NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3471 of 3833

CHARGING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

Removal and Installation EKS0031A

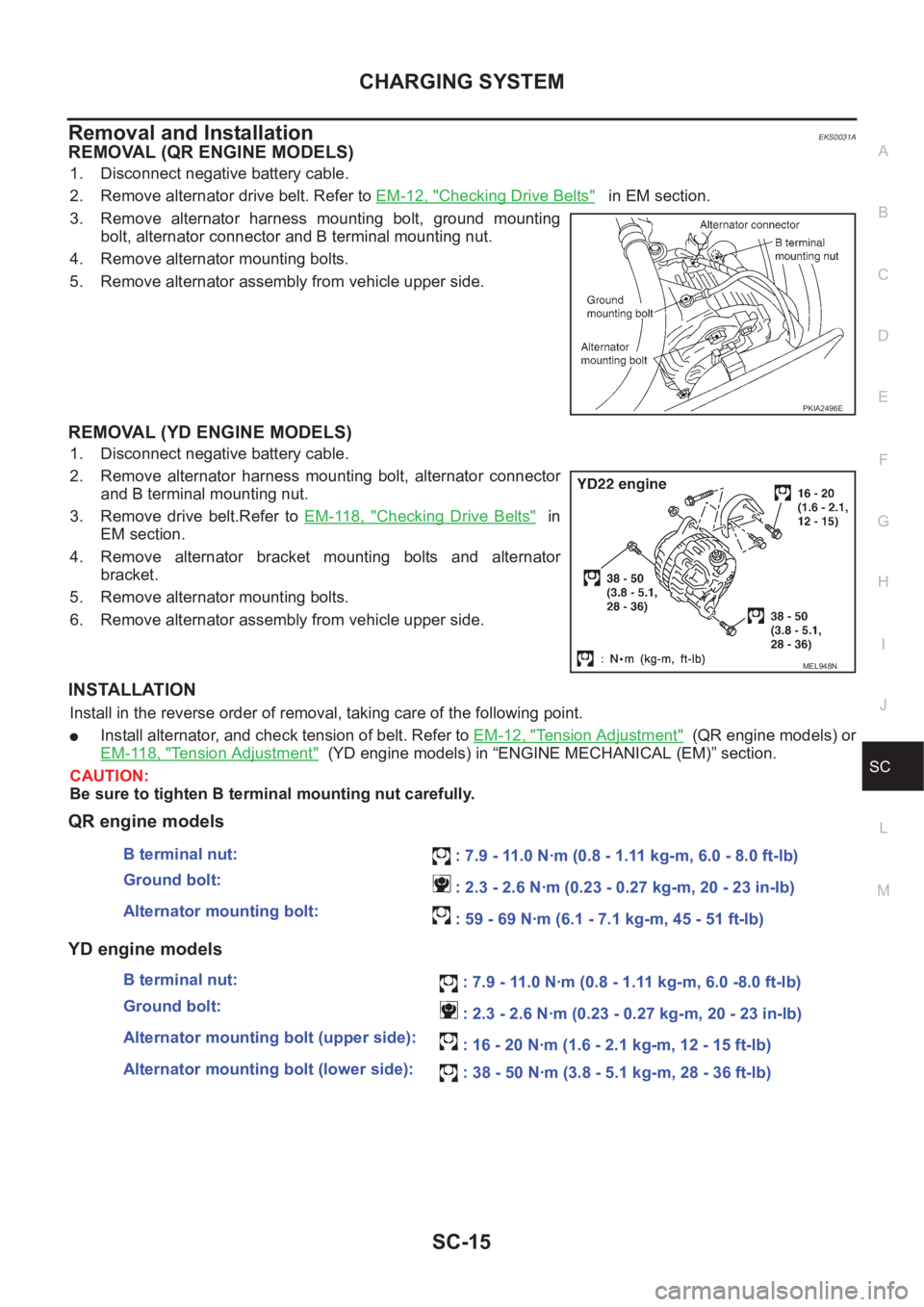

REMOVAL (QR ENGINE MODELS)

1. Disconnect negative battery cable.

2. Remove alternator drive belt. Refer to EM-12, "

Checking Drive Belts" in EM section.

3. Remove alternator harness mounting bolt, ground mounting

bolt, alternator connector and B terminal mounting nut.

4. Remove alternator mounting bolts.

5. Remove alternator assembly from vehicle upper side.

REMOVAL (YD ENGINE MODELS)

1. Disconnect negative battery cable.

2. Remove alternator harness mounting bolt, alternator connector

and B terminal mounting nut.

3. Remove drive belt.Refer to EM-118, "

Checking Drive Belts" in

EM section.

4. Remove alternator bracket mounting bolts and alternator

bracket.

5. Remove alternator mounting bolts.

6. Remove alternator assembly from vehicle upper side.

INSTALLATION

Install in the reverse order of removal, taking care of the following point.

●Install alternator, and check tension of belt. Refer to EM-12, "Tension Adjustment" (QR engine models) or

EM-118, "

Tension Adjustment" (YD engine models) in “ENGINE MECHANICAL (EM)” section.

CAUTION:

Be sure to tighten B terminal mounting nut carefully.

