RENAULT KANGOO 2013 X61 / 2.G Diesel DCM 1.2 Injection Workshop Manual

Manufacturer: RENAULT, Model Year: 2013, Model line: KANGOO, Model: RENAULT KANGOO 2013 X61 / 2.GPages: 204, PDF Size: 0.99 MB

Page 181 of 204

13B-181

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

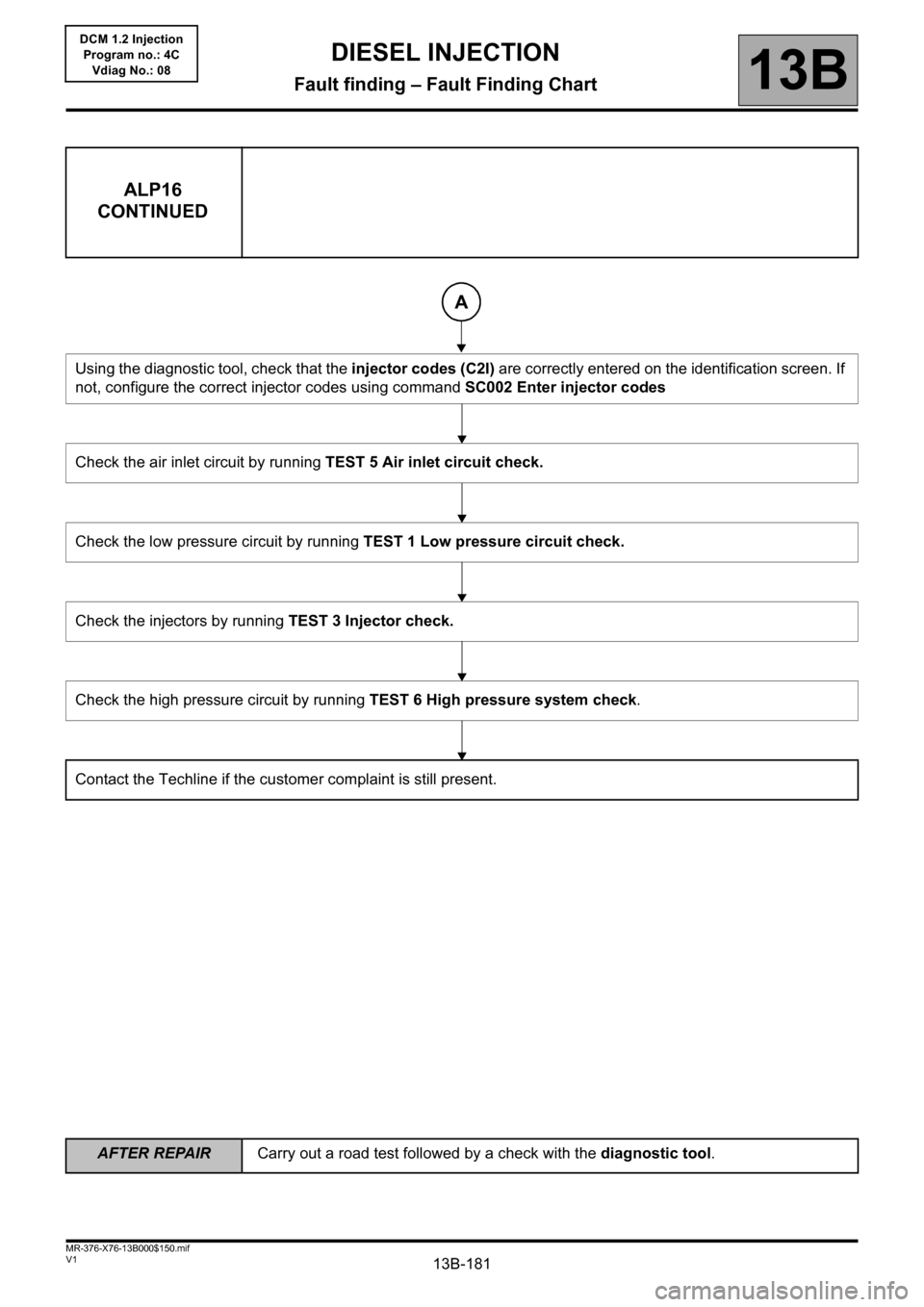

ALP16

CONTINUED

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Check the air inlet circuit by running TEST 5 Air inlet circuit check.

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Check the high pressure circuit by running TEST 6 High pressure system check.

Contact the Techline if the customer complaint is still present.

