ignition RAM CHASSIS CAB 2021 Owners Manual

[x] Cancel search | Manufacturer: RAM, Model Year: 2021, Model line: CHASSIS CAB, Model: RAM CHASSIS CAB 2021Pages: 463, PDF Size: 21.5 MB

Page 377 of 463

SERVICING AND MAINTENANCE375

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools, we recommend having your

vehicle serviced at an authorized dealer.

DRAINING FUEL/WATER SEPARATOR

F

ILTER

There are two fuel filter assemblies. One is

located on the driver's side of the engine.

The best access to this water drain valve is from

under the hood. The second one is on the under

body, located in front of the rear axle above the

drive shaft on pick-up models. The Chassis Cab

models second filter location is on the frame

behind the front axle. The best access to this

water drain valve is from under the vehicle. If water is detected in the water separator while

the engine is running, or while the ignition

switch is in the ON position, the “Water In Fuel

Indicator Light” will illuminate and an audible

chime will be heard five times. At this point you

should stop the engine and drain the water from

both of the filters.

If the “Water In Fuel Indicator Light” comes on

and a single chime is heard while you are

driving, or with the ignition switch in the ON

position, there may be a problem with your

water separator wiring or sensor. See an

authorized dealer for service.

Upon proper draining of the water from both

fuel filters, the “Water In Fuel Indicator Light”

will remain illuminated for approximately

10 seconds. If the water was drained while

the engine was running, the “Water In Fuel

Indicator Light” may remain on for

approximately three minutes.NOTE:

Care should be taken in disposing of used fluids

from your vehicle. Used fluids, indiscriminately

discarded, can present a problem to the envi

-

ronment. Contact an authorized dealer, service

station, or government agency for advice on

recycling programs and for where used fluids

and filters can be properly disposed of in your

area.

Drain the fuel/water separator filters when the

“Water In Fuel Indicator Light” is ON. Within

10 minutes of vehicle shutdown, turn the engine

mounted filter drain valve (located on the side of

the filter assembly) counterclockwise a quarter

turn, and turn the under body mounted filter

drain valve (located on the bottom of the filter

assembly) counterclockwise 1 full turn. Then turn

the ignition switch to the ON position, and allow

any accumulated water to drain. Leave the drain

valve open until all water and contaminants have

been removed. When clean fuel is visible, close

the drain valve following these guidelines:

1. Rotate the drain clockwise to close until you feel resistance from the internal seal.

2. Continue turning the drain half of a turn to properly compress the seal.

CAUTION!

Do not drain the fuel/water separator filter

when the engine is running.

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

CAUTION!

If the “Water In Fuel Indicator Light” remains

on, DO NOT START the engine before you

drain water from the fuel filters to avoid

engine damage.

8

21_DPF_OM_EN_USC_t.book Page 375

Page 378 of 463

376SERVICING AND MAINTENANCE

NOTE:

Over-compression of the seal due to over-tight -

ening of the drain will damage the seal, cause

a leak, and require the entire sensor to be

replaced.

3. Turn the ignition switch to OFF.

The sensor drain should not be over-tightened

during normal service operations to avoid

internal damage and future fuel leaks.

The drain should be closed and secured

without the use of tools.

If more than a couple ounces/milliliters of fuel

have been drained, follow the directions for

“Priming If The Engine Has Run Out Of Fuel”

Ú page 378

ENGINE MOUNTED FUEL FILTER

R

EPLACEMENT

NOTE:

Using a fuel filter that does not meet the

manufacturer's filtration and water sepa -

rating requirements can severely impact fuel

system life and reliability.

The engine mounted filter housing is

equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

a. No filter is installed.

b. Inferior/Non-approved filter is used. Use of OEM filter is required to ensure

vehicle will run.

Engine Mounted Fuel Filter Assembly

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter drain

hose.

3. Open the water drain valve a quarter turn counterclockwise and completely drain fuel

and water into the approved container.

4. Close the water drain valve.

5. Remove lid using a socket or strap wrench. Rotate counterclockwise for removal.

Remove used o-ring and discard it.

1 — Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving

surfaces. Drain the filter into an appro-

priate container.

Do not prefill the fuel filter when installing a

new fuel filter. There is a possibility debris

could be introduced into the fuel filter

during this action. It is best to install the

filter dry and allow the in-tank lift pump to

prime the fuel system.

21_DPF_OM_EN_USC_t.book Page 376

Page 380 of 463

378SERVICING AND MAINTENANCE

7. Wipe clean the sealing surfaces of the lid

and housing.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean

engine oil.

