Seat Alhambra 2011 Owner's Manual

Manufacturer: SEAT, Model Year: 2011, Model line: Alhambra, Model: Seat Alhambra 2011Pages: 385, PDF Size: 7.92 MB

Page 331 of 385

329

If and when fig. 203,

fig. 204 A B C

Indicators (small lamp

holder) Dipped beam head-

lights Daylight driving lights Main beam headlights Side lights

3. Remove the rubber cover on the rear of the headlight.

4. Rotate the lamp holder

1 to the left all the way

and pu l

l it out back-

wards with the bulb. Rotate the lamp holder to the left all the way and

pul

l it out backwards with the bulb. Press the wire clip down-

war d

s and pull the lamp

holder 2 out with the

bu l

b. Pull the lamp holder

3 out backwards with the

bul

b. 5. Depending on the model, the bulb is removed directly from the lamp holder or it may need to be rotated and then removed.

6. Replace the faulty bulb by a new identical bulb.

7. Place the bulb holder in the headlight and rotate to the right all the way. Place the lamp holder in

the hea

dlight

and pull the

wire clip upwards until it

clicks into place. Place the lamp holder in

the hea dlight

and insert

completely. 8. Insert the rubber cover.

Note

The images show the left hand headlight from behind. The structure of the

right h and s

ide headlight is symmetric. Safety First Operating instructions Practical tips Technical Data

Page 332 of 385

330

If and when

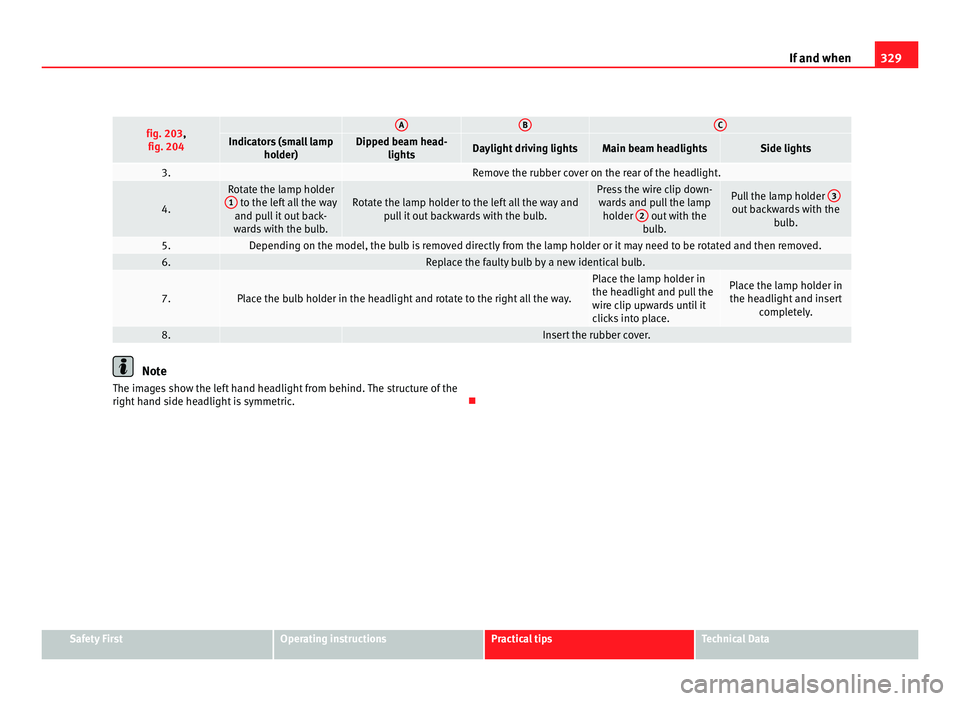

To replace the xenon headlights bulb Fig. 205 In the engine

comp

ar

tment: Turn signal

cover. Fig. 206 Turn signal in-

dicat

or l

amp holder 1 and turning light

2 .

There is no need to remove the headlight to replace bulbs.

