination meter and fuel level sensor unit terminals (meter-side and harness-side) for poor con-

nection.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace terminals or connectors.

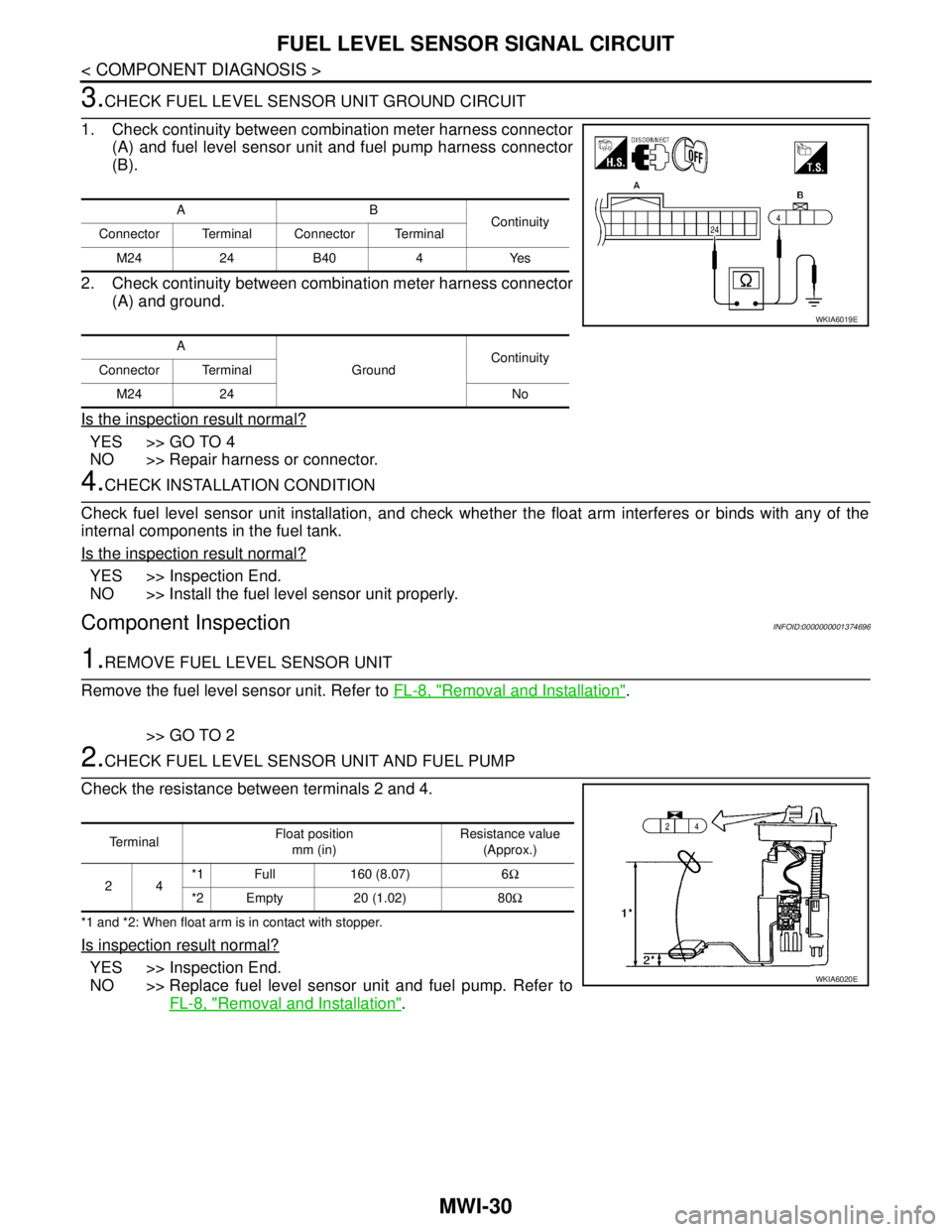

2.CHECK FUEL LEVEL SENSOR UNIT CIRCUIT

1. Disconnect combination meter connector and fuel level sensor

unit connector.

2. Check continuity between combination meter harness connector

(A) and fuel level sensor unit and fuel pump harness connector

(B).

