PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1201 of 1825

REPAIR PRQCEDURES

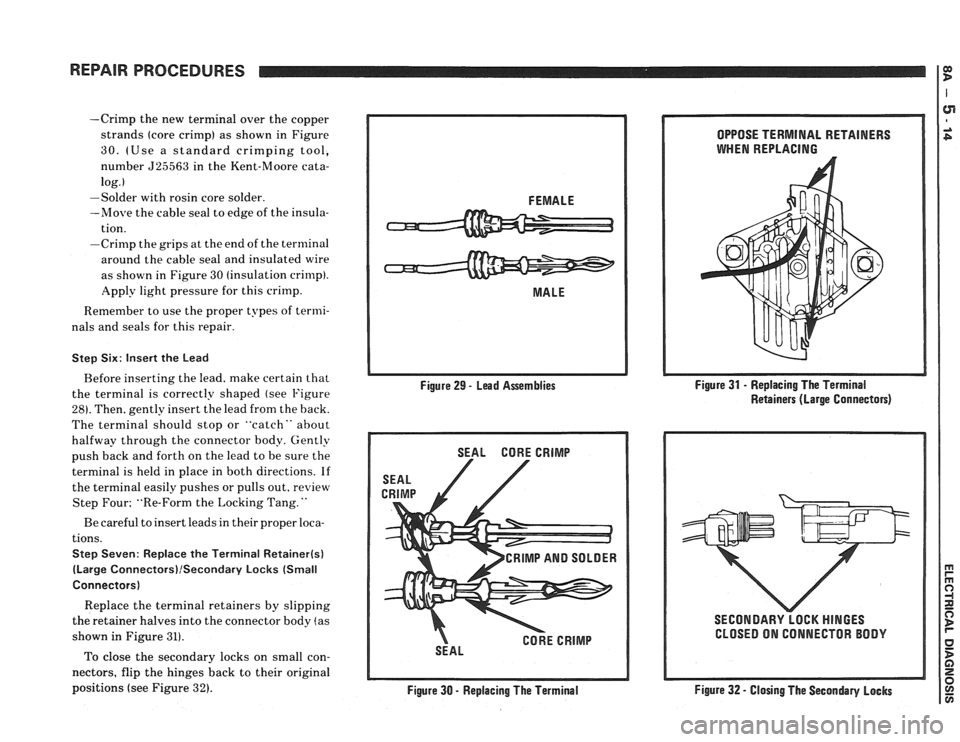

-Crimp the new terminal over the copper

strands (core crimp) as shown in Figure

30. (Use a standard crimping tool,

number

525563 in the Kent-Moore cata-

log.

I

-Solder with rosin core solder.

-Move the cable seal to edge of the insula-

tion.

-Crimp the grips at the end of the terminal

around the cable seal and insulated

wire

as shown in Figure 30 (insulation crimp).

Apply light pressure for this crimp.

Remember to use the proper types of termi-

nals and seals for this repair.

Step Six: Insert the Lead

Before inserting the lead. make certain that

the terminal is correctly shaped (see Figure

281. Then. gently insert the lead from the back.

The terminal should stop or "catch" about

halfway through the connector body. Gently

push back and forth on the lead to be sure the

terminal is held in place in both directions.

If

the terminal easily pushes or pulls out, review

Step Four; "Re-Form the Locking Tang.

"

Be careful to insert leads in their proper loca-

tions.

Step Seven: Replace the Terminal Retainer(s)

(Large Connectors)lSecondary Locks (Small

Connectors)

Replace the terminal retainers by slipping

the retainer halves into the connector body

!as

shown in Figure 31).

To close the secondary locks on small con-

nectors, flip the hinges back to their original

positions (see Figure

32).

