NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3451 of 3833

HEATER UNIT

MTC-25

C

D

E

F

G

H

I

K

L

MA

B

MTC

7. Remove the mounting bolts from heater unit.

8. Remove the steering member.

9. Remove the heater unit.

INSTALLATION

1. Installation is basically the reverse order of removal.

NOTE:

When filling radiator with coolant, refer to QR engine CO-9, "

Changing Engine Coolant" , YD engine CO-29,

"Changing Engine Coolant" .

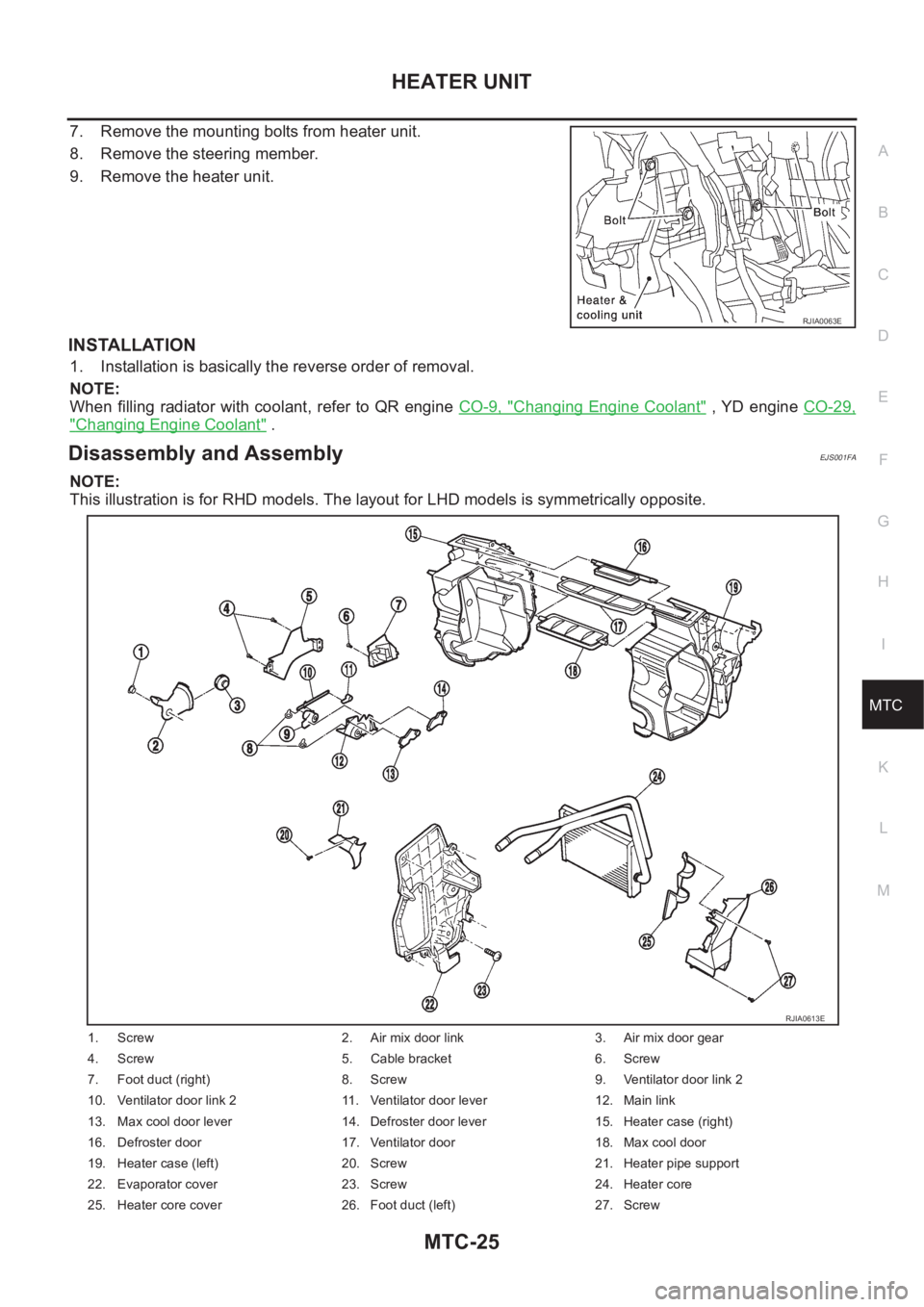

Disassembly and AssemblyEJS001FA

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0063E

1. Screw 2. Air mix door link 3. Air mix door gear

4. Screw 5. Cable bracket 6. Screw

7. Foot duct (right) 8. Screw 9. Ventilator door link 2

10. Ventilator door link 2 11. Ventilator door lever 12. Main link

13. Max cool door lever 14. Defroster door lever 15. Heater case (right)

16. Defroster door 17. Ventilator door 18. Max cool door

