engine RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 92 of 208

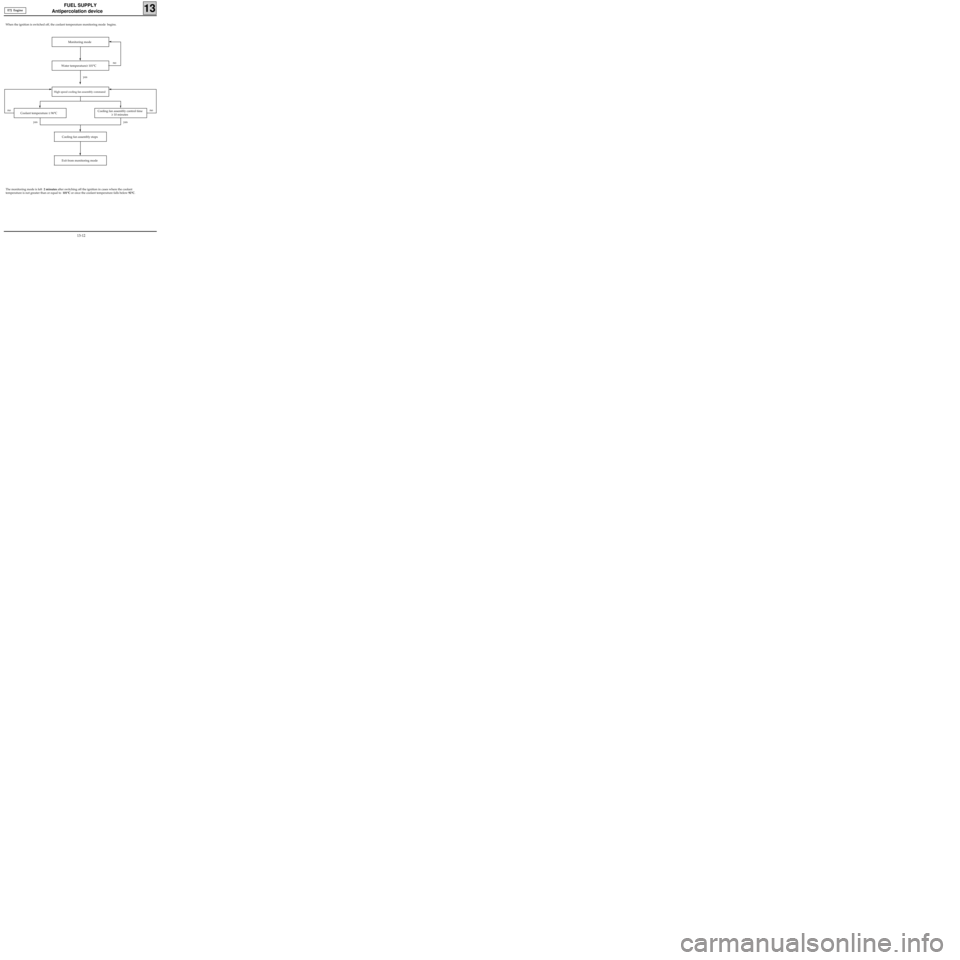

FUEL SUPPLY

Antipercolation device

13

When the ignition is switched off, the coolant temperature monitoring mode begins.

E7J Engine

Monitoring mode

Water temperature≥ 101°C

Coolant temperature ≤ 96°C Cooling fan assembly control time

≥ 10 minutes

Cooling fan assembly stops

Exit from monitoring mode

The monitoring mode is left 2 minutes after switching off the ignition in cases where the coolant

temperature is not greater than or equal to 101°C or once the coolant temperature falls below 92°C.

no

yes

nono

yes yes

High speed cooling fan assembly command

13-12

Page 93 of 208

DIESEL EQUIPMENT

General

13

The use of electronic injection in Diesel engines has allowed the operational power of these engines to be

optimised, thus reducing the emission rate of pollutant gases.

The system consists of a computer, which receives information from:

- the coolant temperature sensor,

- the air temperature sensor,

- the engine speed sensor,

- the vehicle speed sensor,

- the load potentiometer,

- the injection start sensor, which forms part of the injector of cylinder n° 3 (injector with sensor).

It controls :

- the injection pump :

• the altimetric corrector (F8Q 630) via a relay

• the advance solenoid valve.

