RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 151 of 204

13B-151

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

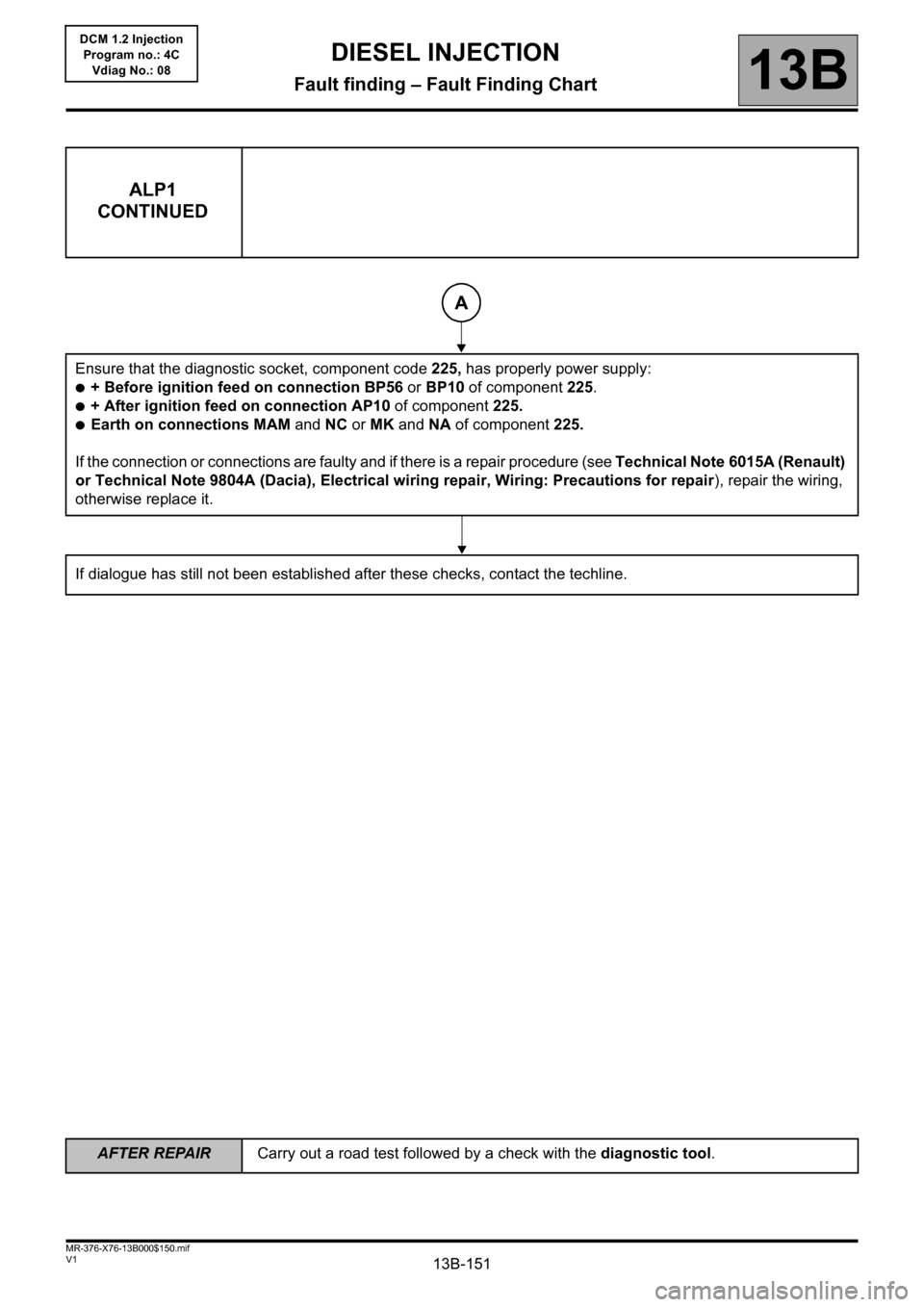

ALP1

CONTINUED

Ensure that the diagnostic socket, component code 225, has properly power supply:

●+ Before ignition feed on connection BP56 or BP10 of component 225.

●+ After ignition feed on connection AP10 of component 225.

●Earth on connections MAM and NC or MK and NA of component 225.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A (Renault)

or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

If dialogue has still not been established after these checks, contact the techline.