19. Heater case (left) 20. Screw 21. Heater pipe support

22. Evaporator cover 23. Screw 24. Heater core

25. Heater core cover 26. Foot duct (left) 27. Screw

RJIA0613E

Page 3452 of 3833

MTC-26

HEATER CORE

HEATER CORE

PFP:27140

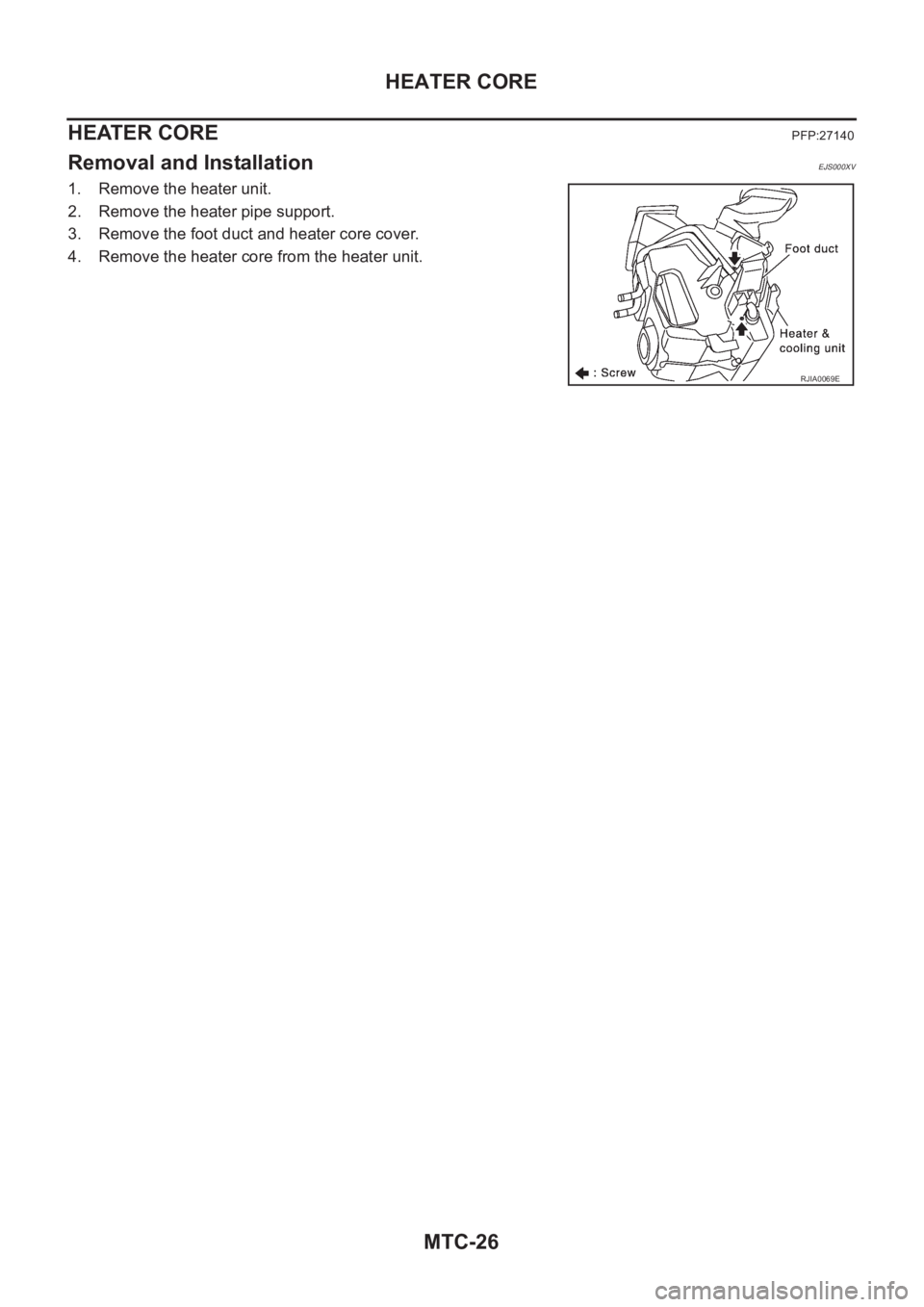

Removal and InstallationEJS000XV

1. Remove the heater unit.

2. Remove the heater pipe support.

3. Remove the foot duct and heater core cover.

4. Remove the heater core from the heater unit.

RJIA0069E

Page 3453 of 3833

MODE DOOR

MTC-27

C

D

E

F

G

H

I

K

L

MA

B

MTC

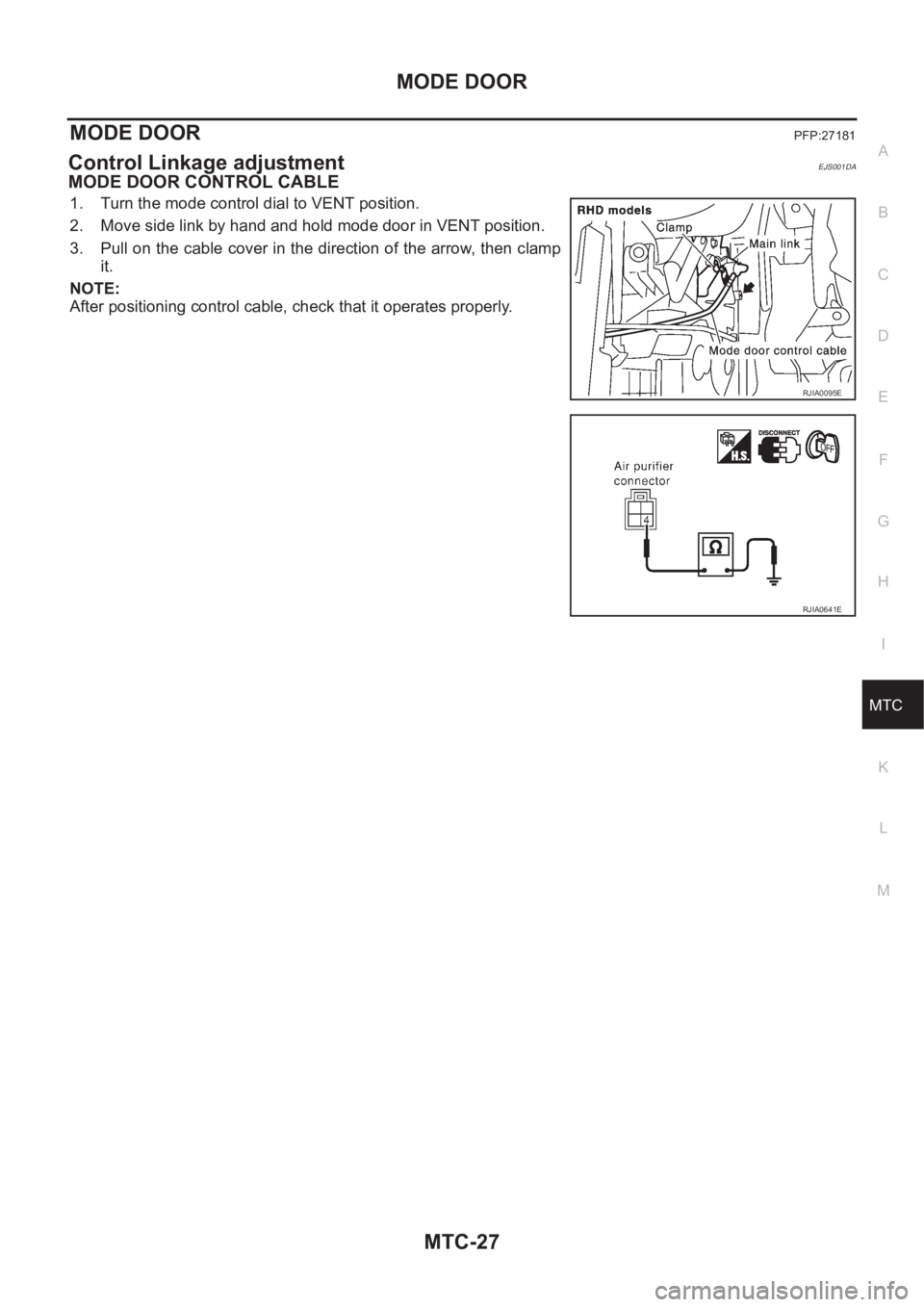

MODE DOORPFP:27181

Control Linkage adjustmentEJS001DA

MODE DOOR CONTROL CABLE

1. Turn the mode control dial to VENT position.

2. Move side link by hand and hold mode door in VENT position.

3. Pull on the cable cover in the direction of the arrow, then clamp

it.

NOTE:

After positioning control cable, check that it operates properly.

