RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 141 of 204

13B-141V1 MR-376-X76-13B000$110.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

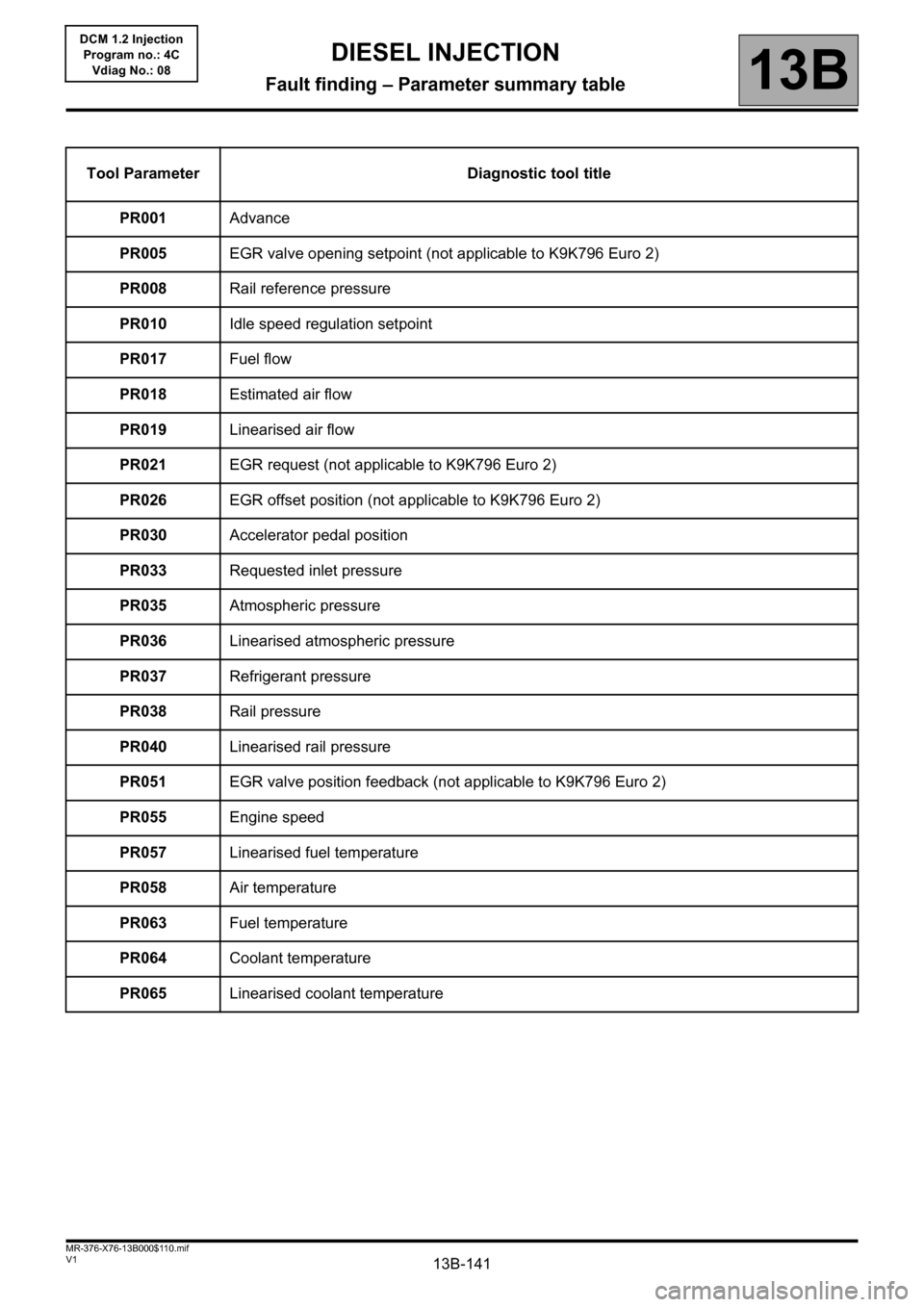

Tool Parameter Diagnostic tool title

PR001Advance

PR005EGR valve opening setpoint (not applicable to K9K796 Euro 2)

PR008Rail reference pressure

PR010Idle speed regulation setpoint

PR017Fuel flow

PR018Estimated air flow

PR019Linearised air flow

PR021EGR request (not applicable to K9K796 Euro 2)

PR026EGR offset position (not applicable to K9K796 Euro 2)

PR030Accelerator pedal position

PR033Requested inlet pressure

PR035Atmospheric pressure

PR036Linearised atmospheric pressure

PR037Refrigerant pressure

PR038Rail pressure

PR040Linearised rail pressure

PR051EGR valve position feedback (not applicable to K9K796 Euro 2)

PR055Engine speed

PR057Linearised fuel temperature

PR058Air temperature

PR063Fuel temperature

PR064Coolant temperature

PR065Linearised coolant temperature

DIESEL INJECTION

Fault finding – Parameter summary table

Page 142 of 204

13B-142V1 MR-376-X76-13B000$110.mif

DIESEL INJECTION

Fault finding – Parameter summary table13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