A

Page 182 of 204

13B-182

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

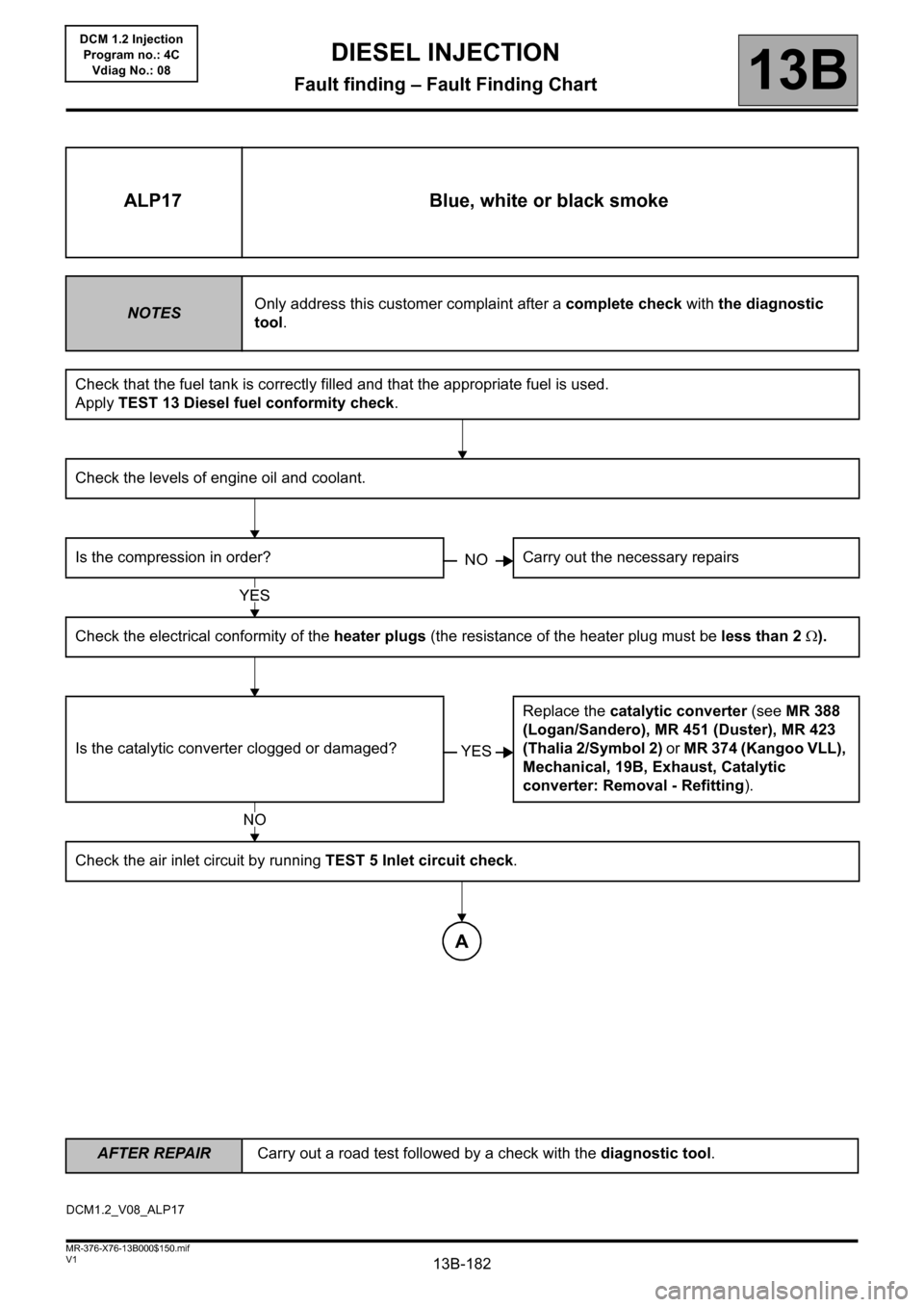

ALP17 Blue, white or black smoke

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Is the compression in order? Carry out the necessary repairs

Check the electrical conformity of the heater plugs (the resistance of the heater plug must be less than 2 ).

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR 388

(Logan/Sandero), MR 451 (Duster), MR 423

(Thalia 2/Symbol 2) or MR 374 (Kangoo VLL),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Check the air inlet circuit by running TEST 5 Inlet circuit check.

