PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1181 of 1825

TROUBLESHOOTING PROCEDURES

The following four-step troubleshooting pro-

cedure is recommended:

Step 1: Check the problem.

Perform a System Check to be sure you

understand what's wrong. Don't waste time

fixing part of the problem! Do not begin dis-

assembly or testing until you have narrowed

down the possible causes.

Step 2: Read the Electrical Schematic.

Study the schematic. Read the Circuit Oper-

ation text if you do not understand how the

circuit

should work. Check circuits that share

wiring with the problem circuit. The names of

circuits that share the same fuse, ground,

switch, etc., are included on each electrical

schematic. (Shared circuits are also shown on

Power Distribution, Ground Distribution,

Fuse Block Details, and Light Switch pages.)

Try to operate the shared circuits. If the

shared circuits work, then the shared wiring is

OK. The cause must be within the wiring used

only by the problem circuit. If several circuits

fail at the same time, chances are the power

(fuse) or ground circuit is faulty.

Step 3: Find the Cause and Repair.

* Narrow down the possible causes.

@ Use the Troubleshooting Hints.

@ Make the necessary measurements as

given in the System Diagnosis.

Step 4: Test the Repair

Repeat the System Check to be sure you

have fixed the whole problem.

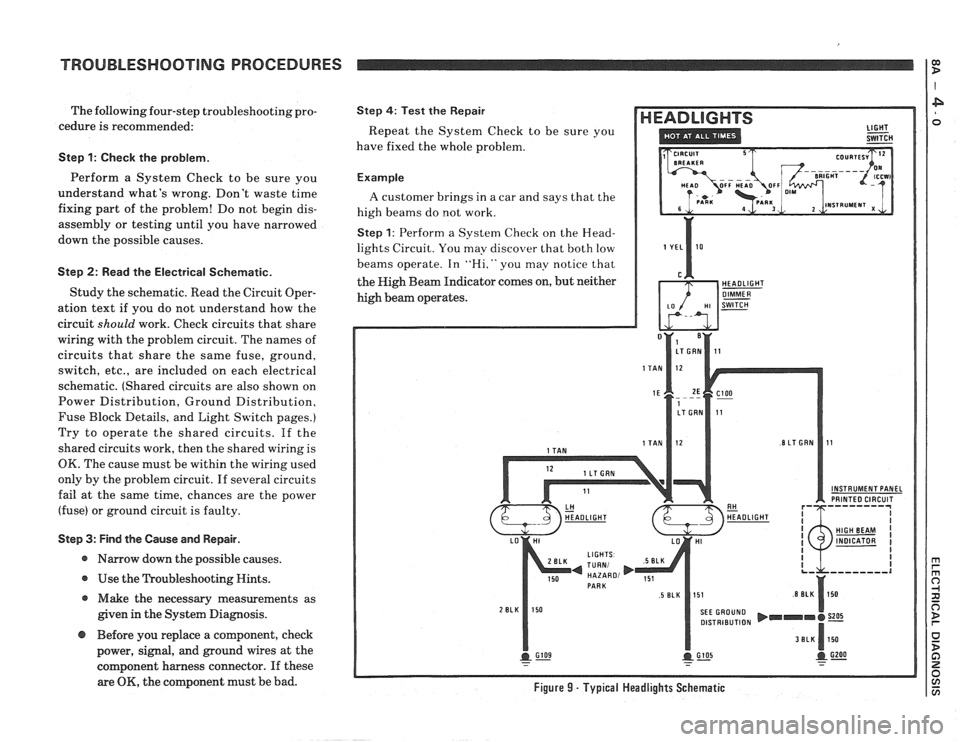

Example

A customer brings in a car and says that the

high beams do not work.

Step 1: Perform a System Check on the Head-

lights Circuit. You may discover that both low

beams operate. In

"Hi," you may notice that

the High Beam Indicator comes on, but neither

high beam operates.

INSTRUMENT PANEL PRINTED CIRCUIT

DISTRIBUTION

@ Before you replace a component, check

power, signal, and ground wires at the

component harness connector. If these

are

OK, the component must be bad. Figure 9 - Typical Headlights Schematic

Page 1182 of 1825

TROUBLESHOOTING PROCEDURES

Step 2: Read the Headlights electrical sche-

matic, see figure

9. This is the step that will

save you time and labor. Remember, it is

essential to understand how a circuit

should

work, before trying to figure out why it

doesn't.

After you understand how the circuit should

operate, read the schematic again, this time

keeping in mind what you have learned by

operating the circuit.

Since both low beams work. you know that

the

Light Switch. the YEI, wire. the I,o con-

tacts of the Headlight Dimmer Switch. termi-

nal

1E of C100. the TAN wires. and grounds

6105 and G 109 are all good.

Furthermore, since you saw that the High

Beam Indicator came on when the Headlight

Dimmer Switch was moved to Hi. you know

that the Hi contacts of the

dimmer switch and

the

I,T GRN wire between the dimmer switch

and ClOO are good.

At this point. you could test for

voltage at

the RH Headlight with the dimmer switch in

Hi. However. it is extremely unlikely that the

high beam filaments have burned out in

both

headlights. or that both headlight connections

are bad. The cause must be a bad connection at

C100, or a break in the I,T GRN wire between

ClOO and the RH Headlight.

I,T GRN wire, locate the exact trouble point,

and make the repair.

Step 4: Check the repair by performing a sys-

tem check on the Headlights circuit. This, of

course, means making sure that both high

beams, both low beams, and the High Beam

Indicator are all working.

Now suppose that the symptoms were dif-

ferent. You may have operated the Headlights

and found that the low beams were working,

but neither the high beams nor the High Beam

Indicator were working. Looking at the sche-

matic, you might conclude the

following.