QR engine models

YD engine models

PKIA2496E

MEL948N

B terminal nut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 6.0 - 8.0 ft-lb)

Ground bolt:

: 2.3 - 2.6 N·m (0.23 - 0.27 kg-m, 20 - 23 in-lb)

Alternator mounting bolt:

: 59 - 69 N·m (6.1 - 7.1 kg-m, 45 - 51 ft-lb)

B terminal nut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 6.0 -8.0 ft-lb)

Ground bolt:

: 2.3 - 2.6 N·m (0.23 - 0.27 kg-m, 20 - 23 in-lb)

Alternator mounting bolt (upper side):

: 16 - 20 N·m (1.6 - 2.1 kg-m, 12 - 15 ft-lb)

Alternator mounting bolt (lower side):

: 38 - 50 N·m (3.8 - 5.1 kg-m, 28 - 36 ft-lb)

Page 3472 of 3833

SC-16

CHARGING SYSTEM

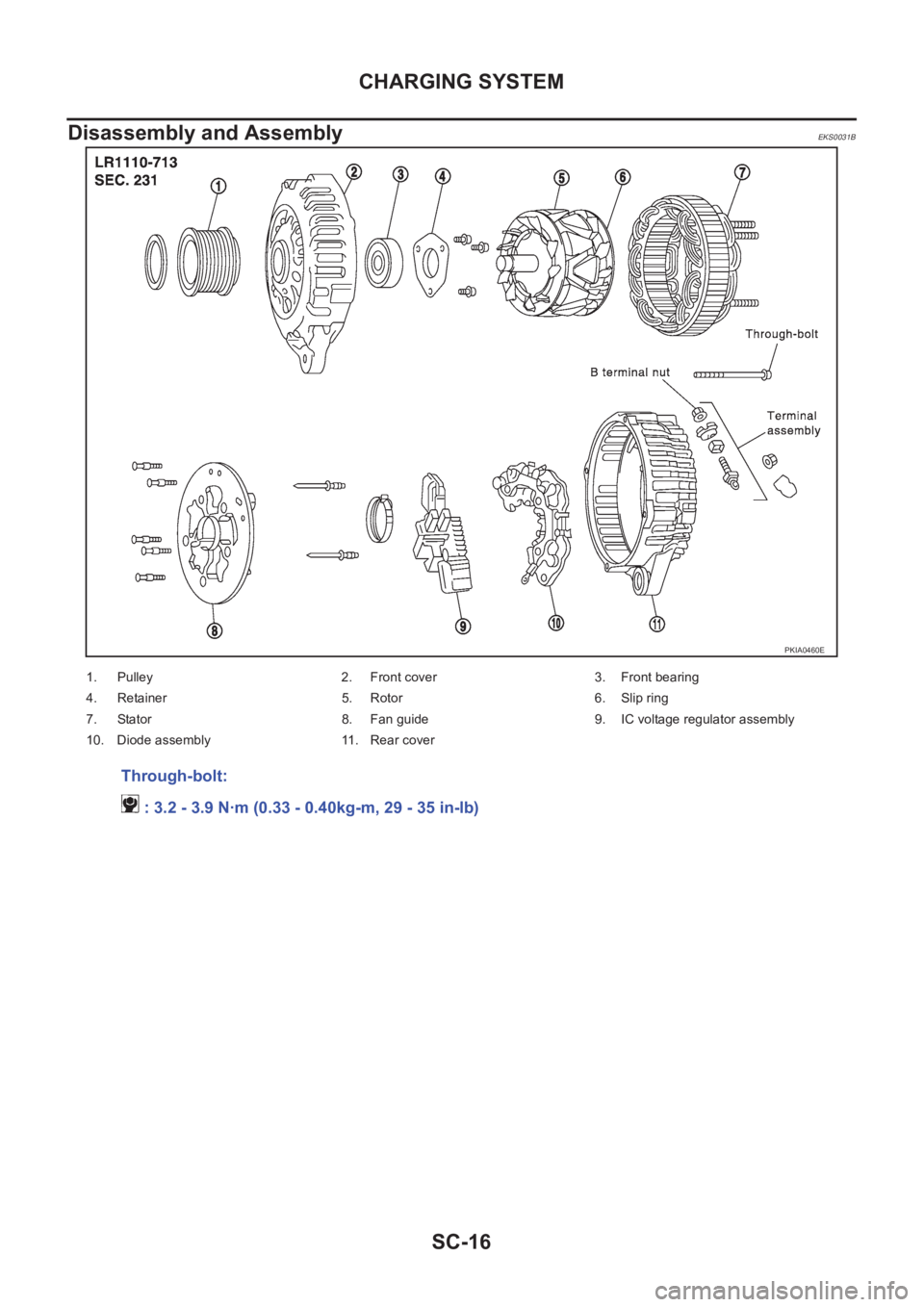

Disassembly and Assembly

EKS0031B

PKIA0460E

1. Pulley 2. Front cover 3. Front bearing

4. Retainer 5. Rotor 6. Slip ring

7. Stator 8. Fan guide 9. IC voltage regulator assembly

10. Diode assembly 11. Rear cover

Through-bolt:

: 3.2 - 3.9 N·m (0.33 - 0.40kg-m, 29 - 35 in-lb)