3. Check continuity between combination meter harness connector

(A) and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair harness or connector.

Fuel gauge pointer Reference value of data monitor [lit.]

Full Approx. 49

3/4 Approx. 34

1/2 Approx. 22

1/4 Approx. 10

Empty Approx. 4

AB

Continuity

Connector Terminal Connector Terminal

M24 6 B40 2 Yes

A

GroundContinuity

Connector Terminal

M24 6 No

WKIA6018E

Page 4337 of 5883

MWI-30

< COMPONENT DIAGNOSIS >

FUEL LEVEL SENSOR SIGNAL CIRCUIT

3.CHECK FUEL LEVEL SENSOR UNIT GROUND CIRCUIT

1. Check continuity between combination meter harness connector

(A) and fuel level sensor unit and fuel pump harness connector

(B).

2. Check continuity between combination meter harness connector

(A) and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair harness or connector.

4.CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any of the

internal components in the fuel tank.

Is the inspection result normal?

YES >> Inspection End.

NO >> Install the fuel level sensor unit properly.

Component InspectionINFOID:0000000001374696

1.REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to FL-8, "

Removal and Installation".

>> GO TO 2

2.CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP

Check the resistance between terminals 2 and 4.

*1 and *2: When float arm is in contact with stopper.

Is inspection result normal?

YES >> Inspection End.

NO >> Replace fuel level sensor unit and fuel pump. Refer to

FL-8, "

Removal and Installation".

AB

Continuity

Connector Terminal Connector Terminal

M24 24 B40 4 Yes

A

GroundContinuity

Connector Terminal

M24 24 No

WKIA6019E

Te r m i n a lFloat position

mm (in)Resistance value

(Approx.)

24*1 Full 160 (8.07) 6Ω

*2 Empty 20 (1.02) 80Ω

WKIA6020E

Page 4338 of 5883

MWI

OIL PRESSURE SWITCH SIGNAL CIRCUIT

MWI-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

OIL PRESSURE SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000001374697

Detects the engine oil pressure and transmits the oil pressure switch signal to the IPDM E/R.

Component Function CheckINFOID:0000000001374698

1.COMBINATION METER INPUT SIGNAL

1. Select “METER/M&A” on CONSULT-III.

2. Monitor “OIL W/L” of “DATA MONITOR” while operating ignition switch.

>> Inspection End.