I

FEMALE

MALE

Figure 29

- Lead Assemblies

SEAL CORE CRIMP

CRIMP AND SOLDER

CORE CRIMP

SEAL

Figure

30 - Replacing The Terminal OPPOSE

TERMINAL RETAINERS

WHEN REPLACING

Figure 31

- Replacing The Terminal

Retainers (Large Connectors)

SECONDARY LOCK

HINGES

CLOSED ON CONNECTOR BODY

Figure 32 - Closing The Secondary Locks

Page 1202 of 1825

REPAIR PROCEDURES m I L

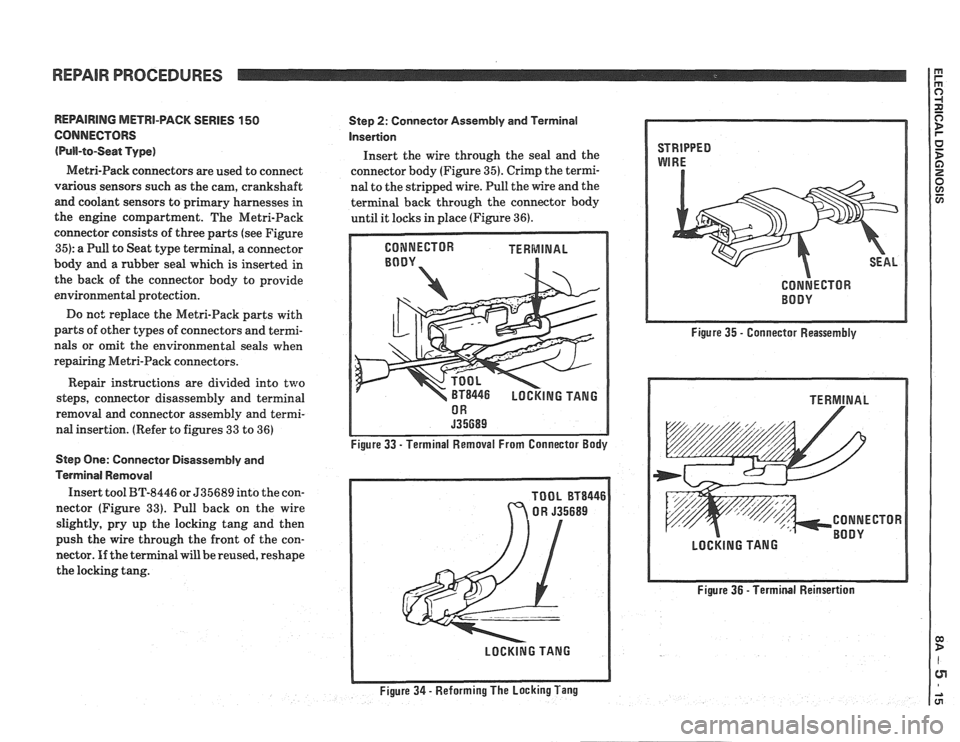

REPAlRlNG METRI-PACK SERIES 150

CONNECTORS

(Pull-to-Seat Type)

Metri-Pack connectors are used to connect

various sensors such as the cam, crankshaft

and coolant sensors to primary harnesses in

the engine compartment. The Metri-Pack

connector consists of three parts (see Figure

35): a Pull to Seat type terminal, a connector

body and

a rubber seal which is inserted in

the back of the connector body to provide

environmental protection.

Do

nc: replace the Metri-Pack parts with

parts of other types of connectors and termi-

nals or omit the environmental seals when

repairing Metri-Pack connectors.

Repair instructions are divided into

two

steps, connector disassembly and terminal

removal and connector assembly and termi-

nal insertion. (Refer to figures

33 to 36)

Step One: Connector Disassembly and

Terminal Removal

Insert tool BT-8446 or 535689 into the con-

nector (Figure

33). Pull back on the wire

slightly, pry up the locking tang and then

push the wire through the front of the con-

nector. If the terminal will be reused, reshape

the locking tang.

Step 2: Connector Assembly and Terminal

Insertion

Insert the wire through the seal and the

connector body (Figure

35). Crimp the termi-

nal to the stripped wire. Pull the wire and the

terminal back through the connector body

until it locks in place (Figure

36).