NO

YES

YES

NO

A

DCM1.2_V08_ALP17

Page 183 of 204

13B-183

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

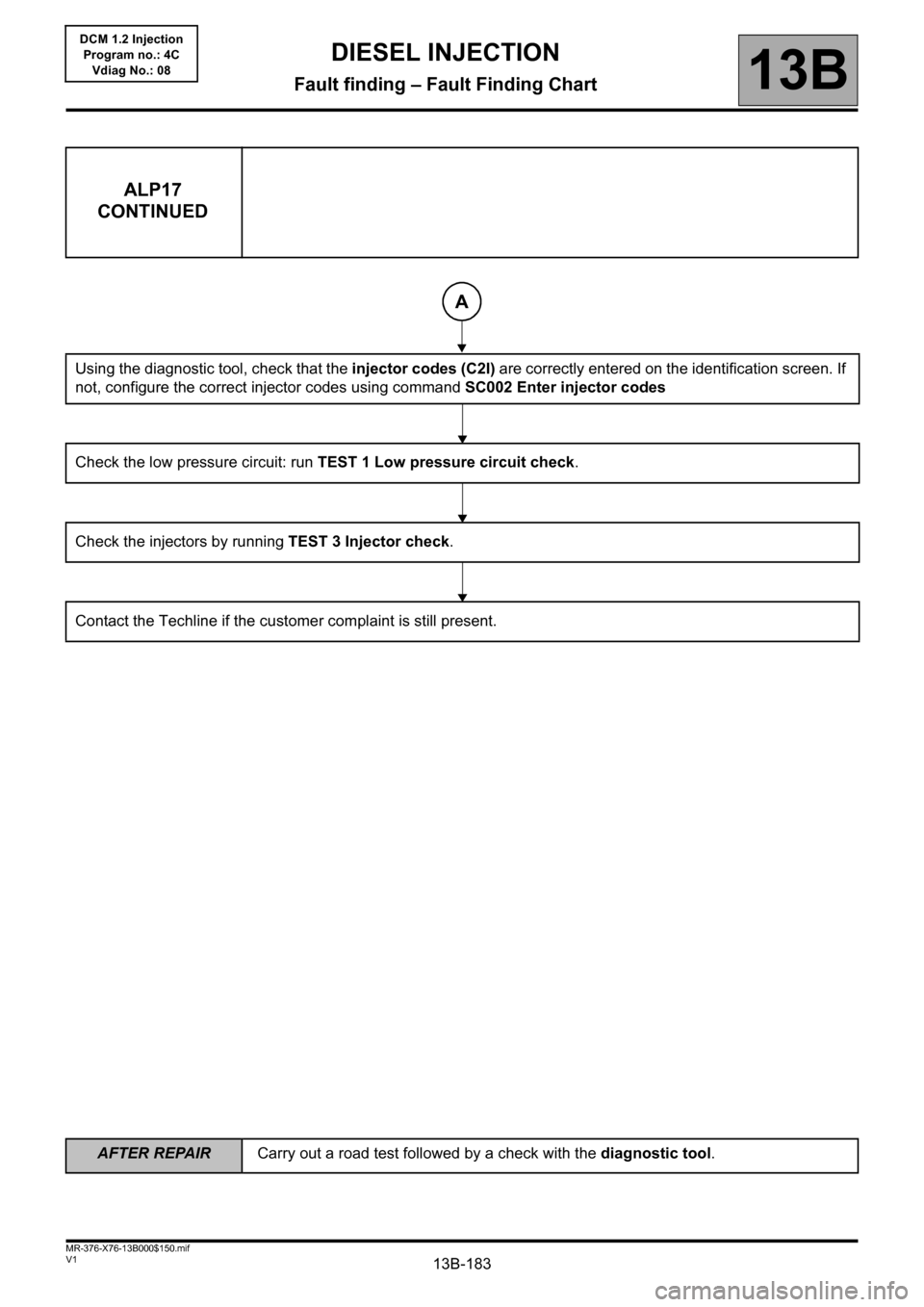

ALP17

CONTINUED

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Contact the Techline if the customer complaint is still present.

