engine RENAULT KANGOO 1997 KC / 1.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 208

Page 147 of 208

STARTING - CHARGING

Starter motor

16

OPTIMA 5800 Diagnostic station

CHECKING THE STARTER MOTOR USING THE DIAGNOSTIC STATION

Checking of the starter motor is carried out using the OPTIMA 5800, by measuring the battery voltage and

the current absorbed in the engine starting phase. The following operation faults may be highlighted :

- a fault in the battery ( the voltage falls during the starting phase),

- locking of the starter motor (the current absorbed is too high),

- a fault in the engine starter gear (the current absorbed is too low).

In order to carry out the measurement, it is necessary to stop the vehicle from starting :

- for D7F and E7J engines : disconnect the engine speed sensor (located on the clutch housing ,

- for

F8Q engines : disconnect the pump electrical solenoid and isolate the terminal.

NOTE :

- an open circuit on the engine speed sensor or the ignition creates a fault memorised by the injection

computer, this fault must then be erased from the memory using the

XR25 (see "Injection" section),

- if the engine is fitted with an immobiliser, it is sufficient to lock the doors using the remote control.

FAULT FINDING

SPECIAL TOOLING REQUIRED

16-8

Page 148 of 208

STARTING - CHARGING

Starter motor

16

REMOVAL

Place the vehicle on a lift, and disconnect the bat-

tery.

Disconnect the starter electrical connections.

10076R

Remove the two starter mounting bolts.

REMOVAL

Refitting is the reverse of removal. D7F Engine

16-9

Page 149 of 208

STARTING - CHARGING

Starter motor

16

REMOVAL

Place the vehicle on a two post lift.

Remove :

- the battery,

- the injection computer mounting, after ha-

ving disconnected the 55 track connector as

well as the impact switch connector,

13088S

- the mounting (1) for the power assisted stee-

ring pipe, along with the strut at (A),

13336-1R

- the front right hand wheel ,

- the driveshaft pin using punches B. Vi. 31-01,

- the upper shock absorber bolt and slacken the

lower bolt.

Tilt the hub and release the driveshaft assembly

from the gearbox.

Remove the starter connections , as well as the

mounting bolts and extract these from the bot-

tom of the vehicle.

REFITTING

Refitting is the reverse of removal.

Check for the presence of the centring dowel

which should be located at (B).

13087R

E7J Engine

16-10

Page 150 of 208

STARTING - CHARGING

Starter motor

16

REMOVAL

Place the vehicle on a two post lift.

Remove:

- the air filter inlet pipe,

- the battery,

- the computer support mounting bolts as well

as the connectors at (1), then move the

computer support/ diesel filter assembly to

one side.

13088R3

- the starter mounting bolts and the heat shield

(A),- the starter connections,

- the starter motor itself.

REFITTING

Refitting is the reverse of removal.

Check for the presence of the centring dowel,

which should be located at (B).

13087R1

F8Q Engine

16-11

Page 151 of 208

IGNITION

Semi-static ignition

17

PRESENTATION

The system comprises:

- the injection computer (the ignition power

stage is integrated into the computer),

- two dual output coils, (for the

D7F engine,

these are moulded into one),

- four spark plugs,

- an anti-interference condenser (4).

DESCRIPTION - OPERATING PRINCIPLE

COMPUTER

The injection computer (120), depending on the

information received from various sensors, but

principally depending on the engine speed and

load, determines:

- the number of degrees of advance to be used

and consequently the ignition point,

- which cylinders are at TDC and consequently

the ignition coil to be operated.

The spark is created at the two cylinders at TDC by

cutting the earth to the coil concerned.

COILS (1)

There are two coils. They are of the dual output

type (they cannot be separated in the

D7F en-

gine ).

They are controlled separately by the computer.

They create two sparks simultaneously.

Both coils are connected to an anti-interference

condenser.

99931-1R2

D7F Engine

E7J Engine

13242R

Special features of the E7J engine

The coil at (2) has a black electrical connector. It

creates a spark simultaneously at cylinders 1 and

4. It is controlled by track 28 of the injection

computer.

The coil at (3) has a grey electrical connector . It

creates a spark simultaneously at cylinders 2 and

3. It is controlled by track 29 of the injection

computer.

