check engine NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1920 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-806

[YD]

EGR VOLUME CONTROL SYSTEM

Diagnostic Procedure

EBS0035R

1.CHECK EGR VOLUME CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch “OFF”.

2. Set the oscilloscope probe between ECM term NISSAN X-TRAIL 2003 Electronic Repair Manual EC-806

[YD]

EGR VOLUME CONTROL SYSTEM

Diagnostic Procedure

EBS0035R

1.CHECK EGR VOLUME CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch “OFF”.

2. Set the oscilloscope probe between ECM term](/img/5/57402/w960_57402-1919.png)

EC-806

[YD]

EGR VOLUME CONTROL SYSTEM

Diagnostic Procedure

EBS0035R

1.CHECK EGR VOLUME CONTROL SYSTEM OVERALL FUNCTION

1. Turn ignition switch “OFF”.

2. Set the oscilloscope probe between ECM terminals B3, B4, B5, B6 and ground.

3. Start engine and let it idle.

4. Check the oscilloscope screen when revving engine up to 3,200 rpm and return to idle.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK EGR VOLUME CONTROL VALVE POWER SUPPLY CIRCUIT-I

1. Turn ignition switch “OFF”.

2. Disconnect EGR volume control valve harness connector.

3. Turn ignition switch “ON”.

4. Check voltage between EGR volume control valve terminals 2, 5

and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 7.

NG >> GO TO 3.The pulse signal as shown in the figure should appear.

PBIB0430E

PBIB0380E

Voltage: Battery voltage

PBIB0431E

Page 1936 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-822

[YD]

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EBS003PV

1.CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check “PW/ST SIGNAL” in “DATA MONITOR” mode with CON-

NISSAN X-TRAIL 2003 Electronic Repair Manual EC-822

[YD]

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EBS003PV

1.CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check “PW/ST SIGNAL” in “DATA MONITOR” mode with CON-](/img/5/57402/w960_57402-1935.png)

EC-822

[YD]

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EBS003PV

1.CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check “PW/ST SIGNAL” in “DATA MONITOR” mode with CON-

SULT-II under the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK POWER STEERING OIL PRESSURE SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect power steering oil pressure switch harness connec-

tor.

3. Check harness continuity between power steering oil pressure

switch terminal 2 and engine ground. Refer to Wiring Diagram.

4. Also check harness for short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to power in harness or con-

nectors.

3.CHECK POWER STEERING OIL PRESSURE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal E12 and power steering oil pressure switch terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK POWER STEERING OIL PRESSURE SWITCH

Refer toEC-823, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> Replace power steering oil pressure switch.

Conditions PW/ST SIGNAL

Steering in neutral position OFF

Steering is turned ON

PBIB0434E

Continuity should exist.

PBIB0375E

Continuity should exist.

Page 1937 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual POWER STEERING OIL PRESSURE SWITCH

EC-823

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component Inspec NISSAN X-TRAIL 2003 Electronic Repair Manual POWER STEERING OIL PRESSURE SWITCH

EC-823

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component Inspec](/img/5/57402/w960_57402-1936.png)

POWER STEERING OIL PRESSURE SWITCH

EC-823

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK INTERMITTENT INCIDENT

Refer toEC-699, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Component InspectionEBS003PW

POWER STEERING OIL PRESSURE SWITCH

1. Disconnect power steering oil pressure switch harness connector and then start engine.

2. Check continuity between power steering oil pressure switch ter-

minal 1 and 2 under the following conditions.

Removal and InstallationEBS008ZH

POWER STEERING OIL PRESSURE SWITCH

Refer toPS-33, "HYDRAULIC LINE".

