engine RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 137 of 208

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

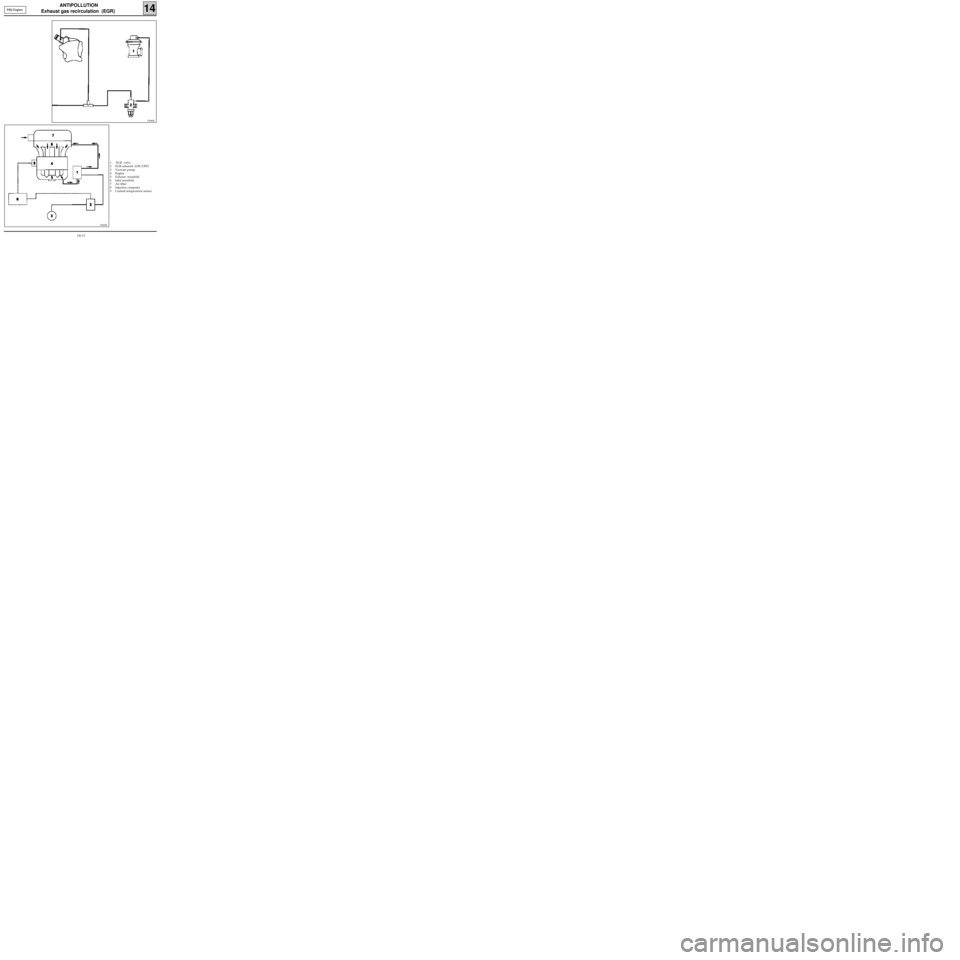

1 EGR valve

2 EGR solenoid (ON/OFF)

3 Vacuum pump

4 Engine

5 Exhaust manifold

6 Inlet manifold

7 Air filter

8 Injection computer

9 Coolant temperature sensor

13046R

F8Q Engine

13045R

14-11

Page 138 of 208

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

SPECIAL NOTES

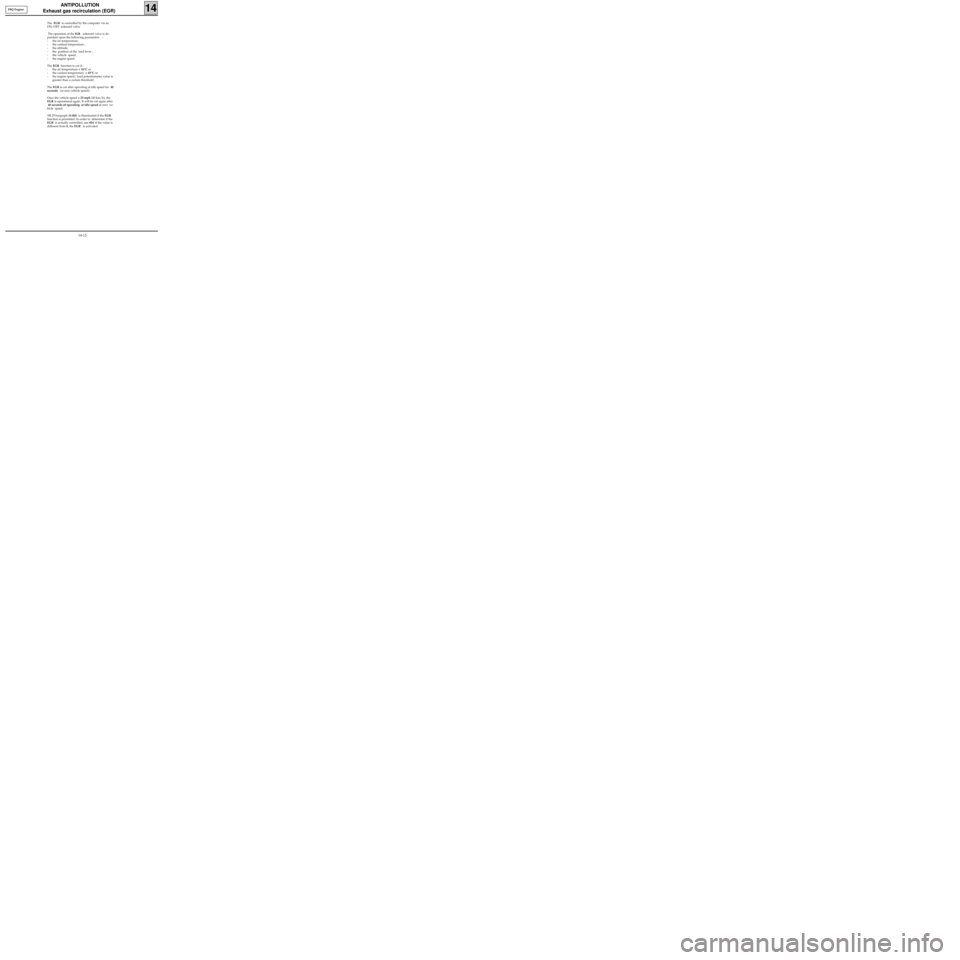

In order to remove the steel pipe connecting the

EGR valve to the air filter, it is necessary to

remove the

EGR valve .

12871R1

F8Q Engine

13047-1R2

To remove the EGR solenoid (2), remove the air

filter .

To remove the

EGR valve (1), remove the air filter

first, and replace the seal between the solenoid

valve and the inlet manifold after each removal

operation.

14-12

Page 139 of 208

ANTIPOLLUTION

Exhaust gas recirculation (EGR)

14

The EGR is controlled by the computer via an

ON/OFF solenoid valve.

The operation of the

EGR solenoid valve is de-

pendent upon the following parameters :

- the air temperature,

- the coolant temperature ,

- the altitude,

- the position of the load lever ,

- the vehicle speed ,

- the engine speed .

The EGR function is cut if :

- the air temperature < 16°C or

- the coolant temperature < 45°C or

- the engine speed/ load potentiometer value is

greater than a certain threshold .

The EGR is cut after operating at idle speed for 40

seconds (at zero vehicle speed).

Once the vehicle speed > 25 mph (40 km/h), the

EGR is operational again. It will be cut again after

40 seconds of operating at idle speed at zero ve-

hicle speed.