A

Page 184 of 204

13B-184

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

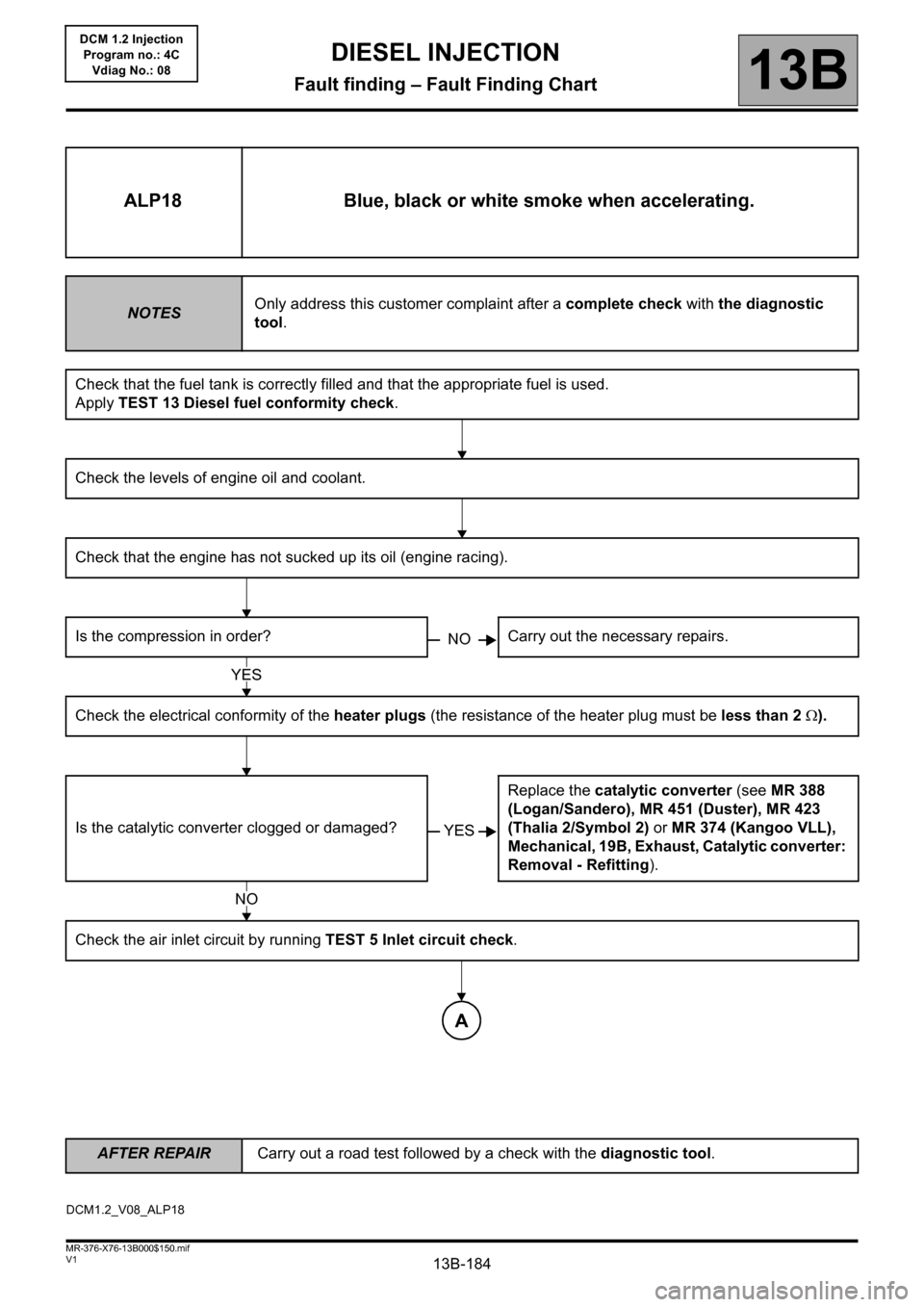

ALP18 Blue, black or white smoke when accelerating.

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Check that the fuel tank is correctly filled and that the appropriate fuel is used.

Apply TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check that the engine has not sucked up its oil (engine racing).

Is the compression in order? Carry out the necessary repairs.

Check the electrical conformity of the heater plugs (the resistance of the heater plug must be less than 2 ).

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR 388

(Logan/Sandero), MR 451 (Duster), MR 423

(Thalia 2/Symbol 2) or MR 374 (Kangoo VLL),

Mechanical, 19B, Exhaust, Catalytic converter:

Removal - Refitting).

Check the air inlet circuit by running TEST 5 Inlet circuit check.

NO

YES

YES

NO

A

DCM1.2_V08_ALP18

Page 185 of 204

13B-185

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

V1 MR-376-X76-13B000$150.mif

DIESEL INJECTION

Fault finding – Fault Finding Chart13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

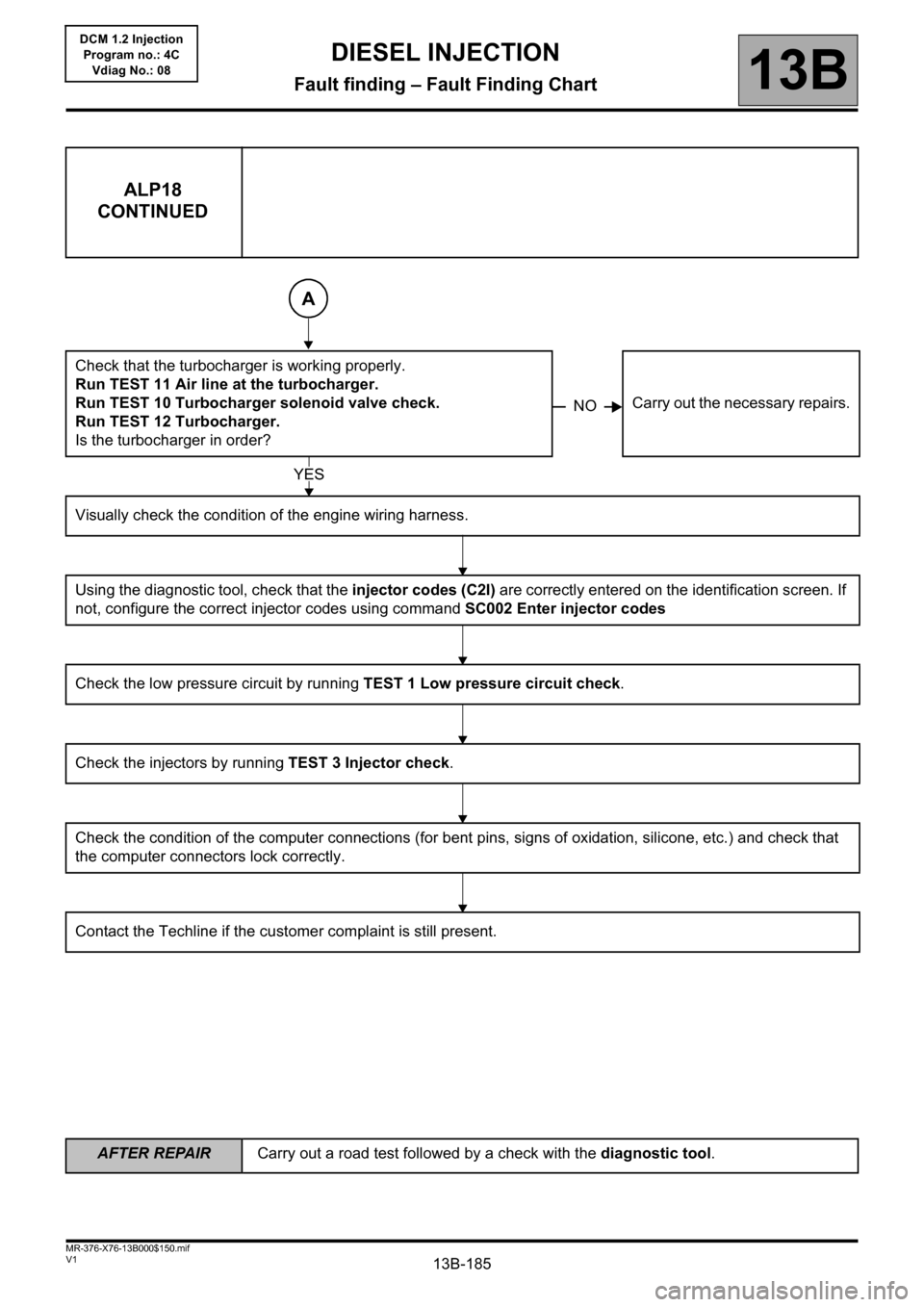

ALP18

CONTINUED

Check that the turbocharger is working properly.