It is unlikely that both high beam filaments

and the High Beam Indicator have all burned

out at once. The cause is probably the dimmer

switch or its connector.

You have quickly narrowed the possible

causes down to one specific area, and have

done absolutely

no work on the car itself.

Step 3: Find the cause and repair it. Using the

Component Location List and the correspond-

ing figure. you can quickly find ClOO and the

Page 1183 of 1825

TROUBLESHOOT1NG TOOLS

Electrical troubleshooting requires the use

of common electrical test equipment.

TEST LIGHTIVOLTMETER

Use a test light to check for voltage. A Test

Light (BT-7905 or equivalent) is made up of a

12-Volt light bulb with apair of leads attached.

After grounding one lead, touch the other lead

to various points along the circuit where volt-

age should be present. When the bulb goes on,

there is voltage at the point being tested.

A voltmeter can be used instead of a test

light. While a test light shows whether or not

voltage is present, a voltmeter indicates how

much voltage is present.

An increasing number of circuits include

solid state control modules. One example is the

Electronic Control Module

(ECM) used with

Computer Command Control and Electronic

Fuel Injection. Voltages in these circuits

should be tested only with a 10-megohm or

higher impedance digital voltmeter or multi-

meter (5-29125 or equivalent). Never use a test

light on circuits that contain solid state compo-

nents, since damage to these components may

result.

When testing for voltage or continuity at a

connection, you do not have to separate the

two halves of the connector. Unless you are

testing a "weather-pack" connector, you

should probe the connector from the back.

Always check both sides of the connector. An

accumulation of dirt and corrosion between

contact surfaces is sometimes a cause of elec-

trical problems.

CONNECTOR TEST ADAPTERS

A connector Adapter Kit is available

(535616) for making tests and measurements at

separated connectors. This kit contains an

assortment of probes which mate with many of

the types of connectors you will see. Avoid

using paper clips and other substitutes since

they can damage terminals and cause incorrect

measurements.

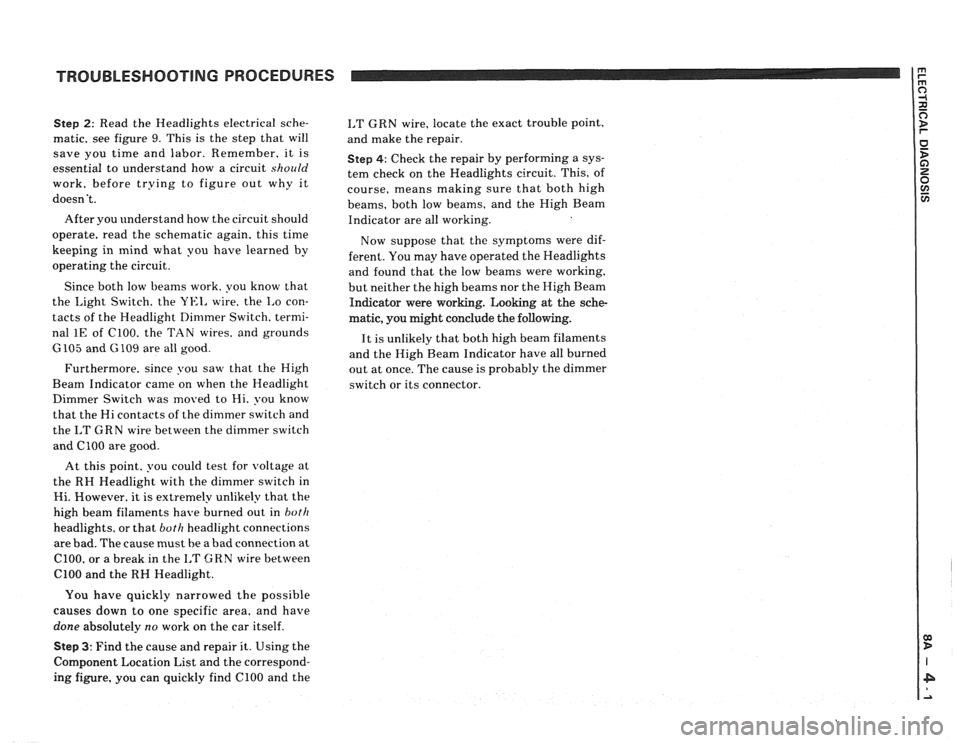

SELF-POWERED TEST LIGHT

Use a self-powered test light (5-21008 or

equivalent) to check for continuity. This tool is

made up of a light bulb, battery, and two leads.

If the leads are touched together, the bulb will

go on.

A self-powered test light is used only on an

unpowered circuit. First disconnect the car's

Battery, or remove the fuse which feeds the cir-

cuit you're working on. Select two specific

points along the circuit through which there

should be continuity. Connect one lead of the

self-powered test light to each point. If there is

continuity, the test light's circuit will be com-

pleted and the bulb will go on.

Never use a self-powered test light on cir-

cuits that contain solid state components,

since damage to these components may result. Self-Powered Test Light

OHMMETER

An ohmmeter can be used instead of a self-

powered test light. The ohmmeter shows how

much resistance there is between two points

along a circuit. Low resistance means good

continuity.

Circuits which include any solid state con-

trol modules, such as the Electronic Control

Module

(ECM), should be tested only with a 10-

megohm or higher impedance digital multi-

meter

(5-29125 or equivalent).

VIThen measuring resistance with a digital

multimeter. the vehicle Battery should be dis-

connected. This will prevent incorrect read-

ings. Digital meters apply such a small voltage

to measure resistance that the presence of

voltages can upset a resistance reading.

Diodes and solid state components in a cir-

cuit can cause an ohmmeter to give a false

reading. To find out if a component is affecting

a measurement, take a reading once, reverse

the leads and take a second reading.