Conditions Continuity

Steering wheel is being fully turned. Yes

Steering wheel is not being turned. No

PBIB0435E

Page 1971 of 3066

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EM

ENGINE MECHANICAL

QR20DE

PRECAUTIONS .......................................................... 5

Precautions for Drain Coolant .................................. 5

Precautions for Disconnecting Fuel Piping .............. 5

Precautions for Removal and Disassembly ............. 5

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 5

Precautions for Assembly and Installation ............... 5

Parts Requiring Angular Tightening ......................... 5

Precautions for Liquid Gasket .................................. 6

REMOVAL OF LIQUID GASKET SEALING .......... 6

LIQUID GASKET APPLICATION PROCEDURE..... 6

PREPARATION ........................................................... 7

Special Service Tools ............................................... 7

Commercial Service Tools ........................................ 8

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ...............................................11

NVH Troubleshooting —Engine Noise ....................11

Use the Chart Below to Help You Find the Cause

of the Symptom. ..................................................... 12

DRIVE BELTS ........................................................... 13

Checking Drive Belts .............................................. 13

Tension Adjustment ................................................ 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

Removal and Installation of Auxiliary Drive Belt

Auto- tensioner ....................................................... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

AIR CLEANER AND AIR DUCT ............................... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

CHANGING AIR CLEANER ELEMENT .............. 16INTAKE MANIFOLD ................................................. 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 20

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST .......................................................................... 22

Removal and Installation ........................................ 22

REMOVAL ........................................................... 22

INSPECTION AFTER REMOVAL ....................... 23

INSTALLATION ................................................... 23

OIL PAN AND OIL STRAINER ................................. 24

Removal and Installation ........................................ 24

REMOVAL ........................................................... 24

INSPECTION AFTER REMOVAL ....................... 25

INSTALLATION ................................................... 25

INSPECTION AFTER INSTALLATION ................ 26

IGNITION COIL ......................................................... 27

Removal and Installation ........................................ 27

REMOVAL ........................................................... 27

INSTALLATION ................................................... 27

SPARK PLUG ........................................................... 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 28

INSPECTION AFTER REMOVAL ....................... 28

INSTALLATION ................................................... 28

FUEL INJECTOR AND FUEL TUBE ........................ 29

Removal and Installation ........................................ 29

REMOVAL ........................................................... 29

INSTALLATION ................................................... 30

INSPECTION AFTER INSTALLATION ................ 30

ROCKER COVER ..................................................... 31

Removal and Installation ........................................ 31

REMOVAL ........................................................... 31

INSTALLATION ................................................... 31

CAMSHAFT .............................................................. 33

Removal and Installation ........................................ 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 35

Page 1972 of 3066

EM-2

INSPECTION AFTER REMOVAL ........................ 38

Valve Clearance ...................................................... 40

INSPECTION ....................................................... 40

ADJUSTMENT .................................................... 41

TIMING CHAIN .......................................................... 43

Removal and Installation ........................................ 43

REMOVAL ........................................................... 44

INSPECTION AFTER REMOVAL ........................ 47

INSTALLATION .................................................... 48

CYLINDER HEAD ..................................................... 52

On-Vehicle Service ................................................. 52

CHECKING COMPRESSION PRESSURE ......... 52

Removal and Installation ........................................ 53

REMOVAL ........................................................... 53

INSPECTION AFTER REMOVAL ........................ 54

INSTALLATION .................................................... 54

Disassembly and Assembly .................................... 55

DISASSEMBLY ................................................... 55

ASSEMBLY ......................................................... 56

Inspection After Disassembly ................................. 56

CYLINDER HEAD DISTORTION ........................ 56

VALVE DIMENSIONS .......................................... 57

VALVE GUIDE CLEARANCE .............................. 57

VALVE GUIDE REPLACEMENT ......................... 57

VALVE SEAT CONTACT ..................................... 58

VALVE SEAT REPLACEMENT ........................... 58

VALVE SPRING SQUARENESS ......................... 60

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD ............................... 60