- the cold engine starting system (heater plugs and pre-postheating unit),

- the exhaust gas recycling system (EGR),

- the diesel injection fault warning light,

- the preheating warning light,

- the solenoid valve controlling the fast idle speed LDA,

- the relay controlling the power assisted steering electric pump assembly (for vehicles with air conditio-

ning), the pump assembly is supplied once the engine speed exceeds 650 rpm.

It carries out a self diagnosis procedure which may be visualised through the

XR25.

SPECIAL FEATURES

On the injection pump it is possible to replace:

- the load potentiometer,

- the advance solenoid valve,

- the altimetric corrector,

- the electrical solenoid.

13-13

Page 94 of 208

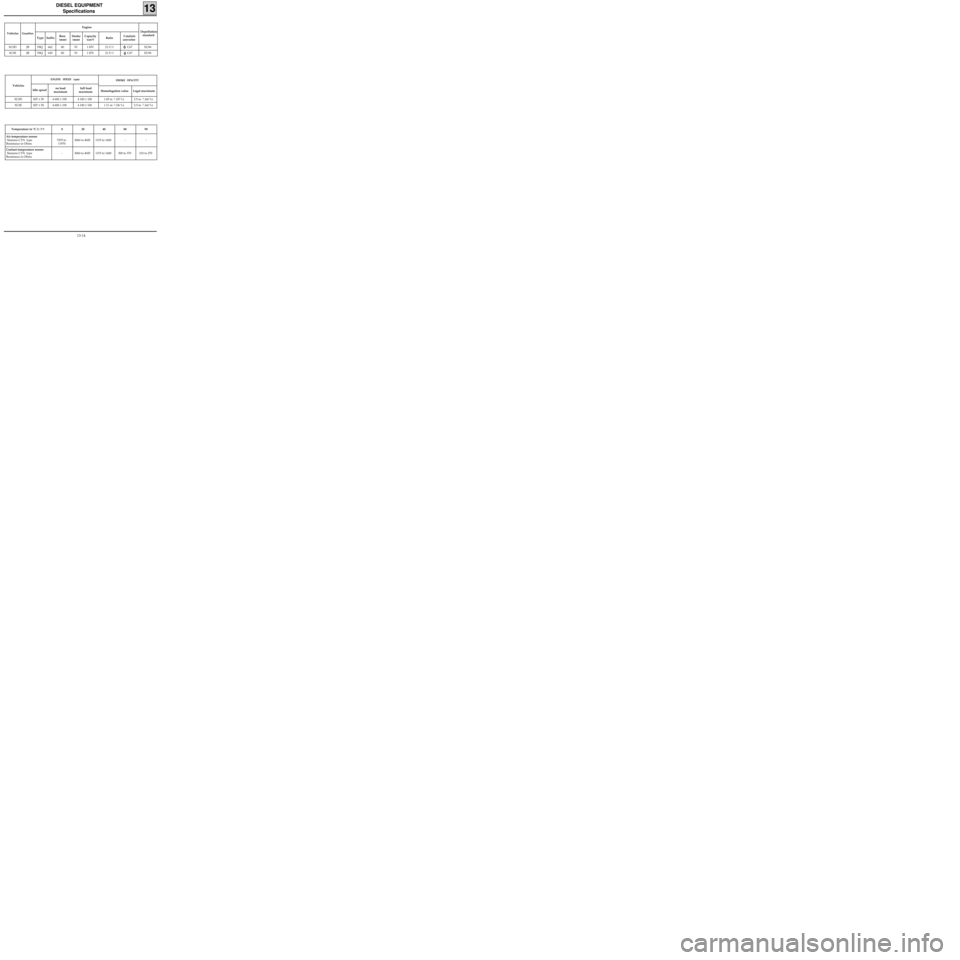

DIESEL EQUIPMENT

Specifications

13

Vehicles GearboxEngine

Type SuffixBore

(mm)Stroke

(mm)Capacity

(cm

3)RatioCatalytic

converterDepollution

standard

XC0D JB F8Q 662 80 93 1 870 21.5/1 C67 EU96

XC0E JB F8Q 630 80 93 1 870 21.5/1 C67 EU96

Vehicles

ENGINE SPEED (rpm)

Idle speedno load

maximumfull load

maximum

SMOKE OPACITY

Homologation value Legal maximum

XC0D 825 ± 50 4 600 ± 100 4 100 ± 100 1.05 m

-1 (35 %) 2.5 m -1 (64 %)