RJIA0095E

RJIA0641E

Page 3454 of 3833

MTC-28

AIR MIX DOOR

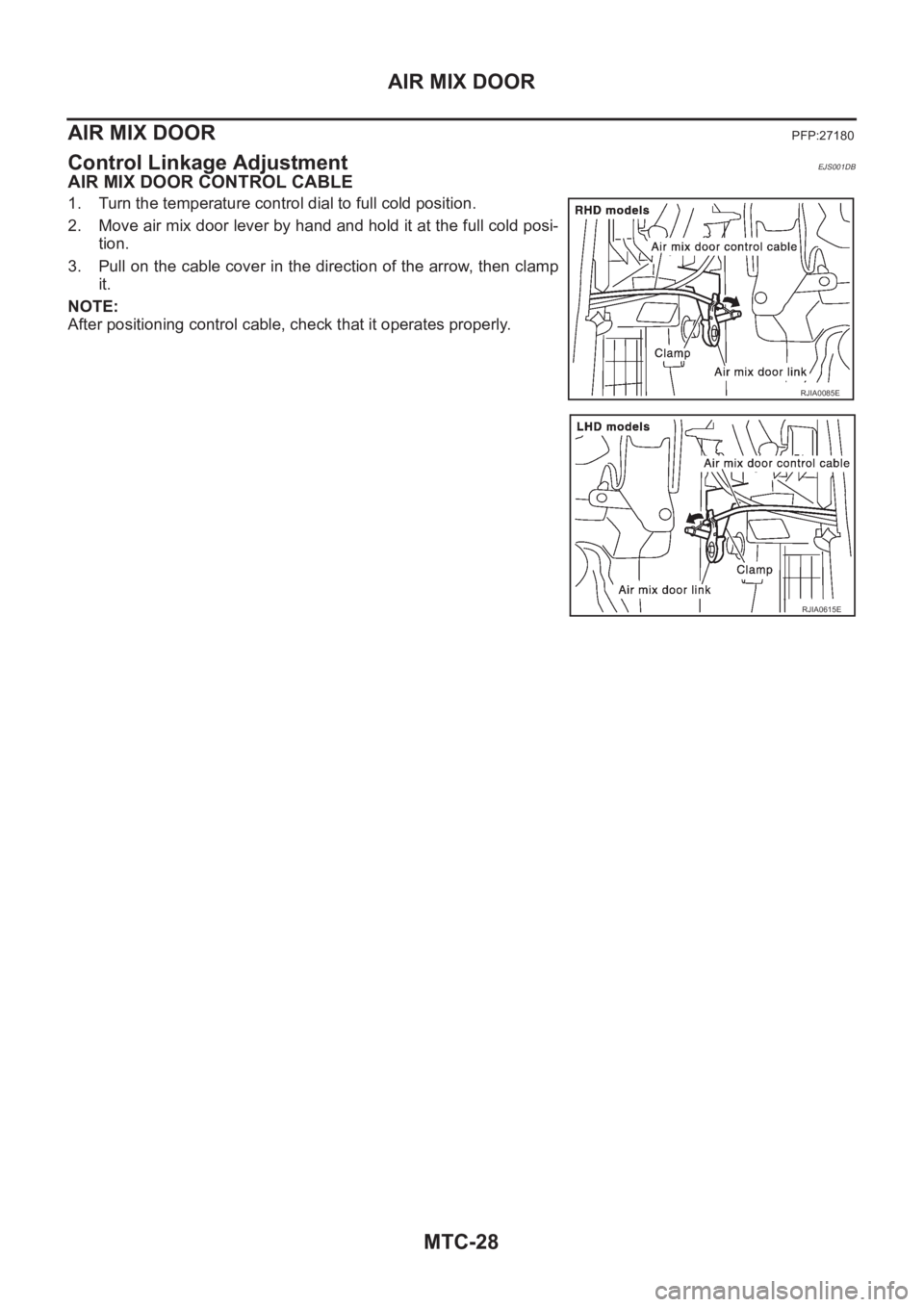

AIR MIX DOOR

PFP:27180

Control Linkage AdjustmentEJS001DB

AIR MIX DOOR CONTROL CABLE

1. Turn the temperature control dial to full cold position.

2. Move air mix door lever by hand and hold it at the full cold posi-

tion.

3. Pull on the cable cover in the direction of the arrow, then clamp

it.

NOTE:

After positioning control cable, check that it operates properly.

RJIA0085E