ENGINE ASSEMBLY ................................................ 61

Removal and Installation ........................................ 61

REMOVAL ........................................................... 61

INSTALLATION .................................................... 63

INSPECTION AFTER INSTALLATION ................ 63

CYLINDER BLOCK ................................................... 64

Disassembly and Assembly .................................... 64

DISASSEMBLY ................................................... 65

ASSEMBLY ......................................................... 69

How to Select Piston and Bearing .......................... 73

DESCRIPTION .................................................... 73

HOW TO SELECT PISTON ................................. 74

HOW TO SELECT CONNCTING ROD BEARING... 74

HOW TO SELECT MAIN BEARING .................... 77

Inspection After Disassembly ................................. 80

CRANKSHAFT SIDE CLEARANCE .................... 80

CONNECTING ROD SIDE CLEARANCE ........... 81

PISTON AND PISTON PIN CLEARANCE .......... 81

PISTON RING SIDE CLEARANCE ..................... 82

PISTON RING END GAP .................................... 82

CONNECTING ROD BEND AND TORSION ....... 82

CONNECTING ROD BEARING (BIG END) ........ 83

CONNECTING ROD BUSHING OIL CLEAR-

ANCE (SMALL END) ........................................... 83

CYLINDER BLOCK DISTORTION ...................... 84

INNER DIAMETER OF MAIN BEARING HOUS-

ING ...................................................................... 85

PISTON TO CYLINDER BORE CLEARANCE .... 85

OUTER DIAMETER OF CRANKSHAFT JOUR-NAL ......................................................................86

OUTER DIAMETER OF CRANKSHAFT PIN ......86

OUT-OF-ROUND AND TAPER OF CRANK-

SHAFT .................................................................87

CRANKSHAFT RUNOUT ....................................87

OIL CLEARANCE OF CONNECTING ROD

BEARING .............................................................87

OIL CLEARANCE OF MAIN BEARING ...............88

CRUSH HEIGH OF MAIN BEARING ...................88

OUTER DIAMETER OF LOWER CYLINDER

BLOCK MOUNTING BOLT ..................................88

OUTER DIAMETER OF CONNECTING ROD

BOLT ....................................................................89

MOVEMENT AMOUNT OF FLYWHEEL (M/T

MODELS) .............................................................89

SERVICE DATA AND SPECIFICATIONS (SDS) ......90

Standard and Limit ..................................................90

GENERAL SPECIFICATIONS .............................90

INTAKE MANIFOLD AND EXHAUST MANI-

FOLD ...................................................................90

DRIVE BELTS ......................................................90

CYLINDER HEAD ................................................91

VALVE ..................................................................91

CAMSHAFT AND CAMSHAFT BEARING ...........94

CYLINDER BLOCK ..............................................94

PISTON, PISTON RING AND PISTON PIN ........95

CONNECTING ROD ............................................96

CRANKSHAFT .....................................................97

MAIN BEARING ...................................................98

CONNECTING ROD BEARING ...........................99

Tightening Torque ................................................. 100

YD22DDTi

PRECAUTIONS ....................................................... 102

Precautions for Drain Coolant ............................... 102

Precautions for Disconnecting Fuel Piping ........... 102

Precautions for Removal and Disassembly .......... 102

Precautions for Inspection, Repair and Replace-

ment ...................................................................... 102

Precautions for Assembly and Installation ............ 102

Parts Requiring Angular Tightening ...................... 102

Precautions for Liquid Gasket ............................... 103

REMOVAL OF LIQUID GASKET SEALING ...... 103

LIQUID GASKET APPLICATION PROCEDURE. 103

PREPARATION ....................................................... 104

Special Service Tools ............................................ 104

Commercial Service Tools .................................... 106

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................ 108

NVH Troubleshooting —Engine Noise .................. 108

Use the Chart Below to Help You Find the Cause

of the Symptom. .................................................... 109

DRIVE BELTS ..........................................................110

Checking Drive Belts .............................................110

Tension Adjustment ...............................................110

AIR CONDITIONER COMPRESSOR BELT ...... 111

Page 1973 of 3066

EM-3

C

D

E

F

G

H

I

J

K

L

M

EMA ALTERNATOR AND WATER PUMP BELT ....... . 111