NECTOR TERMINAL

BT8446 LOCKING TANG

Figure 33

- Terminal Removal From Connector Body

TOOL

BT8446

Figure 35 - Connector Reassembly

Figure 36

- Terminal Reinsertion

Page 1203 of 1825

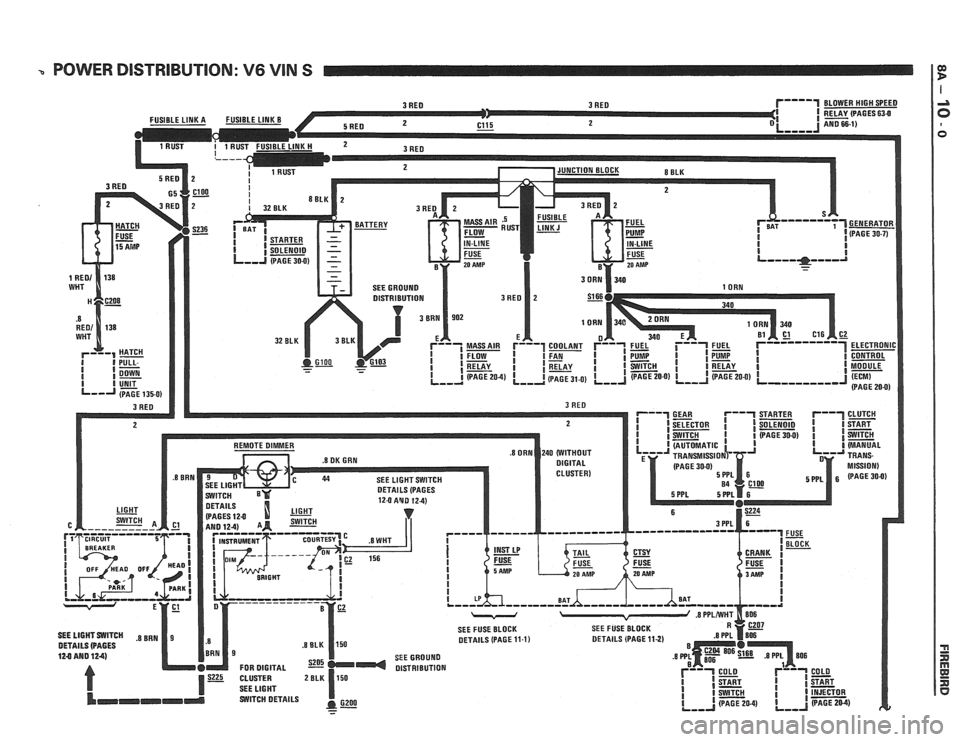