Page 3473 of 3833

CHARGING SYSTEM

SC-17

C

D

E

F

G

H

I

J

L

MA

B

SC

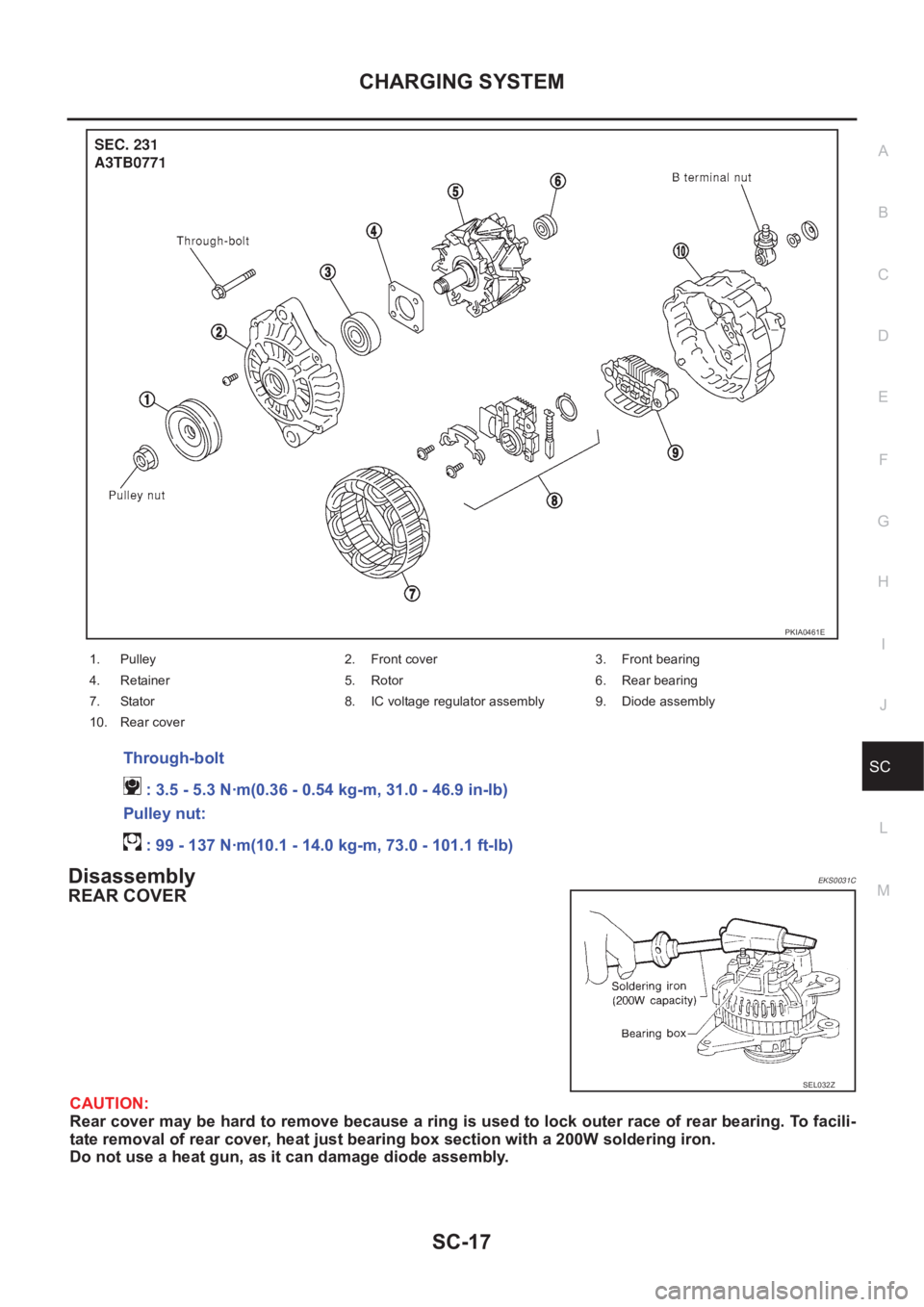

DisassemblyEKS0031C

REAR COVER

CAUTION:

Rear cover may be hard to remove because a ring is used to lock outer race of rear bearing. To facili-

tate removal of rear cover, heat just bearing box section with a 200W soldering iron.

Do not use a heat gun, as it can damage diode assembly.

PKIA0461E

1. Pulley 2. Front cover 3. Front bearing

4. Retainer 5. Rotor 6. Rear bearing

7. Stator 8. IC voltage regulator assembly 9. Diode assembly

10. Rear cover

Through-bolt

: 3.5 - 5.3 N·m(0.36 - 0.54 kg-m, 31.0 - 46.9 in-lb)

Pulley nut:

: 99 - 137 N·m(10.1 - 14.0 kg-m, 73.0 - 101.1 ft-lb)