NOTE:

Water In Fuel (WIF) sensor is re-usable. Service

kit comes with new o-ring for filter canister and

WIF sensor.

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL

1. Add a substantial amount of fuel to the

tank, approximately 2 to 5 gal (8L to 19L).

2. Three priming cycles must be completed.

Turn ignition to the RUN position and wait

approximately 30 seconds. This will activate

the in tank fuel pump. Turn the ignition

switch to the off position, and leave off for at

least 30 seconds. Repeat this procedure

three times before cranking the engine.

3. Start the engine using the “Normal Starting” procedure Ú page 119.

4. Once the engine starts, allow the engine to idle for a minimum of 30 seconds.

NOTE:

The engine may run rough until the air is forced

from all the fuel lines. NOTE:

A maximum blend of 5% biodiesel, meeting

ASTM specification D-975 may be used with

your Cummins diesel engine. (Chassis Cab

models not configured with B20 capability.)

A maximum blend of 20% biodiesel, meeting

ASTM specification D-7467 may be used with

your Cummins diesel engine. (Pickup models

and Chassis Cab models configured with B20

capability.)

WARNING!

Do not open the high pressure fuel system

with the engine running. Engine operation

causes high fuel pressure. High pressure fuel

spray can cause serious injury or death.

CAUTION!

Do not engage the starter motor for more

than 15 seconds at a time. Allow two minutes

between the cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel

blending agent. They can be unstable under

certain conditions and be hazardous or

explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or

gasoline, the use of these fuels can cause

damage to the fuel system.

21_DPF_OM_EN_USC_t.book Page 378

Page 385 of 463

SERVICING AND MAINTENANCE383

Under normal operating conditions, the catalytic

converter will not require maintenance. However,

it is important to keep the engine properly tuned

to ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:

Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

malfunctioning engine operation, a scorching

odor may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn off

the engine and allow it to cool. Service, including a

tune-up to manufacturer's specifications, should be

obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the trans

-

mission is in gear and the vehicle is in

motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition

components disconnected or removed, such

as when diagnostic testing, or for prolonged

periods during very rough idle or malfunc -

tioning operating conditions.

COOLING SYSTEM CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri -

ously reduce engine performance and

cause serious damage to the engine.

Damage to the catalytic converter can result

if your vehicle is not kept in proper operating

condition. In the event of engine malfunc -

tion, particularly involving engine misfire or

other apparent loss of performance, have

your vehicle serviced promptly. Continued

operation of your vehicle with a severe

malfunction could cause the converter to

overheat, resulting in possible damage to

the converter and vehicle.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radiator

or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts automati -

cally and may start at any time, whether the

engine is running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the

ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.

8

21_DPF_OM_EN_USC_t.book Page 383

Page 396 of 463

394SERVICING AND MAINTENANCE

(Continued)

FUSES

General Information The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery

discharge.

Blade Fuses

PERFORMED BY

PERFORMED AT

Noise Systems Maintenance Chart and Service Log — Insert Month, Day, Year under column mileage closest to the mileage at which

service was performed.

WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans

-

mission system) or steering system blows,

contact an authorized dealer.

WARNING! (Continued)

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

21_DPF_OM_EN_USC_t.book Page 394

Page 399 of 463

SERVICING AND MAINTENANCE397

F32– –Spare

F33 20 Amp Blue –Trans Control Module – If Equipped

F34 30 Amp Pink –Vehicle System Interface Module #2 – If Equipped

F35 30 Amp Pink –Sunroof – If Equipped

F36 30 Amp Pink –Electric Back Light – If Equipped

F37 30 Amp Pink –Diesel Frame / Fuel Heater #2– If Equipped

F38 30 Amp Pink –Integrated Trailer Brake Module – If Equipped

F39 – –Spare

F40 –10 Amp Red Ventilated Seats – If Equipped

F41 –10 Amp Red Active Grille Shutter / Active Air Dam – If Equipped

F42 –20 Amp Yellow Horn

F43 –15 Amp Blue Heated Steering Wheel – If Equipped

F44 –10 Amp Red Diagnostic Port

F46 –10 Amp Red Upfitters Relay Coil – If Equipped

F47 – –Spare

F48 – –Spare

F49 –10 Amp Red IP Cluster / CSG

F50 –20 Amp Yellow Air Suspension Control Module – If Equipped

F51 –10 Amp RedIgnition Node Module / Keyless Ignition Node Module, Radio Frequency