Run TEST 11 Air line at the turbocharger.

Run TEST 10 Turbocharger solenoid valve check.

Run TEST 12 Turbocharger.

Is the turbocharger in order?Carry out the necessary repairs.

Visually check the condition of the engine wiring harness.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes

Check the low pressure circuit by running TEST 1 Low pressure circuit check.

Check the injectors by running TEST 3 Injector check.

Check the condition of the computer connections (for bent pins, signs of oxidation, silicone, etc.) and check that

the computer connectors lock correctly.

Contact the Techline if the customer complaint is still present.

A

NO

YES

Page 186 of 204

13B-186V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

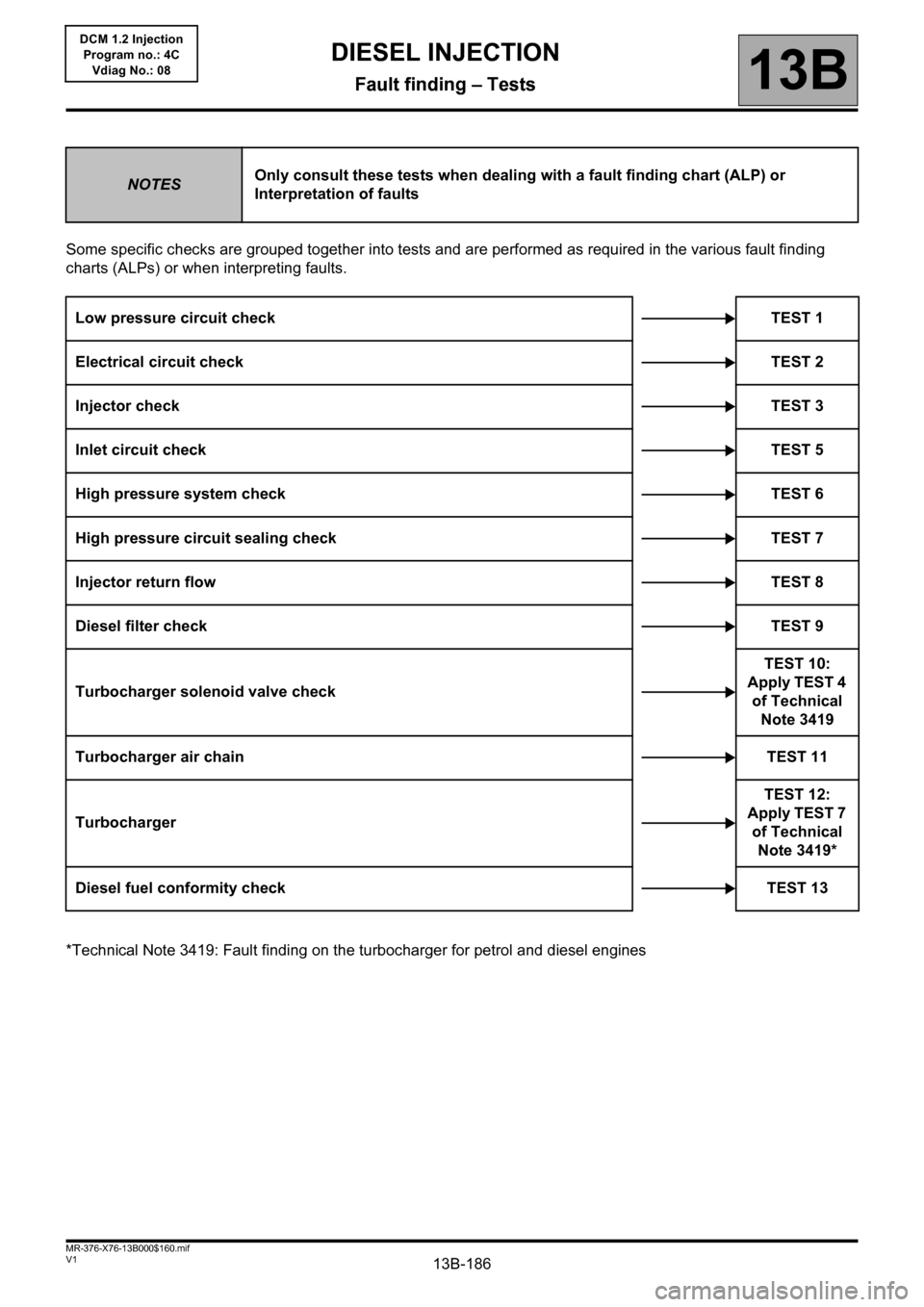

Some specific checks are grouped together into tests and are performed as required in the various fault finding

charts (ALPs) or when interpreting faults.