RJIA0615E

Page 3455 of 3833

DUCTS AND GRILLES

MTC-29

C

D

E

F

G

H

I

K

L

MA

B

MTC

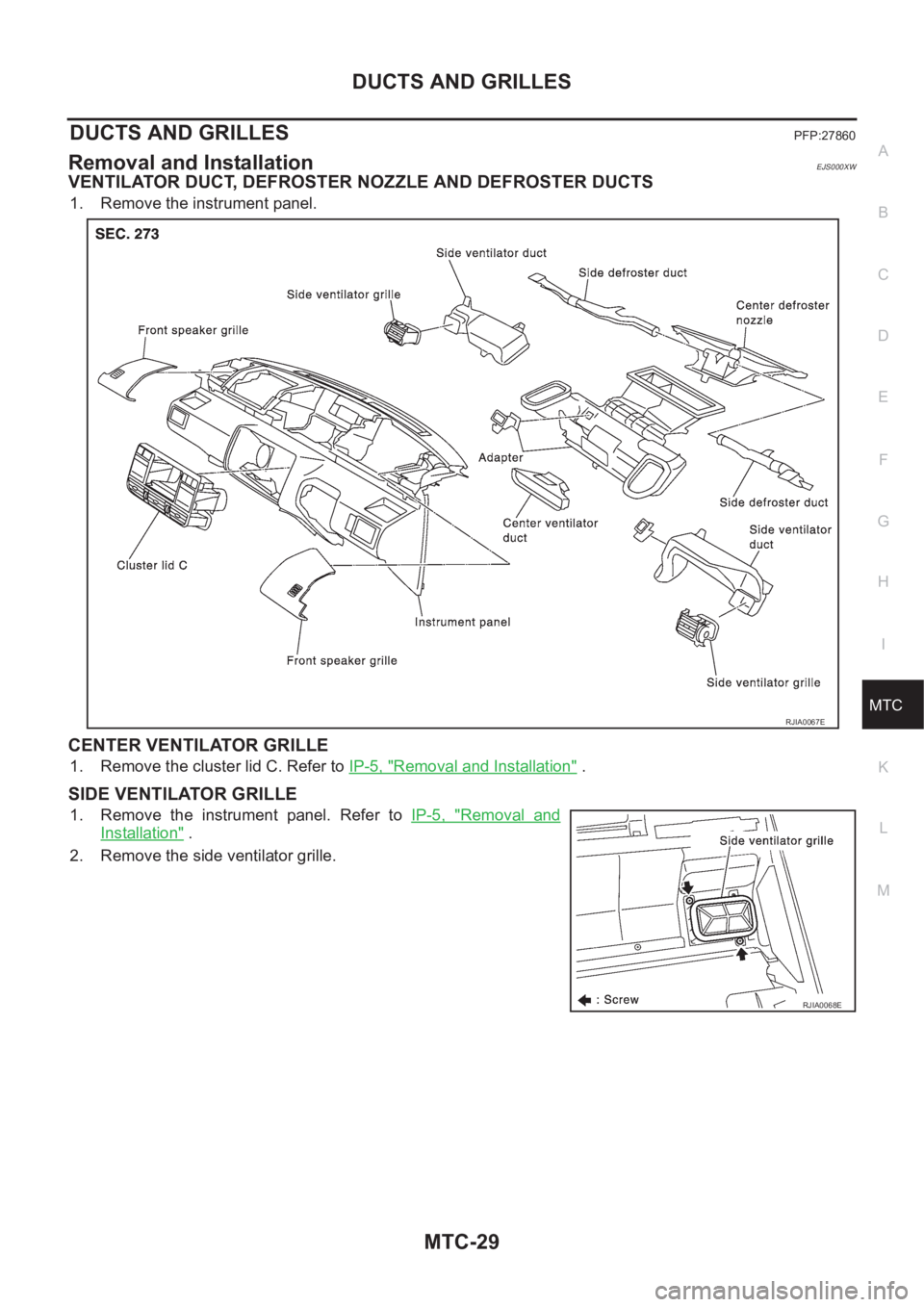

DUCTS AND GRILLESPFP:27860

Removal and InstallationEJS000XW

VENTILATOR DUCT, DEFROSTER NOZZLE AND DEFROSTER DUCTS

1. Remove the instrument panel.

CENTER VENTILATOR GRILLE

1. Remove the cluster lid C. Refer to IP-5, "Removal and Installation" .

SIDE VENTILATOR GRILLE

1. Remove the instrument panel. Refer to IP-5, "Removal and

Installation" .