If the

readings differ, the solid state component is

affecting the measurement.

Page 1184 of 1825

TROUBLESHOOTING TOOLS TROUBLESHOOTING TESTS

FUSED JUMPER WIRE

A fused jumper is available (5-36169 or equiv-

alent) with small clamp connectors providing

adaptation to most connectors without

damage. This fused jumper wire is supplied

with a

20 amp fuse which may not be suitable

for some circuits. Do not use a fuse with a

higher rating than the fuse that protects the

circuit being tested.

CAUTION: Do not use fused jumper wire

in any instance to substitute for inputs or

outputs at the ECM (Electronic Control

Module), BCM (Body Control Module), or

any microprocessor device.

SHORT FINDER

Short Finders are available (5-8681 or equiv-

alent) to locate hidden shorts to ground. The

short finder creates a pulsing magnetic field in

the shorted circuit and shows you the location

of the short through body trim or sheet metal.

FUSE TESTER

A simple tester that indicates a blown fuse is

available (5-34764 or equivalent). To check a

fuse the tester

is applied directly to the fuse in

the fuse block. Two probes contact the fuse. The

probes are either placed into the slots of a flat

fuse or to the metal ends of a glass fuse. With

power on, a red

LED in the tester lights if the

fuse is open. The handle of the tester is a tool for

removing either type of fuse.

TROUBLESHOOTING TESTS

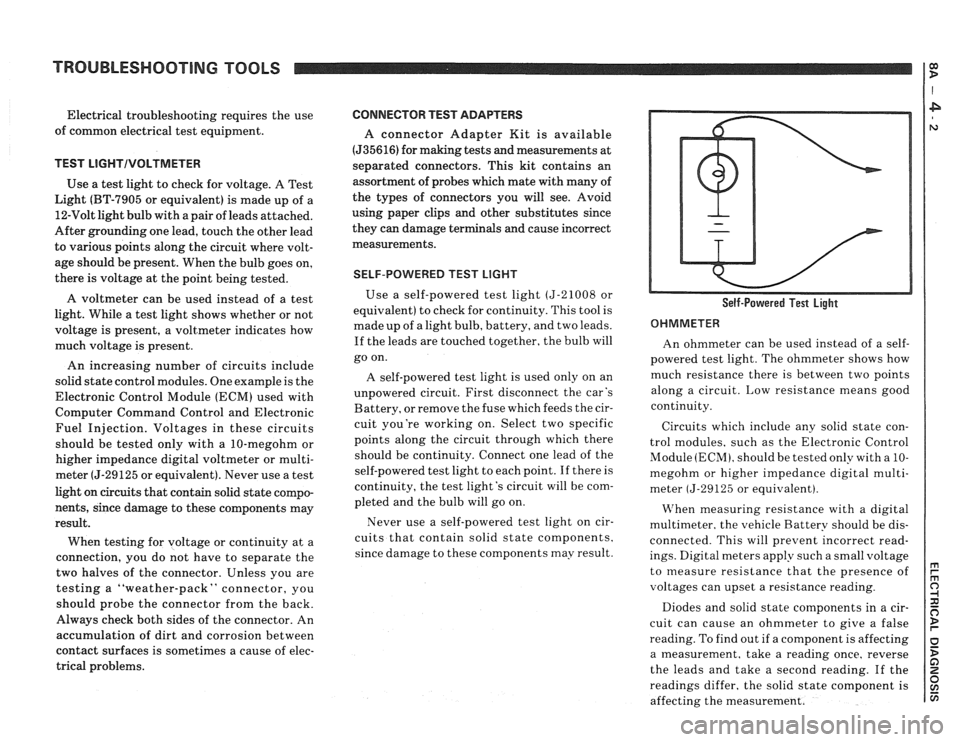

TESTING FOR VOLTAGE

1. Connect one lead of a test light to a known

good ground. If you are using a voltmeter,

be sure it is the voltmeter's negative lead

that you have connected to ground.

2. Connect the other lead of the test light or

voltmeter to a selected test point (connec-

tor or terminal).

3. If the test light glows, there is voltage pre-

sent. If you are using a voltmeter, note the

voltage reading. It should be within one

volt of measured Battery voltage.

A loss of

more than one volt indicates a problem.

Voltage Check .

