RENAULT KANGOO 1997 KC / 1.G Chassis User Guide

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 11 of 105

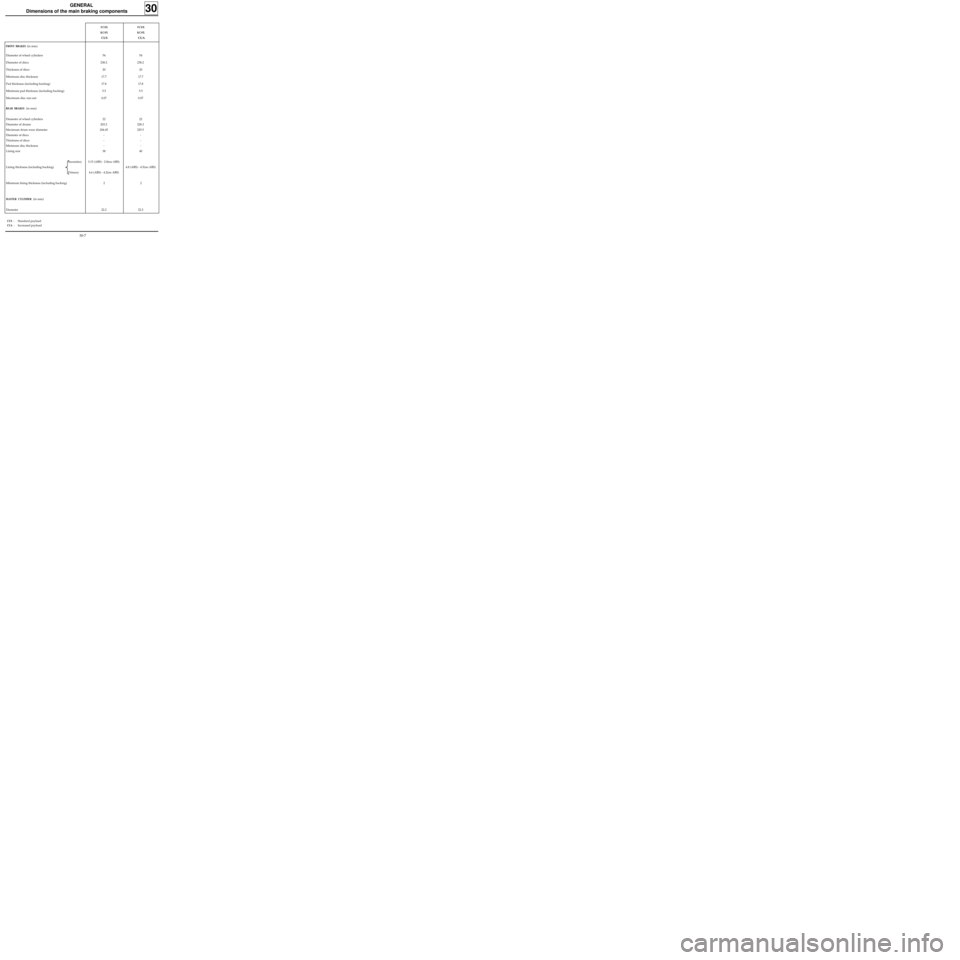

FRONT BRAKES (in mm)

Diameter of wheel cylinders

Diameter of discs

Thickness of discs

Minimum disc thickness

Pad thickness (including backing)

Minimum pad thickness (including backing)

Maximum disc run-out

REAR BRAKES (in mm)

Diameter of wheel cylinders

Diameter of drums

Maximum drum wear diameter

Diameter of discs

Thickness of discs

Minimum disc thickness

Lining size

Secondary

Lining thickness (including backing)

Primary

Minimum lining thickness (including backing)

MASTER CYLINDER (in mm)

Diameter

GENERAL

Dimensions of the main braking components

30

FC0X

KC0X

CUS

FC0X

KC0X

CUA

54

238.2

20

17.7

17.8

5.5

0.07

22

203.2

204.45

-

-

-

38

3.15 (ABS) - 2.8(no ABS)

4.6 (ABS) - 4.2(no ABS)

2

22.254

238.2

20

17.7

17,8

5.5

0.07

22

228.3

229.5

-

-

-

40

4.8 (ABS) - 4.5(no ABS)