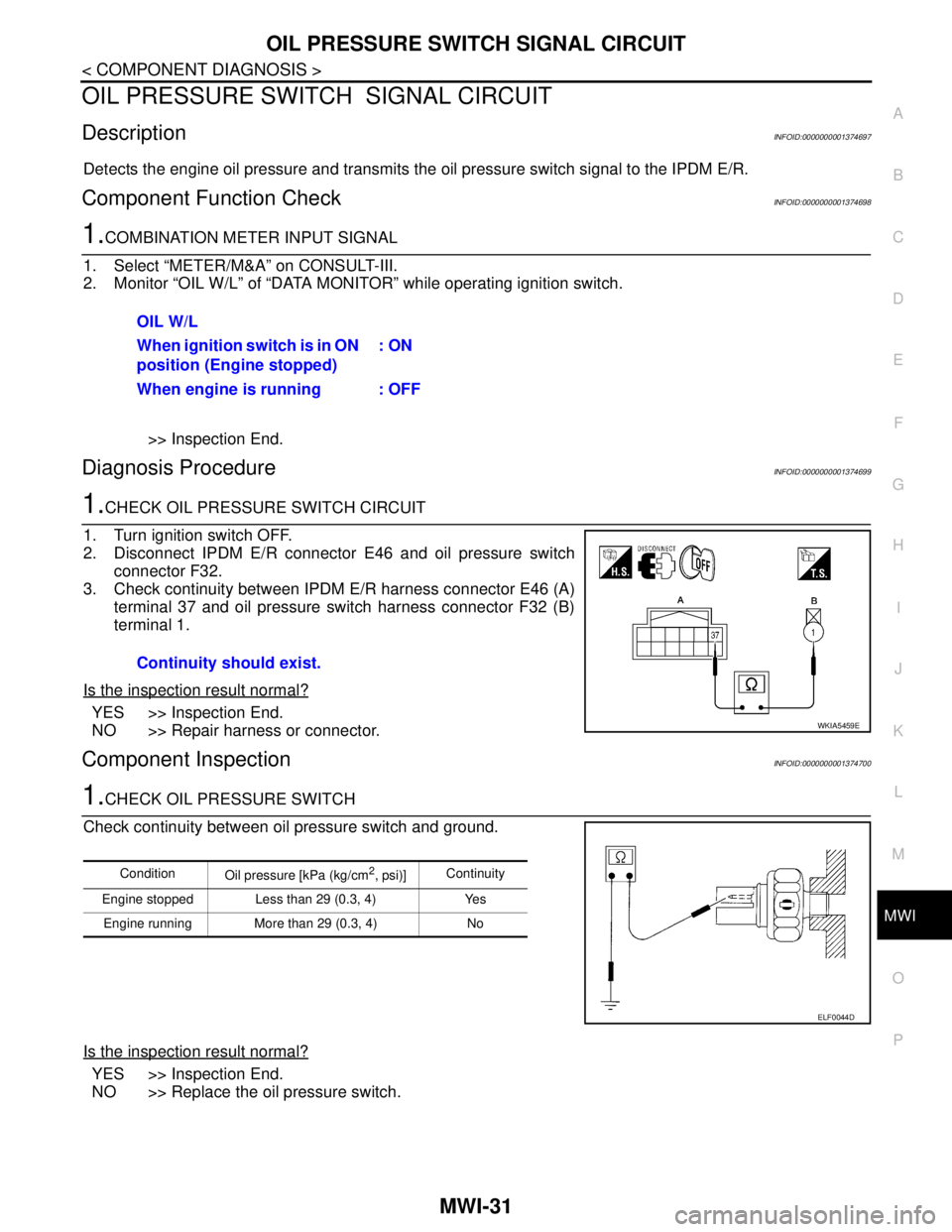

Diagnosis ProcedureINFOID:0000000001374699

1.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E46 and oil pressure switch

connector F32.

3. Check continuity between IPDM E/R harness connector E46 (A)

terminal 37 and oil pressure switch harness connector F32 (B)

terminal 1.

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000001374700

1.CHECK OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace the oil pressure switch.OIL W/L

When ignition switch is in ON

position (Engine stopped): ON

When engine is running : OFF

Continuity should exist.

WKIA5459E

Condition

Oil pressure [kPa (kg/cm2, psi)]Continuity

Engine stopped Less than 29 (0.3, 4) Yes

Engine running More than 29 (0.3, 4) No

ELF0044D

Page 4339 of 5883

MWI-32

< COMPONENT DIAGNOSIS >

OIL LEVEL SENSOR SIGNAL CIRCUIT

OIL LEVEL SENSOR SIGNAL CIRCUIT

DescriptionINFOID:0000000001537460

Transmits the oil level sensor signal to the combination meter.