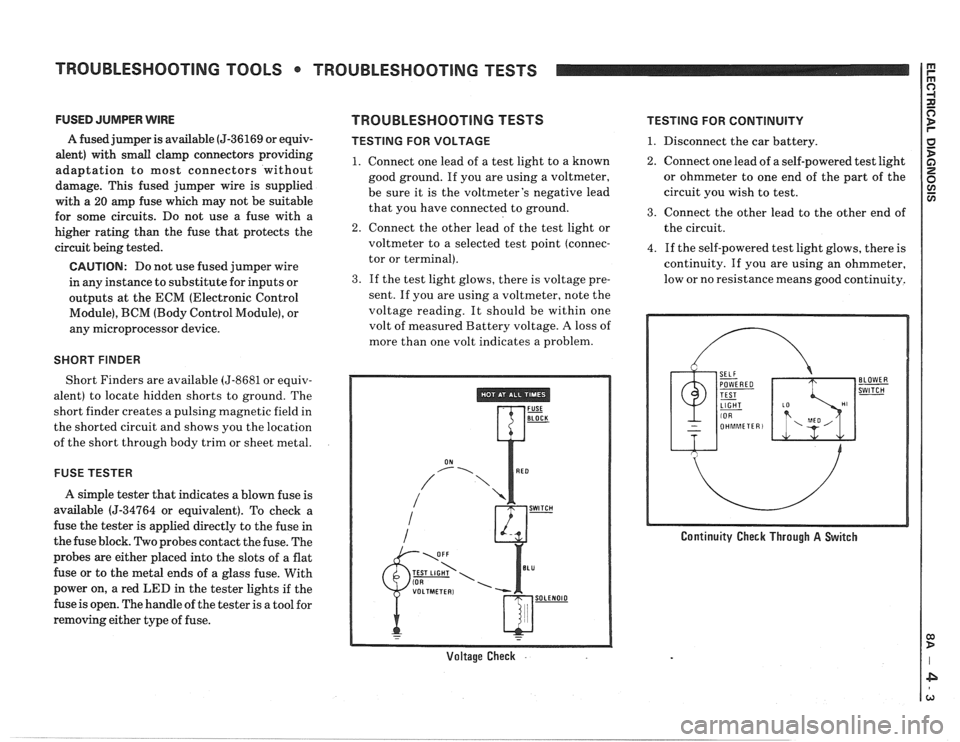

TESTING FOR CONTINUITY

1. Disconnect the car battery.

2. Connect one lead of a self-powered test light

or ohmmeter to one end of the part of the

circuit you wish to test.

3. Connect the other lead to the other end of

the circuit.

4. If the self-powered test light glows, there is

continuity. If you are using an ohmmeter,

low or no resistance means good continuity.

Continuity Check Through A Switch

Page 1185 of 1825

TROUBLESHOOTING TESTS

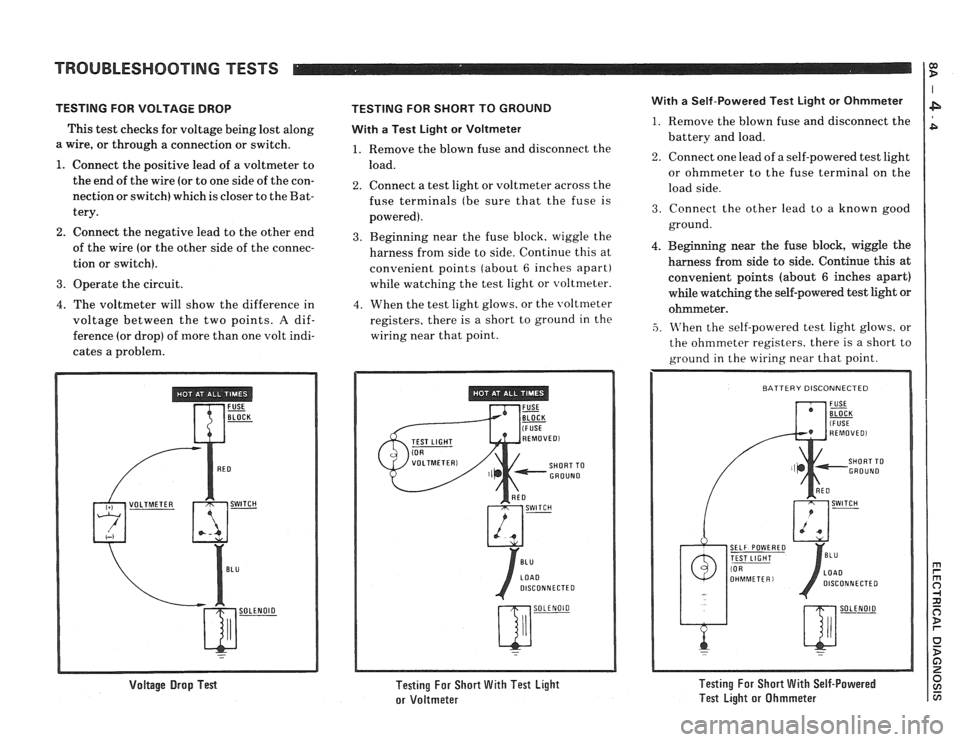

TESTING FOR VOLTAGE DROP

This test checks for voltage being lost along

a wire, or through a connection or switch.

1. Connect the positive lead of a voltmeter to

the end of the wire (or to one side of the con-

nection or switch) which

is closer to the Bat-

tery.

2. Connect the negative lead to the other end

of the wire (or the other side of the connec-

tion or switch).

3. Operate the circuit.

4. The voltmeter will show the difference in

voltage between the two points.

A dif-

ference (or drop) of more than one volt indi-

cates a problem.