A

Page 152 of 204

13B-152

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

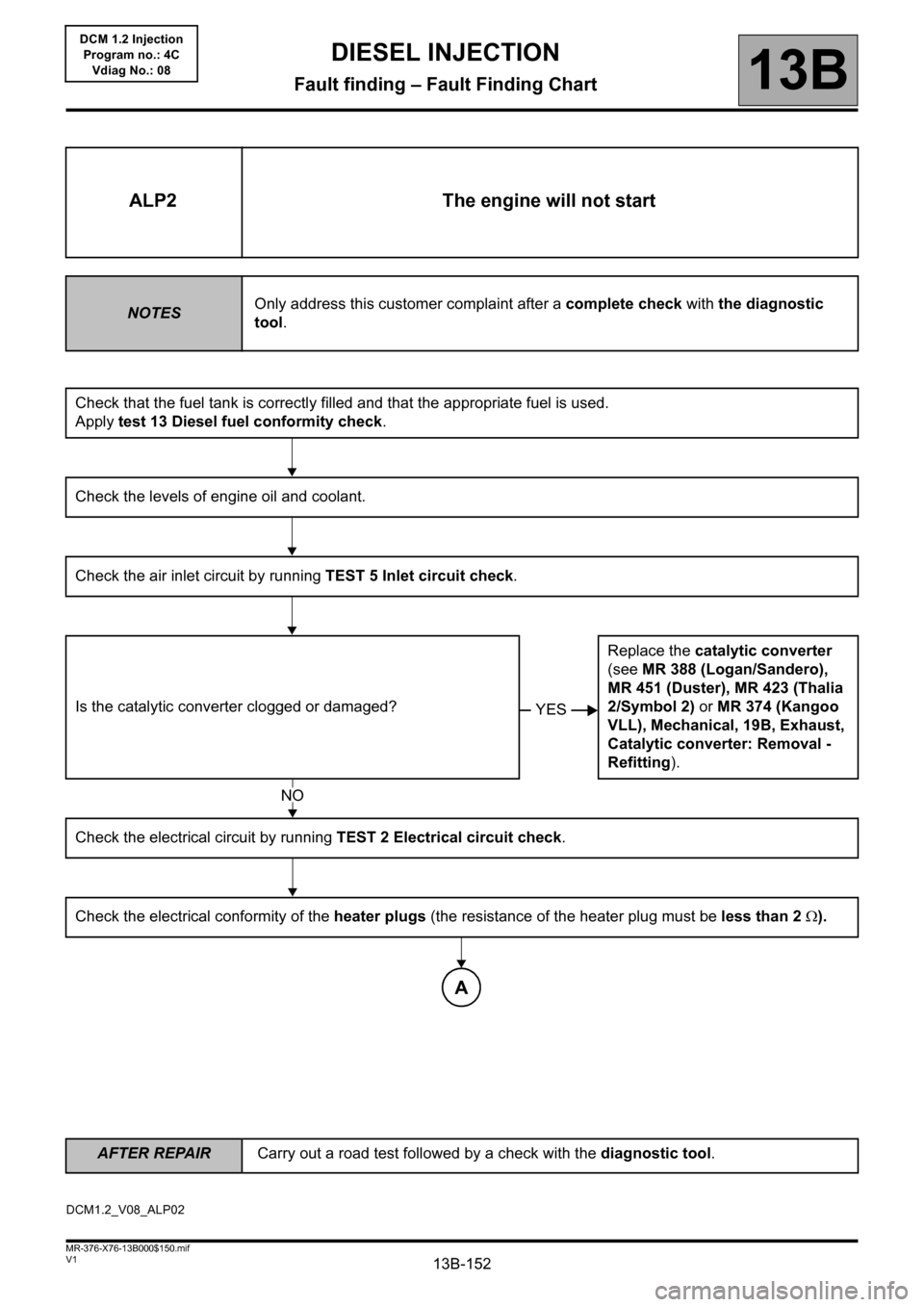

ALP2 The engine will not start

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply test 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter

(see MR 388 (Logan/Sandero),

MR 451 (Duster), MR 423 (Thalia

2/Symbol 2) or MR 374 (Kangoo

VLL), Mechanical, 19B, Exhaust,

Catalytic converter: Removal -

Refitting).

Check the electrical circuit by running TEST 2 Electrical circuit check.

Check the electrical conformity of the heater plugs (the resistance of the heater plug must be less than 2 ).