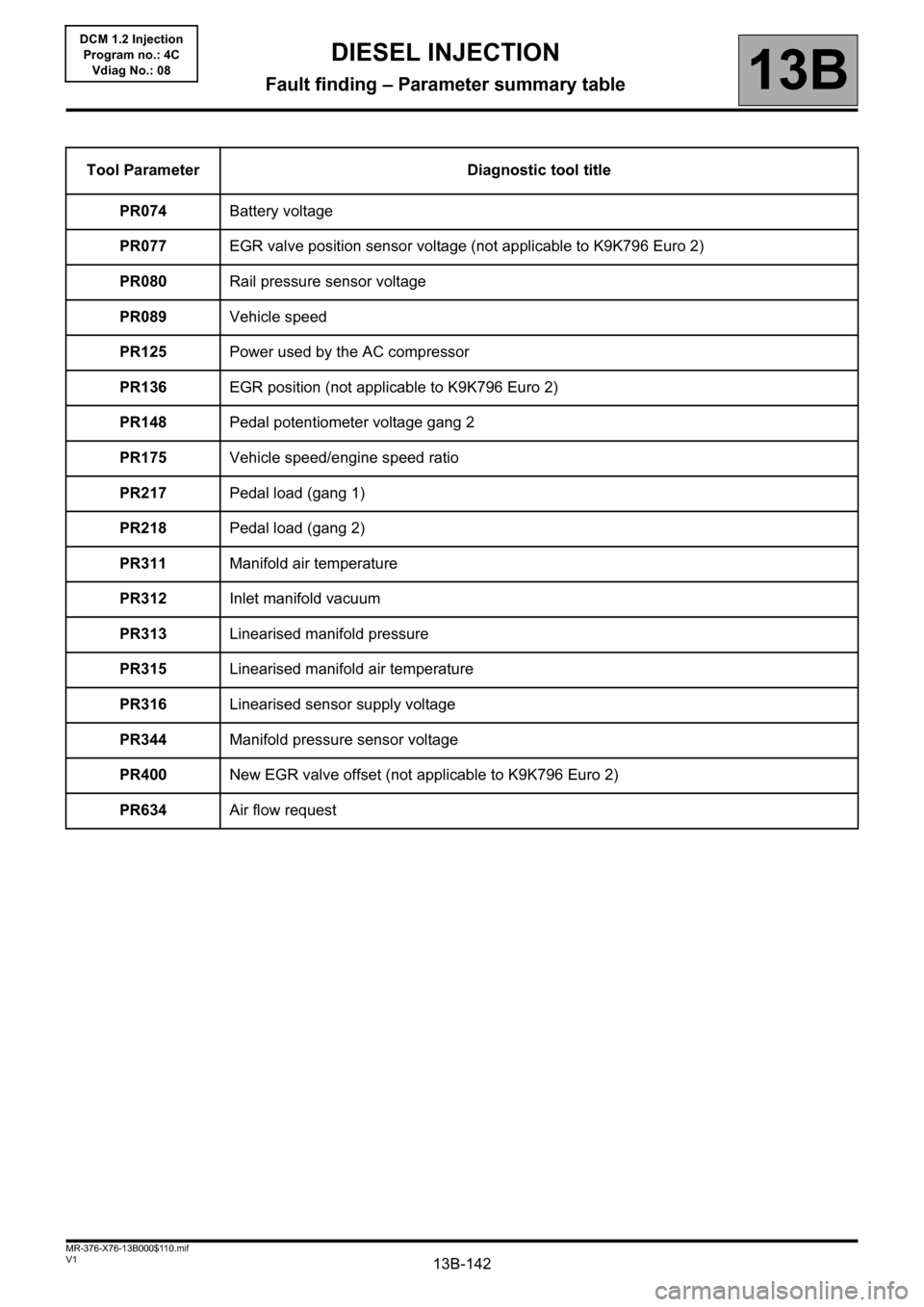

Tool Parameter Diagnostic tool title

PR074Battery voltage

PR077EGR valve position sensor voltage (not applicable to K9K796 Euro 2)

PR080Rail pressure sensor voltage

PR089Vehicle speed

PR125Power used by the AC compressor

PR136EGR position (not applicable to K9K796 Euro 2)

PR148Pedal potentiometer voltage gang 2

PR175Vehicle speed/engine speed ratio

PR217Pedal load (gang 1)

PR218Pedal load (gang 2)

PR311Manifold air temperature

PR312Inlet manifold vacuum

PR313Linearised manifold pressure

PR315Linearised manifold air temperature

PR316Linearised sensor supply voltage

PR344Manifold pressure sensor voltage

PR400New EGR valve offset (not applicable to K9K796 Euro 2)