SEL032Z

Page 3474 of 3833

SC-18

CHARGING SYSTEM

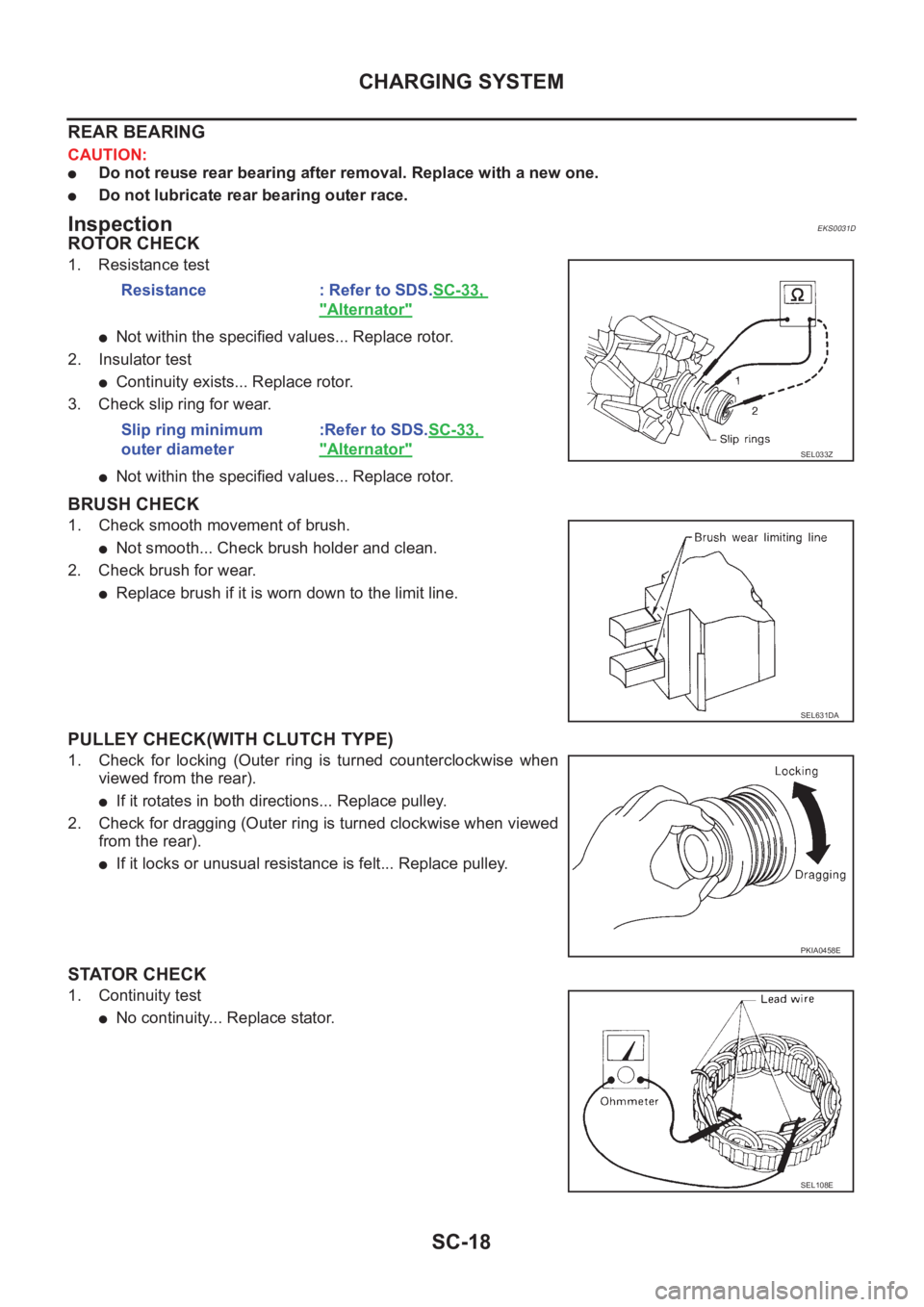

REAR BEARING

CAUTION:

●Do not reuse rear bearing after removal. Replace with a new one.

●Do not lubricate rear bearing outer race.

InspectionEKS0031D

ROTOR CHECK

1. Resistance test

●Not within the specified values... Replace rotor.

2. Insulator test

●Continuity exists... Replace rotor.

3. Check slip ring for wear.

●Not within the specified values... Replace rotor.

BRUSH CHECK

1. Check smooth movement of brush.

●Not smooth... Check brush holder and clean.

2. Check brush for wear.

●Replace brush if it is worn down to the limit line.

PULLEY CHECK(WITH CLUTCH TYPE)

1. Check for locking (Outer ring is turned counterclockwise when

viewed from the rear).

●If it rotates in both directions... Replace pulley.

2. Check for dragging (Outer ring is turned clockwise when viewed

from the rear).

●If it locks or unusual resistance is felt... Replace pulley.

STATOR CHECK

1. Continuity test

●No continuity... Replace stator.Resistance : Refer to SDS.SC-33,

"Alternator"