YES

NO

A

DCM1.2_V08_ALP02

Page 153 of 204

13B-153

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

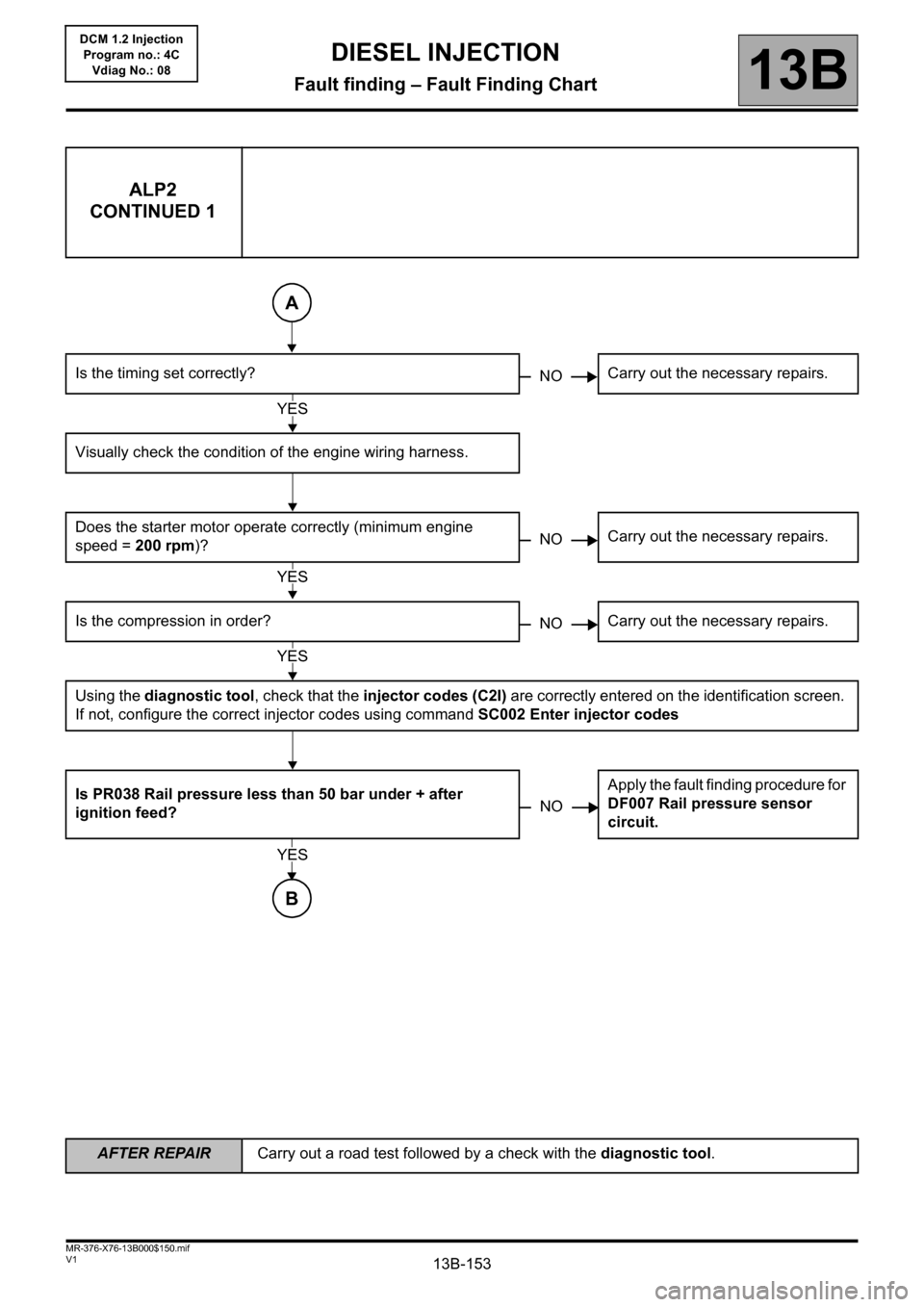

ALP2

CONTINUED 1

Is the timing set correctly? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

Does the starter motor operate correctly (minimum engine

speed = 200 rpm)?Carry out the necessary repairs.

Is the compression in order? Carry out the necessary repairs.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen.

If not, configure the correct injector codes using command SC002 Enter injector codes

Is PR038 Rail pressure less than 50 bar under + after

ignition feed?Apply the fault finding procedure for

DF007 Rail pressure sensor

circuit.