2. Remove the side ventilator grille.

RJIA0067E

RJIA0068E

Page 3456 of 3833

MTC-30

DUCTS AND GRILLES

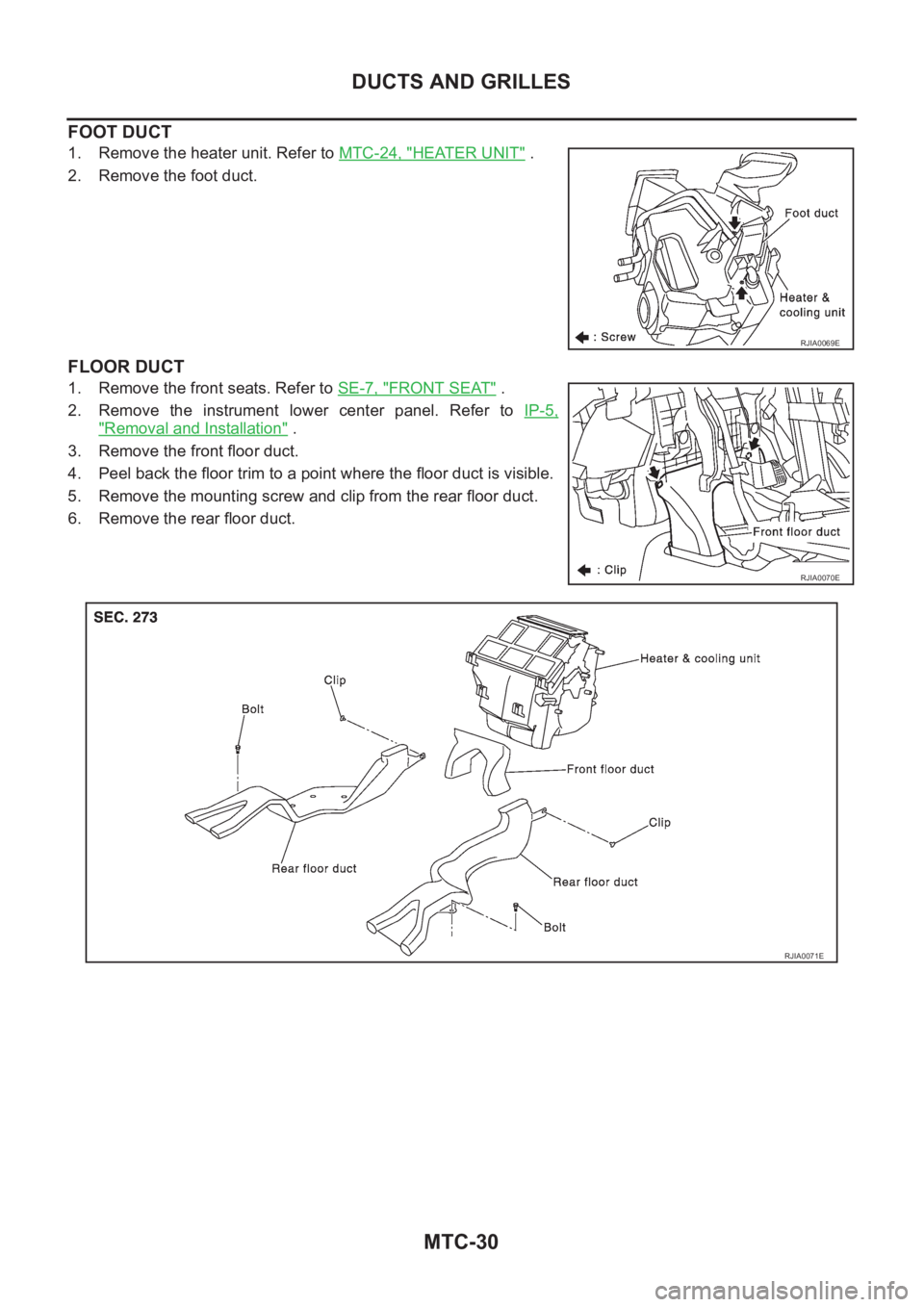

FOOT DUCT

1. Remove the heater unit. Refer to MTC-24, "HEATER UNIT" .

2. Remove the foot duct.

FLOOR DUCT

1. Remove the front seats. Refer to SE-7, "FRONT SEAT" .

2. Remove the instrument lower center panel. Refer to IP-5,

"Removal and Installation" .