Comp l

ete operations only in the sequence given: Turn signal indicators

1 Turning lights

2 1. Always take the checklist into account and take the necessary ac-

tions ⇒

page 327. 2. Open the bonnet

⇒ page 275. 3. Rotate the cover ⇒

fig. 205 in the dir

ection of the arrow and remove

it. 4. Rotate the lamp holder

1 ⇒ fig. 206 to the left all the way

and p

u

ll it out backwards with

the bulb. Press the wire clip downwards

and pu

l

l the lamp holder 2 ⇒ fig. 206 out w

ith the b

ulb. 5. Depending on the model, the bulb is removed directly from the

lamp ho l

der or it may need to be rotated and then removed. 6. Replace the faulty bulb by a new identical bulb.

7. Place the bulb holder in the

hea

dlight

and rotate to the right

all the way. Place the lamp holder in the

hea

dlight

and pull the wire clip

upwards until it clicks into place. 8. Rotate the cover ⇒

fig. 205 in the op

posite direction to the arrow as

far as it will go. Always seek the help of a specialist when changing the Xenon dipped beam

and fu

l

l beam headlamps ⇒ in Introduction on page 326.

Note

The illustrations show the left hand headlight. The structure of the right

hand s ide he

adlight is symmetric.

Page 333 of 385

331

If and when

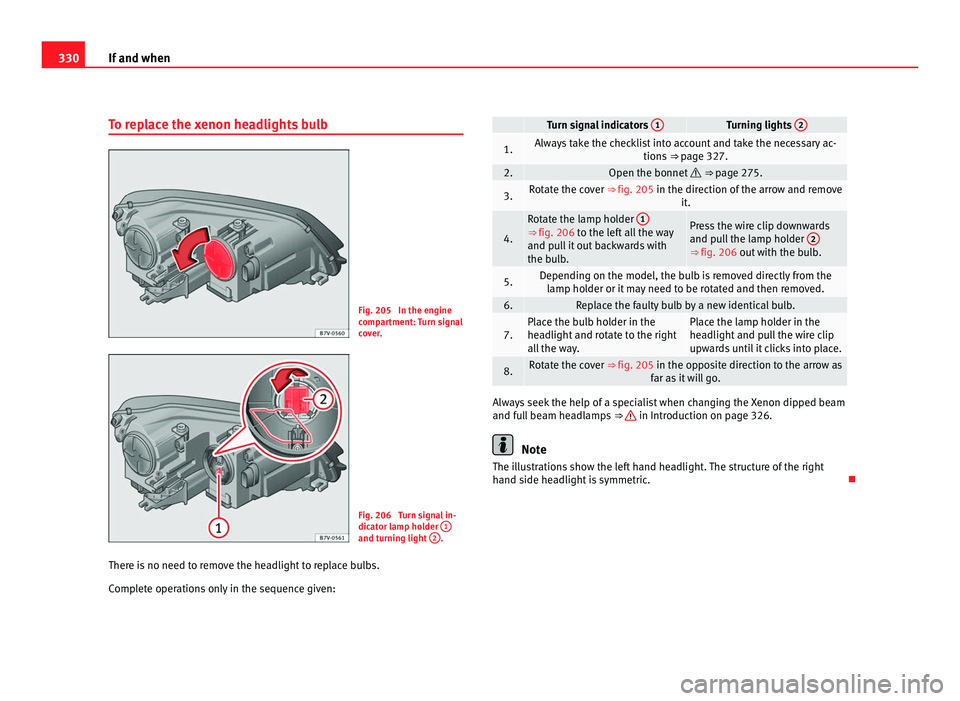

To replace the front bumper bulbs Fig. 207 On the right-

hand s

ide of

the front

bumper: Removing the

headlights Fig. 208 Changing the

bu

l

bs in the headlights.

Complete operations only in the sequence given: 1. Always take the checklist into account and take the necessary ac-

tions

⇒

page 327. 2. Pull the cover forwards, in the direction of the arrow

⇒ fig. 207. 3. Unscrew the attachment screw

⇒ fig. 207 1 using the screwdriver

from the on-bo ar

d tools ⇒ page 320. 4. Tilt the headlight slightly forward and extract it from its lateral at-

tac

hments

⇒ fig. 208 (small arrows). 5. Release the connector ⇒ fig. 208

1 and remove it.

6. Rotate the lamp holder ⇒ fig. 208

2 to the left all the way, in the

direction of the arr

ow, and pull it out backwards with the bulb. 7. Replace the faulty bulb by a new identical bulb.