XR 25 bargraph 14 RH is illuminated if the EGR

function is permitted. In order to determine if the

EGR is actually controlled, use #24. if the value is

different from 0, the EGR is activated . F8Q Engine

14-13

Page 140 of 208

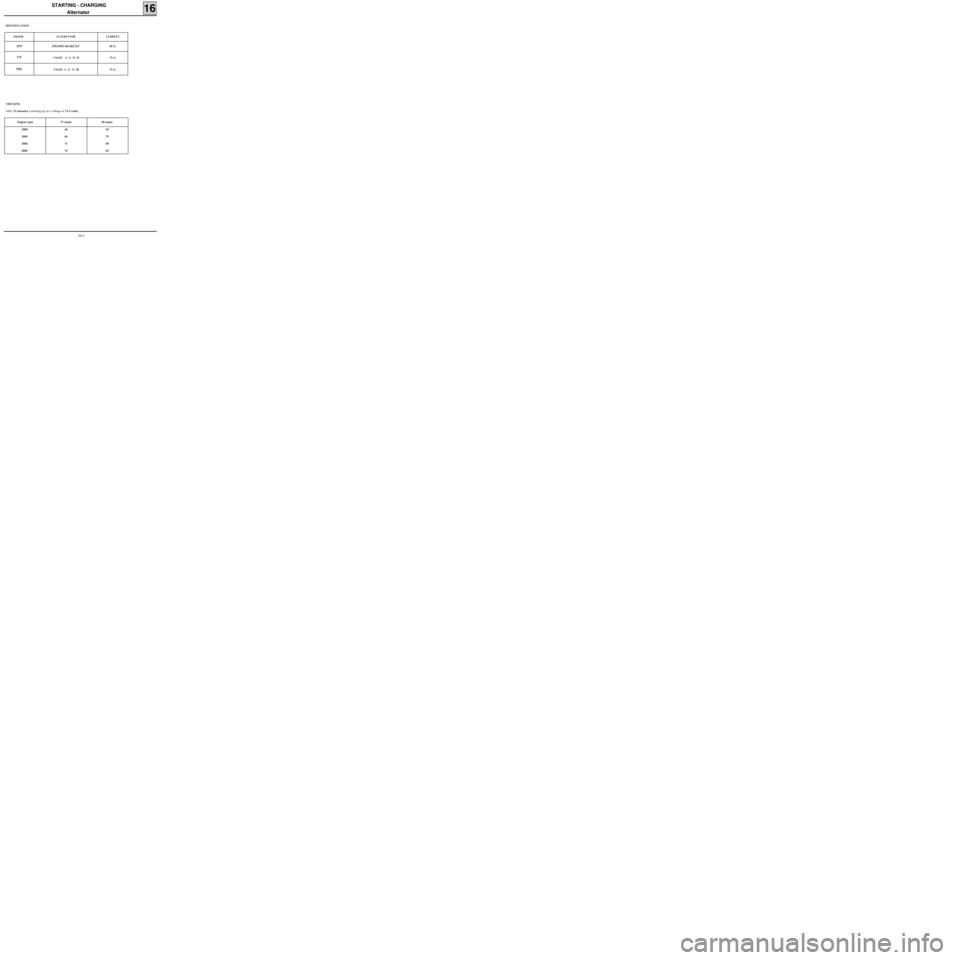

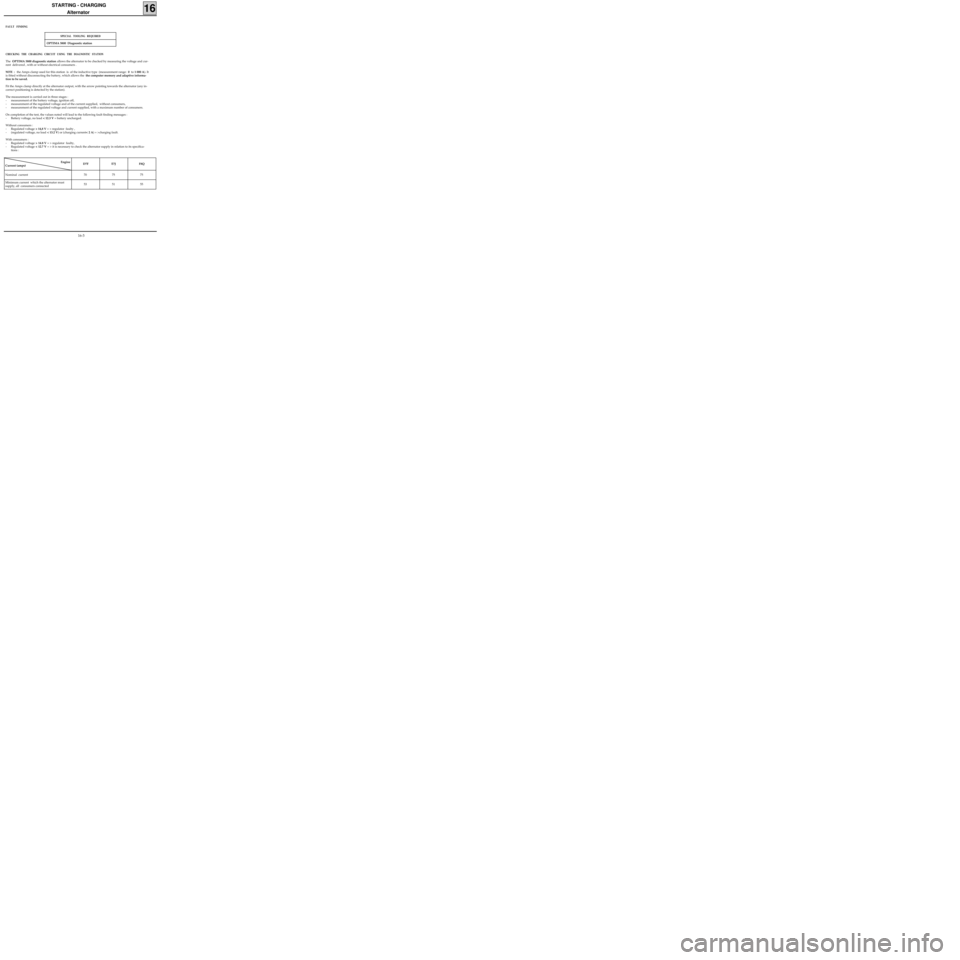

CHECKING

After 15 minutes warming up at a voltage of 13.5 volts.

STARTING - CHARGING

Alternator

16

IDENTIFICATION

ENGINE ALTERNATOR CURRENT

D7F DELPHI 104 802 215 80 A

E7J

VALEO A 11 VI 8775 A

F8Q

VALEO A 11 VI 8875 A

Engine rpm 75 amps 80 amps

1000

2000

3000

400046

68

71

7254

75

80

82

16-1

Page 141 of 208

STARTING - CHARGING

Alternator

16

OPERATION - FAULT FINDING

These vehicles are equipped with alternators with

internal ventilation and integral regulator, also

with a warning light on the instrument panel

which has the following functions :

- when the ignition is switched on, the light illu-

minates

- when the engine is started the light extin-

guishes,

- if the light illuminates whilst the engine is

running there is a "charging "fault.

LOOKING FOR FAULTS

The warning light does not illuminate when the

ignition is switched on.

Check:

- all electrical connections are good.

- the bulb has not blown. (Earth the circuit and

the bulb should illuminate).

The warning light illuminates when the engine is

running.

This indicates a charging fault which could be

caused by :

- the alternator drive belt being broken or the

charging wiring being cut,

- internal alternator damage (rotor, stator,

diodes or brush),

- a regulator fault,

- excess voltage.The customer complains of a lack of charge and

the warning light is operating correctly.

If the regulated voltage is less than 13.5 V, check

the alternator. The fault could be caused by :

- a diode which has been damaged,

- a phase which is cut,

- contaminated or worn tracks.

Checking the voltage

Connect a voltmeter across the battery terminals

and read the battery voltage.

Start the engine and increase the engine speed

until the needle registers a stable regulated

voltage.