XC0E 825 ± 50 4 600 ± 100 4 100 ± 100 1.11 m

-1 (36 %) 2.5 m -1 (64 %)

Temperature in °C (± 1°) 0 20 40 80 90

Air temperature sensor

Siemens CTN type

Resistance in Ohms7470 to

119703060 to 4045 1315 to 1600 - -

Coolant temperature sensor

Siemens CTN type

Resistance in Ohms- 3060 to 4045 1315 to 1600 300 to 370 210 to 270

13-14

Page 98 of 208

DIESEL EQUIPMENT

Location of components

13

20 EGR valve

13047-1R

7Engine speed sensor

13048R

87970R

17Diesel injection fault warning light

18Preheating warning light

Warning light illuminates when ignition is

switched on during preheating phase.

12839S

C Power assisted steering pump assembly relay

HAltimetric corrector relay

LInjection locking relay

MDiesel heating relay

13-18

Page 101 of 208

DIESEL EQUIPMENT

Advance solenoid valve

13

ITB191917

REFITTING

It is VITAL to remove the small filter (3) situated at

the bottom of the system, using a pair of thin-

nose pliers, and replace with a new filter.

The outer part serves as a seal and locks on

tightening the actuator.

Replace, in the following order : the seal at (4) of

the "banjo" return connection (5) ; the new

activator (1) fitted with an external filter, along

with the the two seals at (6) and (7).

Tighten the actuator to a torque of 3 daN.m

using socket Mot. 997-01.

Place the new protective cover (2)on the actuator.

Reconnect the two terminals to the connector.

Reconnect the connector itself.

Replace the protective sheath on the wiring,

along with the retaining clip.Bleed the diesel circuit using the priming pump

before starting the engine.

It is IMPERATIVE to erase the computer memory

by pressing G0**.

It is vital to road test the vehicle after the

operation.

13127R

13-21

Page 104 of 208

DIESEL EQUIPMENT

Altimetric corrector

13

REFITTING

It is VITAL to remove the small filter (2) situated at

the bottom of the system using a pair of thin -

nosed pliers, and replace it with a new one.

Tighten the actuator (1) to a torque of 3 daN.m

using the socket Mot. 1440.

Place a new protective cover on the actuator.

Reconnect the two terminals to the connector.Reconnect the connector.

Replace the protective sheath on the wiring,

along with the retaining clip.

Bleed the diesel circuit using the priming pump

before starting the engine.

It is IMPERATIVE to erase the computer memory

by pressing G0**.

It is vital to road test the vehicle after this

operation.

13128R

F8Q 662

FUNCTION : it acts on the flow in proportion to altitude ; if the vehicle is running at

an altitude greater than or equal to 1 000 metres, the computer reduces the flow by

3 mm

3/stroke. The conventional flow is reestablished if the vehicle runs at an alti-

tude lower than 900 metres.

13-24

Page 107 of 208

DIESEL EQUIPMENT

Coded solenoid valve

13

On this type of vehicle, the replacement of the

solenoid valve and of the coded electronic unit (A)

requires the removal of the injection pump from

the engine.

REMOVAL

With the pump on the bench, remove the protec-

tive fittings at (B).

These are secured by shear bolts which may be re-

moved either :

- using a small cold chisel or a punch and hitting

on the conical heads of bolts (C), (D) and (E)

to loosen them,

- using tool Mot. 1372 for bolt (F), drilling it

using the 4 mm diameter drill (drilling depth

approximately 4 mm) and the large diameter

drilling guide tube on the fitting side (2).

Use extractor (3) and its handle to remove it .

REFITTING

Tighten the fuel cut off solenoid valve to a torque

of 2 daN.m.

Refit a heat shrink cover on the fuel cut off sole-

noid, ensuring the wiring is correctly routed.

Refit the fittings using shear bolts and observing

their location and that of the spacers,

(depending on fitting).

IMPORTANT : using a torque wrench, tighten the

bolts, then remove the bolt heads by bending

them using a tube inserted in the bolt heads.

Location of bolts :

D :

∅ 5 x 25 mm ; torque =0.55 daN.m

C and F :

∅ 6 x 40 mm ; torque =1.2 daN.m

E :

∅ 5 x 33 mm ; torque =0.55 daN.m

Refit the cable of the fast idle speed LDA and

tighten the cable grip, leaving 2 mm play.