PR634Air flow request

Page 143 of 204

13B-143

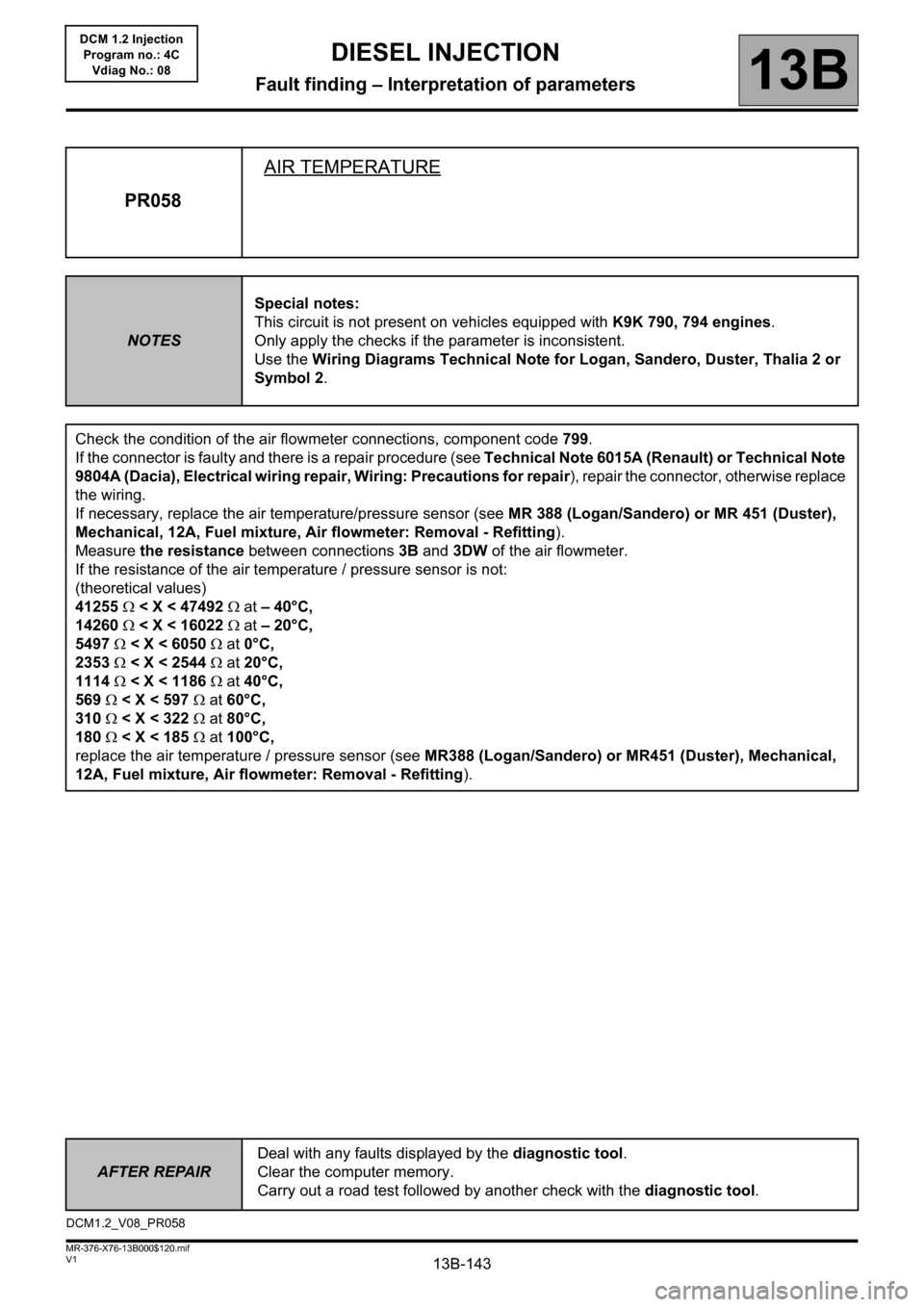

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$120.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

PR058AIR TEMPERATURE

NOTESSpecial notes:

This circuit is not present on vehicles equipped with K9K 790, 794 engines.

Only apply the checks if the parameter is inconsistent.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2 or

Symbol 2.

Check the condition of the air flowmeter connections, component code 799.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A (Renault) or Technical Note

9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace

the wiring.

If necessary, replace the air temperature/pressure sensor (see MR 388 (Logan/Sandero) or MR 451 (Duster),

Mechanical, 12A, Fuel mixture, Air flowmeter: Removal - Refitting).

Measure the resistance between connections 3B and 3DW of the air flowmeter.

If the resistance of the air temperature / pressure sensor is not:

(theoretical values)

41255 < X < 47492 at – 40°C,

14260 < X < 16022 at – 20°C,

5497 < X < 6050 at 0°C,

2353 < X < 2544 at 20°C,

1114 < X < 1186 at 40°C,

569 < X < 597 at 60°C,

310 < X < 322 at 80°C,

180 < X < 185 at 100°C,

replace the air temperature / pressure sensor (see MR388 (Logan/Sandero) or MR451 (Duster), Mechanical,

12A, Fuel mixture, Air flowmeter: Removal - Refitting).