Voltage Drop Test

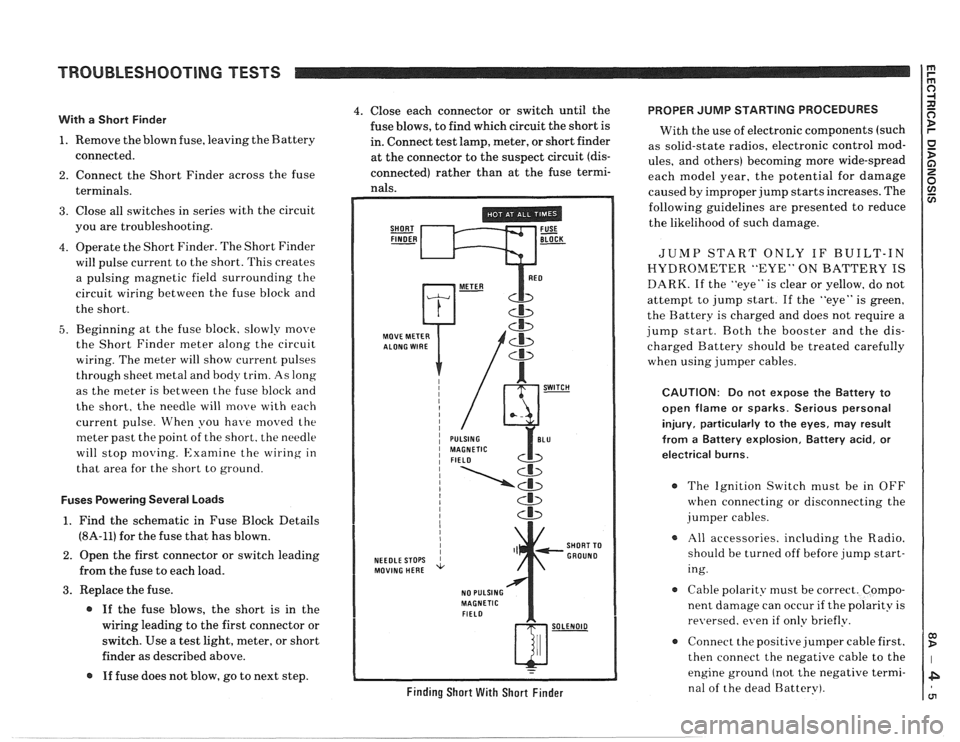

TESTING FOR SHORT TO GROUND

With

a Test Light or Voltmeter

1. Remove the blown fuse and disconnect the

load.

2. Connect a test light or voltmeter across the

fuse terminals (be sure that the fuse is

powered).

3. Beginning near the fuse block, wiggle the

harness from side to side. Continue this at

convenient points (about

6 inches apart)

while watching the test light or voltmeter.

4. When the test light glows, or the \voltmeter

registers. there is a short to ground in the

wiring near that point.

Testing For Short With Test Light

or Voltmeter

With a Self-Powered Test Light or Ohmmeter

1. Remove the blown fuse and disconnect the

battery and load.

2. Connect one lead of a self-powered test light

or ohmmeter to the fuse terminal on the

load side.

3. Connect the other lead to a known good

ground.

4. Beginning near the fuse block, wiggle the

harness from side to side. Continue

this at

convenient points (about

6 inches apart)

while watching the self-powered test light or

ohmmeter.

,5. M'hen the self-powered test light glows, or

the ohmmeter registers. there is a short to

ground in the wiring near that point.

SELF POWERED

DISCONNECTED

Testing For Short With Self-Powered

Test Light or Ohmmeter

Page 1186 of 1825

TROUBLESHOOTING TESTS m r rn 0

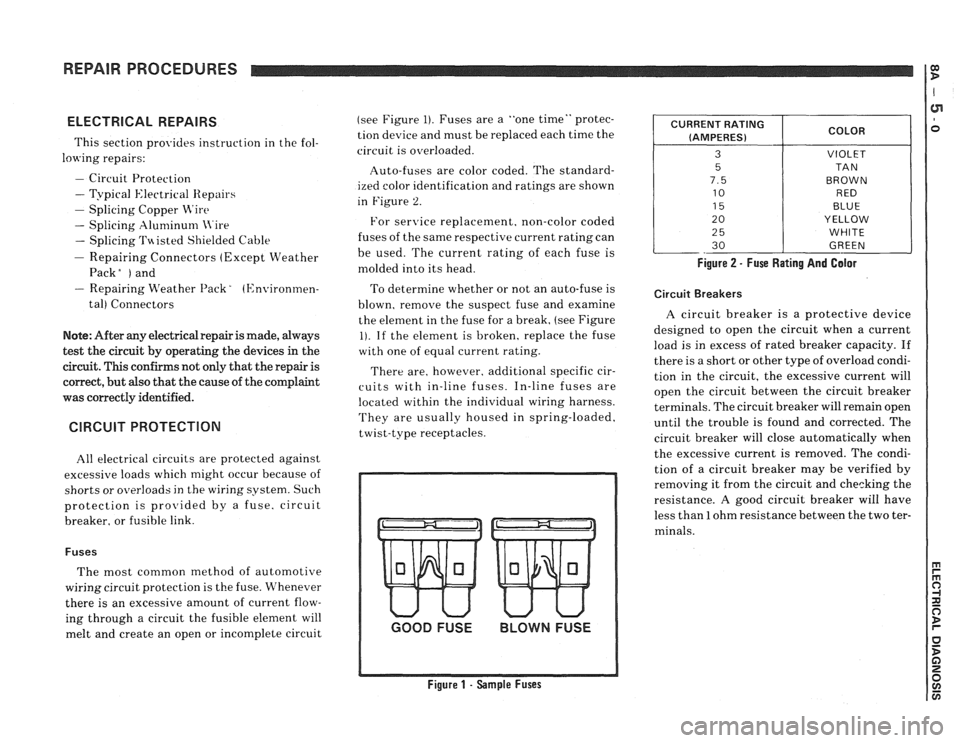

With a Short Finder

1. Remove the blown fuse, leaving the Battery

connected.

2. Connect the Short Finder across the fuse

terminals.

3. Close all switches in series with the circuit

you are troubleshooting.

4. Operate the Short Finder. The Short Finder

will pulse current to the short. This creates

a pulsing magnetic field surrounding the

circuit wiring between the fuse block and

the short.

5. Beginning at the fuse block. slowly move

the Short Finder meter along the circuit

wiring. The meter will show current pulses

through sheet

inetal and body trim. As long

as the meter is between the fuse block and

the short, the needle will move with each

current pulse. When you have

moved the

meter past the point of the short. the needle

will stop

moving. Examine the wiring in

that area for the short to ground.

Fuses Powering Several Loads

1. Find the schematic in Fuse Block Details

(8A-11) for the fuse that has blown.

2. Open the first connector or switch leading

from the fuse to each load.

3. Replace the fuse.

@ If the fuse blows, the short is in the

wiring leading to the first connector or

switch. Use a test light, meter, or short

finder as described above.

@ If fuse does not blow, go to next step.