3. Remove the front floor duct.

4. Peel back the floor trim to a point where the floor duct is visible.

5. Remove the mounting screw and clip from the rear floor duct.

6. Remove the rear floor duct.

RJIA0069E

RJIA0070E

RJIA0071E

Page 3457 of 3833

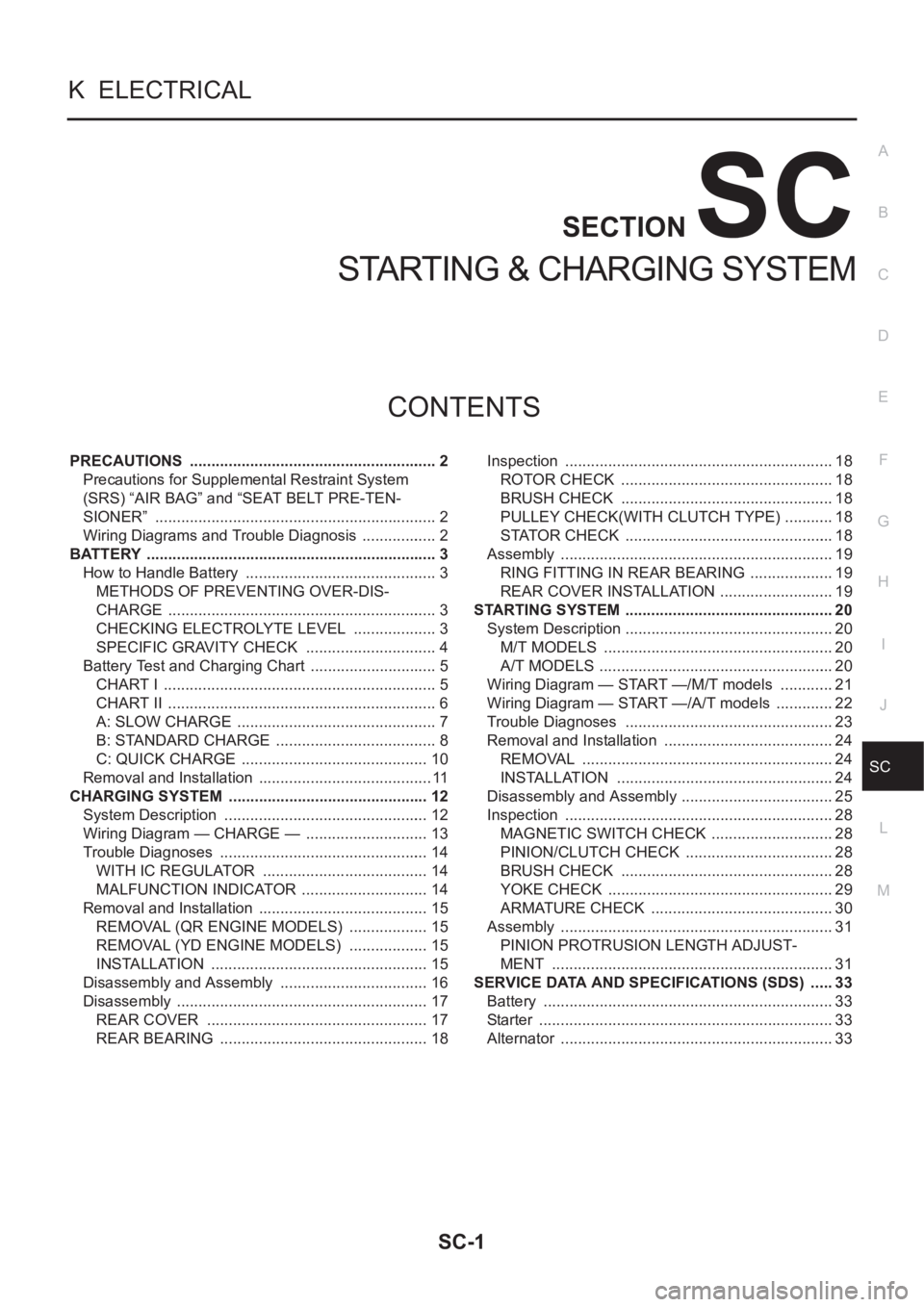

SC-1

STARTING & CHARGING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

SC

STARTING & CHARGING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Wiring Diagrams and Trouble Diagnosis .................. 2

BATTERY .................................................................... 3

How to Handle Battery ............................................. 3

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................................................... 3

CHECKING ELECTROLYTE LEVEL .................... 3

SPECIFIC GRAVITY CHECK ............................... 4

Battery Test and Charging Chart .............................. 5

CHART I ................................................................ 5

CHART II ............................................................... 6

A: SLOW CHARGE ............................................... 7

B: STANDARD CHARGE ...................................... 8

C: QUICK CHARGE ............................................ 10

Removal and Installation ......................................... 11

CHARGING SYSTEM ............................................... 12

System Description ................................................ 12

Wiring Diagram — CHARGE — ............................. 13

Trouble Diagnoses ................................................. 14

WITH IC REGULATOR ....................................... 14

MALFUNCTION INDICATOR .............................. 14

Removal and Installation ........................................ 15

REMOVAL (QR ENGINE MODELS) ................... 15

REMOVAL (YD ENGINE MODELS) ................... 15

INSTALLATION ................................................... 15

Disassembly and Assembly ................................... 16

Disassembly ........................................................... 17

REAR COVER .................................................... 17

REAR BEARING ................................................. 18Inspection ............................................................... 18

ROTOR CHECK .................................................. 18

BRUSH CHECK .................................................. 18

PULLEY CHECK(WITH CLUTCH TYPE) ............ 18

STATOR CHECK ................................................. 18

Assembly ................................................................ 19

RING FITTING IN REAR BEARING .................... 19

REAR COVER INSTALLATION ........................... 19

STARTING SYSTEM ................................................. 20

System Description ................................................. 20

M/T MODELS ...................................................... 20

A/T MODELS ....................................................... 20

Wiring Diagram — START —/M/T models ............. 21

Wiring Diagram — START —/A/T models .............. 22

Trouble Diagnoses ..............................................