DCM1.2_V08_PR058

DIESEL INJECTION

Fault finding – Interpretation of parameters

Page 144 of 204

13B-144

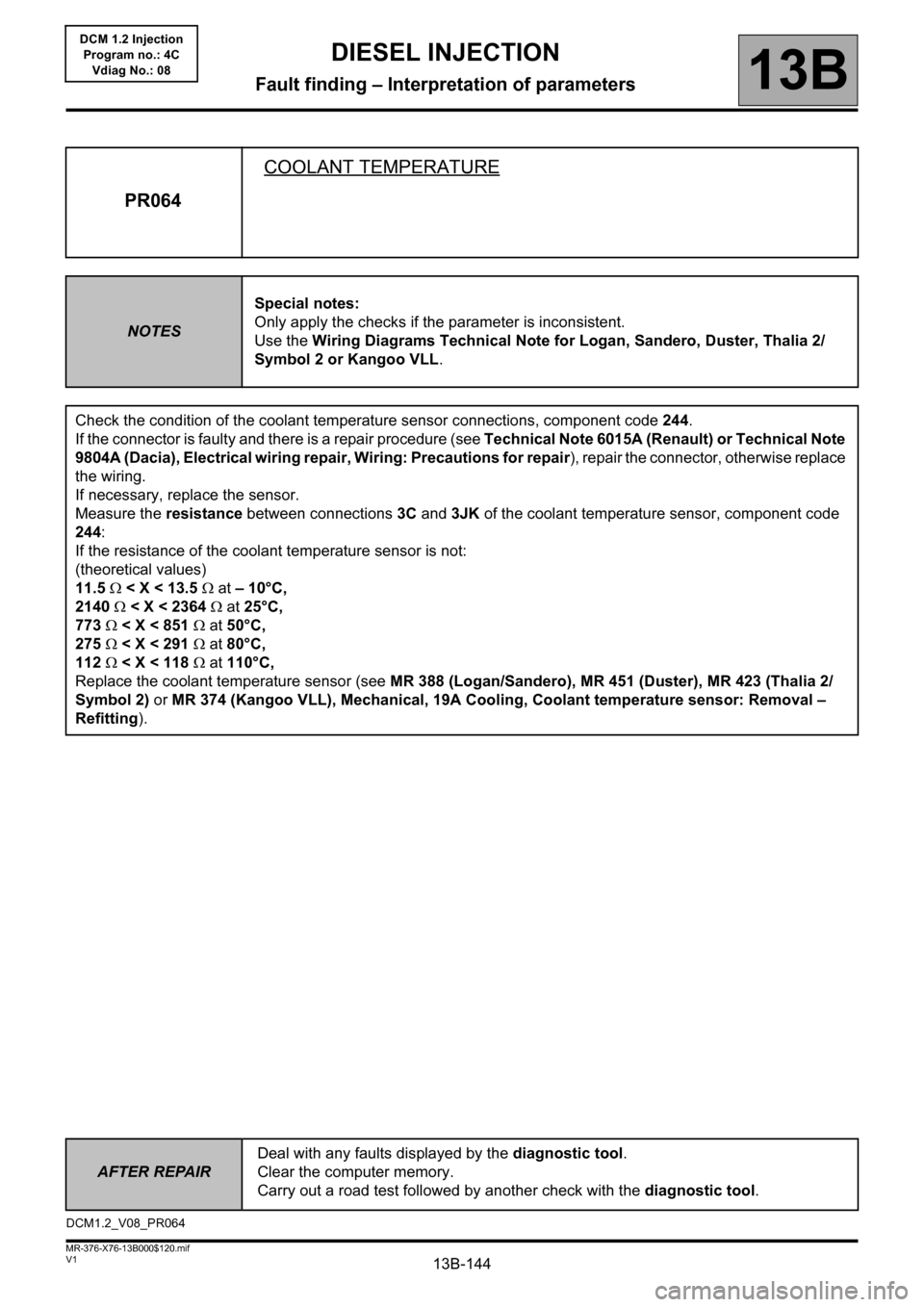

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer memory.

Carry out a road test followed by another check with the diagnostic tool.

V1 MR-376-X76-13B000$120.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

PR064COOLANT TEMPERATURE

NOTESSpecial notes:

Only apply the checks if the parameter is inconsistent.

Use the Wiring Diagrams Technical Note for Logan, Sandero, Duster, Thalia 2/

Symbol 2 or Kangoo VLL.

Check the condition of the coolant temperature sensor connections, component code 244.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A (Renault) or Technical Note

9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the connector, otherwise replace

the wiring.

If necessary, replace the sensor.

Measure the resistance between connections 3C and 3JK of the coolant temperature sensor, component code

244:

If the resistance of the coolant temperature sensor is not:

(theoretical values)

11.5 < X < 13.5 at – 10°C,

2140 < X < 2364 at 25°C,

773 < X < 851 at 50°C,

275 < X < 291 at 80°C,

112 < X < 118 at 110°C,

Replace the coolant temperature sensor (see MR 388 (Logan/Sandero), MR 451 (Duster), MR 423 (Thalia 2/

Symbol 2) or MR 374 (Kangoo VLL), Mechanical, 19A Cooling, Coolant temperature sensor: Removal –

Refitting).

DCM1.2_V08_PR064

Page 145 of 204

13B-145V1 MR-376-X76-13B000$130.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