Removal and Installation ...................................... . 111

REMOVAL ......................................................... . 111

INSTALLATION ................................................. . 111

AIR CLEANER AND AIR DUCT .............................. 112

Removal and Installation ....................................... 112

REMOVAL .......................................................... 112

INSTALLATION .................................................. 112

CHANGING AIR CLEANER ELEMENT ............. 112

CHARGE AIR COOLER .......................................... 114

Removal and Installation ....................................... 114

REMOVAL .......................................................... 114

INSPECTION AFTER REMOVAL ...................... 114

INSTALLATION .................................................. 114

INTAKE MANIFOLD ................................................ 115

Removal and Installation ....................................... 115

REMOVAL .......................................................... 115

INSPECTION AFTER REMOVAL ...................... 116

INSTALLATION .................................................. 116

INSPECTION AFTER INSTALLATION .............. 117

CATALYST ............................................................... 118

Removal and Installation ....................................... 118

REMOVAL .......................................................... 118

INSTALLATION .................................................. 118

EXHAUST MANIFOLD AND TURBOCHARGER ... 119

Removal and Installation ....................................... 119

REMOVAL .......................................................... 119

INSTALLATION ................................................. 120

INSPECTION AFTER INSTALLATION ............. 120

Disassembly and Assembly ................................. 121

REMOVAL ......................................................... 121

INSPECTION AFTER REMOVAL ..................... 121

Turbocharger ........................................................ 122

ROTOR SHAFT CLEARANCE ......................... 122

ROTOR SHAFT END PLAY .............................. 122

TURBINE WHEEL ............................................. 123

COMPRESSOR WHEEL .................................. 123

WASTEGATE VALVE ACTUATOR ................... 123

TROUBLE DIAGNOSIS OF TURBOCHARGER. 123

OIL PAN AND OIL STRAINER ............................... 125

Removal and Installation ...................................... 125

REMOVAL ......................................................... 125

INSPECTION AFTER REMOVAL ..................... 127

INSTALLATION ................................................. 127

INSPECTION AFTER INSTALLATION ............. 129

GLOW PLUG .......................................................... 130

Removal and Installation ...................................... 130

REMOVAL ......................................................... 130

INSTALLATION ................................................. 130

VACUUM PUMP ..................................................... 131

Removal and Installation ...................................... 131

INSPECTION BEFORE REMOVAL .................. 131

REMOVAL ......................................................... 131

INSTALLATION ................................................. 132

INSPECTION AFTER INSTALLATION ............. 132

Disassembly and Assembly ................................. 133

DISASSEMBLY ................................................. 133

ASSEMBLY ....................................................... 133INJECTION TUBE AND FUEL INJECTOR ............135

Removal and Installation ......................................135

REMOVAL .........................................................135

INSTALLATION .................................................136

INSPECTION AFTER INSTALLATION ..............137

FUEL SUPPLY PUMP .............................................138

Removal and Installation ......................................138

REMOVAL .........................................................138

INSPECTION AFTER REMOVAL .....................143

INSTALLATION .................................................143

ROCKER COVER ...................................................147

Removal and Installation ......................................147

REMOVAL .........................................................147

INSTALLATION .................................................148

INSPECTION AFTER INSTALLATION ..............148

CAMSHAFT ............................................................149

Removal and Installation ......................................149

REMOVAL .........................................................149

INSPECTION AFTER REMOVAL .....................150

INSTALLATION .................................................153