8. Place the bulb holder in the headlight and rotate to the right all the

wa

y

. 9. Insert the connector

⇒ fig. 208 1 on the lamp holder

⇒ fig. 208 2 . The connector must audibly click into place.

10. Place the headlight into its position

⇒ fig. 208 (small

arrows) and

tilt it backwards. 11. Tighten the attachment screw

⇒ fig. 207 1 using the screwdriver.

12. Replace the cover on the bumper ⇒ fig. 207.

Safety First Operating instructions Practical tips Technical Data

Page 334 of 385

332

If and when

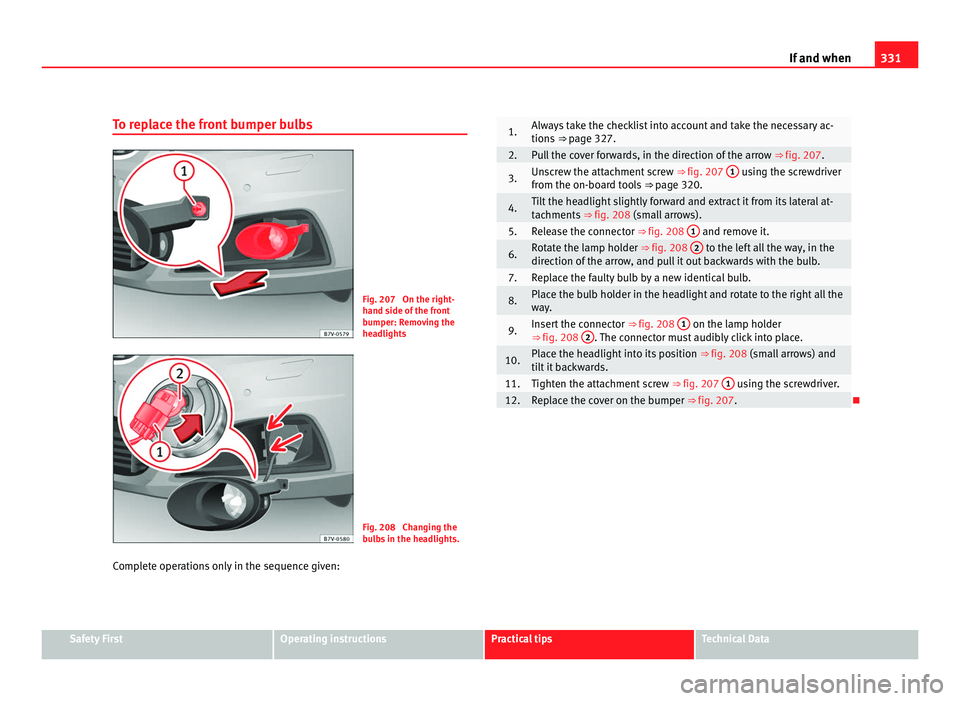

To replace the tailgate light bulbs Fig. 209 On the boot lid:

Remo

v

e the cover. Fig. 210 On the boot lid:

Remo

v

e the lamp holder. Complete operations only in the sequence given: 1. Always take the checklist into account and take the necessary ac-

tions

⇒

page 327. 2. Open the tailgate ⇒ pag

e 84. 3. Extract the cover carefully using the flat part of the screwdriver as a

lev

er (

⇒ fig. 198) on the indent ⇒ fig. 209 1 .

4. Release the lamp holder connector by pulling on the red connector

bloc

k. 5. Press on the attachment tabs in the direction of the arrow

⇒ fig. 210 and pu

l

l out the lamp holder. 6. Replace the faulty bulb by a new identical bulb.

7. Install the lamp holder. The attachment tabs should audibly click

into p

l

ace. 8. Insert the cover. The cover should lock into place.