4. Close each connector or switch until the PROPER JUMP STARTING PROCEDURES

fuse blows, to find which circuit the short is

With the use of electronic components (such

in. Connect test lamp, meter, or short finder

as solid-state radios, electronic control

mod- at the connector to the suspect circuit (dis- ules, and others) becoming more wide-spread

connected) rather than at the fuse termi- each model year, the potential for damage nals. caused by improper jump starts increases. The

SHORT FUSE FINDER - BLOCK -

MOVE METER

NEEDLE STOPS

MOVING HERE

NO PULSING

MAGNETIC

FIELD

Cb

SHORT TO

GROUND

w-

Finding Short With Short Finder

following guidelines are presented to reduce

the likelihood of such damage.

JUMP START ONLY IF BUILT-IN

HYDROMETER "EYE" ON BATTERY IS

DARK. If the "eye" is clear or yellow, do not

attempt to jump start. If the "eye" is green,

the Battery is charged and does not require a

jump start. Both the booster and the dis-

charged Battery should be treated carefully

when using jumper cables.

CAUTION: Do not expose the Battery to

open flame or sparks. Serious personal

injury, particularly

to the eyes, may result

from

a Battery explosion, Battery acid, or

electrical burns.

The Ignition Switch must be in OFF

when connecting or disconnecting the

jumper cables.

All accessories. including the Radio.

should be turned off before jump start-

ing.

Cable polarity must be correct. Compo-

nent damage can occur

if the polarity is

re~~ersed. even if only briefly.

a Connect the positive jumper cable first.

then connect the negative cable to the

engine ground (not the negative termi-

nal of the dead Battery).

Page 1187 of 1825

REPAIR PROCEDURES 0) B

ELECTRICAL REPAIRS

This section provides instruction in the fol-

lowing repairs:

- Circuit Protection

- Typical Electrical Repairs

- Splicing Copper Wire

- Splicing Aluminum \l.ire

- Splicing Txisted Shielded Cable

- Repairing Connectors (Except Weather

Pack

V and

- Repairing breather I'ack * (Environmen-

tal) Connectors

Note: After any electrical repair is made, always

test the circuit by operating the devices in the

circuit. This confirms not only that the repair is

correct, but also that the cause of the complaint

was correctly identified.

CIRCUIT PROTECTION

All electrical circuits are protected against

excessive loads which might occur because of

shorts or overloads in the wiring system. Such

protection is

prolrided by a fuse. circuit

breaker. or fusible link.

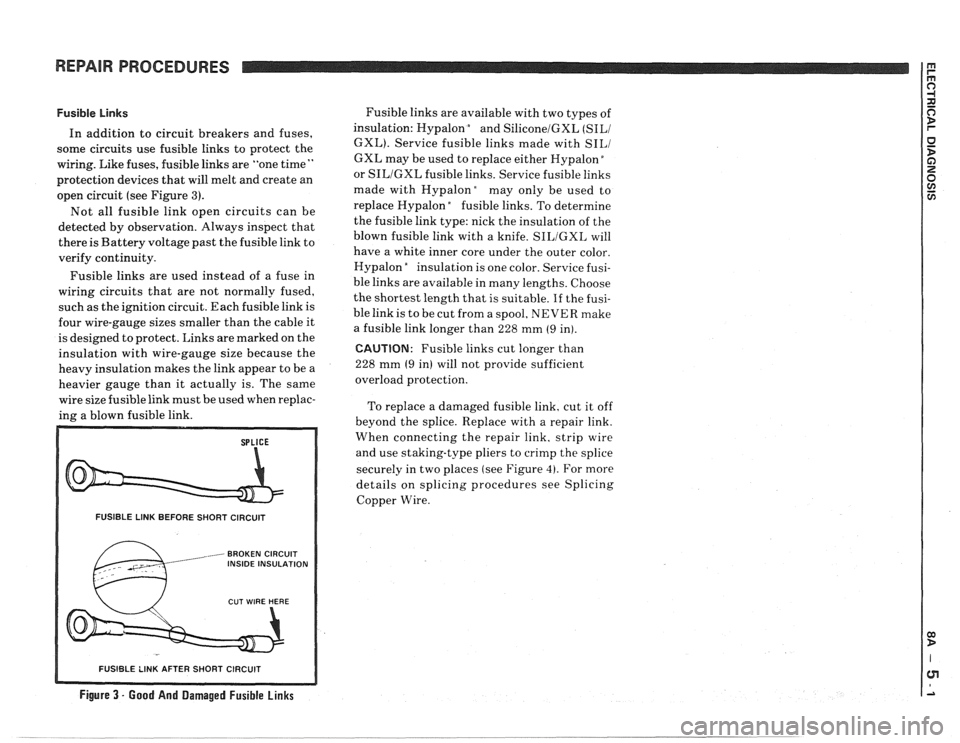

Fuses

The most common method of automotive

wiring circuit protection is the fuse. Whenever

there is an excessive amount of current flow-

ing through a circuit the fusible element will

melt and create an open or incomplete circuit (see

Figure

1). Fuses are a "one time" protec-

tion device and must be replaced each time the

circuit is overloaded.

Auto-fuses are color coded. The standard-

ized color identification and ratings are shown

in Figure

2.

For senrice replacement. non-color coded

fuses of the same respective current rating can

be used. The current rating of each fuse is

molded into its head.

To determine whether or not an auto-fuse is

blown, remove the suspect fuse and examine

the element in the fuse for a break, (see Figure

1). If the element is broken, replace the fuse

with one of equal current rating.

There are, however. additional specific cir-

cuits with in-line fuses. In-line fuses are

located within the individual wiring harness.

They are usually housed in spring-loaded,

twist-type receptacles.