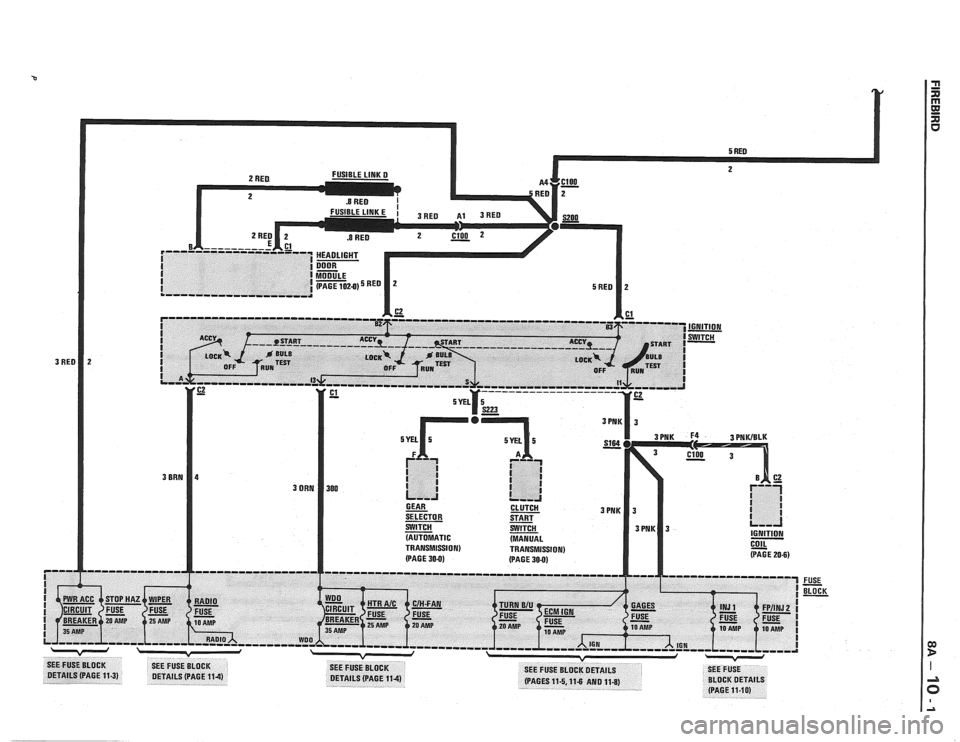

3 POWER DISTRIBUTION: V6 VlN S

Page 1204 of 1825

Page 1205 of 1825

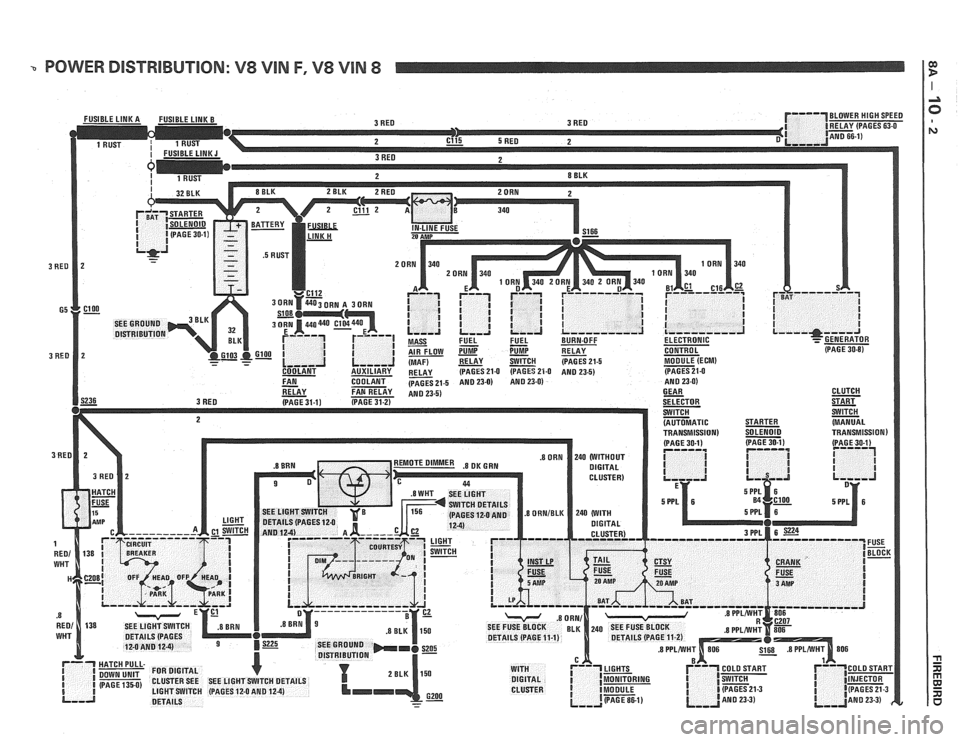

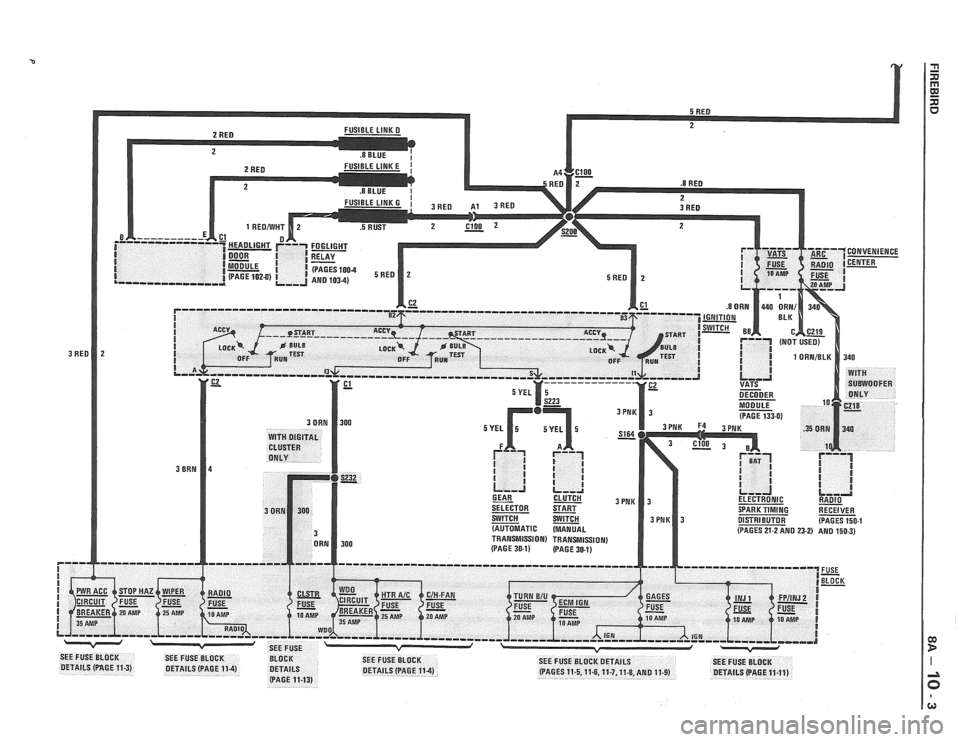

- POWER DISTRIBUTION: V8 VIN F, V8 VIN 8 I:

Page 1206 of 1825

Page 1207 of 1825

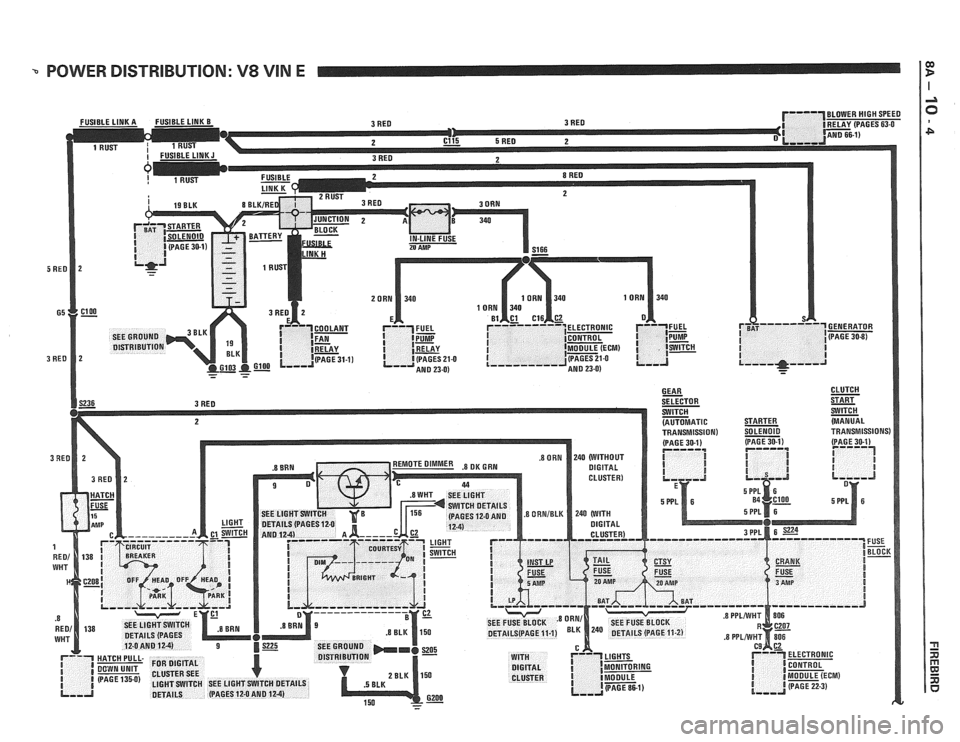

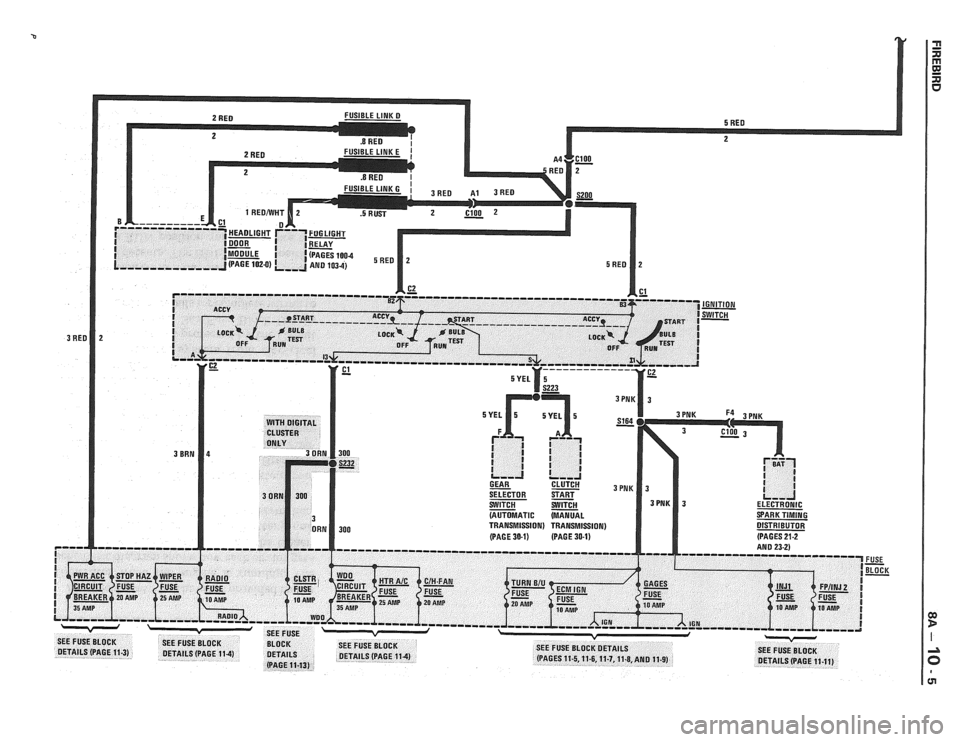

-. POWER DISTRIBUTION: V8 VIN E I

Page 1208 of 1825

Page 1209 of 1825

POWER DISTRIBUTION

CIRCUIT OPERATION

Electrical power for the car is provided by the

Generator when the engine is running. The

schematic diagram shows how each circuit gets

its power. For more details about the Gener-

ator, and connections to the Battery and

Starter, see Starter and Charging System, Sec-

tion

8A-30.

The car's Power Distribution System con-

sists of Fusible Links, Fuses, Circuit Breakers,

the Light Switch and the Ignition Switch. Fusi-

ble Links are short pieces of wire to which they

supply power. They are covered with a special

high-temperature insulation. When conducting

a high current, the Fusible Link will melt and

stop current flow. They are designed to protect

the car's electrical system from electrical

shorts where it is not protected by the Circuit

Breakers and Fuses. See Fuse Block Details

and Light Switch Details for complete wiring to

the first component in each circuit.

The Ignition Switch has six positions, five of

which have detents. The BULB TEST position

is after the RUN position and just before the

START position. BULB TEST does not have a

detent. As shown in the schematic, circuits

which are supplied from the Ignition Switch are

On (Hot) for different switch positions. Indi-

vidual schematics show their fuses supplied

from headings such as "Not In Run. "The head-

ing corresponds to the Ignition Switch position

in which power is On.