2

22.2

CUS : Standard payload

CUA : Increased payload

30-7

Page 12 of 105

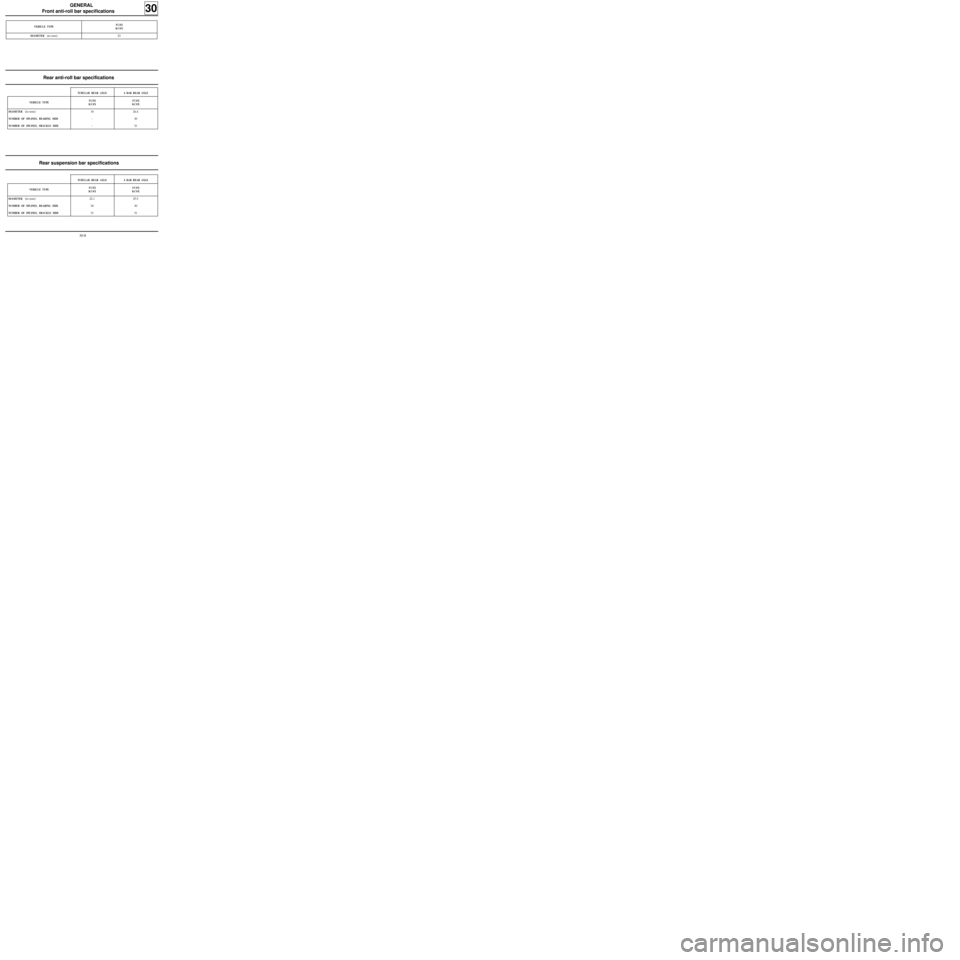

GENERAL

Front anti-roll bar specifications

30

VEHICLE TYPEFC0X

KC0X

DIAMETER

(in mm) 23

Rear anti-roll bar specifications

Rear suspension bar specifications

VEHICLE TYPEFC0X

KC0XFC0X

KC0X

DIAMETER

(in mm)

NUMBER OF SPLINES, BEARING SIDE

NUMBER OF SPLINES, SHACKLE SIDE

18

-

-26.4

30

31

TUBULAR REAR AXLE4 BAR REAR AXLE

VEHICLE TYPEFC0X

KC0XFC0X

KC0X

DIAMETER

(in mm)