17-1

Page 152 of 208

IGNITION

Semi-static ignition

17

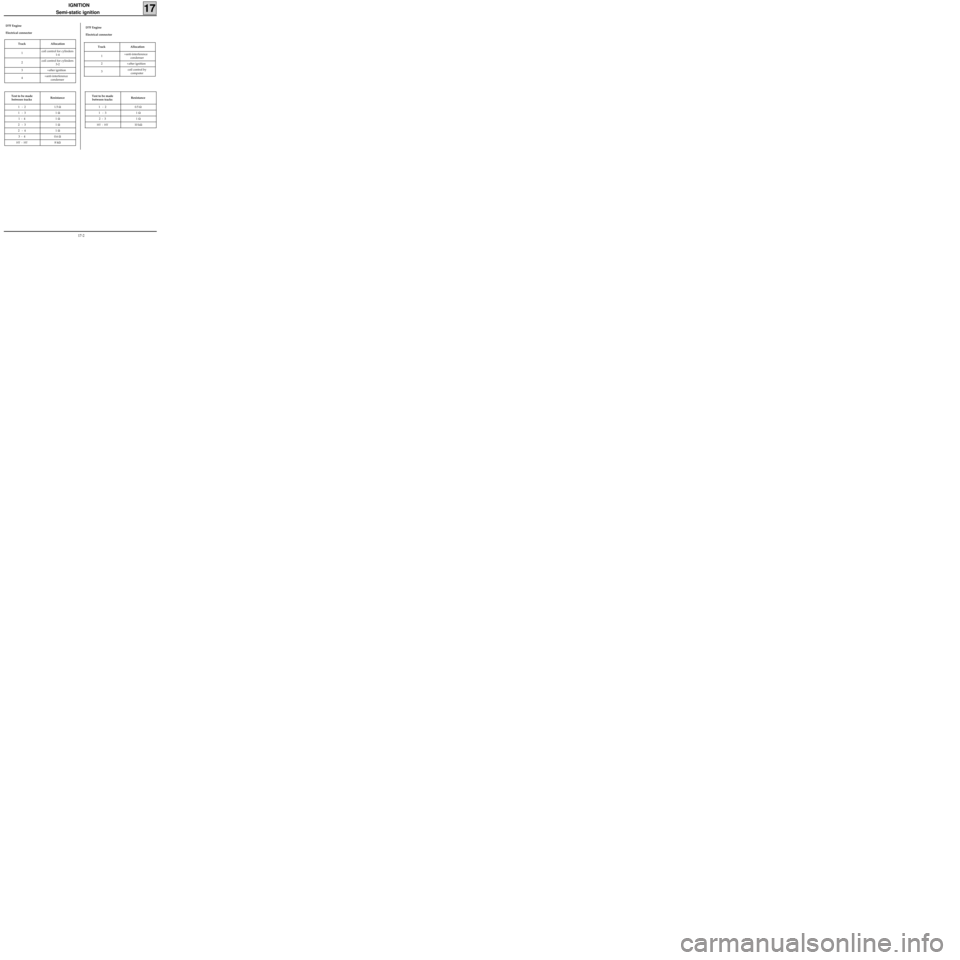

Test to be made

between tracksResistance

1 - 2 1.5 Ω

1 - 3 1 Ω

1 - 4 1 Ω

2 - 3 1 Ω

2 - 4 1 Ω

3 - 4 0.6 Ω

HT - HT8 kΩ

D7F Engine

Electrical connector

Track Allocation

1coil control for cylinders

1-4

2coil control for cylinders

3-2

3 +after ignition

4+anti-interference

condenser

Test to be made

between tracksResistance

1 - 2 0.5 Ω

1 - 3 1 Ω

2 - 3 1 Ω

HT - HT10 kΩ

Track Allocation

1+anti-interference

condenser

2 +after ignition

3coil control by

computer

D7F Engine

Electrical connector

17-2

Page 153 of 208

IGNITION

Spark plugs

17

Engine Make Type

D7F

EYQUEM

NGK

RFC 50 LZ 2E

BKR 5EK

E7JEYQUEM

CHAMPIONRFC 52 LS

RC 10 PYC

Flat skirt with seal

Gap: 0.9 mm

Tightening torque : 2.5 to 3 daN.m

D7F Engine

To disconnect the spark plug leads, use the tool (3), which is integrated to the plastic cover (4) on the cylin-

der head.

99940R

99894R1

D7F/E7J

Engines

NOTE : to remove the spark plugs, use the tool kit, Ele. 1382.

17-3

Page 154 of 208

INJECTION

General

17

SPECIAL NOTES FOR MULTIPOINT INJECTION

• 35 track SAGEM or MAGNETI MARELLI computer for vehicles without options.

• 55 track SAGEM computer ,

SAFIR or MAGNETI MARELLI type for versions with air conditioning.

•Semi-sequential multipoint injection. Injectors controlled two by two (injectors for cylinders 1 and 4 fol-

lowed by injectors for cylinders 2 and 3).

•Semi-static ignition with dual single unit coils.

•Canister bleed solenoid valve controlled by RCO signal.

•Computer configuration depending on gearbox type (manual gearbox or automatic transmission).

•The maximum engine speed permitted is 6 200 rpm.

•Idle speed correction depending on :

- battery voltage,

- air conditioning

- power assisted steering pressostat.

•Injection warning light on instrument panel not operational.

•Use fault finding fiche n° 27. D7F Engine

FITTING A 2ND GENERATION ENGINE IMMOBILISER REQUIRES A SPECIAL PROCEDURE FOR REPLACING THE

COMPUTER.