GOOD FUSE BLOWN FUSE

Figure 1 - Sample Fuses Figure

2 - Fuse Rating And Galor

CURRENT

RATING

(AMPERES)

3

5

7.5

10

15

20

2

5

30

Circuit Breakers

COLOR

VIOLET

TA N

BROWN RED

BLUE

YELLOW

WHITE

GREEN

A circuit breaker is a protective device

designed to open the circuit when a current

load is in excess of rated breaker capacity. If

there is a short or other type of overload condi-

tion in the circuit, the excessive current will

open the circuit between the circuit breaker

terminals. The circuit breaker will remain open

until the trouble is found and corrected. The

circuit breaker will close automatically when

the excessive current is removed. The condi-

tion of a circuit breaker may be verified by

removing it from the circuit and checking the

resistance.

A good circuit breaker will have

less than

1 ohm resistance between the two ter-

minals.

Page 1188 of 1825

REPAIR PROCEDURES

Fusible Links

In addition to circuit breakers and fuses,

some circuits use fusible links to protect the

wiring. Like fuses, fusible links are "one time

"

protection devices that will melt and create an

open circuit (see Figure

3).

Not all fusible link open circuits can be

detected by observation. Always inspect that

there is Battery voltage past the fusible link to

verify continuity.

Fusible links are used instead of a fuse in

wiring circuits that are not normally fused,

such as the ignition circuit. Each fusible link is

four wire-gauge sizes smaller than the cable it

is designed to protect. Links are marked on the

insulation with wire-gauge size because the

heavy insulation makes the link appear to be a

heavier gauge than it actually is. The same

wire size fusible link must be used when replac-

ing a blown fusible link.

FUSIBLE LINK BEFORE SHORT CIRCUIT

, BROKEN CIRCUIT INSIDE INSULATION

Fusible links are available with two types of

insulation: Hypalon

bnd SiliconelGXL (SILI

GXL). Service fusible links made with SILI

GXL may be used to replace either Hypalon "

or SILIGXL fusible links. Service fusible links

made with

Hypalonday only be used to

replace Hypalon

"fusible links. To determine

the fusible link type: nick the insulation of the

blown fusible link with a knife.

SILIGXL will

have a white inner core under the outer color.

Hypalon

"nsulation is one color. Service fusi-

ble links are available in many lengths. Choose

the shortest length that is suitable.

If the fusi-

ble link is to be cut from a spool, NEVER make

a fusible link longer than 228 mm

(9 in).

CAUTION: Fusible links cut longer than

228 mm

(9 in) will not provide sufficient

overload protection.

To replace a damaged fusible link, cut it off

beyond the splice. Replace with a repair link.

When connecting the repair link. strip wire

and use staking-type pliers to crimp the splice

securely in two places (see Figure

4). For more

details on splicing procedures see Splicing

Copper Wire.

R SHORT CIRCUIT

Figure 3 - Good And Damaged Fusible Links

-- - - - - -- - - - - -- - - -

Page 1189 of 1825

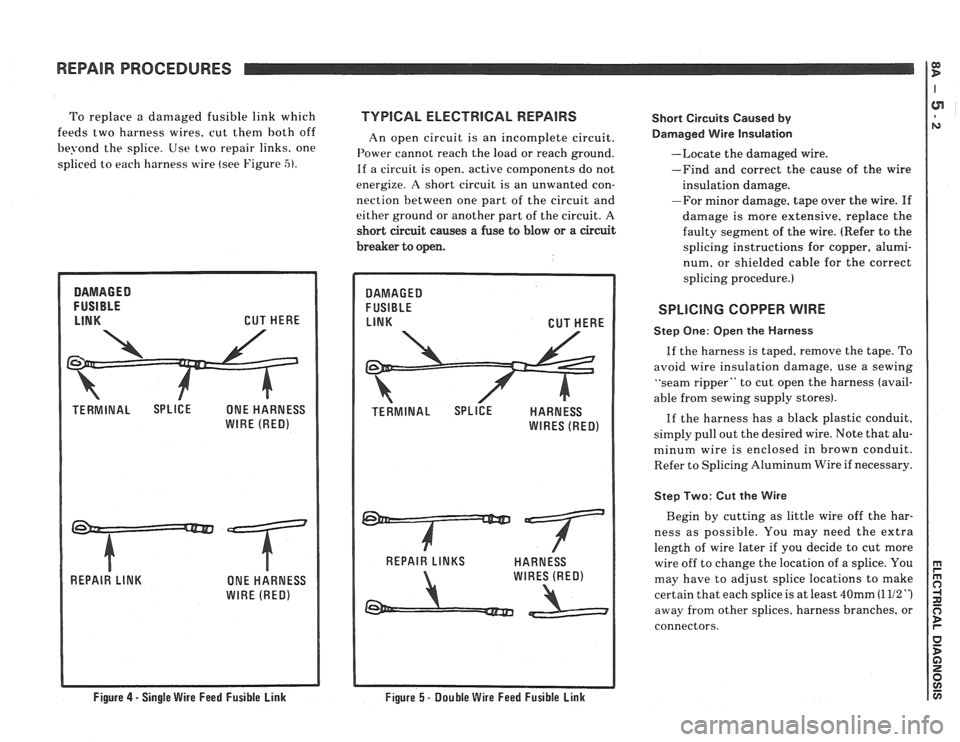

To replace a damaged fusible link which TVPlCAL ELECTRlCAL REPAIRS

feeds two harness wires. cut then1 both off

An open circuit is an incomplete circuit.

be?-ond the splice. Use two repair links. one I'ower cannot reach the load or reach ground.

spliced to each harness wire (see Figure -5). If a circuit is open. active components do not

energize.

A short circuit is an unwanted con-

nection between one part of the circuit and

either ground or another part of the circuit. A

short circuit causes

a fuse to blow or a circuit

breaker to open. Short

Circuits Caused

by

Darnaged Wire Insulation

--Locate the damaged wire.