Page 1210 of 1825

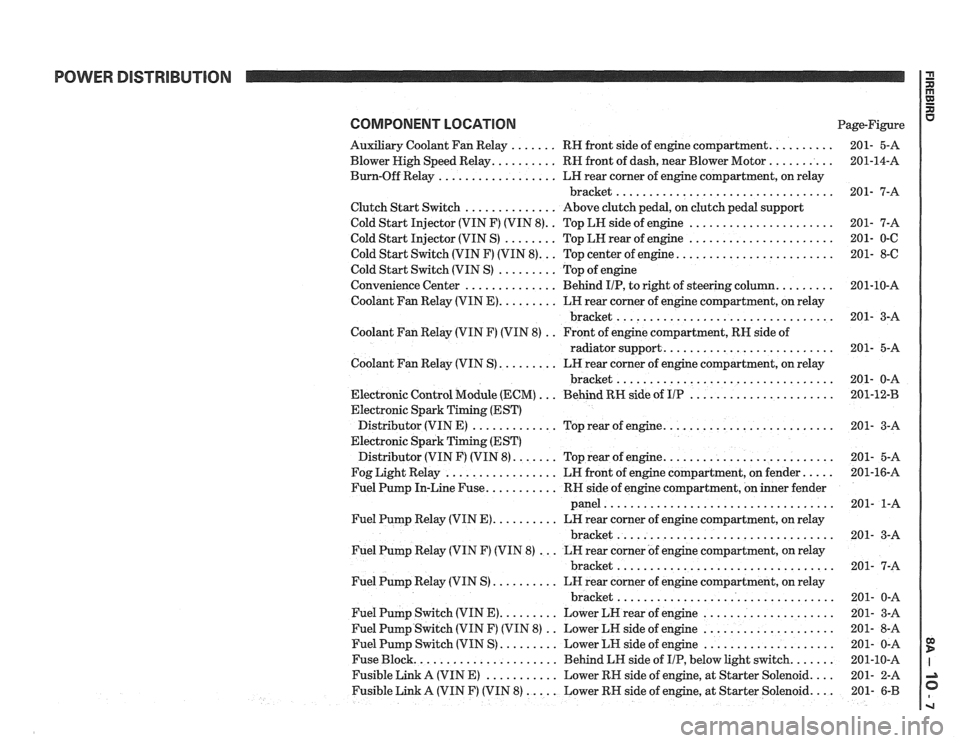

BOWER DISTRIBUTION

COMPONENT LOCATION Page-Figure

Auxiliary Coolant Fan Relay

. . . . . . . RH front side of engine compartment. . . . . . . . . .

Blower High Speed Relay. . . . . . . . . . RN front of dash, near Blower Motor . . . . . . . . . .

Burn-Off Relay . . . . . . . . . . . . . . . . . . LH rear corner of engine compartment, on relay

bracket

.................................

Clutch Start Switch . . . . . . . . . . . . . . Above clutch pedal, on clutch pedal support

Cold Start Injector (VIN F) (VIN

8). . Top LH side of engine . . . . . . . . . . . . . . . . . . . . . .

Cold Start Injector (VIN S) . . . . . . . . Top LH rear of engine . . . . . . . . . . . . . . . . . . . . . .

Cold Start Switch (VIN F) (VIN 8). . . Top center of engine. . . . . . . . . . . . . . . . . . . . . . . .

Cold Start Switch (VIN S) . . . . . . . . . Top of engine

Convenience Center

. . . . . . . . . . . . . . Behind IIP, to right of steering column. . . . . . . . .

Coolant Fan Relay (VIN E). . . . . . . . . LN rear corner of engine compartment, on relay

bracket

.................................

Coolant Fan Relay (VIN F) (VIN 8) . . Front of engine compartment, RH side of

radiator support.

. . . . . . . . . . . . . . . . . . . . . . . . .

Coolant Fan Relay (VIN S) . . . . . . . . . LH rear corner of engine compartment, on relay

bracket

.................................

Electronic Control Module (ECM) . . . Behind RN side of UP . . . . . . . . . . . . . . . . . . . . . .

Electronic Spark Timing (EST)

Distributor (VIN E)

. . . . . . . . . . . . . Top rear of engine. . . . . . . . . . . . . . . . . . . . . . . . . .

Electronic Spark Timing (EST)

Distributor (VIN F) (VIN

8). . . . . . . Top rear of engine. . . . . . . . . . . . . . . . . . . . . . . . . .

Fog Light Relay . . . . . . . . . . . . . . . . . LR front of engine compartment, on fender. . . . .

Fuel Pump In-Line Fuse. . . . . . . . . . . RR side of engine compartment, on inner fender

panel

...................................

Fuel Pump Relay (VIN E). . . . . . . . . . LN rear corner of engine compartment, on relay

bracket

.................................

Fuel Pump Relay (VIN F) (VIN 8) . . . LN rear corner of engine compartment, on relay

bracket

.................................

Fuel Pump Relay (VIN S) . . . . . . . . . . LH rear corner of engine compartment, on relay

bracket

.................................

Fuel Pump Switch (VIN E). . . . . . . . . Lower LN rear of engine . . . . . . . . . . . . . . . . . . . .

Fuel Pump Switch (VIN F) (VIN 8) . . Lower LN side of engine . . . . . . . . . . . . . . . . . . . .

Fuel Pump Switch (VIN S) . . . . . . . . . Lower LN side of engine . . . . . . . . . . . . . . . . . . . .

Fuse Block. . . . . . . . . . . . . . . . . . . . . . Behind LH side of IIP, below light switch. . . . . . .

Fusible Link A (VIN E) . . . . . . . . . . . Lower RN side of engine, at Starter Solenoid. . . .

Fusible Link A (VIN F) (VIN 8) . . . . . Lower RH side of engine, at Starter Solenoid. . . . 201- 6-B