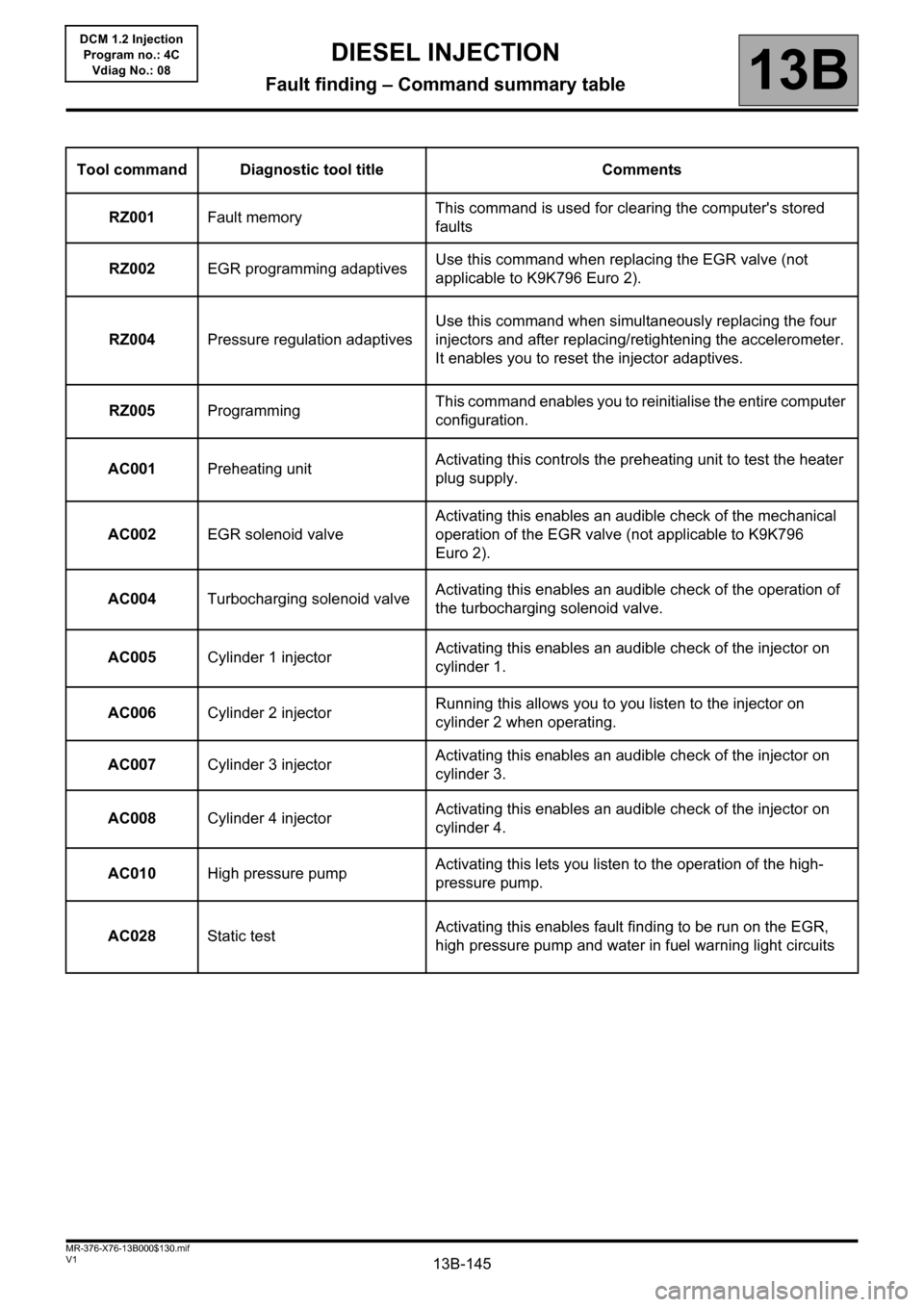

Tool command Diagnostic tool title Comments

RZ001Fault memoryThis command is used for clearing the computer's stored

faults

RZ002EGR programming adaptivesUse this command when replacing the EGR valve (not

applicable to K9K796 Euro 2).

RZ004Pressure regulation adaptivesUse this command when simultaneously replacing the four

injectors and after replacing/retightening the accelerometer.

It enables you to reset the injector adaptives.

RZ005ProgrammingThis command enables you to reinitialise the entire computer

configuration.

AC001Preheating unitActivating this controls the preheating unit to test the heater

plug supply.

AC002EGR solenoid valveActivating this enables an audible check of the mechanical

operation of the EGR valve (not applicable to K9K796

Euro 2).

AC004Turbocharging solenoid valveActivating this enables an audible check of the operation of

the turbocharging solenoid valve.

AC005Cylinder 1 injectorActivating this enables an audible check of the injector on

cylinder 1.

AC006Cylinder 2 injectorRunning this allows you to you listen to the injector on

cylinder 2 when operating.

AC007Cylinder 3 injectorActivating this enables an audible check of the injector on

cylinder 3.

AC008Cylinder 4 injectorActivating this enables an audible check of the injector on

cylinder 4.

AC010High pressure pumpActivating this lets you listen to the operation of the high-

pressure pump.

AC028Static testActivating this enables fault finding to be run on the EGR,

high pressure pump and water in fuel warning light circuits

DIESEL INJECTION

Fault finding – Command summary table

Page 146 of 204

13B-146V1 MR-376-X76-13B000$130.mif

DIESEL INJECTION

Fault finding – Command summary table13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

