RENAULT KANGOO 1997 KC / 1.G Chassis Owner's Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 105

Page 21 of 105

FRONT AXLE

Stub axle carrier bearing

31

79057S

REFITTING

Fit the bearing on the press, into the stub axle car-

rier using a tube of external diameter

70 mm and bore 66 mm, taking the weight on the

external bush.

IMPORTANT: do not take the weight on the inter-

nal bush to avoid damaging the bearing as the

force required to push the bearing on is quite

considerable.

79058-1S

Fit a new locking spring ring.

Coat each sealing lip of the bearing with multi-

purpose grease.

Fit on the press, using a tube of external diameter

48 mm and internal diameter 42 mm, taking the

weight on the inner bearing bush.

85902S1

Refit the hub / stub axle carrier / bearing assembly

to the vehicle.

Refitting is then the reverse of removal. Observe the

correct tightening torques.

31-8

Page 22 of 105

Spring compressor

FRONT AXLE

Spring and shock absorber assembly

31

Shock absorber base mounting bolt 18

Rebound stop nut 6

Wheel bolts 9

REMOVAL

Put the vehicle on a four post lift.

Remove:

- the wheels,

- the shock absorber base mounting bolts.

NOTE : release the ABS sensor wiring if this is

fitted on the base of the shock absorber.

Remove the upper shock absorber nut in the

engine compartment.

Remove the shock absorber and spring assembly.

TIGHTENING TORQUES (in daN.m)

EQUIPMENT REQUIRED

Replacing a shock absorber

When replacing a shock absorber, fit it in a vice

and compress the spring using the spring

compressor tool.

Remove the spring retaining nut.

Remove the spring and the intermediate parts.

If necessary, replace the shock absorber pad and

the rotating stop.

When refitting, ensure all components are

replaced in the correct location and then

decompress the spring.

NOTE : apply grease between the ends of the

spring and its stops.

REFITTING

Refitting is then the reverse of removal. Observe

the correct tightening torques.

31-9

Page 23 of 105

FRONT AXLE

Anti-roll bar

REFITTING

Refit:

- the rubber mounting nuts using tool

Sus. 1414,

31

REMOVAL

Put the vehicle on a four post lift.

Remove:

- the two lower bolts from the exhaust

downpipe,

- the two sub-frame reinforcements (4 bolts),

12993-1R

Central bearing bolt 3

Rubber mounting nut 1.5

TIGHTENING TORQUES (in daN.m)

SPECIAL TOOLING REQUIRED

Sus. 1413 Central bearing compressor

Sus. 1414 Rubber mounting compressor

- the two rubber mounting nuts at the ends of

the anti-roll bar,

- the two bolts from the central bearings on the

bar.

Check the condition of the bearings and the

rubber mountings and replace them if necessary.

12992R

31-10

Page 24 of 105

FRONT AXLE

Anti-roll bar

31

- the central bearing bolts using tool

Sus. 1413.

12991R

- the two sub-frame reinforcements,

- the lower bolts on the exhaust downpipe.

Rubber bush locking position :

UNLADEN.

31-11

Page 25 of 105

FRONT AXLE

Engine sub-frame

Remove:

- the two nuts for the steering rack heat shield,

- the mounting nuts for the steering rack and

attach it to the exhaust manifold.

31

12988R

SPECIAL TOOLING REQUIRED

Mot. 1040 -01 Dummy sub-frame for removing/refitting engine/transmission assembly

T. Av. 476 Ball joint extractor

REMOVAL

Disconnect the battery.

Put the vehicle on a two post lift.

Remove the wheels.

Disconnect the track rod ends using tool T. Av.

476.

Remove the key on the stub axle carrier.

Release but do not remove the mudguards to

reach the upper bolt on the sub-frame - side mem-

ber tie rod and remove it.

Remove:

- the exhaust downpipe and attach the catalytic

converter,

- the bolt (engine side) for the engine tie bar.

- the gear control by removing the two bolts at

the ends of the control. To do this, the cataly-

tic converter heat shield must be removed and

the gaiter on the gearbox side must also be re-

moved.

TIGHTENING TORQUES (in daN.m)

Wheel bolts 9

Track rod end nut 3.7

Steering universal joint bolt 2.5

Sub-frame mounting bolt front Ø10 6

rear Ø 12 10.5

Sub-frame - side member tie rod nut 3

Key nut on stub axle carrier 5.5

Engine tie bar 6.5

Steering box mounting bolt 5

Fit tool Mot. 1040-01 under the engine sub-frame.

12993-1R1

31-12

Page 26 of 105

FRONT AXLE

Engine sub-frame

31

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts.

Carefully raise the lift.

REFITTING

Systematically renew the engine sub-frame moun-

ting bolts and ensure they are tightened to the

correct torque.

Refitting is the reverse of removal.

NOTE : the engine sub-frame is fitted to the body

in the following manner.:

- fit 2 pins in place of the front mounting bolts,

- offer up the sub-frame,

- tighten, but do not lock, the rear mounting

bolts (begin with the longest rear right hand

bolt),

- replace the pins with mounting bolts at the

front,

- tighten the four mounting bolts to the correct

torque, beginning at the rear,

- ensure the heat shields are correctly refitted.

31-13

Page 27 of 105

REAR AXLE

Rear axle assembly

TIGHTENING TORQUES (in daN.m)

Bearing mounting nut 11

Wheel bolt 9

Shock absorber base bolt 8.5

REMOVAL

Put the vehicle on a two post lift.

Fit the pedal press.

Remove:

- the two lower shock absorber mountings,

- the brake pipes,

- the compensator control,

- the central heat shield,

- the handbrake cables, disconnecting them

from the central control,

Unclip the cables from the fuel tank.