A

NO

YES

NO

YES

NO

YES

NO

B

YES

Page 154 of 204

13B-154

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

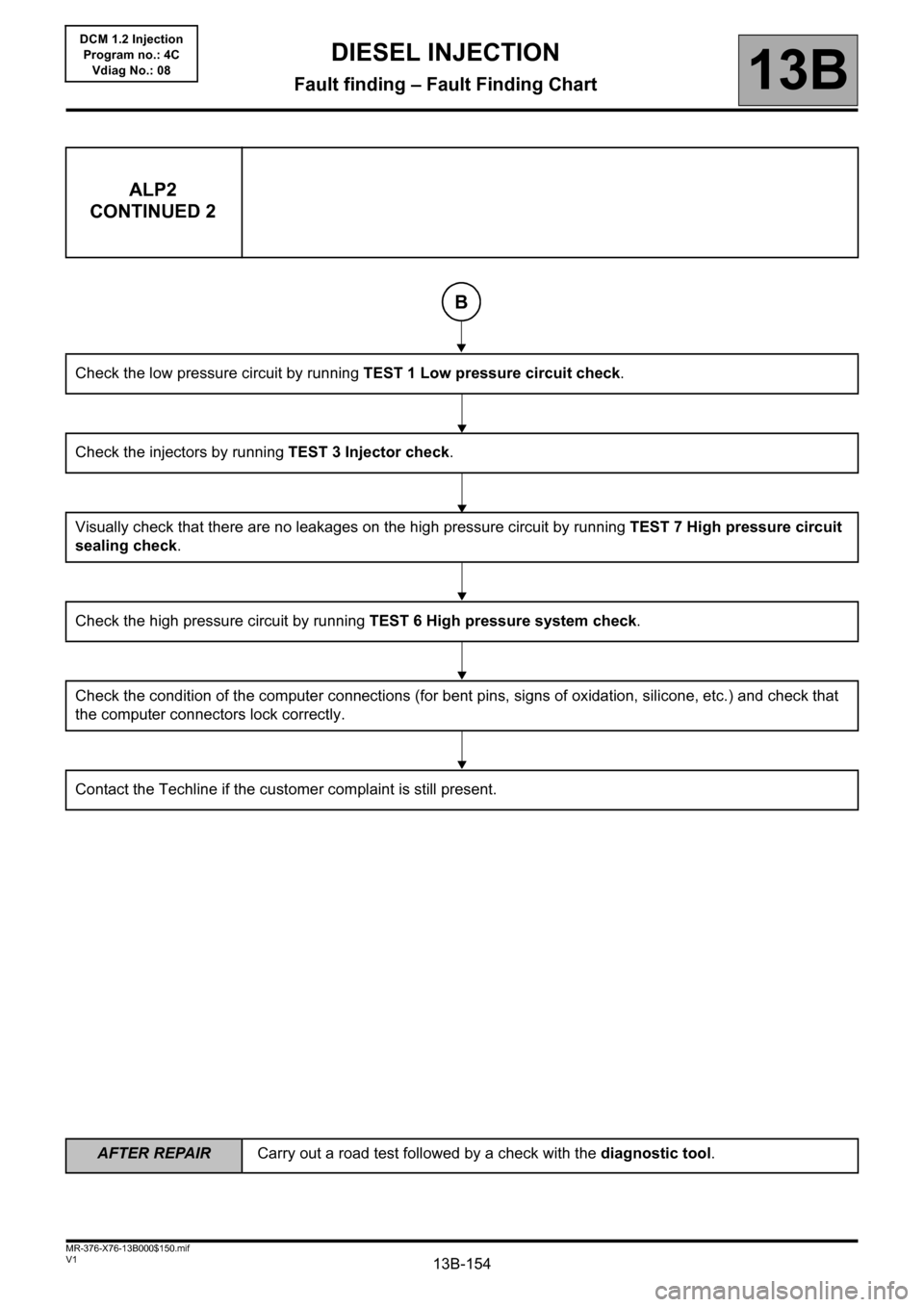

ALP2

CONTINUED 2

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Visually check that there are no leakages on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the high pressure circuit by running TEST 6 High pressure system check.

Check the condition of the computer connections (for bent pins, signs of oxidation, silicone, etc.) and check that

the computer connectors lock correctly.

Contact the Techline if the customer complaint is still present.

B

Page 155 of 204

13B-155

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

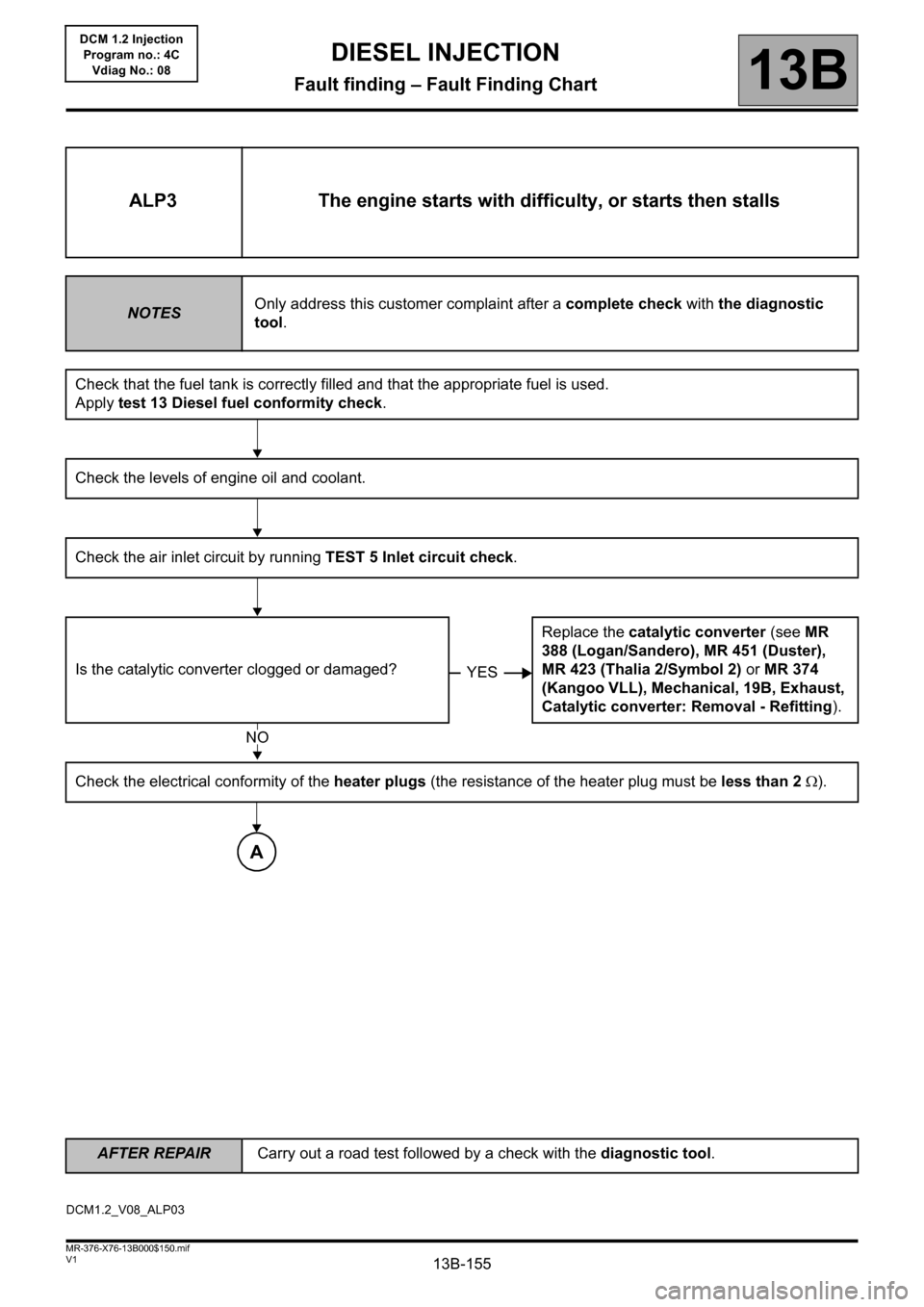

ALP3 The engine starts with difficulty, or starts then stalls

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply test 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR

388 (Logan/Sandero), MR 451 (Duster),

MR 423 (Thalia 2/Symbol 2) or MR 374

(Kangoo VLL), Mechanical, 19B, Exhaust,

Catalytic converter: Removal - Refitting).

Check the electrical conformity of the heater plugs (the resistance of the heater plug must be less than 2 ).