Page 335 of 385

333

If and when

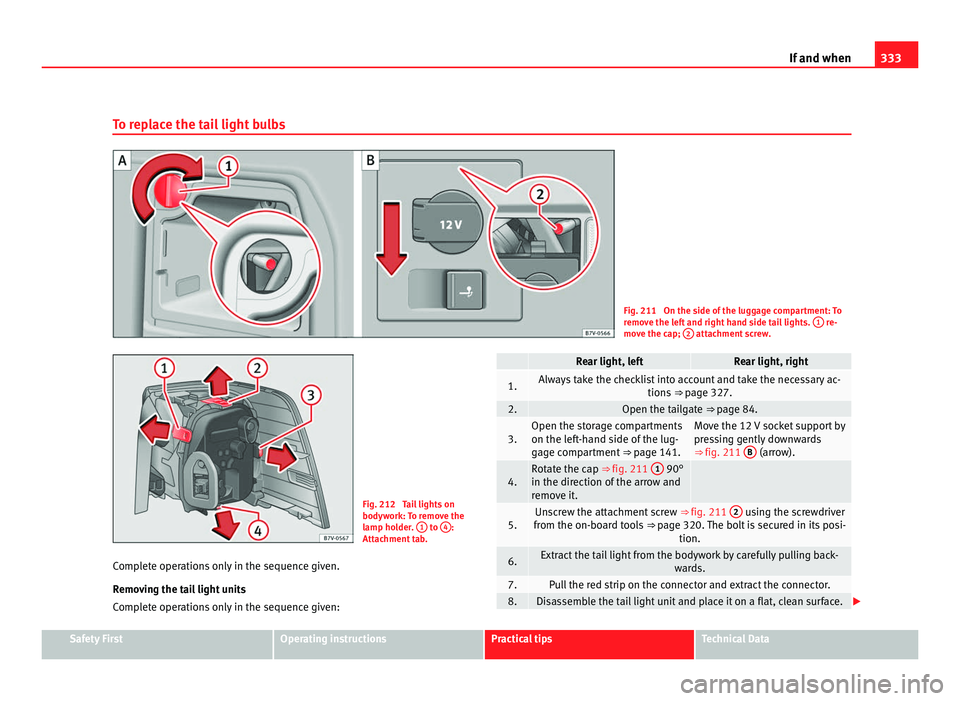

To replace the tail light bulbs Fig. 211 On the side of the luggage compartment: To

remo

v

e the left and right hand side tail lights. 1 re-

mov e the c

ap; 2 attachment screw.

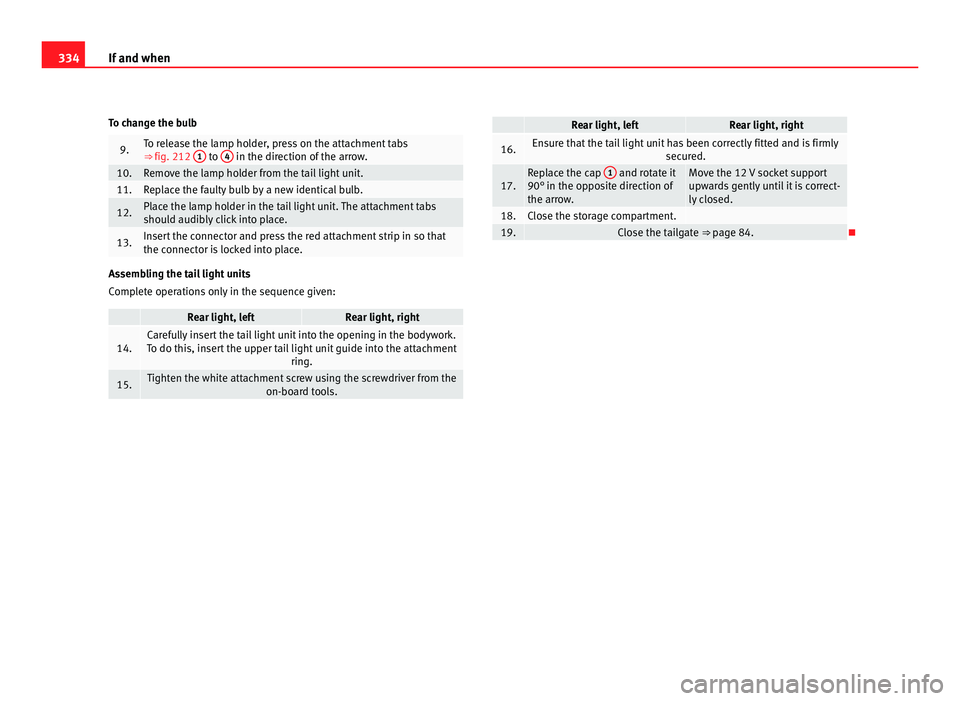

Fig. 212 Tail lights on

bodywork:

T

o remove the

lamp holder. 1 to

4 :

Attac hment

tab.