NUMBER OF SPLINES, BEARING SIDE

NUMBER OF SPLINES, SHACKLE SIDE

22.1

30

3125.5

30

31

TUBULAR REAR AXLE4 BAR REAR AXLE

30-8

Page 13 of 105

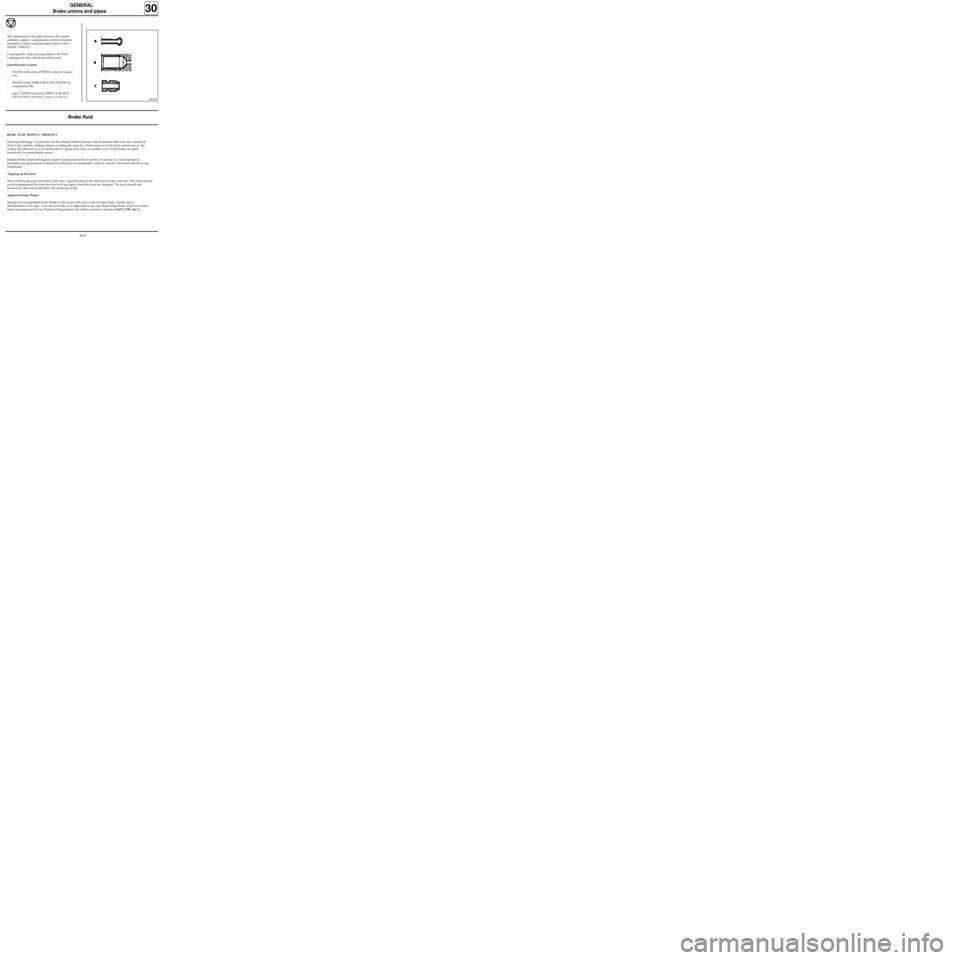

Brake fluid

78491R

GENERAL

Brake unions and pipes

30

The connection of the pipes between the master

cylinder, calipers, compensator and the hydraulic

assembly is made using threaded unions with a

METRIC THREAD.

Consequently, only parts specified in the Parts

Catalogue for this vehicle should be used.

Identification of parts

- SHAPE of the ends of PIPES in steel or copper

(A),

- SHAPE of the THREADED LOCATIONS on

components (B),

- pipe UNIONS coloured GREEN or BLACK:

HEXAGONAL OUTSIDE 11 mm or 12 mm (C).

BRAKE FLUID RENEWAL FREQUENCY

Braking technology, in particular for disc brakes (hollow pistons which transmit little heat, low volume of

fluid in the cylinder, sliding calipers avoiding the need for a fluid reservoir in the least cooled area of the

wheel), has allowed us to avoid the risk of vapour lock as far as possible, even if the brakes are used

intensively (in mountainous areas).

Modern brake fluids still degrade slightly during the first few months of use due to a small uptake of

humidity and replacement of the fluid is therefore recommended (refer to vehicle’s Warranty and Servicing

Handbook).

Topping up the level:

Wear of the brake pads and shoes will cause a gradual drop in the fluid level in the reservoir. This drop should

not be compensated for since the level will rise again when the pads are changed. The level should not

however be allowed to fall below the minimum mark.

Approved brake fluids:

Mixing two incompatible brake fluids in the circuit will cause a risk of major leaks, mainly due to

deterioration of the cups. To avoid such risks, it is important to use only those brake fluids which have been

tested and approved by our Technical Department and which conform to standard SAE J 1703 dot 4.

30-9

Page 14 of 105

FRONT AXLE

Lower wishbone

31

85875R2

12992R

Wheel bolts 9

Lower wishbone nut on sub-frame 9

Key nut on stub-axle carrier 5.5

Anti-roll bar bearing nut 1.5

TIGHTENING TORQUES (in daN.m)

REMOVAL

Put the vehicle on a two post lift.

Remove both wheels.

Remove the mounting nuts for the anti-roll bar on

the lower wishbones.

Release the anti-roll bar downwards.

Remove:

- the nut and key on the stub-axle carrier,

- the two mounting bolts for the wishbone on

the sub-frame,

- the wishbone.

REFITTING

NOTE :

ensure the plastic protective washer ( A ) is

present on the lower ball joint shaft.