YES

NO

A

DCM1.2_V08_ALP03

Page 156 of 204

13B-156

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

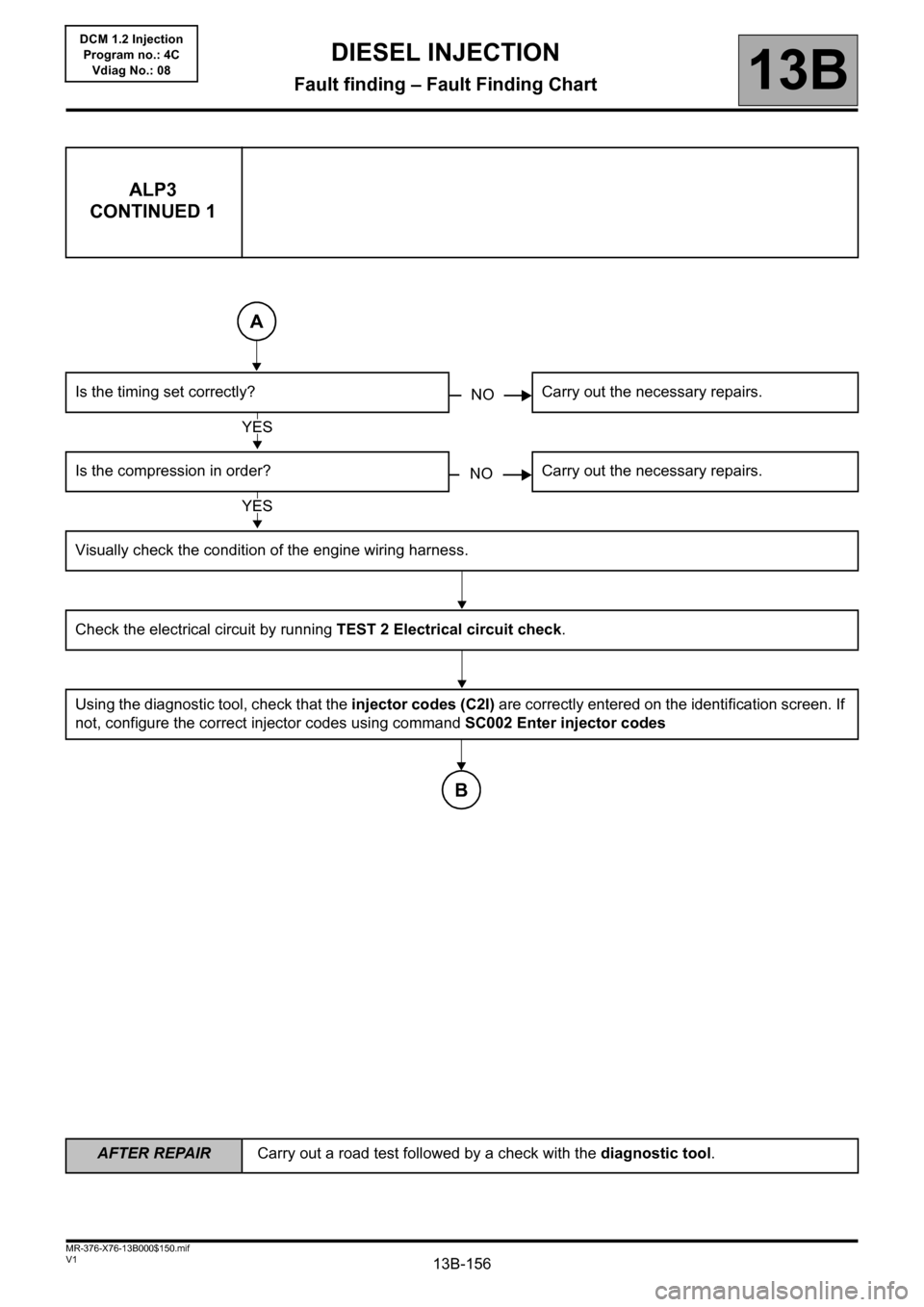

ALP3

CONTINUED 1

Is the timing set correctly? Carry out the necessary repairs.

Is the compression in order? Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

Check the electrical circuit by running TEST 2 Electrical circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