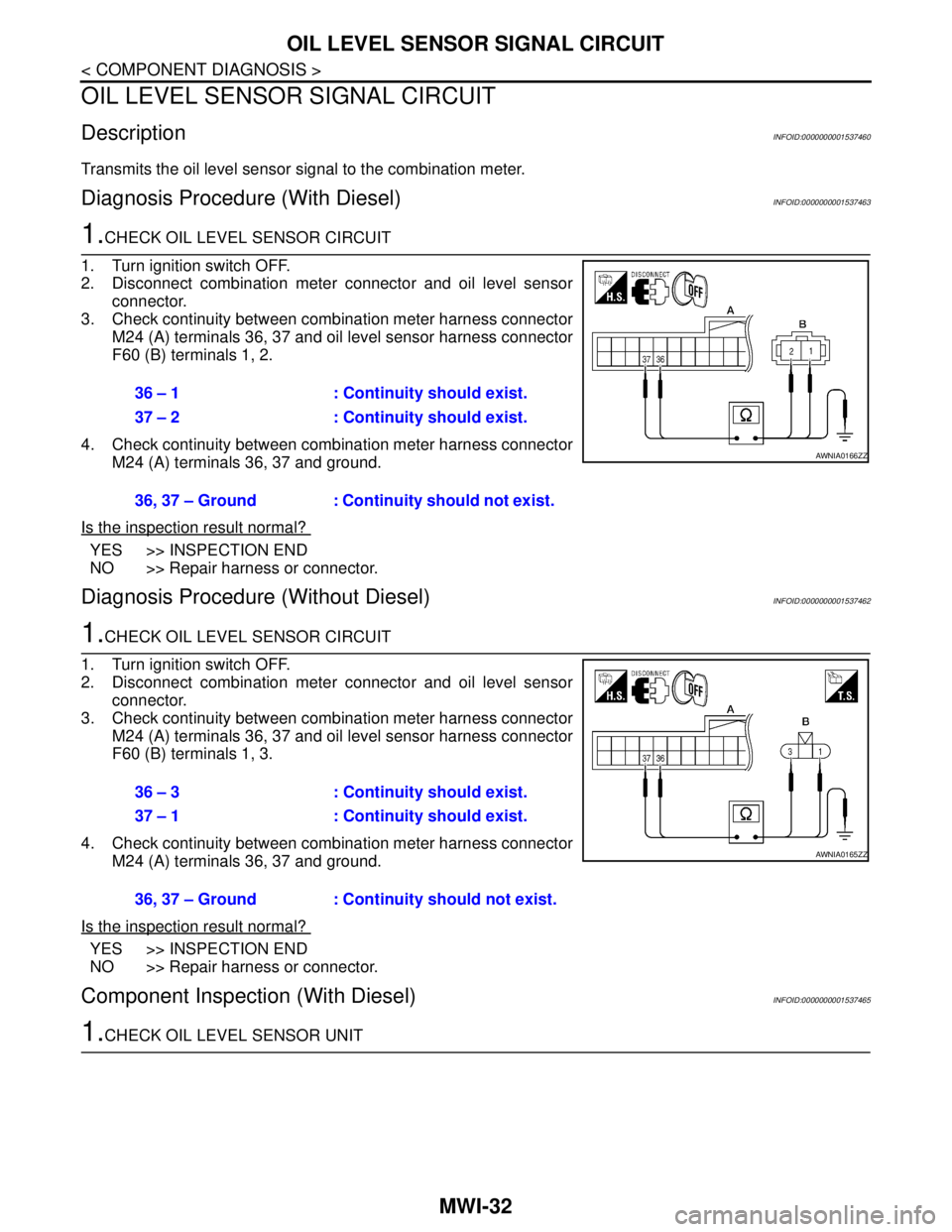

Diagnosis Procedure (With Diesel)INFOID:0000000001537463

1.CHECK OIL LEVEL SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and oil level sensor

connector.

3. Check continuity between combination meter harness connector

M24 (A) terminals 36, 37 and oil level sensor harness connector

F60 (B) terminals 1, 2.

4. Check continuity between combination meter harness connector

M24 (A) terminals 36, 37 and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Diagnosis Procedure (Without Diesel)INFOID:0000000001537462

1.CHECK OIL LEVEL SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and oil level sensor

connector.

3. Check continuity between combination meter harness connector

M24 (A) terminals 36, 37 and oil level sensor harness connector

F60 (B) terminals 1, 3.

4. Check continuity between combination meter harness connector

M24 (A) terminals 36, 37 and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

Component Inspection (With Diesel)INFOID:0000000001537465

1.CHECK OIL LEVEL SENSOR UNIT36 – 1 : Continuity should exist.

37 – 2 : Continuity should exist.

36, 37 – Ground : Continuity should not exist.

AWNIA0166ZZ

36 – 3 : Continuity should exist.

37 – 1 : Continuity should exist.

36, 37 – Ground : Continuity should not exist.