Valve Clearance ...................................................154

INSPECTION ....................................................154

ADJUSTMENTS ................................................155

SECONDARY TIMING CHAIN ................................158

Removal and Installation ......................................158

REMOVAL .........................................................158

INSPECTION AFTER REMOVAL .....................160

INSTALLATION .................................................161

PRIMARY TIMING CHAIN ......................................163

Removal and Installation ......................................163

REMOVAL .........................................................165

INSPECTION AFTER REMOVAL .....................168

INSTALLATION .................................................168

CYLINDER HEAD ...................................................173

On-Vehicle Service ...............................................173

CHECKING COMPRESSION PRESSURE .......173

Removal and Installation ......................................174

REMOVAL .........................................................174

INSPECTION AFTER REMOVAL .....................175

INSTALLATION .................................................175

Disassembly and Assembly ..................................178

DISASSEMBLY .................................................178

ASEMBLY ..........................................................179

INSPECTION AFTER DISASSEMBLY ..............179

ENGINE ASSEMBLY ..............................................184

Removal and Installation ......................................184

REMOVAL .........................................................184

INSTALLATION .................................................186

INSPECTION AFTER INSTALLATION ..............186

CYLINDER BLOCK ................................................188

Disassembly and Assembly ..................................188

DISASSEMBLY .................................................189

ASSEMBLY .......................................................193

How to Select Piston and Bearing ........................197

DESCRIPTION ..................................................197

HOW TO SELECT PISTON ..............................197

HOW TO SELECT CONNECTING ROD BEAR-

ING ....................................................................198

Page 1975 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

EM-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR20DE]PRECAUTIONSPFP:00001

Precautions for Drain CoolantEBS009QD

lDrain coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEB NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

EM-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR20DE]PRECAUTIONSPFP:00001

Precautions for Drain CoolantEBS009QD

lDrain coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEB](/img/5/57402/w960_57402-1974.png)

PRECAUTIONS

EM-5

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

[QR20DE]PRECAUTIONSPFP:00001

Precautions for Drain CoolantEBS009QD

lDrain coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS009QE

lBefore starting work, make sure no fire or spark producing items are in the work area.

lRelease fuel pressure before disassembly.

lAfter disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS009QF

lWhen instructed to use special service tools, use the specified tools. Always be careful to work safely,

avoid forceful or uninstructed operations.

lExercise maximum care to avoid damage to mating or sliding surfaces.

lCover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

lMark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

lWhen loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS009QG

lBefore repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way,

and replace if necessary.

Precautions for Assembly and InstallationEBS009QH

lUse torque wrench to tighten bolts or nuts.

lWhen tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

lReplace with new gasket, packing, oil seal or O-ring.

lThoroughly wash, clean, and air-blow each part. Carefully check oil or coolant passages for any restriction

and blockage.

lAvoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

lRelease air within route after draining coolant.

lAfter repairing, start engine and increase engine speed to check coolant, fuel, oil, and exhaust systems

for leakage.

Parts Requiring Angular TighteningEBS009QI

lUse an angle wrench for the final tightening of the following engine parts.

–Cylinder head bolts

–Lower cylinder block bolts

–Connecting rod cap bolts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angular

tightening)

lDo not use a torque value for final tightening.

lThe torque value for these parts are for a preliminary step.

lEnsure thread and seat surfaces are clean and coated with engine oil.