Complete operations only in the sequence given.

Remov

ing the tail light units

Complete operations only in the sequence given: Rear light, left Rear light, right

1. Always take the checklist into account and take the necessary ac-

tions ⇒

page 327. 2. Open the tailgate ⇒ pag

e 84. 3. Open the storage compartments

on the lef

t

-hand side of the lug-

gage compartment ⇒ page 141. Move the 12 V socket support by

pre

s

sing gently downwards

⇒ fig. 211 B (arrow).

4. Rotate the cap ⇒ fig. 211

1 90°

in the direction of the arr

ow and

remove it.

5. Unscrew the attachment screw

⇒ fig. 211 2 using the screwdriver

from the on-bo ar

d tools ⇒ page 320. The bolt is secured in its posi-

tion. 6. Extract the tail light from the bodywork by carefully pulling back-

ward

s. 7. Pull the red strip on the connector and extract the connector.

8. Disassemble the tail light unit and place it on a flat, clean surface.

Safety First Operating instructions Practical tips Technical Data

Page 336 of 385

334

If and when

To change the bulb 9. To release the lamp holder, press on the attachment tabs

⇒ fig. 212

1 to

4 in the direction of the arrow.

10. Remove the lamp holder from the tail light unit.

11. Replace the faulty bulb by a new identical bulb.

12. Place the lamp holder in the tail light unit. The attachment tabs

shoul

d audib

ly click into place. 13. Insert the connector and press the red attachment strip in so that

the connect

or i

s locked into place.Assembling the tail light units

Comp

l

ete operations only in the sequence given: Rear light, left Rear light, right

14. Carefully insert the tail light unit into the opening in the bodywork.

To do thi s, in

sert the upper tail light unit guide into the attachment ring.15. Tighten the white attachment screw using the screwdriver from the

on-board t

ools. Rear light, left Rear light, right

16. Ensure that the tail light unit has been correctly fitted and is firmly

secured. 17. Replace the cap

1 and rotate it

90° in the oppo s

ite direction of

the arrow. Move the 12 V socket support

upw

ar

ds gently until it is correct-

ly closed. 18. Close the storage compartment.

19. Close the tailgate ⇒

pag

e 84.