... 23

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSTALLATION ................................................... 24

Disassembly and Assembly .................................... 25

Inspection ............................................................... 28

MAGNETIC SWITCH CHECK ............................. 28

PINION/CLUTCH CHECK ................................... 28

BRUSH CHECK .................................................. 28

YOKE CHECK ..................................................... 29

ARMATURE CHECK ........................................... 30

Assembly ................................................................ 31

PINION PROTRUSION LENGTH ADJUST-

MENT .................................................................. 31

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 33

Battery .................................................................... 33

Starter ..................................................................... 33

Alternator ................................................................ 33

Page 3458 of 3833

SC-2

PRECAUTIONS

PRECAUTIONS

PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS007AR

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

●To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

●Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

●Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness connec-

tors.

Wiring Diagrams and Trouble Diagnosis EKS00312

When you read wiring diagrams, refer to the followings:

●Refer to GI-13, "How to Read Wiring Diagrams" in GI section

●Refer to PG-2, "POWER SUPPLY ROUTING" for power distribution circuit in PG section

When you perform trouble diagnosis, refer to the followings:

●Refer to GI-10, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES" in GI section

●Refer to GI-23, "How to Perform Efficient Diagnosis for an Electrical Incident" in GI section

Page 3459 of 3833

BATTERY

SC-3

C

D

E

F

G

H

I

J

L

MA

B

SC

BATTERY PFP:00011

How to Handle Battery EKS00313

CAUTION:

●If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

●After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

●Never add distilled water through the hole used to check specific gravity.

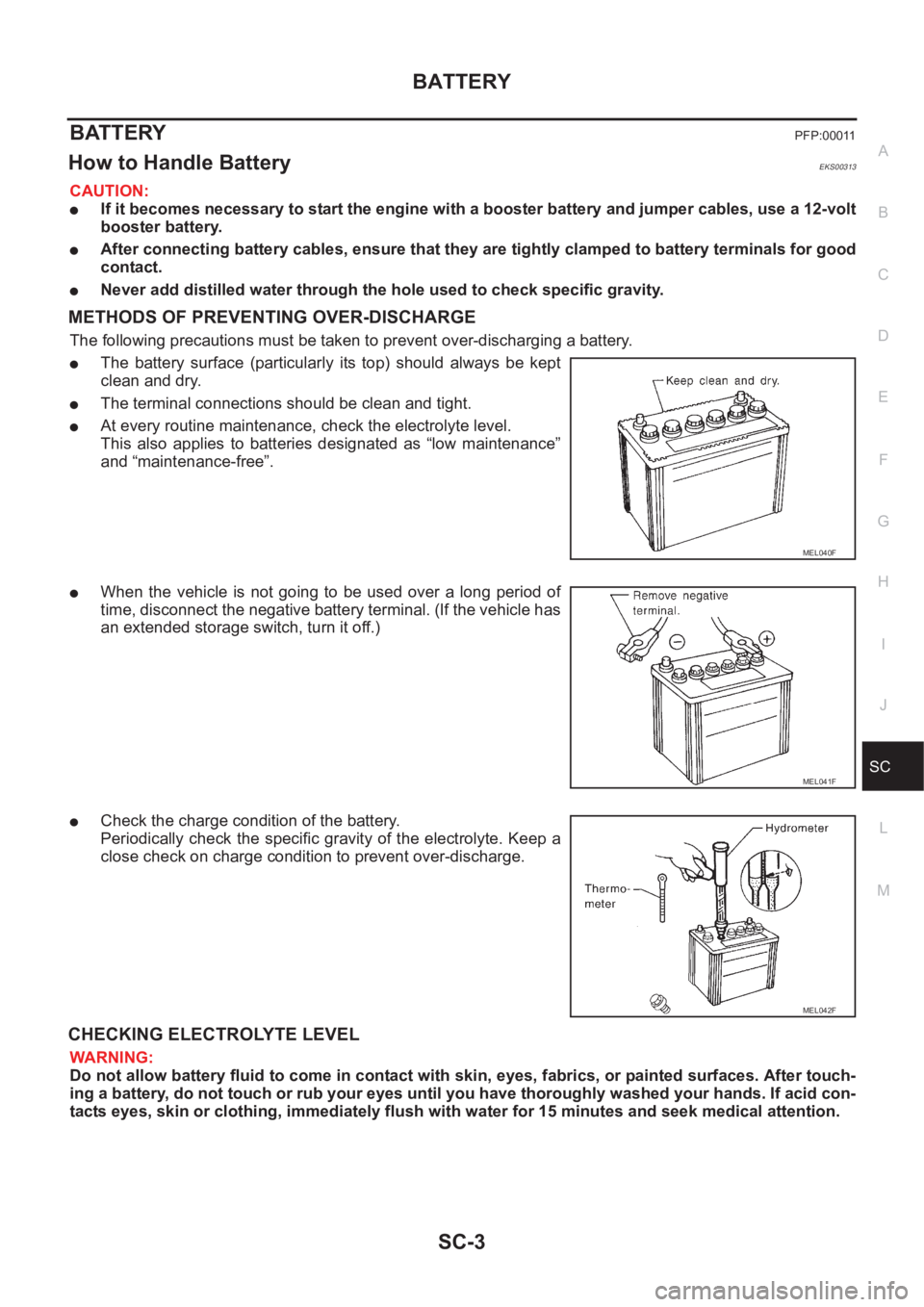

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

●The battery surface (particularly its top) should always be kept

clean and dry.