Refit:

- the wishbone,

- the two bolts, without tightening them,

- the ball joint shaft in the stub-axle carrier and

tighten the key nut.

Refit the anti-roll bar and fit the mounting nuts

using tool Sus. 1414 (see method in anti-roll bar

section).

This tool allows the rubber mounting to be

compressed to fit the nut.

NOTE : bounce the suspension and tighten the

wishbone and anti-roll bar bearing nuts to the re-

commended torque (tightening position: vehicle

unladen).

31-1

Page 15 of 105

FRONT AXLE

Lower wishbone rubber bushes

31

90404R

REPLACEMENT

To ensure the bushes are correctly positioned in

relation to the lower wishbone, they are replaced

one after the other.

On the press, remove one of the worn bushes

using a tube of external diameter 30 mm.

Refit the new bush, ensuring that dimension A =

146.5 mm.

Remove the second bush on the press and proceed

in the same manner as for the first bush, ensuring

the new bush is fitted so that dimension A =

146.5 mm.

31-2

Page 16 of 105

FRONT AXLE

Lower wishbone ball joint

31

85875R1

Remove:

- the two ball joint mounting bolts (4) ,

- the ball joint.

REFITTING

Note : ensure the plastic protective washer ( A ) is

present on the lower ball joint shaft.

Fit the ball joint and torque tighten the

mountings.

Then proceed in the same manner as for refitting

the lower wishbone.

REMOVAL

If the gaiter is damaged, the complete ball joint

must be replaced.

Proceed in the same manner as for removing the

lower wishbone.

Slacken but do not remove the two mounting

bolts (3) for the wishbone on the sub-frame.

31-3

Page 17 of 105

FRONT AXLE

Brake pads

31

REMOVAL

Disconnect the wear warning light wire (if fitted).

Push the piston back, sliding the caliper by hand.

Remove the lower brake caliper guide bolt.

SPECIAL TOOLING REQUIRED

Fre. 823 Tool for pushing piston back

Wheel bolts 9

Brake caliper guide bolt 4

12994R

REFITTING

Push back the caliper piston using tool Fre. 823.

Fit new brake pads.

The brake pad with the wear warning light wire

(if fitted) is fitted to the inside.

Refit the caliper into position and fit the lower

guide bolt.

Tighten the guide bolt to the recommended

torque 4 daN.m.

Reconnect the wear warning light wire (if fitted).

Press the brake pedal several times to bring the

piston into contact with the pads.

TIGHTENING TORQUES (in daN.m)

Pivot the caliper around the upper bolt.

Remove the brake pads.

Check:

- the condition and mounting of the piston dust

cover,

- the condition of the guide dust cover.