Page 337 of 385

335

If and when

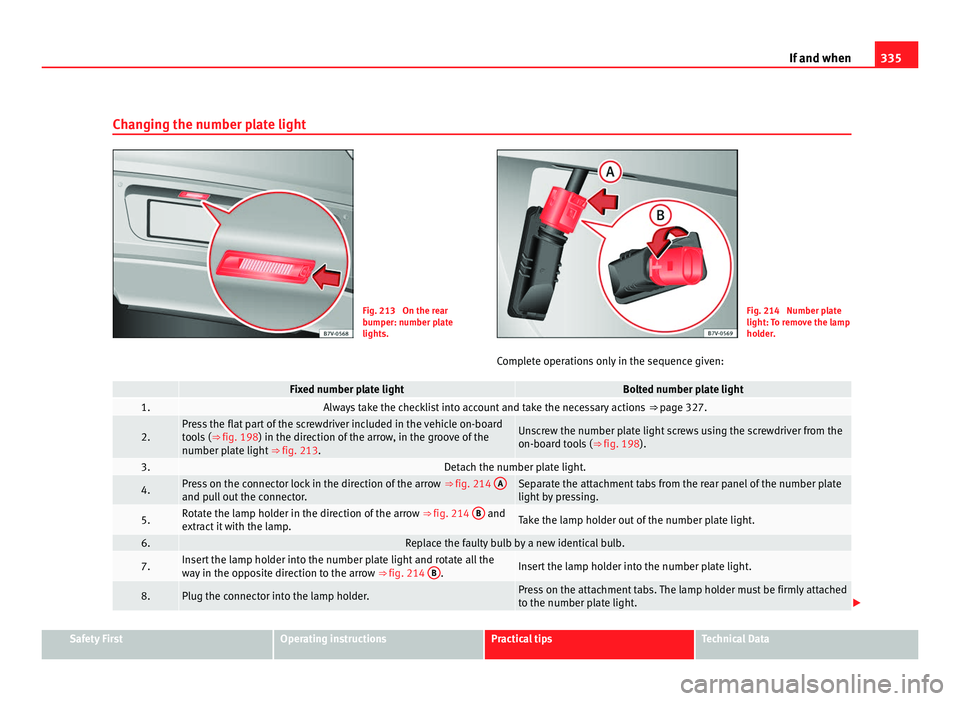

Changing the number plate light Fig. 213 On the rear

bumper: number p

l

ate

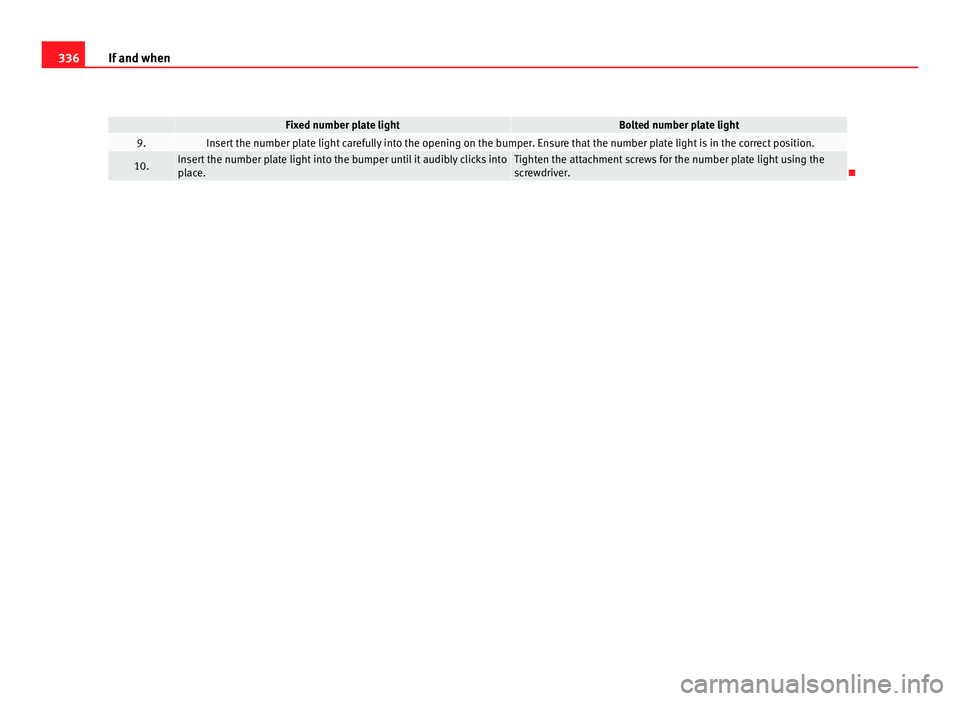

lights. Fig. 214 Number plate

light: T

o r

emove the lamp

holder.

Complete operations only in the sequence given: Fixed number plate light Bolted number plate light

1. Always take the checklist into account and take the necessary actions

⇒ page 327. 2. Press the flat part of the screwdriver included in the vehicle on-board

too

l

s (⇒ fig. 198) in the direction of the arrow, in the groove of the

number plate light ⇒ fig. 213. Unscrew the number plate light screws using the screwdriver from the

on-boar

d t

ools (⇒ fig. 198). 3. Detach the number plate light.

4. Press on the connector lock in the direction of the arrow

⇒ fig. 214 A and pull out the connector. Separate the attachment tabs from the rear panel of the number plate

light b

y

pressing. 5. Rotate the lamp holder in the direction of the arrow

⇒ fig. 214 B and

extr act

it with the lamp. Take the lamp holder out of the number plate light.

6. Replace the faulty bulb by a new identical bulb.

7. Insert the lamp holder into the number plate light and rotate all the

wa

y

in the opposite direction to the arrow ⇒ fig. 214 B . Insert the lamp holder into the number plate light.