This voltage should be between 13.5 V and 14.8 V.

Connect as many consumers as possible, the

regulated voltage should be between 13.5 V and

14.8 V.

IMPORTANT: if arc welding work is to be carried

out on the vehicle, the battery and regulator

must be disconnected.

16-2

Page 142 of 208

STARTING - CHARGING

Alternator

16

OPTIMA 5800 Diagnostic station

CHECKING THE CHARGING CIRCUIT USING THE DIAGNOSTIC STATION

The OPTIMA 5800 diagnostic station allows the alternator to be checked by measuring the voltage and cur-

rent delivered , with or without electrical consumers .

NOTE : the Amps clamp used for this station is of the inductive type (measurement range: 0 to 1 000 A). It

is fitted without disconnecting the battery, which allows the the computer memory and adaptive informa-

tion to be saved.

Fit the Amps clamp directly at the alternator output, with the arrow pointing towards the alternator (any in-

correct positioning is detected by the station).

The measurement is carried out in three stages :

- measurement of the battery voltage, ignition off,

- measurement of the regulated voltage and of the current supplied, without consumers,

- measurement of the regulated voltage and current supplied, with a maximum number of consumers.

On completion of the test, the values noted will lead to the following fault finding messages :

- Battery voltage, no load < 12.3 V = battery uncharged.

Without consumers :

- Regulated voltage > 14,8 V = > regulator faulty ,

- (regulated voltage, no load < 13.2 V) or (charging current< 2 A) = >charging fault.

With consumers :

- Regulated voltage > 14.8 V = > regulator faulty,

- Regulated voltage < 12.7 V = > it is necessary to check the alternator supply in relation to its specifica-

tions :

Engine

Current (amps)D7F E7J F8Q

Nominal current 70 75 75

Minimum current which the alternator must

supply, all consumers connected 53 51 55

FAULT FINDING

SPECIAL TOOLING REQUIRED

16-3

Page 143 of 208

STARTING - CHARGING

Alternator

16

If the electrical supply measured is too low, check:

- the wear of the alternator (brush...),

- the battery connections,

- the engine earth strap,

- the conformity of the alternator,

- the belt tension.

If the electrical supply measured is correct and the regulated voltage is too low, the alternator is not faulty.

The cause of the problem is to be attributed to one of the following sources :

- the vehicle has too many electrical consumers,

- the battery is discharged.

FAULT FINDING (continued)

16-4

Page 144 of 208

STARTING-CHARGING

Alternator

16

REMOVAL

Place the vehicle on a two post lift .

Disconnect the battery as well as all electrical

connections leading to the alternator.

Remove :

- the alternator belt and that of the power as-

sisted steering pump for the D7F engine (if

fitted),

- the alternator.

REFITTING

Refitting is the reverse of removal.

D7F Engine

Tensioning of the alternator belt is carried out

using the locally manufactured tool shown be-

low (threaded rod 100 mm in length (X) and three

M6 nuts).

D7F / E7J

Engines

SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

10617R

E7J Engine

Tension the belt using the bolt at (1) and tighten

the nut at (2) , having measured the tension.

13363R

See section 07 "Accessories belt tension" for the

tension values.

16-5

Page 145 of 208

STARTING-CHARGING

Alternator

16

REMOVAL

Place the vehicle on a two post lift.

Disconnect the battery as well as all electrical

connections leading the alternator.

Remove :

- the front right wheel arch,

- the alternator mountings as well as the belt,

- the support (A),

SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

13092R

- the cross member mounting bolts and remove

it in order to remove the alternator.

13188S

REFITTING

Refitting is the reverse of removal.

See section 07 "Accessories belt tension" for the

tension values. F8Q Engine

16-6

Page 146 of 208

STARTING - CHARGING

Starter motor

16

ENGINE STARTER MOTOR

D7FVALEO D7 E1

Bosch 0001116001

E7J

D6 RA 73

F8Q Bosch 0001108180

IDENTIFICATION

16-7