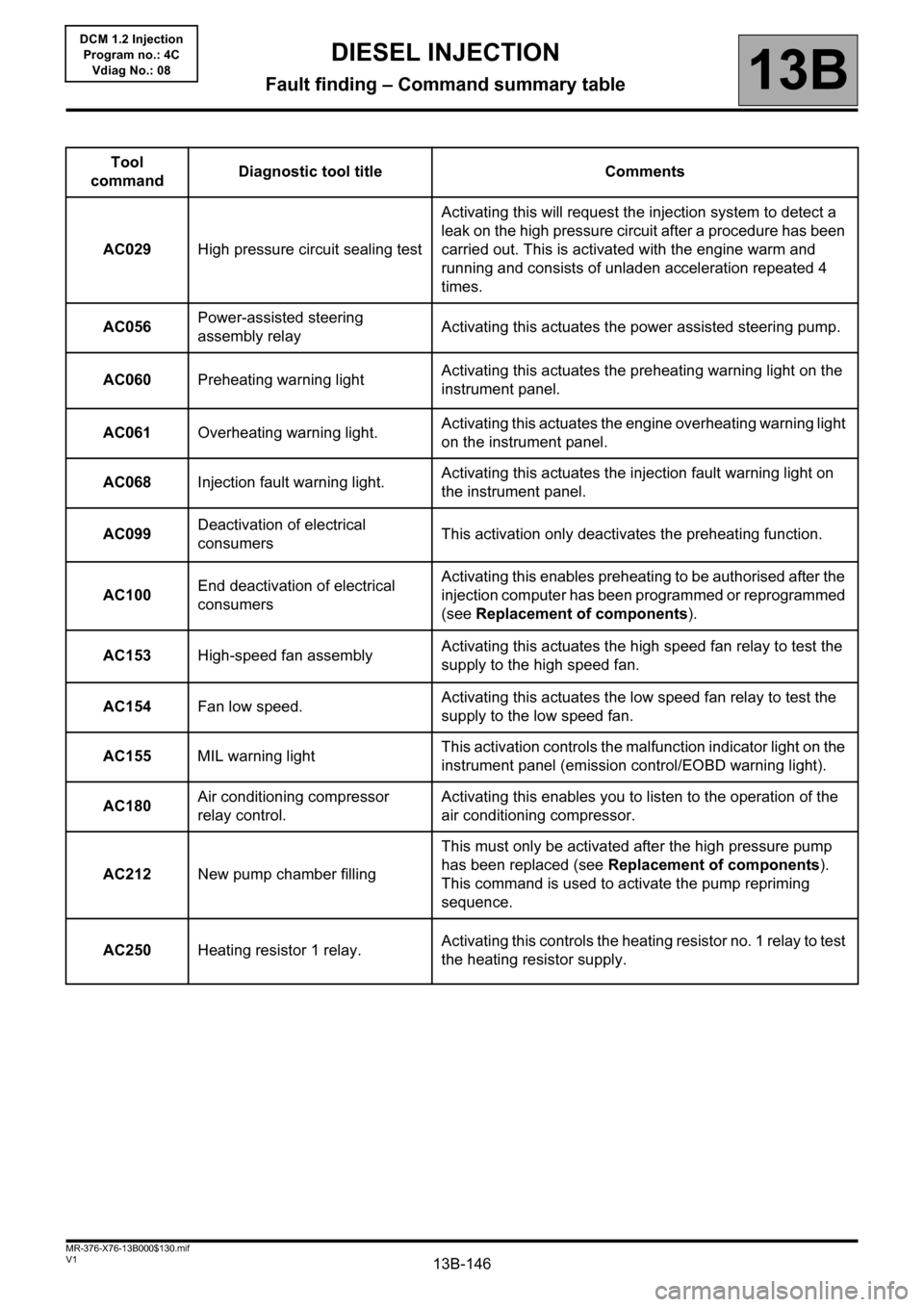

Tool

commandDiagnostic tool title Comments

AC029 High pressure circuit sealing testActivating this will request the injection system to detect a

leak on the high pressure circuit after a procedure has been

carried out. This is activated with the engine warm and

running and consists of unladen acceleration repeated 4

times.

AC056 Power-assisted steering

assembly relayActivating this actuates the power assisted steering pump.

AC060 Preheating warning lightActivating this actuates the preheating warning light on the

instrument panel.

AC061 Overheating warning light.Activating this actuates the engine overheating warning light

on the instrument panel.

AC068Injection fault warning light.Activating this actuates the injection fault warning light on

the instrument panel.

AC099Deactivation of electrical

consumersThis activation only deactivates the preheating function.

AC100End deactivation of electrical

consumersActivating this enables preheating to be authorised after the

injection computer has been programmed or reprogrammed

(see Replacement of components).

AC153 High-speed fan assemblyActivating this actuates the high speed fan relay to test the

supply to the high speed fan.

AC154 Fan low speed.Activating this actuates the low speed fan relay to test the

supply to the low speed fan.

AC155MIL warning lightThis activation controls the malfunction indicator light on the

instrument panel (emission control/EOBD warning light).

AC180 Air conditioning compressor

relay control.Activating this enables you to listen to the operation of the

air conditioning compressor.

AC212 New pump chamber fillingThis must only be activated after the high pressure pump

has been replaced (see Replacement of components).

This command is used to activate the pump repriming

sequence.

AC250 Heating resistor 1 relay.Activating this controls the heating resistor no. 1 relay to test

the heating resistor supply.

Page 147 of 204

13B-147V1 MR-376-X76-13B000$130.mif

DIESEL INJECTION

Fault finding – Command summary table13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

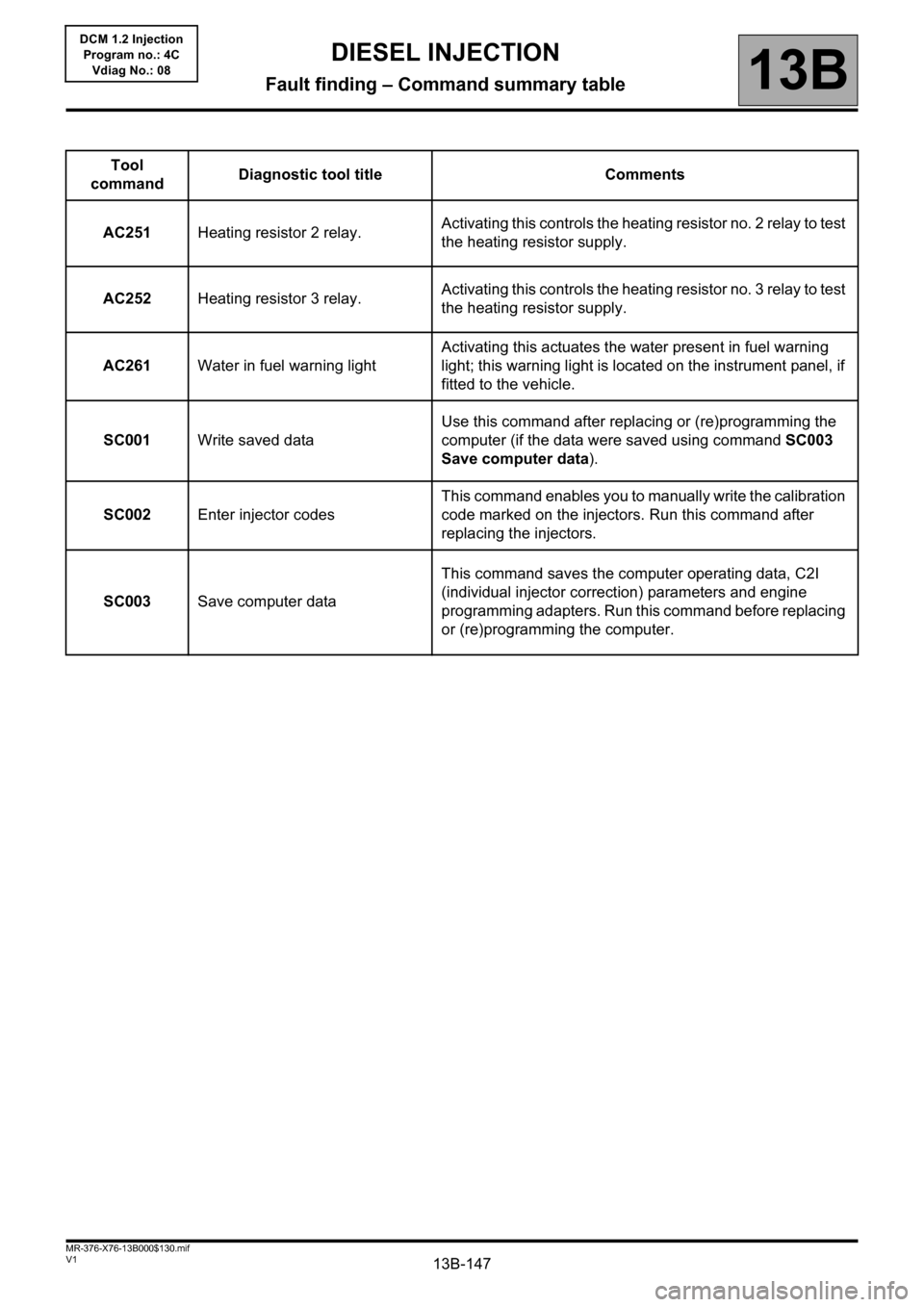

Tool

commandDiagnostic tool title Comments

AC251 Heating resistor 2 relay.Activating this controls the heating resistor no. 2 relay to test

the heating resistor supply.