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel engines

NOTESOnly consult these tests when dealing with a fault finding chart (ALP) or

Interpretation of faults

Low pressure circuit checkTEST 1

Electrical circuit checkTEST 2

Injector checkTEST 3

Inlet circuit checkTEST 5

High pressure system check TEST 6

High pressure circuit sealing check TEST 7

Injector return flowTEST 8

Diesel filter checkTEST 9

Turbocharger solenoid valve checkTEST 10:

Apply TEST 4

of Technical

Note 3419

Turbocharger air chainTEST 11

TurbochargerTEST 12:

Apply TEST 7

of Technical

Note 3419*

Diesel fuel conformity check TEST 13

DIESEL INJECTION

Fault finding – Tests

Page 187 of 204

13B-187V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

TEST 1 Low pressure circuit check

Check the conformity of the low pressure circuit

connections

Are the low pressure circuit connections correct? Carry out the necessary repairs.

Check the condition of the priming bulb, and that it is

working properly.

Look for leaks at the unions.

Are there leaks from the hoses and unions? Carry out the necessary repairs

Check that there are no air bubbles in the diesel fuel. Bleed the low-pressure circuit.

Place a container under the filter.

– Disconnect the return hose from the filter

and plug the filter.

– Pump using the priming bulb until there is no

air left.

– Reconnect the return hose immediately. Check if there are air bubbles in the low pressure

circuit.

Low pressure circuit correct.

NO

YES

YES

NO

YES

NO

DCM1.2_V08_TEST01

Page 188 of 204

13B-188V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

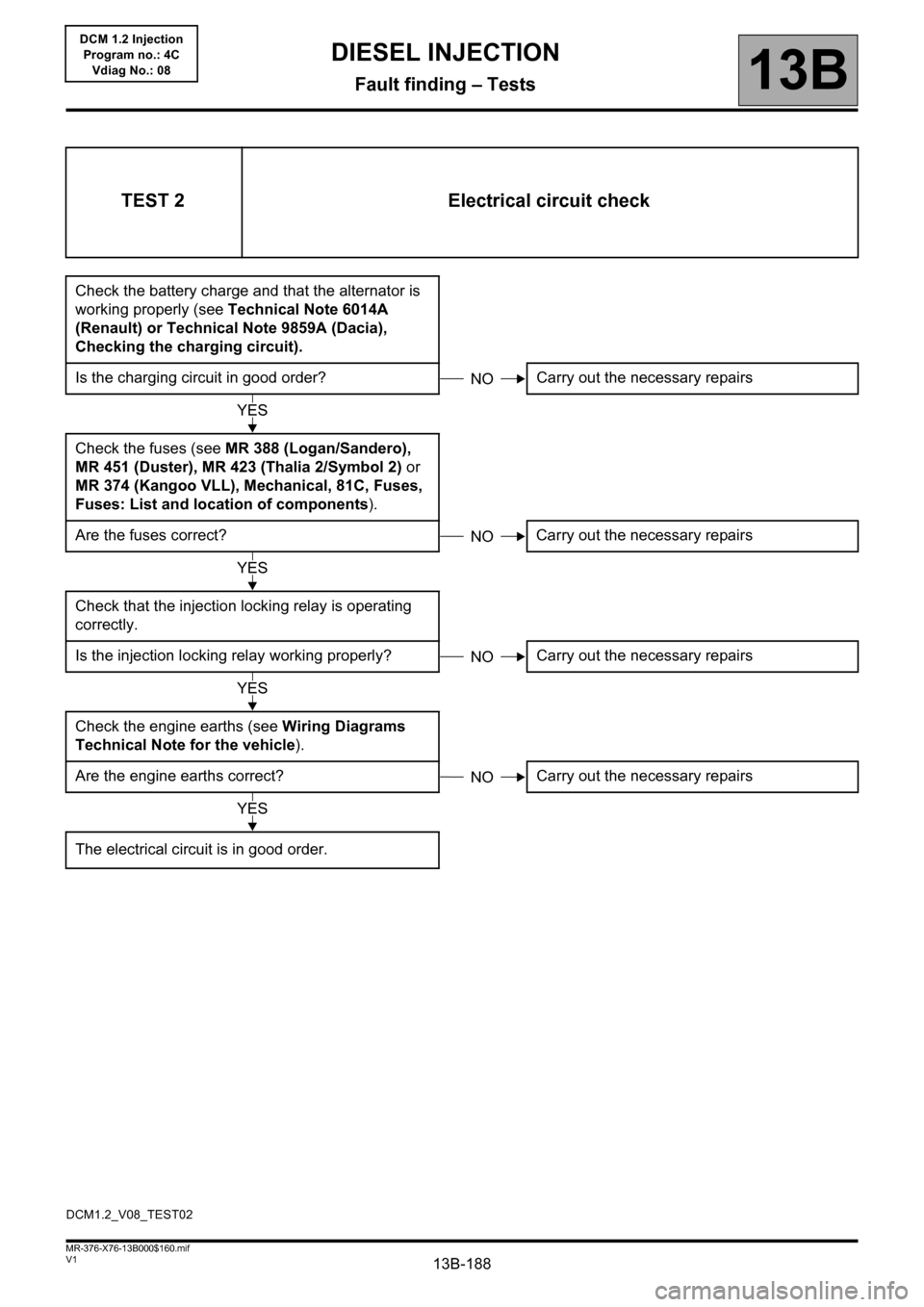

TEST 2 Electrical circuit check

Check the battery charge and that the alternator is

working properly (see Technical Note 6014A

(Renault) or Technical Note 9859A (Dacia),

Checking the charging circuit).