Page 1982 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-12

[QR20DE]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS009QN

1. Locate the area where noise occurs.

2. Confirm the type NISSAN X-TRAIL 2003 Electronic Repair Manual EM-12

[QR20DE]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS009QN

1. Locate the area where noise occurs.

2. Confirm the type](/img/5/57402/w960_57402-1981.png)

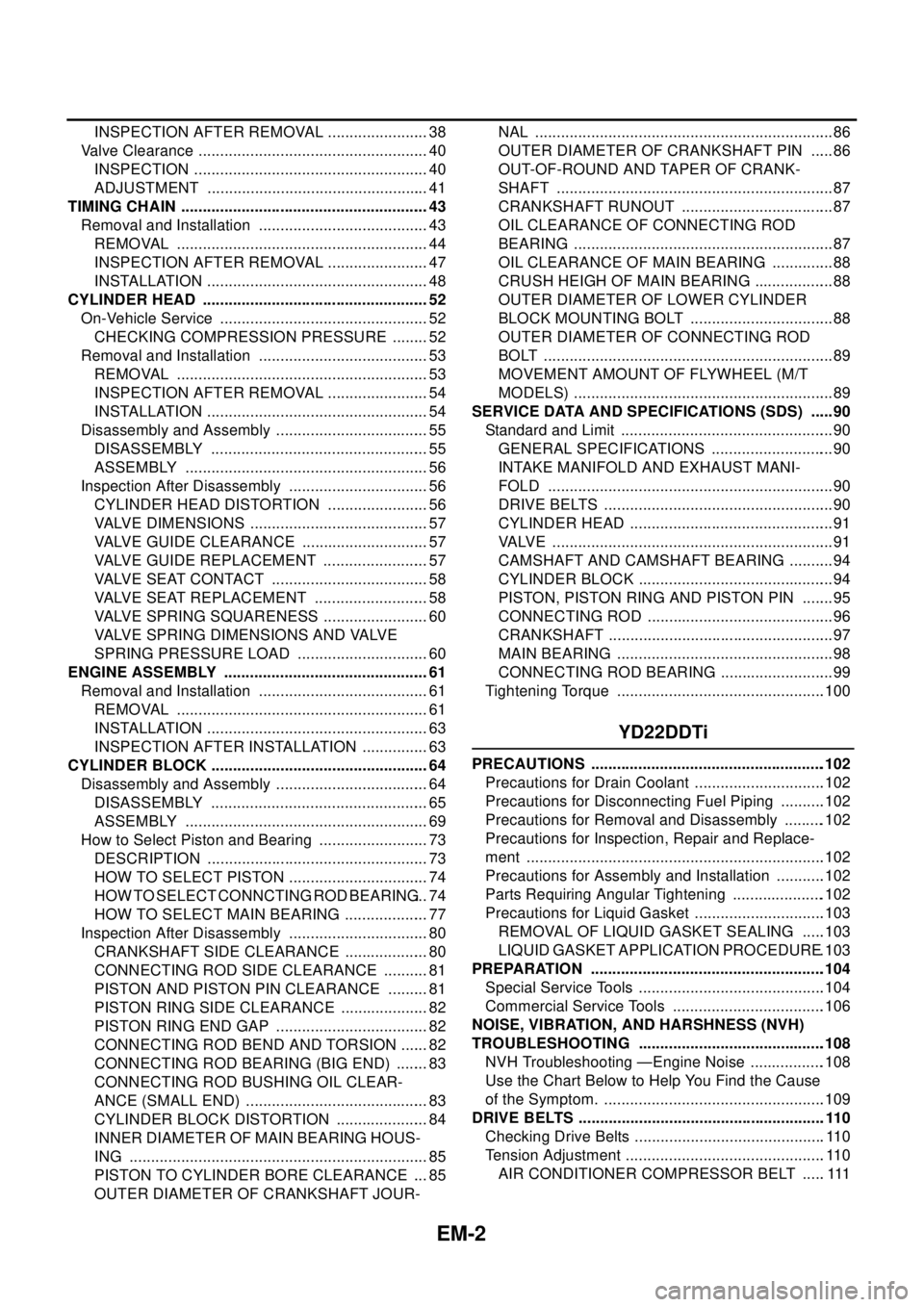

EM-12

[QR20DE]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom.

EBS009QN

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemRefer-

ence page Before

warm-

upAfter

warm-

upWhen

start-

ingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTick ing or

clickingCA—AB—Tappet

noiseValve clearanceEM-40

Rattle C A — A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-38EM-38

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock—A—BB—Piston pin

noisePiston and piston pin

clearance

Connecting rod bush-

ing clearanceEM-83

EM-83

Slap or

rapA ——BBAPiston

slap noisePiston-to-bore clear-

ance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-82EM-82

EM-82

EM-82

Knock A B CBBBConnect-

ing rod

bearing

noiseConnecting rod bush-

ing clearance (Small

end)