AC252 Heating resistor 3 relay.Activating this controls the heating resistor no. 3 relay to test

the heating resistor supply.

AC261 Water in fuel warning lightActivating this actuates the water present in fuel warning

light; this warning light is located on the instrument panel, if

fitted to the vehicle.

SC001 Write saved dataUse this command after replacing or (re)programming the

computer (if the data were saved using command SC003

Save computer data).

SC002 Enter injector codesThis command enables you to manually write the calibration

code marked on the injectors. Run this command after

replacing the injectors.

SC003 Save computer dataThis command saves the computer operating data, C2I

(individual injector correction) parameters and engine

programming adapters. Run this command before replacing

or (re)programming the computer.

Page 148 of 204

13B-148V1 MR-376-X76-13B000$140.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

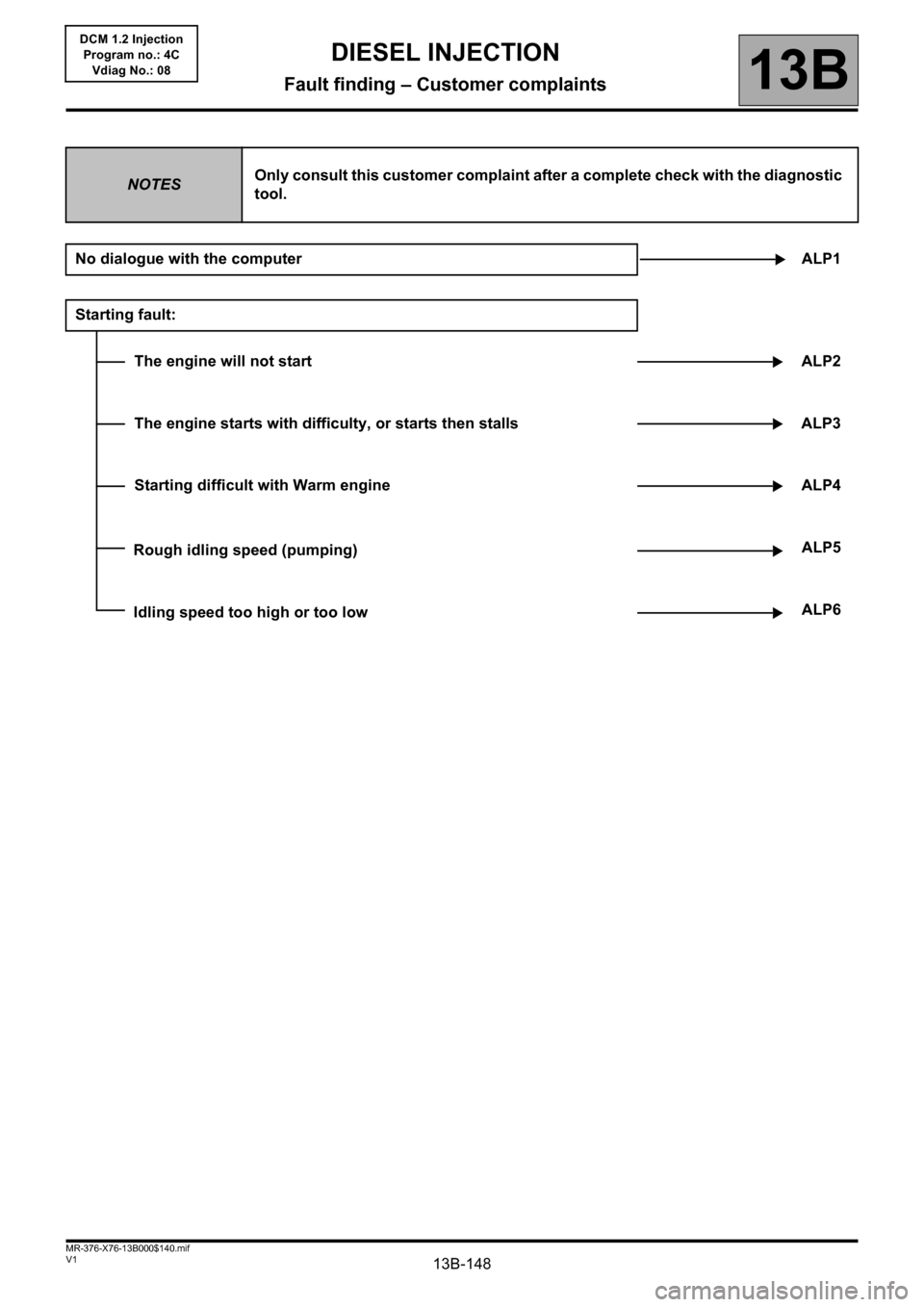

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

No dialogue with the computerALP1

Starting fault:

The engine will not start ALP2

The engine starts with difficulty, or starts then stalls ALP3

Starting difficult with Warm engine ALP4

Rough idling speed (pumping)ALP5

Idling speed too high or too lowALP6

DIESEL INJECTION

Fault finding – Customer complaints

Page 149 of 204

13B-149V1 MR-376-X76-13B000$140.mif

DIESEL INJECTION

Fault finding – Customer complaints13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