31-4

Page 18 of 105

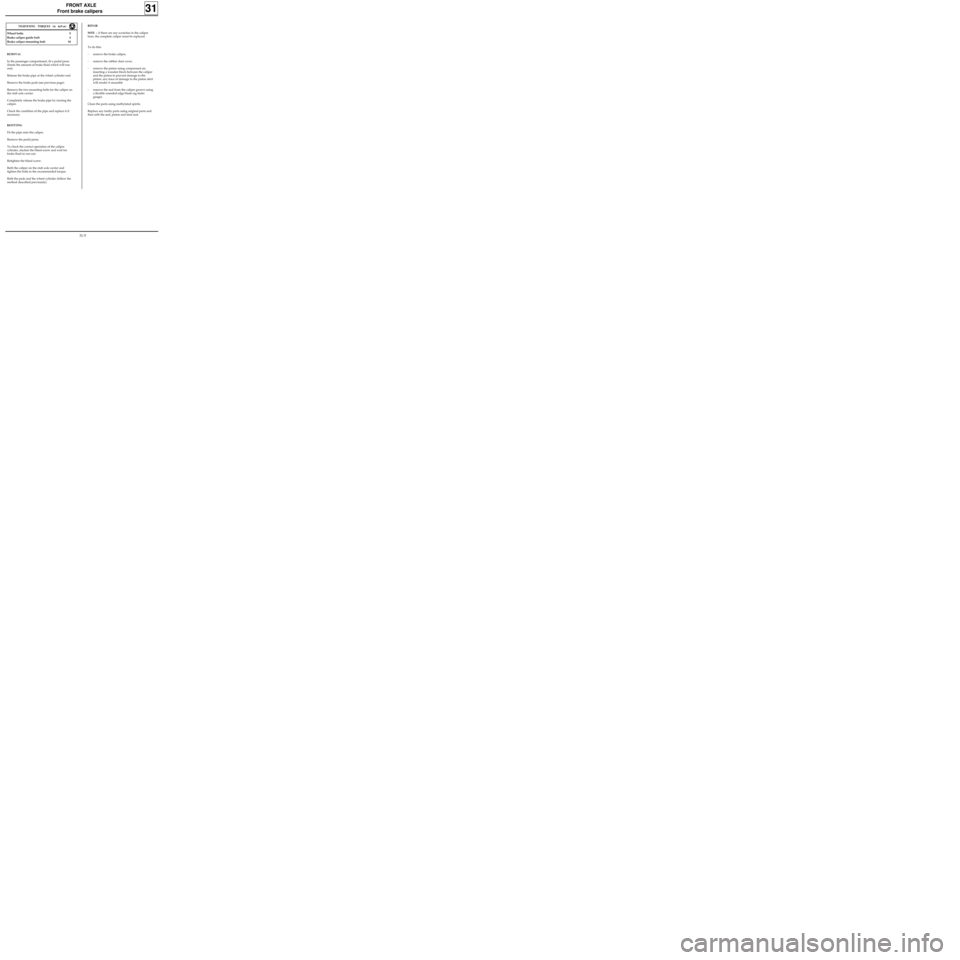

FRONT AXLE

Front brake calipers

31

REPAIR

NOTE :

if there are any scratches in the caliper

bore, the complete caliper must be replaced.

To do this:

- remove the brake caliper,

- remove the rubber dust cover,

- remove the piston using compressed air,

inserting a wooden block between the caliper

and the piston to prevent damage to the

piston: any trace of damage to the piston skirt

will render it unusable

- remove the seal from the caliper groove using

a flexible rounded edge blade (eg feeler

gauge).

Clean the parts using methylated spirits.

Replace any faulty parts using original parts and

then refit the seal, piston and dust seal.

REMOVAL

In the passenger compartment, fit a pedal press

(limits the amount of brake fluid which will run

out).

Release the brake pipe at the wheel cylinder end.

Remove the brake pads (see previous page).

Remove the two mounting bolts for the caliper on

the stub axle carrier.

Completely release the brake pipe by turning the

caliper.

Check the condition of the pipe and replace it if

necessary.

REFITTING

Fit the pipe onto the caliper.

Remove the pedal press.

To check the correct operation of the caliper

cylinder, slacken the bleed screw and wait for

brake fluid to run out.

Retighten the bleed screw.

Refit the caliper on the stub axle carrier and

tighten the bolts to the recommended torque.

Refit the pads and the wheel cylinder (follow the

method described previously).

Wheel bolts 9

Brake caliper guide bolt 4

Brake caliper mounting bolt 10

TIGHTENING TORQUES (in daN.m)

31-5

Page 19 of 105

FRONT AXLE

Brake discs

31

Brake discs cannot be reground. If they are too

heavily worn or are scratched they must be repla-

ced.

Wheel bolts 9

Brake caliper mounting bolt 10

REMOVAL

Remove:

- the two brake assembly mounting bolts

(attach the assembly to the spring),

- the two mounting bolts securing the disc to

the hub,

- the disc.

REFITTING

Refitting is the reverse of removal.

NOTE : when a brake disc is replaced, the pads

must also be renewed.

TIGHTENING TORQUES (in daN.m)

31-6

Page 20 of 105

FRONT AXLE

Stub axle carrier bearing

31

SPECIAL TOOLING REQUIRED

Rou. 15 -01 Shaft protector

Rou. 604 -01 Hub locking tool

T.Av.476 Ball joint extractor

T.Av. 1050-02 Tool for pushing driveshaft back

Driveshaft nut 28

Wheel bolts 9

Shock absorber base nut 18

Brake caliper mounting bolt 10

Track rod end nut 3.7

Key nut on stub axle carrier 5.5

83348G

REMOVAL

Disconnect the battery.

Remove:

- the wheel,

- the brake caliper and attach it to the spring so

the pipe is not damaged,

- the track rod end using tool

T.Av. 476,

- the driveshaft nut.

Push back the driveshaft using tool :

T. Av. 1050-02.

Remove:

- the brake disc,

- the lower ball joint nut and key,

- the two shock absorber base bolts,

- the hub / stub axle carrier / bearing assembly.

TIGHTENING TORQUES (in daN.m)Remove the hub on the press.

Remove the lower bush from the hub using an ex-

tractor with jaws and tool Rou. 15-01.

Remove the locking spring ring from the stub axle

carrier.

On the press remove the remainder of the bea-

ring, taking care to take the weight on the inner

bush using a tube of the same diameter.

31-7