●The terminal connections should be clean and tight.

●At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

●When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle has

an extended storage switch, turn it off.)

●Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

Page 3460 of 3833

SC-4

BATTERY

●Remove the cell plug using a suitable tool.

●Add distilled water up to the MAX level.

Sulphation

A battery will be completely discharged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a battery has been “sulphated”, note its voltage

and current when charging it. As shown in the figure, less cur-

rent and higher voltage are observed in the initial stage of

charging sulphated batteries.

A sulphated battery may sometimes be brought back into ser-

vice by means of a long, slow charge, 12 hours or more, fol-

lowed by a battery capacity test.

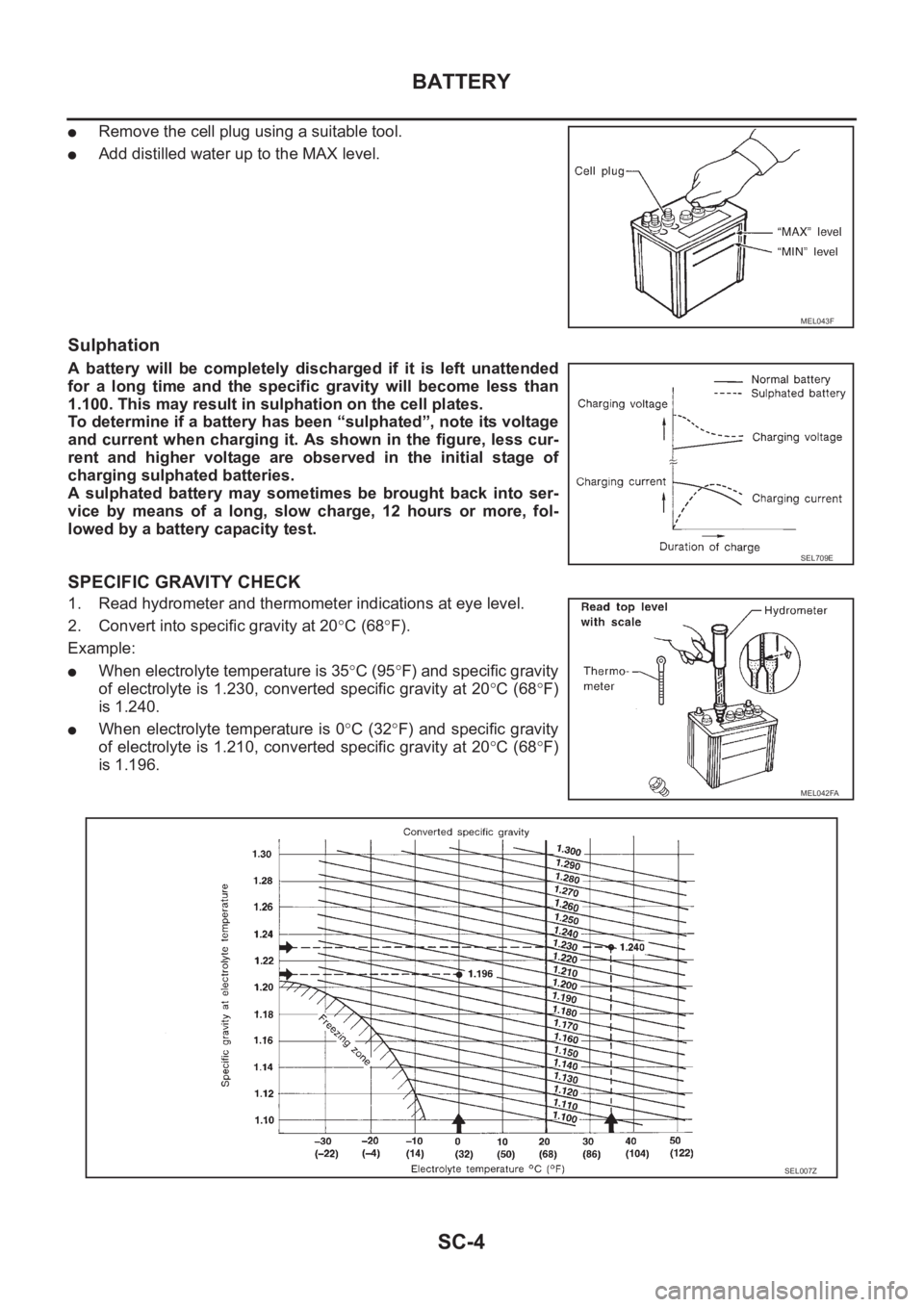

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermometer indications at eye level.

2. Convert into specific gravity at 20°C (68°F).

Example:

●When electrolyte temperature is 35°C (95°F) and specific gravity

of electrolyte is 1.230, converted specific gravity at 20°C (68°F)

is 1.240.

●When electrolyte temperature is 0°C (32°F) and specific gravity

of electrolyte is 1.210, converted specific gravity at 20°C (68°F)

is 1.196.

MEL043F

SEL709E

MEL042FA

SEL007Z