-Find and correct the cause of the wire

insulation damage.

-For minor damage, tape over the wire.

If

damage is more extensive, replace the

faulty segment of the wire. (Refer to the

splicing instructions for copper, alumi-

num, or shielded cable for the correct

splicing procedure.)

REPAIR PROCEDURES

SPLICING COPPER WIRE

Q) D

Step One: Open the Harness

If the harness is taped, remove the tape. To

avoid wire insulation damage, use a sewing

"seam ripper" to cut open the harness (avail-

able from sewing supply stores).

If the harness has a black plastic conduit,

simply pull out the desired wire. Note that alu-

minum wire is enclosed in brown conduit.

Refer to Splicing Aluminum Wire if necessary.

Step Two: Cut the Wire

Begin by cutting as little wire off the har-

ness as possible. You may need the extra

length of wire later if you decide to cut more

wire off to change the location of a splice. You

may have to adjust splice locations to make

certain that each splice is at least

40mm (1 112 ")

away from other splices, harness branches, or

connectors.

Figure 4 - Single Wire Feed Fusible Link

Figure 5 - Double Wire Feed Fusible Link

Page 1190 of 1825

REPAIR PROCEDURES

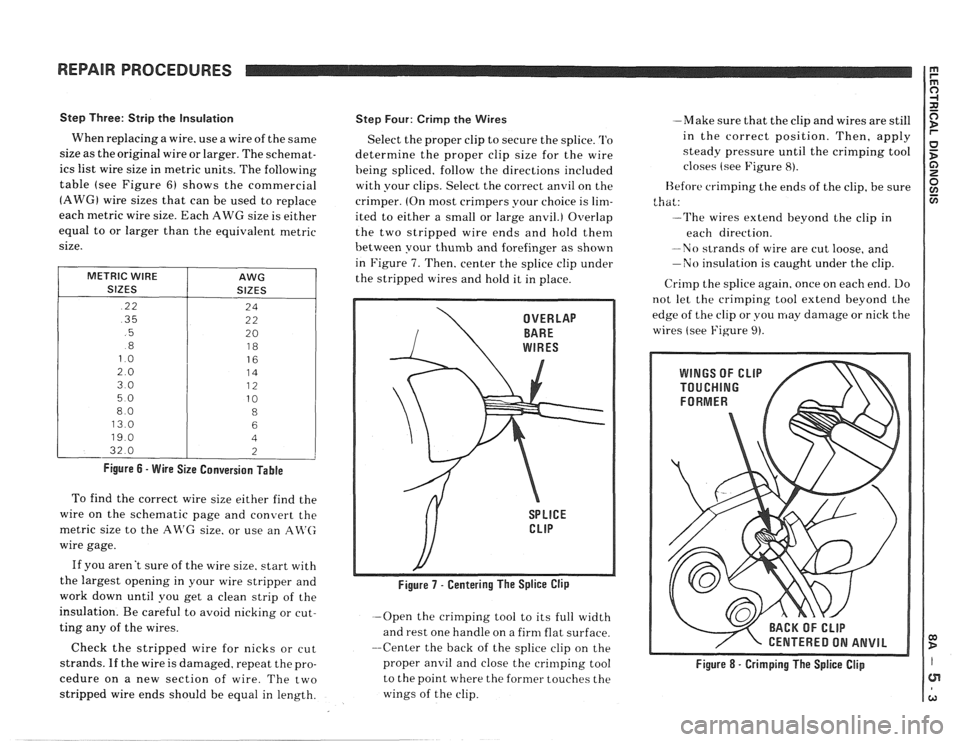

Step Three: Strip the Insulation

When replacing a wire. use a wire of the same

size as the original wire or larger. The schemat-

ics list wire size in metric units. The following

table (see Figure

6) shows the commercial

(AWG) wire sizes that can be used to replace

each

metric wire size. Each AWG size is either

equal to or larger than the equivalent metric

size.

METRIC WIRE

SIZES

.22

.35

.5

.8

13.0

32.0

AWG

SIZES

Figure 6 - Wire Size Conversion Table

To find the correct wire size either find the

wire on the schematic page and convert the

metric size to the AR'G size. or use an

An'(;

wire gage.

If you aren't sure of the wire size. start with

the largest opening in your wire stripper and

work down until you get a clean strip of the

insulation. Be careful to avoid nicking or cut-

ting any of the wires.

Check the stripped wire for nicks or cut

strands. If the wire is damaged. repeat the pro-

cedure on a new section of wire. The two

stripped wire ends should be equal in length.

Step Four: Crirnp the Wires

Select the proper clip to secure the splice. '1'0

determine the proper clip size for the wire

heing spliced. follow the directions included

with your clips. Select the correct anvil on the

crimper. (On most crimpers your choice is

lim-

ited to either a small or large anvil.) Overlap

the two stripped wire ends and hold them

between your

thumb and forefinger as shown

in Figure

7. Then, center the splice clip under

the stripped wires and hold it in place.

-Open the crimping tool to its full width

and rest one handle on a firm flat surface.

--Center the back of the splice clip on the

proper

anvil and close the crinlping tool

to the point where the former touches the

wings of the clip. -Make

sure that the clip and wires are still

in the correct position. Then, apply

steady pressure until the crimping tool

closes (see Figure

8).

Before crimping the ends of the clip, be sure

that:

--The wires extend beyond the clip in

each direction.

-No strands of wire are cut loose, and

-No insulation is caught under the clip.

Crirnp the splice again. once on each end. Do

not let the crimping tool extend beyond the

edge of the clip or you may damage or nick the

wires (see Figure

9).

/ CENTERED ON ANVIL

Figure 8 - Crimping The Splice Clip