Slip ring minimum

outer diameter:Refer to SDS.SC-33,

"Alternator"SEL033Z

SEL631DA

PKIA0458E

SEL108E

Page 3475 of 3833

CHARGING SYSTEM

SC-19

C

D

E

F

G

H

I

J

L

MA

B

SC

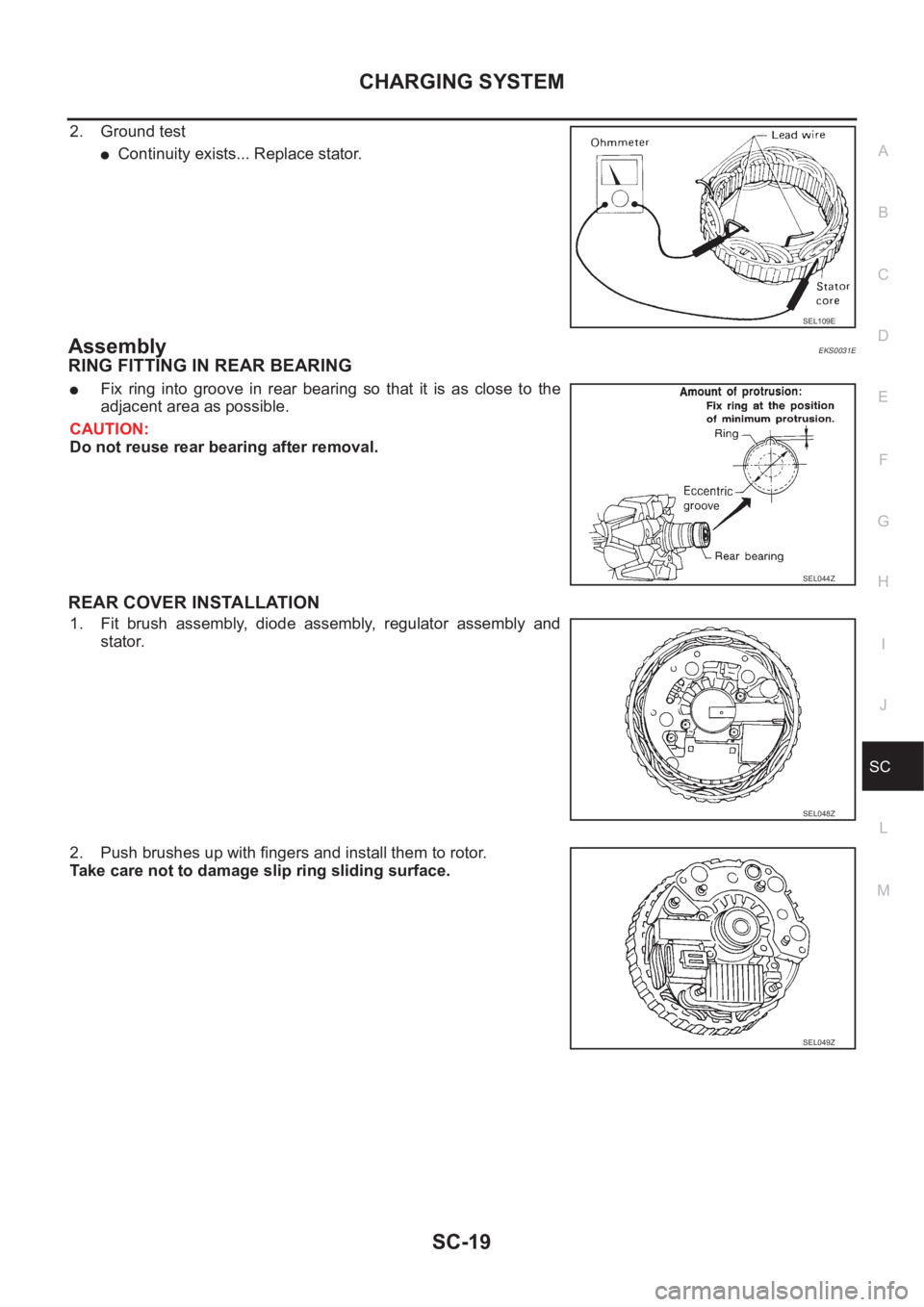

2. Ground test

●Continuity exists... Replace stator.

AssemblyEKS0031E

RING FITTING IN REAR BEARING

●Fix ring into groove in rear bearing so that it is as close to the

adjacent area as possible.

CAUTION:

Do not reuse rear bearing after removal.

REAR COVER INSTALLATION

1. Fit brush assembly, diode assembly, regulator assembly and

stator.

2. Push brushes up with fingers and install them to rotor.

Take care not to damage slip ring sliding surface.

SEL109E

SEL044Z

SEL048Z

SEL049Z

Page 3476 of 3833

SC-20

STARTING SYSTEM

STARTING SYSTEM

PFP:00011

System Description EKS0031F

M/T MODELS

Power is supplied at all times

●through 30A fusible link (letter J, located in the fuse and fusible link box)

●to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

●from ignition switch terminal 5

●to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

A/T MODELS

Power is supplied at all times

●through 30A fusible link (letter J, located in the fuse and fusible link box)

●to ignition switch terminal 1.

With the ignition switch in the START position, power is supplied

●from ignition switch terminal 5

●to park/neutral position relay terminal 5.

With the ignition switch in the ON or START position, power is supplied

●through 10A fuse [No,13 located in the fuse block (J/B)]

●to park/neutral position relay terminal 1.

With the selector lever in the P or N position, ground is supplied

●to park/neutral position relay terminal 2

●through the park/neutral position switch terminals 1 and 2,and

●through body grounds F9 and F10.