Support the rear axle assembly and remove the

nuts ( 1 ).

Remove the rear axle assembly.

NOTE : the bolts can be reached under the rear

bench seat (depending on version) after

removing the blanking covers.

REFITTING

Refitting is the reverse of removal.

Bleed the brake circuit.

Adjust the handbrake (see section 37).

Check and if necessary adjust the braking

compensator ( see section 37 ).

33

13132R

33-1

Page 28 of 105

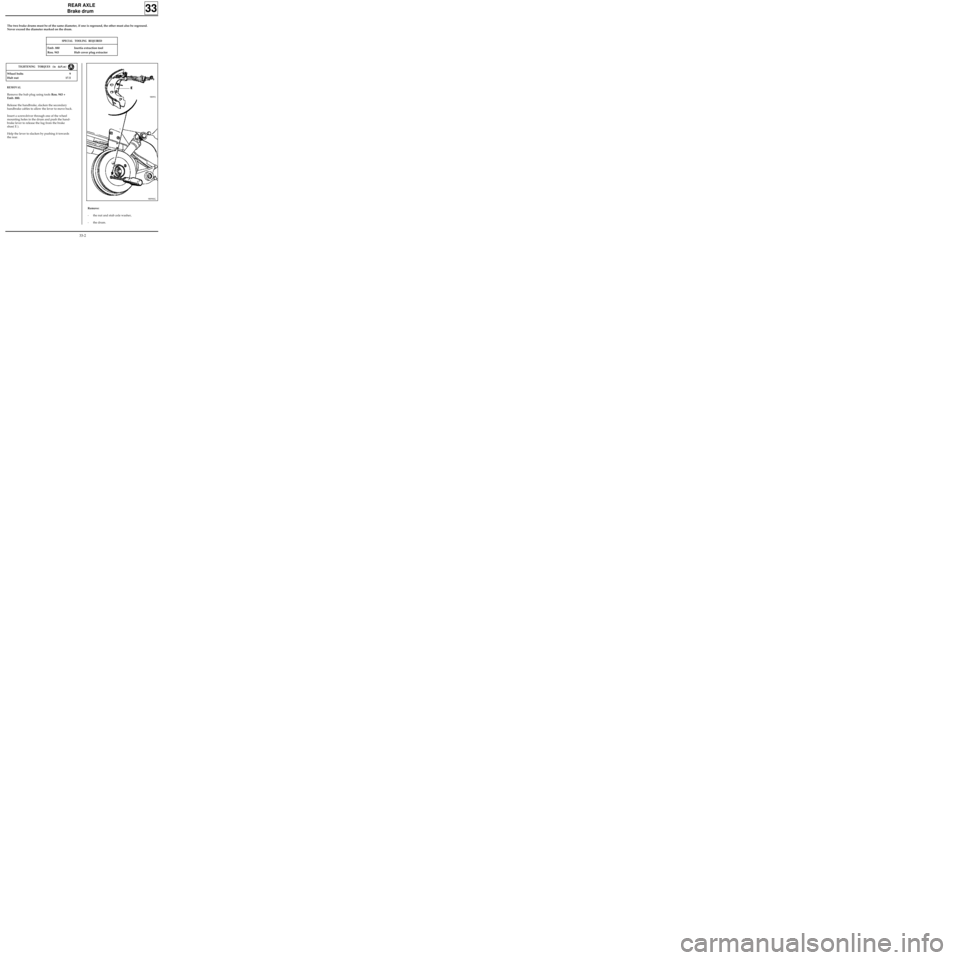

98991

REAR AXLE

Brake drum

Remove:

- the nut and stub axle washer,

- the drum.

The two brake drums must be of the same diameter, if one is reground, the other must also be reground.

Never exceed the diameter marked on the drum.

SPECIAL TOOLING REQUIRED

Emb. 880 Inertia extraction tool

Rou. 943 Hub cover plug extractor

TIGHTENING TORQUES (in daN.m)

Wheel bolts 9

Hub nut 17.5

REMOVAL

Remove the hub plug using tools Rou. 943 +

Emb. 880.

Release the handbrake, slacken the secondary

handbrake cables to allow the lever to move back.

Insert a screwdriver through one of the wheel

mounting holes in the drum and push the hand-

brake lever to release the lug from the brake

shoe( E ).

Help the lever to slacken by pushing it towards

the rear.

33

98990G

33-2

Page 29 of 105

REAR AXLE

Brake drum

REFITTING

Remove all dust from the drum and the linings

using brake cleaner.

Fit:

- the drum,

- the washer and the nut, which must be torque

tightened,

- the plug.

Adjust:

- the linings by repeatedly pressing the brake

pedal,

- the handbrake (see section 37 "Controls").

33

33-3

Page 30 of 105

REAR AXLE

Brake cylinder

REFITTING

Remove all dust from the drums and the linings

using brake cleaner.

Refitting is the reverse of removal.

Bleed the braking circuit (see section 38).

Adjust the linings by repeatedly pressing the

brake pedal.

Check the cut-out pressure (see section 37

"Controls").

TIGHTENING TORQUES (in daN.m)

Wheel bolts 9

Hub nut 17.5

Bleed screw 0.5 to 0.8

Pipe bolt 1.7

REMOVAL

Remove:

- the drum (see corresponding section),

- the upper return spring (see paragraph

"Brake linings").

Separate the shoes.

Slacken:

- the rigid pipe union on the wheel cylinder

using a pipe wrench,

- the two cylinder mounting bolts on the

backing plate and remove it.

Check the condition of the shoes. If they have

traces of oil on them, renew them.

33

33-4