A

NO

YES

NO

YES

B

Page 157 of 204

13B-157

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

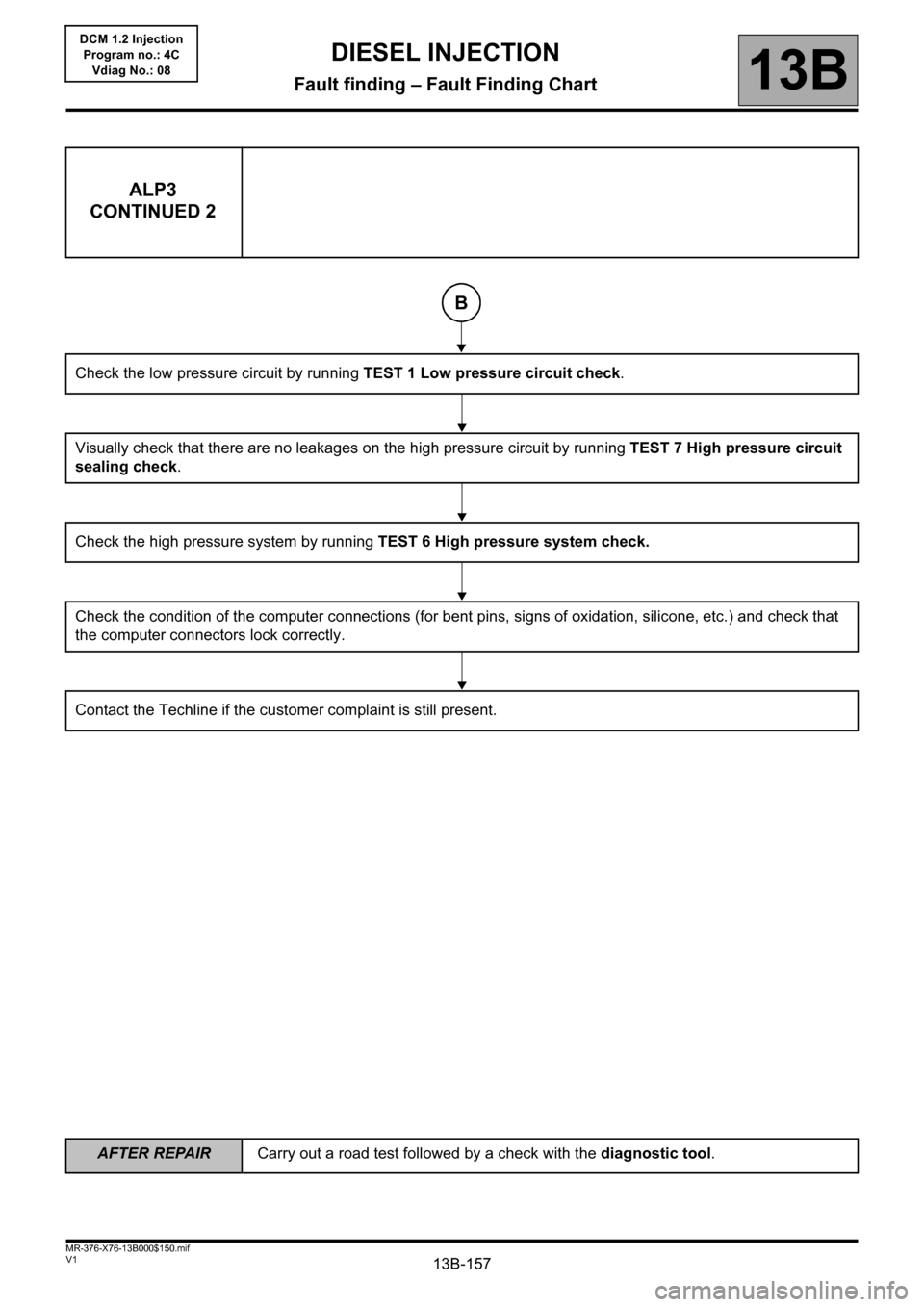

ALP3

CONTINUED 2

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Visually check that there are no leakages on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

Check the high pressure system by running TEST 6 High pressure system check.

Check the condition of the computer connections (for bent pins, signs of oxidation, silicone, etc.) and check that

the computer connectors lock correctly.

Contact the Techline if the customer complaint is still present.