Then park/neutral position relay is energized and power is supplied

●from park/neutral position relay terminal 3

●to starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

Page 3477 of 3833

STARTING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

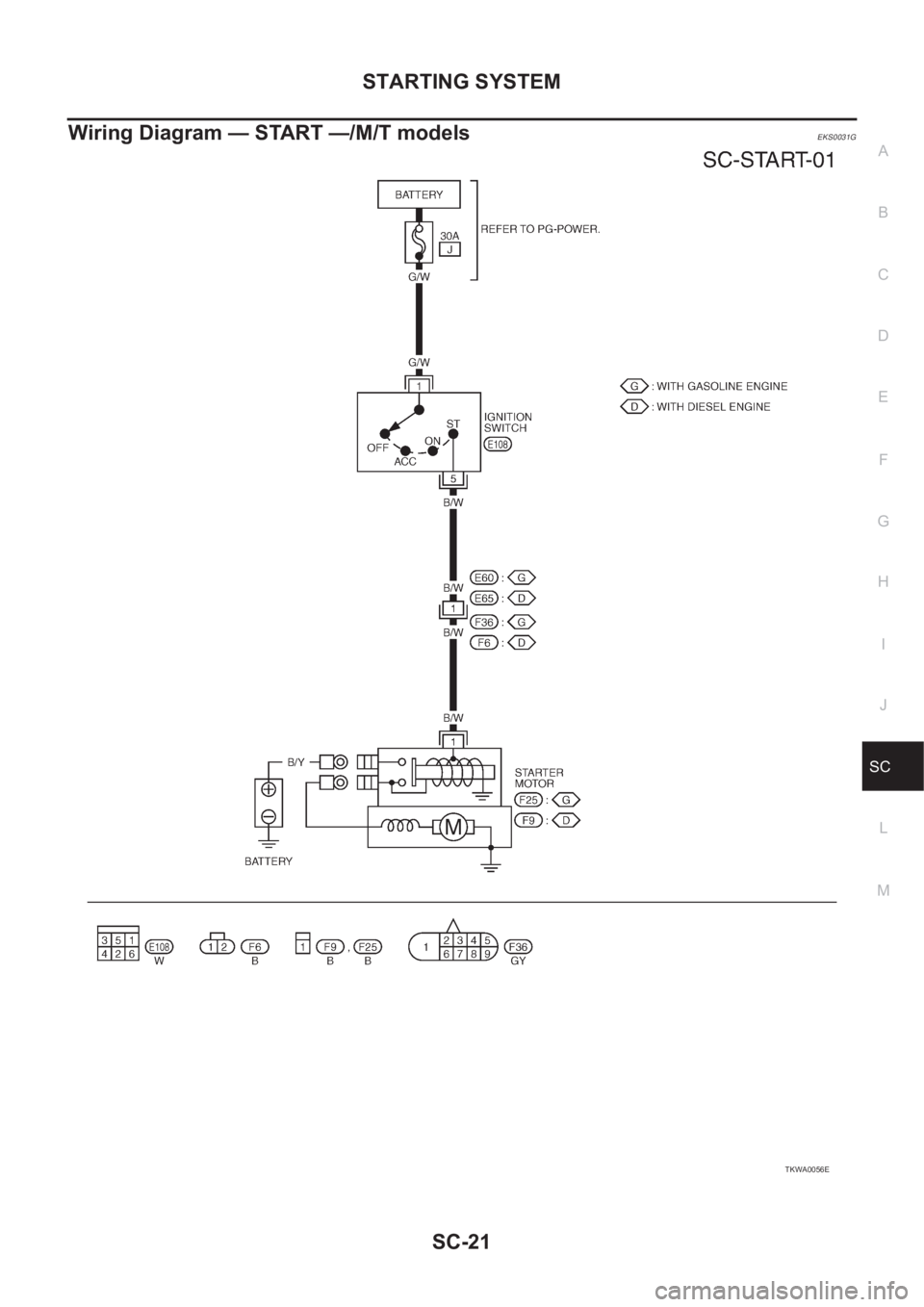

Wiring Diagram — START —/M/T modelsEKS0031G

TKWA0056E