8. Plug the connector into the lamp holder. Press on the attachment tabs. The lamp holder must be firmly attached

to the number p

l

ate light. Safety First Operating instructions Practical tips Technical Data

Page 338 of 385

336

If and when Fixed number plate light Bolted number plate light

9. Insert the number plate light carefully into the opening on the bumper. Ensure that the number plate light is in the correct position.

10. Insert the number plate light into the bumper until it audibly clicks into

pl

ac

e. Tighten the attachment screws for the number plate light using the

sc

r

ewdriver.

Page 339 of 385

337

If and when

Starting assistance

Introduction If the engine fails to start because of a discharged battery, the battery of an-

other v

ehic

le can be used to start the engine. Before starting, check the

magic eye on the battery ⇒ page 288.

For starting assistance, jump lead cables conforming to the standard

DIN 72553 are required (see the cable manufacturer instructions). The jump

lead cable must be at least 25 mm 2

in section (0.038 inches 2

) for petrol en-

gines, and 35 mm 2

(0.054 inches 2

) for diesel engines.

For vehicles whose battery is not in the engine compartment, the jump

leads should only be connected to the starting assistance connection

points in the engine compartment.

Additional information and warnings:

● Starter assist systems (Start-Stop function) ⇒ pag

e 194

● Working in the engine compartment ⇒ pag

e 275

● Selective Catalytic Reduction (AdBlue) ⇒ pag

e 271

● Vehicle battery ⇒ pag

e 288 WARNING

Incorrect use of jump leads and incorrectly jump starting could cause the

batt er

y to explode resulting in serious injury. Please observe the follow-

ing rules to minimise the risk of a battery explosion:

● All work involving the vehicle battery and electrical system can cause

corro

sion, fire and serious electric shocks. Always read and take into ac-

count the safety warnings and standards before beginning work on the

battery ⇒ page 288, Vehicle battery. WARNING (Continued)

● The b attery providing current must have the same voltage (12V) and

ap pr

oximately the same capacity (see markings on battery) as the flat

battery.

● Never charge a frozen or recently thawed battery. A flat battery can

freeze at

temperatures around 0°C (+32°F).

● If a battery is frozen and/or has been frozen then it must be replaced.

● A highly explosive mixture of gases is released when the battery is

being ch

arged. Always keep lit cigarettes, open flames, sparks and fire

far from the battery. Never use a mobile telephone when connecting and

removing the jump leads.

● Charge the battery only in well ventilated areas given that when the

batter

y is charged by outside assistance, it creates a mix of highly explo-

sive gases.

● Jump leads should never enter into contact with moving parts in the

engine comp

artment.

● Never switch the positive and negative poles or connect the jump

lea

ds incorrectly.

● Note the instructions provided by the manufacturer of the jump leads. CAUTION

To avoid considerable damage to the vehicle electrical system, note the fol-

low in

g carefully:

● If the jump leads are incorrectly connected, this could result in a short

circ

uit.

● The vehicles must not touch each other, otherwise electricity could flow

as soon a

s the positive terminals are connected. Safety First Operating instructions Practical tips Technical Data