Refit the injection pump on the engine.

13-27

Page 112 of 208

DIESEL EQUIPMENT

Injection warning light

13

OPERATING PRINCIPLE OF THE DIESEL INJECTION WARNING LIGHT ON THE INSTRUMENT PANEL

On switching on the ignition, the diesel injection fault warning light is illuminated. It extinguishes as the en-

gine begins to run.

•Fault in a component of the injection assembly

Faults in the following components may cause the warning light to illuminate :

- injector with sensor

- advance solenoid valve,

- engine speed sensor ,

- load lever potentiometer,

- pre-postheating (according to version).

13-32

Page 113 of 208

DIESEL EQUIPMENT

Pre-postheating control

13

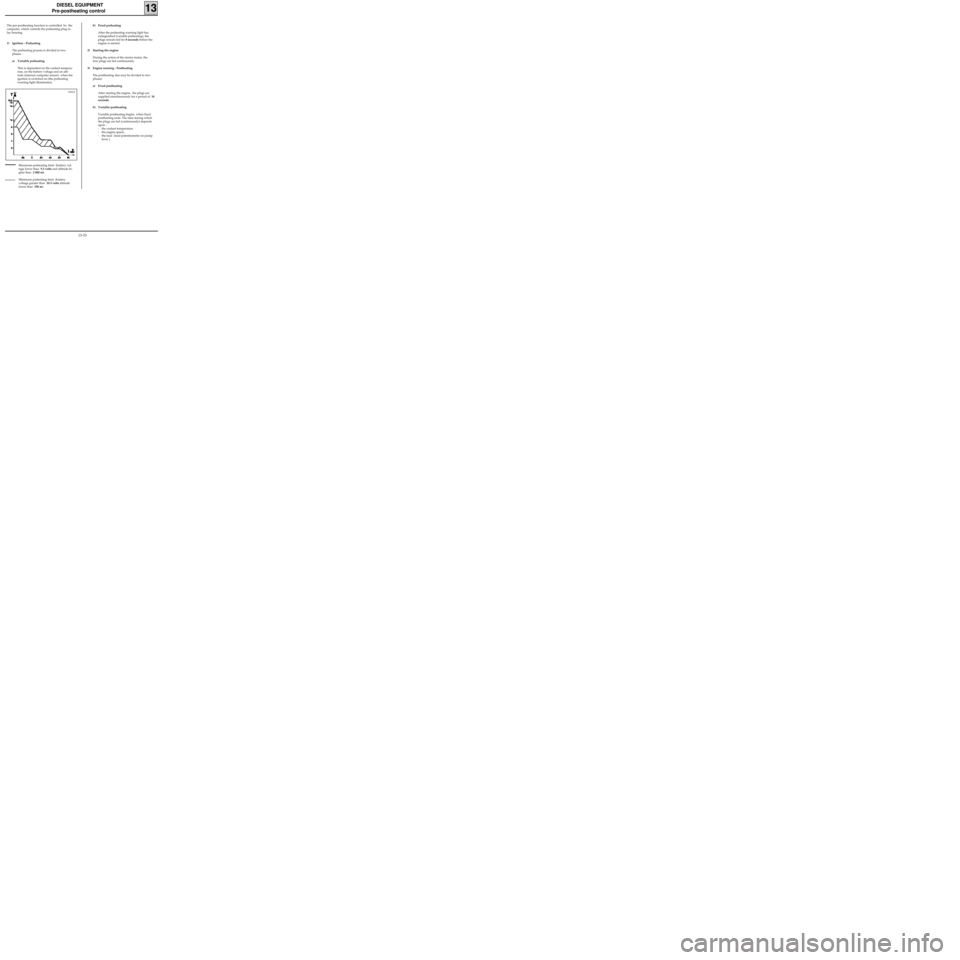

The pre-postheating function is controlled by the

computer, which controls the preheating plug re-

lay housing.

1) Ignition - Preheating

The preheating process is divided in two

phases :

a) Variable preheating

This is dependent on the coolant tempera-

ture, on the battery voltage and on alti-

tude (internal computer sensor) when the

ignition is switched on (the preheating

warning light illuminates).b) Fixed preheating

After the preheating warning light has

extinguished (variable preheating), the

plugs remain fed for 8 seconds before the

engine is started.