Page 3478 of 3833

SC-22

STARTING SYSTEM

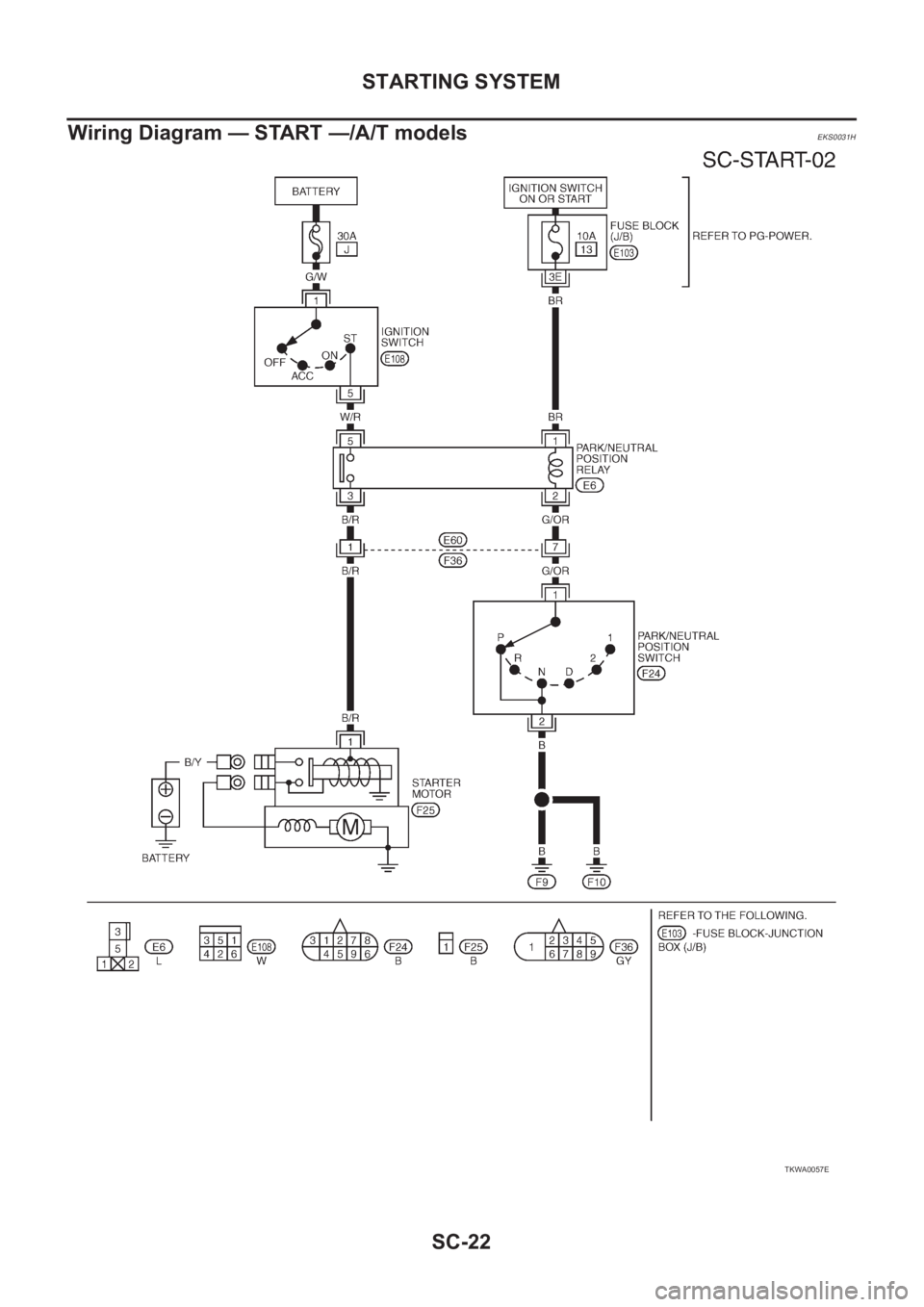

Wiring Diagram — START —/A/T models

EKS0031H

TKWA0057E

Page 3479 of 3833

STARTING SYSTEM

SC-23

C

D

E

F

G

H

I

J

L

MA

B

SC

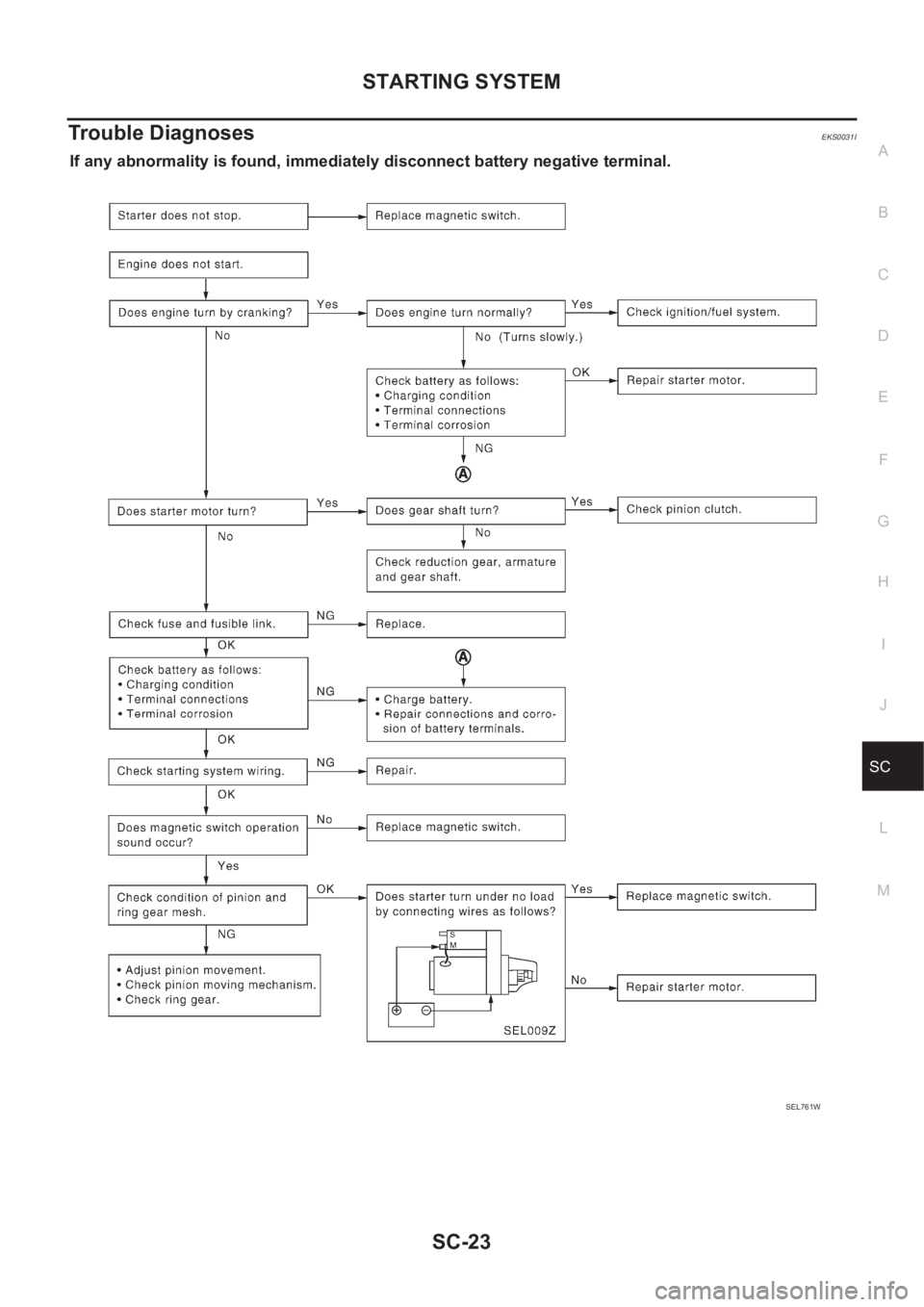

Trouble DiagnosesEKS0031I

If any abnormality is found, immediately disconnect battery negative terminal.