Page 340 of 385

338

If and when

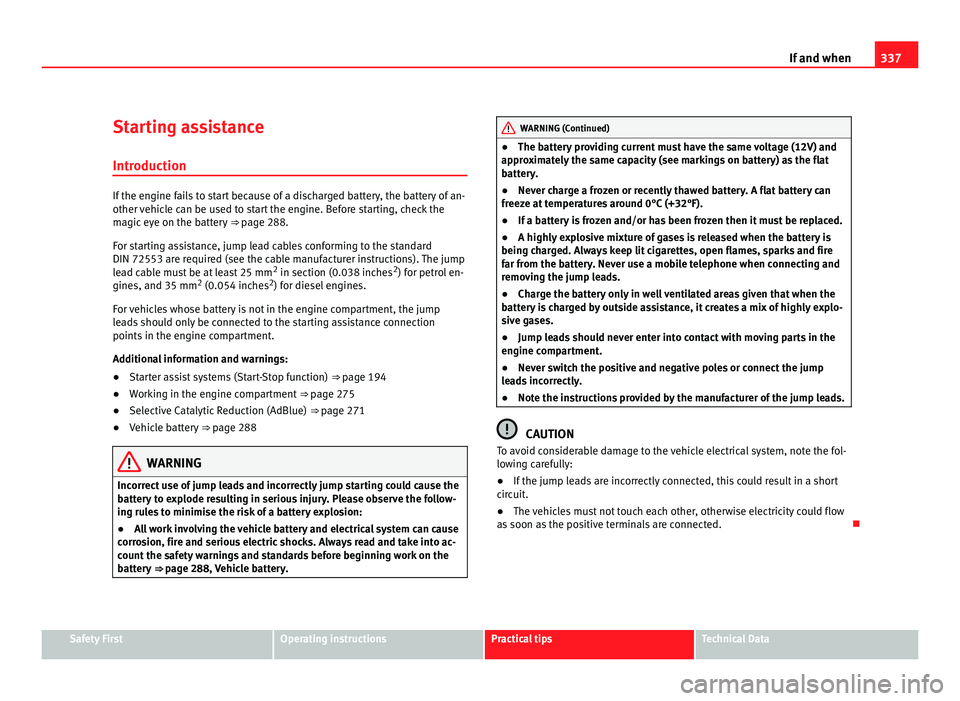

Positive pole on the starting assistance points Fig. 215 In the engine

comp

ar

tment: positive

pole for starting assis-

tance + .

On some vehicles, there is a starting assistance terminal in the engine com-

par tment, u

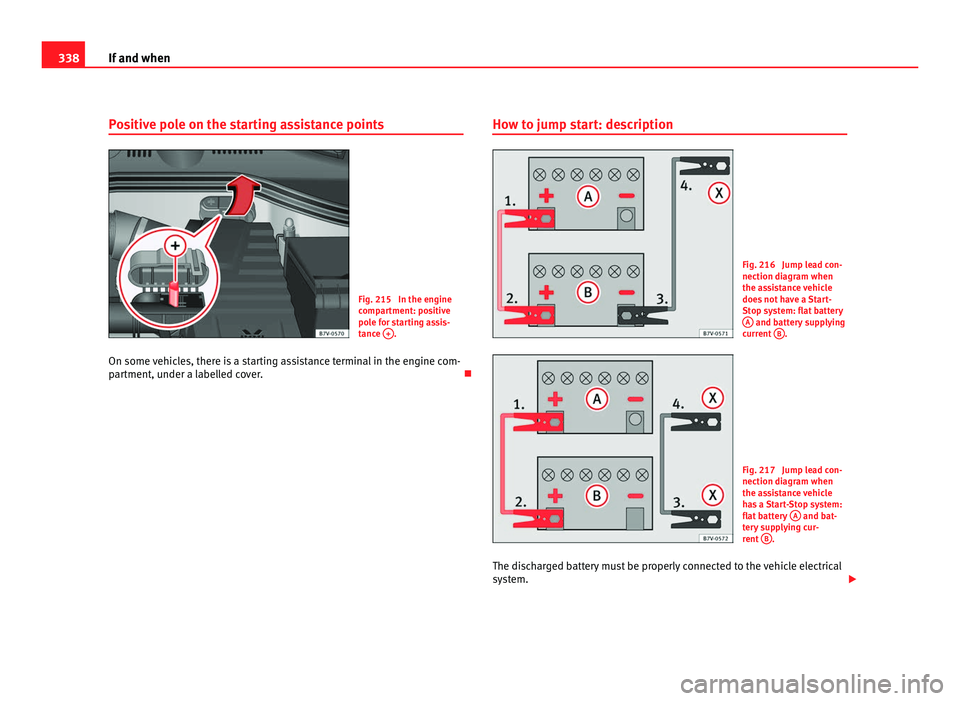

nder a labelled cover. How to jump start: description Fig. 216 Jump lead con-

nection diagr

am when

the a

ssistance vehicle

does not have a Start-

Stop system: flat battery A and battery supplying

curr ent

B .

Fig. 217 Jump lead con-

nection diagr

am when

the a

ssistance vehicle

has a Start-Stop system:

flat battery A and bat-

ter y

supplying cur-

rent B .

The discharged battery must be properly connected to the vehicle electrical

sys t

em.