17-4

Page 155 of 208

INJECTION

General

17

SPECIAL NOTES FOR MULTIPOINT INJECTION

• 55 track SIEMENS FENIX 5 computer.

•Semi-sequential multipoint injection. Injectors are controlled two by two (injectors for cylinders 1 and 4

followed by cylinders 2 and 3).

•Semi-static ignition with dual coils.

•Canister bleed solenoid controlled by RCO signal.

•Computer configuration depending on gearbox type (manual gearbox or automatic transmission)

•Idle speed correction depending on :

- air conditioning,

- power assisted steering pressostat,

- battery voltage.

•Injection warning light on instrument panel operational.

•Use fault finding fiche n° 27.

•Maximum speed :

-6 200 rpm if 1st , 2nd or 3rd gears

-6 000 rpm if 4th,or 5th gears. E7J Engine

FITTING A 2ND GENERATION ENGINE IMMOBILISER REQUIRES A SPECIAL PROCEDURE FOR REPLACING THE

COMPUTER.

17-5

Page 156 of 208

INJECTION

General

17

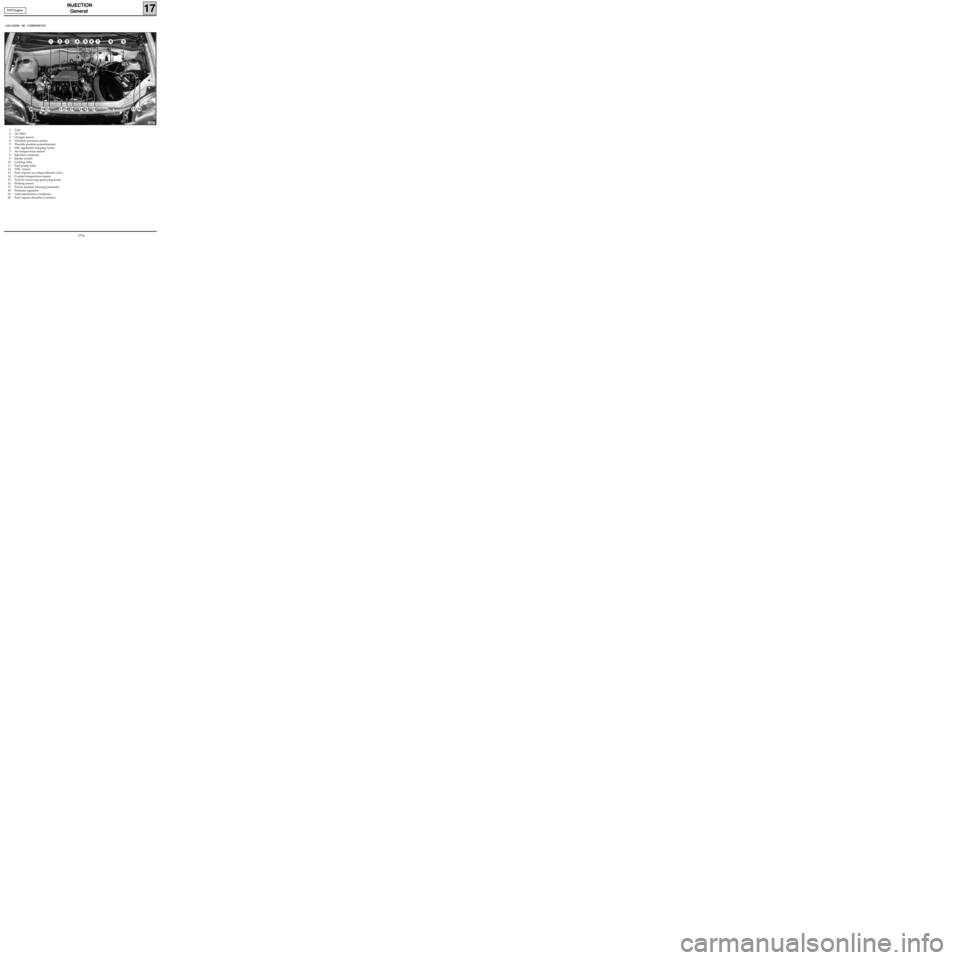

1 Coil

2 Air filter

3 Oxygen sensor

4 Absolute pressure sensor

5 Throttle position potentiometer

6 Idle regulation stepping motor

7 Air temperature sensor

8 Injection computer

9 Inertia switch

10 Locking relay

11 Fuel pump relay

12 TDC sensor

13 Fuel vapour recycling solenoid valve

14 Coolant temperature sensor

15 Tool for removing spark plug leads

16 Pinking sensor

17 Power assisted steering pressostat

18 Pressure regulator

19 Anti-interference condenser

20 Fuel vapour absorber (canister)

LOCATION OF COMPONENTS

13081

D7F Engine

17-6