B

Page 158 of 204

13B-158

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

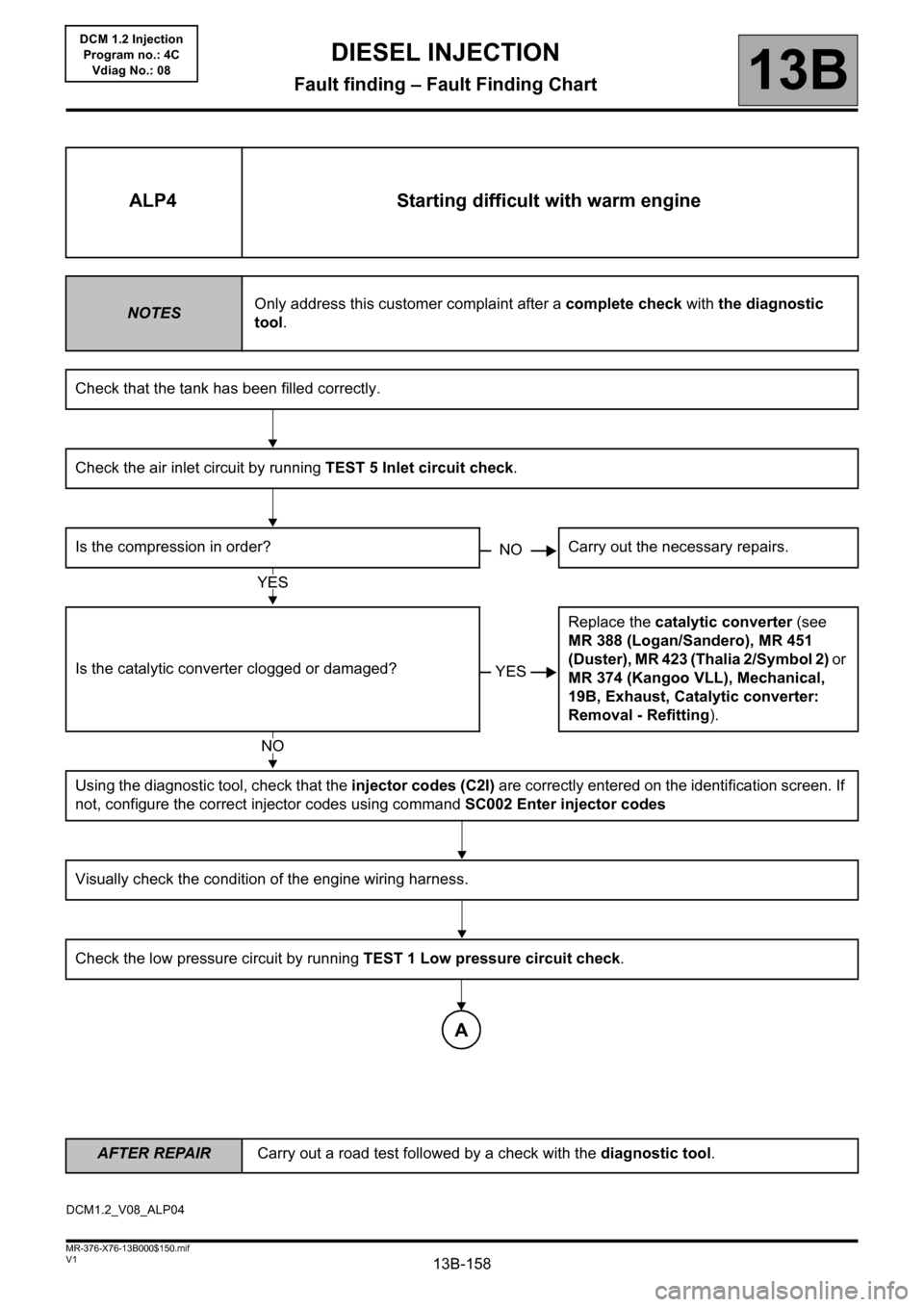

ALP4 Starting difficult with warm engine

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the tank has been filled correctly.

Check the air inlet circuit by running TEST 5 Inlet circuit check.

Is the compression in order? Carry out the necessary repairs.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see

MR 388 (Logan/Sandero), MR 451

(Duster), MR 423 (Thalia 2/Symbol 2) or

MR 374 (Kangoo VLL), Mechanical,

19B, Exhaust, Catalytic converter:

Removal - Refitting).

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Visually check the condition of the engine wiring harness.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

NO

YES

YES

NO

A

DCM1.2_V08_ALP04

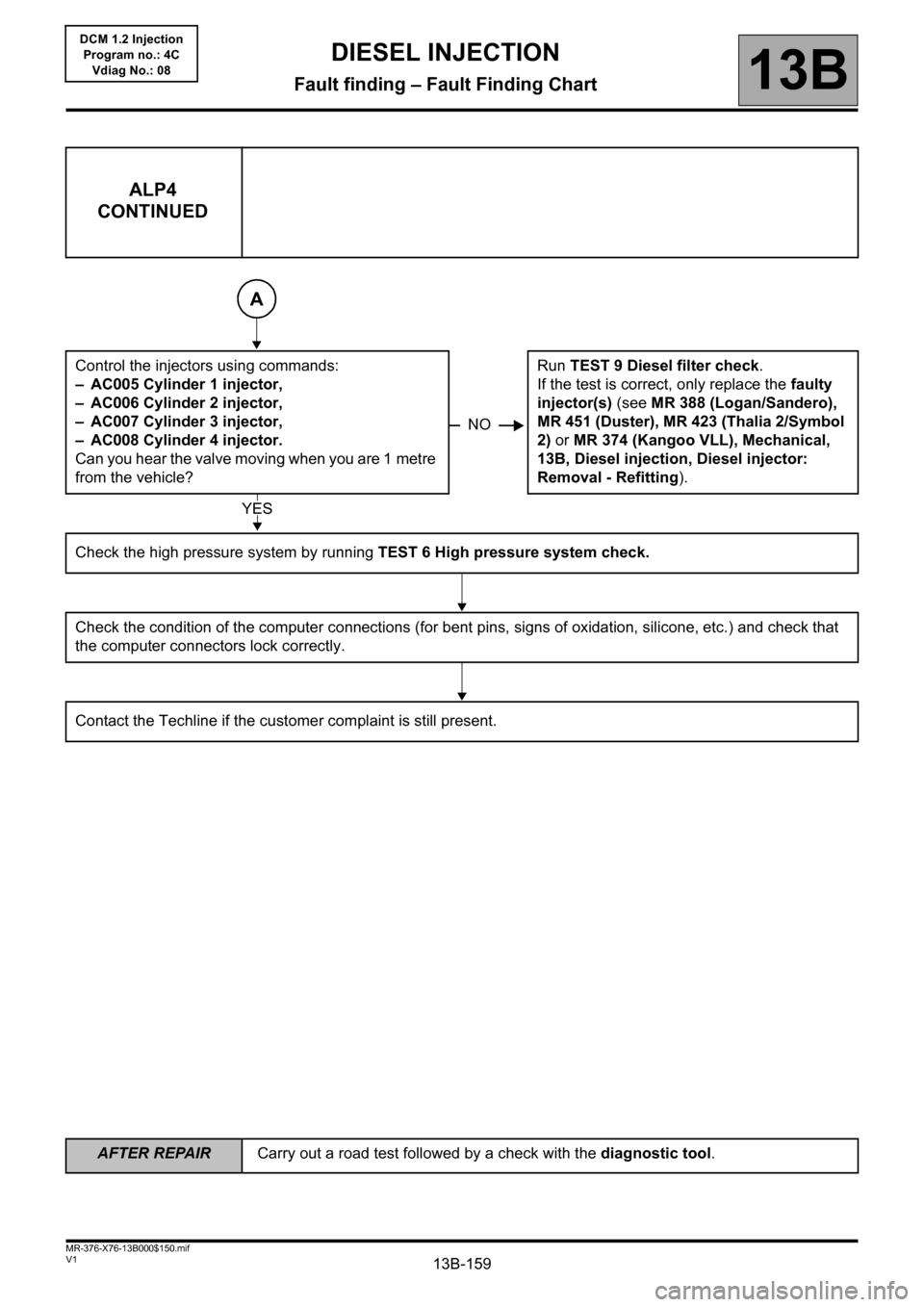

Page 159 of 204

13B-159

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

ALP4

CONTINUED

Control the injectors using commands:

– AC005 Cylinder 1 injector,

– AC006 Cylinder 2 injector,

– AC007 Cylinder 3 injector,

– AC008 Cylinder 4 injector.