Hub Module / Electric Steering Column Lock - If Equipped

F52 –5 Amp Tan Battery Sensor

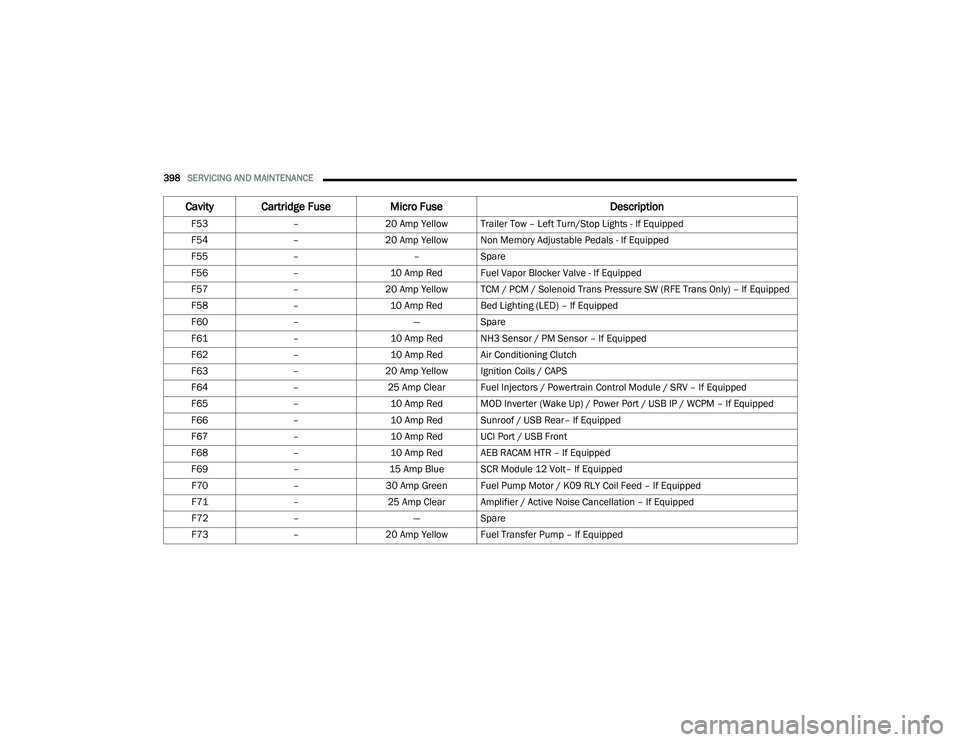

Cavity Cartridge Fuse Micro Fuse Description

8

21_DPF_OM_EN_USC_t.book Page 397

Page 400 of 463

398SERVICING AND MAINTENANCE

F53–20 Amp Yellow Trailer Tow – Left Turn/Stop Lights - If Equipped

F54 –20 Amp Yellow Non Memory Adjustable Pedals - If Equipped

F55 – –Spare

F56 –10 Amp Red Fuel Vapor Blocker Valve - If Equipped

F57 –20 Amp Yellow TCM / PCM / Solenoid Trans Pressure SW (RFE Trans Only) – If Equipped

F58 –10 Amp Red Bed Lighting (LED) – If Equipped

F60 – —Spare

F61 –10 Amp Red NH3 Sensor / PM Sensor – If Equipped

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils / CAPS

F64 –25 Amp Clear Fuel Injectors / Powertrain Control Module / SRV – If Equipped

F65 –10 Amp Red MOD Inverter (Wake Up) / Power Port / USB IP / WCPM – If Equipped

F66 –10 Amp Red Sunroof / USB Rear– If Equipped

F67 –10 Amp Red UCI Port / USB Front

F68 –10 Amp Red AEB RACAM HTR – If Equipped

F69 –15 Amp Blue SCR Module 12 Volt– If Equipped

F70 –30 Amp Green Fuel Pump Motor / K09 RLY Coil Feed – If Equipped

F71 –25 Amp Clear Amplifier / Active Noise Cancellation – If Equipped

F72 – —Spare

F73 –20 Amp Yellow Fuel Transfer Pump – If Equipped

Cavity Cartridge Fuse Micro Fuse Description

21_DPF_OM_EN_USC_t.book Page 398

Page 427 of 463

SERVICING AND MAINTENANCE425

(Continued)

Dual Rear Wheels

Tire Rotation

The tires used on dual wheel assemblies should

be matched for wear to prevent overloading one

tire in a set. To check if tires are even, lay a

straight edge across all four tires. The straight

edge should touch all the tires.