Is the charging circuit in good order? Carry out the necessary repairs

Check the fuses (see MR 388 (Logan/Sandero),

MR 451 (Duster), MR 423 (Thalia 2/Symbol 2) or

MR 374 (Kangoo VLL), Mechanical, 81C, Fuses,

Fuses: List and location of components).

Are the fuses correct? Carry out the necessary repairs

Check that the injection locking relay is operating

correctly.

Is the injection locking relay working properly? Carry out the necessary repairs

Check the engine earths (see Wiring Diagrams

Technical Note for the vehicle).

Are the engine earths correct? Carry out the necessary repairs

The electrical circuit is in good order.

NO

YES

NO

YES

NO

YES

NO

YES

DCM1.2_V08_TEST02

Page 189 of 204

13B-189V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

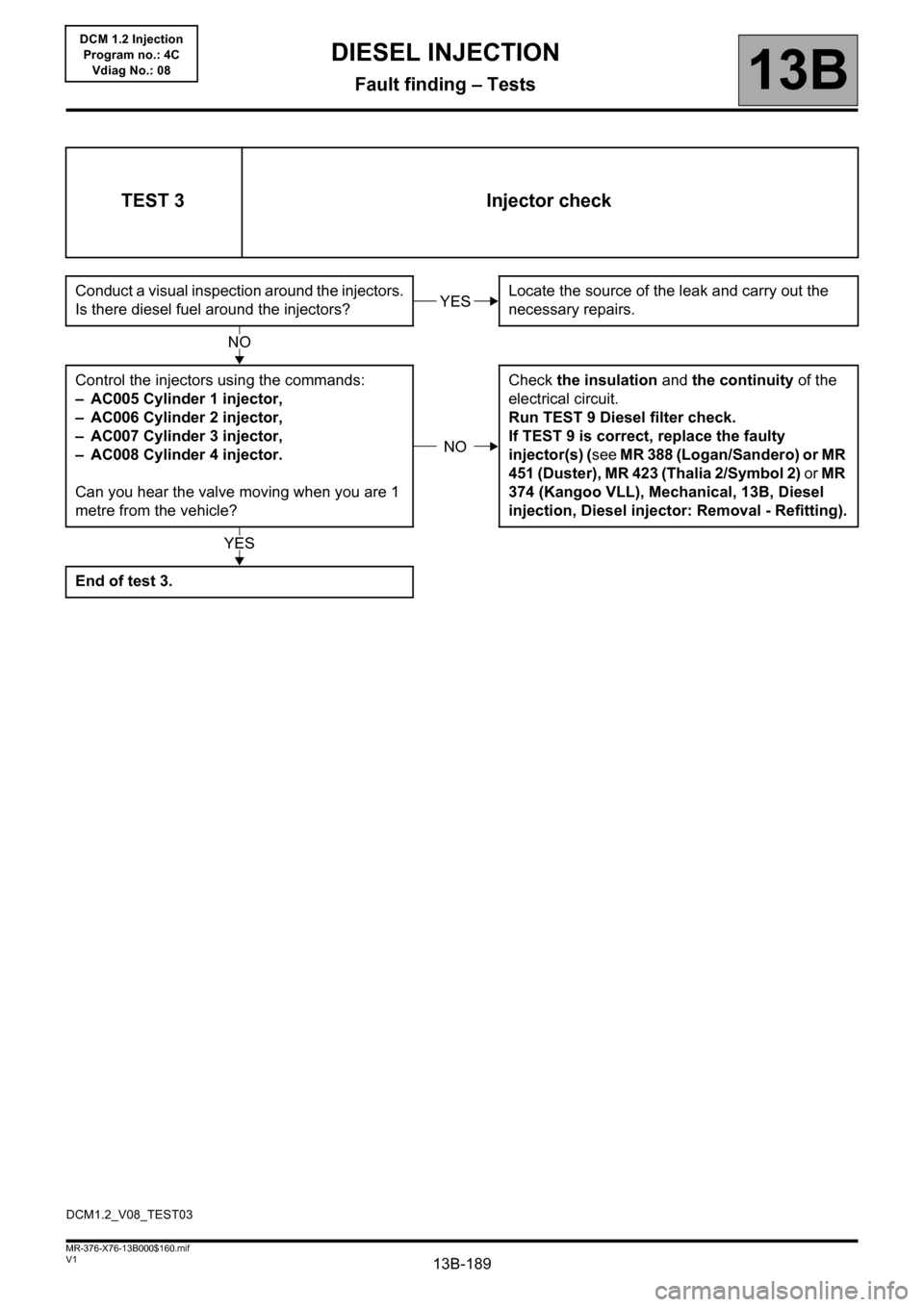

TEST 3 Injector check

Conduct a visual inspection around the injectors.

Is there diesel fuel around the injectors?Locate the source of the leak and carry out the

necessary repairs.

Control the injectors using the commands:

– AC005 Cylinder 1 injector,

– AC006 Cylinder 2 injector,

– AC007 Cylinder 3 injector,

– AC008 Cylinder 4 injector.