SEL761W

Page 3480 of 3833

SC-24

STARTING SYSTEM

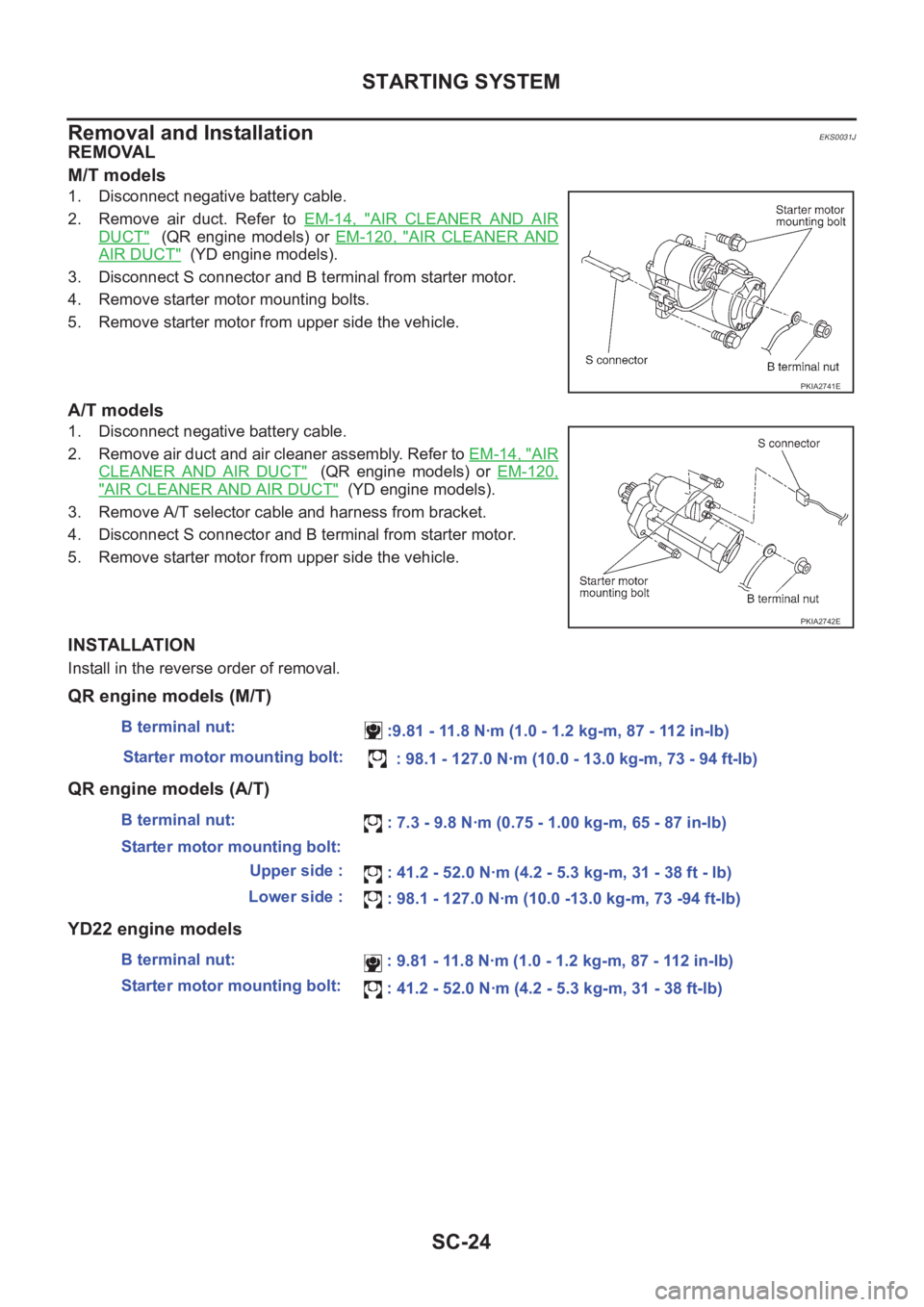

Removal and Installation

EKS0031J

REMOVAL

M/T models

1. Disconnect negative battery cable.

2. Remove air duct. Refer to EM-14, "

AIR CLEANER AND AIR

DUCT" (QR engine models) or EM-120, "AIR CLEANER AND

AIR DUCT" (YD engine models).

3. Disconnect S connector and B terminal from starter motor.

4. Remove starter motor mounting bolts.

5. Remove starter motor from upper side the vehicle.

A/T models

1. Disconnect negative battery cable.

2. Remove air duct and air cleaner assembly. Refer to EM-14, "

AIR

CLEANER AND AIR DUCT" (QR engine models) or EM-120,

"AIR CLEANER AND AIR DUCT" (YD engine models).

3. Remove A/T selector cable and harness from bracket.

4. Disconnect S connector and B terminal from starter motor.

5. Remove starter motor from upper side the vehicle.

INSTALLATION

Install in the reverse order of removal.

QR engine models (M/T)

QR engine models (A/T)

YD22 engine models

PKIA2741E

PKIA2742E

B terminal nut:

:9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting bolt:

: 98.1 - 127.0 N·m (10.0 - 13.0 kg-m, 73 - 94 ft-lb)

B terminal nut:

: 7.3 - 9.8 N·m (0.75 - 1.00 kg-m, 65 - 87 in-lb)

Starter motor mounting bolt:

Upper side :

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft - lb)

Lower side :

: 98.1 - 127.0 N·m (10.0 -13.0 kg-m, 73 -94 ft-lb)

B terminal nut:

: 9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting bolt:

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft-lb)