AWNIA0165ZZ

Page 4340 of 5883

MWI

OIL LEVEL SENSOR SIGNAL CIRCUIT

MWI-33

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

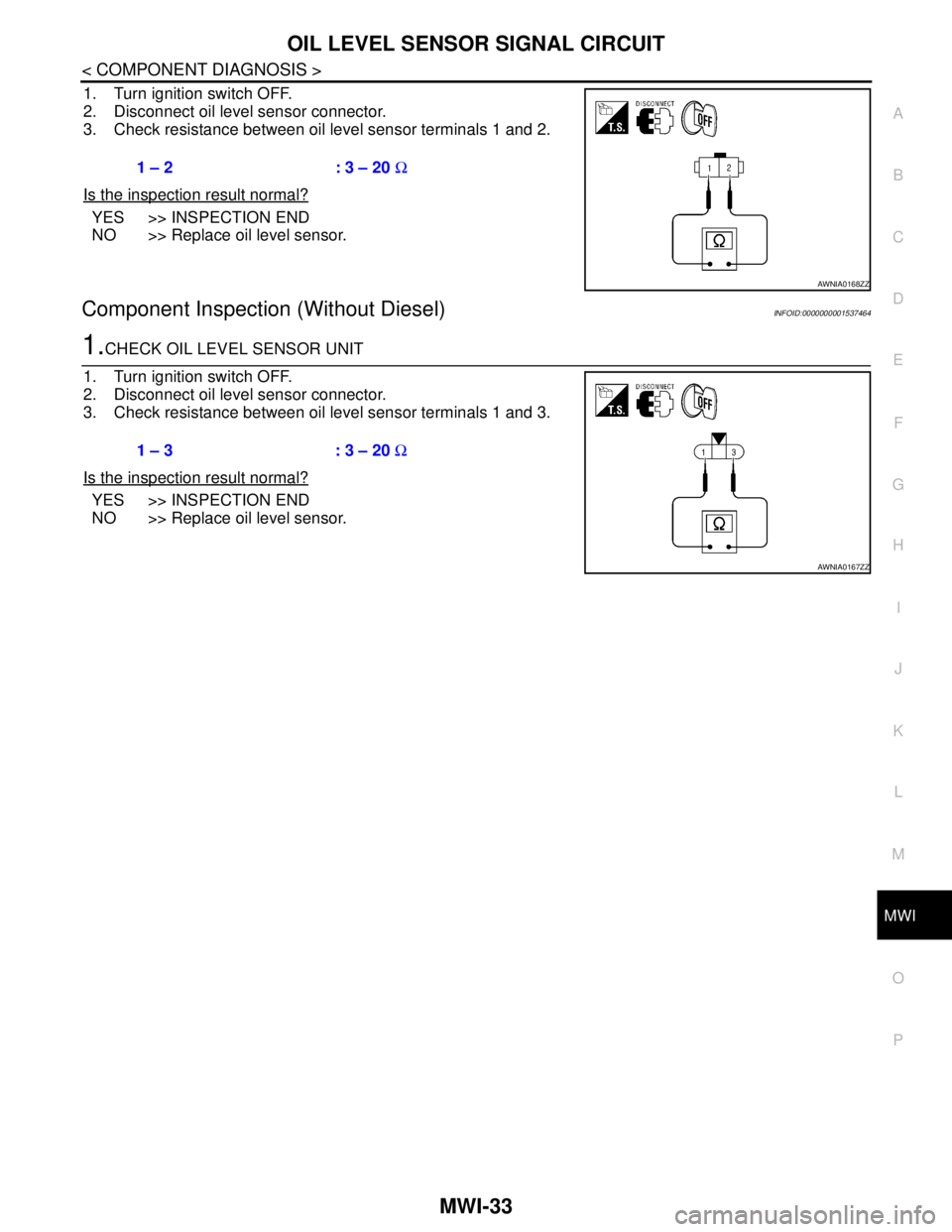

1. Turn ignition switch OFF.

2. Disconnect oil level sensor connector.

3. Check resistance between oil level sensor terminals 1 and 2.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace oil level sensor.

Component Inspection (Without Diesel)INFOID:0000000001537464

1.CHECK OIL LEVEL SENSOR UNIT

1. Turn ignition switch OFF.

2. Disconnect oil level sensor connector.

3. Check resistance between oil level sensor terminals 1 and 3.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace oil level sensor.1 – 2 : 3 – 20 Ω

AWNIA0168ZZ

1 – 3 : 3 – 20 Ω

AWNIA0167ZZ