Can you hear the valve moving when you are 1

metre from the vehicle?Check the insulation and the continuity of the

electrical circuit.

Run TEST 9 Diesel filter check.

If TEST 9 is correct, replace the faulty

injector(s) (see MR 388 (Logan/Sandero) or MR

451 (Duster), MR 423 (Thalia 2/Symbol 2) or MR

374 (Kangoo VLL), Mechanical, 13B, Diesel

injection, Diesel injector: Removal - Refitting).

End of test 3.YES

NO

NO

YES

DCM1.2_V08_TEST03

Page 190 of 204

13B-190V1 MR-376-X76-13B000$160.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program no.: 4C

Vdiag No.: 08

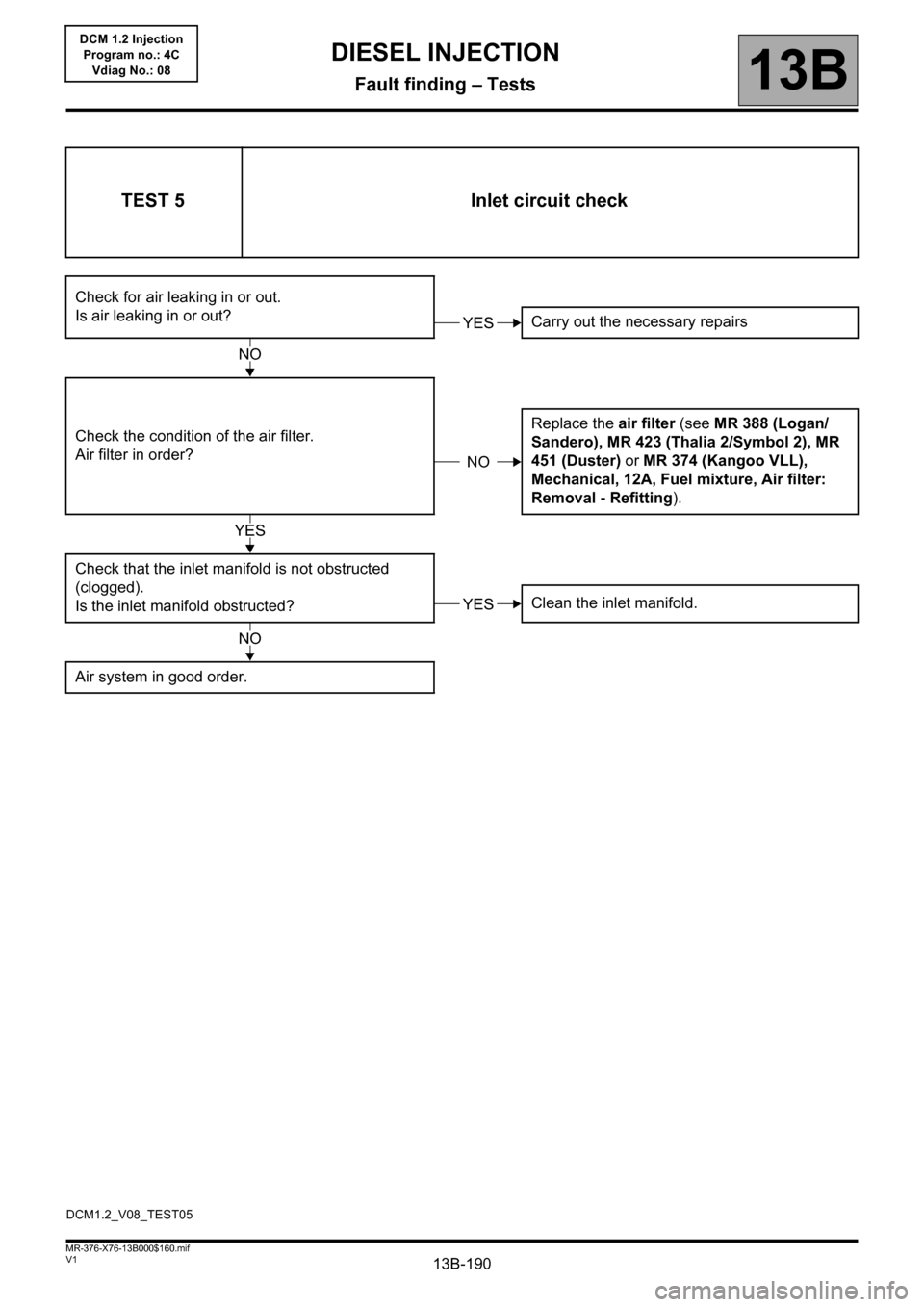

TEST 5 Inlet circuit check

Check for air leaking in or out.

Is air leaking in or out?

Carry out the necessary repairs

Check the condition of the air filter.

Air filter in order?Replace the air filter (see MR 388 (Logan/

Sandero), MR 423 (Thalia 2/Symbol 2), MR

451 (Duster) or MR 374 (Kangoo VLL),

Mechanical, 12A, Fuel mixture, Air filter:

Removal - Refitting).

Check that the inlet manifold is not obstructed

(clogged).

Is the inlet manifold obstructed?Clean the inlet manifold.

Air system in good order.

YES

NO

NO

YES

YES

NO

DCM1.2_V08_TEST05