Connecting rod bear-

ing clearance (Big end)EM-83EM-83

Knock A B — A B CMain

bearing

noiseMain bearing oil clear-

ance

Crankshaft runoutEM-88EM-87

Front of

engine

Timin g

chain

coverTa p p i n g o r

tickingA A —BBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-47

EM-43

Front of

engineSqueak-

ing or fizz-

ingAB—B—CDrive belts

(Sticking

or slip-

ping)Drive belts deflection

EM-13

CreakingA B ABABDrive belts

(Slipping)Idler pulley bearing

operation

Squall

CreakA B —BABWater

pump

noiseWater pump operationCO-19,

"WATER

PUMP"

Page 1983 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DRIVE BELTS

EM-13

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS009QO

WA RN ING:

Be sure to perform when the engine is stopped.

lMake sure that the stamp mark of auxil NISSAN X-TRAIL 2003 Electronic Repair Manual DRIVE BELTS

EM-13

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS009QO

WA RN ING:

Be sure to perform when the engine is stopped.

lMake sure that the stamp mark of auxil](/img/5/57402/w960_57402-1982.png)

DRIVE BELTS

EM-13

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

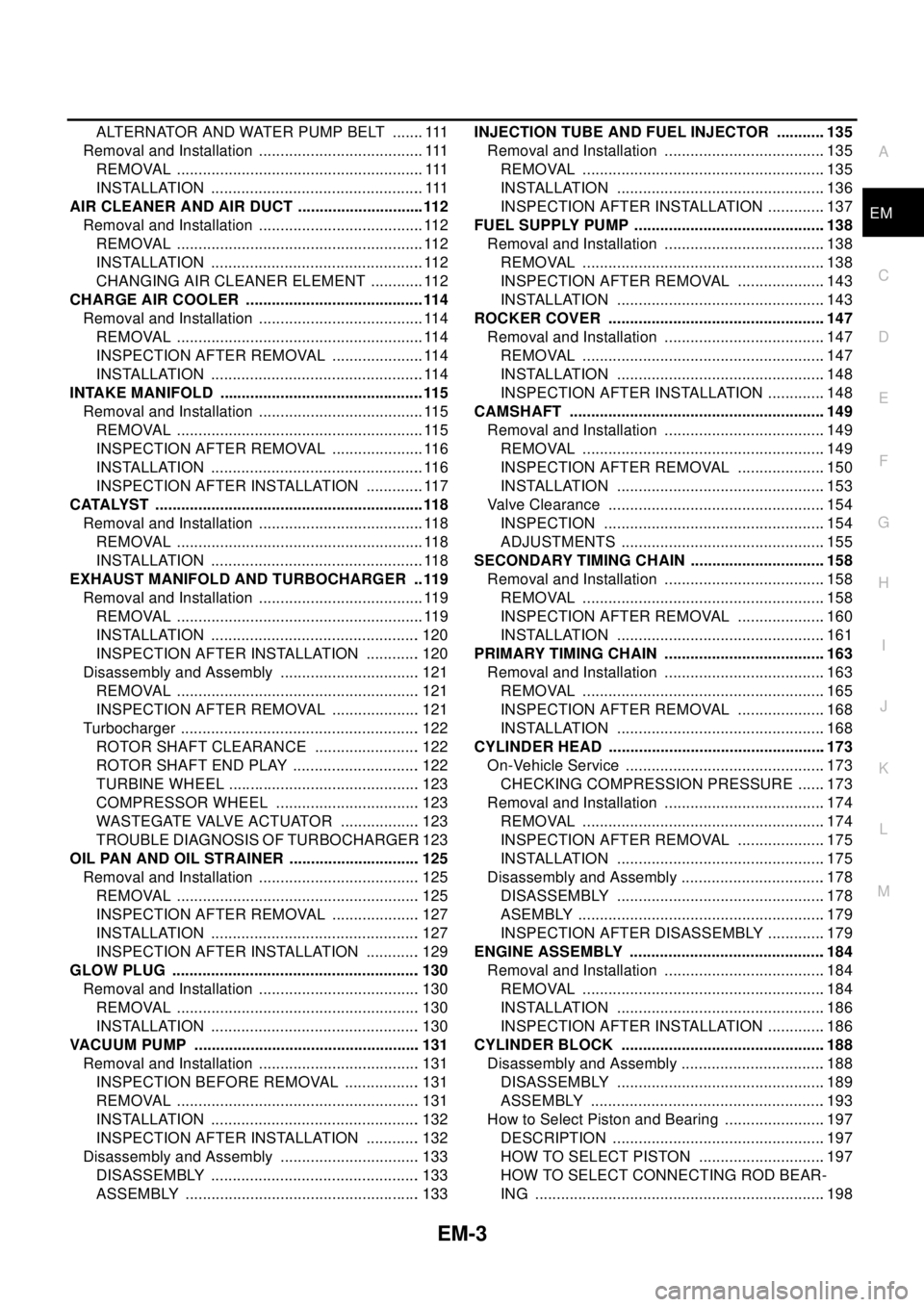

DRIVE BELTSPFP:02117

Checking Drive BeltsEBS009QO

WA RN ING:

Be sure to perform when the engine is stopped.

lMake sure that the stamp mark of auxiliary drive belt auto-tensioner is within the usable range.

NOTE:

lCheck the automatic tensioner indication when the engine is cold.

lWhen the new drive belt is installed, the range should be A.

lVisually check entire belt for wear, damage or cracks.

lIf the indicator is out of allowable use range or belt is damaged, replace the belt.

Tension AdjustmentEBS009QP

lBelt tensioning is not necessary, as it is automatically adjusted by auto-tensioner.

Removal and InstallationEBS009QQ

REMOVAL

1. Remove front RH engine side cover.

2. With box wrench, and while securely holding the hexagonal part

in pulley center of automatic tensioner, move the wrench handle

in the direction of arrow (loosening direction of tensioner).

CAUTION:

Avoid placing hand in a location where pinching may occur

if the holding tool accidentally comes off.

3. Insert a rod approximately 6mm (0.24in) in diameter through the

rear of engine into holding boss to fix tensioner pulley.

lLeave tensioner pulley arm locked until belt is installed again.

4. Loosen auxiliary drive belt from water pump pulley in sequence,

and remove it.

INSTALLATION

1. With box wrench, and while securely holding the hexagonal part in pulley center of automatic tensioner,

move the wrench handle in the direction of arrow [loosening direction of tensioner].

CAUTION:

Avoid placing hand in a location where pinching may occur if the holding tool accidentally comes off.

PBIC0256E

KBIA0088E

Page 1984 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys e NISSAN X-TRAIL 2003 Electronic Repair Manual EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys e](/img/5/57402/w960_57402-1983.png)

EM-14

[QR20DE]

DRIVE BELTS

2. Insert a rod approximately 6 mm (0.24in) in diameter through the rear of engine into holding boss to fix

tensioner pulley.

3. Hook auxiliary drive belt onto all pulleys except for water pump. Hook belt onto water pump pulley at the

end.

CAUTION:

Confirm belts are completely set to pulleys.

4. Release tensioner, and apply tensions to belt.

5. Turn crankshaft pulley clockwise several times to equalize tension between each pulley.

6. Confirm tensions of belt at indicator is within the allowable use range. Refer toEM-13, "

Checking Drive

Belts".

Removal and Installation of Auxiliary Drive Belt Auto- tensionerEBS009QR

REMOVAL

1. Remove front RH engine side cover.

2. Remove auxiliary drive belt.

lKeep tensioner pulley fixed with a tool such as a short-length screwdriver.

3. Remove alternator and then auxiliary drive belt auto-tensioner.

lRemove and install auxiliary drive belt auto-tensioner by fixing tension pulley.

INSTALLATION

lInstall in the reverse order of removal.

CAUTION:

Install auxiliary drive belt auto-tensioner carefully not to damage the water pump pulley.

KBIA0092E