NOTE:

If your vehicle is equipped with a Tire Pressure

Information System (TPIS):

The Tire Pressure Information System (TPIS)

uses unique sensors in the inner rear wheels

to help identify them from the outer rear

wheels, because of this, the inner and outer

wheel locations can’t be switched.

After a tire rotation is completed, as shown

below, the system can auto learn the locations

of each sensor ID. Auto learning/localization

occurs when the vehicle ignition status is

changed from Off to On and speeds of greater

than 5 mph (8 km/h) are obtained and remain

over 5 mph (8 km/h) for at about a 15 minute

period. You may need to drive for 20 minutes

to account slower speeds and stops.

If the tires are rotated incorrectly, the Auto

localization of the TPIS sensors will fail to

locate correctly resulting in incorrect loca -

tions for the pressure values displayed in the

Instrument Cluster.

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES

The following tire grading categories

were established by the National

Highway Traffic Safety Administration.

The specific grade rating assigned by the

tire's manufacturer in each category is

shown on the sidewall of the tires on

your vehicle.

CAUTION!

4500/5500 Dual Rear Tires may only have

one approved direction of rotation. This is

to accommodate the asymmetrical design

(tread pattern) of the On/Off road tire.

When replacing a flat, the spare tire may

have to be remounted on the rim or

installed at a different location to maintain

the correct placement of the tire on the

wheel relative to the tire/wheel position on

the vehicle. For example, if the spare is

used to replace an outer rear tire it will have

to be remounted on the rim so that the

wheel is dished inward. That way the tread

design of asymmetrical tires will maintain

proper position.

CAUTION! (Continued)

8

21_DPF_OM_EN_USC_t.book Page 425

Page 455 of 463

453

Fluid Level Checks Brake

........................................................ 387Power Steering.......................................... 163Fog Lights............................................... 53, 404Fold Flat Load Floor......................................... 70Fold-Flat Seats................................................. 33Forward Collision Warning............................. 281Four Wheel Drive........................................... 153Four-Way Hazard Flasher............................... 334Freeing A Stuck Vehicle................................. 349Front Axle (Differential).................................. 390Fuel............................................ 196, 433, 436Adding....................................................... 195Additives................................................... 434Clean Air.................................................... 433Diesel.............................................. 196, 436Ethanol...................................................... 434Filler Cap (Gas Cap)................................... 196Filter................................................ 375, 440Gasoline.................................................... 433Light.......................................................... 111Materials Added........................................ 434Methanol................................................... 434Octane Rating........................................... 433Requirements................................. 433, 436Specifications............................................ 436Tank Capacity............................................ 439Fuses............................................................. 394

G

Garage Door Opener (HomeLink)..................... 47Gas Cap (Fuel Filler Cap).............................. 196Gasoline, Clean Air........................................ 433Gasoline, Reformulated................................ 433GaugesVoltage..................................................... 128Gear Ranges................................................. 147Gear Selector Override................................. 347Glass Cleaning.............................................. 430Gross Axle Weight Rating.............................. 201Gross Vehicle Weight Rating......................... 201GuideBody Builders.............................................. 10GVWR............................................................ 199

H

HazardDriving Through Flowing, Rising, Or Shallow Standing Water

.................................... 218Hazard Warning Flashers.............................. 334Head Restraints............................................... 38Head Rests...................................................... 38Headlights.................................................... 402Automatic High Beam.................................. 52Cleaning................................................... 427High Beam................................................... 51Lights On Reminder..................................... 53Passing........................................................ 52Switch.......................................................... 50

Heated Mirrors.................................................46Heated Seats...................................................37Hill Descent Control...................................... 278Hill Descent Control Indicator....................... 278Hill Start Assist.............................................. 280HitchesTrailer Towing........................................... 204HomeLink (Garage Door Opener).....................47Hood Prop........................................................79Hood Release...................................................79Hub Caps...................................................... 343

I

Idle-Up Feature............................................. 132Ignition.............................................................18Switch..........................................................18Illuminated Entry..............................................56Inside Rearview Mirror.................... 41, 42, 335Instrument Cluster...................... 85, 86, 88, 89Descriptions.............................................. 115Display.........................................................90Engine Oil Reset..........................................91Instrument Panel Lens Cleaning................... 429Integrated Trailer Brake Control.................... 207Interior Appearance Care.............................. 428Interior Lights...................................................55Intermittent Wipers (Delay Wipers)..................57Intervention Regeneration Strategy..... 101, 379Inverter Outlet (115V)......................................74

11

21_DPF_OM_EN_USC_t.book Page 453