2) Starting the engine

During the action of the starter motor, the

four plugs are fed continuously.

3) Engine running - Postheating

The postheating also may be divided in two

phases:

a) Fixed postheating

After starting the engine, the plugs are

supplied simultaneously for a period of 10

seconds.

b) Variable postheating

Variable postheating begins when fixed

postheating ends. The time during which

the plugs are fed (continuously) depends

upon :

- the coolant temperature

- the engine speed ,

- the load (load potentiometer on pump

lever ).

Maximum preheating limit (battery vol-

tage lower than 9.3 volts and altitude hi-

gher than 2 000 m).

Minimum preheating limit (battery

voltage greater than 10.5 volts altitude

lower than 350 m).

13041S

13-33

Page 114 of 208

DIESEL EQUIPMENT

Pre-postheating control

13

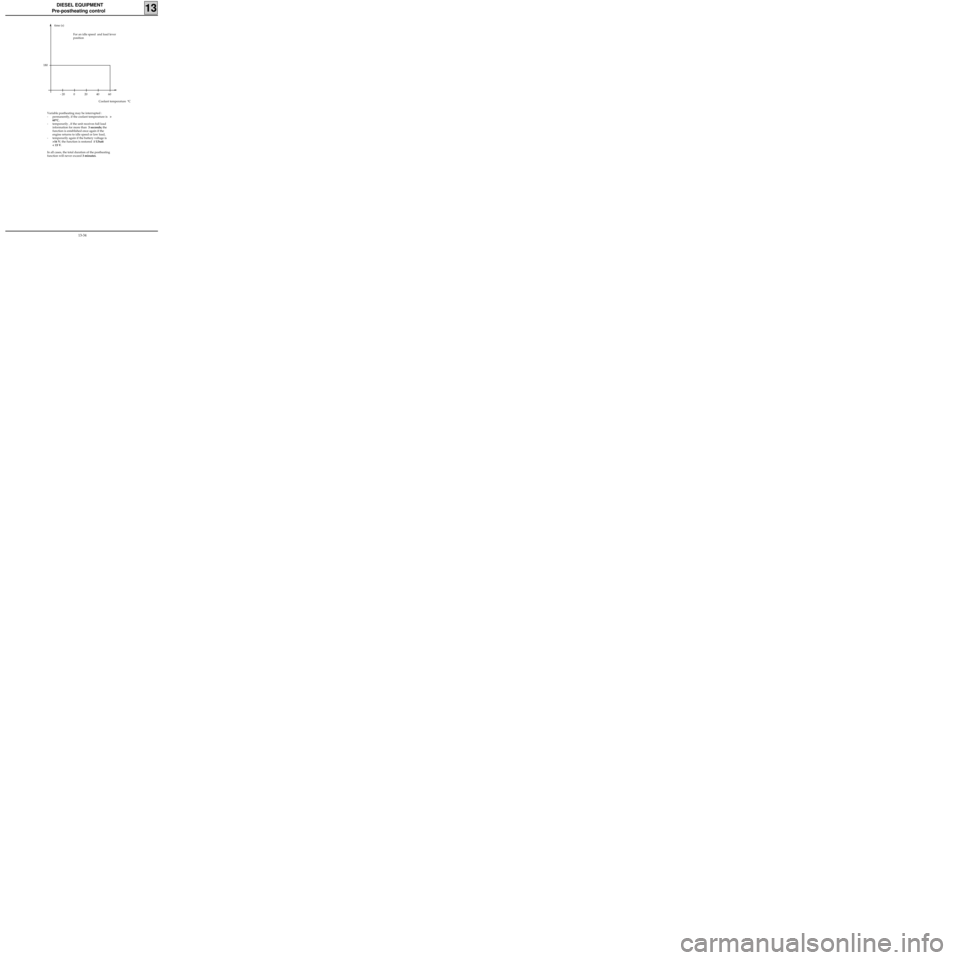

- 20 180time (s)

For an idle speed and load lever

position

Coolant temperature °C0204060

Variable postheating may be interrupted :

- permanently, if the coolant temperature is >

60°C,

- temporarily , if the unit receives full load

information for more than 3 seconds; the

function is established once again if the

engine returns to idle speed or low load,

- temporarily again if the battery voltage is

>16 V; the function is restored if Ubatt

< 15 V.

In all cases, the total duration of the postheating

function will never exceed 3 minutes.

13-34