Behaviour while driving:

Erratic acceleration/deceleration and engine racing ALP7

Acceleration gapALP8

Engine cut-out (stalling)ALP9

Engine buckingALP10

Loss of powerALP11

Too much powerALP 12

Excessive consumptionALP 13

Overspeed when releasing accelerator or changing gearALP 14

Engine dies on pulling awayALP 15

Noise, odours, or smoke:

Engine rattling, noisy engine, turbocharger noise ALP 16

Blue, white or black smoke ALP 17

Smoke (blue, white or black) on accelerationALP 18

Page 150 of 204

13B-150

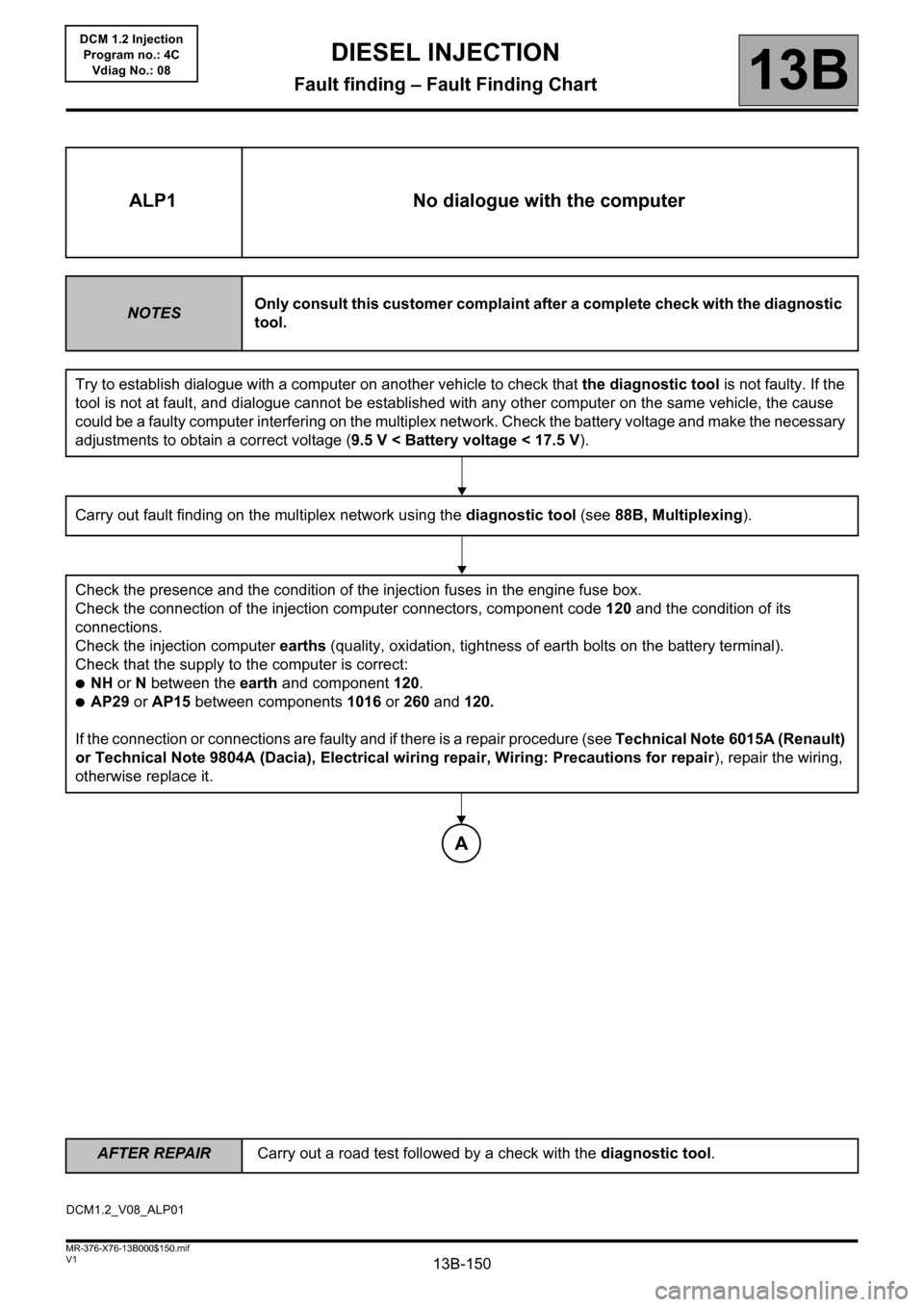

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

ALP1 No dialogue with the computer

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Try to establish dialogue with a computer on another vehicle to check that the diagnostic tool is not faulty. If the

tool is not at fault, and dialogue cannot be established with any other computer on the same vehicle, the cause

could be a faulty computer interfering on the multiplex network. Check the battery voltage and make the necessary

adjustments to obtain a correct voltage (9.5 V < Battery voltage < 17.5 V).

Carry out fault finding on the multiplex network using the diagnostic tool (see88B, Multiplexing).

Check the presence and the condition of the injection fuses in the engine fuse box.

Check the connection of the injection computer connectors, component code 120 and the condition of its

connections.

Check the injection computer earths (quality, oxidation, tightness of earth bolts on the battery terminal).

Check that the supply to the computer is correct:

●NH or N between the earth and component 120.

●AP29 or AP15 between components 1016 or 260 and 120.

If the connection or connections are faulty and if there is a repair procedure (see Technical Note 6015A (Renault)

or Technical Note 9804A (Dacia), Electrical wiring repair, Wiring: Precautions for repair), repair the wiring,

otherwise replace it.

A

DCM1.2_V08_ALP01

DIESEL INJECTION

Fault finding – Fault Finding Chart