Can you hear the valve moving when you are 1 metre

from the vehicle?Run TEST 9 Diesel filter check.

If the test is correct, only replace the faulty

injector(s) (see MR 388 (Logan/Sandero),

MR 451 (Duster), MR 423 (Thalia 2/Symbol

2) or MR 374 (Kangoo VLL), Mechanical,

13B, Diesel injection, Diesel injector:

Removal - Refitting).

Check the high pressure system by running TEST 6 High pressure system check.

Check the condition of the computer connections (for bent pins, signs of oxidation, silicone, etc.) and check that

the computer connectors lock correctly.

Contact the Techline if the customer complaint is still present.

A

NO

YES

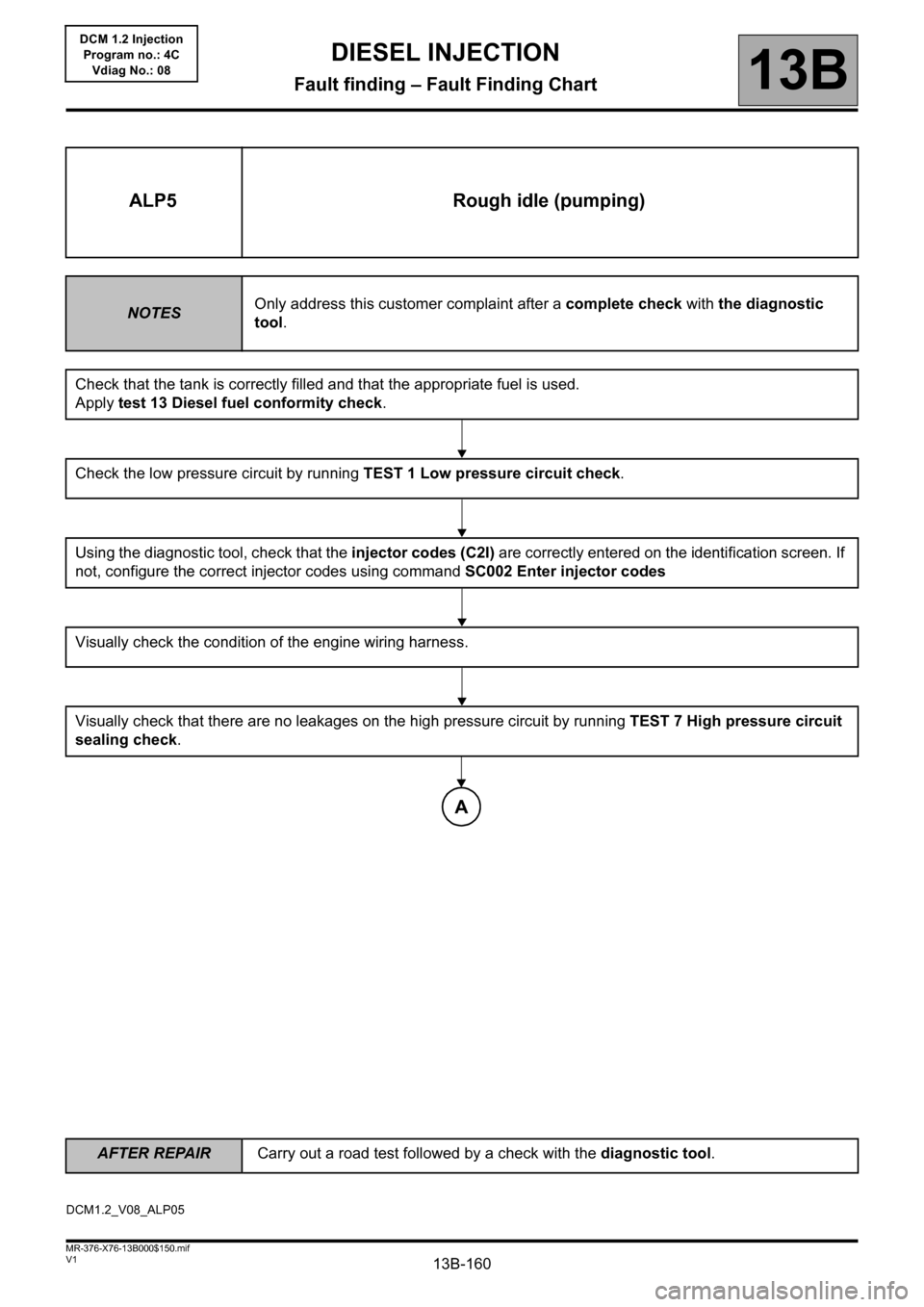

Page 160 of 204

13B-160

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

ALP5 Rough idle (pumping)

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the tank is correctly filled and that the appropriate fuel is used.

Apply test 13 Diesel fuel conformity check.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Visually check the condition of the engine wiring harness.

Visually check that there are no leakages on the high pressure circuit by running TEST 7 High pressure circuit

sealing check.

A

DCM1.2_V08_ALP05